Patents

Literature

79results about How to "Lower peak temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Halogen-free tin-bismuth-copper soldering paste and preparation method thereof

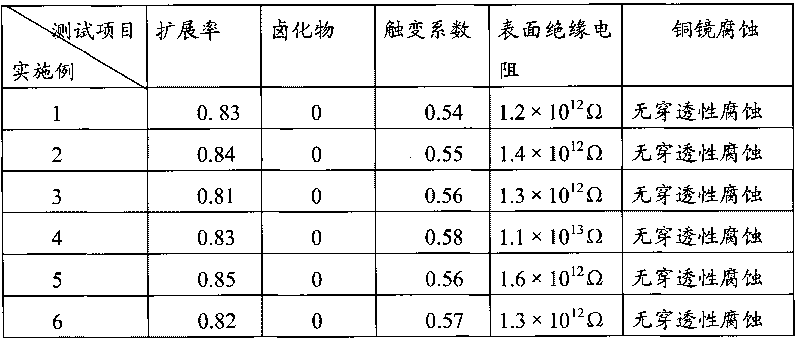

InactiveCN101695794AExtended shelf lifeExtended service lifeWelding/cutting media/materialsSoldering mediaAntioxidantExpansion rate

The invention relates to the technical field of soldering pastes, in particular to a halogen-free tin-bismuth-copper soldering paste and a preparation method thereof. A soldering flux of the halogen-free tin-bismuth-copper soldering paste consists of the following components in percentage by weight: 20 to 40 percent of polymerized rosin, 1 to 6 percent of rosin amine, 4 to 8 percent of thixotropic agent, 5 to 10 percent of organic acid, 5 to 10 percent of organic amine, 1 to 5 percent of antioxidant, 0.5 to 3 percent of surfactant and an organic solvent. The halogen-free tin-bismuth-copper soldering paste is mainly characterized by adopting the organic acid and the organic amine serving as activating agents and comprising no halogens at all, so not only the solderability is not reduced, but also the expansion rate and the insulation resistance value of the soldering paste are improved, and simultaneously the corrosivity of residues after soldering to a base material is reduced and the service life of the soldering paste is prolonged; and particularly, the peak temperature of the soldering paste during soldering is lower in favor of reducing the thermal damages to electronic components.

