An energy-saving and environment-friendly spray drying process

An energy-saving, environmentally friendly and technological technology, applied in spray evaporation and other directions, can solve the problems of small proportion of fresh air supplementary heat energy, low recovery efficiency, large consumption, etc., to promote the trend of condensation heat release, improve heat exchange efficiency, and reduce condensation The effect of sufficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

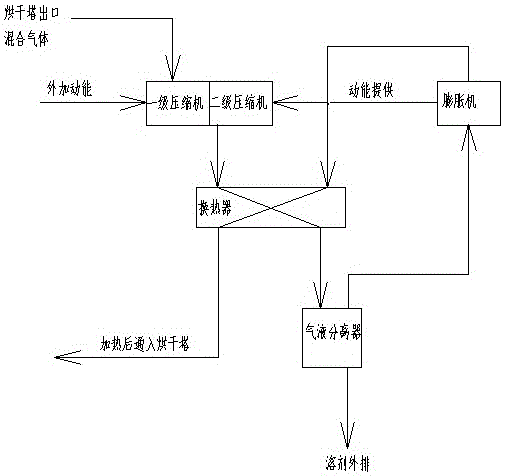

Method used

Image

Examples

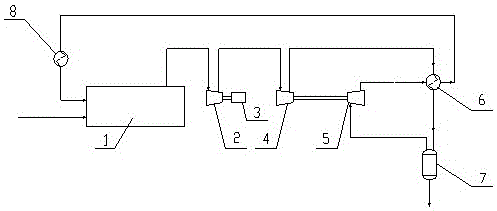

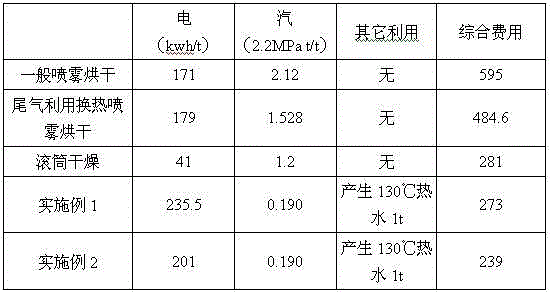

Embodiment 1

[0040] A wheat hydrolyzed protein aqueous solution with a solid content of 25% is spray-dried to make a powder product, and the wet material is sent to the spray drying tower 1, the material feed temperature is 60°C, and the feed flow rate is 14500kg / h. 1. The outlet temperature of the exhaust gas is 80°C, and the outlet pressure is 100kPa(A). After being compressed by the first-stage compressor 2, the pressure rises to 190kPa(A), and then enters the second-stage compressor 4 for further compression to 300kPa(A). The temperature of the mixed gas can rise to 195°C, and then sent to the heat exchanger 6 to condense into a gas-liquid mixture, and the gas-liquid mixture is sent to the gas-liquid separator 7, and the gas-liquid separation produces 761kg / kg of high-temperature hot water at 130-133°C h, the mixed gas produced by gas-liquid separation is sent to the expansion expander 5 to do work, and the kinetic energy obtained is provided to the secondary compressor 2, and the low-t...

Embodiment 2

[0042] A wheat hydrolyzed protein aqueous solution with a solid content of 25% is spray-dried to make a powder product, and the wet material is sent to the spray drying tower 1, the material feed temperature is 60°C, and the feed flow rate is 18605kg / h. 1. The outlet temperature of the exhaust gas is 80°C, and the outlet pressure is 100kPa(A). After being compressed by the first-stage compressor 2, the pressure rises to 190kPa(A), and then enters the second-stage compressor 4 for further compression to 300kPa(A). The temperature of the mixed gas can be raised to 195°C, and then sent to the heat exchanger 6 for heat exchange and condensation to form a gas-liquid mixture, and the gas-liquid mixture is sent to the gas-liquid separator 7, and the gas-liquid separation produces hot water at a temperature of 130-133°C 1000kg / h, the mixed gas produced by the gas-liquid separation is sent to the expansion expander 5 to do work, and the kinetic energy obtained is provided to the seconda...

Embodiment 3

[0048] A mixture of tungsten carbide with a solid content of 40% and a solvent of absolute ethanol is spray-dried to produce tungsten carbide powder products. The system is protected with nitrogen gas, and the wet material is sent to the spray drying tower 1. The material feed temperature 30°C, the feed flow rate is 15725kg / h, the exhaust gas outlet temperature of spray drying tower 1 is 50°C, and the outlet pressure is 100kPa(A). Enter the secondary compressor 4 for further compression to 300kPa (A), the temperature of the mixed gas can rise to 139°C, then send it to the heat exchanger 6 for heat exchange and condense into a gas-liquid mixture, and send the gas-liquid mixture to the gas-liquid separator 7 , the gas-liquid separation produces 1000kg / h of high-temperature ethanol at 107-109°C, and the mixed gas generated by the gas-liquid separation is sent to the expansion expander 5 to do work, and the kinetic energy obtained is provided to the secondary compressor 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com