Assembled prefabricated wallboard

A prefabricated wall panel, prefabricated technology, applied in the direction of walls, building materials, building components, etc., can solve the problems of sound insulation, heat insulation, poor waterproof effect, inability to adapt, etc., to shorten the construction period, increase stability, and facilitate installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention will be further described,

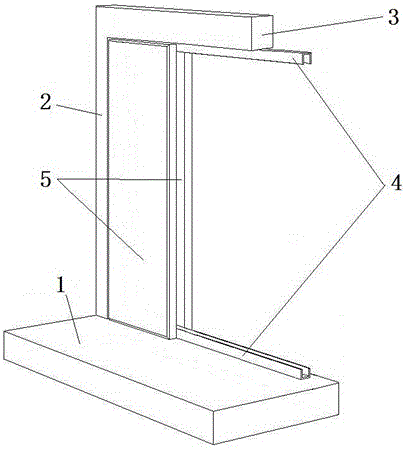

[0017] An assembled prefabricated wall panel, which includes floor slabs 1, columns 2, beams 3, positioning profiles 4 and prefabricated panels 5;

[0018] A positioning profile 4 is installed in the middle of the lower end of the beam 3, and another positioning profile 4 is installed on the projection position of the corresponding floor slab 1, and the upper and lower positioning profiles 4 are aligned, and the plane formed is perpendicular to the floor slab 1;

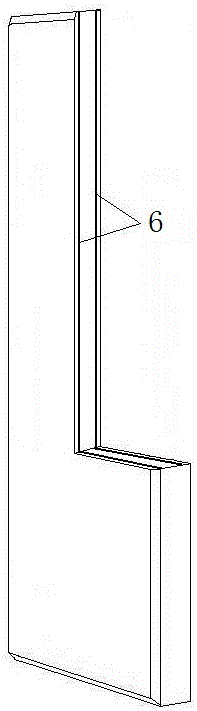

[0019] The prefabricated panel 5 is fixed on both sides of the positioning profile 4; thus the prefabricated panel 5 and the positioning profile 4 form a hollow wall as a whole.

[0020] The four sides of one side of the prefabricated panel 5 have chamfered structures, and grooves are formed at the joints of adjacent prefabricated panels 5, and the grooves are filled and smoothed with cementitious materials.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com