Owner:东莞市特尔佳电子有限公司

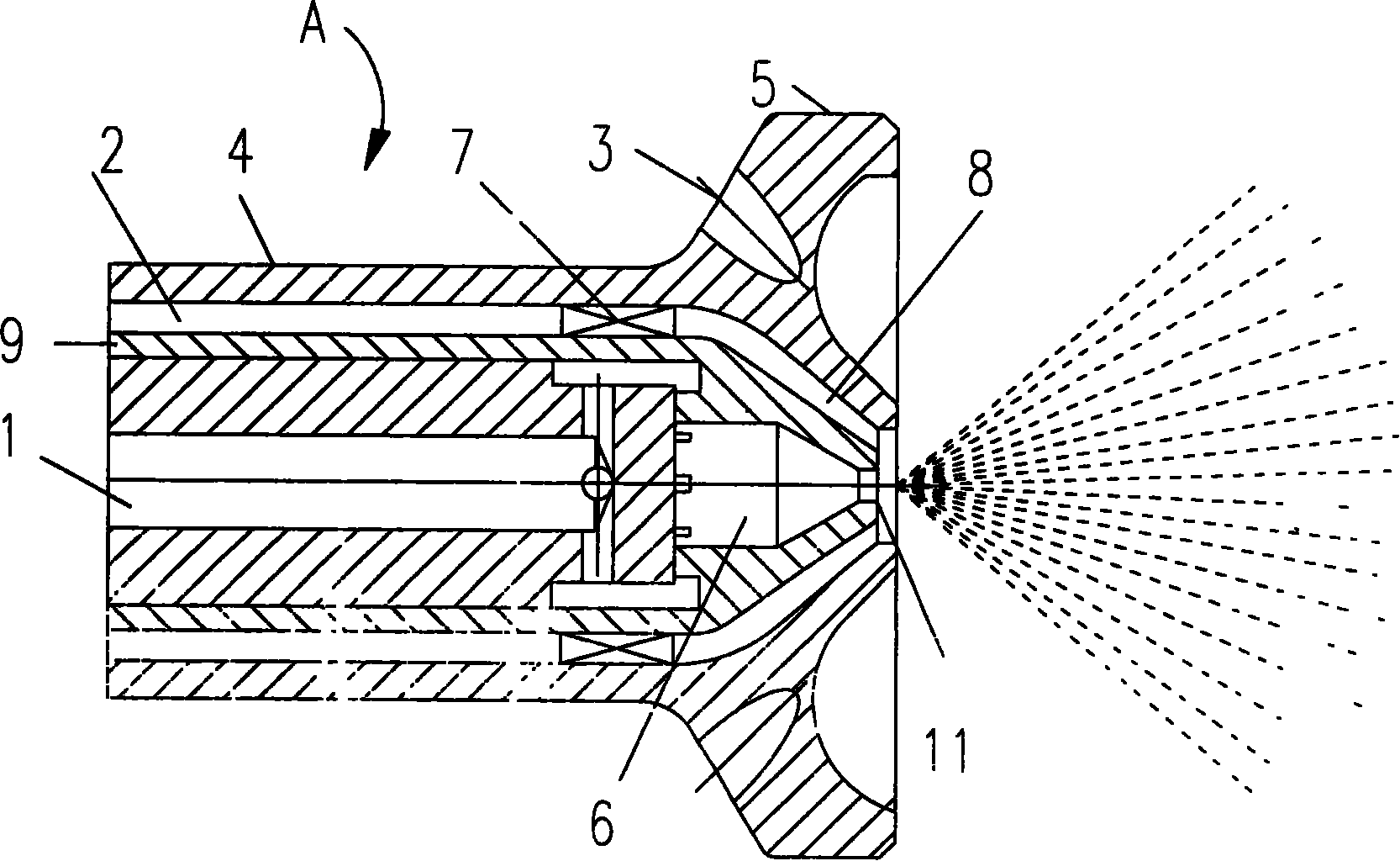

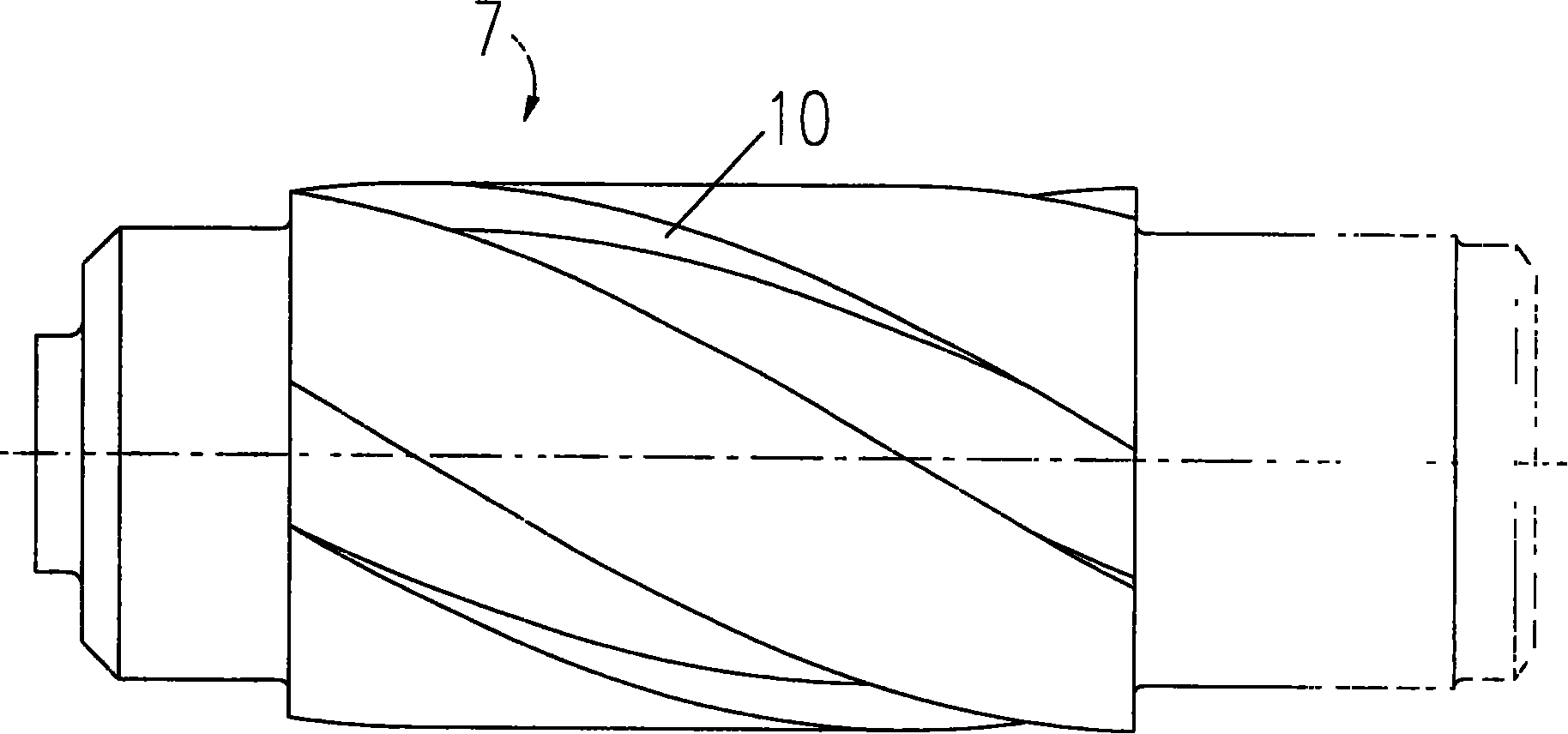

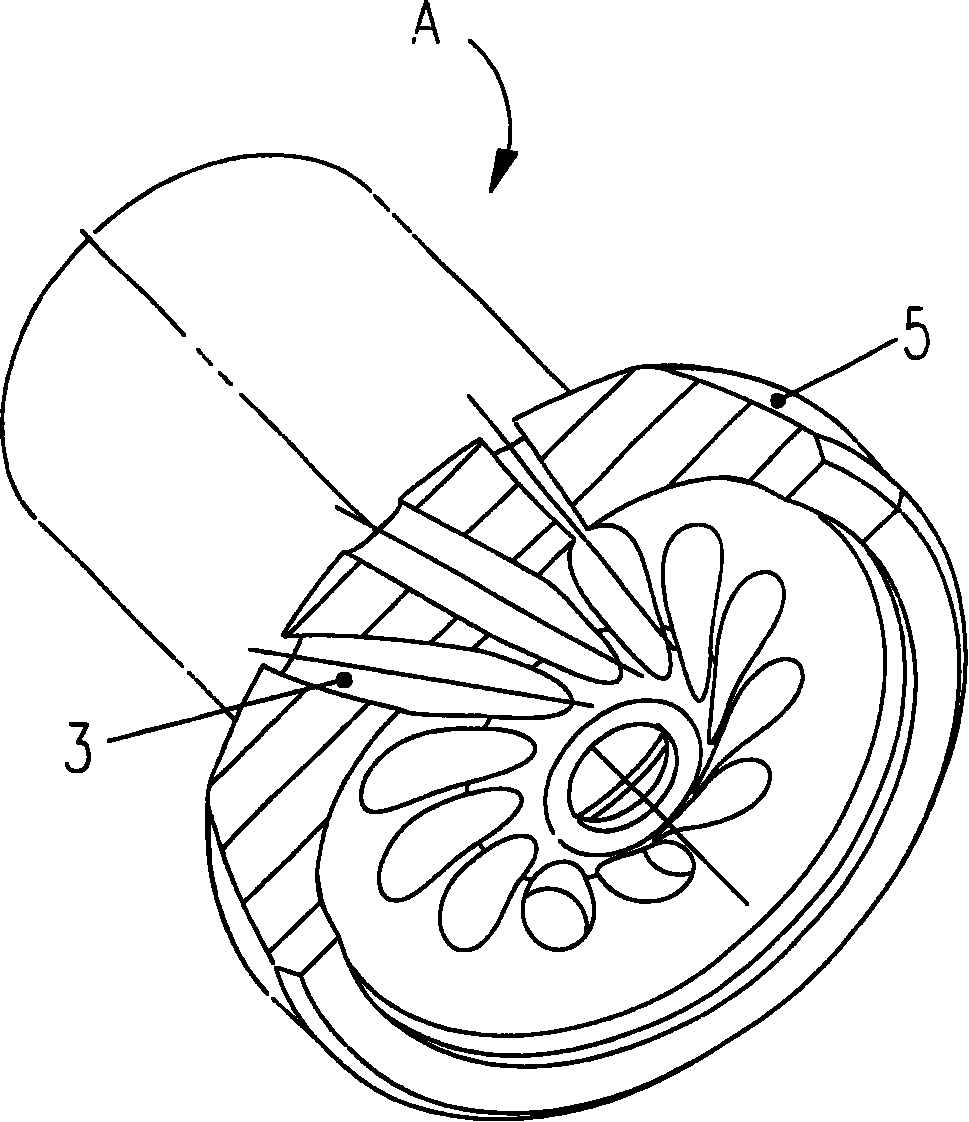

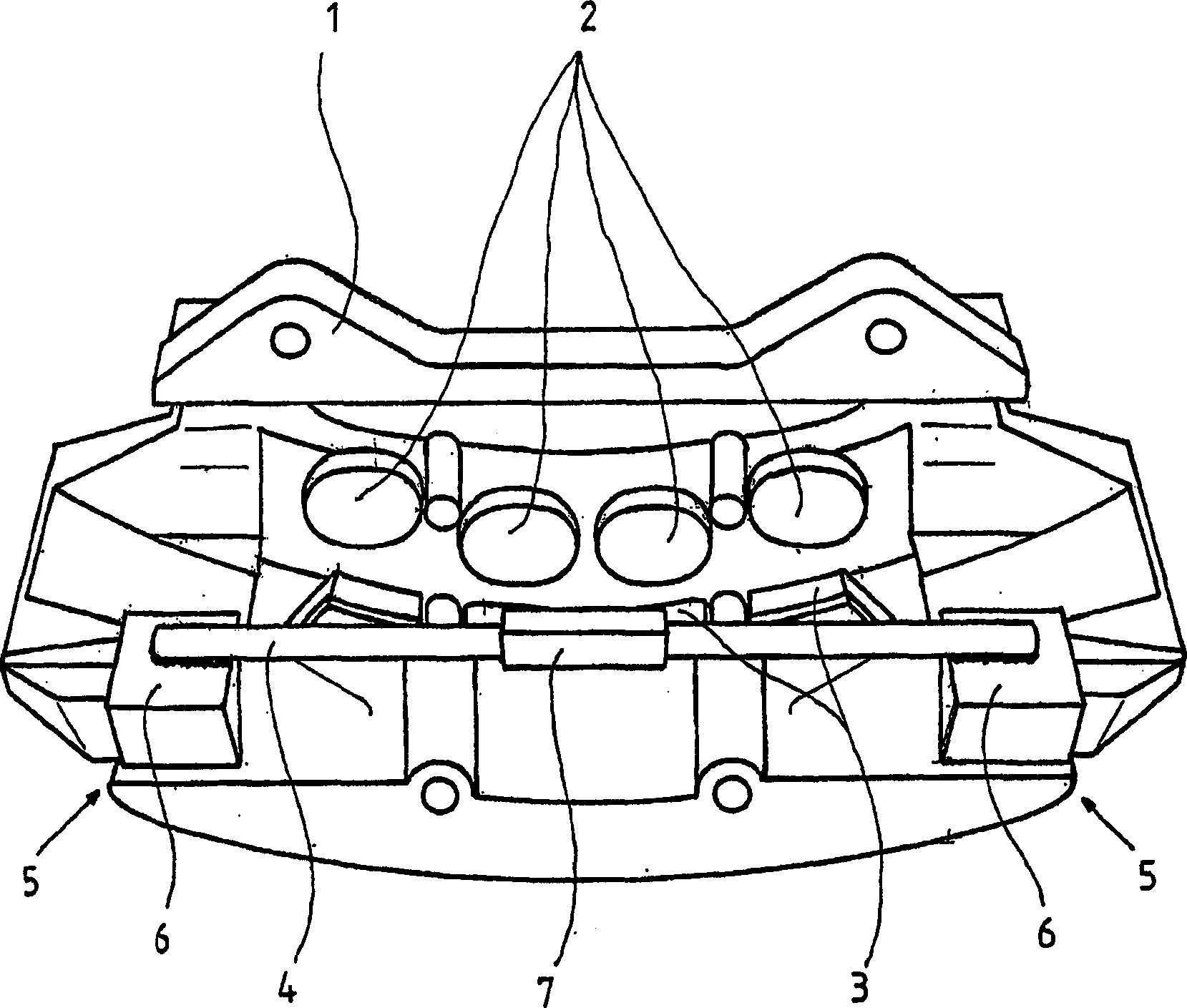

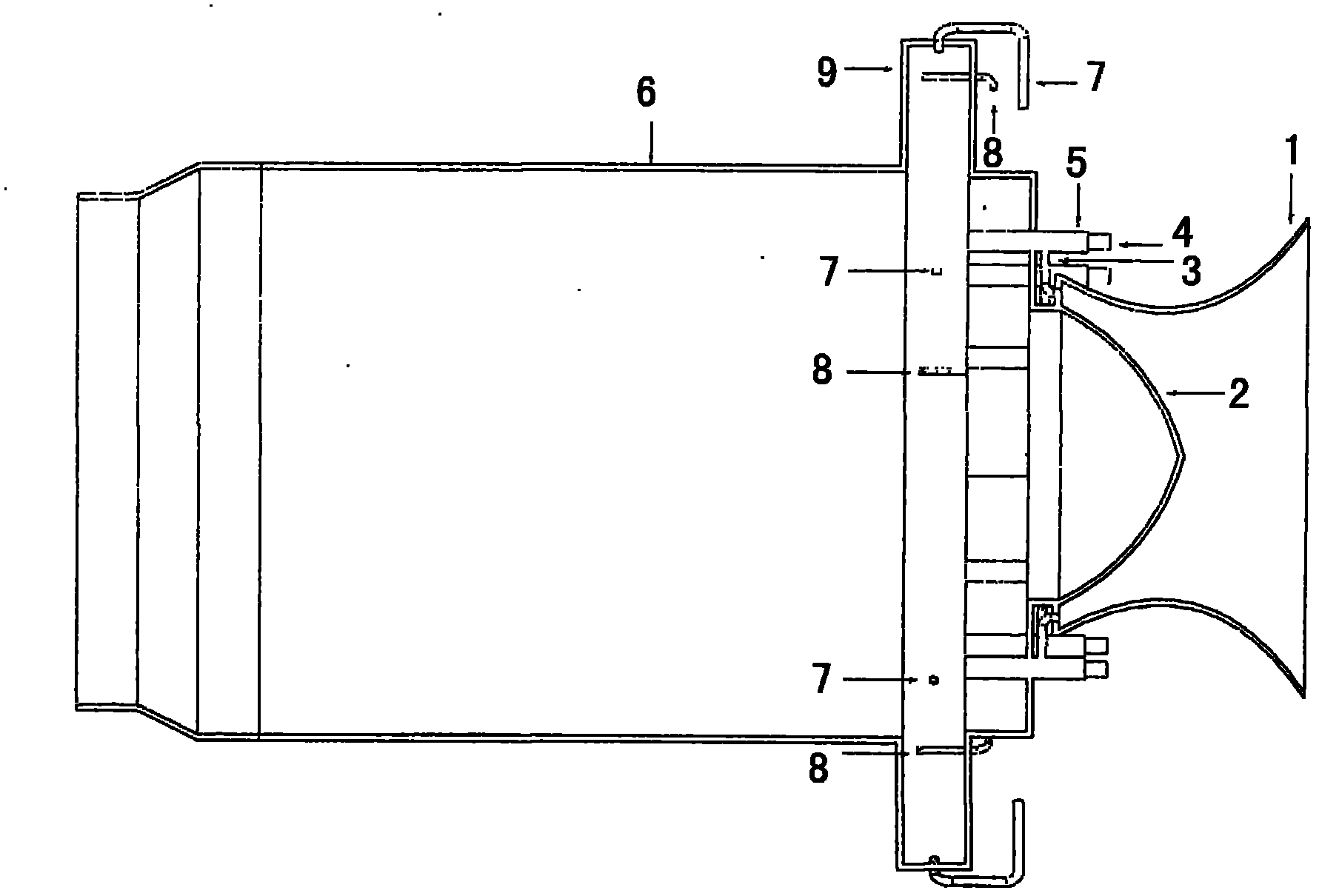

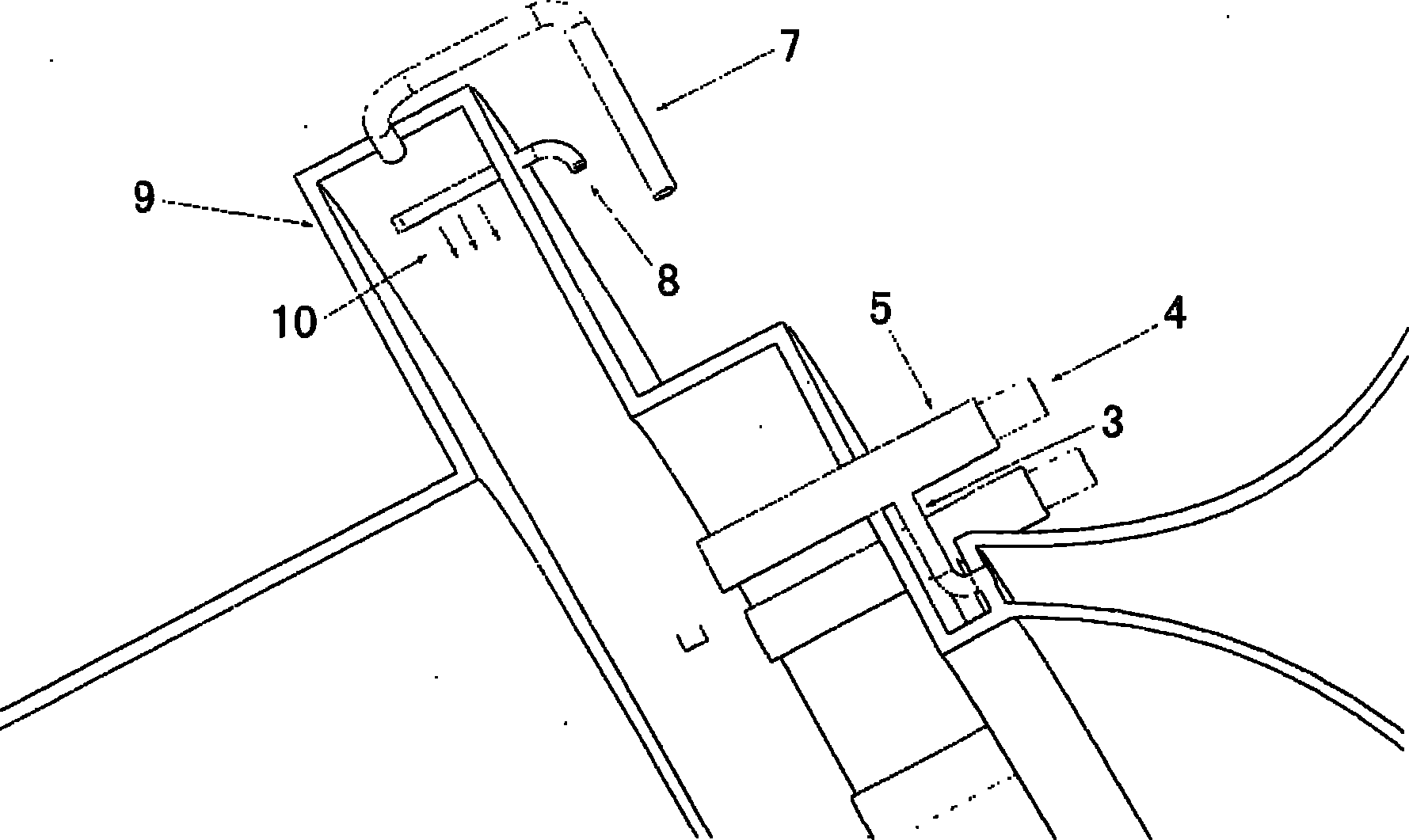

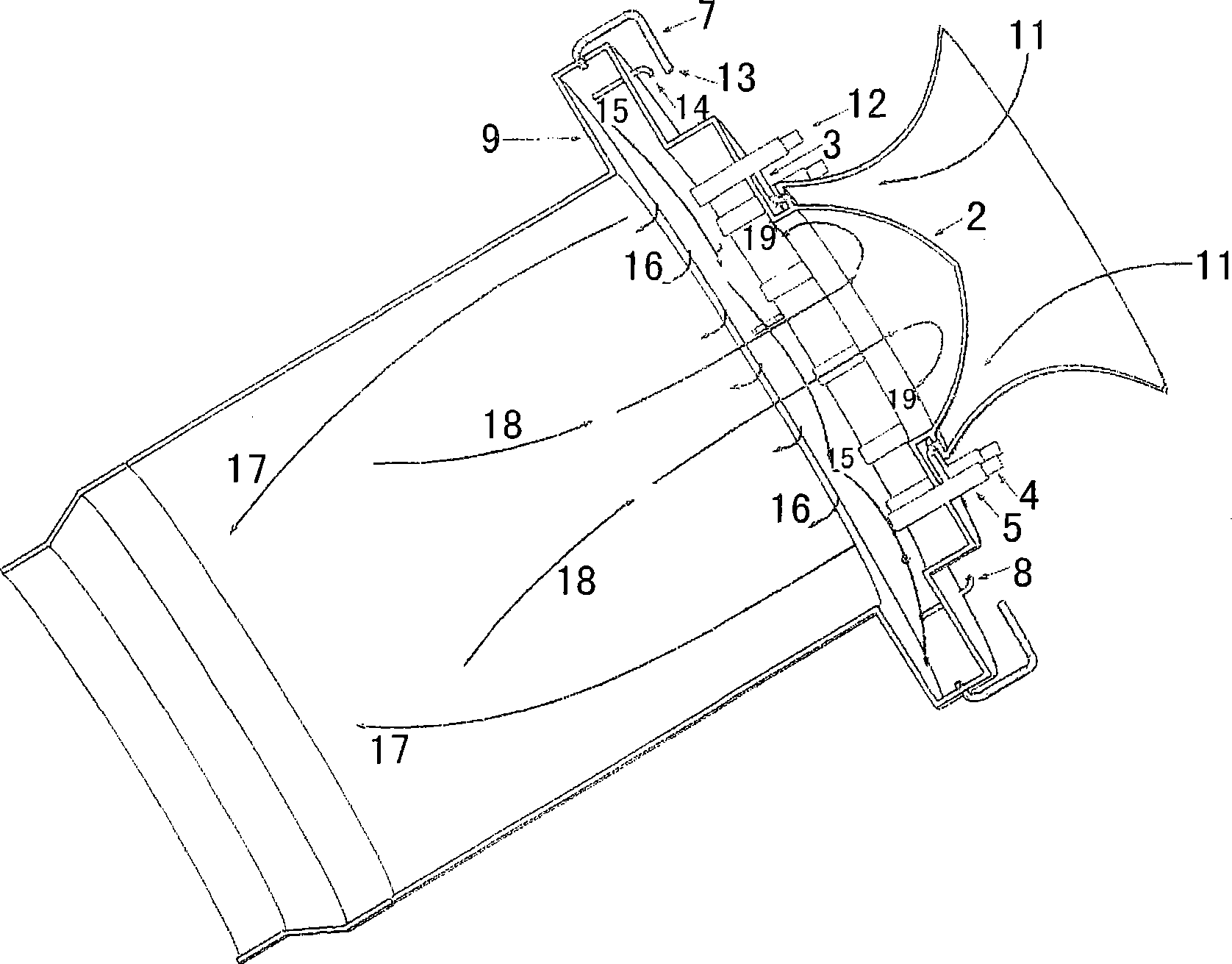

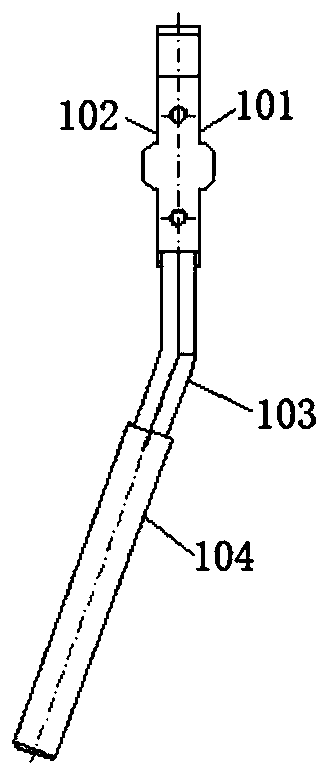

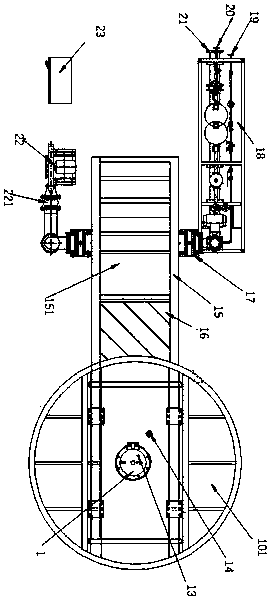

Nozzle for minisize gas-turbine combustor

ActiveCN101206029ACompact structureGood atomization qualityBurnersContinuous combustion chamberPollutantCombustion chamber

The invention discloses a nozzle of a combustion chamber of a miniature gas turbine, relates to the gas turbine technology, and in particular to a small size fluid fuel nozzle used in a combustion chamber of a 100 kW level miniature gas turbine. The nozzle consists of three parts which are a fuel oil passage, a fuel air passage and an air channel at the root of a burner, comprehensively utilizes the advantages of pneumatic nebulization and pressure atomization, and is a combined type high performance pneumatic atomizing nozzle. The nozzle of the invention has the characteristics that: the nozzle adopts a conventional processing method to realize excellent atomization of the fuel in small scale space, so as to meet the requirement for the quality of fuel atomization under a quite wide burden of the combustion chamber of the miniature gas turbine; the nozzle can avoid burnout and overcomes the defect of nozzle blockage caused by high temperature coking of the fuel; meanwhile, the nozzle can make the fuel in the combustion chamber to be combusted more fully and reduce discharge of pollutants such as smoke black and so on.

