Patents

Literature

143results about How to "Achieve heat insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

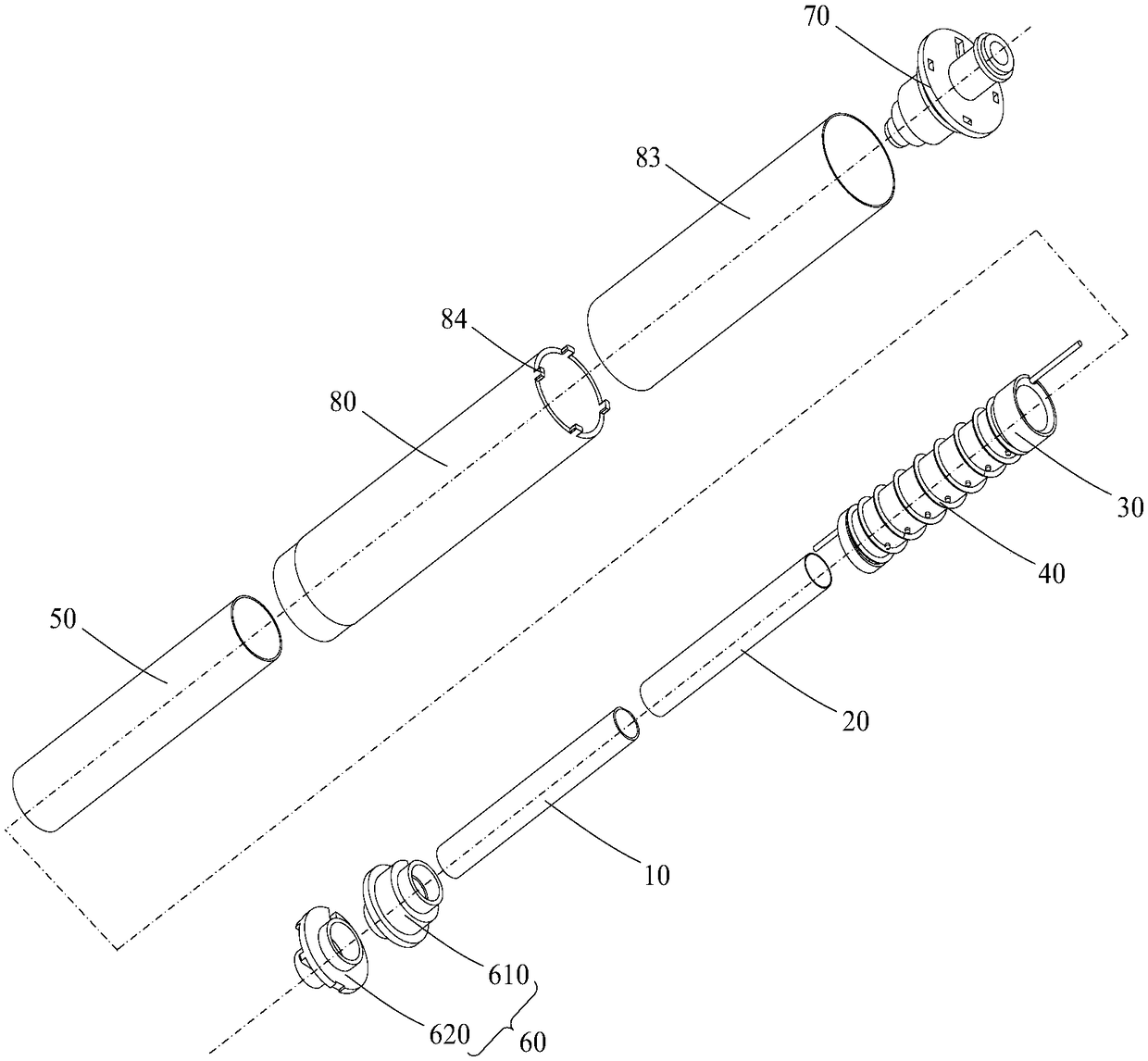

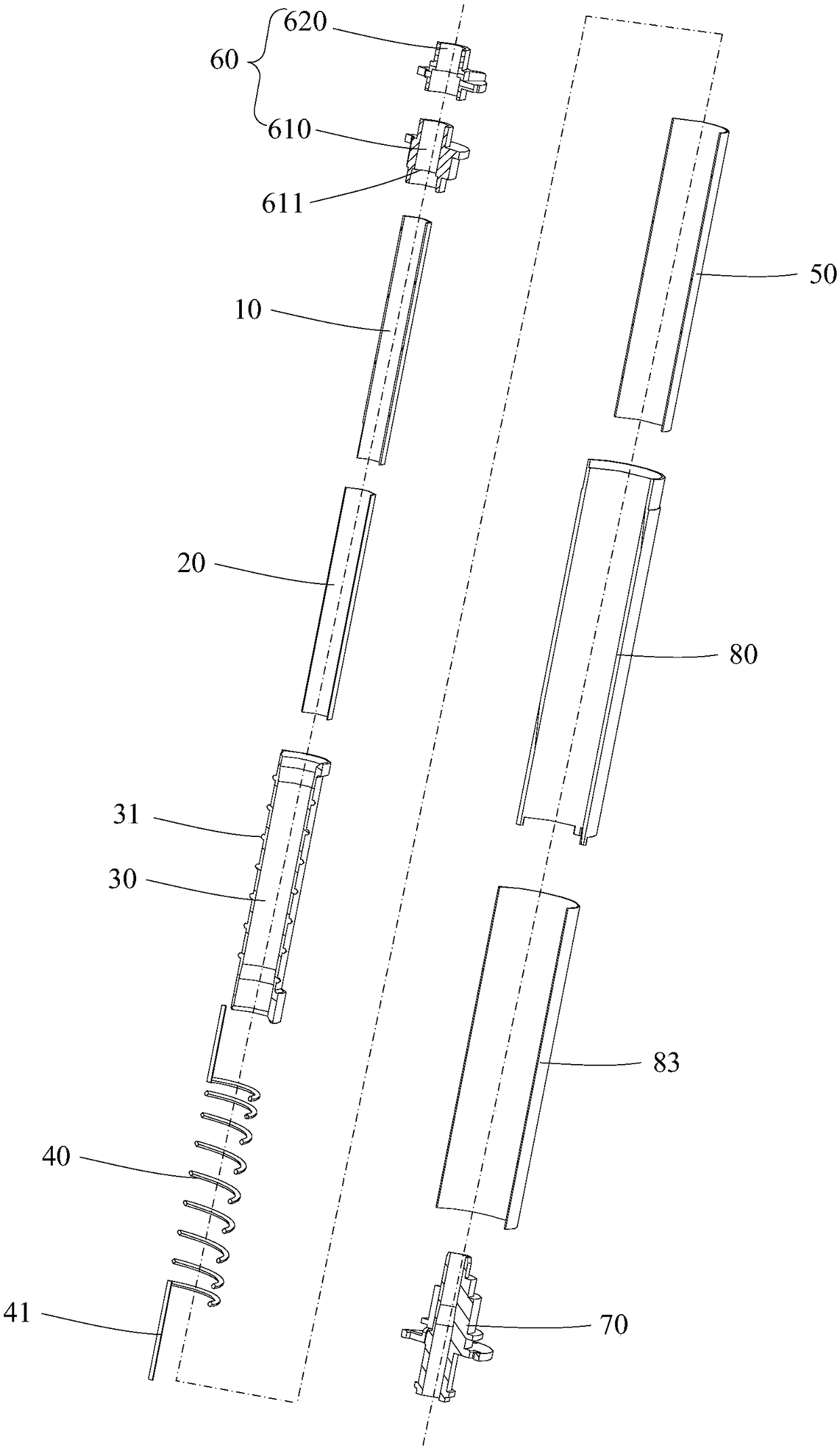

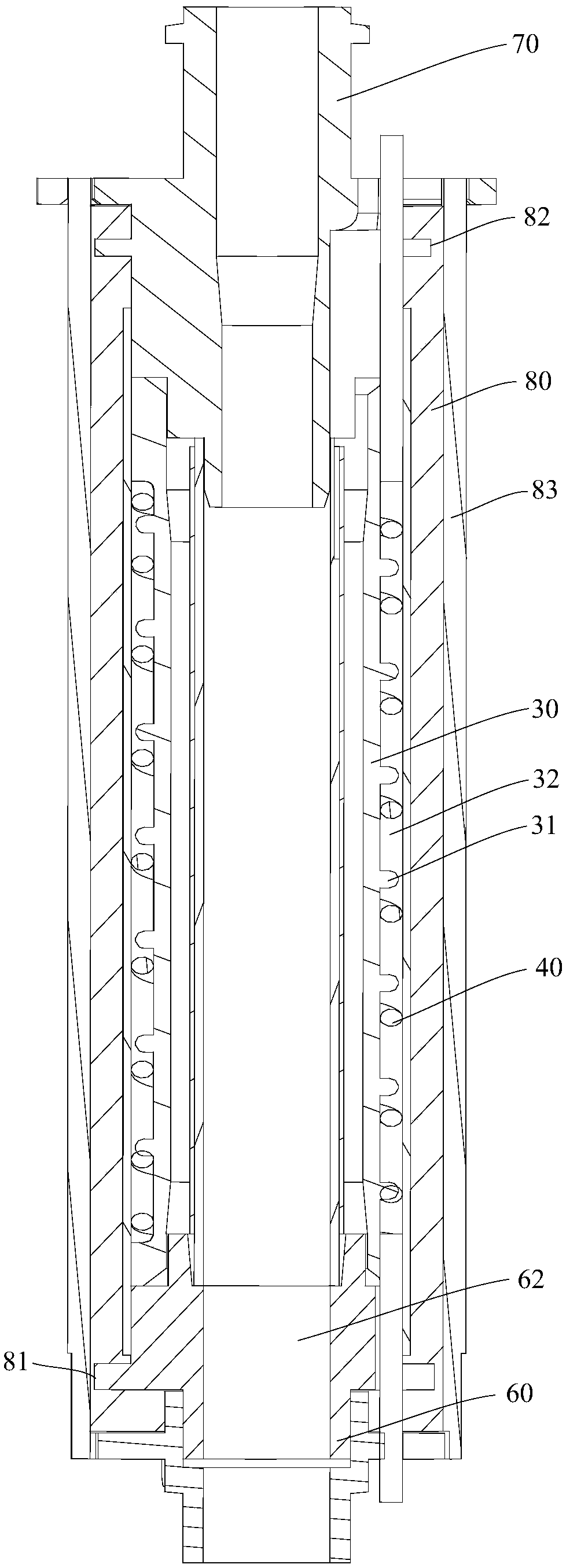

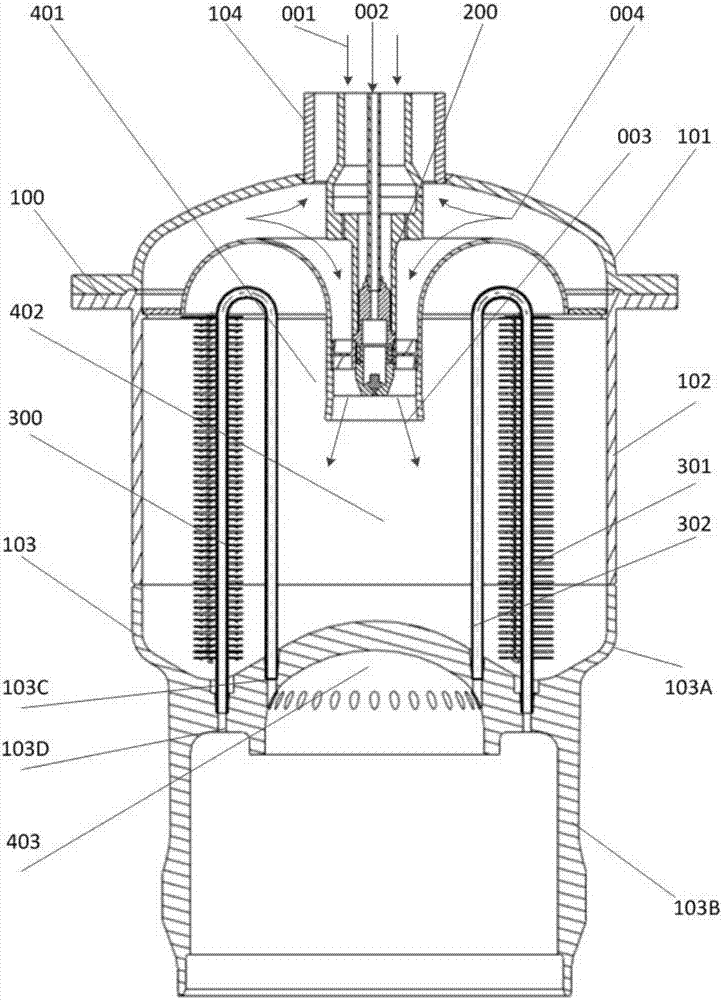

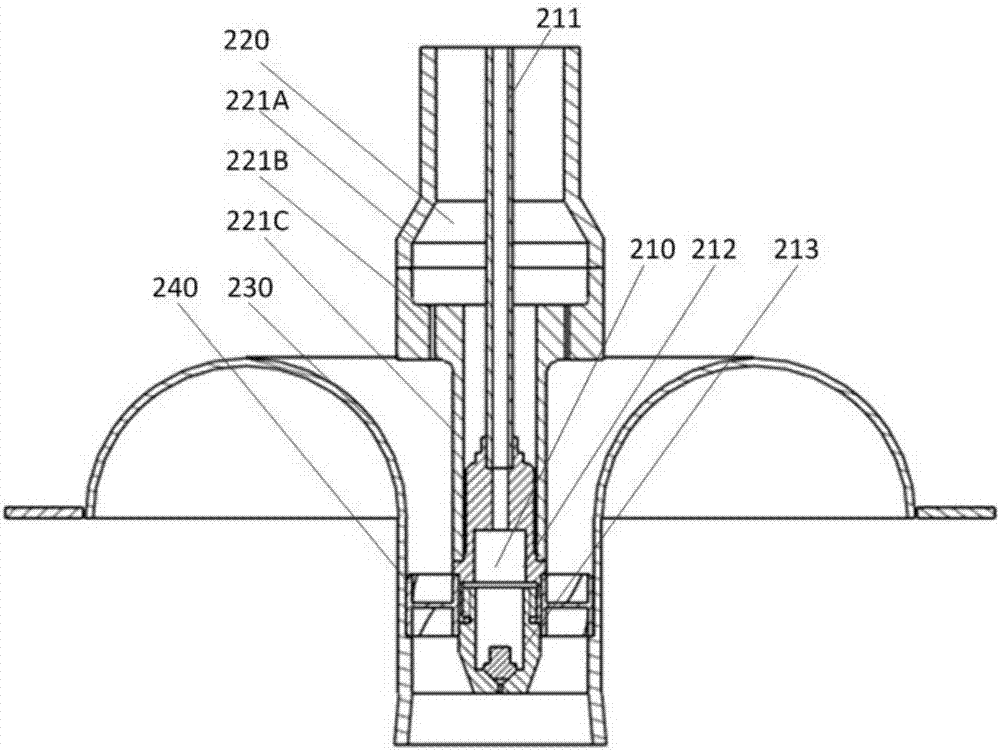

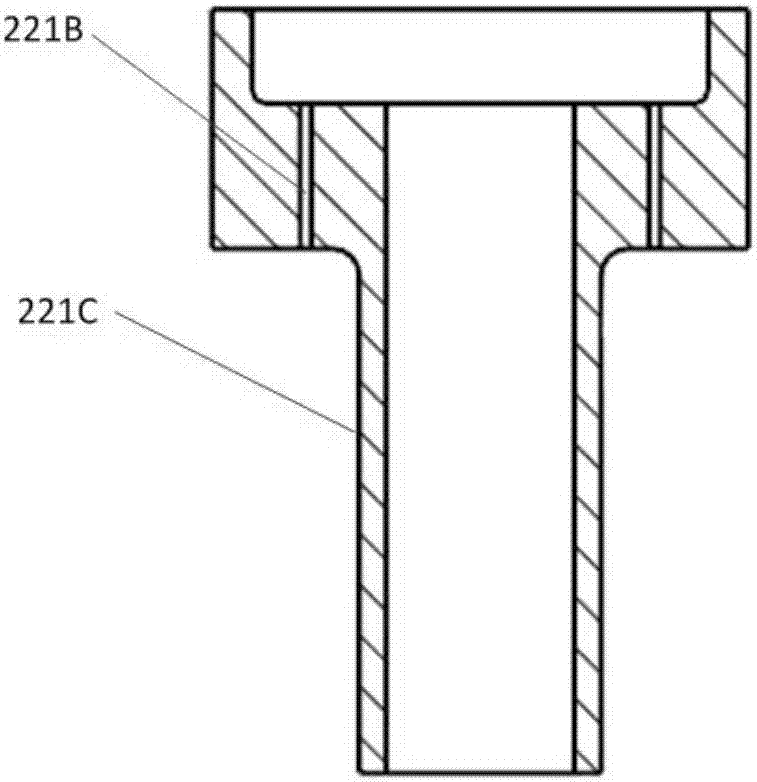

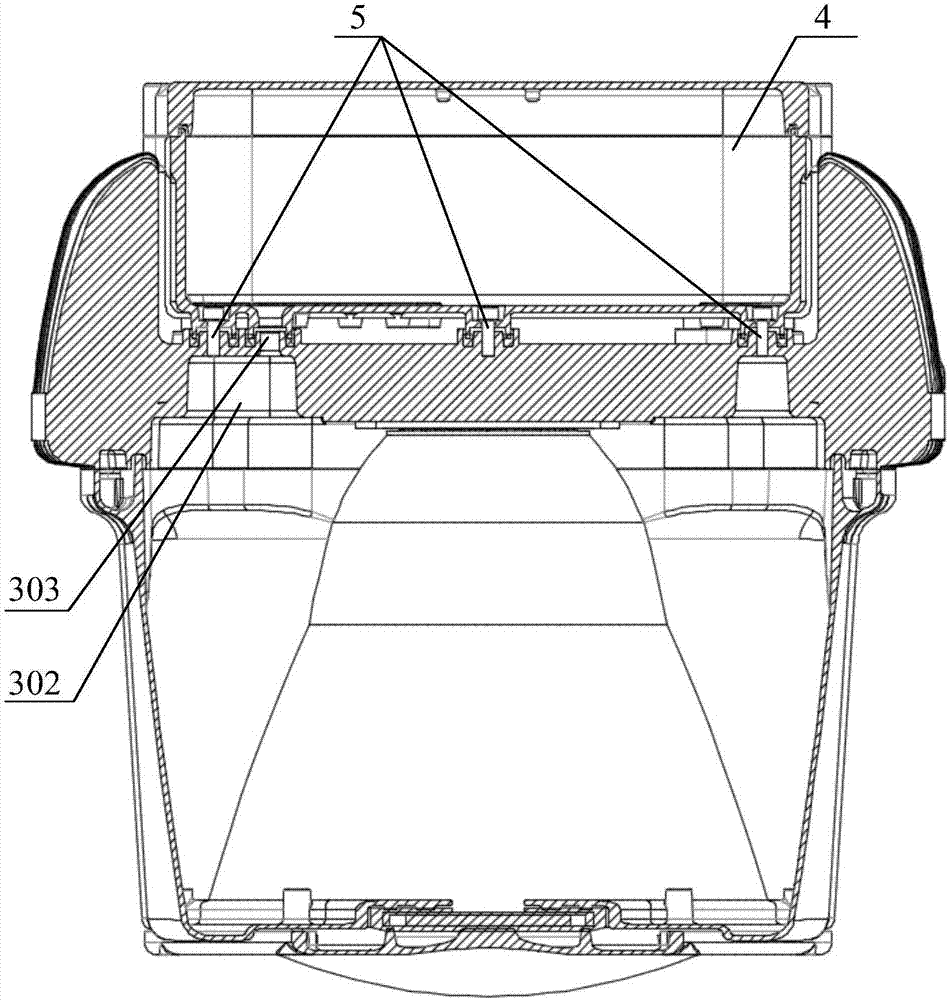

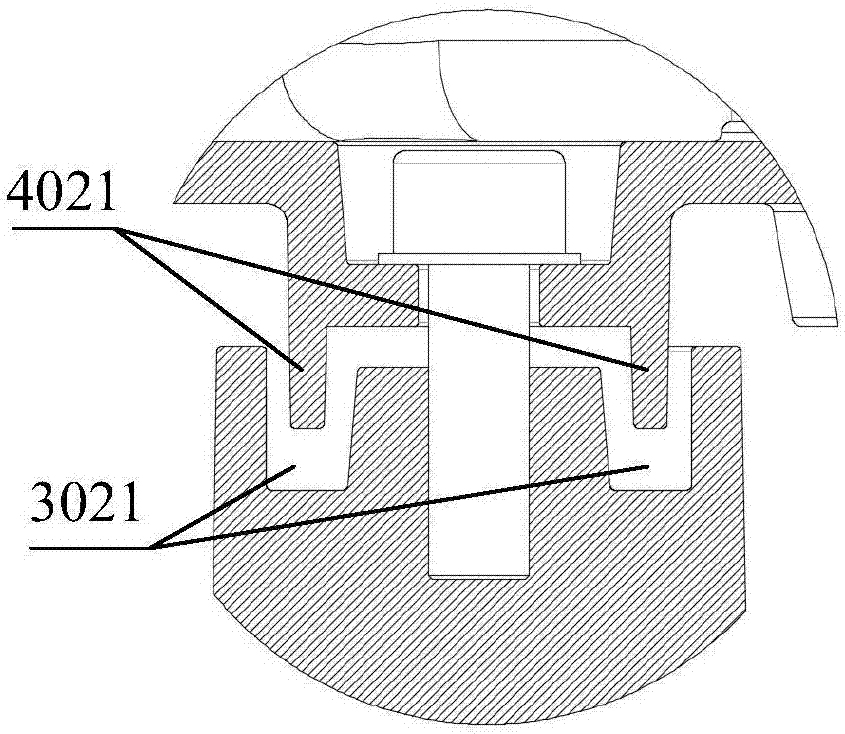

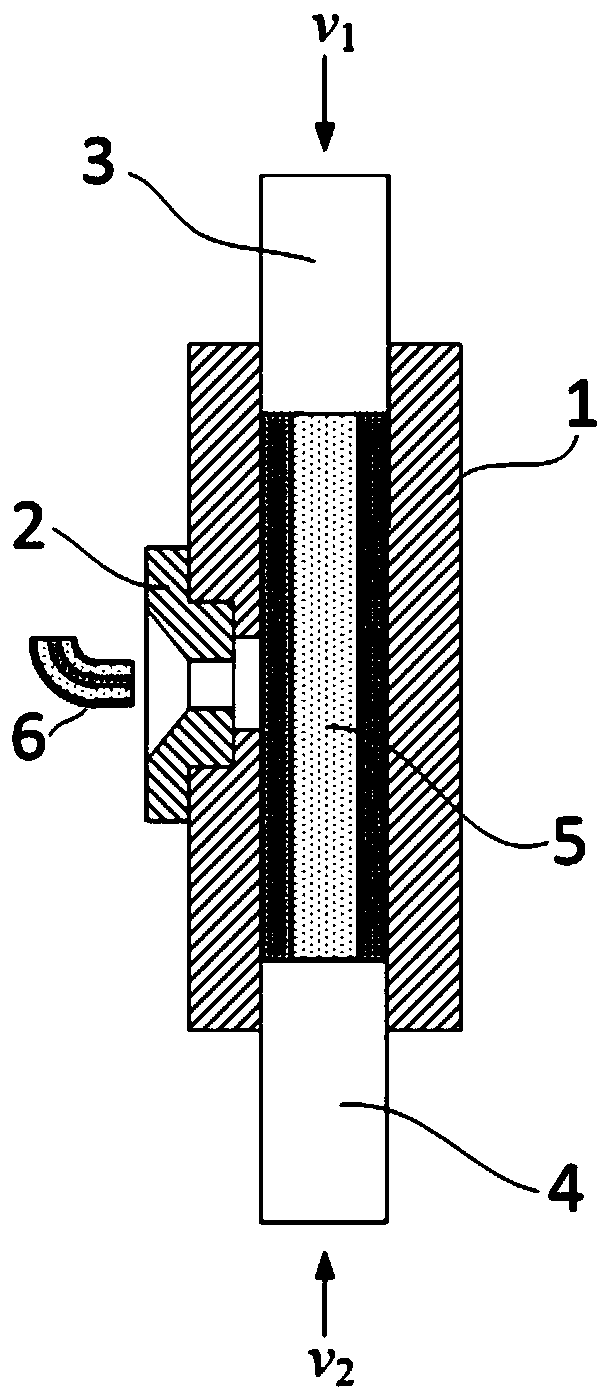

Cigarette heater, electric heating smoking device and heat insulation component

PendingCN109330030APrevent proliferationImprove energy efficiencyTobacco devicesElectricityInsulation layer

