Main body brick used for constructing hollow wall

A hollow, wall technology, applied in the field of main bricks, can solve the problems of insufficient bonding of building blocks, poor wind resistance, poor seismic resistance, inconvenient mortar filling, etc., to shorten the construction time, strong earthquake resistance, The effect of increasing the speed of building walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

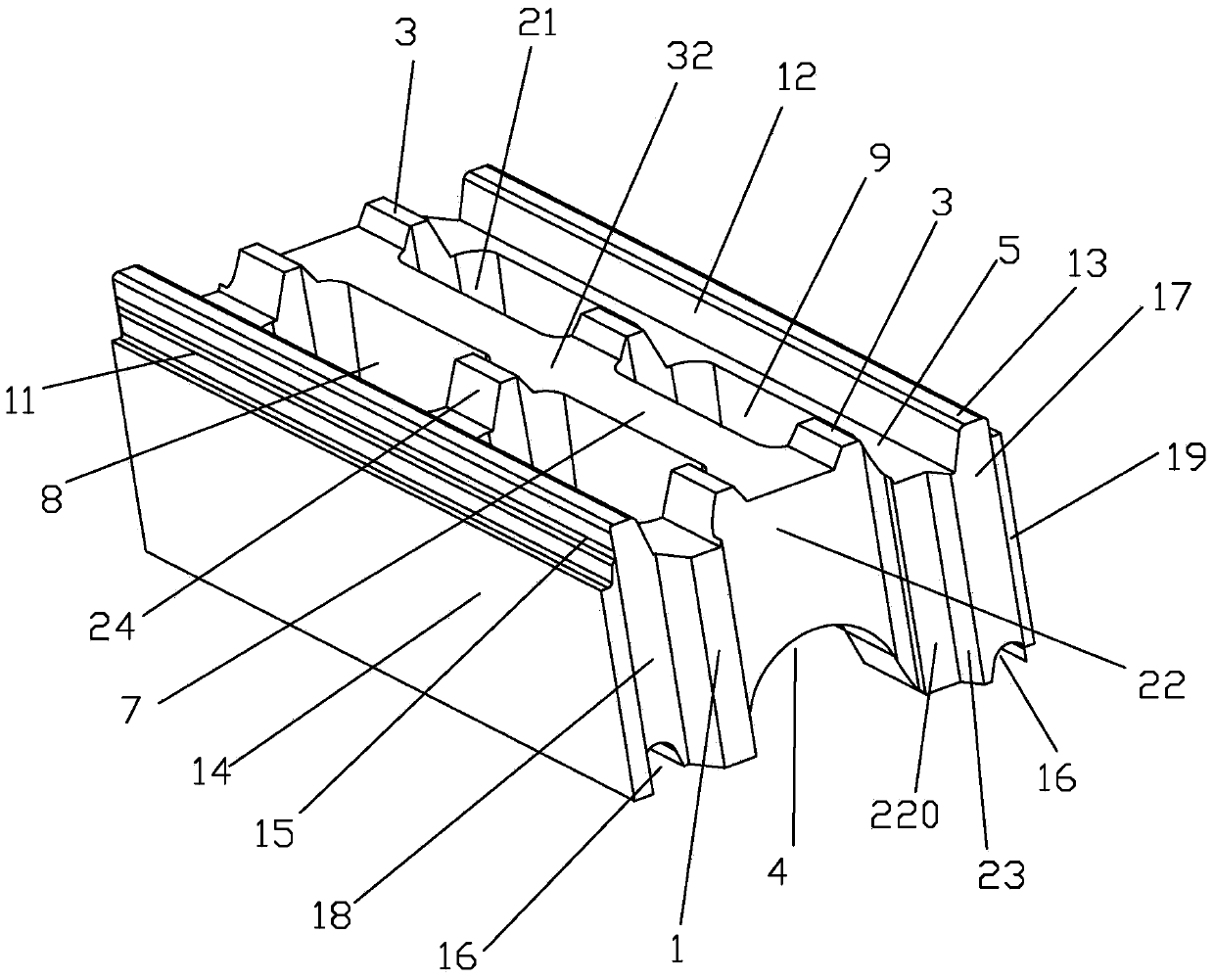

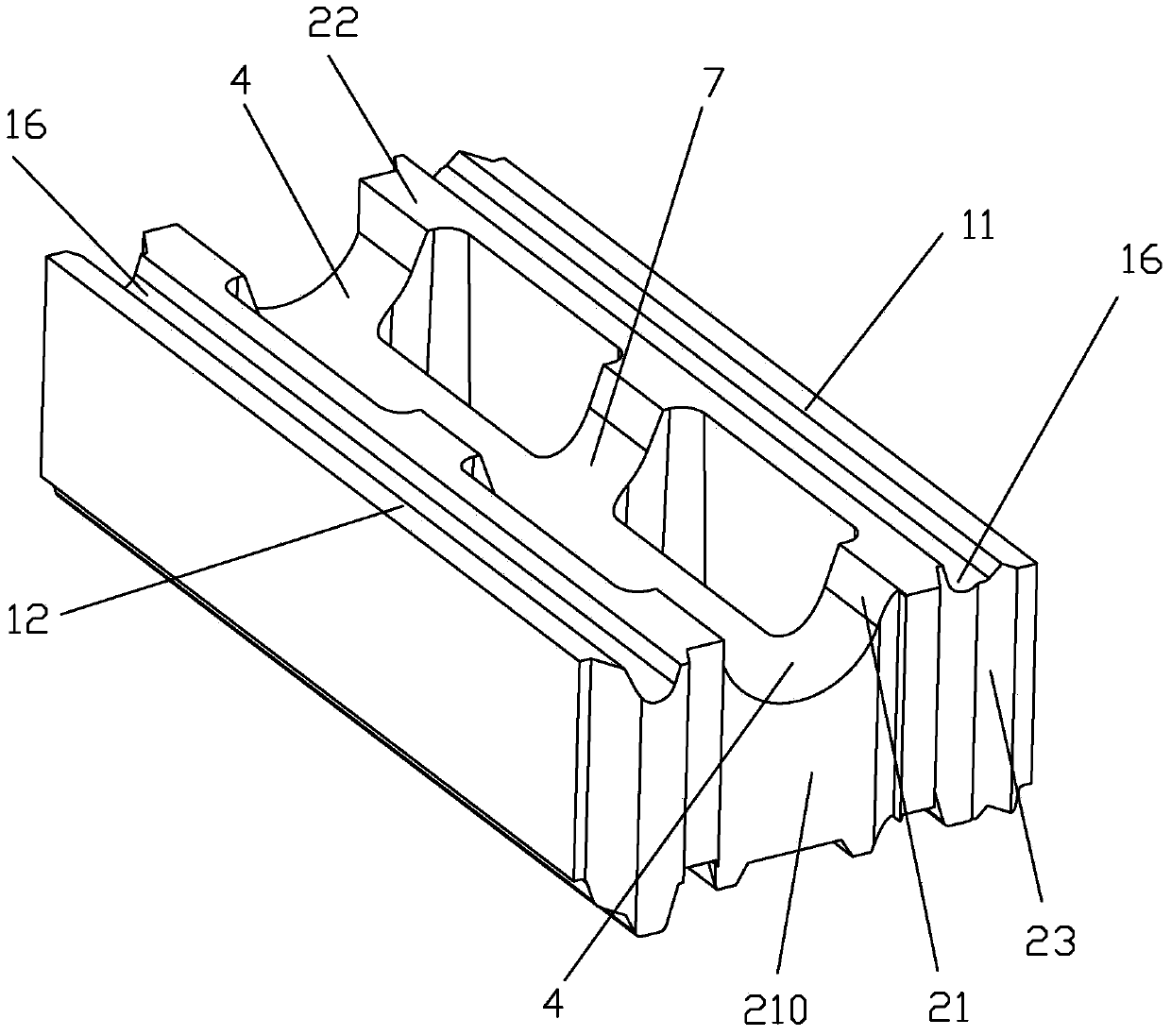

