Combined mechanical seal device

A mechanical seal device and combined technology, which are applied in rocket engine devices, mechanical equipment, jet propulsion devices, etc., can solve the requirements of multiple starts and long-term working conditions, which cannot be guaranteed, and cannot adapt to the high speed of turbo pumps and mechanical seals. Leakage and other problems, to achieve the effect of compact structure, overcoming easy leakage, and improving high temperature and high pressure capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

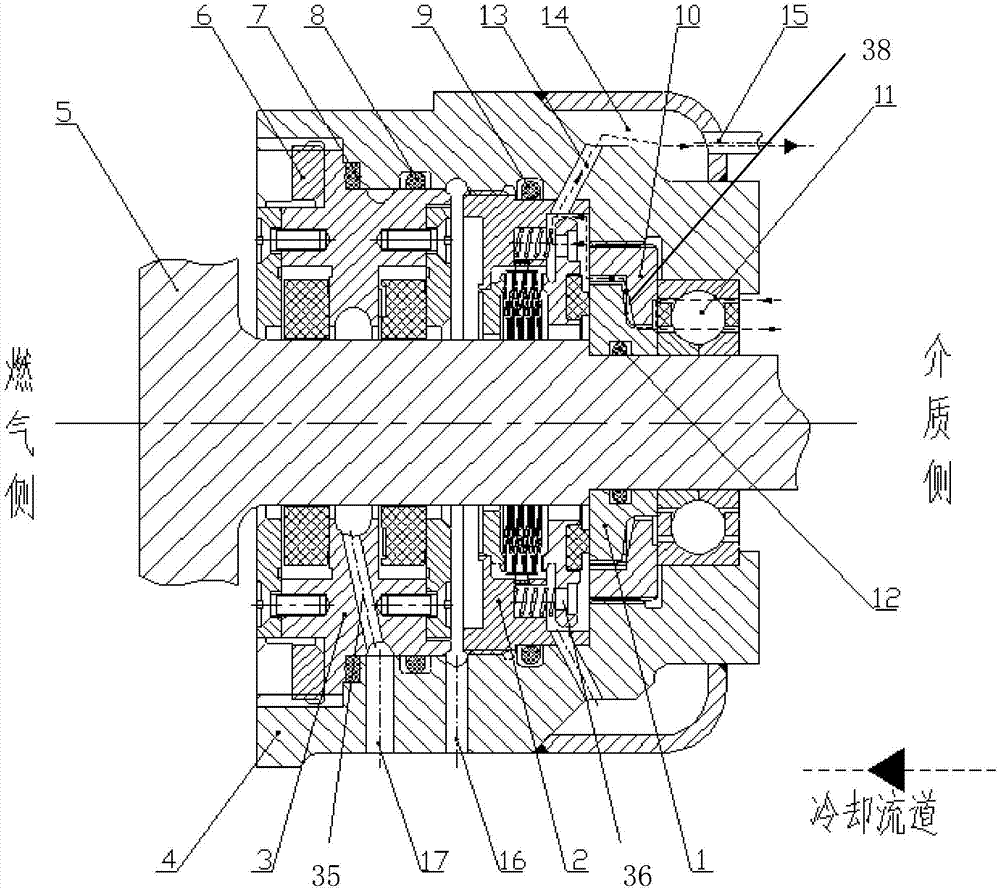

[0031] The invention discloses a combined mechanical sealing device suitable for liquid rocket engines. The sealing device realizes the function of isolating the propellant medium and high-temperature gas of the engine turbo pump. The mechanical sealing device has a compact structure, occupies a small axial space, and can adapt to The liquid rocket engine turbopump requires high speed, high temperature, large vibration, multiple starts and long-term working conditions, and has high sealing reliability to ensure that the medium does not leak a lot during the working and gliding stages, isolate the propellant medium and high-temperature gas, and prevent When the two media meet, the high temperature of the gas is blocked from being transmitted to the oxidant medium of the turbo pump.