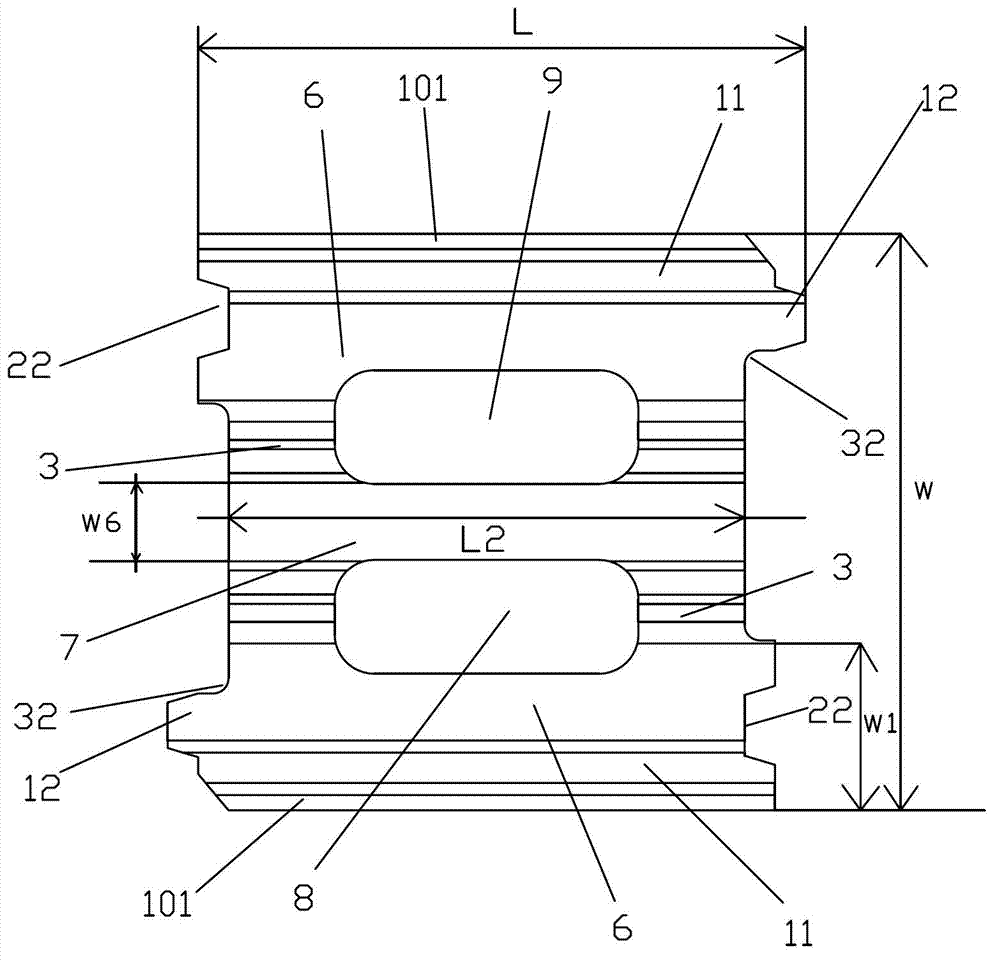

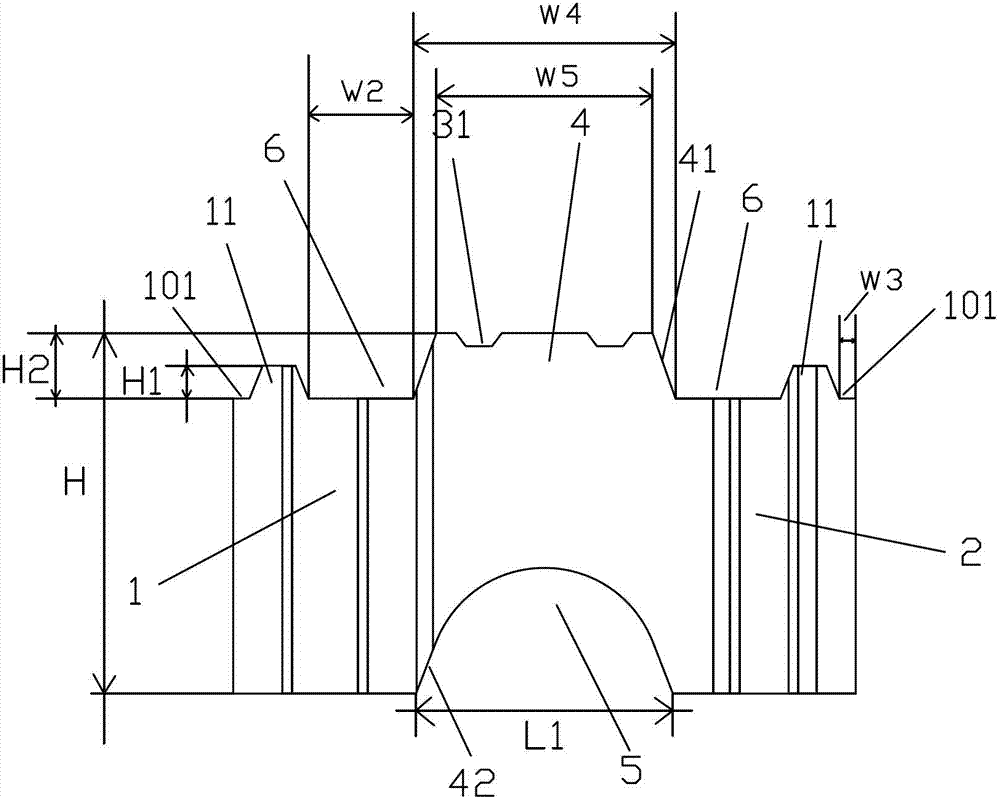

The invention provides a cigarette heater, which comprises a heating component and a heat insulation component used for insulating the heating component; the heating component comprises a bracket, anelectromagnetic coil wound on the bracket and an induction heating body for inducting the electromagnetic coil; the bracket is internally provided with a heating cavity for accommodating cigarettes; the heat insulation component comprises afirst heat insulation layer sleeved outside of the heating component and an outer heat insulation sleeve arranged outside the first heat insulation layer alongthe radial direction of the heating cavity; at least one layer of a second heat insulation layer is laminated between the first heat insulation layer and the outer heat insulation sleeve; the second insulation layer comprises a layer of gaseous medium. According to the invention, the heating part comprises an inner layer induction heating body and the electromagnetic coil; and multiple layersof heat insulation structures are also arranged from the inside to the outside for guiding the heat and limiting the divergency, the diffusion of the heat to the surface layer and the inner part of an electric heating smoking device is prevented as much as possible, and the heat insulation efficiency is better.

Owner:SHENZHEN FIRST UNION TECH CO LTD

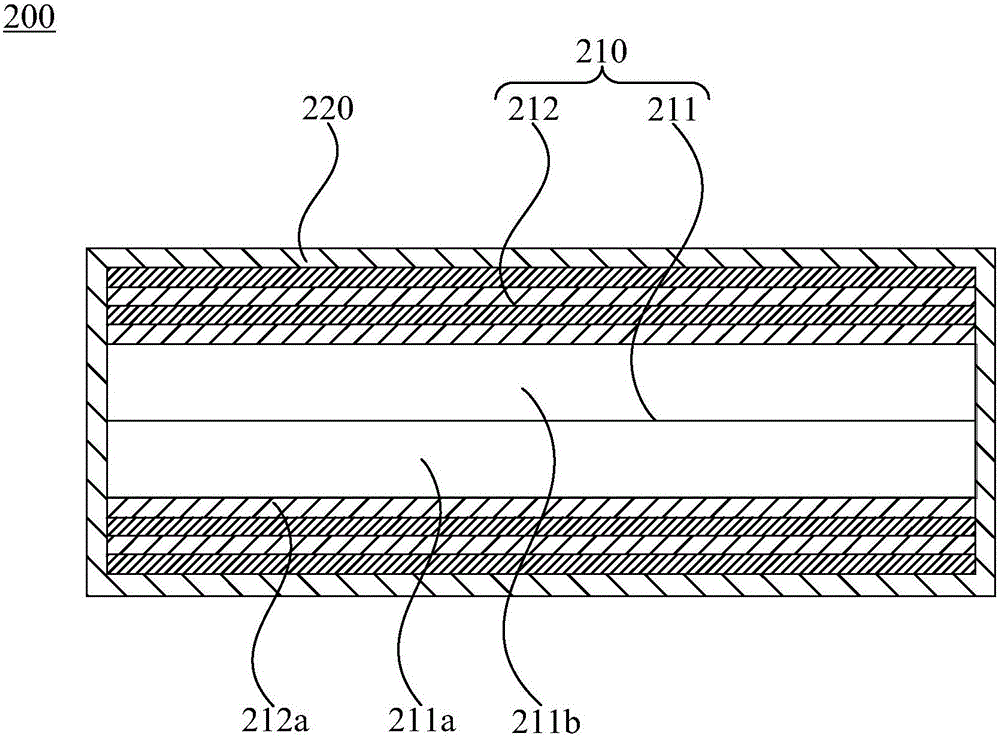

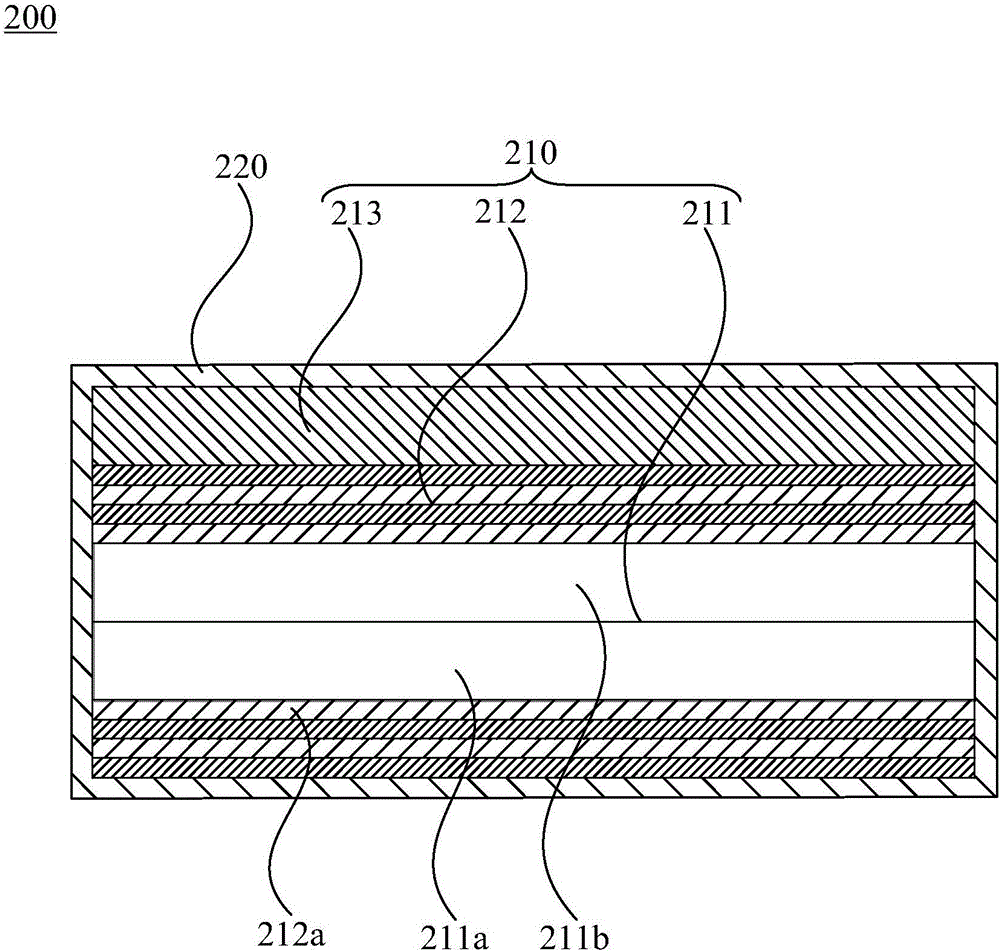

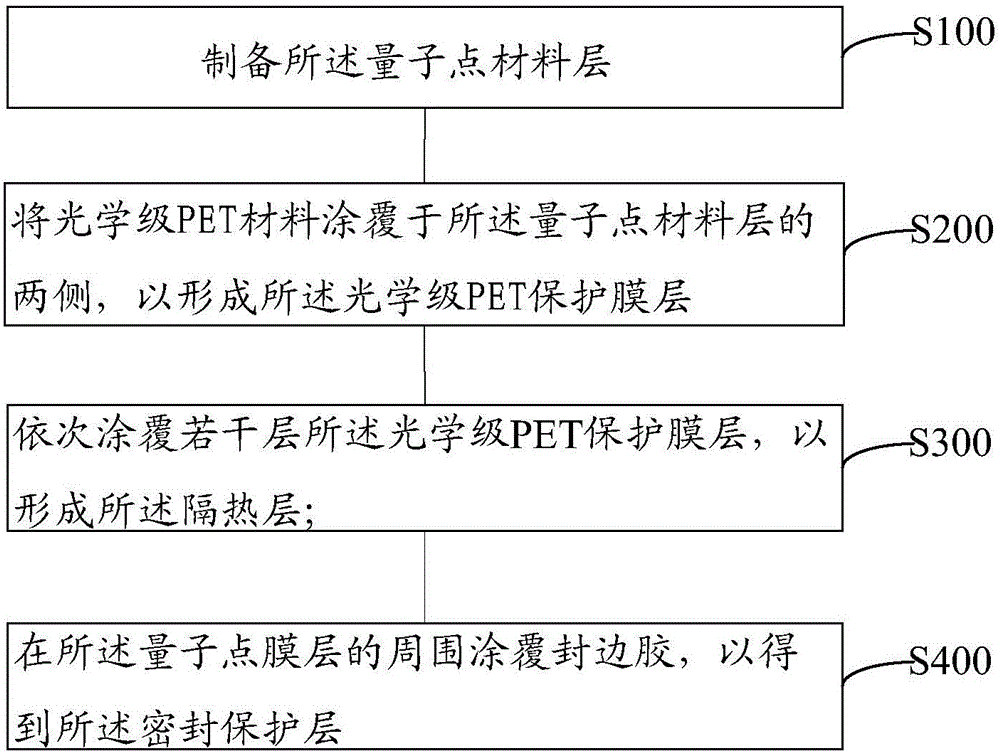

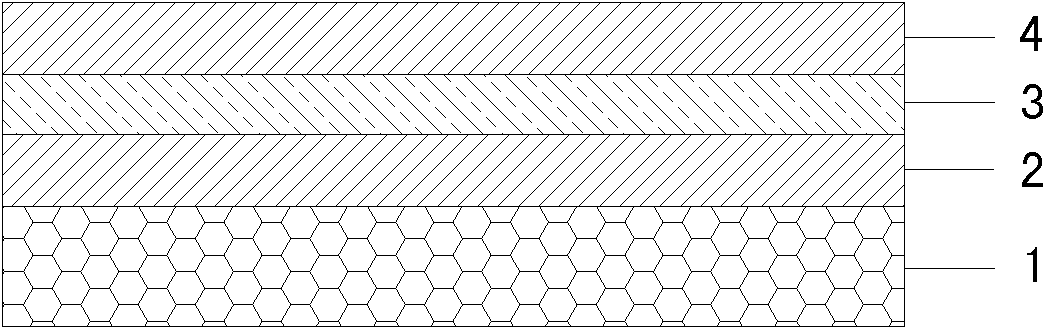

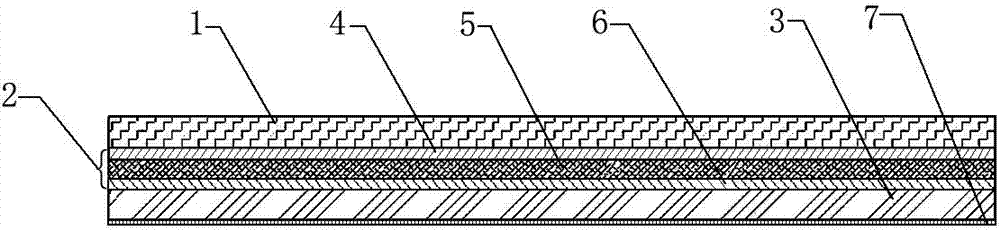

Quantum dot film, preparation method thereof, backlight module group and commercial quantum dot display

ActiveCN106054450AHigh temperature resistanceImprove applicabilityNon-linear opticsThermal insulationDisplay device

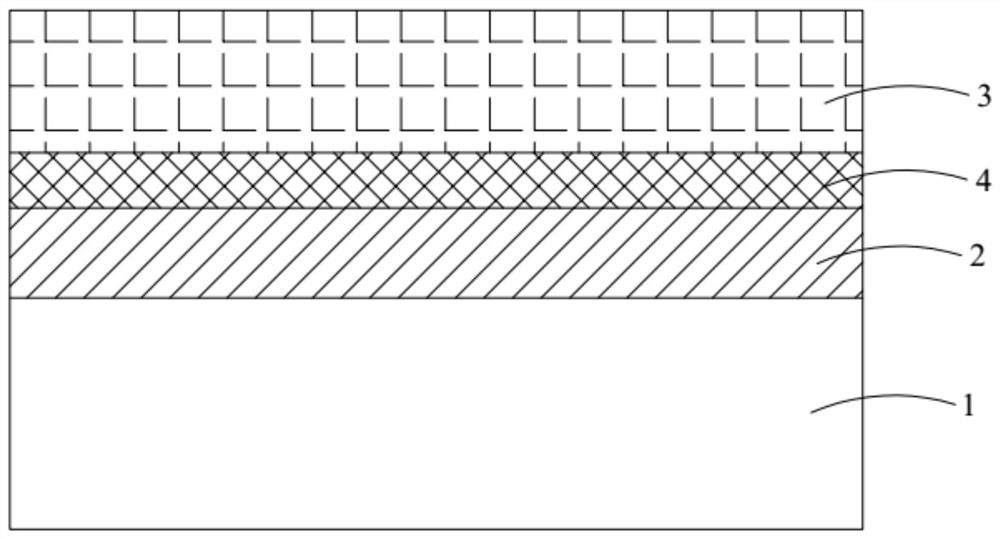

The invention relates to a quantum dot film, a preparation method thereof, a backlight module group and a commercial quantum dot display. In the quantum dot film, a thermal insulation layer and a sealing protection layer are arranged on a quantum dot material layer to realize heat insulation, water-resisting and oxygen isolating protection for the quantum dot material layer. In this way, the quantum dot film has high temperature resistance performance, and is applicable to commercial displays, spliced screens and other large display equipment requiring long-time displaying. The applicability of the quantum dot film is improved. The backlight module group and the commercial quantum dot display employing the quantum dot film realize long-time displaying under relatively high temperature. The service lifetime of the backlight module group and the commercial quantum dot display is prolonged.

