Low-cost and high-efficiency supercritical spray drying method and equipment for slurry

A drying method and technology of spray drying tower are applied in the field of low-cost and high-efficiency supercritical spray drying of slurry, which can solve the problems of unsuitability for large-scale production, complex equipment cost, low production efficiency, etc., and achieve the technological method and equipment performance. The effect of low consumption, simple equipment and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

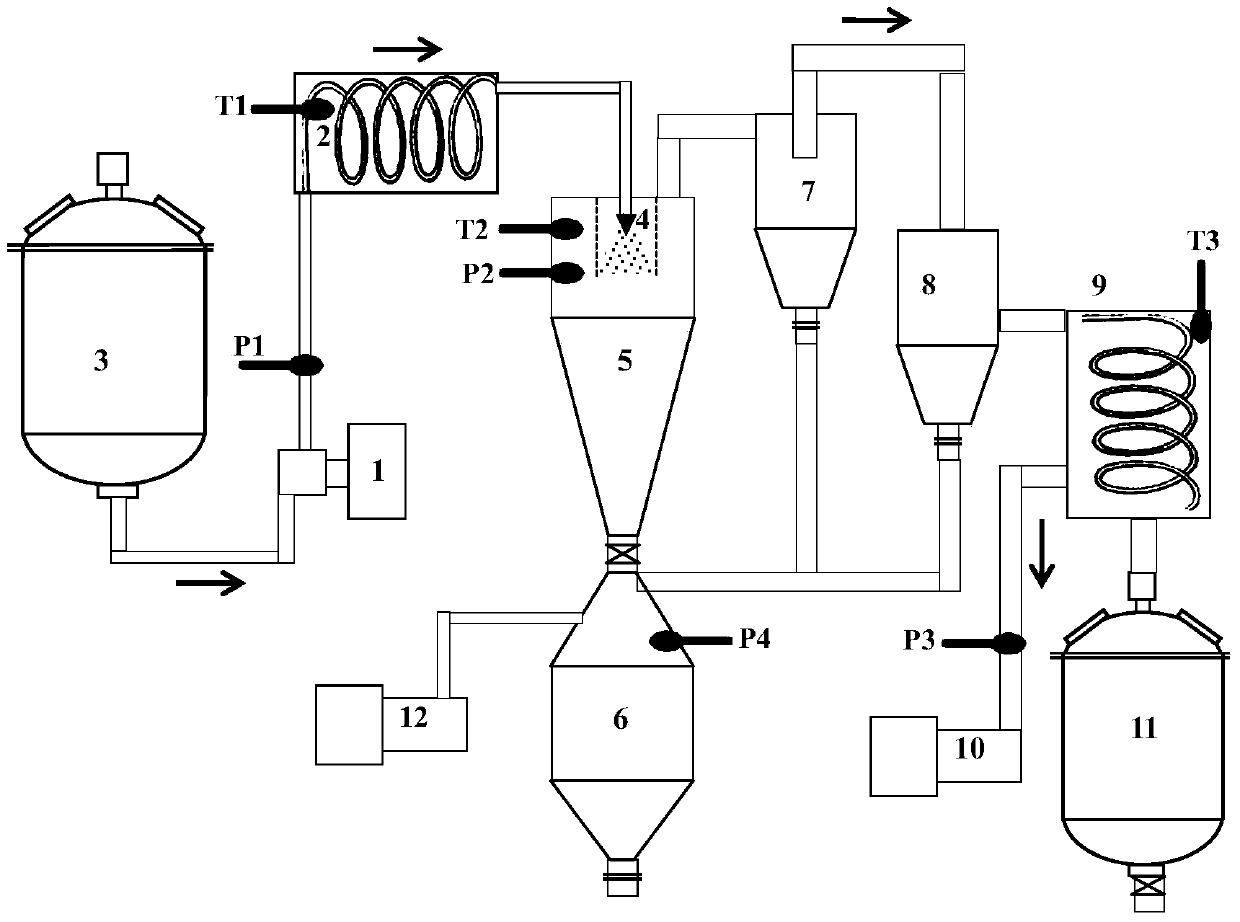

[0038] image 3 It is a kind of supercritical spray drying equipment used in the present invention, which is suitable for continuous drying process. The equipment includes a supercritical generating device for preheating and pressurizing the slurry to reach a supercritical state, a spray drying tower 5, a powder storage tank 6, a cyclone separator 7, a filter bag separator 8, and a condensation recovery tower 9. The bottom of the spray drying tower is connected to the powder storage tank, and the powder storage tank is connected to the second vacuum pump 12; the top of the spray drying tower is connected to the cyclone separator. Outlet and bottom outlet, the top outlet of the cyclone separator is connected to the filter bag separator, the bottom outlet of the cyclone separator and the filter bag separator are both connected to the powder storage tank, and the first outlet of the filter bag separator is connected to the condensation recovery tower , the outlet of the condensa...

Embodiment 2

[0042] Figure 4 Another supercritical spray drying equipment used in the present invention is suitable for batch drying. Compared with Embodiment 1, this equipment does not use a high-pressure pump and a heater, but an autoclave.

[0043] The equipment includes a supercritical generating device for preheating and pressurizing the slurry to reach a supercritical state, a spray drying tower 5, a powder storage tank 6, a cyclone separator 7, a filter bag separator 8, and a condensation recovery tower 9. The bottom of the spray drying tower is connected to the powder storage tank, and the powder storage tank is connected to the second vacuum pump 12; the top of the spray drying tower is connected to the cyclone separator. Outlet and bottom outlet, the top outlet of the cyclone separator is connected to the filter bag separator, the bottom outlet of the cyclone separator and the filter bag separator are both connected to the powder storage tank, and the first outlet of the filter...

Embodiment 3

[0046] Example 3 Low-cost and high-efficiency supercritical spray drying of slurry

[0047] The dry material is nano iron oxide ethanol slurry with a mass ratio of 10%, and the viscosity at room temperature is 1000cP. The supercritical temperature and pressure of ethanol are 241°C and 6.3MPa, respectively. This slurry uses image 3 In the continuous production process shown, the slurry is boosted to 8MPa by a high-pressure pump, and then heated to 250°C by a heater. The temperature of the spray drying tower is 65°C and the pressure is 50kPa (about 0.5 atmospheric pressure), which is lower than the saturated vapor pressure at this temperature, so there is no condensation and condensation in the spray drying tower, and the set temperature of the condensation recovery tower is -10°C , The vapor pressure is about 0.8kPa, and 95% of the vapor is recovered as a solvent. The pressure of the vacuum pump is set at 47kPa, and the pressure loss of the low-pressure system from the spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com