Owner:江苏中国科学院能源动力研究中心 +1

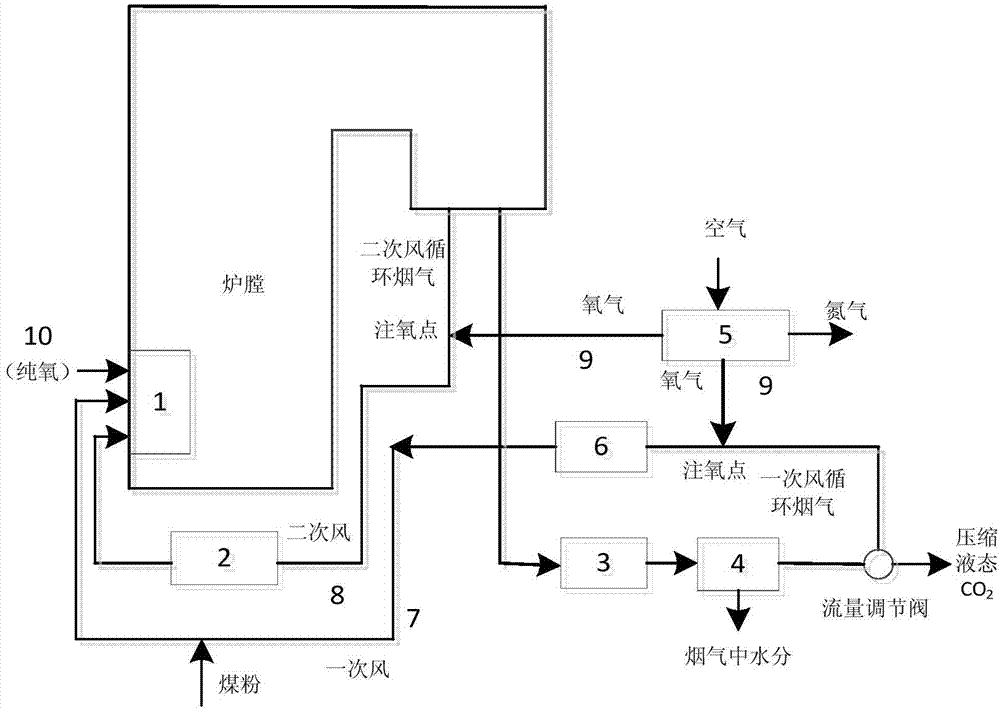

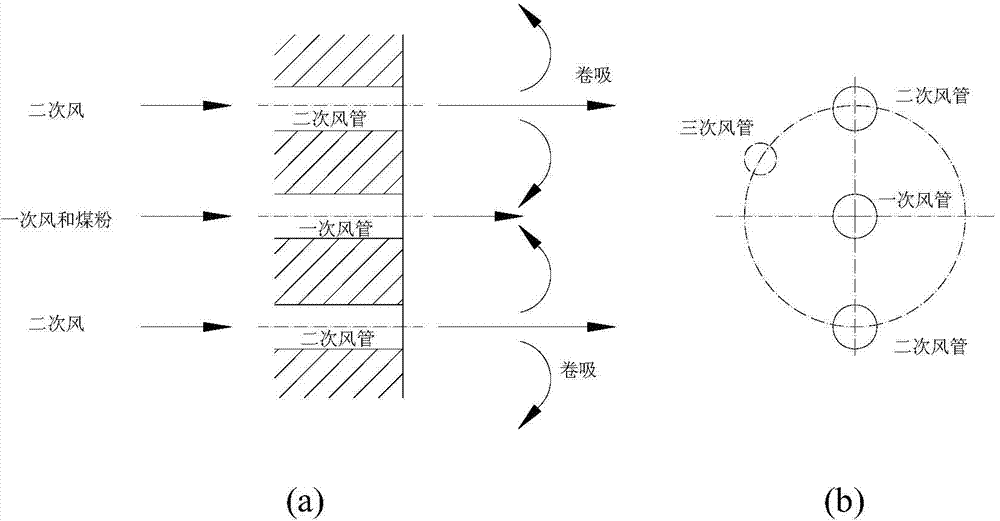

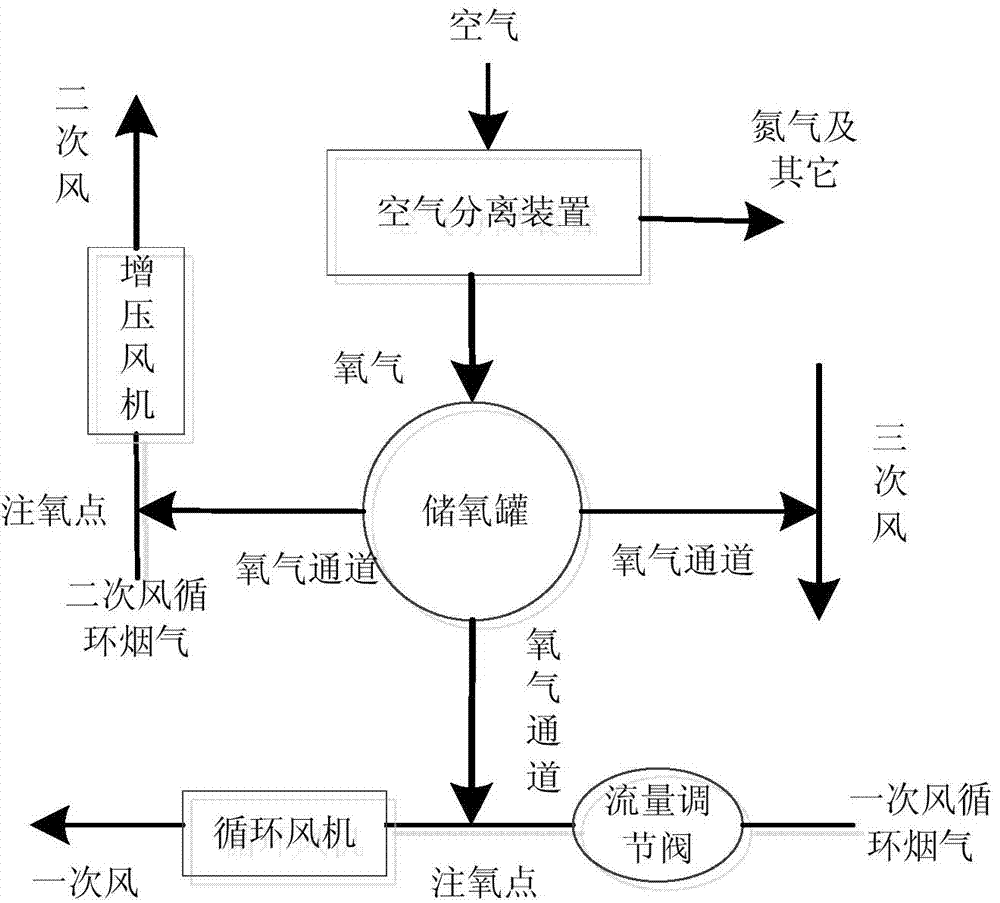

Method and system thereof for oxygen-enriched flameless combustion of coal powder

ActiveCN103615713AIncrease temperatureImprove heat utilization efficiencyDirect carbon-dioxide mitigationIndirect carbon-dioxide mitigationFlue gasInjection point

The invention discloses a method and a system thereof for oxygen-enriched flameless combustion of coal powder. By adopting the method, the stability, burn-off rate and radiative heat transfer of combustion can be improved through flameless combustion on the basis of enriching CO2 during oxygen-enriched combustion. High-temperature flue gas generated by the oxygen-enriched combustion is injected into a hearth in the form of high-speed jet flow through a direct-current flameless burner, and quick and uniform mixing of heat and quality in the hearth can be realized through high-speed jet flow entrainment. The system comprises an oxygen injection system, and a primary air oxygen-injection point is positioned between a circulating fan and a flow regulating valve; a secondary air oxygen-injection point is positioned between a booster fan and a hearth outlet; a primary air pipe of the direct-current flameless burner is positioned in the center, and a secondary air pipe is parallel to the primary air pipe and is circularly arranged around the primary air pipe; the booster fan with a high-pressure head is arranged on a secondary air duct, and secondary air is boosted and speeded up and then enters the hearth in the form of the high-speed jet flow. The heat utilization ratio of the method and the system can be improved by 10-25%, and the generation of NOX can be reduced by 15-40%.

Owner:HUAZHONG UNIV OF SCI & TECH

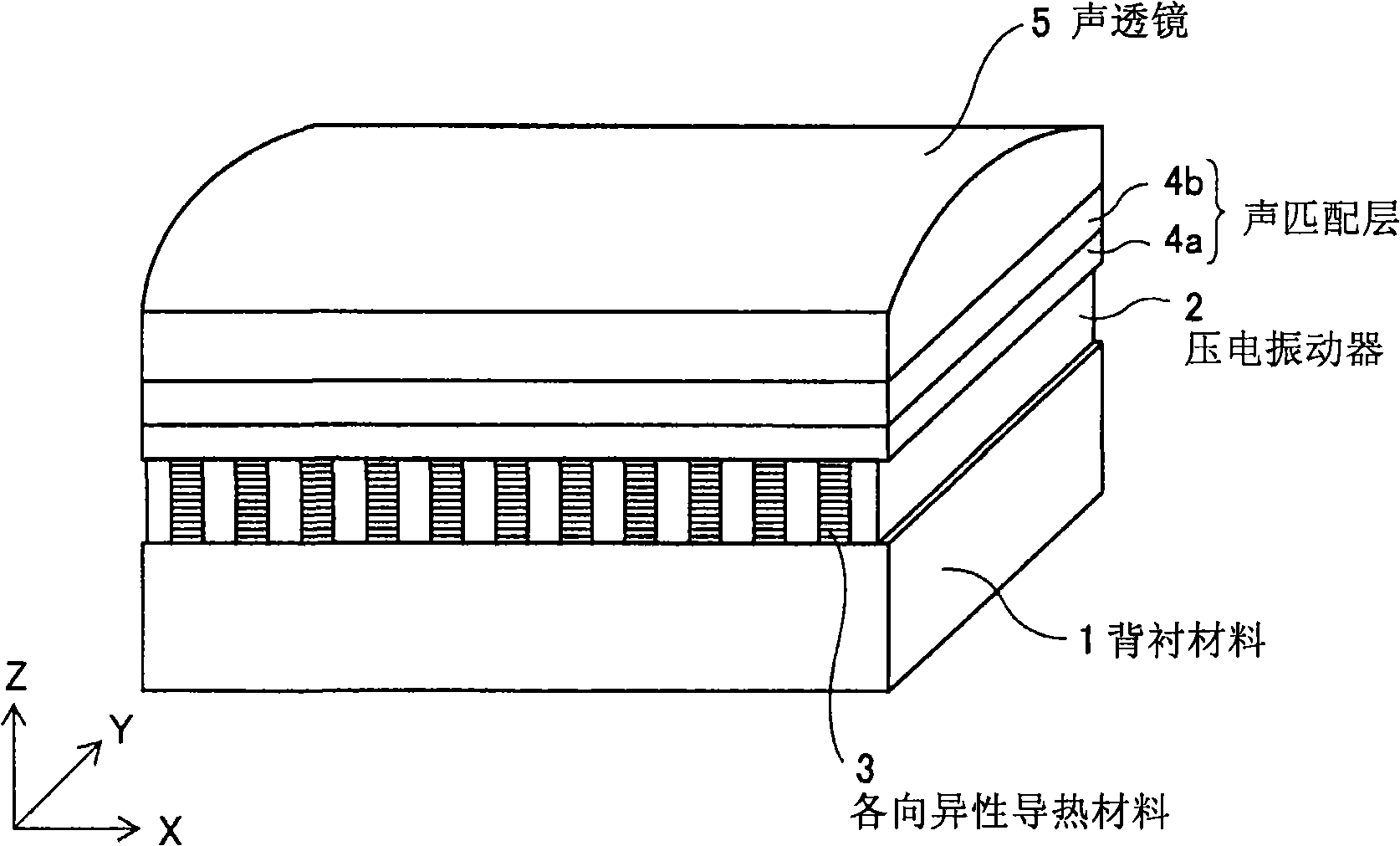

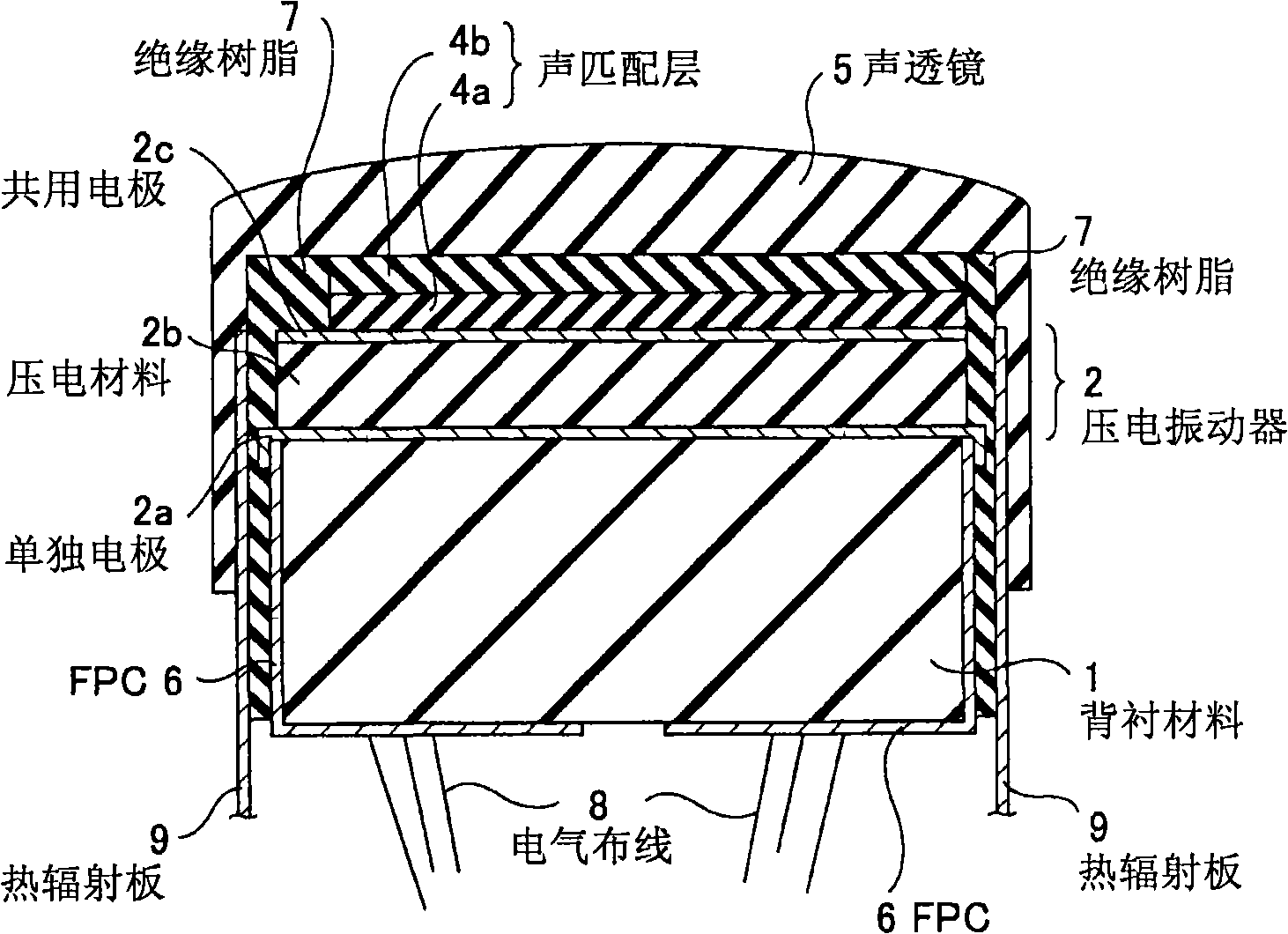

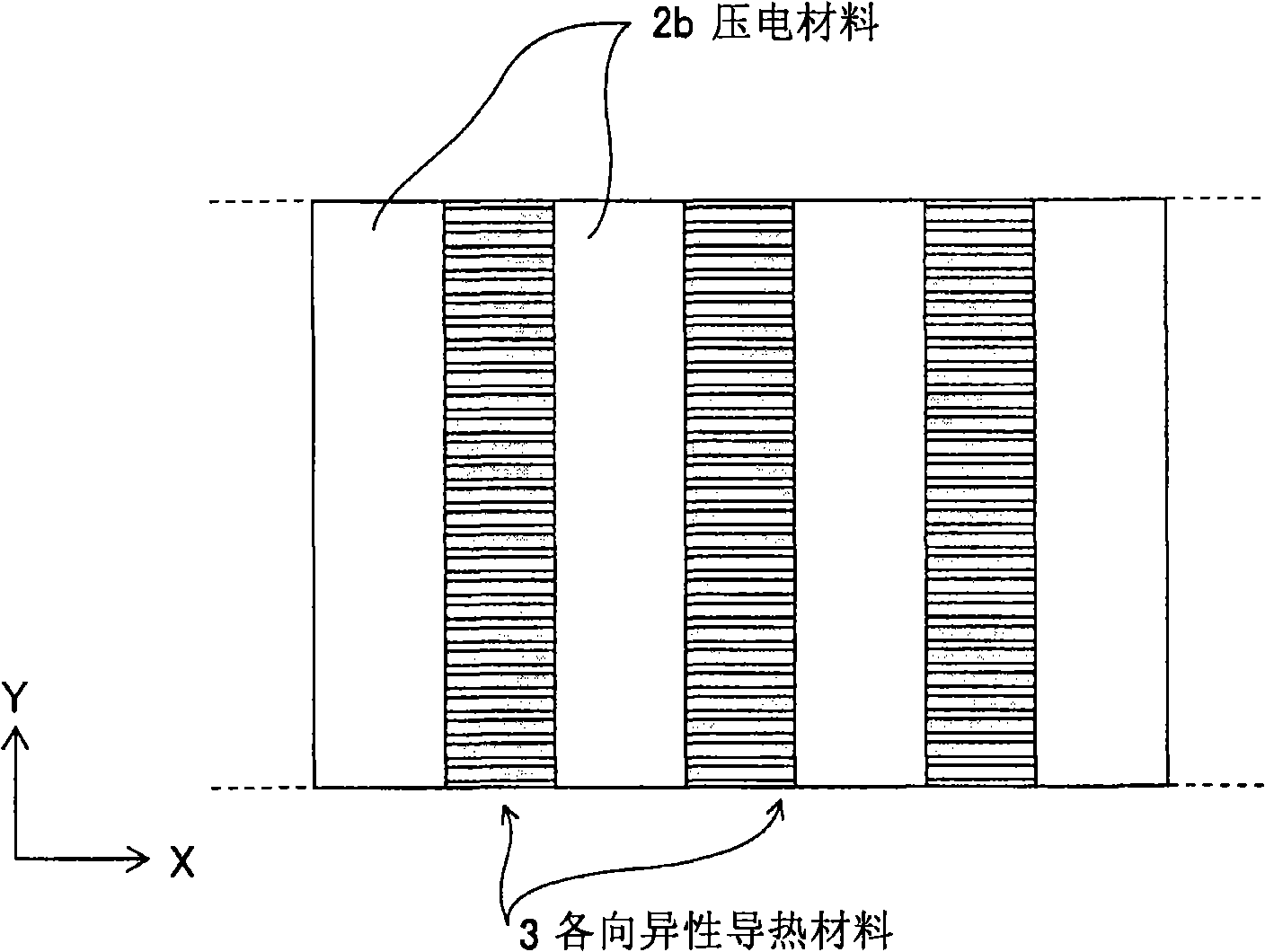

Composite piezoelectric material, ultrasonic probe, ultrasonic endoscope, and ultrasonic diagnostic apparatus