Owner:深圳英伦科技股份有限公司 +1

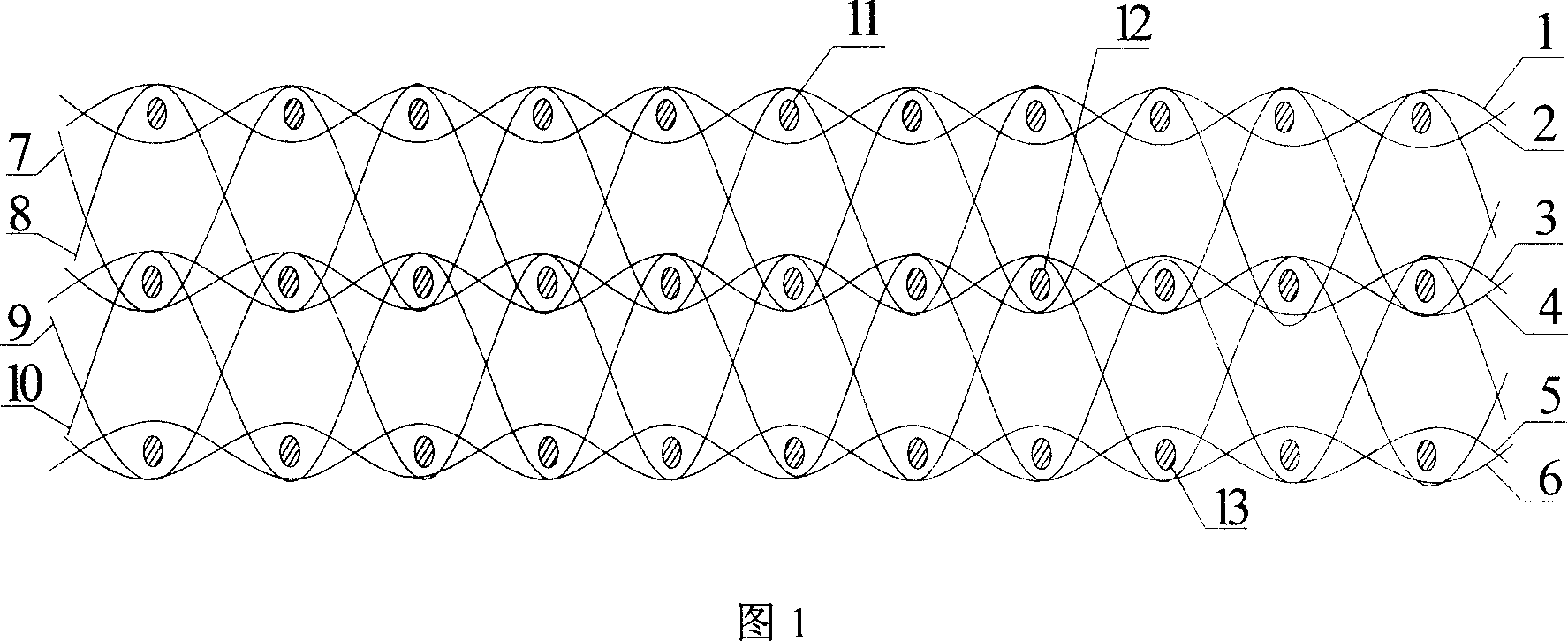

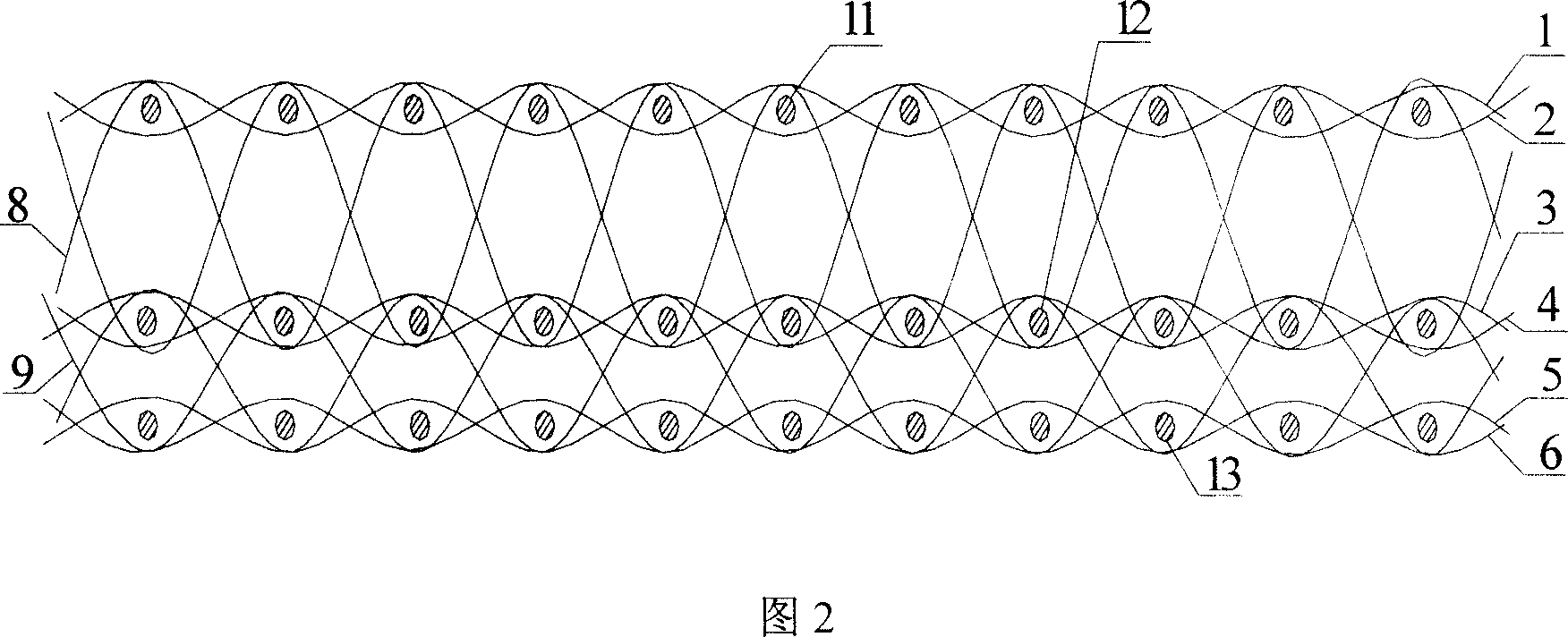

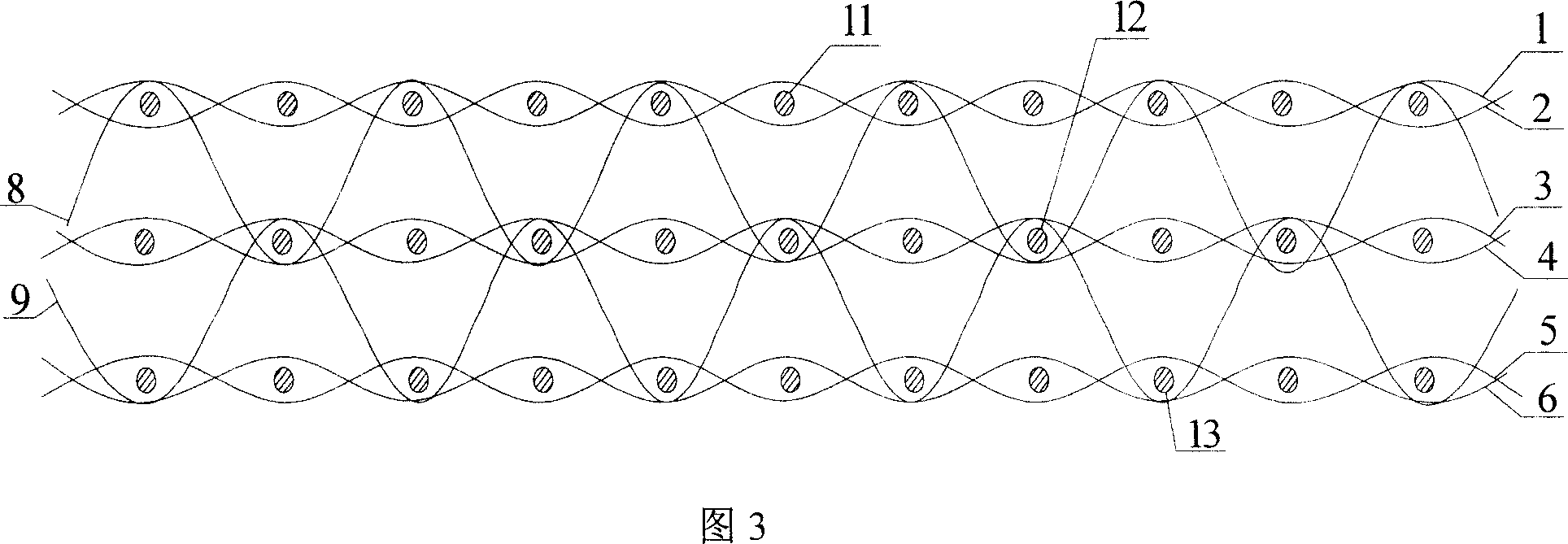

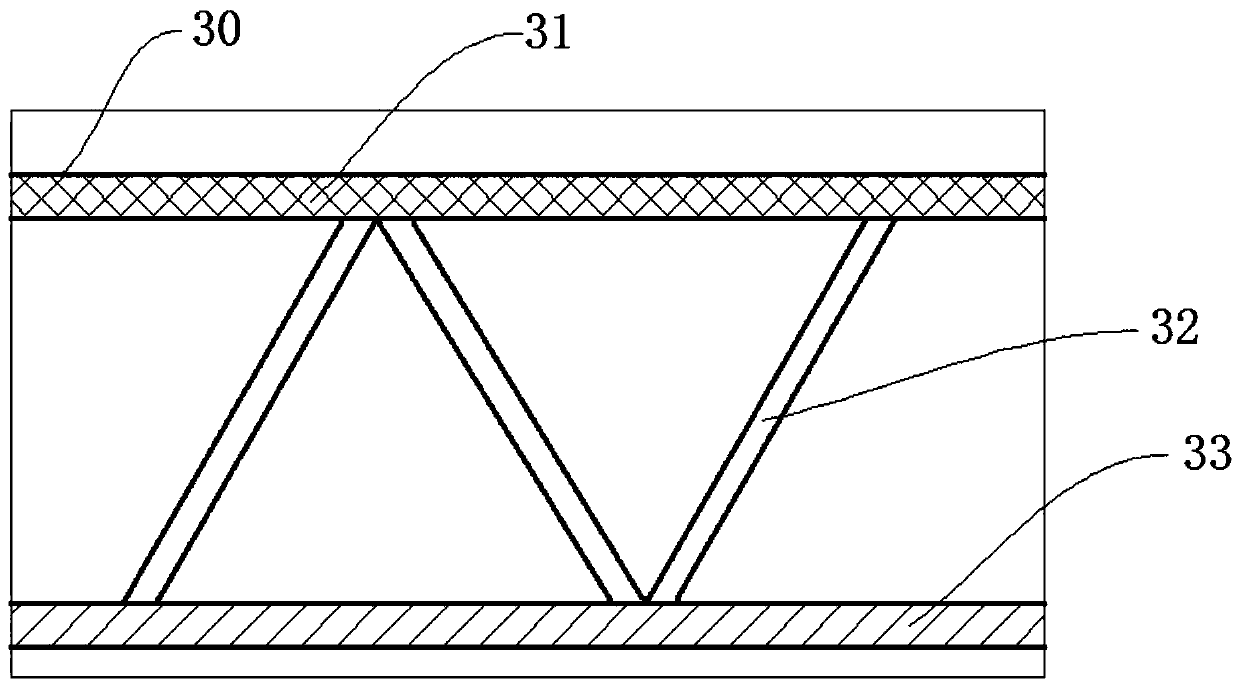

Three-dimensional hollow double sandwiched fabric

InactiveCN1974899ANot too high problem solvingImprove impact resistanceWoven fabricsEngineeringWeft yarn

The three-dimensional hollow double sandwiched fabric consists of one upper layer interwoven with two upper ground warp layers and one upper weft yarn layer, and one lower layer interwoven with two lower ground warp layers and one lower weft yarn layer, as well as one middle layer interwoven with two middle ground warp layers and one middle weft yarn layer. The weft yarn layers in the upper layer, the middle layer and the lower layer are also interwoven with the poil warps, so that the upper layer, the middle layer and the lower layer are connected integrally to form one hollow double sandwiched structure. The fabric of the present invention is uses as reinforcing body of composite material, and the composite material with the fabric is light, high in impact strength, high in antiwear performance, high in bending performance and high in rigidity. The double sandwiched structure may be also used in heat insulation, anticorrosion, real-time monitoring, etc.

Owner:SINOMA SCI & TECH

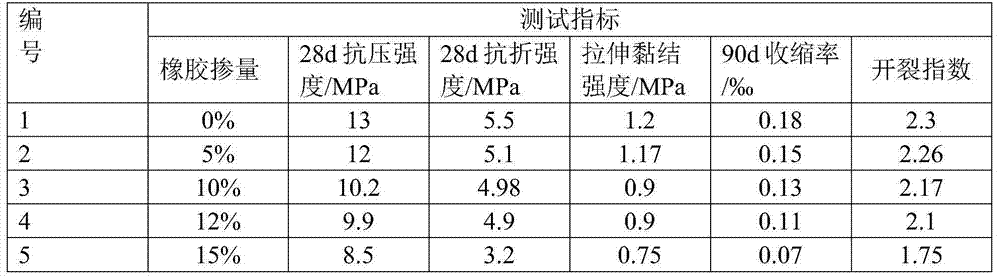

Insulated crack-resistant protective light dry mortar for external thermal insulation of exterior wall and preparation method thereof

The invention discloses insulated crack-resistant protective light dry mortar for external thermal insulation of an exterior wall. The insulated crack-resistant protective light dry mortar comprises the following raw materials by mass percent: 25-35% of cement, 15-25% of vitrified microbead, 8-15% of quartz powder, 5-10% of coal ash floating bead, 1-5% of perlite, 5-15% of rubber particles, 3-10% of metakaolin, 1.0-1.5% of rubber powder, 0.1-0.3% of water reducing agent, 0.2-0.5% of anti-crack fiber, and 0.2-0.4% of cellulose ether, wherein the sum of the components by mass percent is 100%. The preparation method of the dry motor comprises the step of agitating and mixing the weighed raw materials. The using method comprises the steps of agitating and mixing water with the dry motor according to the mass ratio of (4-5):4. By adopting the insulated crack-resistant protective light dry mortar, rubber is added to cement-based crack-resistant protective dry mortar, so that the brittleness of the cement-based protective motor material is improved, the problems that the existing coating mortar is easy to crack and poor in durability are solved, and the thermal insulation and crack-resistant functions are really achieved.

Owner:西安德耐节能科技有限责任公司

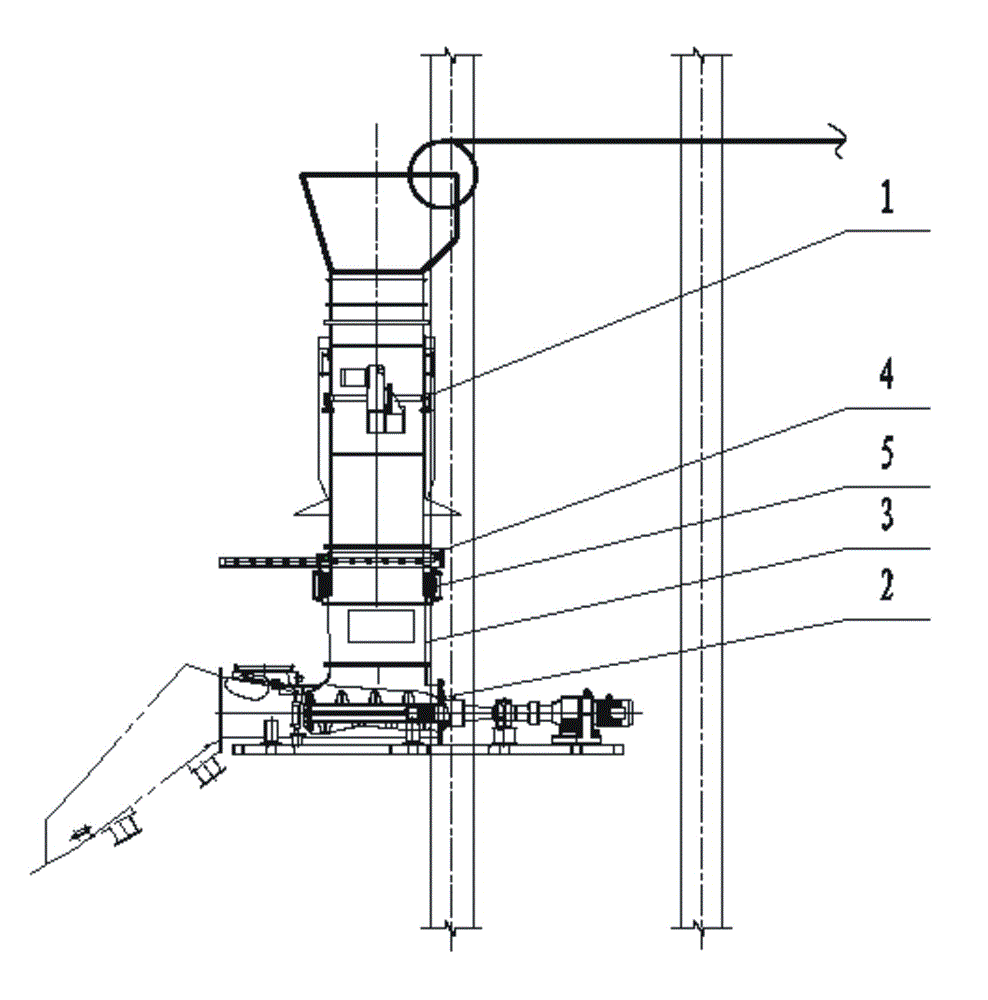

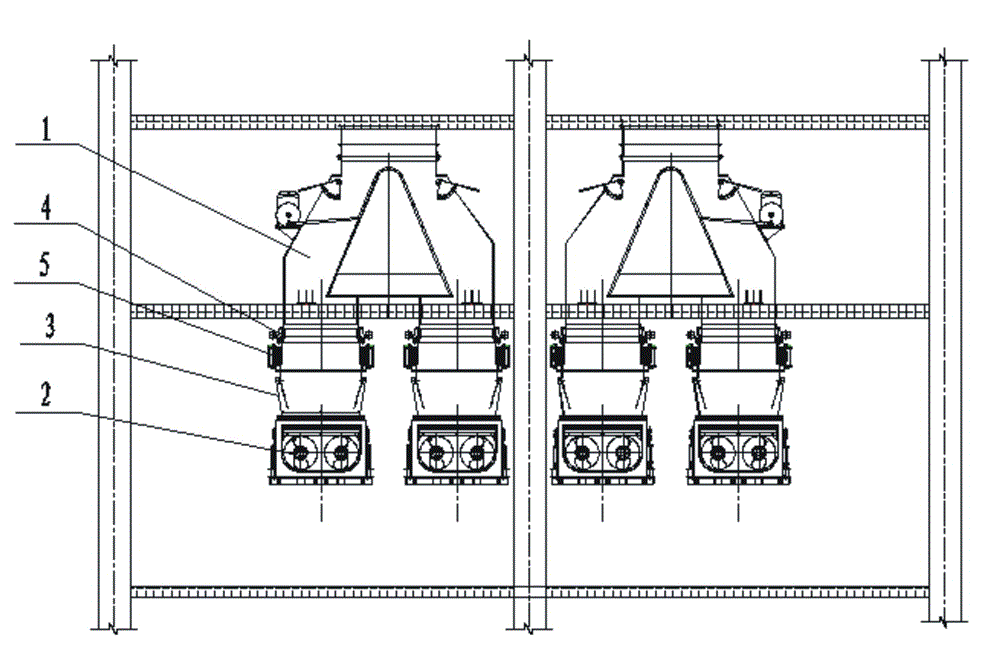

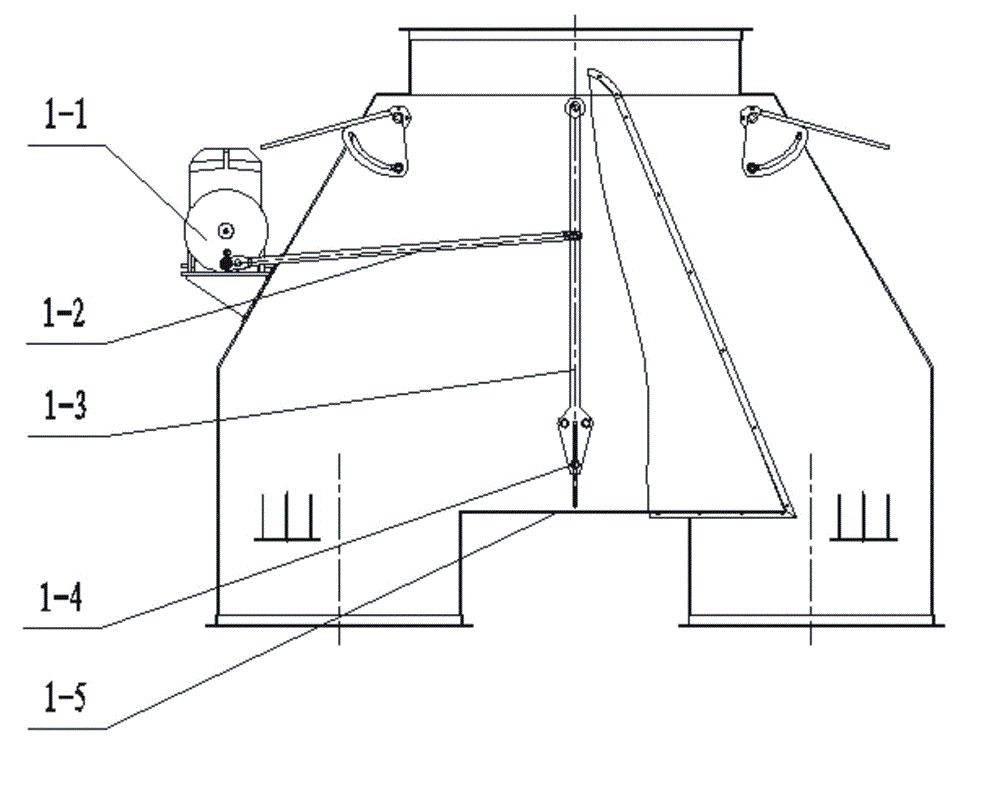

Furnace-free front storage bin feeding device for biomass power plant

InactiveCN102913935ALower the altitudePrevent bridgingFluidized bed combustionLump/pulverulent fuel feeder/distributionFailure ratePower station

The invention relates to a furnace-free front storage bin feeding device for a biomass power plant. The blanking is directly performed by employing a charging belt, a charging belt corresponds to a distributor, a distributor is provided with two discharge openings; the discharge openings of each distributor are butted with a spiral feeding device through a blanking pipe; and four spiral feeding devices respectively corresponds to four feeding holes of a corresponding boiler. The device is easy, convenient and high in adaptability, the transfer link is reduced, the failure rate of the system is reduced, the height of the charging belt is reduced, the bridging and bulking phenomena in the traditional stokehole storage bin are avoided, the floor area is saved, and the cost is saved; and meanwhile, the device has good practical using effect of various biomass fuels, the stability, reliability and the safety of equipment operation in a feeding system are improved, and the device can be widely applied to various boilers for biomass power generation, and are particularly applied to circulating fluidized bed boilers.

Owner:武汉丰盈能源技术工程有限公司

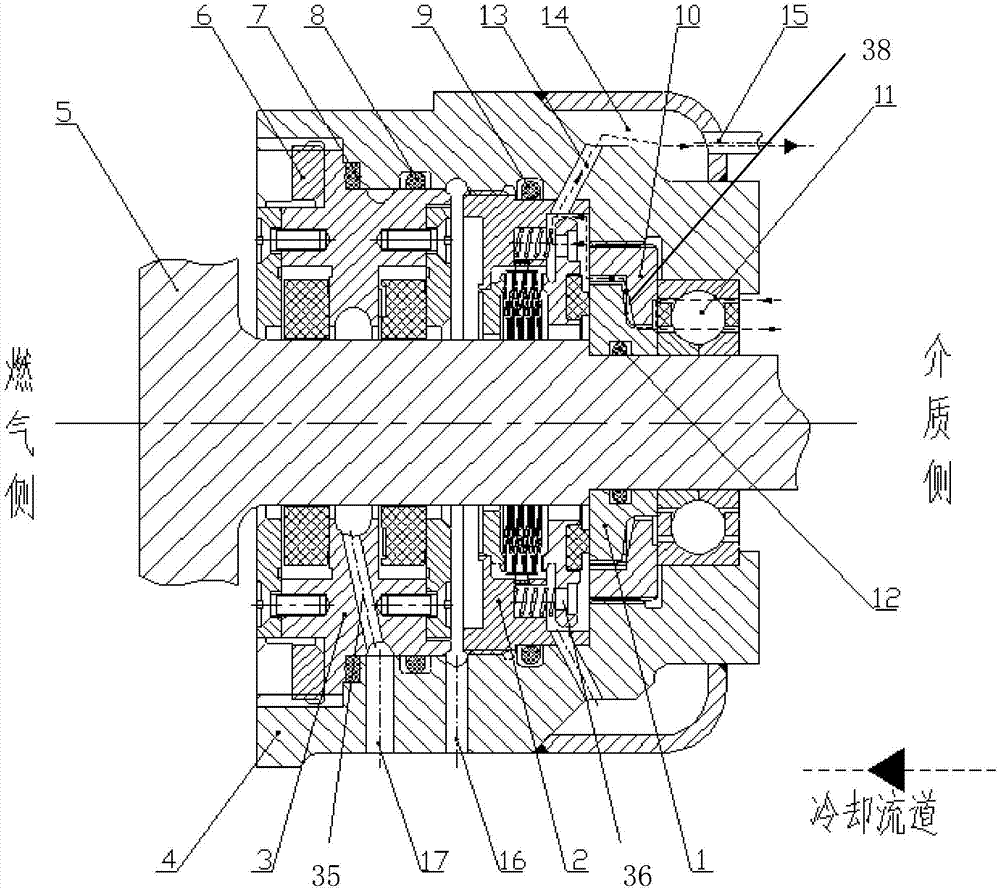

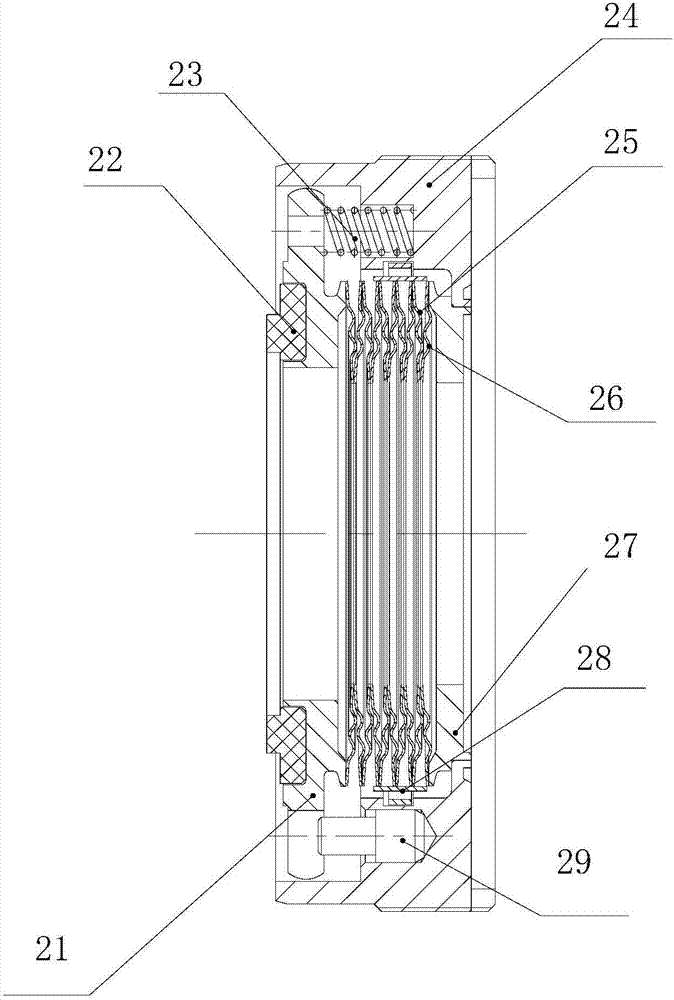

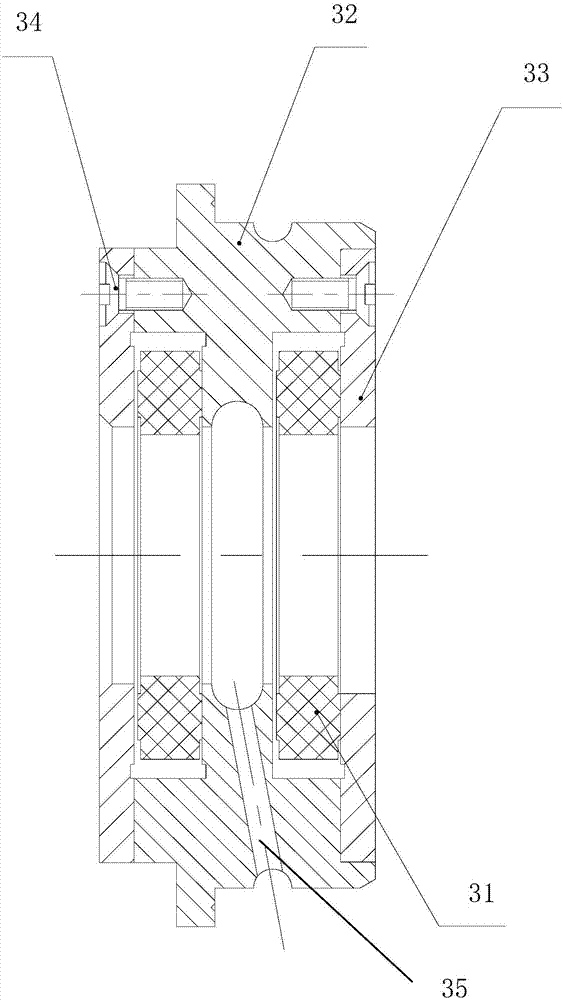

Combined mechanical seal device

ActiveCN107387261AAvoid meetingSimple systemPump componentsNuclear energy generationRubber ringEngineering

The invention particularly relates to a combined mechanical seal device which comprises a moving ring, a static ring assembly, a static ring housing, a floating ring assembly and an O-shaped rubber ring. The static ring assembly is arranged in the static ring housing and comprises an end face block assembly, a rotation-preventing pin, a spring and a damping belt. The end face block assembly comprises a static ring, a static ring seat, a film box assembly and a rear ring which are arranged in sequence. The damping belt is located in an annular groove of the inner surface of the static ring housing. The floating ring assembly comprises a floating ring, a cover plate and a floating ring housing, wherein the floating ring penetrates through a rotor to be arranged in the floating ring housing, and a cover plate penetrates through a rotor to be fixedly arranged on two sides of the floating ring housing respectively. A cooling backflow channel comprises a bearing axial gap, a gap between the moving ring and a pressing ring, a static ring seat balance hole gap, a radial gap between a static ring seat and the static ring housing, a backflow channel I, an accumulated liquid cavity and a backflow channel II which are communicated in sequence. The combined mechanical seal device achieves long-service-life, low-friction and zero-leakage work of a mechanical seal under the working conditions of high temperature and high pressure.

