Geotechnical engineering original position rotation contact-surveying vehicle

A technology of geotechnical engineering and rotary contact, which is applied in basic structure engineering, soil material testing, earthwork drilling and mining, etc. It can solve problems such as ground anchor failure, test failure, and probe rod bending, and achieve reasonable structure, reliable operation, and easy operation. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further illustrate the present invention below in conjunction with embodiment and accompanying drawing.

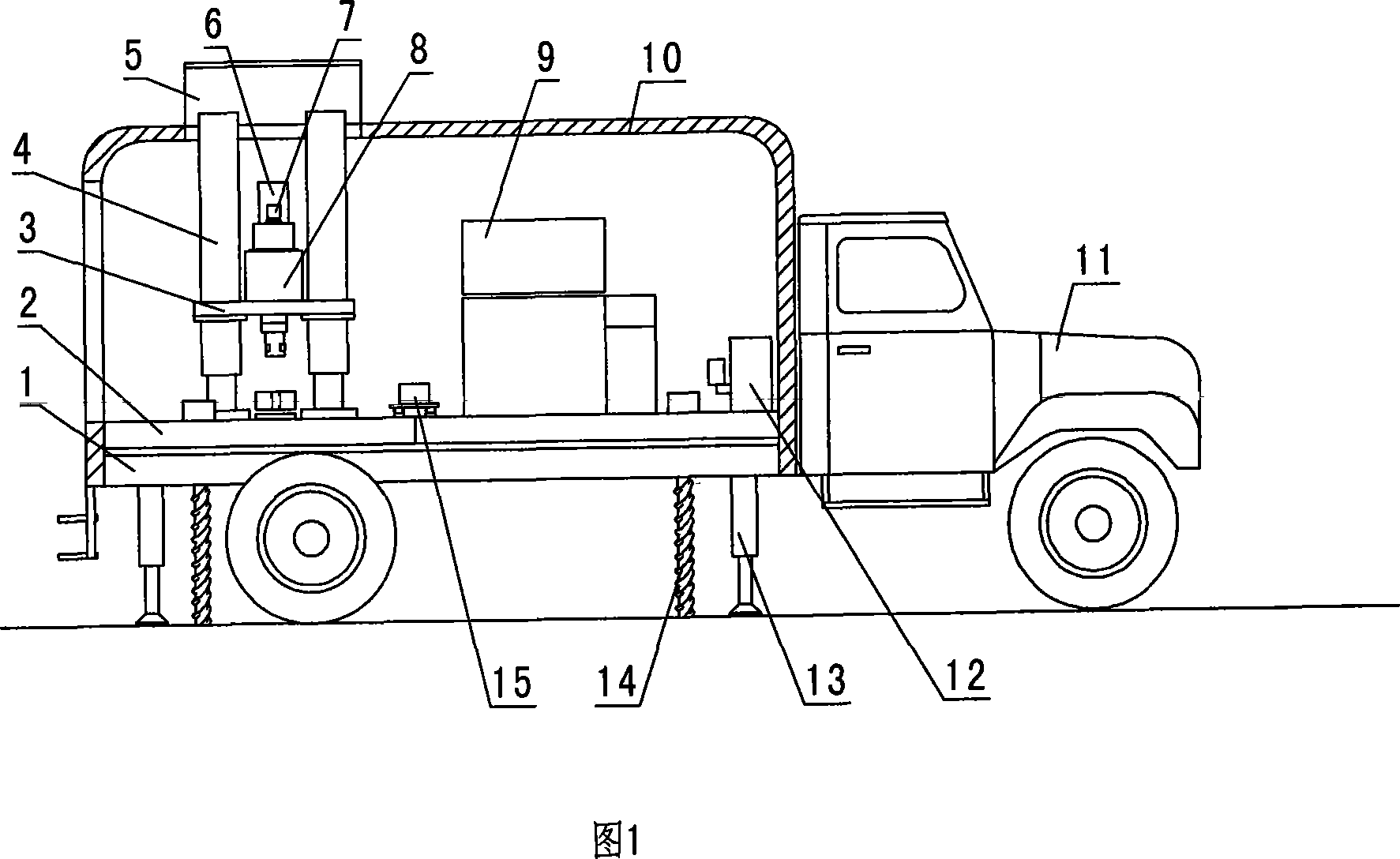

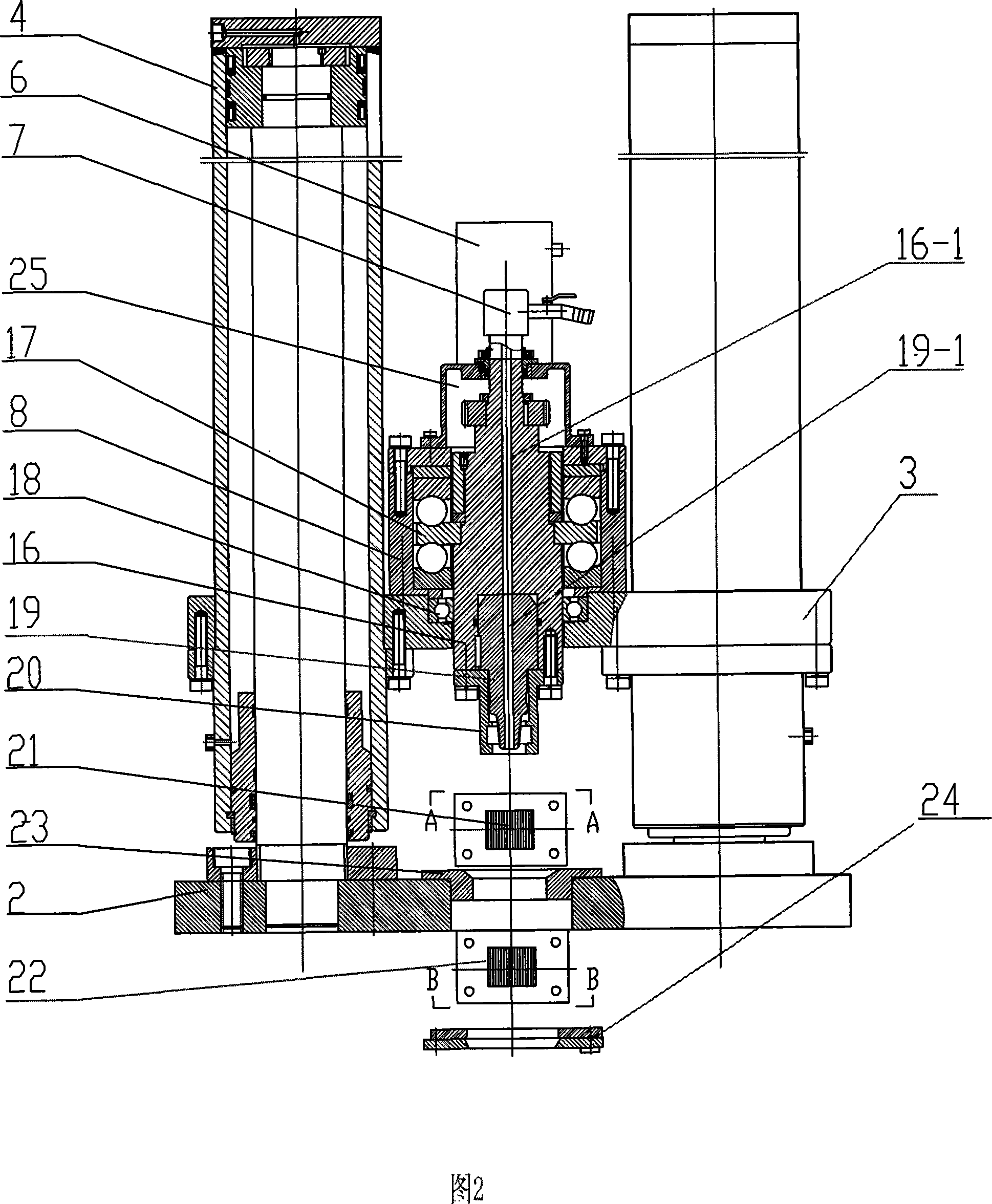

[0020] In the embodiment shown in Figure 1, the rotating penetrating vehicle of this embodiment adopts the body of the static penetrating penetrating vehicle, and the rear part of the vehicle chassis 1 is fixed with a load-bearing base plate 2, and the surface of the load-bearing base plate 2 is provided with two parallel hydraulic cylinders 4 and their The piston rod constitutes a hydraulic device that provides penetrating pressure. The end of the piston rod of the hydraulic device is fixed on the load-bearing floor 2 .

[0021] The base plate at the front part of the automobile chassis 1 is provided with a console 9 and a vehicle-mounted mud pump 12, and the automobile chassis 1 is supported by rails to move the ground anchor oil motor 15. Four sets of hydraulic support legs 13 and ground anchors 14 arranged at both ends of the chassis are symmetrically distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com