Flameless combustion chamber for Stirling engine and implementation method of flameless combustion chamber

A Stirling engine and combustion chamber technology, applied in the combustion method, combustion chamber, continuous combustion chamber, etc., can solve the problems of high local temperature, long flame length, uneven temperature distribution, etc., to reduce the peak temperature and increase the zero temperature. Component life, the effect of ensuring long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0078] Also provided in the present invention is a kind of implementation method, the method that applies aforementioned implementation Stirling engine to use flameless combustion chamber 401 to implement, comprises the following steps:

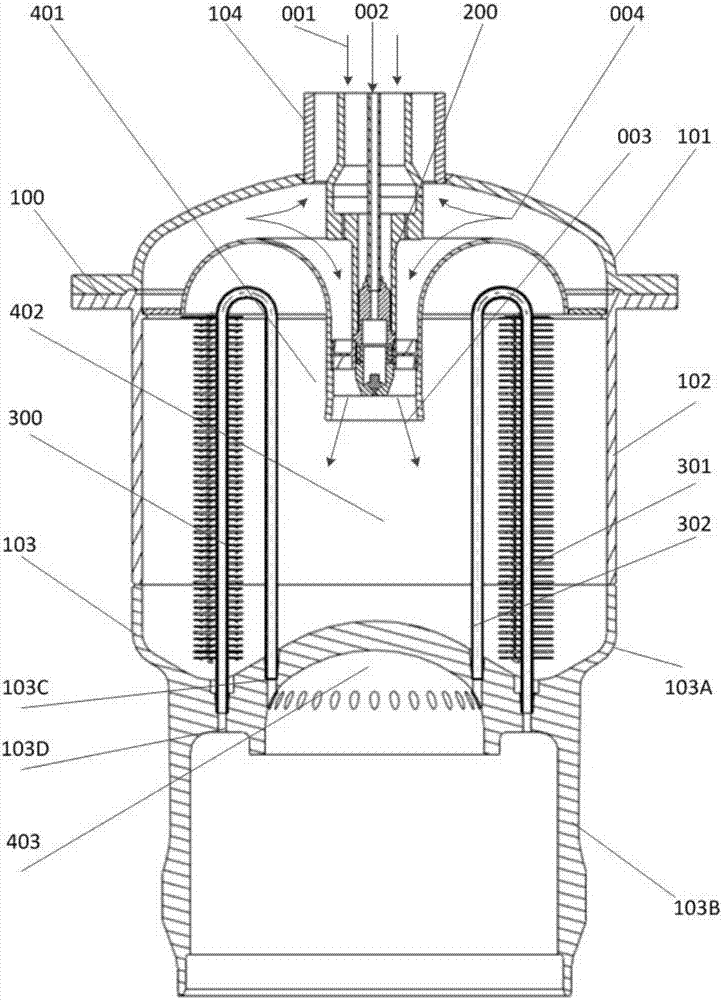

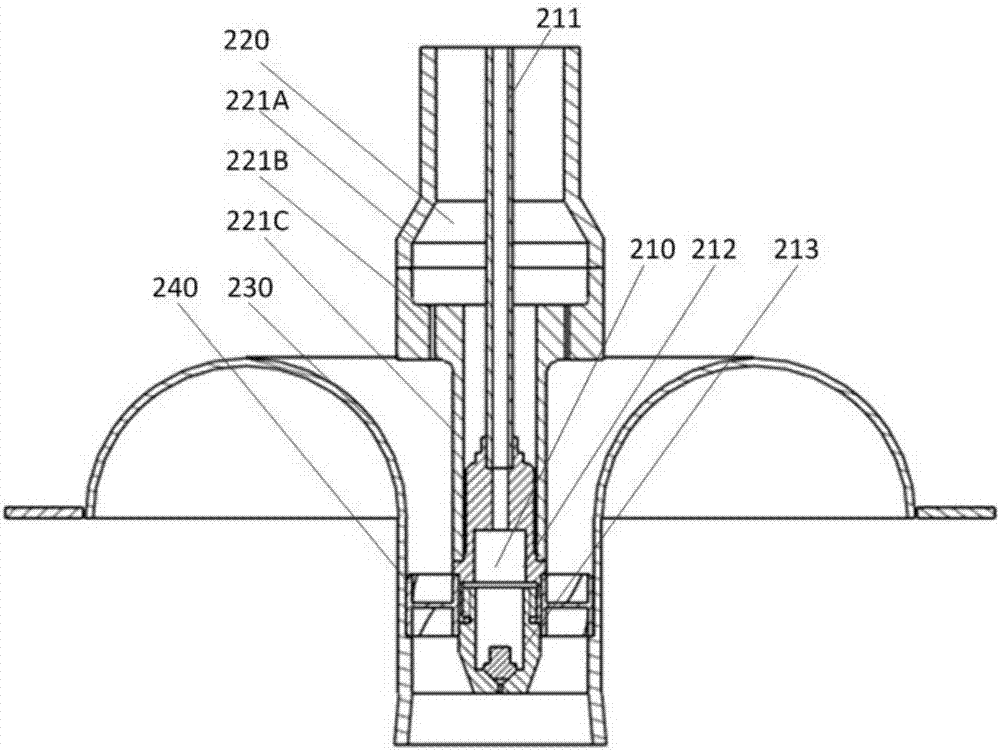

