Charging barrel of infrared dehumidification, crystallization and drying all-in-one machine and crystallization and drying all-in-one machine

An infrared, all-in-one technology, applied in plastic recycling and other directions, can solve the problems of plastic particle adhesion, complex internal wiring safety hazards, adhesion and other problems, and achieve the effects of good heating, high viscosity and good turning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

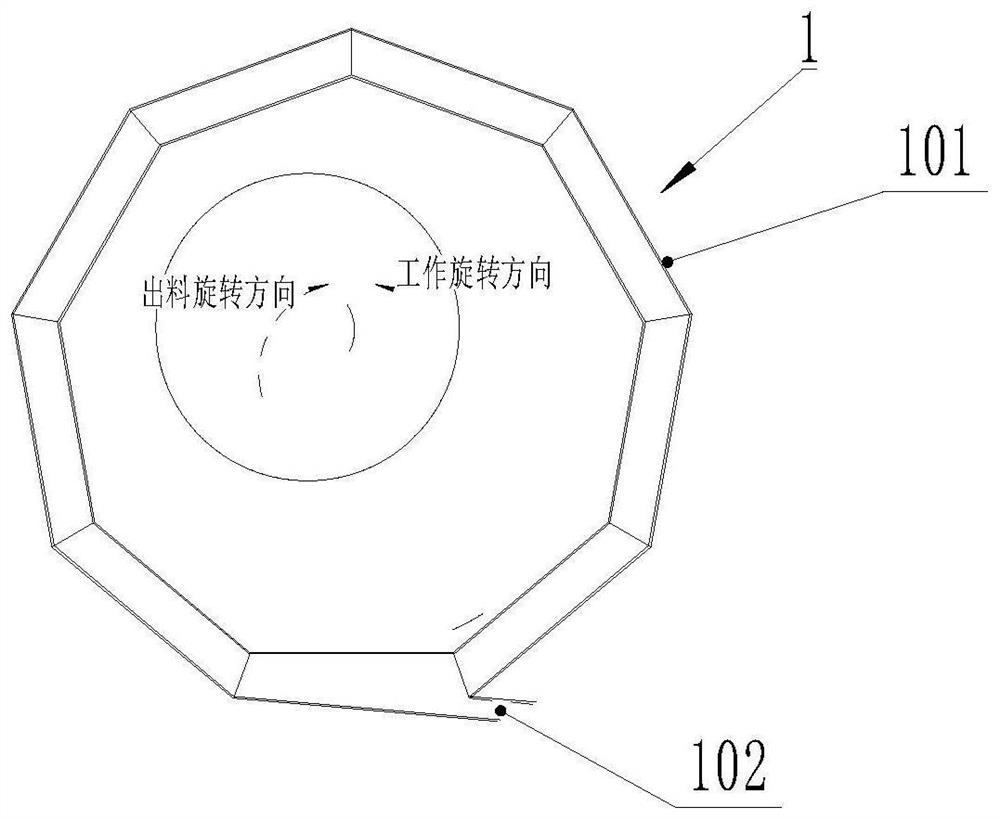

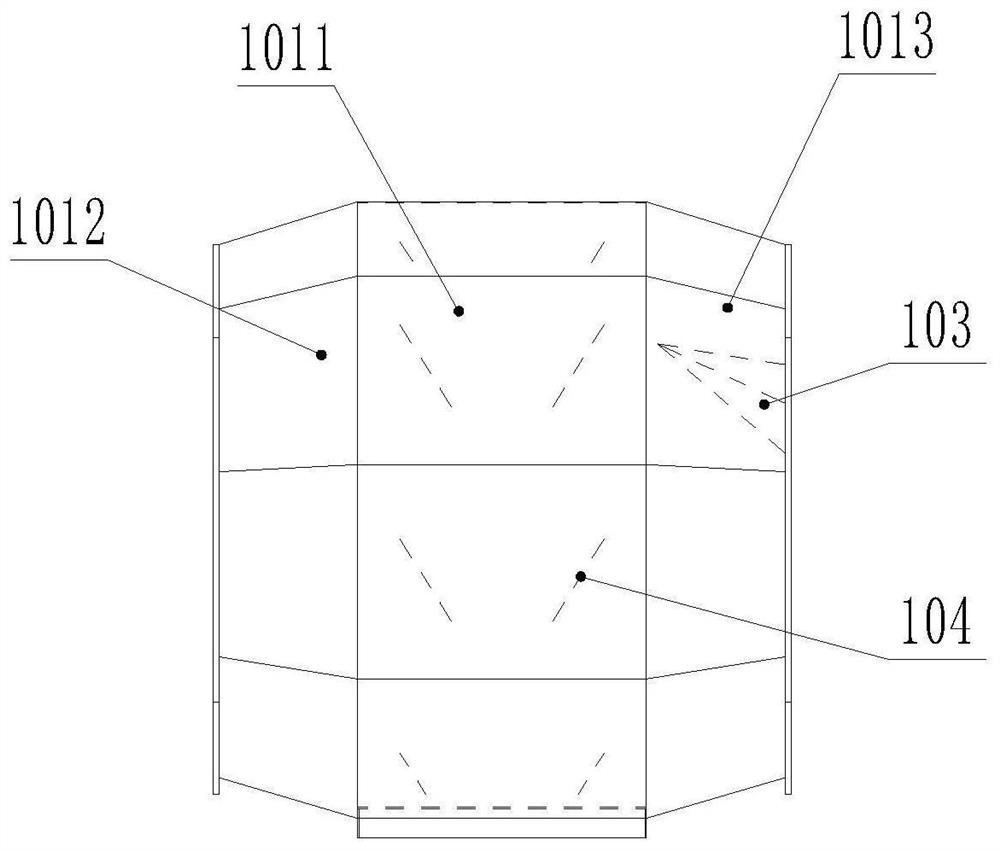

[0051] Such as Figure 1 to Figure 2 As shown, a barrel 1 of an infrared dehumidification, crystallization and drying integrated machine, the cross-sectional shape of the barrel 1 is a polygon with sides larger than a pentagon, preferably, the polygon is a pentagon to a decagon A suitable polygon is selected according to the size of the barrel 1. One end of the barrel 1 is open and is the feeding end. Each plate surface 101 constituting the polygon shaped barrel 1 includes a middle plate portion 1011 and a set The first closing plate portion 1012 and the second closing plate portion 1013 at both ends of the middle plate portion 1011, the first closing plate portion 1012 and the second closing plate portion 1013 form an obtuse angle with the middle plate portion 1011 and close towards the middle , the side wall of the barrel 1 is provided with a discharge port 102 . In this embodiment, the discharge port 102 of the barrel 1 is arranged at the junction of two adjacent plate sur...

Embodiment 2

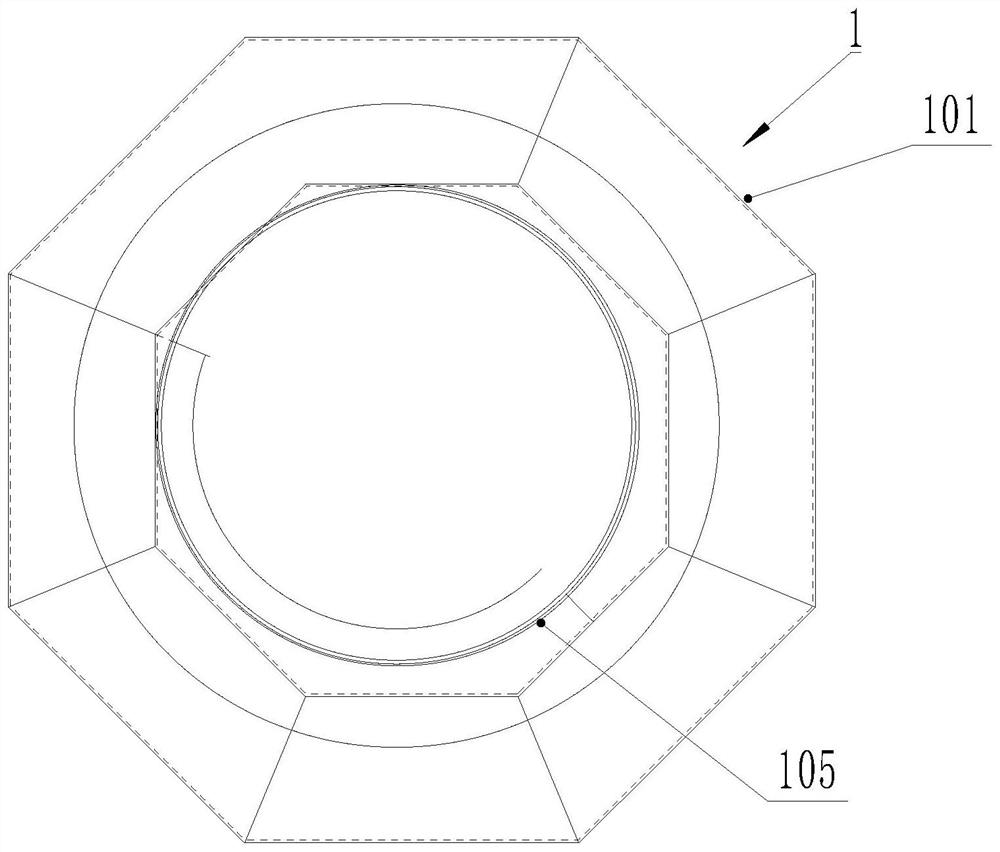