InactiveCN101325241ALower peak temperatureSurgeryPiezoelectric/electrostrictive device material selectionUltrasonic imagingHeat conducting

Owner:FUJIFILM CORP

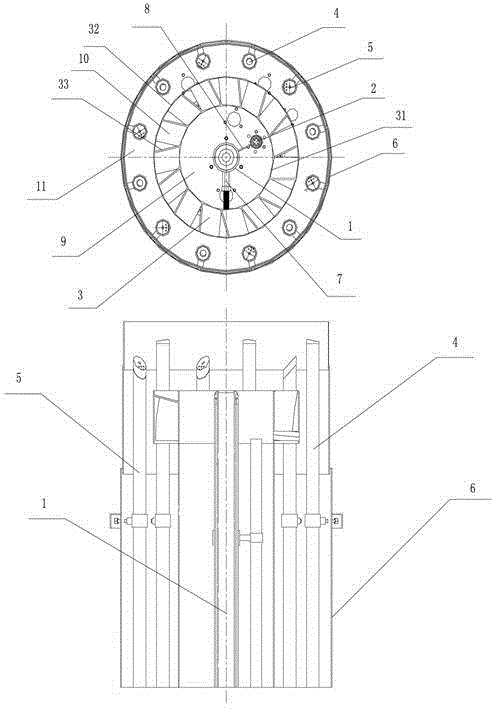

Gas burner with low NOX

ActiveCN102721058ALower peak temperatureReduce combustion excess air coefficientGaseous fuel burnerPollutantGas burner

The invention relates to the technical field of clean gas burning, in particular relates to a gas burner with low NOX, which aims to further reduce the pollutants, especially the generating amount of NOX caused by the gas burner, and simultaneously improves the efficiency of a whole boiler. The gas burner disclosed by the invention integrates the technologies of enhancement of the mixing of gas and combustion air, graded and sectioned burning, burning of thick gas and thin gas, smoke circulation and the like, and can enhance the mixing of the gas and the combustion air so as to achieve the beneficial effects that the burning is reinforced, the peak value temperature of burning flame is reduced, and further the excess air coefficient of the burning is reduced, and the pollutants such as NOX and the like can be reduced to be minimum.

Owner:SHANGHAI WISEBOND TECH

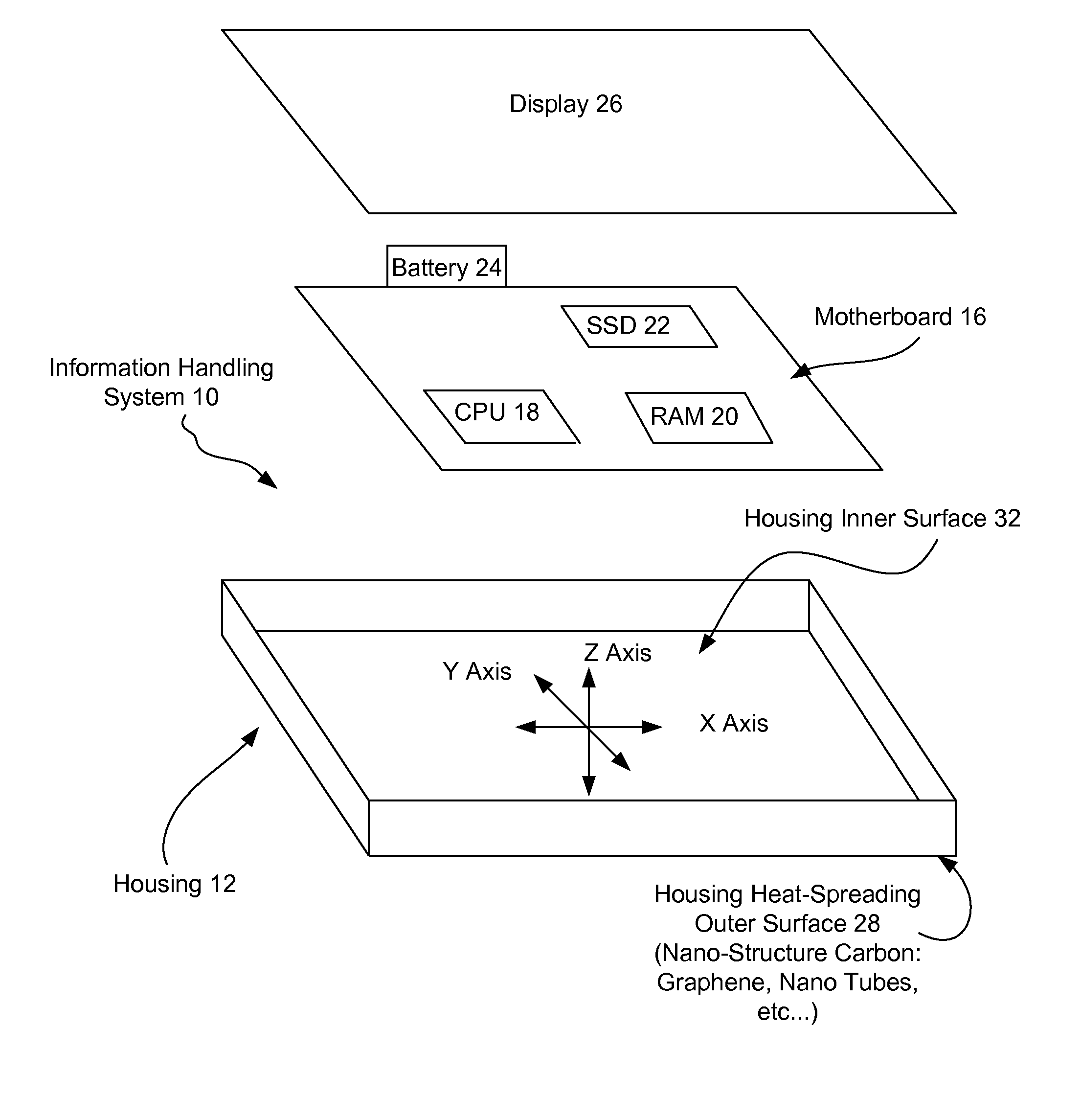

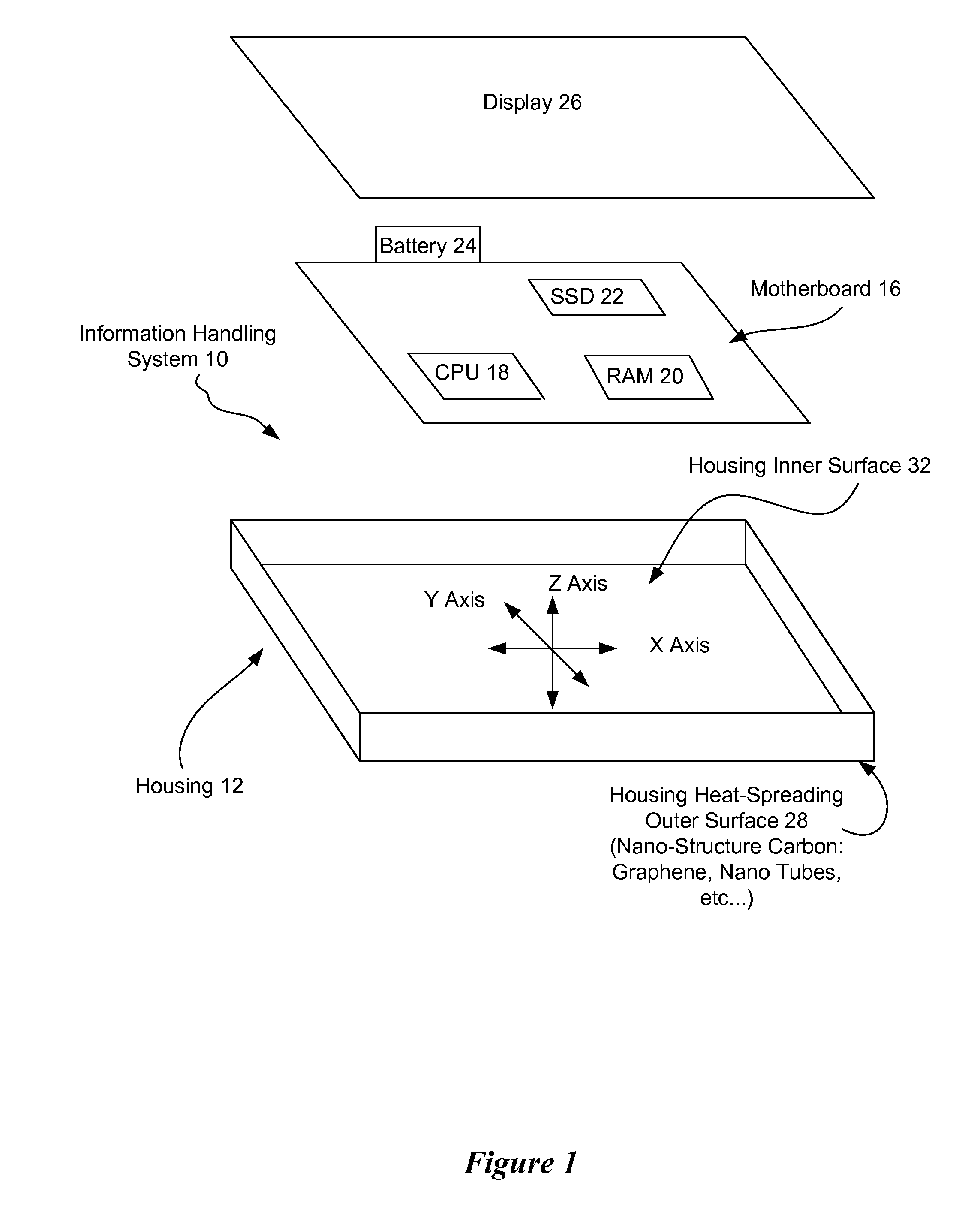

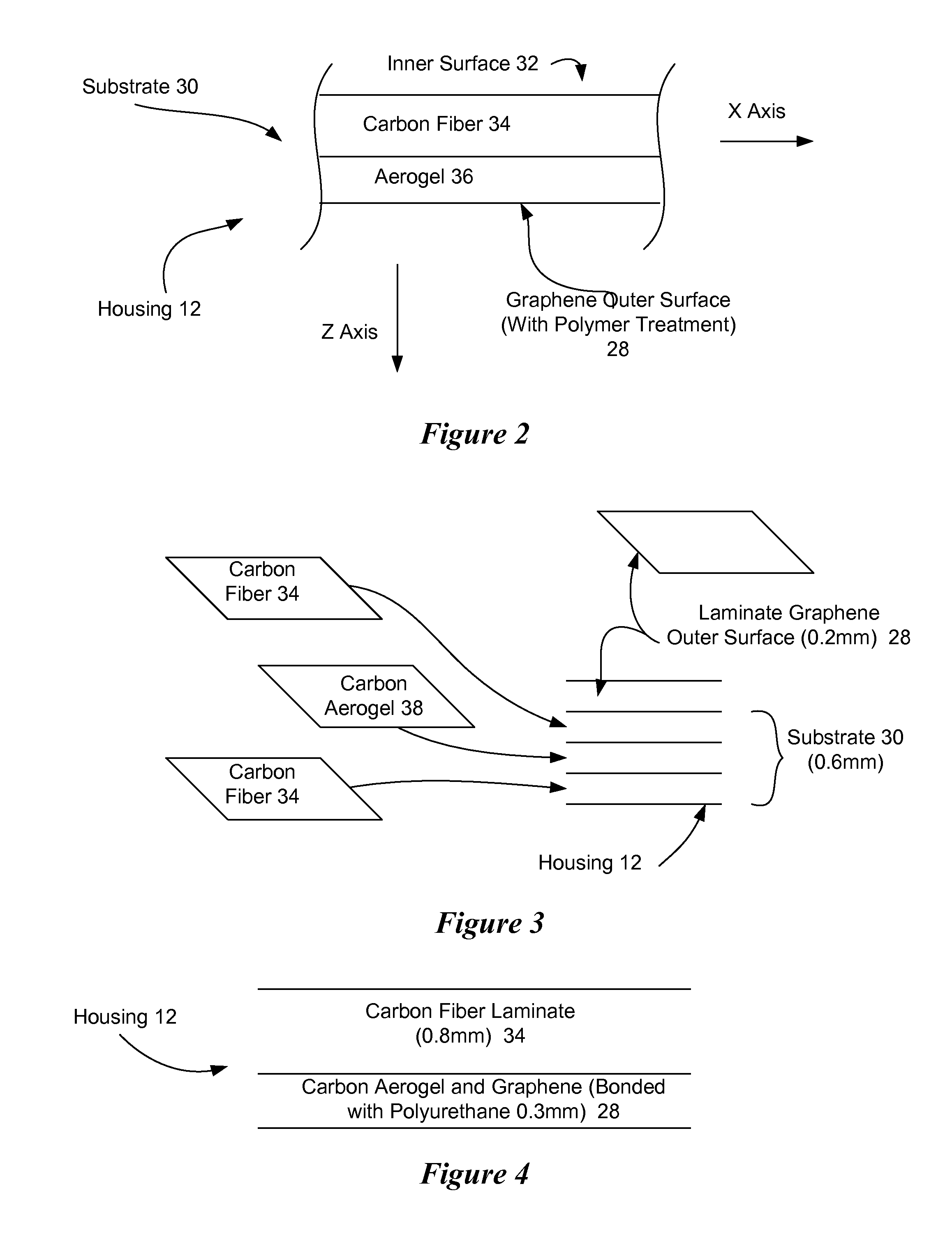

Information handling system housing heat spreader

ActiveUS20140240921A1Reduce disadvantagesReduce problemsWave amplification devicesDigital data processing detailsFiberThermal energy

Thermal energy exposed at the outer surface of an information handling system housing is managed by spreading the thermal energy across the housing X and Y axes while restricting heat transfer from the housing at the Z axis. For example, a graphene outer surface couples to an aerogel substrate strengthened by a carbon fiber laminate. The graphene spreads thermal energy that escapes through the housing across the housing outer surface to limit the impact of thermal energy at any particular location, such as proximate to the location of a processor.