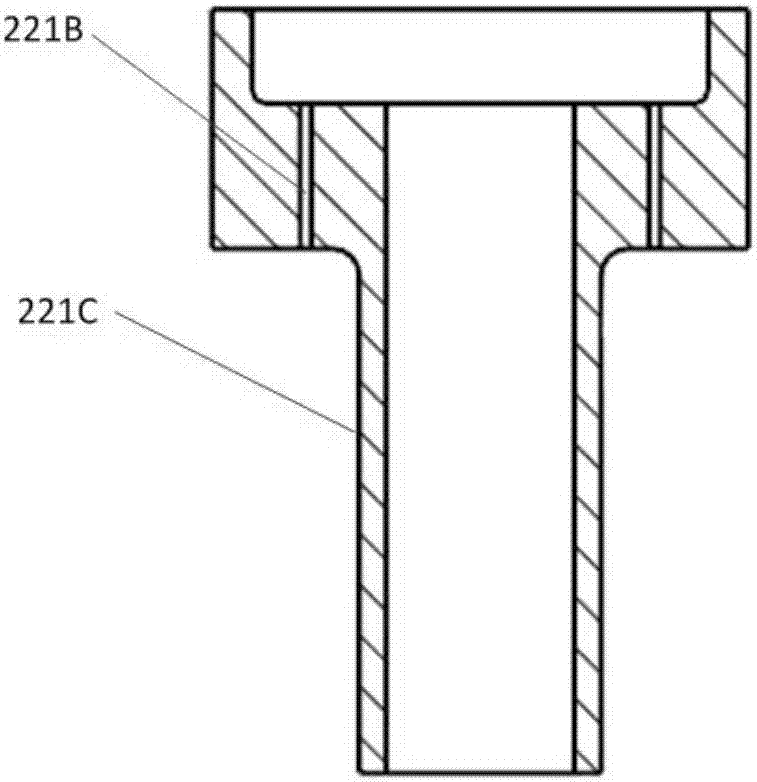

[0079] The oxidant 001 enters from the intake pipe assembly 220, the smoke 004 is drawn into the mixing pipe 230 for mixing, and the mixed gas flows through the swirler 240 to form a backflow in the combustion zone 402 in the housing 100;

[0080] The liquid fuel 002 enters from the fuel injector 210, and after being evaporated, it is mixed with the mixed gas flowing through the swirler 240 to form a combustible mixed gas. The heat exchanger 300 performs heat exchange. Part of the exchanged flue gas 004 flows out of the casing 100 from the exhaust pipe 104 , and the other part is entrained into the mixing pipe 230 to mix with the oxidant 001 entering from the intake pipe assembly 220 .

[0081] In this implementation method, it can be ensured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com