[0055] Such as image 3 with Figure 4As shown, this embodiment discloses another barrel 1 of an infrared dehumidification, crystallization and drying integrated machine. The structure of the barrel 1 is similar to that of Example 1, except that in this embodiment, the side wall of the barrel 1 is not provided with an opening. , and the opening at the other end of the barrel 1 is set as a discharge port; at this time, a spiral discharge guide plate 105 is provided inside the barrel 1 to facilitate material discharge. However, in this embodiment, in order to increase the speed of discharging, and at the same time enable the material to be discharged more thoroughly and avoid residues, in this embodiment, the turning structure includes several groups of turning plates 104 arranged in parallel. The plate surface of the plate 104 intersects with the center line of the barrel to form an angle, and each group of turning plates is arranged on the middle plate portion 1011, and prefe...

Embodiment 3

[0057] Such as Figure 5 to Figure 10 As described above, an infrared dehumidification, crystallization and drying integrated machine includes a frame 2, an organic casing 3 is fixed on the frame 2, and the barrel 1 is mounted on the frame 2 to rotate around the central axis. The frame 2 includes a fixed support frame 21 and a slide seat 22 axially slidably mounted on the fixed support frame 21. Two pairs of support rollers 11 are installed on the slide seat 22, and a convenient barrel 1 is installed on the outer periphery of the barrel 1. Rotating rotary support structure 13 , the barrel 1 is rotatably mounted on the support roller 11 through the rotary support structure 13 , and the limiting device 10 is installed on the sliding seat 22 to limit the axial position of the barrel 1 . One of the two pairs of support rollers 11 is an active support roller 12, the motor 8 is fixed on the frame, and the output shaft of the motor 8 is connected to the axle of the active support rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com