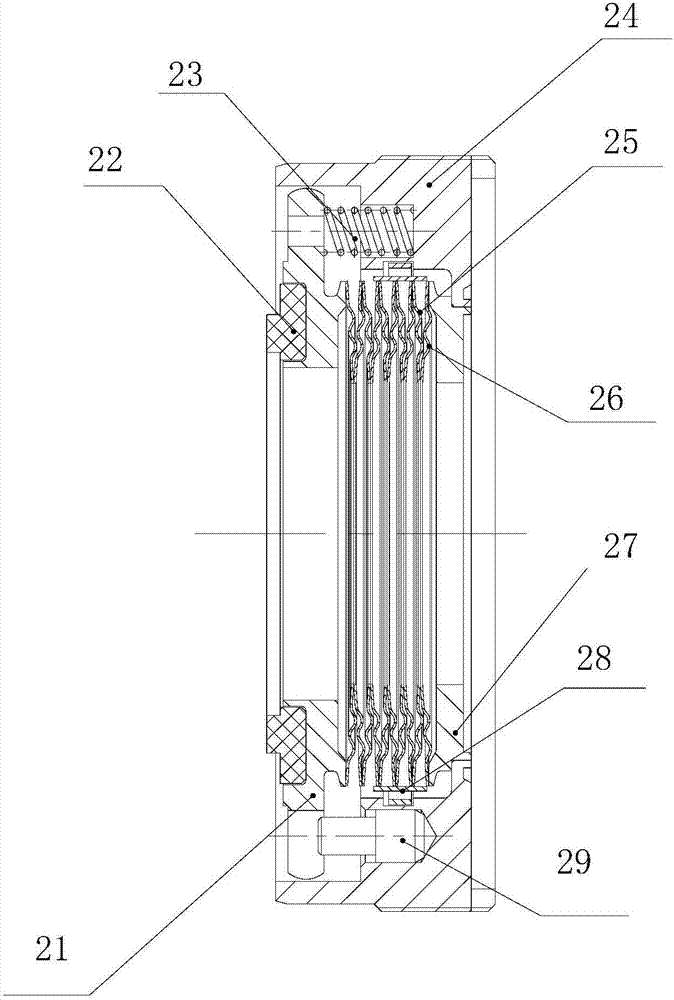

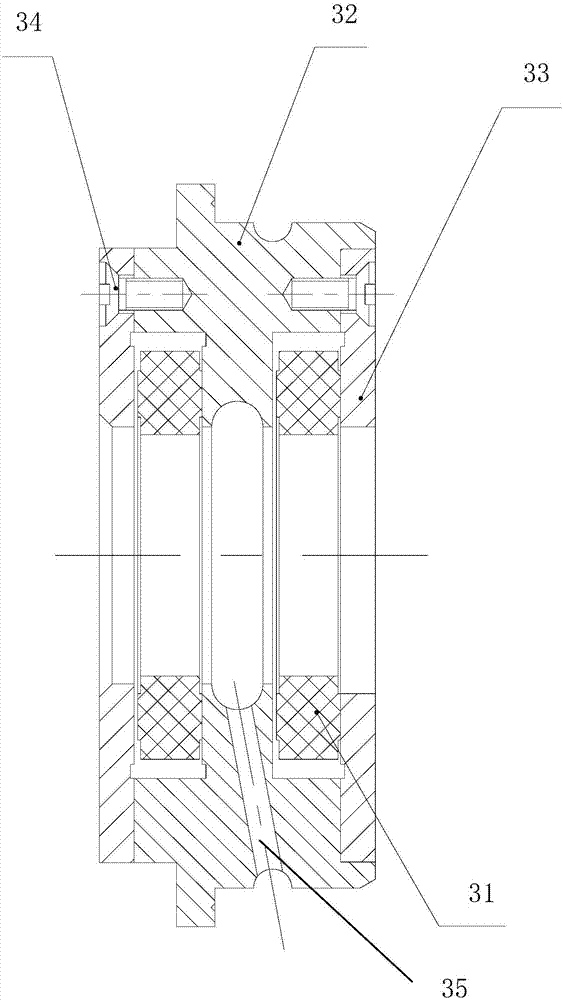

[0032] Such as Figures 1 to 5 As shown, the combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com