Three-dimensional hollow double sandwiched fabric

A double-sandwich, three-dimensional machine technology, used in fabrics, textiles, textiles and papermaking, etc., can solve the problems of reduced mechanical properties of materials, thinning of local fabric thickness, lack of support points, etc., to achieve light weight and reduce collapse deformation. , Conducive to impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

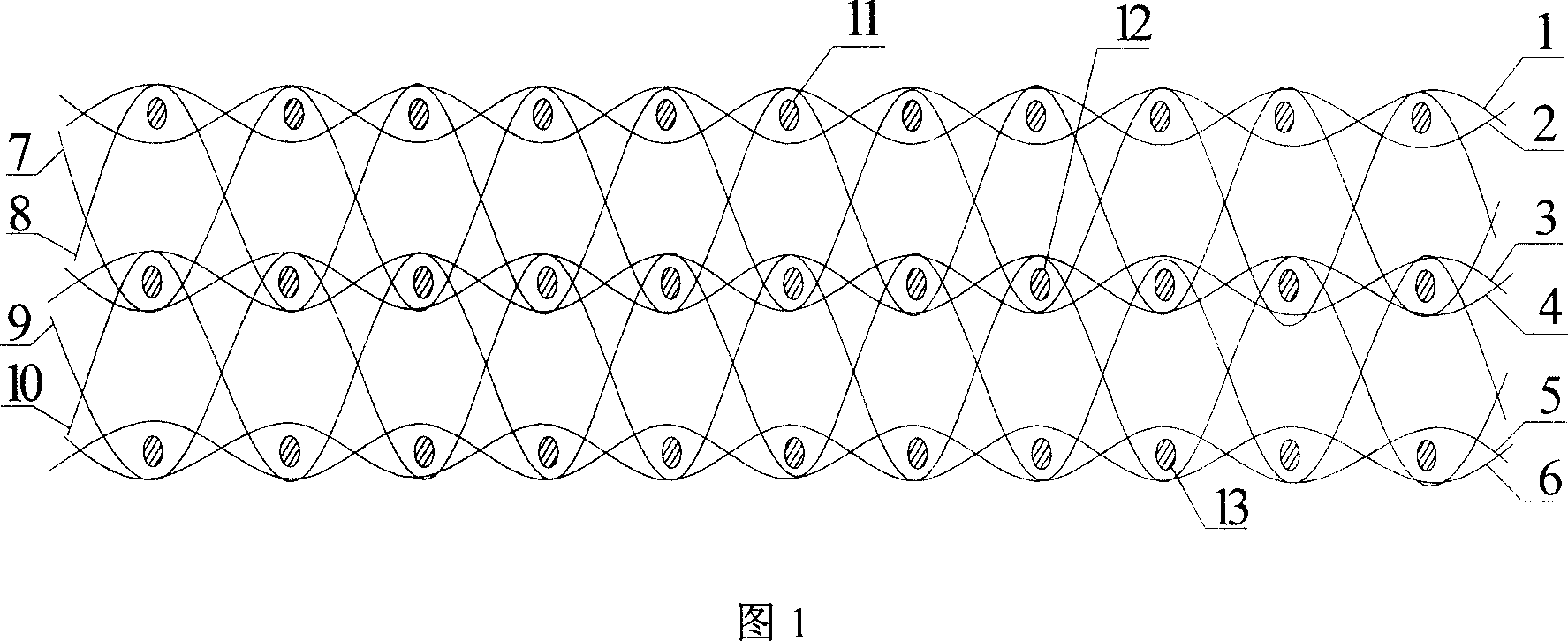

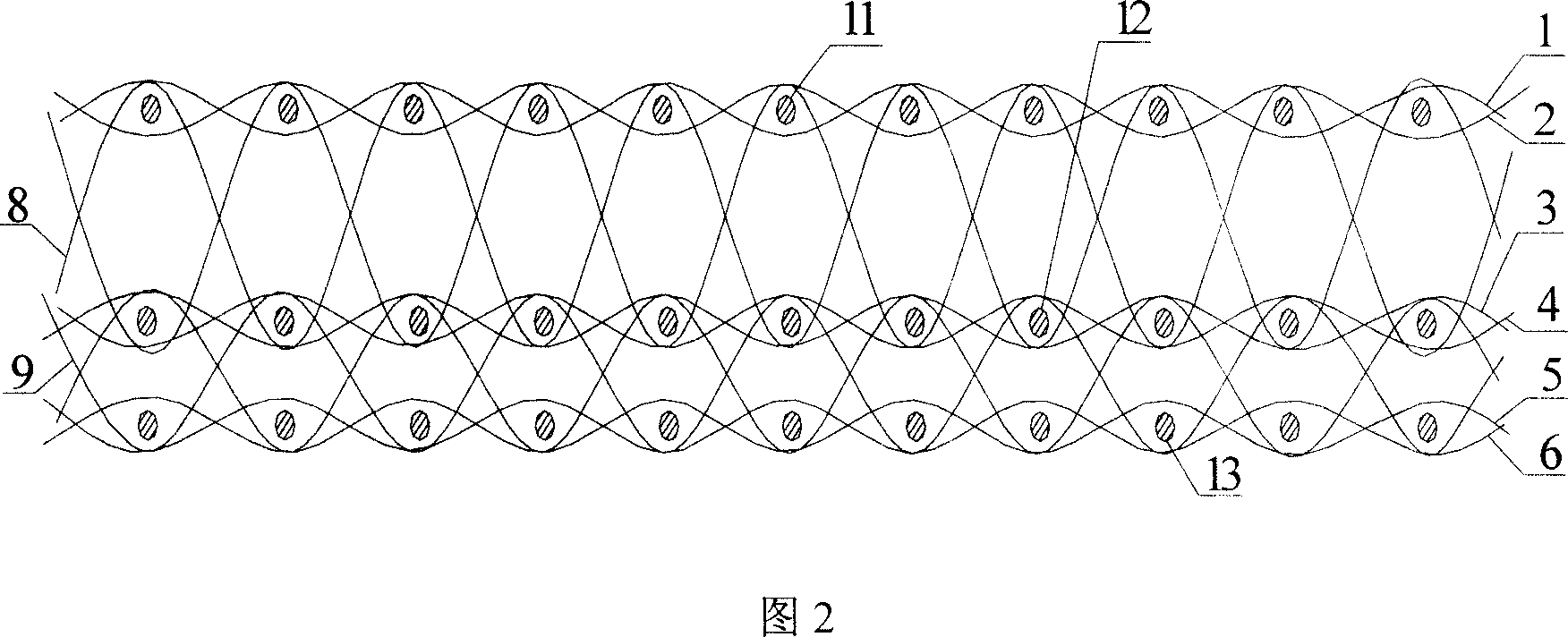

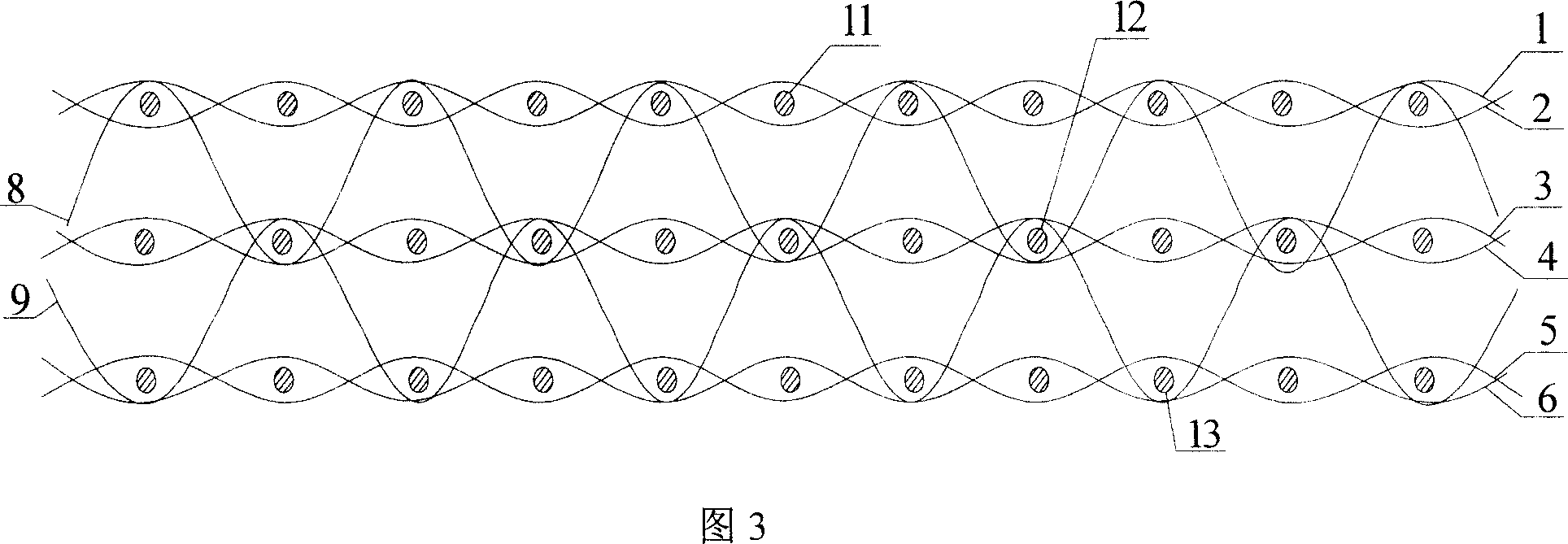

[0019] Referring to Fig. 1, the present invention constitutes double sandwich fabric by interweaving two warp yarn systems (ground warp and pile warp) with the weft yarn of the same system. According to the design of the fabric structure, the weft yarns of the same system are divided into upper layer weft yarns, middle layer weft yarns and lower layer weft yarns; 1. The upper layer weft yarn, the middle layer weft yarn and the lower layer weft yarn alternately introduced up and down are interwoven to form the upper layer fabric, the middle layer fabric and the lower layer fabric.

[0020] The upper layer is formed by interweaving the upper layer warp yarns 1, 2 and the upper layer weft yarn 11, the middle layer is formed by interweaving the middle layer warp yarns 3, 4 and the middle layer weft yarn 12, and the lower layer is formed by the lower layer warp yarns 5, 6 and the lower layer weft yarn 13 interwoven formations. The wefts 11, 12, and 13 in the upper, middle, and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com