Owner:DELL PROD LP

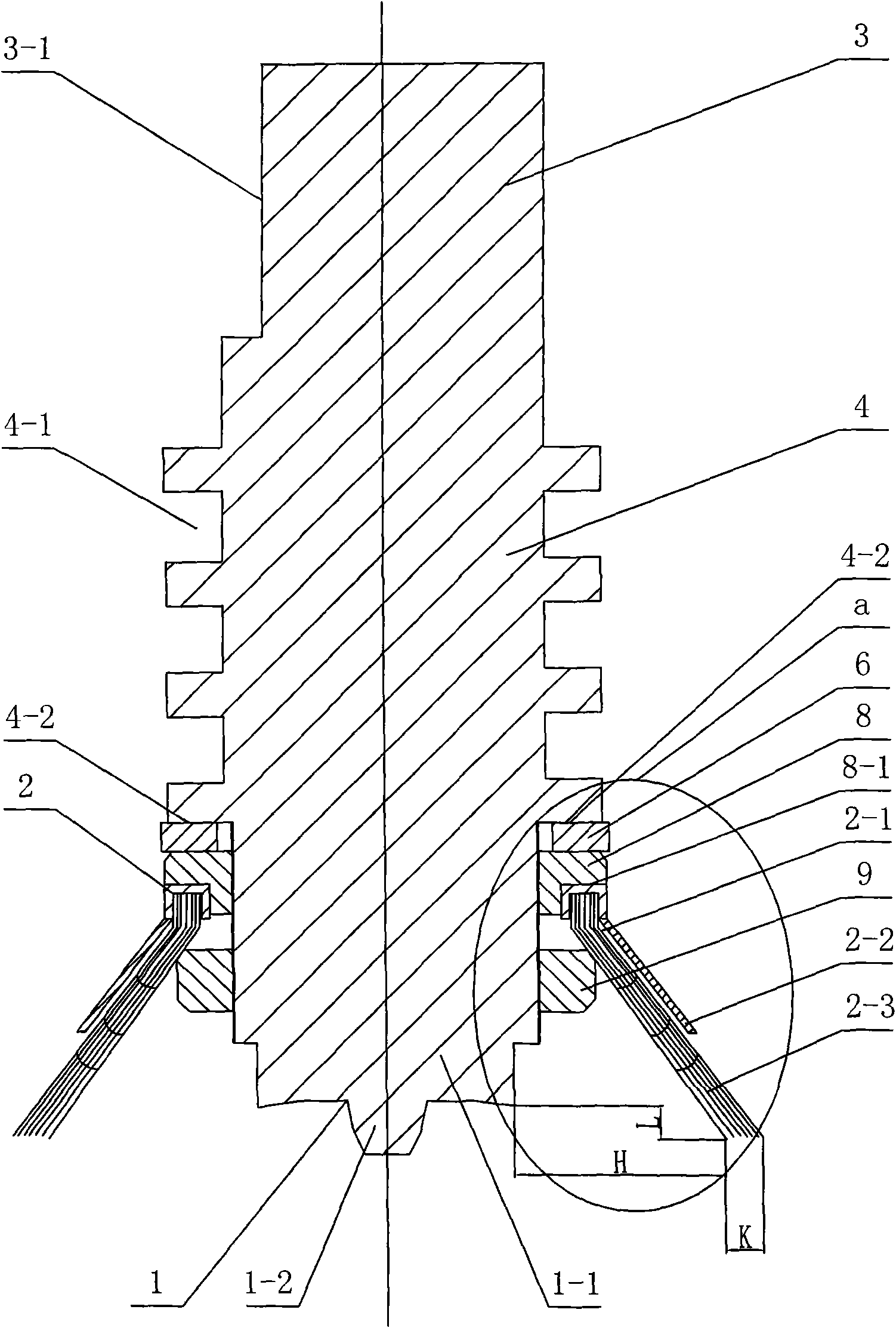

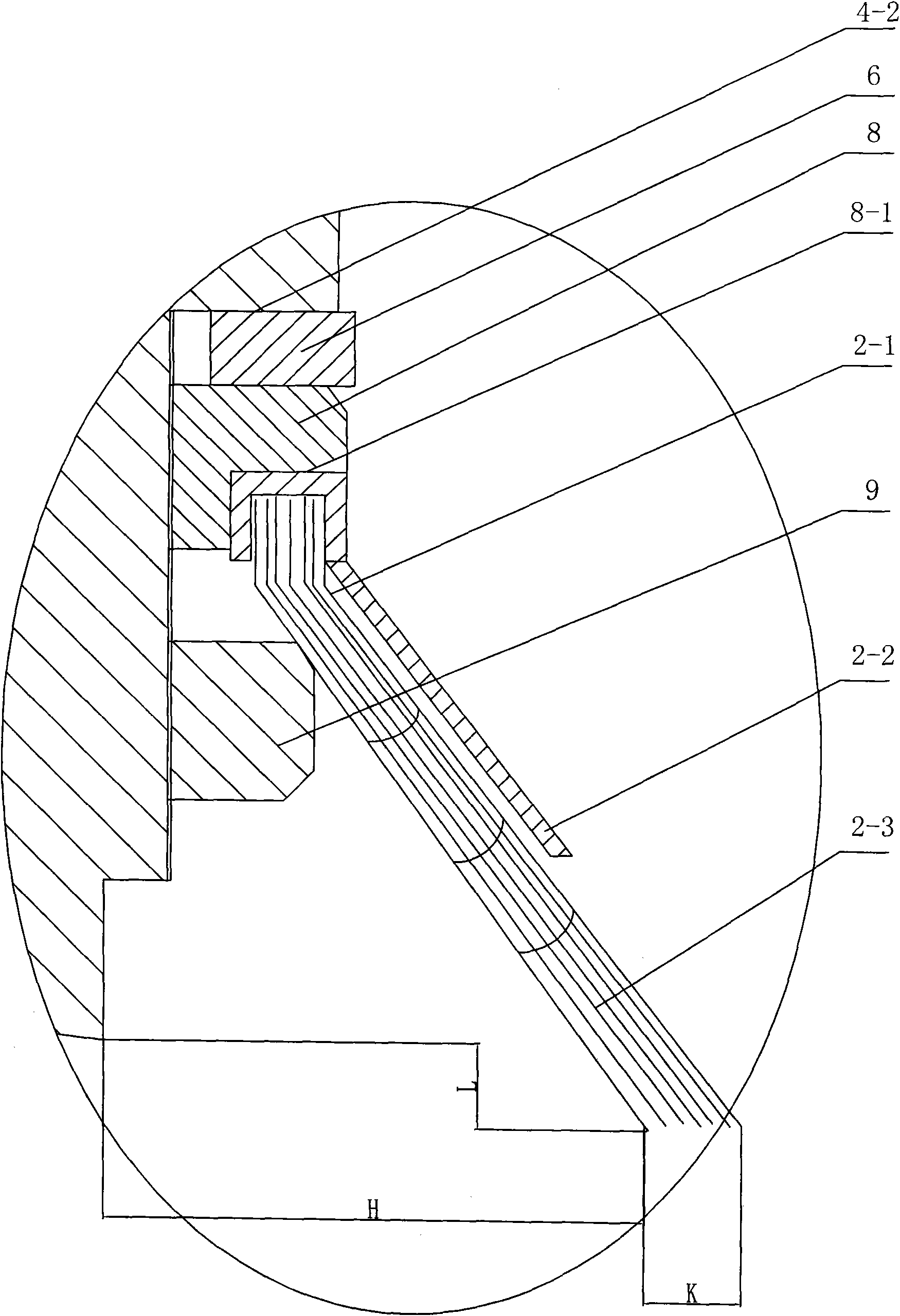

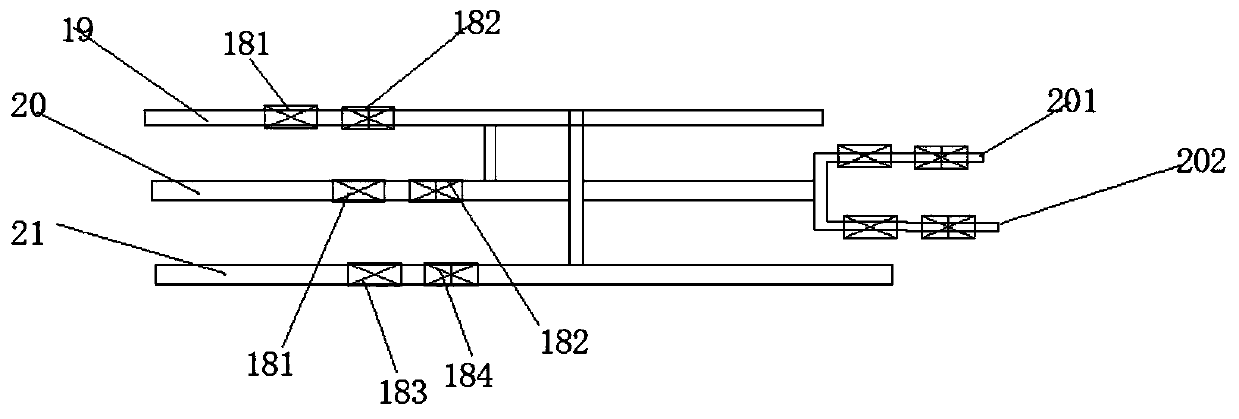

Pin tool suitable for local dry-type friction stir welding in water environment

InactiveCN101554681AAvoid enteringEntry will not happenNon-electric welding apparatusFriction weldingDecomposition

A pin tool suitable for local dry-type friction stir welding in water environment relates to a pin tool of friction stir welding. The invention solves the problems that the existing pin tool of friction stir welding is not applicable to the local dry-type welding in water environment; as underwater welding needs complicated supporting equipment and technical conditions, the difficulty of implementation is comparatively large; and the stability of an electric arc and drop transfer is poor and the decomposition of water at the high temperature of the electric arc can lead to seam hydrogenation so as to cause the deterioration of joint performance. A fitting nut is connected with the upper thread of a shaft shoulder and a positioning backing ring is arranged between the upper end face of the fitting nut and the end face of a shoulder. A U-shaped steel wire brush holder is fixedly installed on the shoulder. The upper ends of a plurality of stainless steel tendons are fixedly installed in the U-shaped steel wire bush holder and an inverted funnel-shaped shade covers the outside of the steel wire brush. The pin tool overcomes the defects of the existing pin tool of friction stir welding in welding under water environment, satisfies the requirements of local dry-type welding under water environment and also boosts the performance of joints.

Owner:HARBIN INST OF TECH

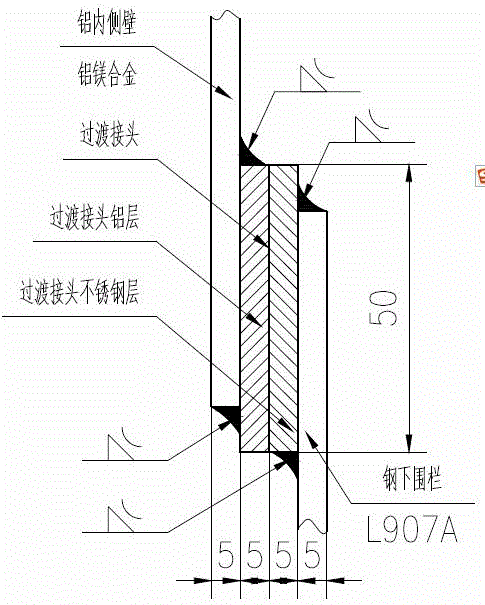

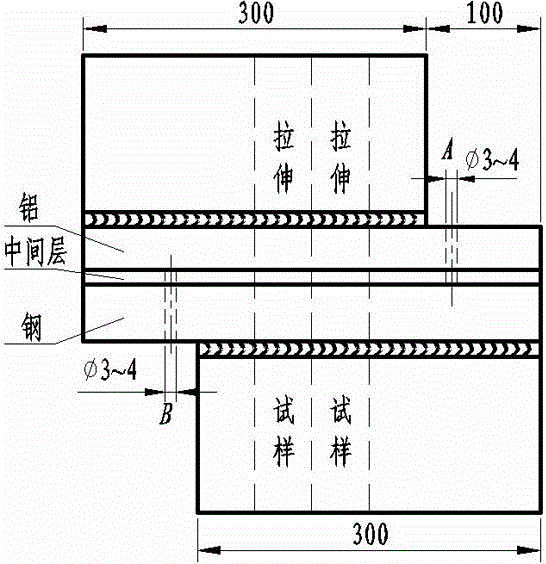

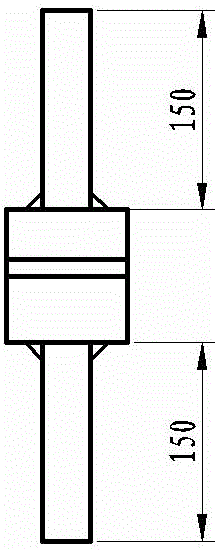

Overlap welding method using ultrathin aluminum-steel compound transition joint

InactiveCN106513945AReduce splashingReduced post-weld cleaning workloadArc welding apparatusAluminiumWelding process

The invention relates to an overlap welding method using an ultrathin aluminum-steel compound transition joint. The method comprises the steps of: pre-welding treatment; and a method of welding aluminum first and then welding steel during welding. The patent provides the welding method of welding aluminum first and then welding steel. As the heat conductivity coefficient of aluminum is about 3 times that of iron. Heat dissipation of an aluminum-steel interface is facilitated if aluminum is welded first, and the peak temperature of the aluminum-steel interface in the welding process is reduced, so that continuous welding is guaranteed, and meanwhile, the aluminum-steel interface of the ultrathin aluminum-steel compound transition joint is not peeled off.

