Hollow load bearing wall

A load-bearing wall, hollow technology, applied in the direction of walls, building components, covering/lining, etc., can solve the problems of poor wall insulation effect, prolong the completion time of the wall, and fail to achieve self-aligning joints, etc. High speed, enhanced anti-leakage performance, and the effect of preventing oblique cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

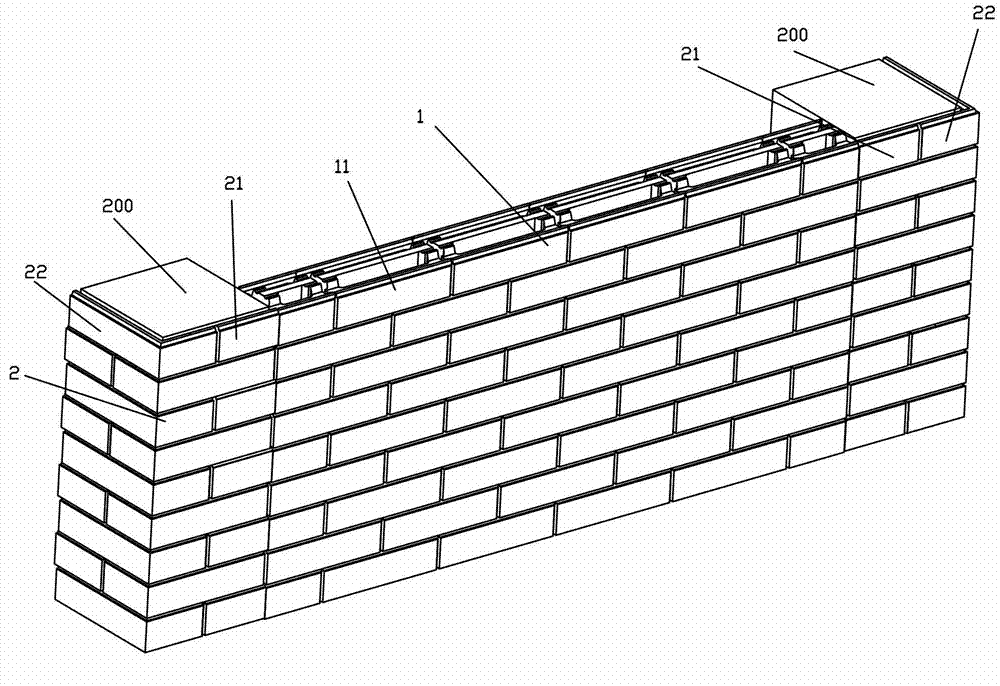

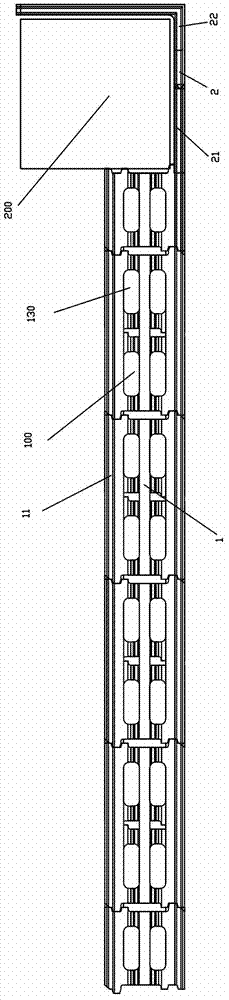

[0039] A hollow load-bearing wall, which is built between two cement columns 200, includes a main wall body 1 and a decorative wall 2 attached to the cement column. The main wall body 1 is made of bricks 11 in several layers, and is Several layers of bricks are built layer by layer, and the positions of the bricks 11 of the upper and lower adjacent layers are staggered; the decorative wall 2 includes single-panel bricks 21 and corner-panel bricks 22 with right angles.

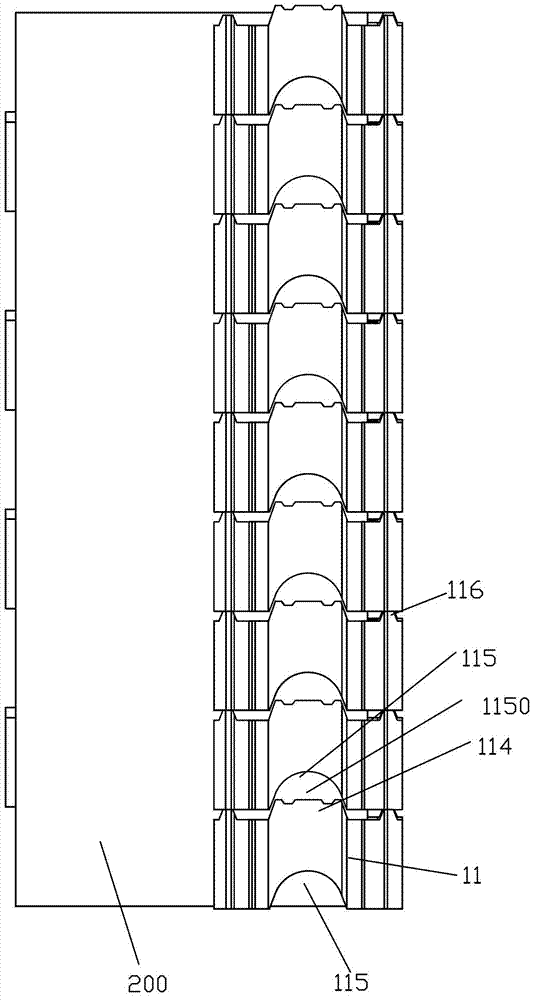

[0040] The brick 11 of the present invention includes the first long side 111 and the second long side 112 arranged at a certain distance apart, and the rib 113 connecting the first long side 111 and the second long side 112; The upper end is provided with a spacer boss 114, and the lower end of the rib 113 is provided with a spacer groove 115 matched with the spacer boss 114. Reserved space 1150, the reserved space 1150 can be used for ventilation, wiring, water pipes, etc., and can also reduce manufacturing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com