Owner:XIAN AEROSPACE PROPULSION INST

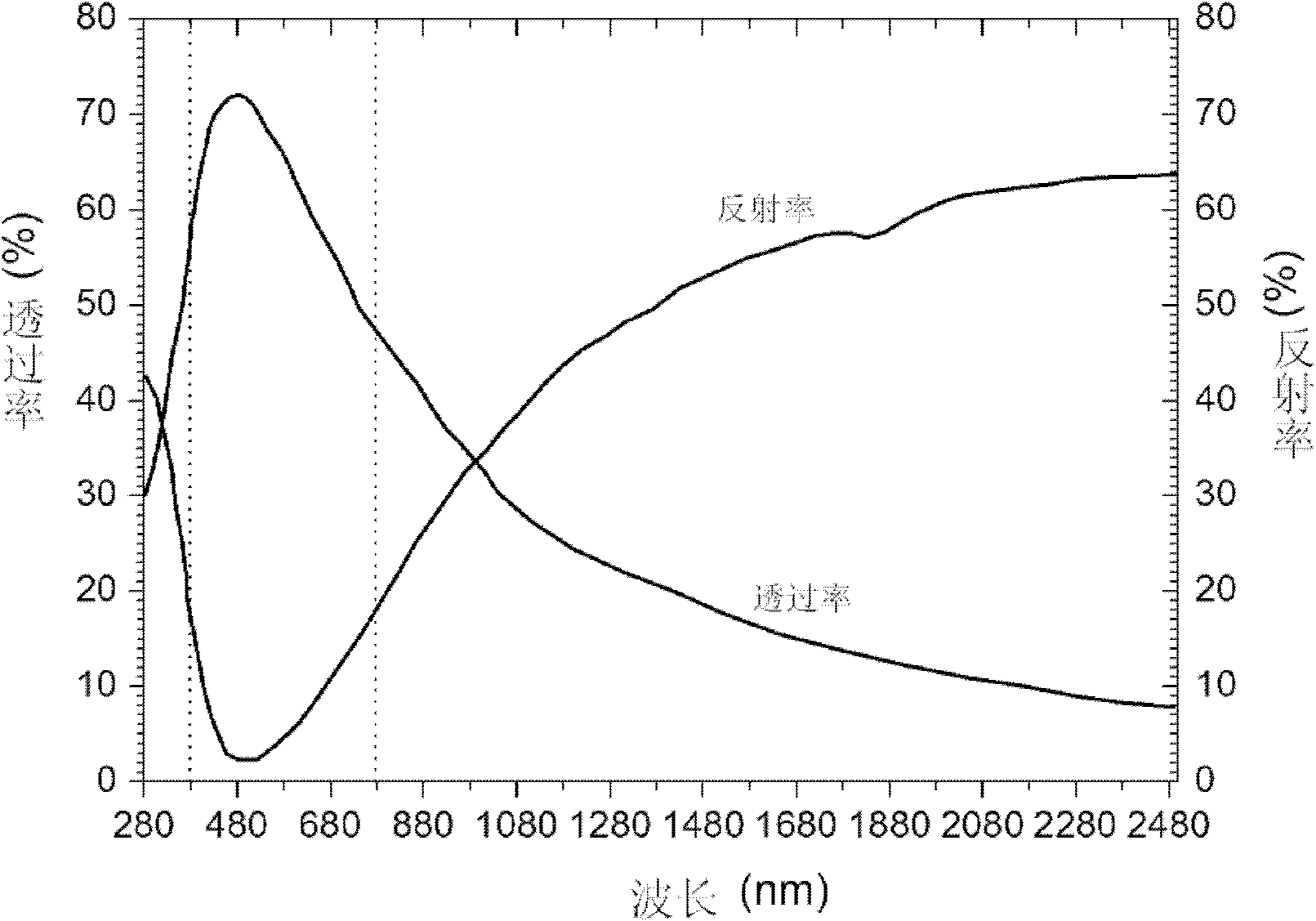

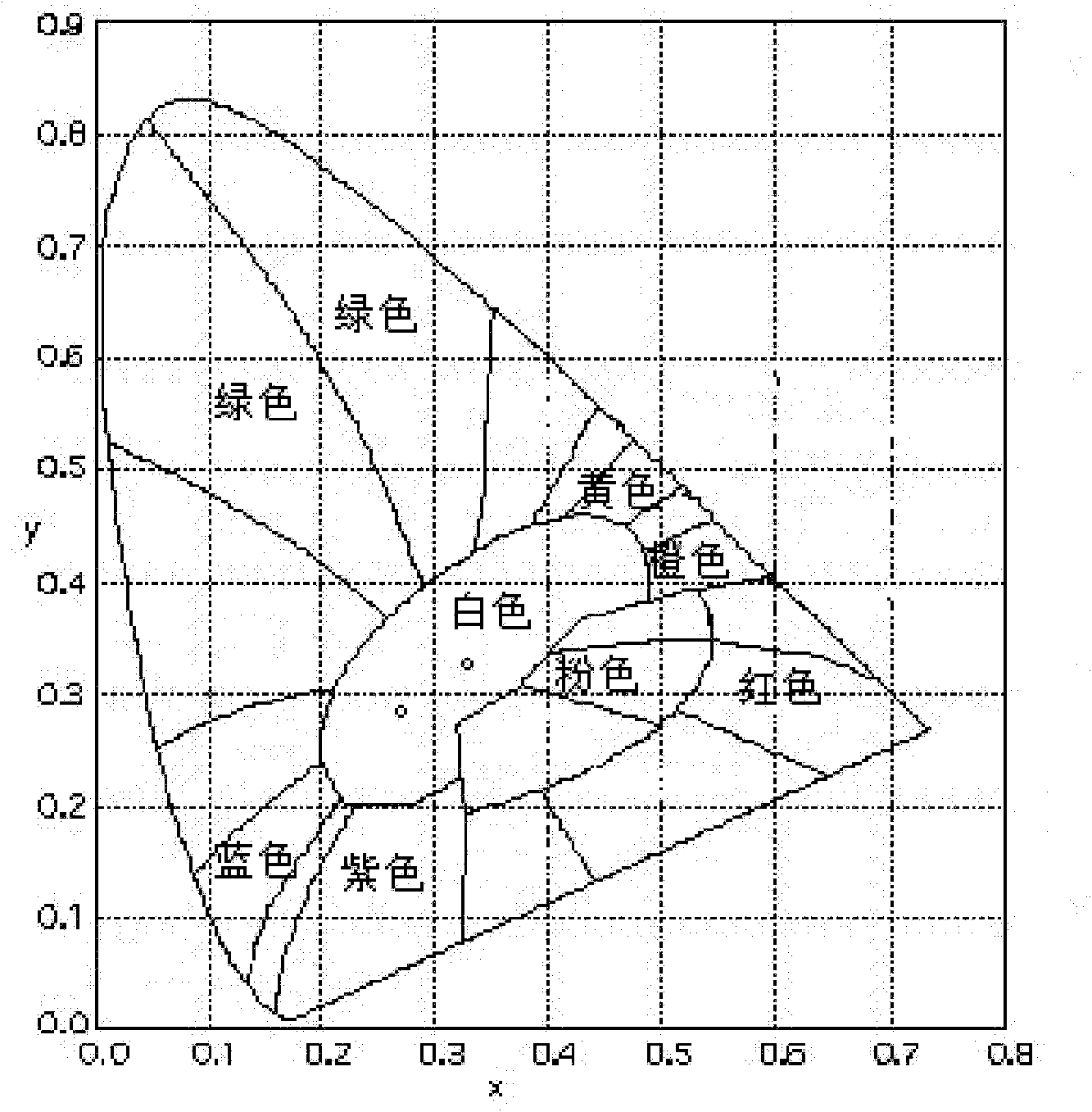

Nanometer ceramic solar film

InactiveCN102837460AGood spectral selectivityImprove transmittanceSynthetic resin layered productsVacuum evaporation coatingInfraredThermal insulation

The present invention relates to a nanometer ceramic solar film. According to the nanometer ceramic solar film, a firs layer titanium dioxide film, a second layer titanium nitride film and a third titanium dioxide film are sequentially plated on a surface of a substrate PET through magnetron sputtering, wherein a thickness of the substrate PET is 23-50 mum, a thickness of the first layer titanium dioxide film is 26-38 nm, a thickness of the second layer titanium nitride film is 20-26 nm, and a thickness of the third layer titanium dioxide film is 26-38 nm. The nanometer ceramic solar film of the present invention has the following characteristics that: good spectral selective permeability, high transmittance in a visible light region, and high reflectivity in an infrared region are provided, wherein infrared rays are blocked so as to reduce heat source, such that thermal insulation is achieved while transmittance on visible light is not affected; and titanium dioxide and titanium nitride have high chemical stability at a room temperature, are not easily oxidized, and do not react with oxygen, water, steam, hydrochloric acid, sulfuric acid and the like under normal circumstances, such that performances are stable, fading and discoloration can not be generated, and a service life is long.

Owner:SOUTHWESTERN INST OF PHYSICS

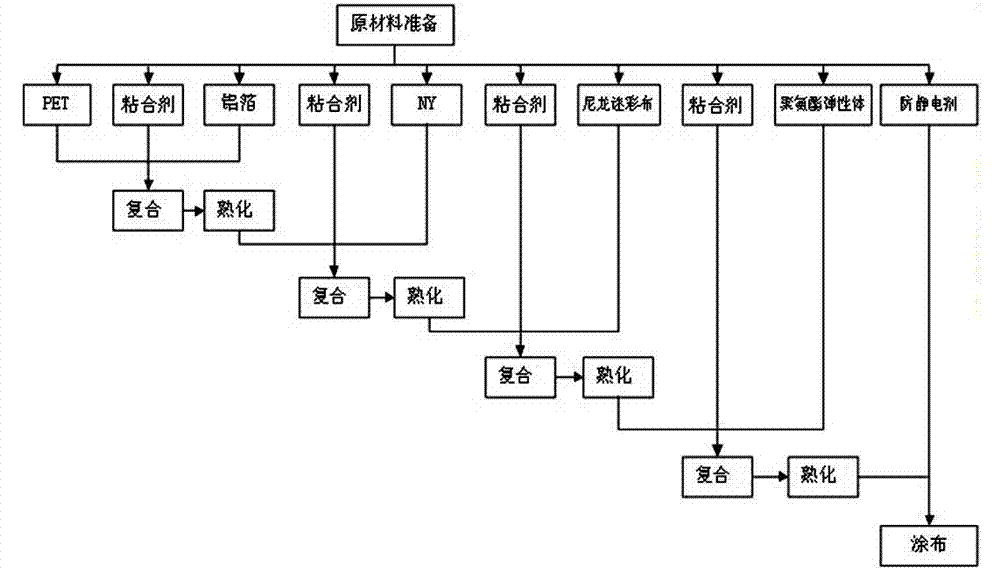

Military puncture-proof, tear-resistant, anti-static and high-barrier camouflage painting composite and preparation method thereof

ActiveCN103029386AImprove mechanical propertiesGood antistatic functionSynthetic resin layered productsLaminationPolyurethane elastomerAntistatic agent

The invention discloses a military puncture-proof, tear-resistant, anti-static and high-barrier camouflage painting composite which sequentially comprises a nylon camouflage cloth camouflage layer, a high-barrier layer taking aluminum foil as a substrate, and a heat sealing layer of a polyurethane elastomer film from the outside in. A preparation method of the composite comprises the steps of A preparing the high-barrier layer, and compositing polyethylene glycol terephthalate film and a polyamide film on the upper and the lower surfaces of the substrate, namely the aluminum foil, B compositing the upper surface of the high-barrier layer with a camouflage layer and curing, C compositing the lower surface of the high-barrier layer with the heat sealing layer of the thermoplastic polyurethane elastomer film and curing, and D coating the internal surface of the heat sealing layer with an antistatic agent, and obtaining the camouflage composite. According to the composite and the method, with the adoption of specific compositing and curing processes, the prepared camouflage composite has puncture-proof, tear-resistant, anti-static and high-barrier functions and the like, a protection envelope prepared by the material can effectively prevent army materials from being damp during long-term field storage and transportation, and the storage and transportation quality of the materials is improved.

Owner:中国人民解放军32181部队

Multifunctional phosphating solution, and preparation method and application thereof

InactiveCN103397324AHigh hardnessStrong impact resistanceMetallic material coating processesPhosphatePhosphoric acid

The invention relates to a multifunctional phosphating solution and a preparation method and application thereof. The multifunctional phosphating solution comprises liquid A and liquid B and is characterized in that a ratio of the liquid A to the liquid B in the multifunctional phosphating solution is 1: 0.1-1. The liquid A comprises the following substances, by mass, 26 to 48 parts of diammonium phosphate, 0.9 to 12 parts of phosphoric acid with a concentration of 85%, 0.8 to 1.8 parts of metal powder, 0.6 to 1.4 parts of animal glue, 0.4 to 10 parts of calcined gypsum powder and 0.3 to 0.8 part of alum, with the balance being water. The liquid B comprises the following substances, by mass, 20 to 46 parts of zinc dihydrogen phosphate, 38 to 55 parts of zinc nitrate, 2 to 3.8 parts of sodium fluoride, 2 to 4 parts of zinc oxide and 2 to 6 parts of phosphoric acid with a concentration of 85%, with the balance being water. The multifunctional phosphating solution provided by the invention is composed of the liquid A and the liquid B, can realize removal of oil and rust at the same time and has the efficacy of rust protection, heat insulation, high temperature resistance, heat preservation, flame retardation, noise abatement, shock prevention, isolation, pollution cleaning and resistance to fire. The multifunctional phosphating solution has the following beneficial effects: a fast rust removal speed, great thickness of a formed film, long antirust time, etc.

Owner:李春清

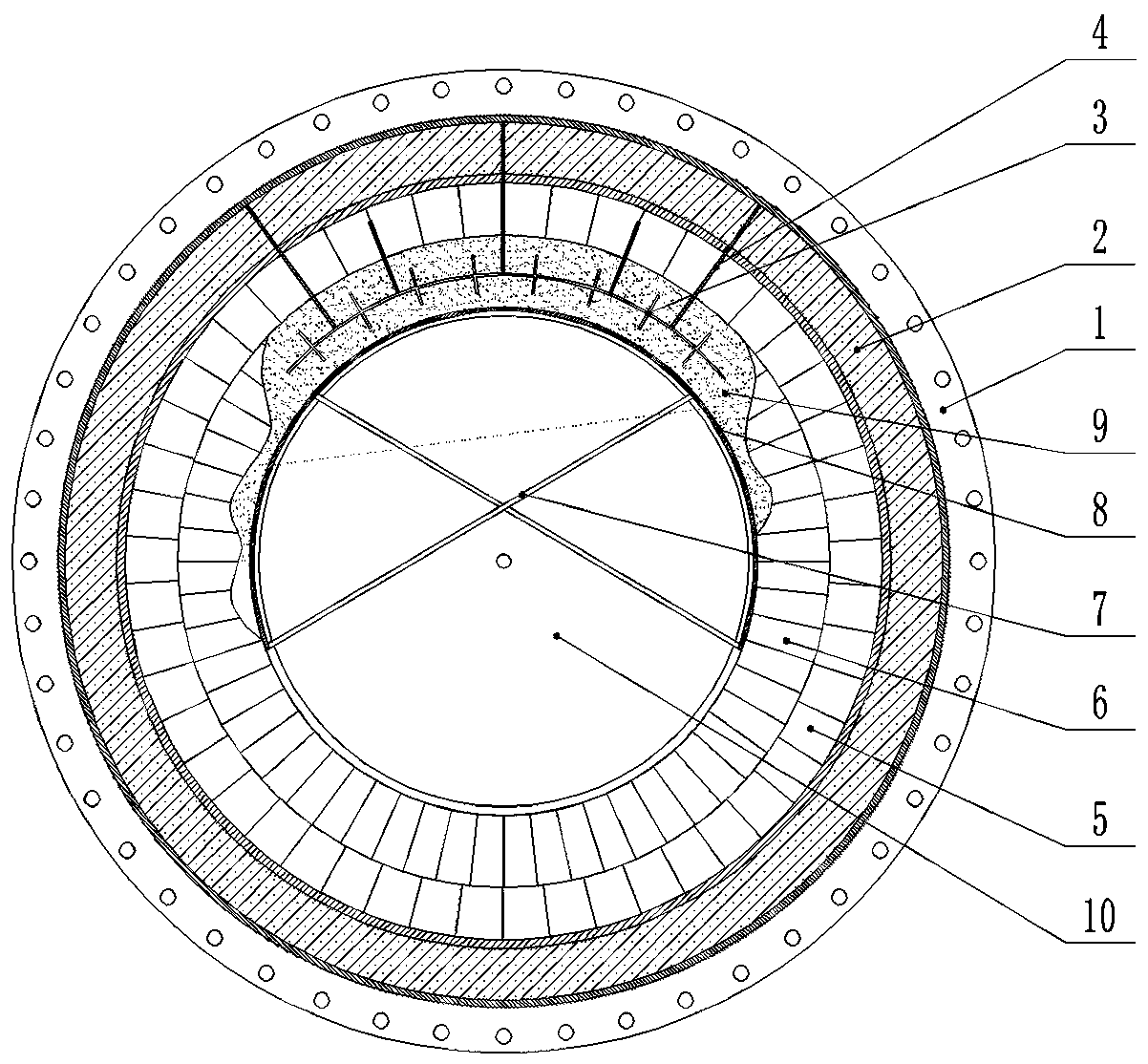

Flameless combustion chamber for Stirling engine and implementation method of flameless combustion chamber

PendingCN107883406AImprove uniformityImprove efficiencyContinuous combustion chamberIndirect carbon-dioxide mitigationStirling engineCombustion chamber

The invention discloses a flameless combustion chamber for a Stirling engine and an implementation method of the flameless combustion chamber. The flameless combustion chamber comprises a combustion chamber housing, a combustor and a heat exchanger; the housing consists of an upper housing part and a lower housing part; an exhaust pipe is arranged at the top of the housing; a heat exchanger barrelis arranged at the bottom of the housing; the lower housing part is connected with the top of the heat exchanger barrel into a whole; the top of the heat exchanger barrel, the lower housing part andthe upper housing part form a combustion chamber space; a hot cavity of the Stirling engine is formed in the lower end of the heat exchanger barrel; the top of the heat exchanger barrel separates thecombustion chamber from the hot cavity; the combustor and the heat exchanger are arranged in the housing from the top to the bottom sequentially; the heat exchanger comprises a circle of heat exchangepipes arranged in a reverse-U-shaped manner; and one ends of the heat exchange pipes communicate with the hot cavity of the Stirling engine, and the other ends of the heat exchange pipes communicatewith a reheater, thus a circuiting working medium system is formed. The implementation method comprises the step that the combustion chamber is used for combustion. The flameless combustion chamber and the implementation method have the characteristics that the combustion chamber is uniform in temperature, the combustion efficiency is high and the safety and reliability are achieved. The flamelesscombustion chamber is particularly suitable for the Stirling engine for use.

Owner:SHANGHAI MICROPOWERS

Plastics composite wall brick

InactiveCN101096882ASpecifications and sizes can be large or smallHigh dimensional accuracyCovering/liningsFlooringBrickEngineering

The invention discloses a plastic composite brick, which is characterized by the following: comprising plastic panel and injection moulding element; squeezing and forming the plastic panel directly; or squeezing; proceeding plastic uptake form; proceeding injection made and form directly; or compositing with multiple of injecting moulding element; binding or welding the upper of the injection moulding element and the lower surface of the plastic panel together; arranging back-off or cog at the bottom of the injection moulding element; arranging orientation and water-retaining structure at the relative two edges; binding or welding the edge of the plastic panel and the coincidence edge of the injection moulding element together. This invention is environment protection, which is a new type wall covering material.