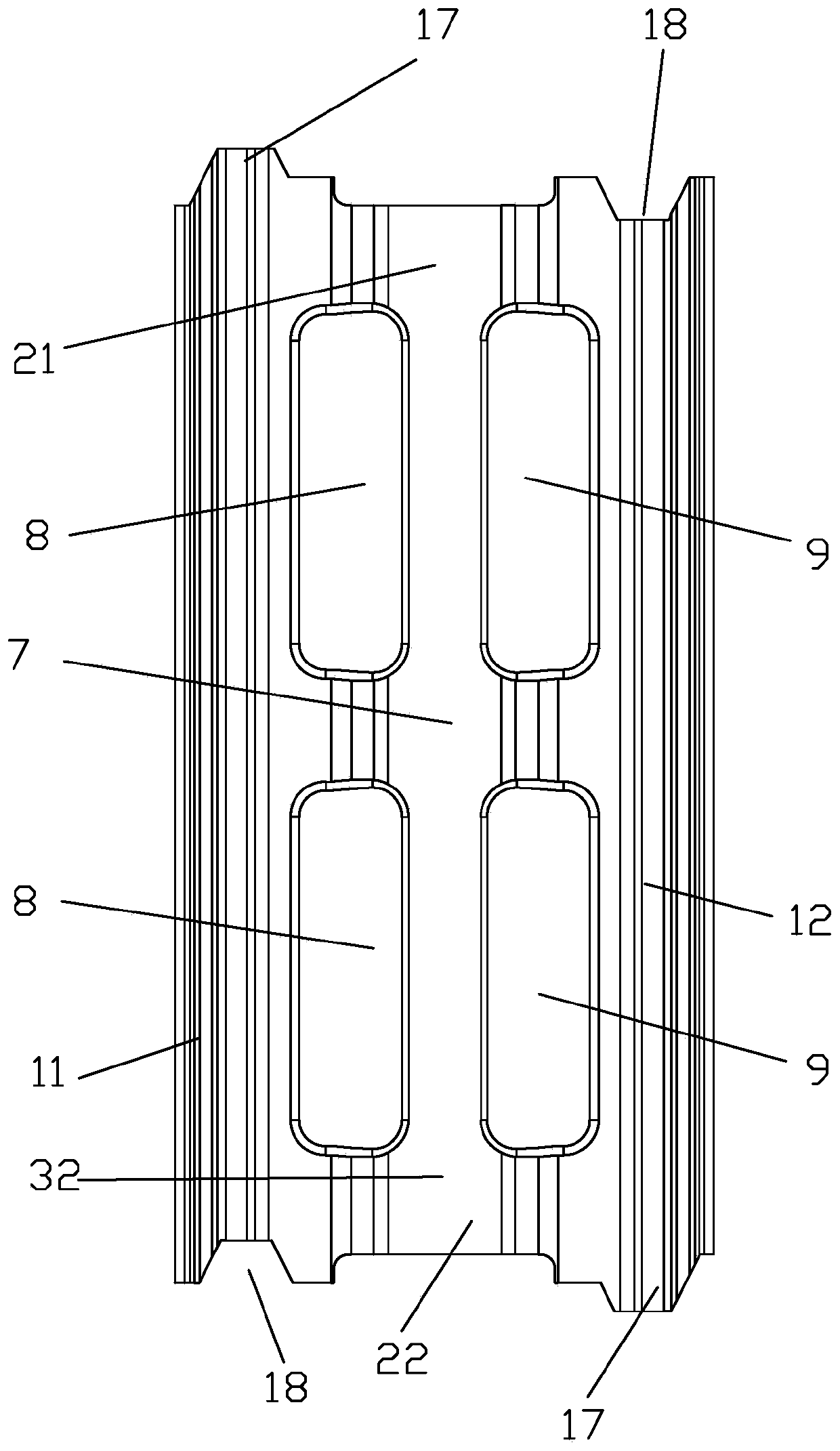

[0021] A main body brick for building a hollow wall, which includes a brick body 1, the brick body 1 includes a first long side 11 and a second long side 12 arranged at a certain distance apart, and a connecting first long side The left rib 21 and the right rib 22 of the strip limit 11 and the second strip limit 12; there is a certain distance between the left rib 21 and the right rib 22; the upper ends of the left rib 21 and the right rib 22 are all provided with The limit boss 3, the lower end of the left rib 21 and the right rib 22 are all provided with a limit groove 4 matched with the limit boss 3, the first long side 11 and the second long side 12 The upper end is provided with a convex strip 13, a transverse decorative recess 15 formed between the convex strip 13 and the outer end surface 14 of the first long side 11 and the second long side 12, and a horizontal decorative groove 15 formed between the convex strip 13 and the limiting boss 3 There is a filling groove 5; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com