Owner:LUOYANG SHUANGRUI METAL COMPOSITE MATERIAL

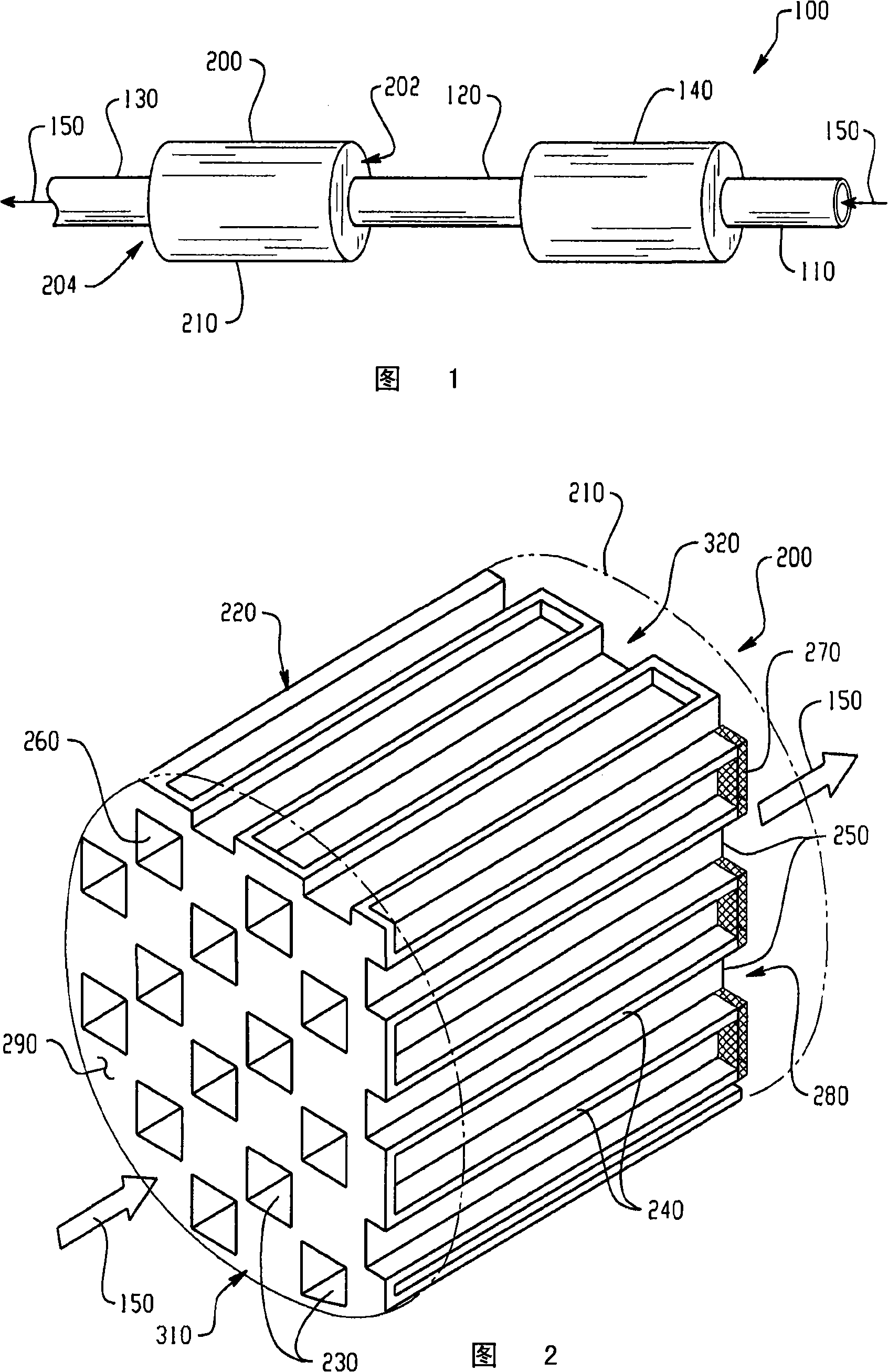

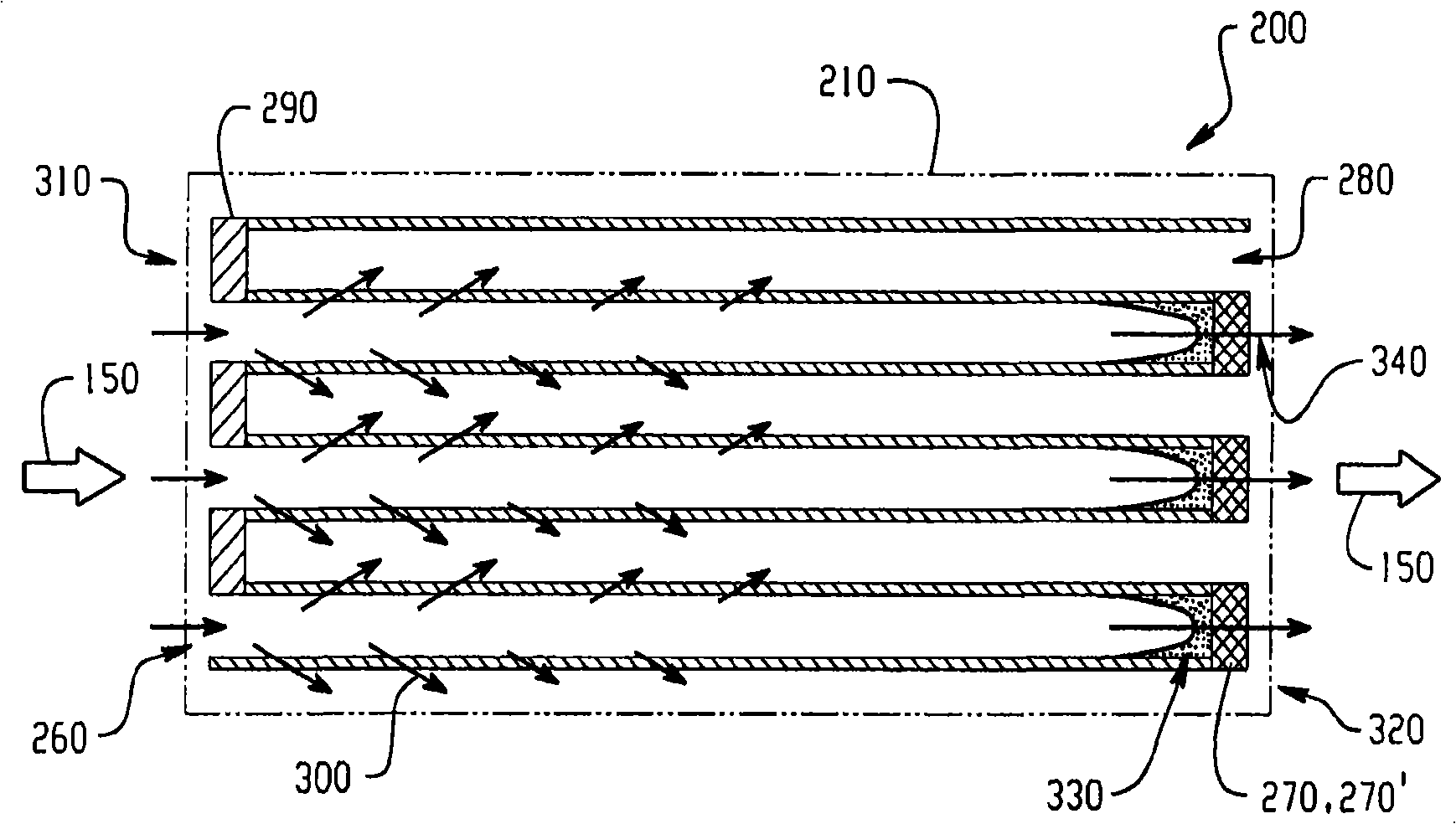

Composite cordierite filters

InactiveCN1602222ALower peak temperatureImprove thermal conductivityDispersed particle filtrationExhaust apparatusBorideCarbide silicon

Composite cordierite honeycomb structures especially suitable for diesel exhaust filtration applications comprise a non-oxide polycrystalline phase constituting 10-70% by weight, with the remainder of the ceramic material constituting a cordierite phase, the non-oxide polycrystalline phase being selected from the group consisting of carbides, nitrides, and borides. Preferably the non-oxide phase is either polycrystalline silicon carbide or polycrystalline silicon nitride and has a particle aspect ratio of less than 3. Inventive ceramic bodies are porous with an open porosity of at least 30%, preferably between 40% and 60%, and a median pore size of at least 5 micrometers, more preferably greater than 8 micrometers and less than 12 micrometers.

Owner:CORNING INC

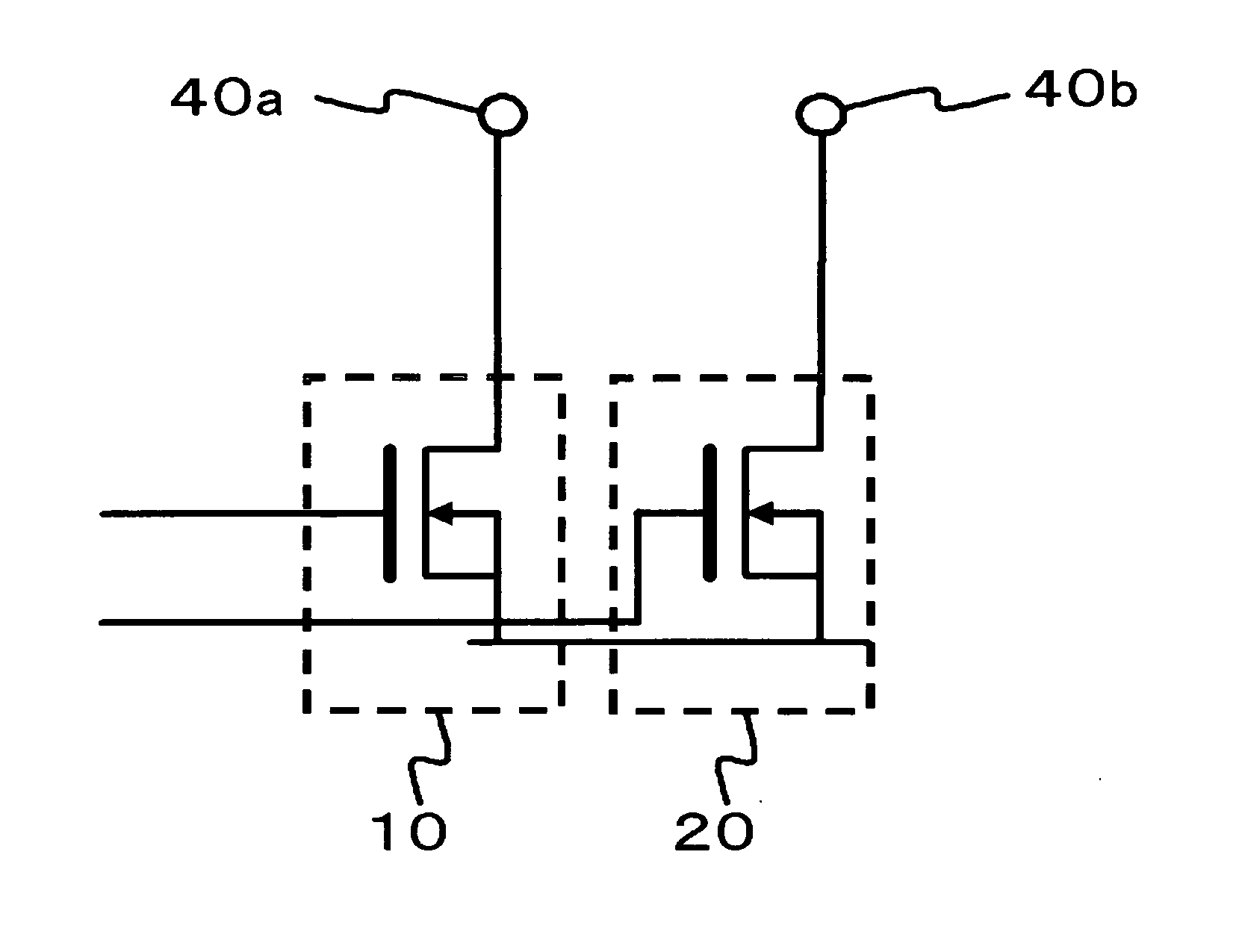

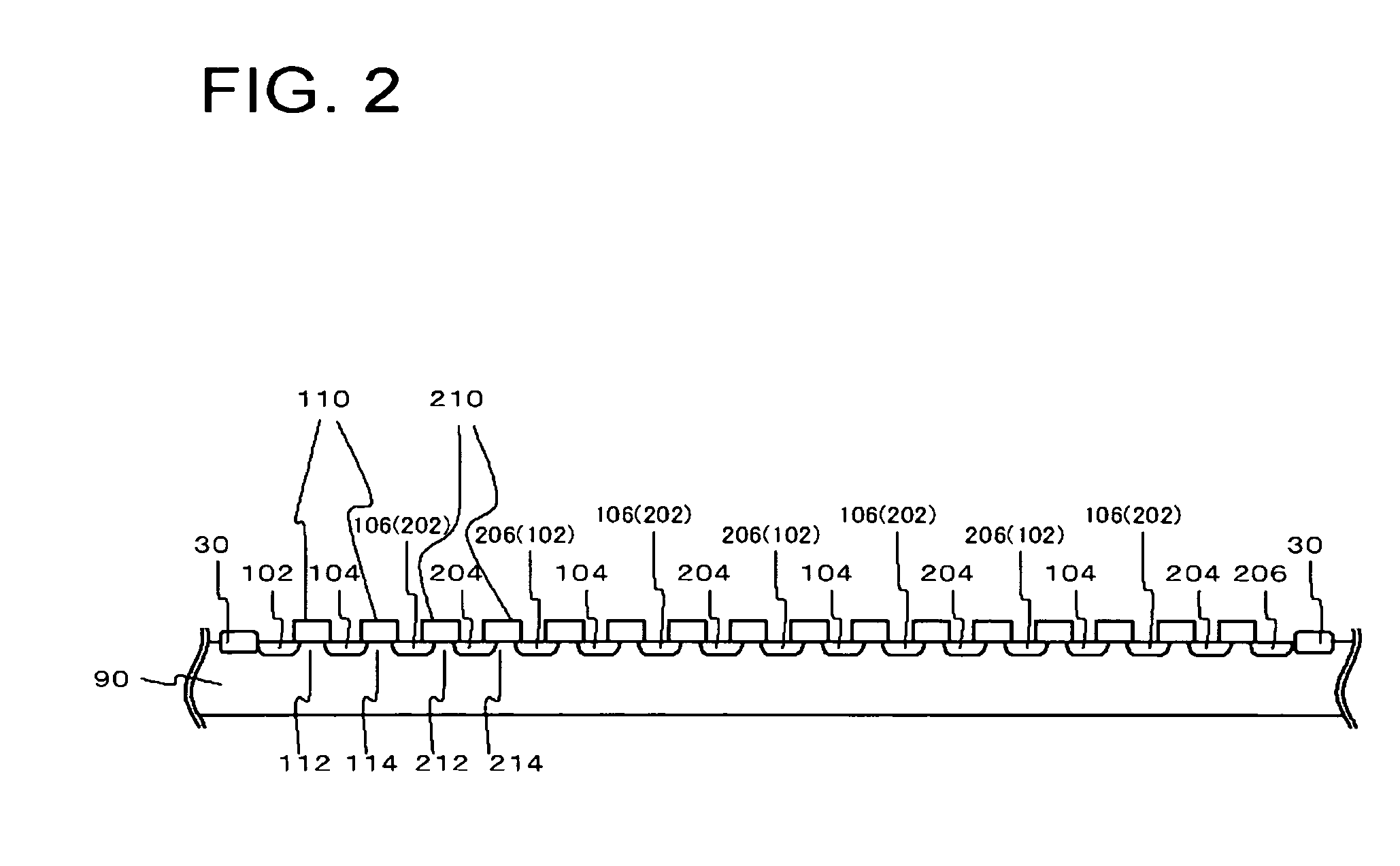

Semiconductor device

InactiveUS20060214693A1Low densityReduce the temperatureTransistorSolid-state devicesMOSFETSemiconductor

The semiconductor device 1 includes transistors 10, 20. Each of the transistors 10 (first transistor) is a MOSFET, and includes source regions 102, 106, a drain region 104, and a gate electrode 110. Each of the transistors 20 (second transistor) is also a MOSFET, and includes source regions 202, 206, a drain region 204, and a gate electrode 210. The source region 106 of the transistor 10 and the source region 202 of the transistor 20 are the identical region in the semiconductor substrate 90. In other words, the source region 106 and the source region 202 are shared by the both transistors.

Owner:RENESAS ELECTRONICS CORP

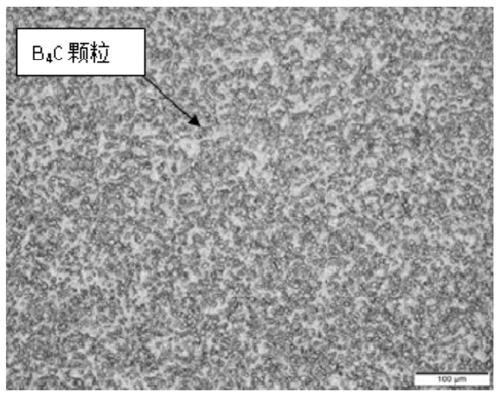

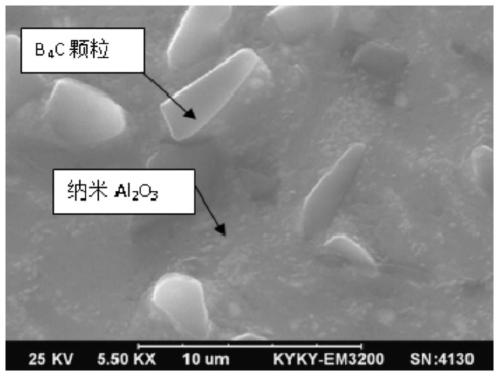

Novel oxide dispersion strengthenedneutron absorption material

InactiveCN109797308AImprove high temperature strengthLower peak temperatureShieldingNano al2o3Rare earth

The invention discloses a novel oxide dispersion strengthenedneutron absorption material. The novel oxide dispersion strengthenedneutron absorption material is prepared from the following materials inpercentage by weight: 5-20% of B4C, 0.8-5% of nano materials, and the balance of powder containing the aluminum element, wherein the nano materials are selected from one or more of nano Al2O3, nano MgO, nano TiO2, nano ZnO, nano ZrO2 and nano rare earth oxides. Compared with the prior art, the novel oxide dispersion strengthenedneutron absorption materialhas high high-temperature intensity, can be used for the neutron absorption function and the structural supporting action at the same time, has a high thermal conductivity coefficient, can be applied to the field of spent fuel storage and transportation, and can greatly reduce the manufacturing cost. In addition, the invention further provides a preparation method of the novel oxide dispersion strengthenedneutron absorption material, theprocess is simple, and the prepared neutron absorption material has the high thermal conductivity coefficient.