Owner:冷鹭浩

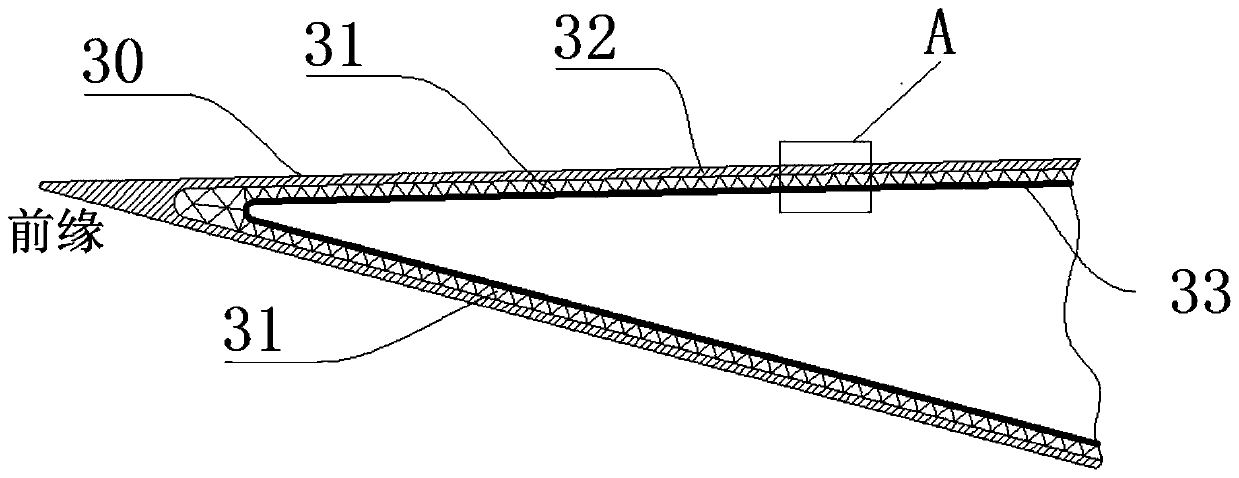

Hypersonic aircraft and thermal protection structure and coolant circulating system thereof

PendingCN109823510AReduce distortionReduce heat fluxAir-treatment apparatus arrangementsHeat reducing structuresInsulation layerThermal insulation

Owner:CENT SOUTH UNIV

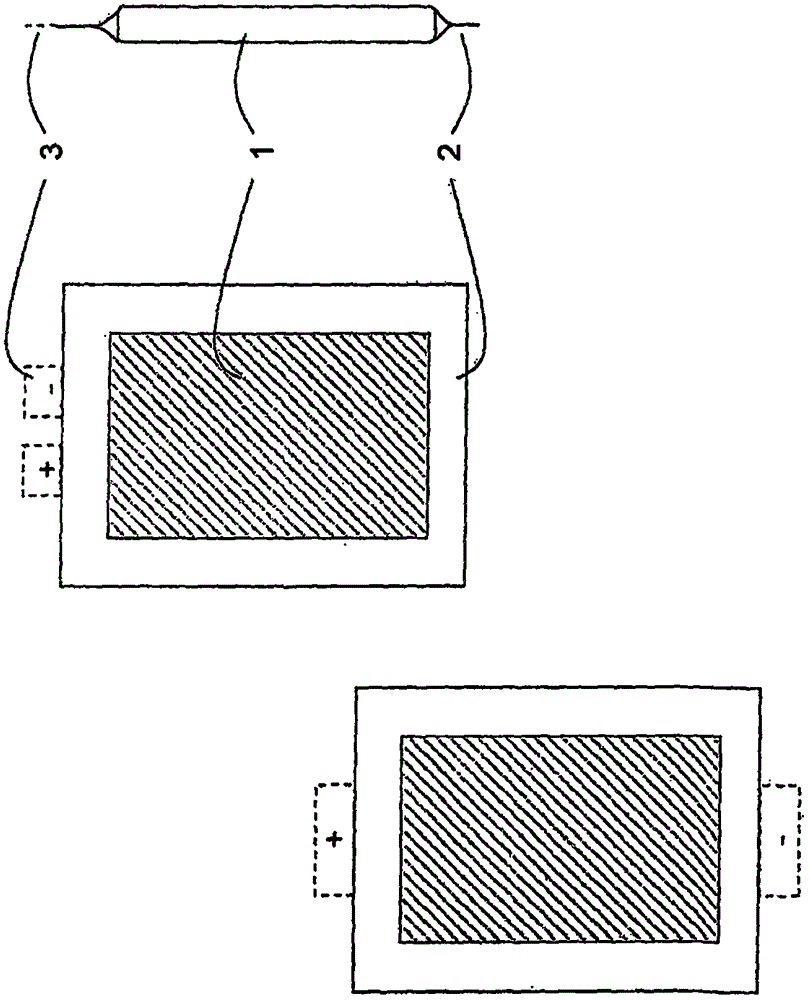

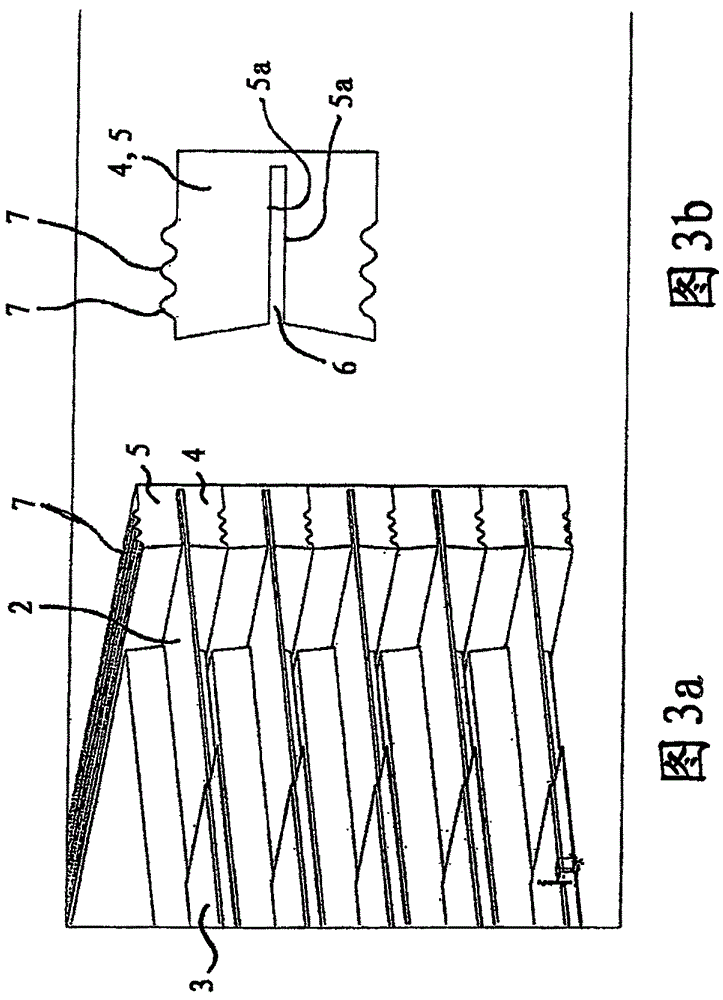

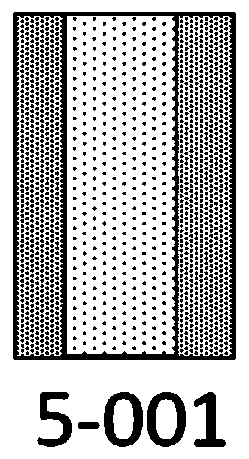

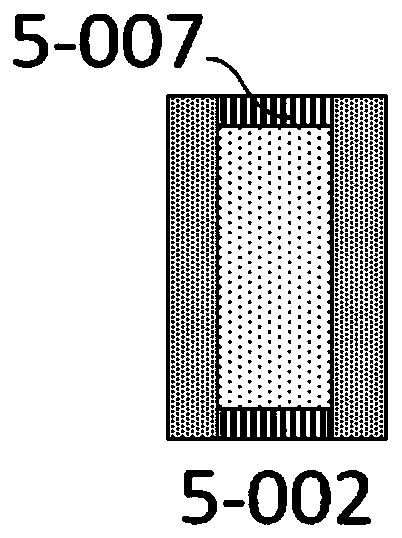

Receiving element for pouch cells

InactiveCN106384795AEasy to processNo penetrationFinal product manufactureBattery isolationEngineeringMechanical engineering

The invention relates to a receiving element (4) for mounting pouch cells, has a base body. The receiving element comprises a base body (5). With respect to an object of receiving the pouch cells securely and cost-effectively in a frame or housing, the receiving element is characterized in that the base body (5) is formed as a profile having a contact surface (5a) for contact against a sealing seam (2) of a pouch cell.

Owner:CARL FREUDENBERG KG

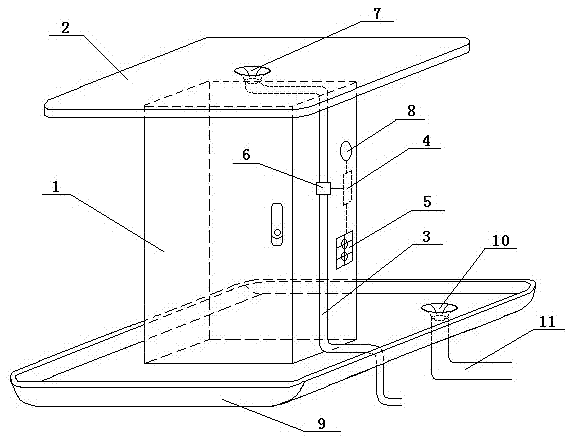

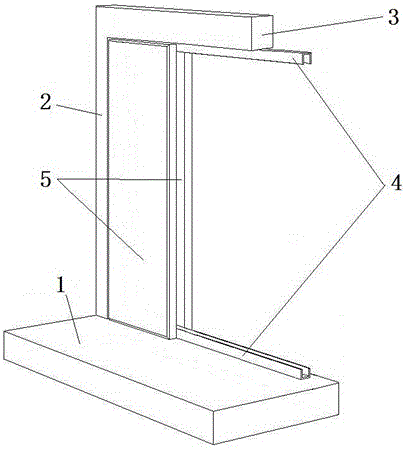

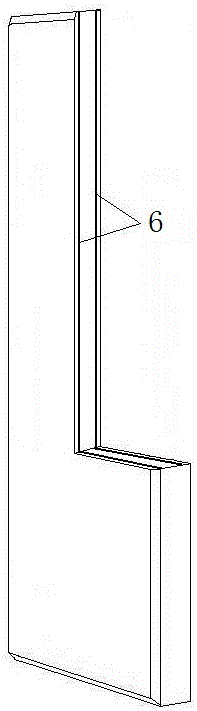

Heat insulation communication chassis

InactiveCN103200797AReduce intrusionReduce the impactCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsEngineeringCommunication device

The invention relates to a heat insulation communication chassis. The heat insulation communication chassis comprises a chassis body (1), and a heat insulation board (2). By arranging the heat insulation board (2) at the top of the chassis body (1), effective heat insulation and heat dissipation effects can be conducted on the chassis body (1), and therefore normal and stable operation of a communication device inside the chassis is guaranteed. Furthermore, the heat insulation communication chassis has the advantages of being simple in structure, easy to implement, and capable of possessing high market promotion value.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

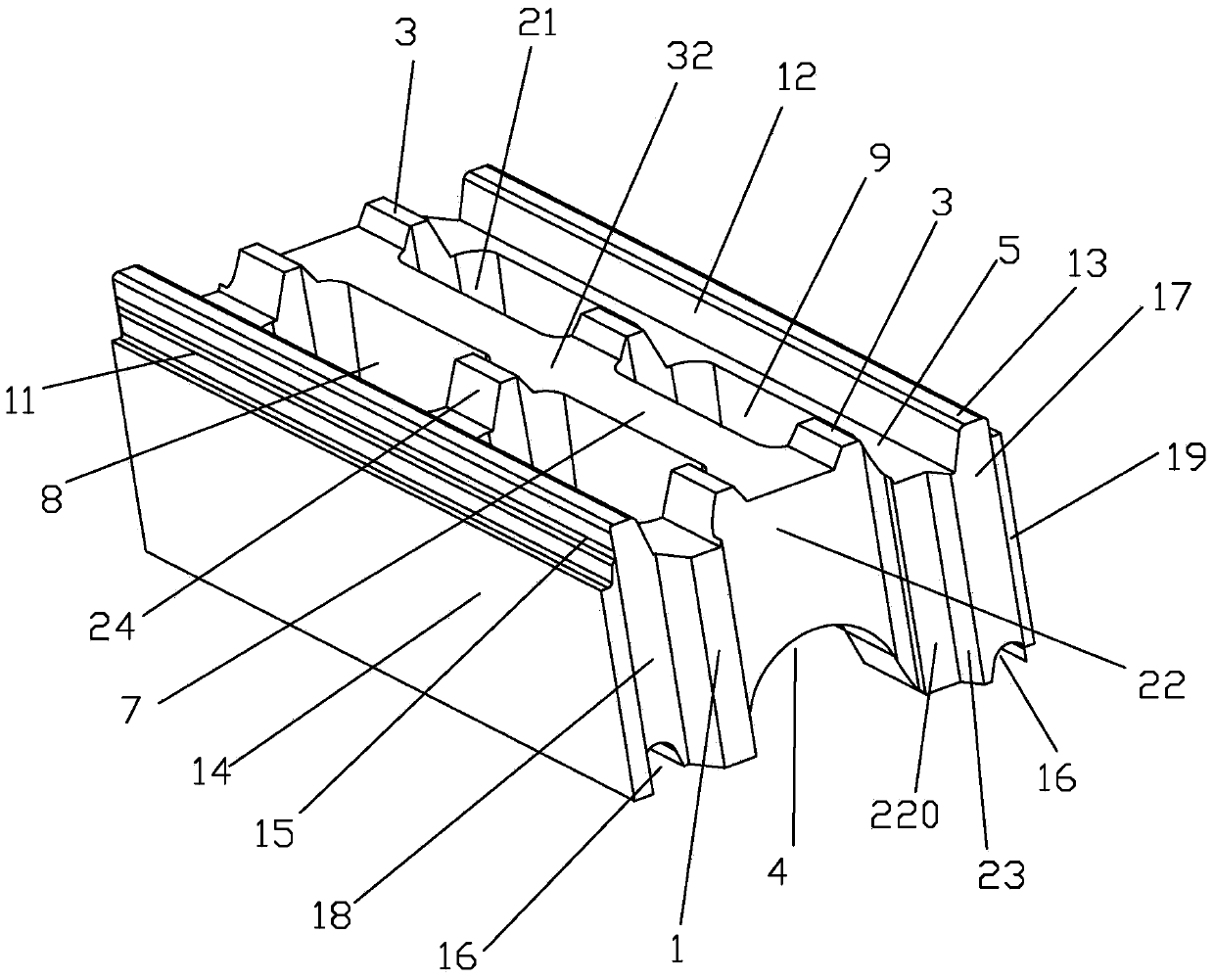

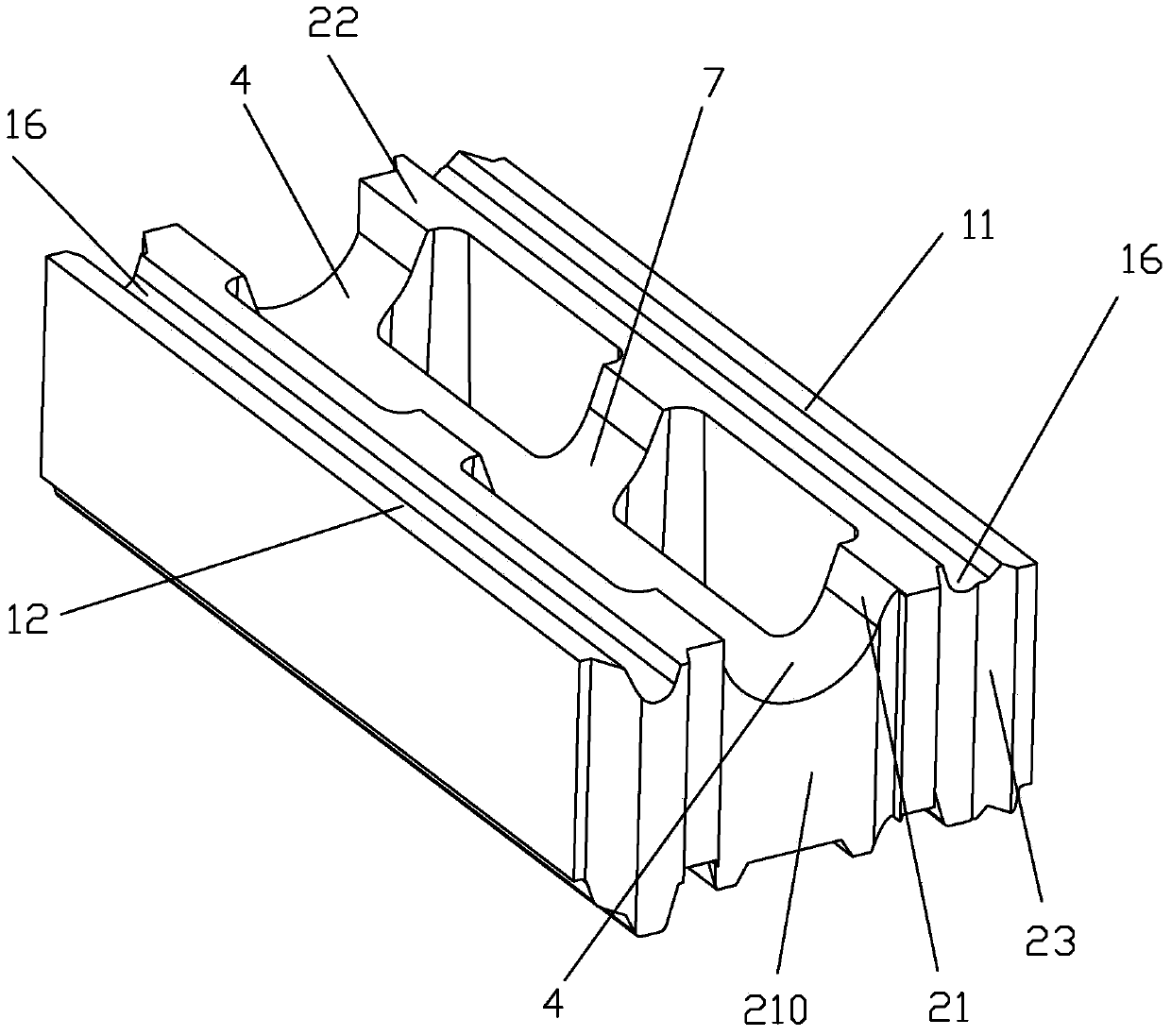

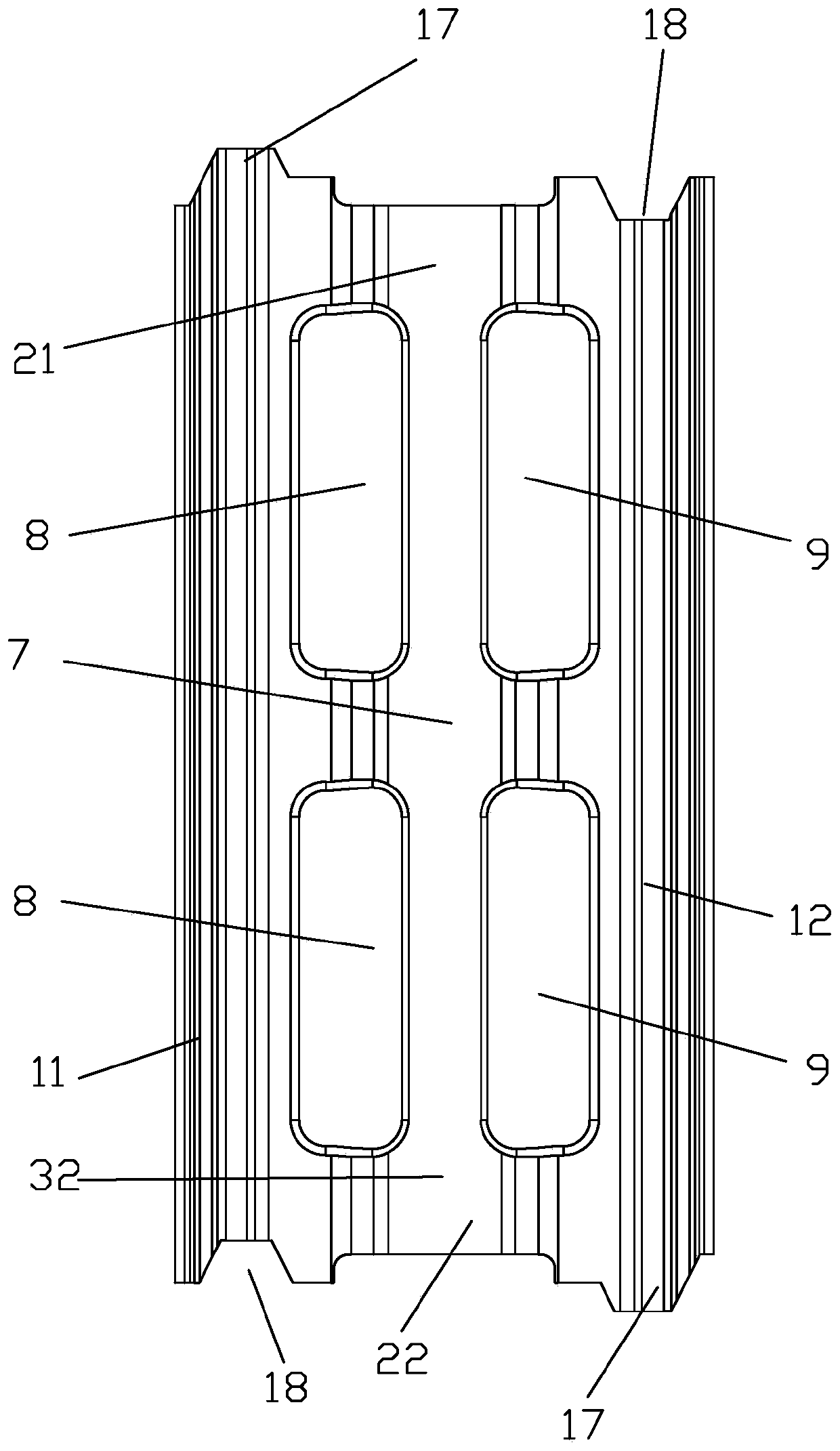

Main body brick used for constructing hollow wall

The invention discloses a main body brick used for constructing a hollow wall. The main body brick comprises a brick body which comprises a first long edge, a second long edge, a left rib and a right rib, limiting bosses are arranged on the upper ends of the left rib and the right rib, limiting grooves matched with the limiting bosses are formed at the lower ends of the left rib and the right rib, protruding strips are arranged at the upper ends of the first long edge and the second long edge, lower grooves matched with the protruding strips are formed at the lower ends of the first long edge and the second long edge, and the brick body is provided with through holes penetrating from top to bottom. When the main body brick is used for constructing the wall, upper-layer building blocks are piled on lower-layer building blocks, and the limiting grooves of the upper-layer building blocks are clamped on the limiting bosses of the lower-layer building blocks, so that the wall can be constructed more quickly and more accurately, and the constructed wall can be straight and smooth without string pulling or other methods. The wall constructed by the main body brick can realize ventilation, temperature preservation and heat insulation.

Owner:东莞市吉吉晟电子科技有限公司

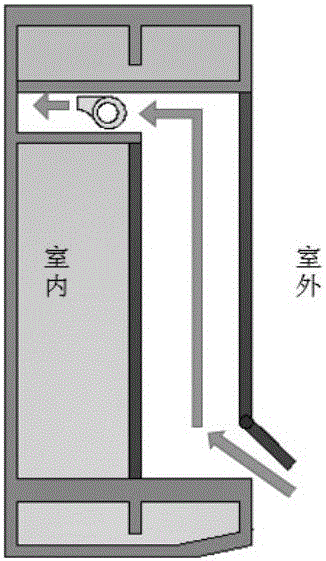

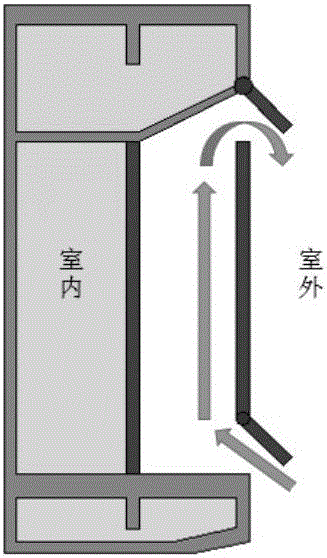

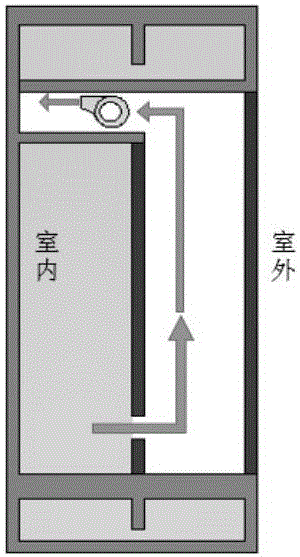

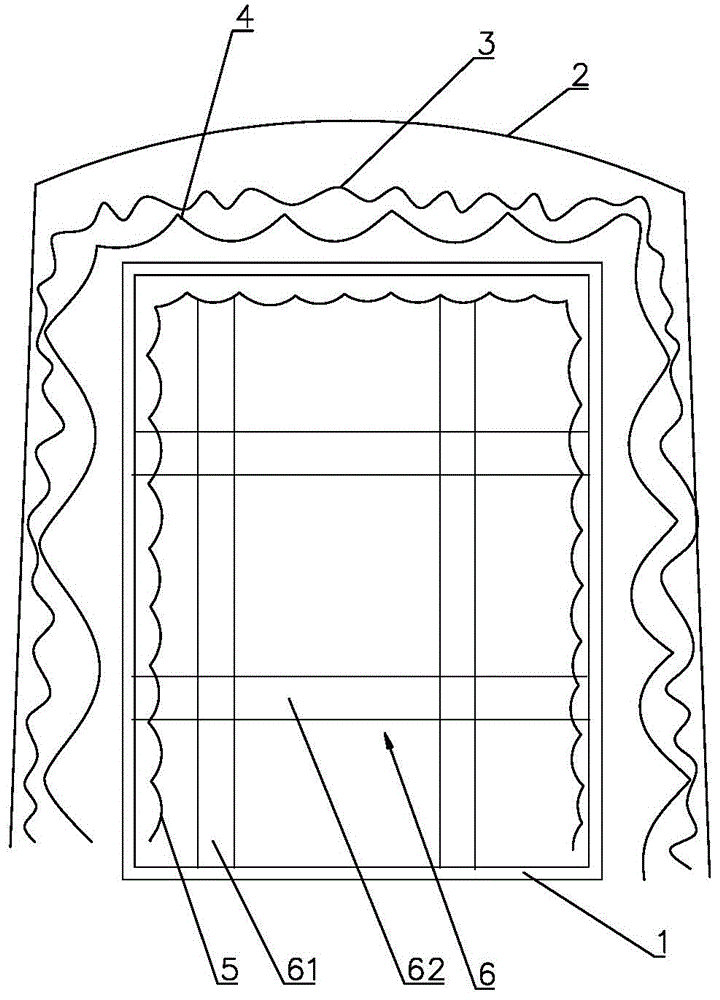

Glass curtain wall

InactiveCN106013538ARealize the insulation effectAchieve heat insulationDoor/window protective devicesWallsEngineeringThrough transmission

The invention discloses a glass curtain wall which comprises single-layer glass arranged on the outer side and double-layer hollow glass arranged on the inner side. A first permeable plate is arranged at a gap between the single-layer glass and the double-layer hollow glass. A second permeable plate is arranged between the double-layer hollow glass and a wall. The single-layer glass located below the first permeable plate is composed of a plurality of first glass louvers. The double-layer hollow glass located below the first permeable plate is composed of a plurality of second glass louvers. The first glass louvers and the second glass louvers are connected with a motor through transmission mechanisms. The motor is controlled by a controller. The glass curtain wall can achieve heat preservation in winter, heat protection and heat insulation in summer and indoor ventilation.

