Integrated circulation air heating furnace

A hot blast stove, an integrated technology, applied in the field of integrated circulating hot blast stove, can solve the problems of poor sealing of the hot blast stove main body, complicated installation, commissioning, maintenance, and insufficient cleanness of the heating furnace air, so as to improve energy use efficiency, Good heat preservation effect and low equipment operation noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

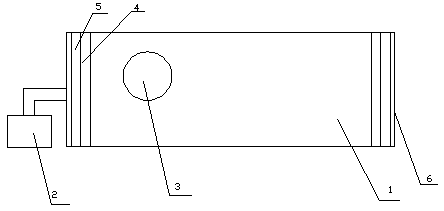

[0008] The integrated circulating hot blast stove includes a hot blast stove body 1, which is integrally connected with a plug-in fan 2 outside the furnace body 1, and a filter 3 and a heating assembly are arranged inside the furnace body 1. The furnace body 1 is a double-layer steel structure, and the inner The layer is galvanized steel plate 4, the outer layer is galvanized corrugated plate 6, and the middle is filled with thermal insulation cotton 5. The fan 2, filter 3, heating assembly and heating furnace body 1 are of an integrated structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com