Owner:中广核工程有限公司 +2

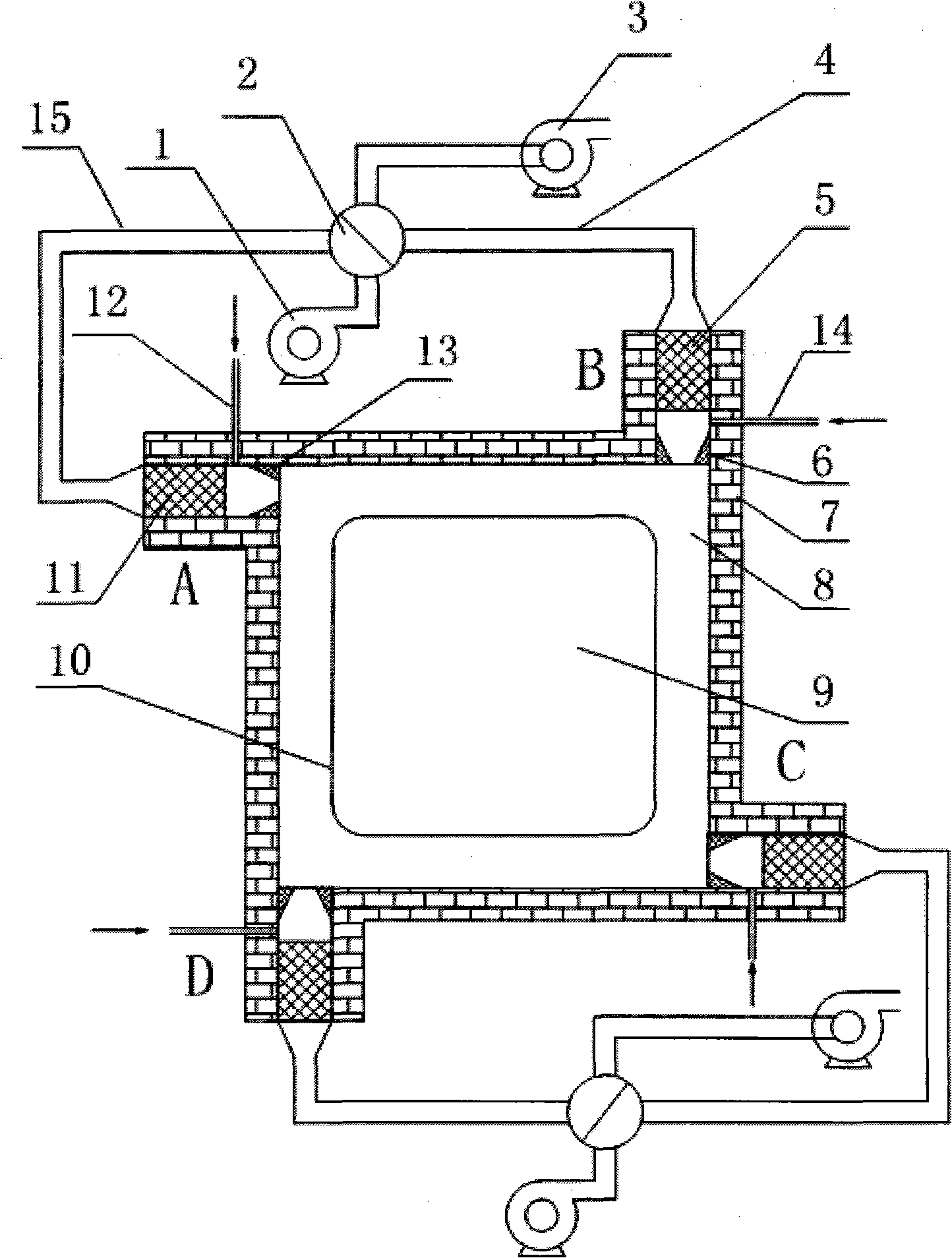

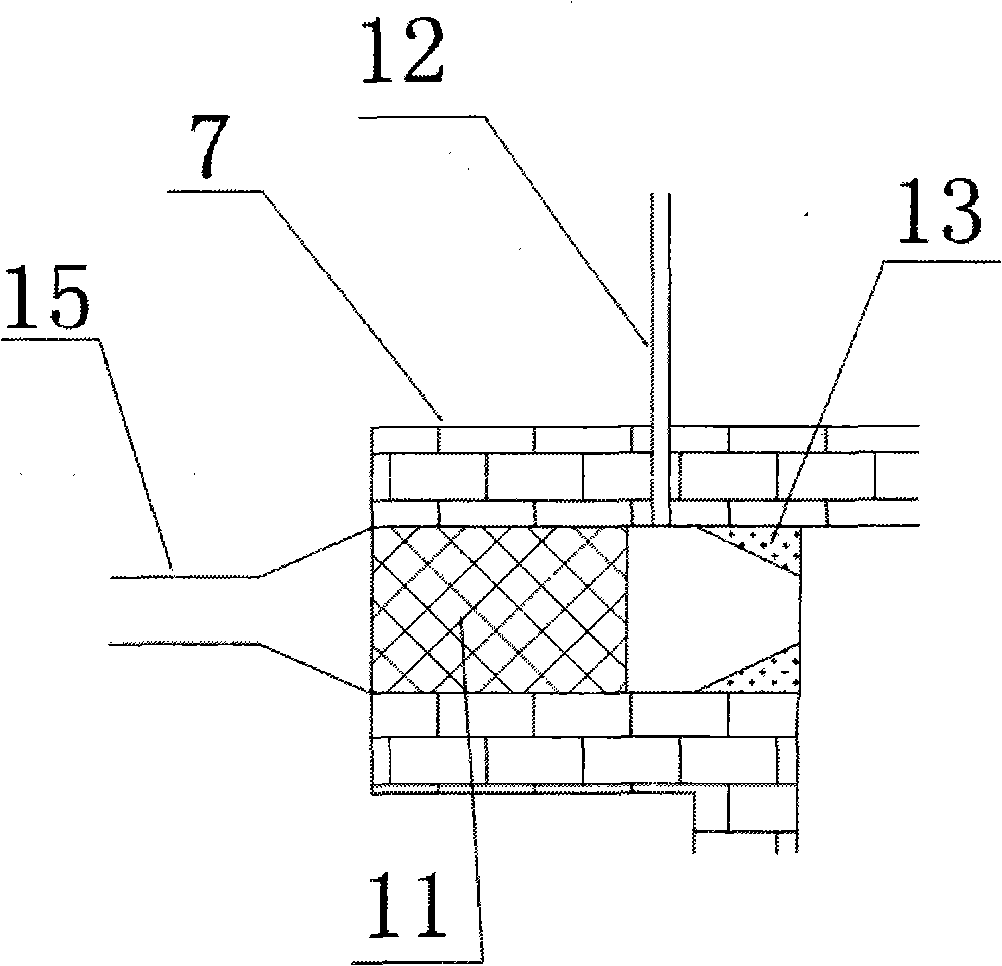

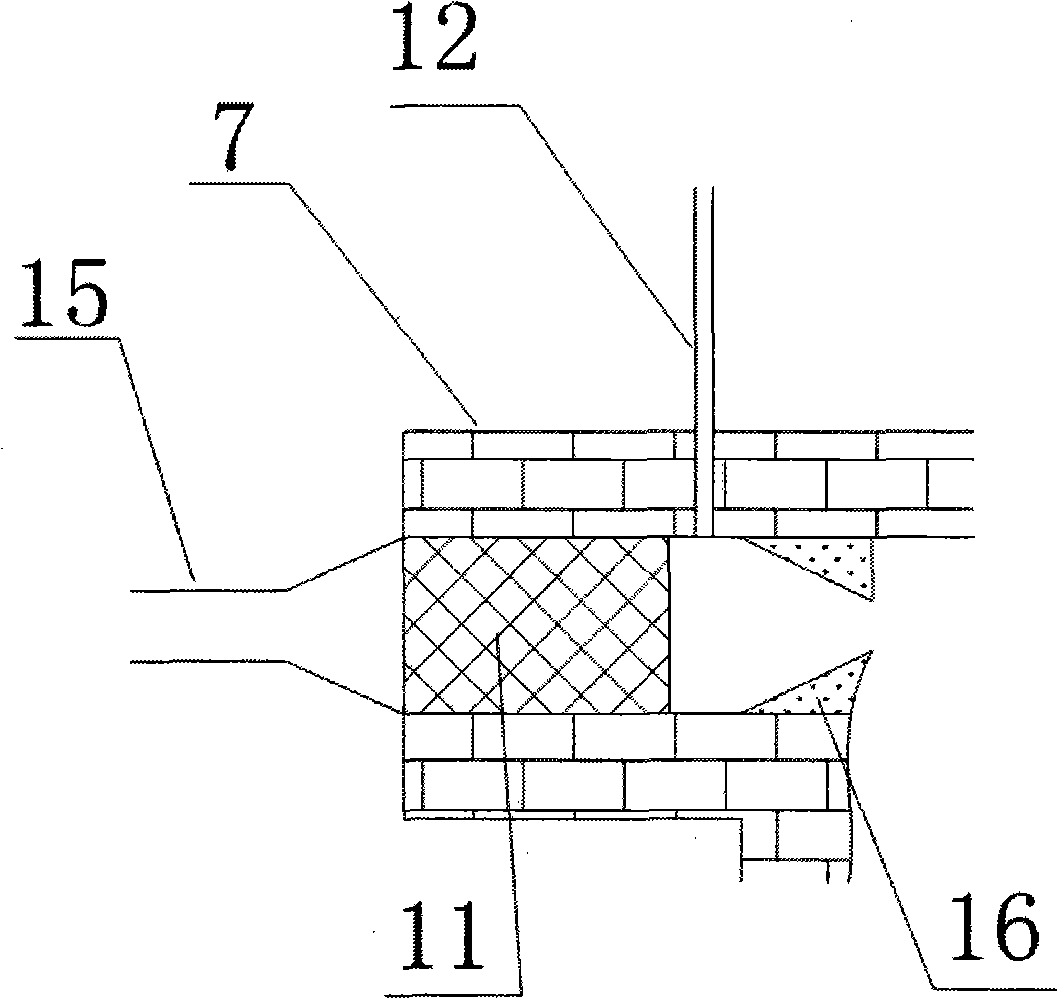

Heat accumulating type heating furnace with smoke backflow

InactiveCN101776392AEmission reductionSave energyCombustion processFurnace typesBrickNitrogen oxides

The invention provides a heat accumulating type heating furnace with smoke backflow, comprising a furnace body, regenerative chambers, a blow-off device, a fume extractor and a reversing device, wherein the furnace body is divided into a furnace cavity and a heating chamber; four corners of the furnace body are provided with four regenerative chambers in which heat accumulators are arranged; the lower course of each regenerative chamber is provided with a fuel nozzle circumscribed with a fuel pipeline; the furnace wall corresponding to the nozzle is provided with a burner block; the furnace cavity is rectangular or round; the regenerative chambers are distributed in four corners of the furnace body; the directions of nozzles are same, i.e. simultaneously clockwise or anticlockwise; the accumulator is spherical or cellular; the burner block can be arch bricks or special-shaped bricks with a guiding function; the furnace cavity and the heating chamber are separated by a refractory material with high thermal coefficient. The invention realizes the purposes of reducing carbon dioxide and nitrogen oxide emission by thermal storage and smoke backflow, separates smoke from workpieces and avoids oxidation and decarburization of workpiece surface.

Owner:UNIV OF SCI & TECH OF CHINA

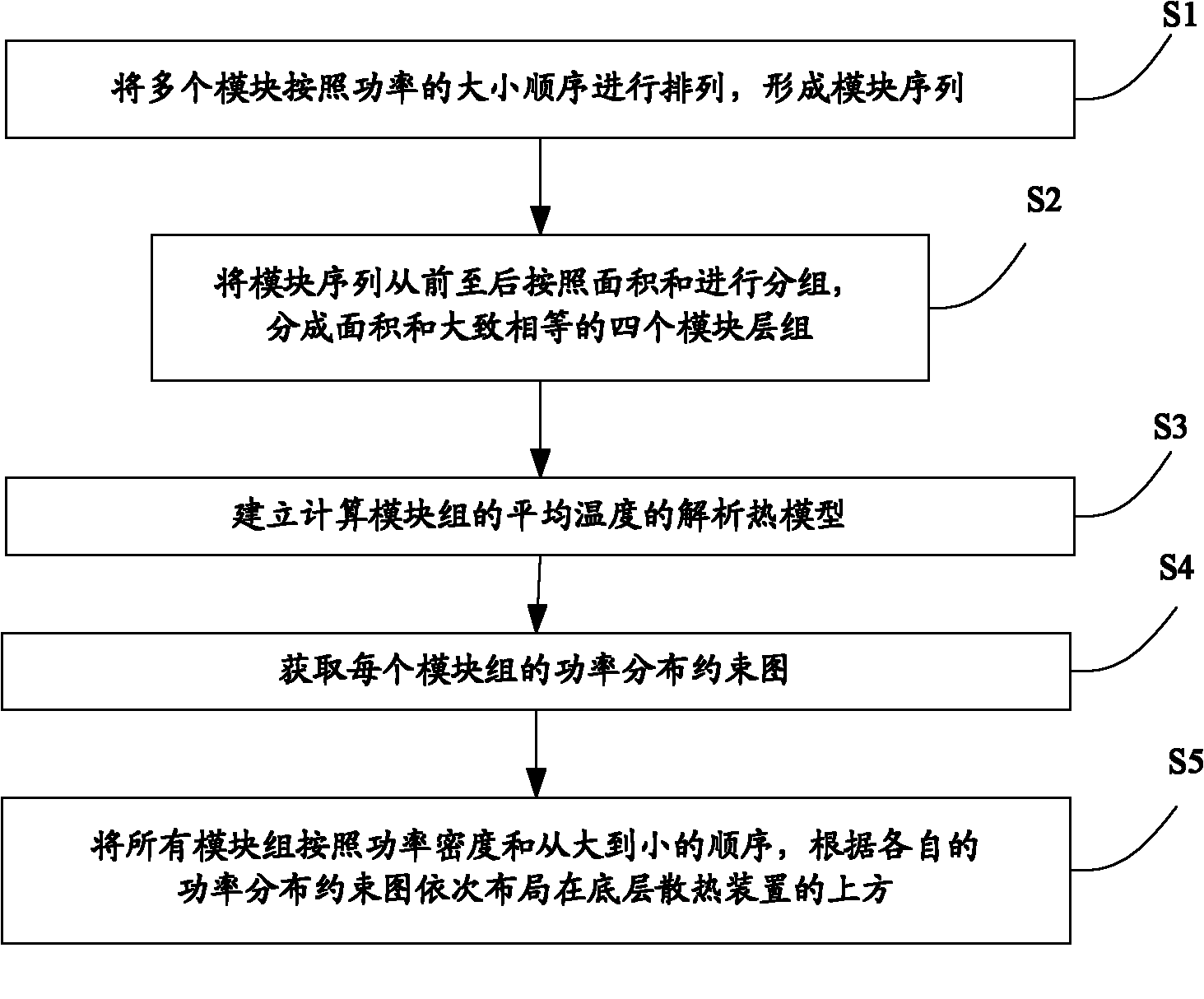

Hierarchical heat driving floor planning and layout method

InactiveCN102063543AAdvantages FloorplanningMerit methodSpecial data processing applicationsComputer moduleHigh power density

The invention discloses a hierarchical heat driving floor planning and layout method which comprises the following steps of: firstly, arranging a plurality of modules according to a power sequence, and forming a module sequence; secondly, grouping the module sequence from front to back according to an area sum, dividing into a plurality of module layer groups with approximately equal area sum; thirdly, establishing an analysis heat mold for calculating the average temperature of the module groups; fourthly, acquiring a power distribution constraint graph of each module group; and fifthly, sequentially arranging the module groups above a heat dissipating device at the bottom layer according to the power density, the sequence from big to small and the respective power distribution constraint graph. In the method, a three-dimensional layout problem is converted to a two-dimensional layout problem, thereby avoiding putting a high-power density device in a pile of vertical regions, realizing power density balanced distribution in vertical and horizontal directions, efficiently reducing the hot spot amount and optimizing the chip area and the interconnecting wire length.