Owner:WUHAN UNIV OF TECH

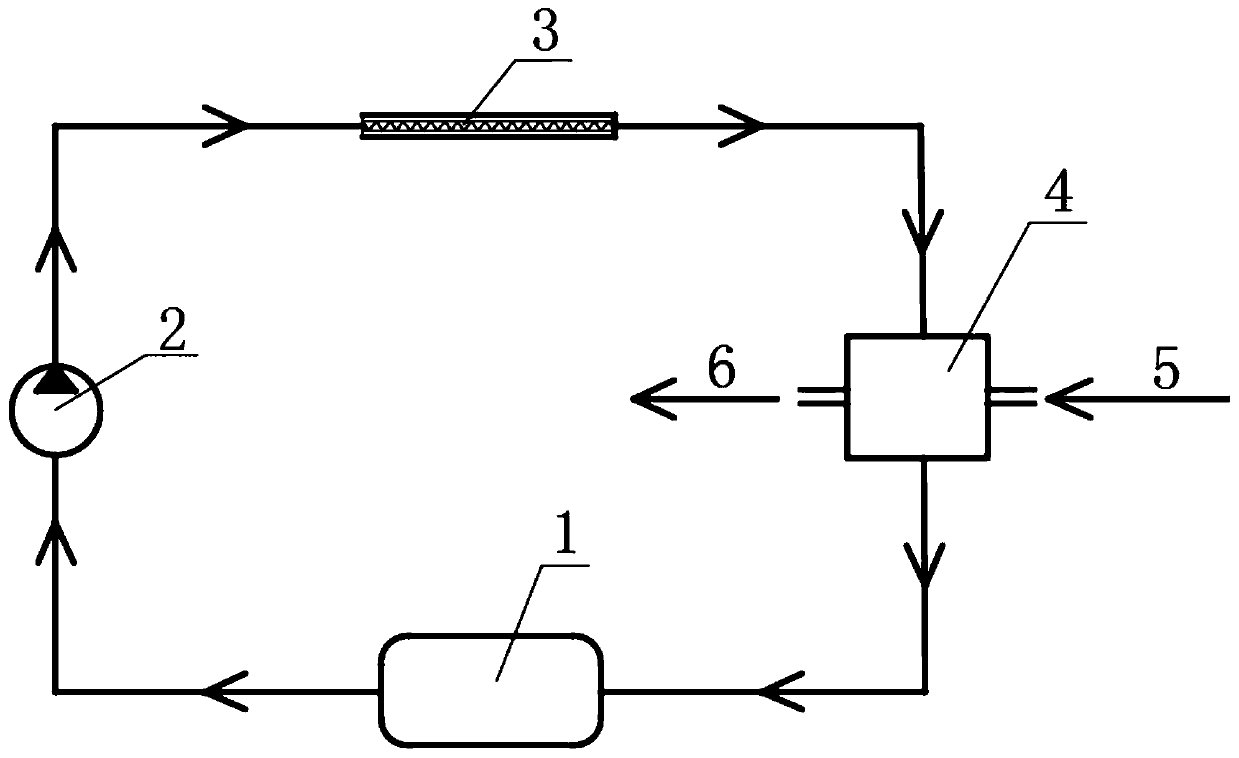

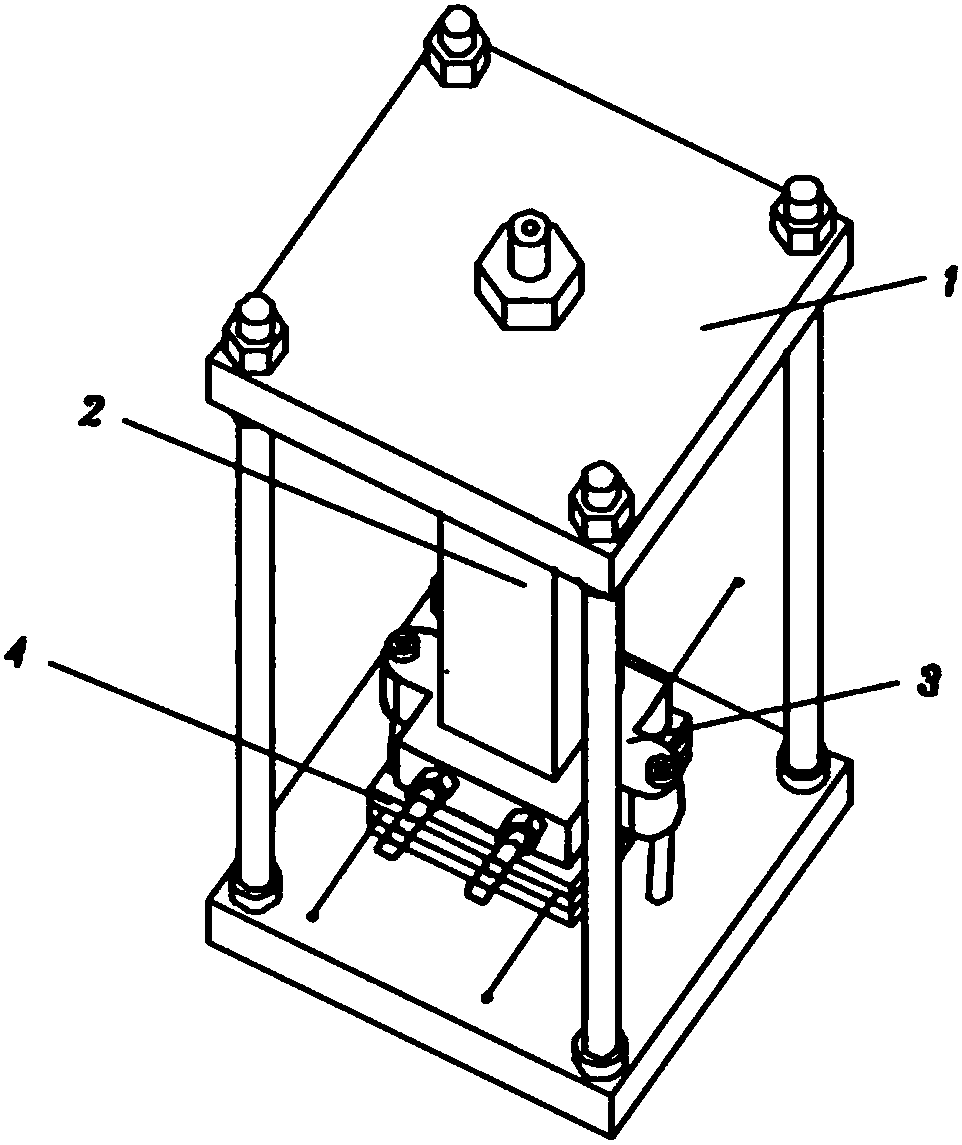

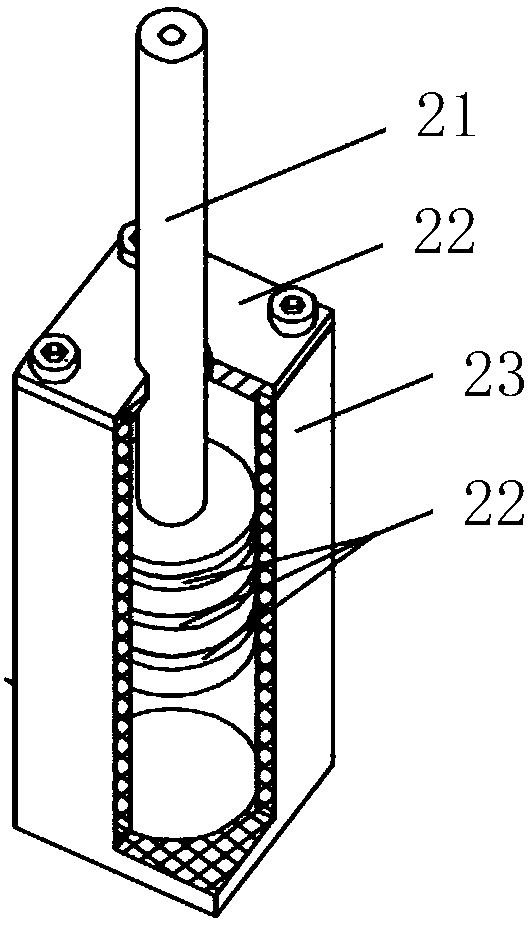

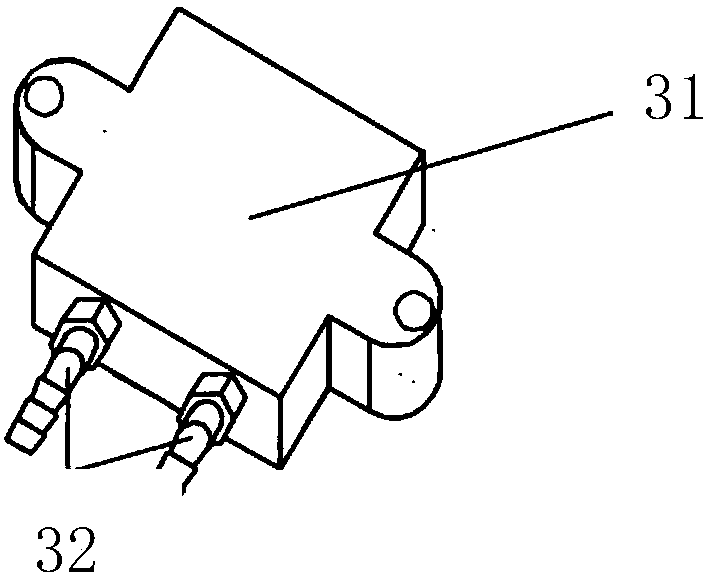

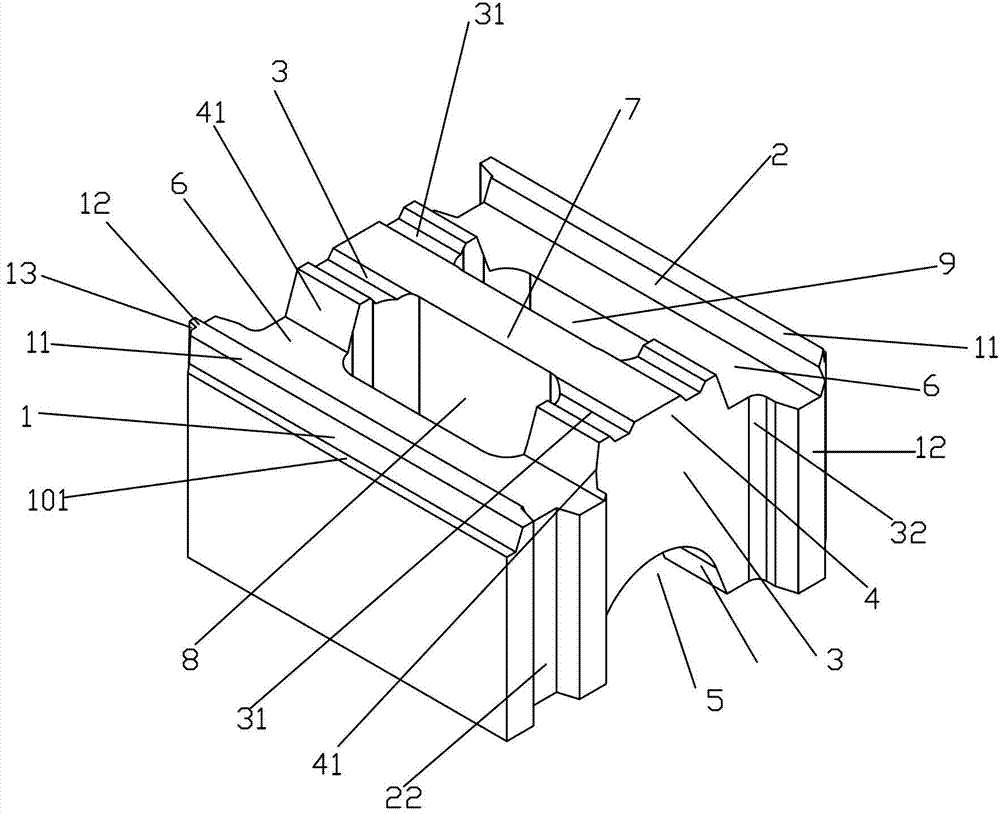

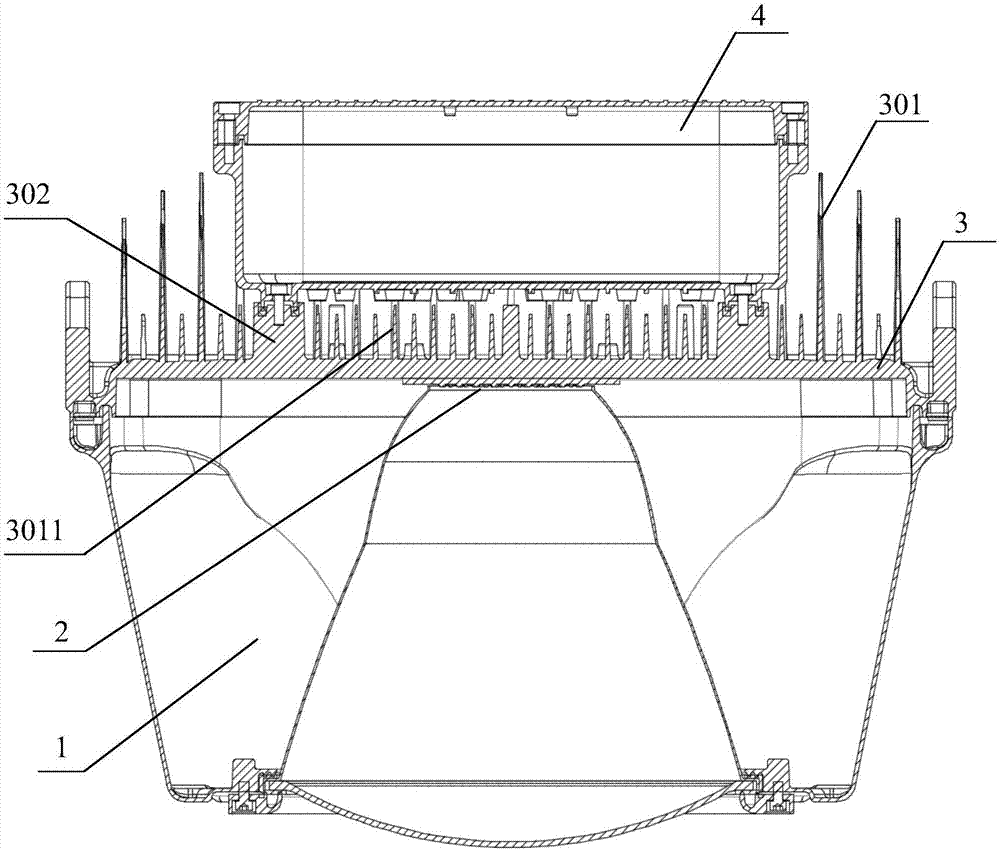

Thermoelectric performance test workbench of thermoelectric generation single module

InactiveCN107727951AUniform and controllable forceImplement performance testingElectrical testingElectricityPressure system

The invention discloses a thermoelectric performance test workbench of a thermoelectric generation single module, comprising a work bench, an air pressure system, a cooling circulatory system, and anelectric heating test system. An upper work surface of the work bench and a lower work surface of the work bench are connected through at least two supporting columns. The lower work surface is provided with the electric heating test system, the cooling circulatory system, and the air pressure system in order from top to bottom. The cooling circulatory system comprises a cooling water sleeve. Twosides of the cooling water sleeve are each provided with a boss. Each boss is provided with a fixing hole. The cooling circulatory system is connected to the lower work surface through the fixing holes. The electric heating test system is clamped and fixed between the cooling circulatory system and the lower work surface. The air pressure system comprises a sliding air pressure valve and a cylinder. The center of the upper work surface is provided with a through hole. The sliding air pressure valve penetrates through the through hole and is connected to and fixed to the upper work surface. Thecylinder presses against the cooling circulatory system. The invention is advantageous in that the influence of uneven pressure on interface contact thermal resistance can be effectively prevented; the heat source power density can be raised; heat insulation between the test system and the external can be realized; the test precision of the thermoelectricity transition can be increased.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Building block

InactiveCN102776975AFaster and more accurateStrong wind resistanceBuilding componentsArchitectural engineeringEngineering

Owner:广东东高新型建材有限公司

Piston manufacturing method and piston

ActiveCN111850557ASmall heat capacityLow thermal conductivityAnodisationVacuum evaporation coatingElectrochemical responseMicro arc oxidation

The invention belongs to the technical field of machining, and discloses a piston manufacturing method and a piston. The piston manufacturing method comprises the steps that the top surface of a piston matrix is coated through magnetic control injection to form a metal layer, wherein the metal layer is a composite metal layer of aluminum oxide and zirconium oxide; and electrochemical reaction is performed on the metal layer by adopting a micro-arc oxidation mode to form a ceramic layer, wherein the ceramic layer is of a hole-shaped structure. According to the piston manufacturing method, aluminum oxide is added on the basis of zirconium oxide due to the composite metal layer of aluminum oxide and zirconium oxide, so that the heat capacity of the metal layer is effectively reduced, the situation that the temperature of a combustion chamber rises because heat insulation stores a lot of heat is avoided, and sufficient combustion of fuel is facilitated. At the same time, the ceramic layeris of a loose structure and has low heat capacity, so that the heat capacity of the piston matrix is further reduced. In addition, the air heat conductivity coefficient in a micro-hole coating is extremely small, and the heat conductivity of air is poor, so that heat transfer from high-temperature gas to the piston matrix can be hindered, and the heat conductivity of the piston matrix is effectively reduced.

Owner:WEICHAI POWER CO LTD

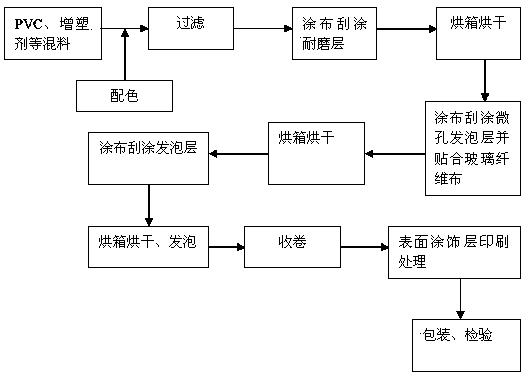

Stable interior wall decorative material and method for manufacturing same

ActiveCN103485503AExcellent sound absorption and heat insulation propertiesGood inhibitory effectCovering/liningsSynthetic resin layered productsGlass fiberFiber

The invention discloses a stable interior wall decorative material which comprises a fiber cloth\glass fiber layer. An upper PVC (polyvinyl chloride) layer and a lower PVC layer are arranged on the upper side and the lower side of the fiber cloth\glass fiber layer, the upper PVC layer comprises a surface abrasion-resistant layer and a microporous cell layer, and the microporous cell layer is arranged between the surface abrasion-resistant layer and the fiber cloth\glass fiber layer; the lower PVC layer is a foam layer, the upper PVC layer further comprises a surface coating layer, and the surface abrasion-resistant layer is arranged between the surface coating layer and the microporous cell layer. The invention further discloses a method for manufacturing the stable interior wall decorative material. The stable interior wall decorative material and the method have the advantages that the high-performance fiber cloth\glass fiber layer is compounded with PVC materials, so that the stability and the strength of the product can be improved, the stable interior wall decorative material is excellent in characteristics such as flame retardance, heat insulation, damp proofing, sound insulation and mildew proofing, and is long in service life, and patterns on the surface of the product are rich and varied.

