Automatic double-layer conveying device on logistics transport line

An automatic conveying device and double-layer technology, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of long conveying time, large site occupation, and large workshop area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

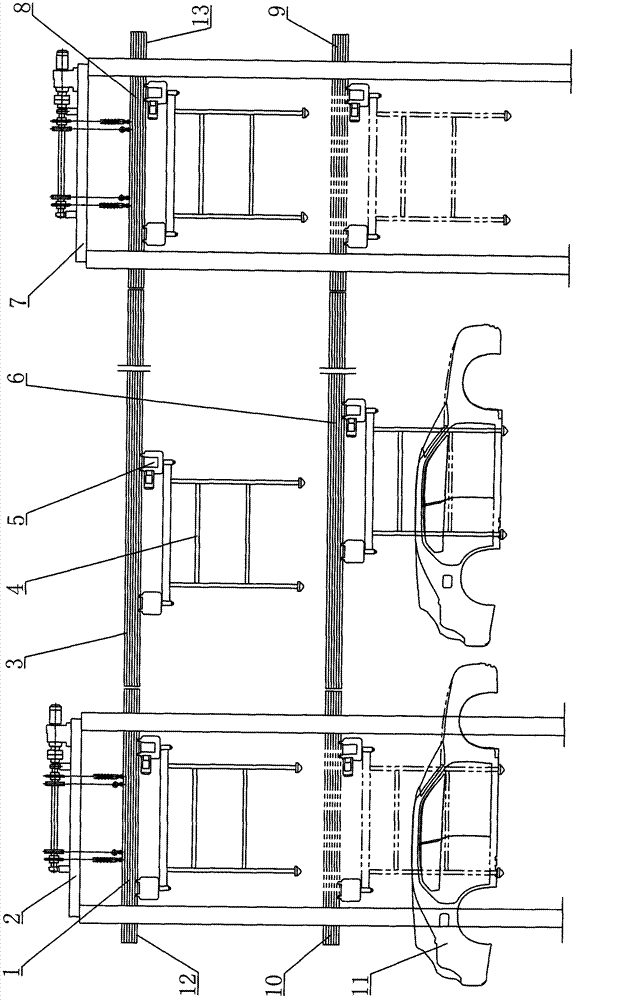

[0007] see figure 1 , the double-layer automatic conveying device of the logistics transfer line of the present invention includes a spreader 4, a self-propelled trolley 5 and a lower track 6, the spreader 4 is connected with the self-propelled trolley 5, and also includes an upper elevator 2, a lower elevator 7 and an upper rail 3. The upper part lifter movable track 1 is housed on the upper part lifter 2, and the upper part lifter movable track 1 can be docked with the lower floor track 6 or the upper floor track 3 easily by the lifting device of the upper part lifter 2. The lower part lifter 7 is equipped with the lower part lifter movable track 8, and the lower part lifter movable track 8 can be easily docked with the lower layer track 6 or the upper layer track 3 through the lifting device of the lower part lifter 7, thereby realizing double-layer automatic conveying.

[0008] When working, the upper piece elevator 2 vertically transports the upper piece elevator movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com