Owner:四川金路高新材料有限公司

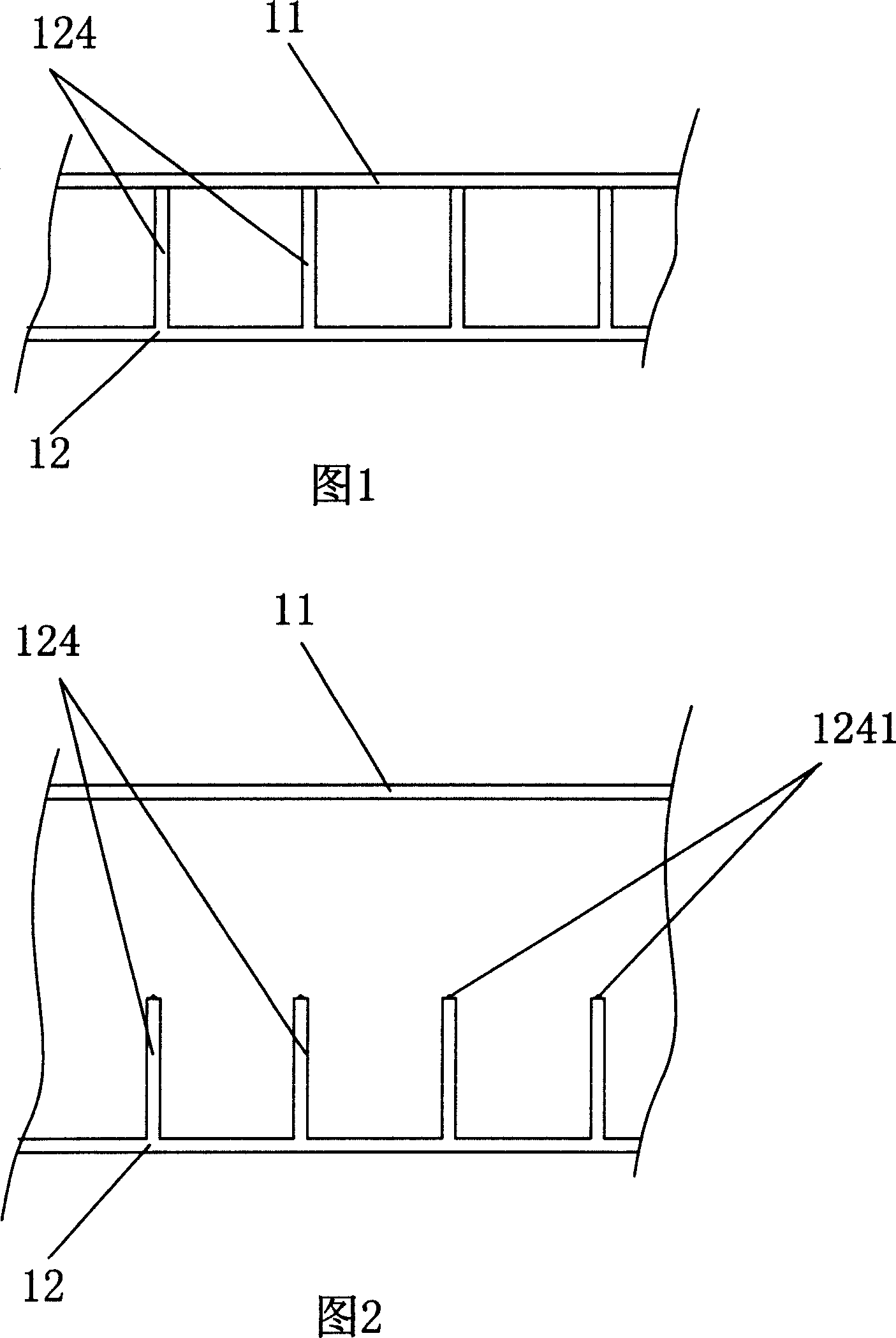

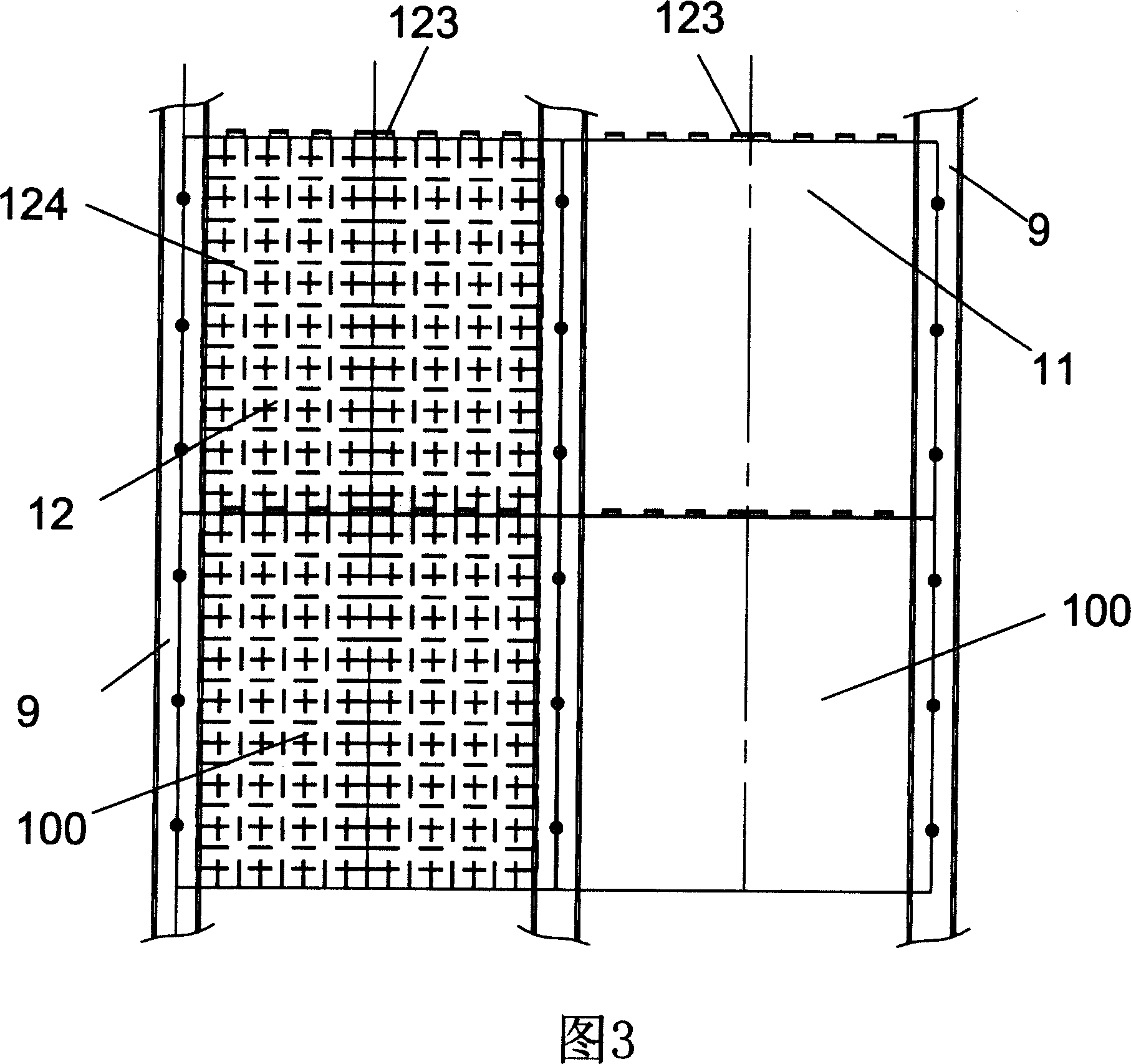

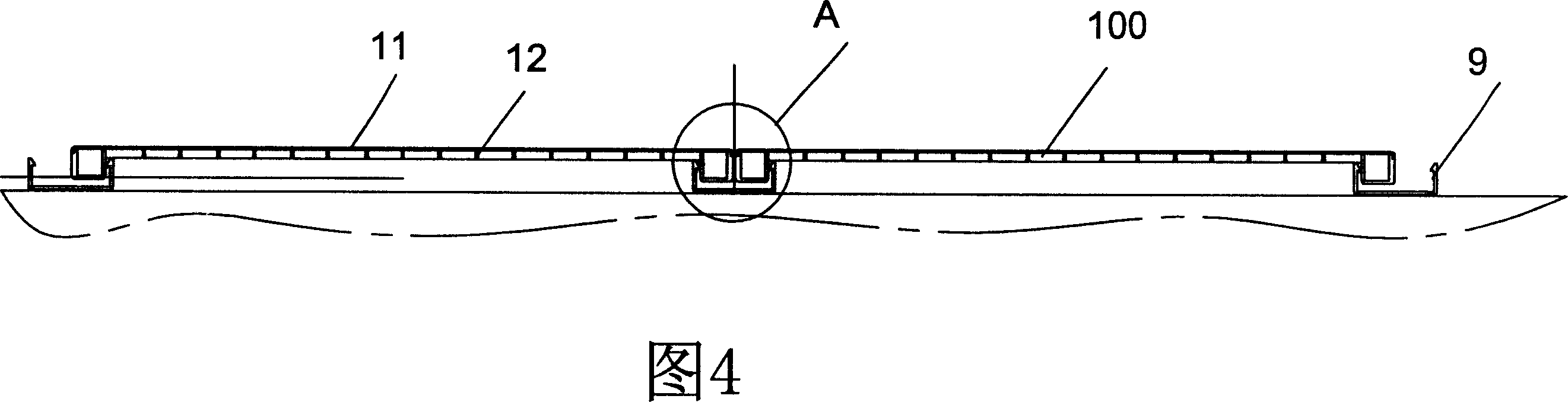

Assembled prefabricated wallboard

InactiveCN105839815ARealize energy savingRealize environmental protectionConstruction materialWallsThermal insulationEngineering

The invention relates to a prefabricated wallboard, in particular to an assembled prefabricated wallboard, belonging to the technical field of building materials. The assembled prefabricated wallboard comprises a floor panel, an upright post, a cross beam, positioning profiles and prefabricated boards; one positioning profile is arranged in the middle of the lower end of the cross beam; the other positioning profile is arranged at a projecting position of the floor panel; the upper and lower positioning profiles are aligned two by two; a plane formed by the positioning profiles is perpendicular to the floor panel; the prefabricated boards are fixed at two sides of the positioning profiles, so that the prefabricated boards and the positioning profiles integrally form a hollow wall body. The prefabricated boards disclosed by the invention are made of foamed concrete; by using a hollow layer formed by assembling, the functions of environmental protection, heat insulation, sound insulation, water resistance, flame retardance and the like of the wallboard are effectively realized. According to the prefabricated wallboard disclosed by the invention, by adopting the positioning profiles, the stability of the wallboard is improved; meanwhile, greater convenience in mounting is realized, and the construction cycle is shortened. The prefabricated boards disclosed by the invention are subjected to chamfering treatment machining and are sequentially spliced and assembled to form ditch joints which are floated with cement, so that cracks are avoided.

Owner:巫智园

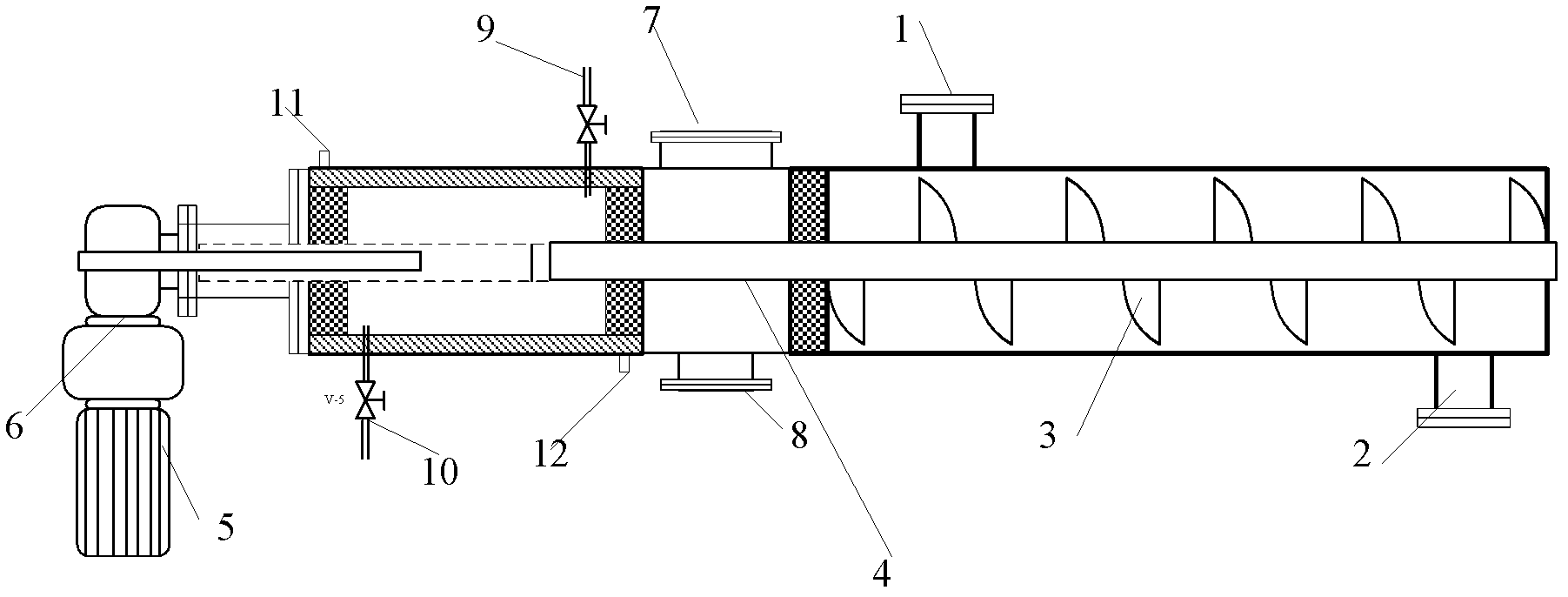

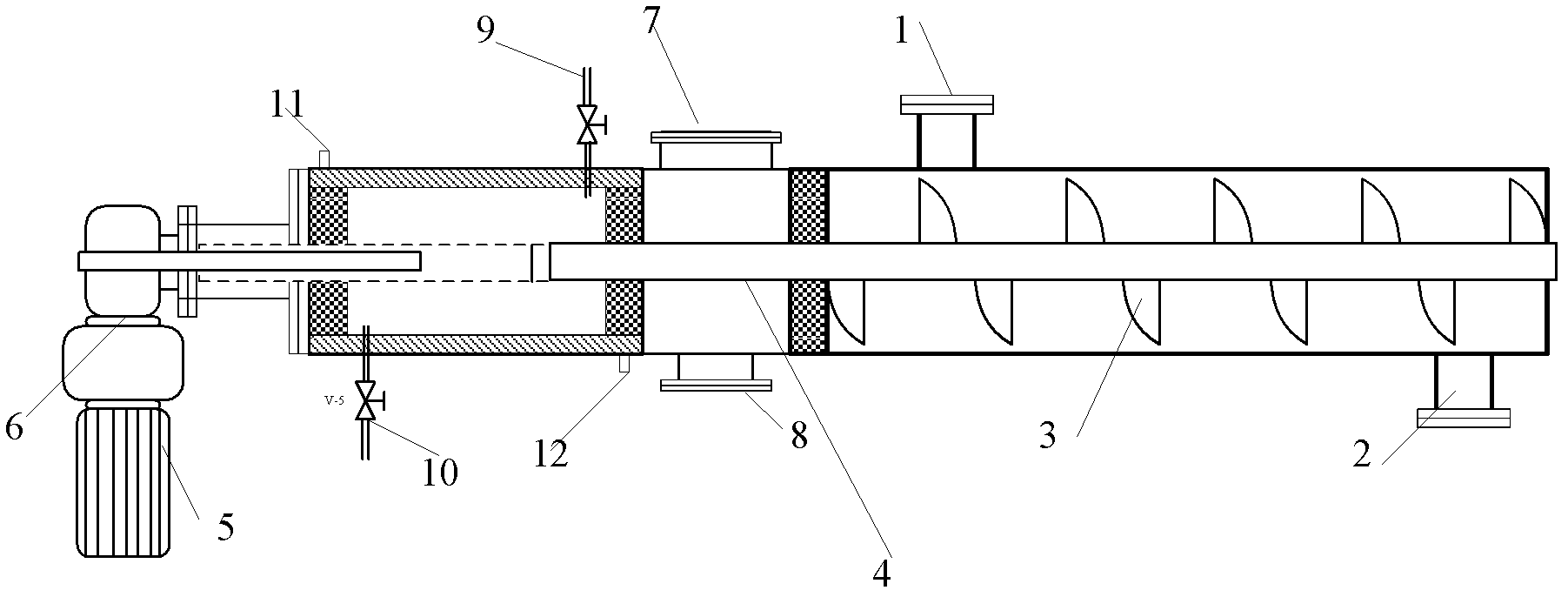

High-temperature-resistant screw conveyor

The invention relates to a high-temperature-resistant screw conveyor, which comprises a motor control system, a material conveying system and a cooling sealing system. The cooling sealing system is coaxially arranged between the material conveying system and the motor control system and comprises a solid heat-insulating and sealing device which is communicated with the material conveying system through a screw shaft connector, a solid feed inlet is arranged above the solid heat-insulating and sealing device, a discharge outlet is arranged below the solid heat-insulating and sealing device, solid particles passing the solid heat-insulating and sealing device are used for heat insulating and cooling. The cooling sealing system further comprises an air cooling device and a liquid circular-cooling device which are coaxially arranged between the solid heat-insulating and sealing device and the motor control system and share the same cylindrical cavity, and a casing of each cylindrical cavity has a hollow interlayer structure. The high-temperature-resistant screw conveyor has the advantages of simple structure and capability of conveying high-temperature materials and the like.

Owner:河北中科能源有限公司 +1

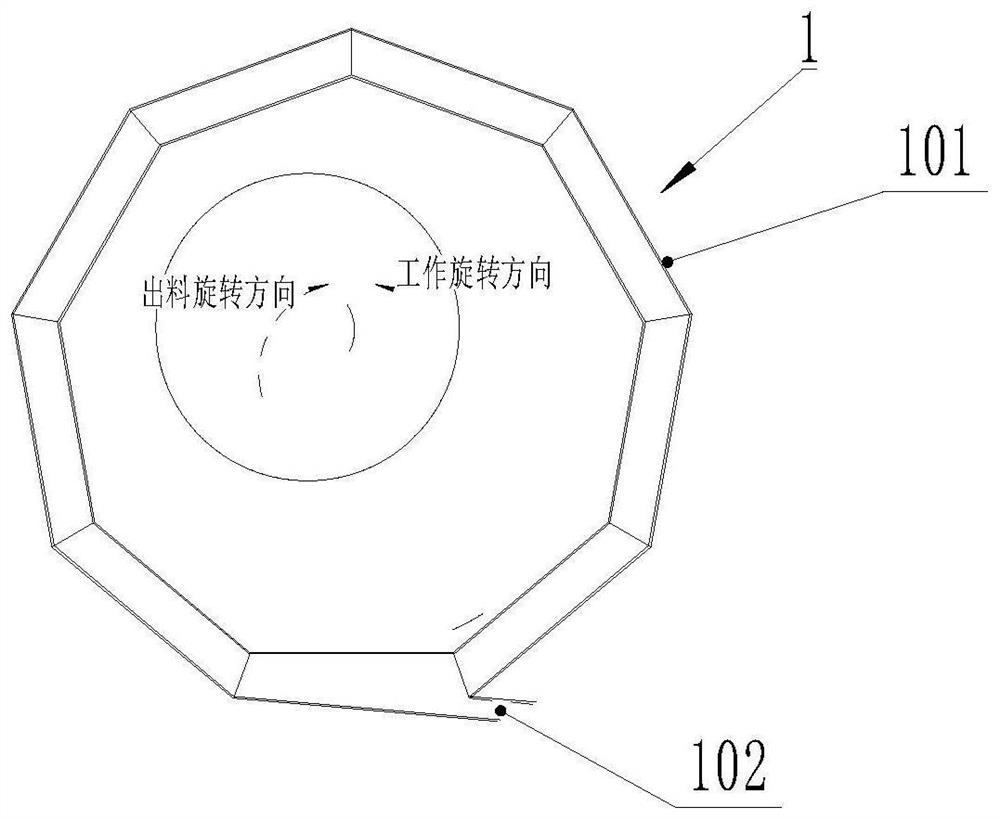

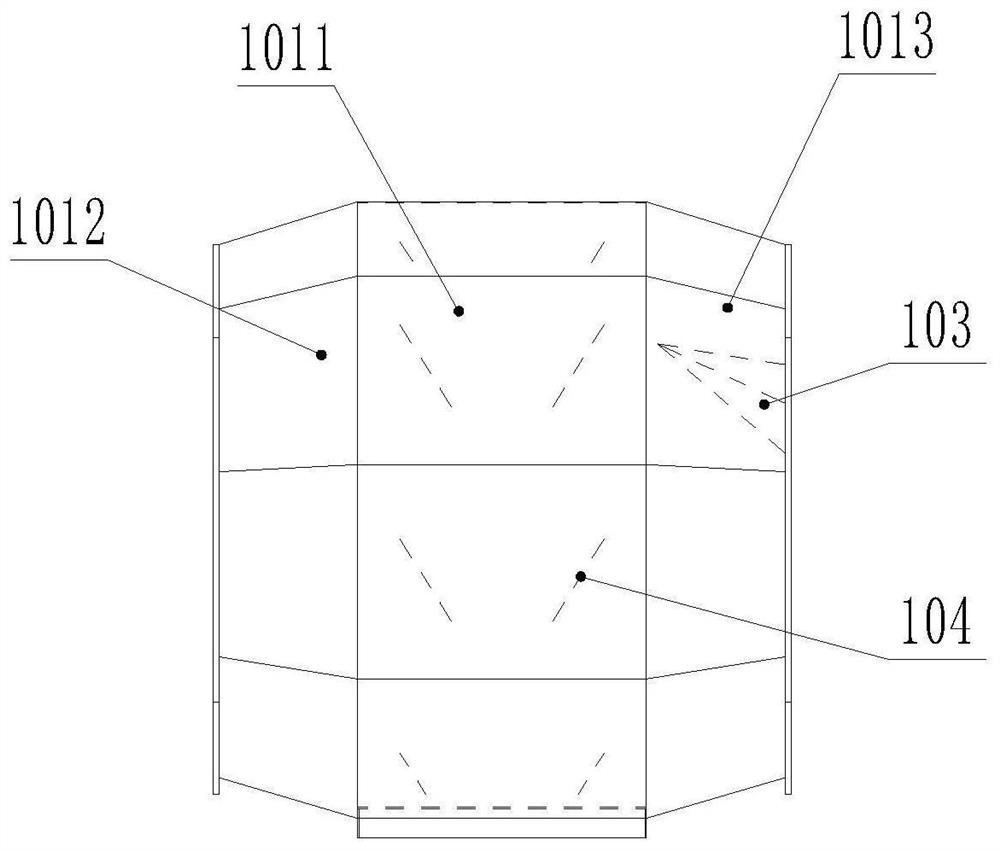

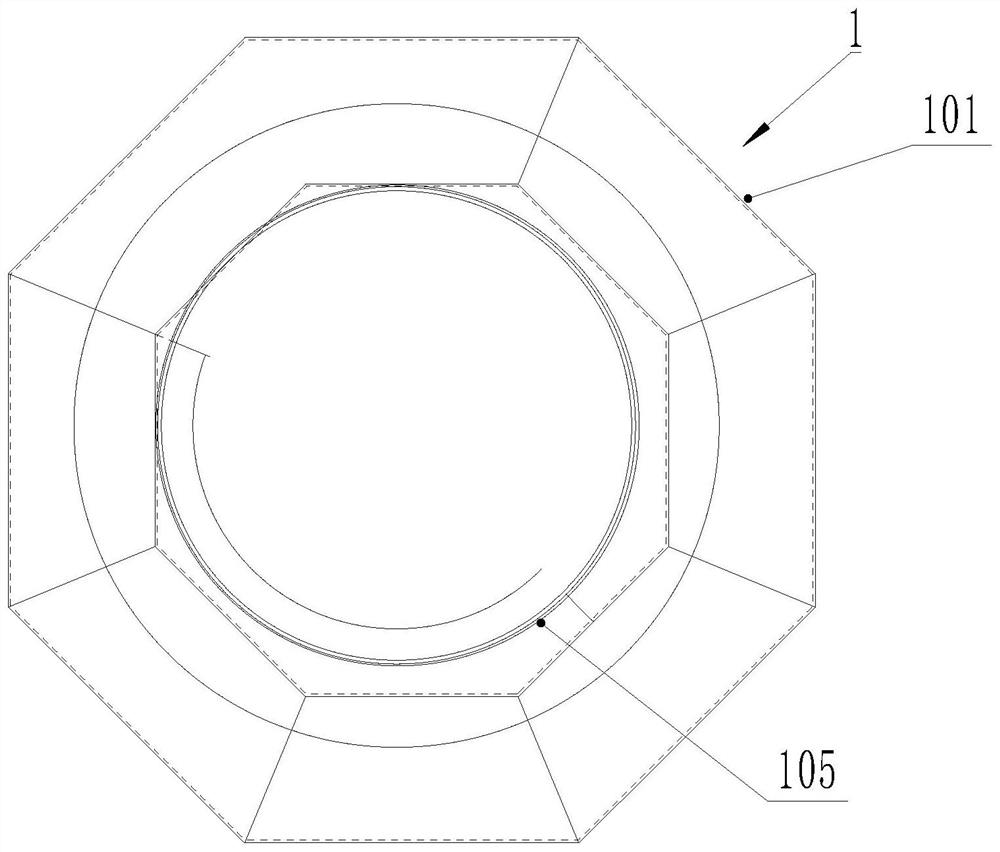

Charging barrel of infrared dehumidification, crystallization and drying all-in-one machine and crystallization and drying all-in-one machine

PendingCN112622091AMeet dryMeet dehumidificationDrying solid materials with heatGranular material dryingInfraredEngineering

The invention discloses a charging barrel of an infrared dehumidification, crystallization and drying all-in-one machine and a drying machine. The cross section of the charging barrel is in the shape of a polygon with the side number larger than the side number of a pentagon; one end of the charging barrel is open and serves as a feeding end; each plate face forming the polygonal charging barrel comprises a middle plate part, a first closing-in plate part and a second closing-in plate part; the first closing-in plate part and the second closing-in plate part are arranged at the two ends of each middle plate part, form obtuse angles with each middle plate part and are closed in the middle; a discharge hole is formed in the side wall of the charging barrel or an opening in the other end of the charging barrel is set as the discharge hole; and when the opening in the other end of the charging barrel is set as the discharge hole, a spiral discharging guide plate facilitating discharging of materials is arranged in the charging barrel. According to the drying machine, the charging barrel is used, the better material turning effect can be achieved under the condition that no material turning plate exists, the machining difficulty is low, and the drying machine is suitable for crystallization and drying of plastic particles with high viscosity.

Owner:ZHANGJIAGANG LIANDA MACHINERY

Blended rubber special protective fabric

InactiveCN104705871AConsider comfortConsider heat resistanceSynthetic resin layered productsRubber layered productsRubber materialCarbon fibers

The invention discloses blended rubber special protective fabric which is composed of a skeleton material and an attachment material. The skeleton material is a mixed material of aramid fibers and carbon fibers, and the attachment material is a rubber material in which nitrile rubber, chloroprene rubber and silicone rubber are used in a blended mode, and the attachment amount of the blended rubber material on the skeleton material is 100-180 g / m<2>. A compounding agent is added in the blended rubber material, and the compounding agent comprises magnesium oxide, zinc oxide, antimonous oxide, chlorinated paraffin, aluminium hydroxide, activated carbon, DBPO dibenzoyl peroxide, accelerant, an anti-aging agent and a swelling agent at a certain proportion. The above attachment material is subjected to the steps of mixing, rubberizing and vulcanization to achieve the preparation of the fabric. According to the blended rubber special protective fabric, inflaming retarding, gas defense and mechanical property are all considered, the fabric can be worn comfortably, the production process is simple, implementation is easy, the application range is wide, and the problems that same fabric in China is single in protective performance, poor in breathing smoothness and not capable of fully performing the synergistic effect of blending of multiple sorts of rubber are solved.

Owner:SHAANXI SCI TECH UNIV

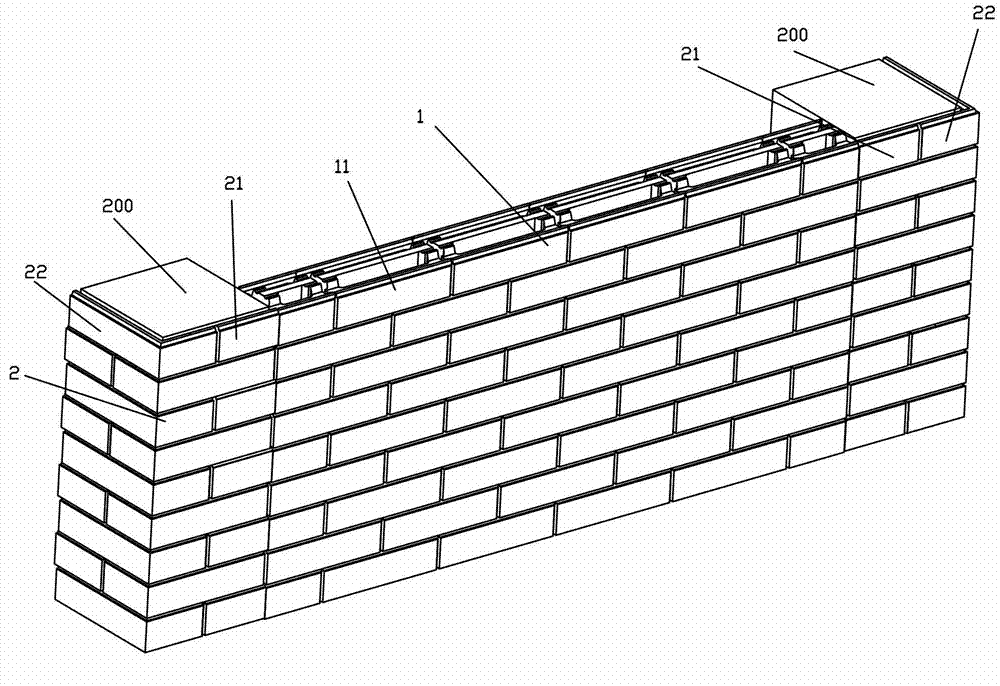

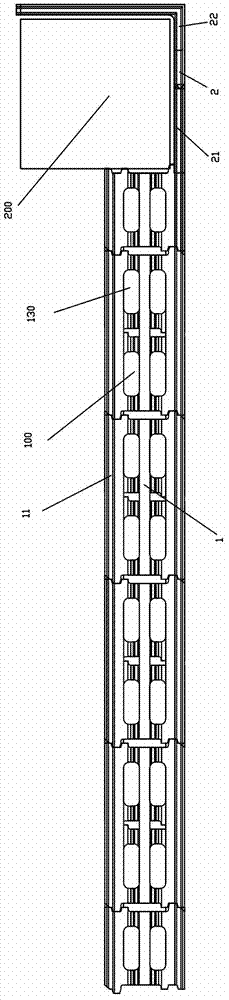

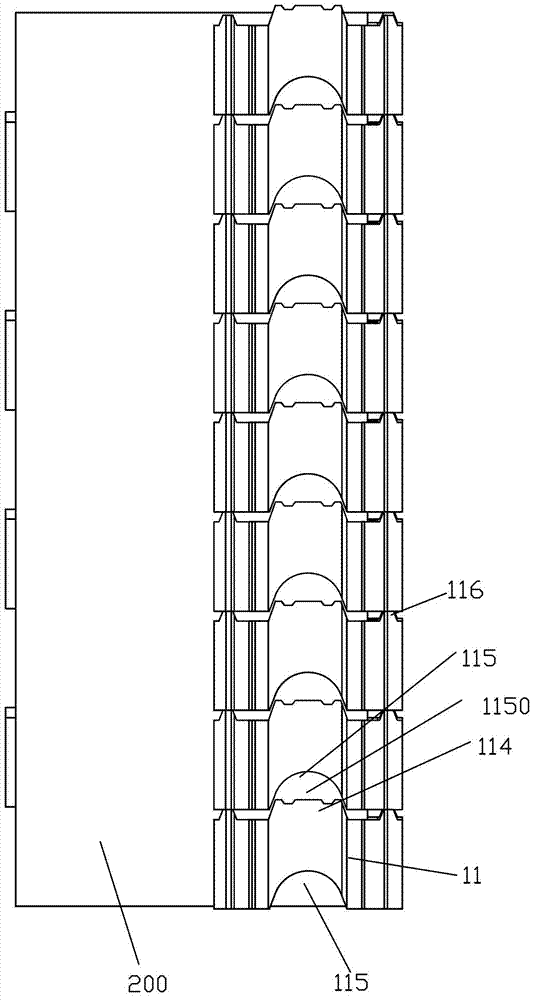

Hollow load bearing wall

The invention discloses a hollow load bearing wall, which is arranged between two concrete columns, and comprises a main wall body and decorative walls adhered to the concrete columns, wherein the main wall body is formed by stacking a plurality of layers of bricks layer by layer; bricks on adjacent upper and lower layers are arranged in a staggered mode; each decorative wall comprises a single-face panel brick and an angle panel brick with a right angle; each brick comprise a first strip side and a second strip side which are arranged at an interval with a certain distance, and a ribbed bar for connecting the first strip side and the second strip side; and each single-face panel brick comprises a single-face panel body. According to the hollow load bearing wall, the butt joint of bricks on the same layer is very convenient, a wall body can be built quickly and accurately without needing other stay wires or other methods, horizontal self alignment between bricks on the same layer is realized, vertical self alignment between an upper layer and a lower layer is realized, and the built wall body is firmer and has good shock resistance; and vent holes of the bricks on the adjacent upper and lower layers are communicated, so that the main wall body is provided with a ventilation and heat-insulation hollow layer, and ventilation, heat preservation and heat insulation are realized.

Owner:广东东高新型建材有限公司

Power source thermal isolation high-power LED lamp

PendingCN108006548AReduce physical contact areaImproved thermal isolationElectric circuit arrangementsLighting heating/cooling arrangementsThermal isolationRubber ring

The invention provides a power source thermal isolation high-power LED lamp. Safety and reliability of a power source of the high-power LED lamp can be improved, and adverse effects on a power sourcebin due to heat dissipation are lowered. In the power source thermal isolation high-power LED lamp, a front face cover, a light source plate and a heat dissipation shell form a light source bin. The power source bin is fixedly connected with the back of the heat dissipation shell. The power source bin and the heat dissipation shell are relatively independent, and a space is kept. A set of bosses are formed on the back of the heat dissipation shell and between heat dissipation fins. The bottom face of the power source bin is fixedly connected with the set of bosses through a set of screws, a space is kept between the bottom face of the power source bin and the heat dissipation fins below the bottom face of the power source bin, and fixed installation of the power source bin is achieved. Atleast one connecting column is further formed on the back of the heat dissipation shell. The connecting column is provided with a center channel communicating with the light source bin so as to achieve penetrating and connecting of circuits. The bottom face of the power source bin is provided with a connector matched with the connecting column, and a seal thermal isolation rubber ring is arrangedon the joint.

Owner:西安锐泽克斯光电科技有限公司

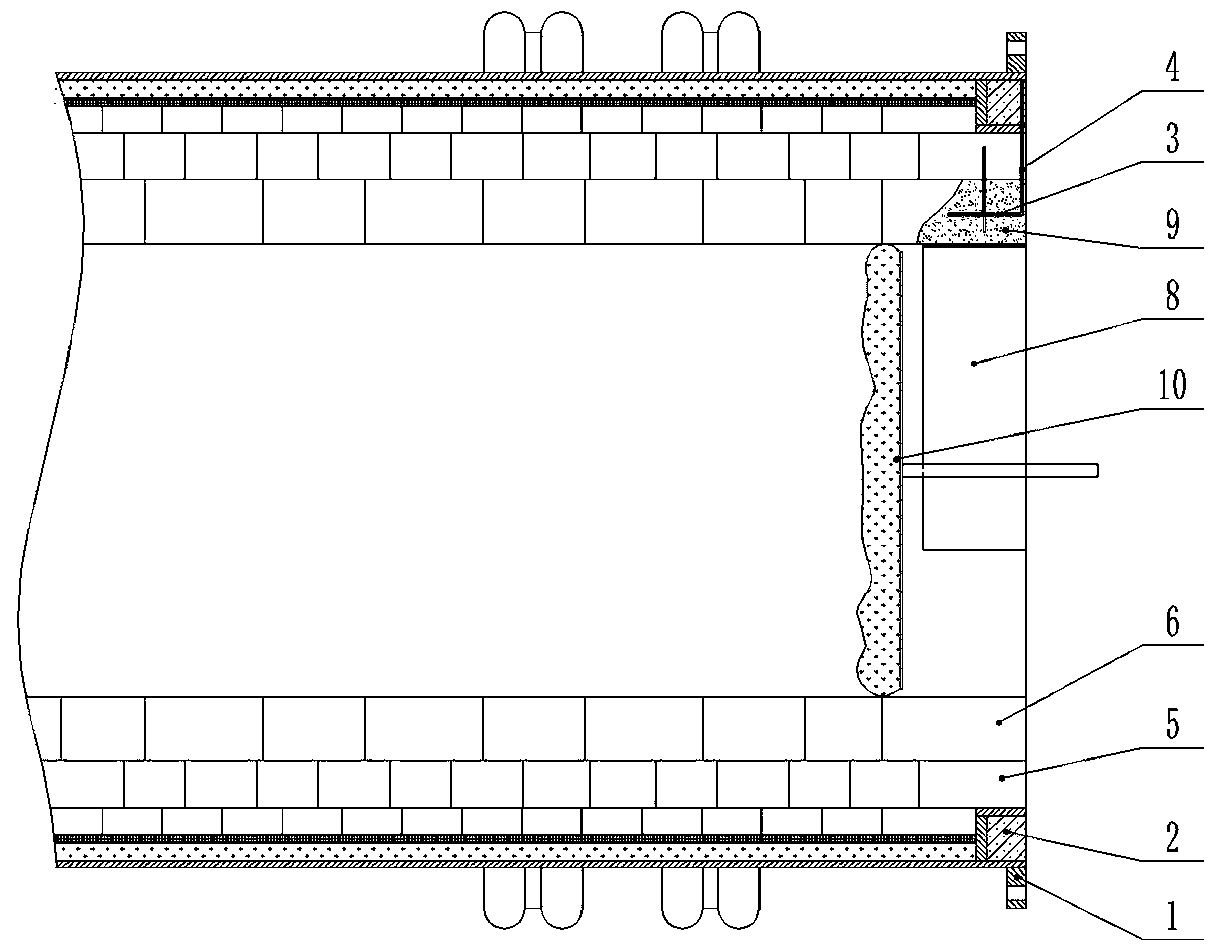

Fungi cultivation room

InactiveCN104396625AAchieve heat insulationAchieve moisturizingClimate change adaptationGreenhouse cultivationThermal insulationEngineering

The invention provides a fungi cultivation room which is simple in structure and low in cost and has the functions of thermal insulation and moisturizing. The fungi cultivation room comprises a cultivation room body, a thermal insulating layer, a first waterproof layer, a thermal insulating layer and a second waterproof layer; the thermal insulating layer, the first waterproof layer and the thermal insulating layer are orderly arranged on the outer surface of the cultivation room body from outside to inside; the second waterproof layer is arranged on the inner surface of the cultivation room body. The fungi cultivation room has the beneficial effects that the thermal insulating layer, the first waterproof layer and the thermal insulating layer are orderly arranged outside the cultivation room body and the second waterproof layer is arranged inside the cultivation room body without buying extra temperature and humidity regulating equipment, and thermal insulation and moisturizing of the fungi cultivation room can be realized by use of simple structure and relatively low cost.

Owner:罗源县庆丰食用菌专业合作社

Blast furnace hot air branch pipe end hole refractory repairing method

InactiveCN110643773AMeet production environment requirementsResume production quicklyBlast furnace detailsHeating stovesFire brickRefractory

The invention relates to a blast furnace hot air branch pipe end hole refractory repairing method. The repairing method comprises the following steps that firstly, a hot air branch pipe end hole refractory damage part is thoroughly cleaned, and the part is blown by compressed air for cleaning; a pouring steel mould is manufactured according to a diameter of the inner wall of a hot air pipeline andfixed through a pouring steel mould fixing bracket; a pouring framework is manufactured and fixed; a pouring sealing plate is welded along a plane or a flange face of a original refractory end hole,and high-strength ceramic material is used for pouring; and curing, demolding and grinding are carried out on the pouring part, and the pouring part is put into use. According to the method, the hot air branch pipe end hole needing to be repaired is repaired through a principle of pouring material indefinite molding; and the pouring framework is welded and fixed to a branch pipe flange and a refractory brick seam to "take root", so that the overall stability of the pouring part is improved. The high-temperature-resistant and extrusion-resistant performance of the pouring material after solidification meets the production environment requirement of the hot air branch pipe, the heat insulation effect of the branch pipe flange is achieved, and the production requirement is met.

Owner:SGIS SONGSHAN CO LTD

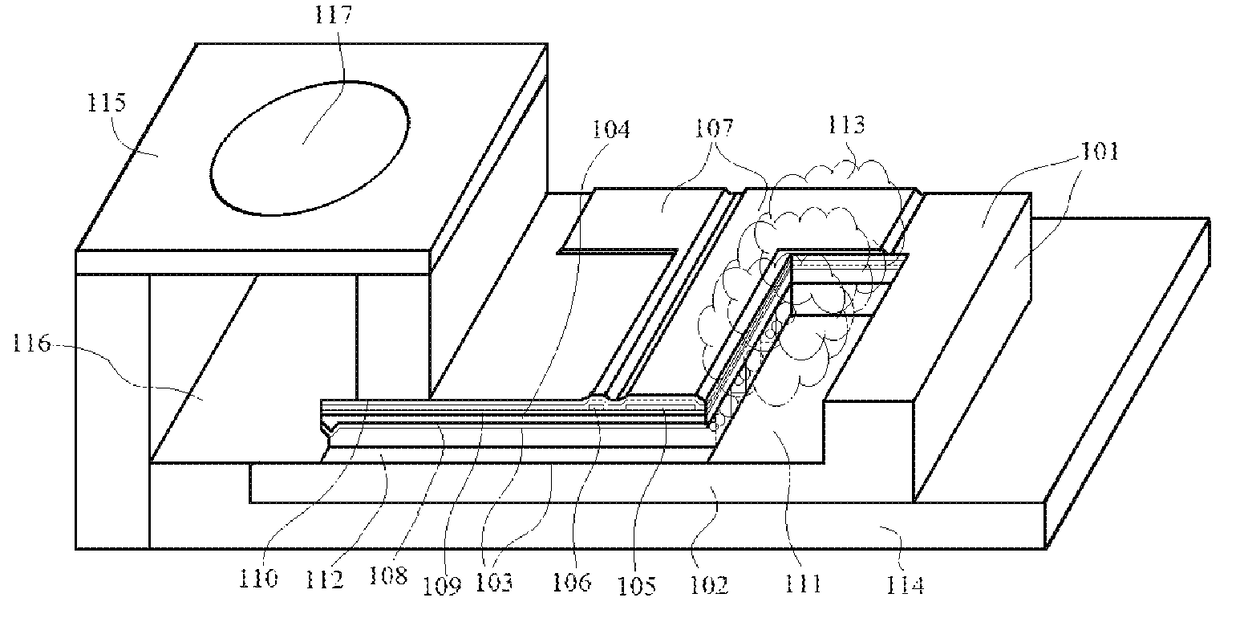

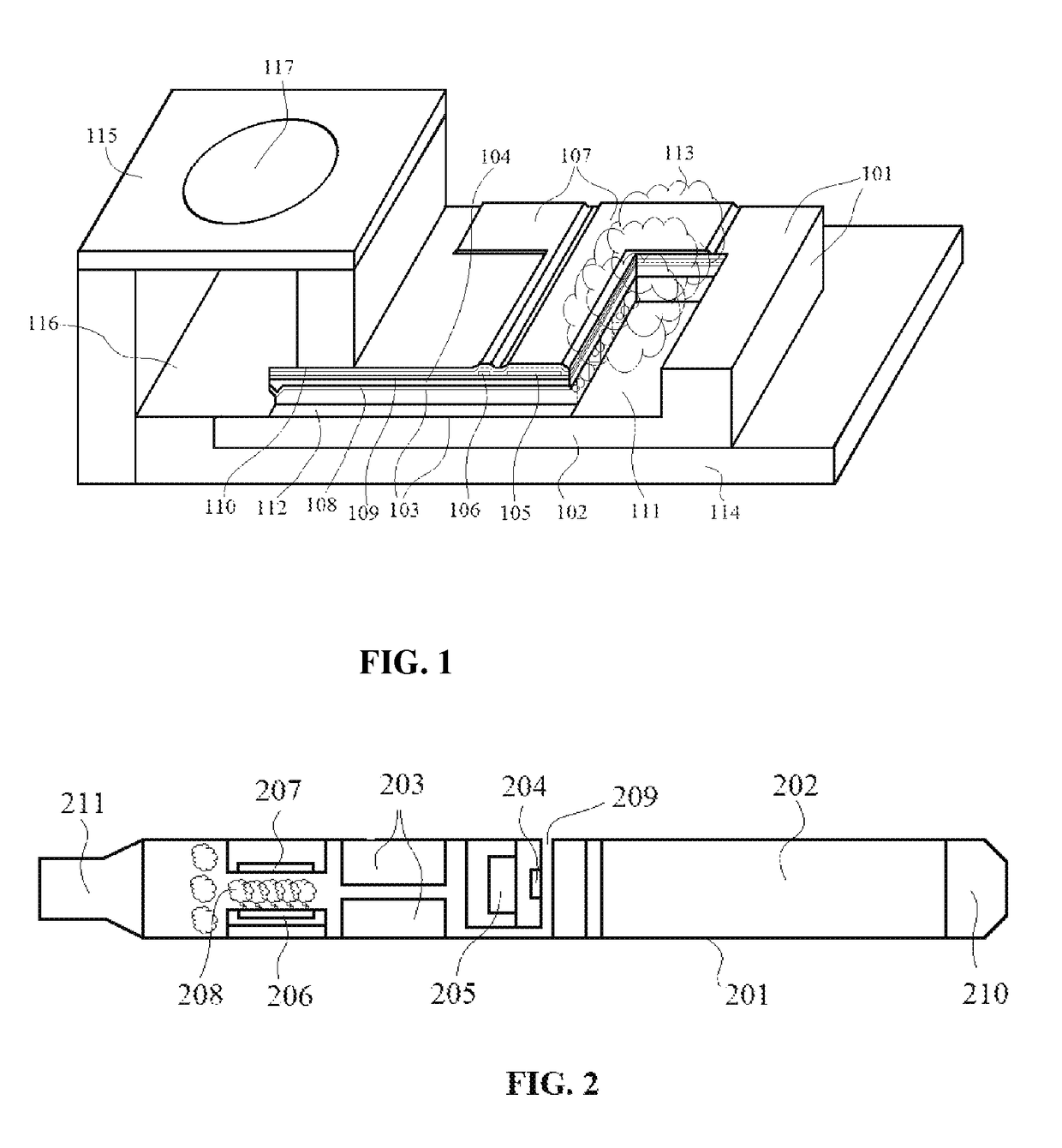

MEMS vaporizer

ActiveUS9801415B2Low costImprove reliabilitySteam generation heating methodsTobacco devicesElectrical resistance and conductanceElectronic cigarette

A MEMS vaporizer is described which can be used for electronic cigarettes. The vaporizer mainly composes: a silicon substrate, a micro-channel array, a membrane suspending over the micro-channel array and supported by the silicon substrate, a resistance heater and a resistance temperature sensor are disposed on the membrane. Since the vaporizer is a silicon-based integrated actuator which provides advantages including small size, compact structure, lower power consumption, lower cost, increased reliability, higher precision, and more environmental friendliness.

Owner:POSIFA TECH LTD

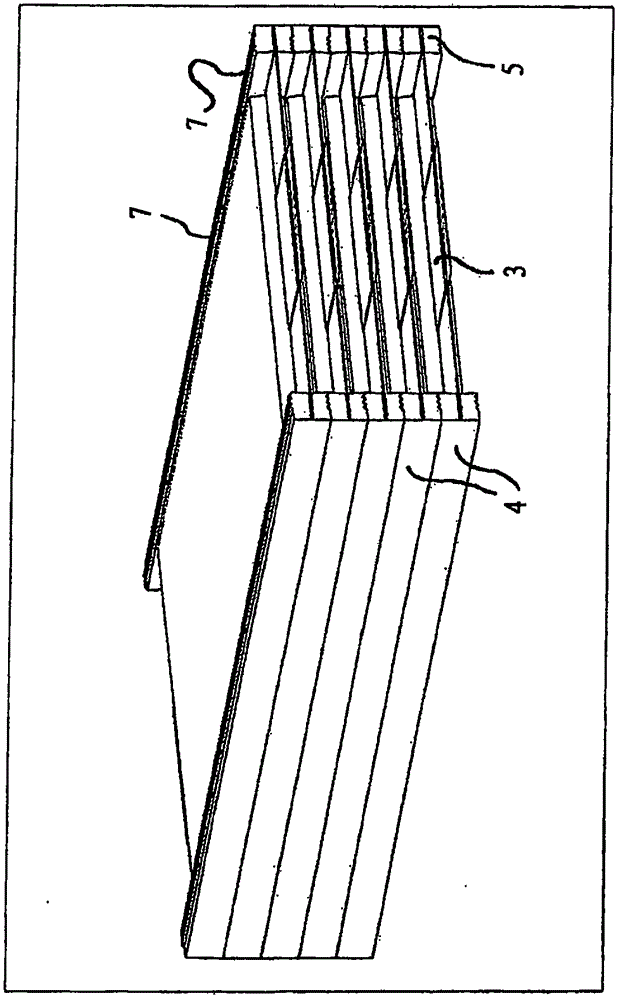

Manufacturing method of multi-layer bending structure

ActiveCN111283008AImprove performanceUniform layer thicknessExtrusion diesExtrusion containersComposite effectEngineering

The invention discloses a manufacturing method of a multi-layer bending structure. The problems that in the prior art, bending forming of a multi-layer material composite structure is difficult to realize, the production efficiency is low, and the application range is narrow are solved. The method has the advantages of being uniform in composite layer thickness, good in interface composite effect,high in composite efficiency, and capable of manufacturing various forms of composite structures. According to the manufacturing method of the multi-layer bending structure, the method comprises thefollowing steps that a composite original blank is prepared; the composite original blank is put into an extrusion barrel, and the composite original blank, the extrusion barrel and a forming die areheated; and a first extrusion push rod and a second extrusion push rod are moved to make contact with the composite original blank; and by varying the propulsion speed v1 of the first extrusion push rod and the propulsion speed v2 of the second extrusion push rod, the composite original blank is made to obtain a varying velocity gradient when passing through a forming channel of the forming die, thereby obtaining the variable curvature multi-layer bending structure.

Owner:CURVEX LIGHTWEIGHT INTELLIGENT MFG RES INST HEZE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com