Owner:WUHAN UNIV OF TECH

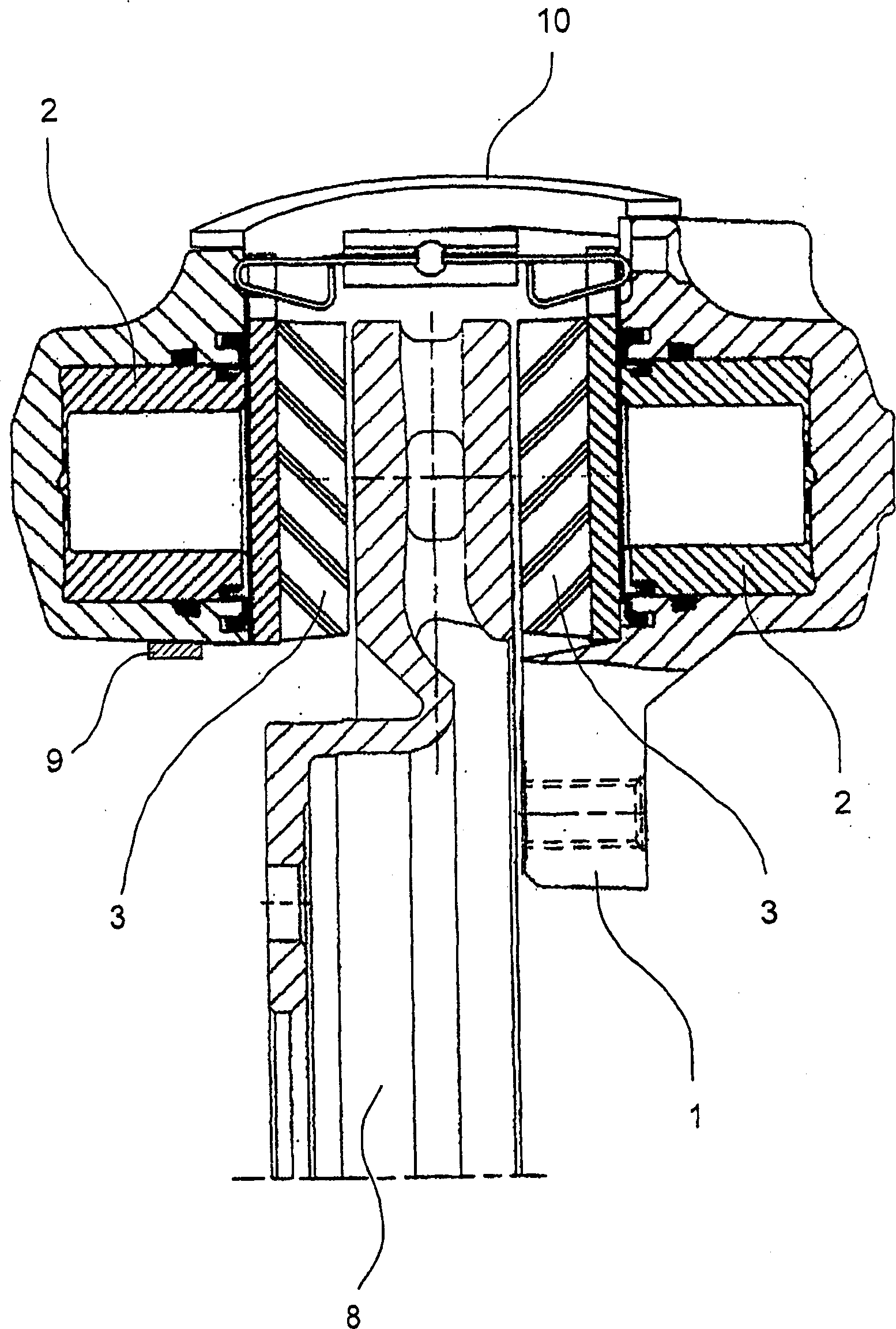

Brake caliper

ActiveCN1816703AReduce thickness differenceReduce noiseNoise/vibration controlAxially engaging brakesEngineeringCalipers

The invention relates to a brake caliper on a brake, in particular a disc brake. The brake caliper comprises raised sections (5), embodied as plateaus (6) in the represented case. The raised sections (5) are tensioned against each other by means of a connector device (4) by the introduction of tensile or compression forces. Noises occurring on braking can thus be significantly reduced.

Owner:AUDI AG

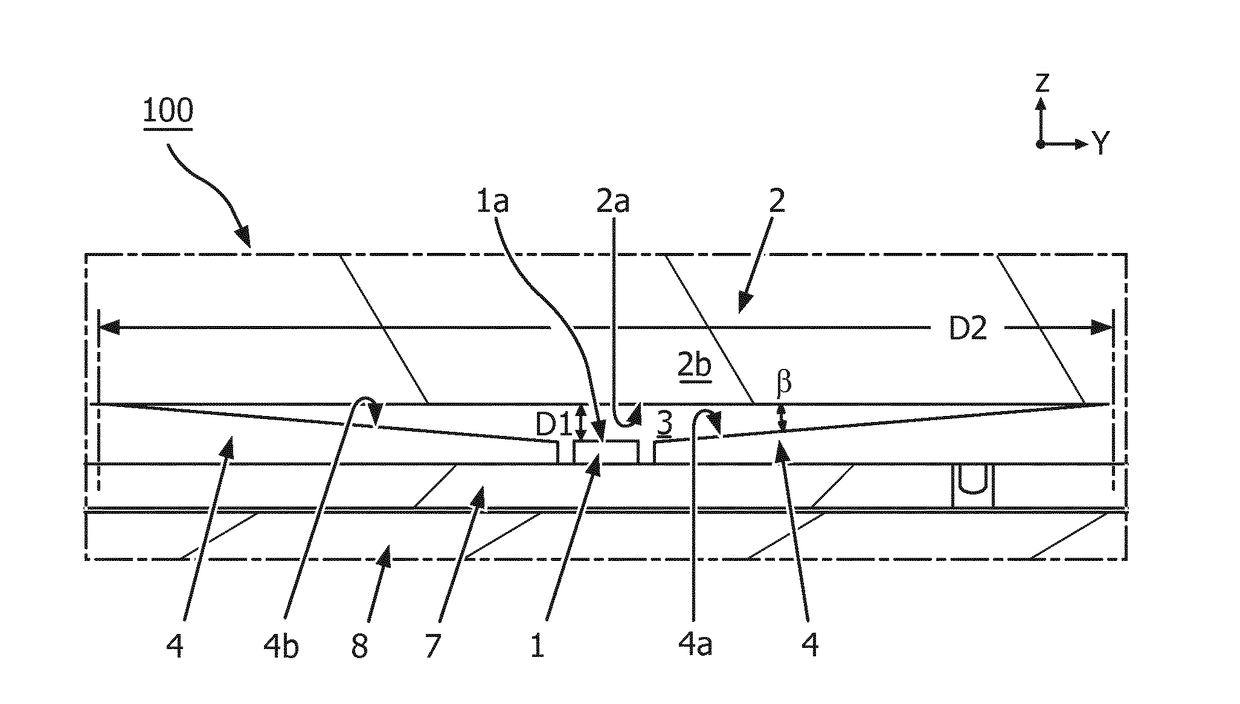

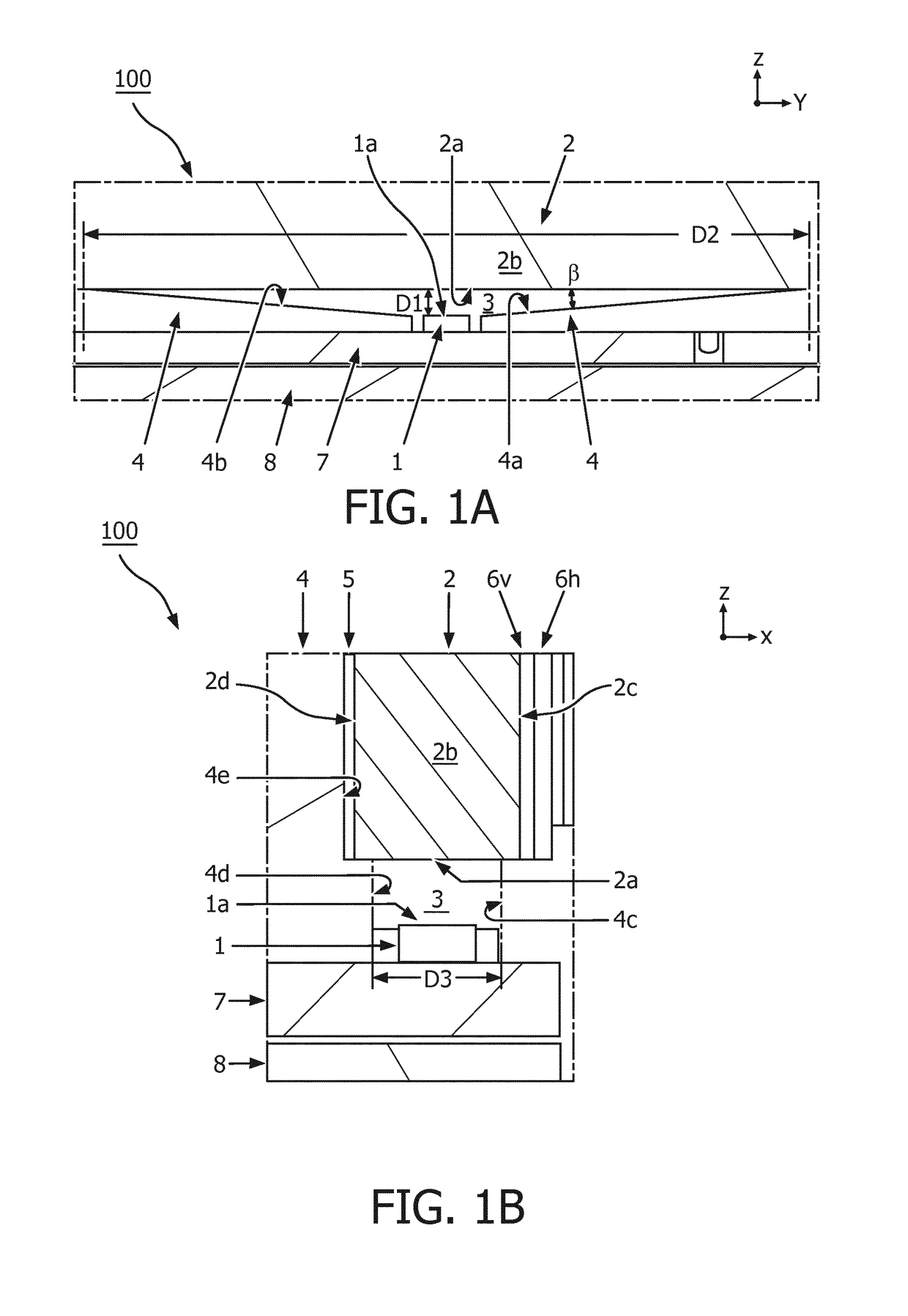

Lighting device for coupling light from a light source into a light guide plate

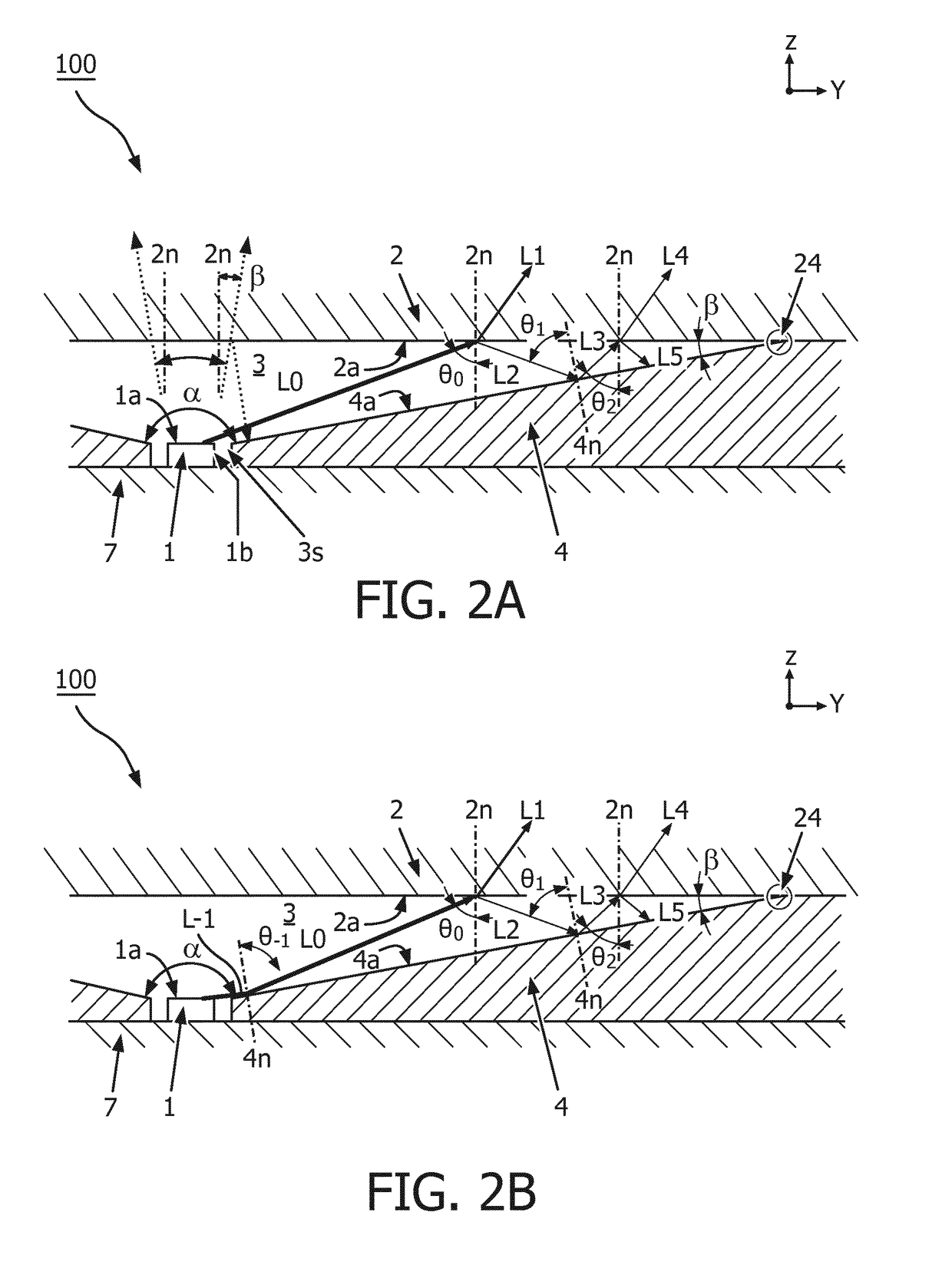

InactiveUS20170212292A1Increase light intensityLight efficiencyMechanical apparatusPlanar/plate-like light guidesLight guideEffect light

The present disclosure concerns a lighting device (100) comprising a light source (1) and a light guide plate (2). The light guide plate (2) is disposed at a distance (D1) from the emitter surface (1a) with an air gap (3) therebetween. A side reflector (4) surrounds the emitter surface (1a) of the light source and bounds the gap (3) between the emitter surface (1a) and the light entry surface (2a). The side reflector (4) comprises a tapered reflection surface (4a) adjacent the emitter surface (1a) and facing the light entry surface (2a). The tapered reflection surface (4a) is disposed at a tapering angle (β) towards the light entry surface (2a). The tapering angle (β) is configured such that any light emitted by the emitter surface (1a) within the opening angle (Φ) of the light source (1) is not reflected by the reflection surface (4a) before being received for the first time by the light entry surface (2a).

Owner:SIGNIFY HLDG BV

Stannum-copper binary alloy leadless solder paste

InactiveCN101269445AAvoid damageLower peak temperatureWelding/cutting media/materialsSoldering mediaBinary alloyPeak value

The invention relates to a lead-free soldering paste. Alloy welding powder is made to the soldering paste through mixing bismuth-tin binary eutectic alloy welding powder Bi48Sn42 and tin-copper binary eutectic alloy welding powder which are in the mixture ratio of 20 to 60:80 to 40 and adding scaling powder. The alloy welding powder is made up of the bismuth-tin binary eutectic alloy welding powder Bi48Sn42 which takes the mass percent of 80 to 90 percent, and the tin-copper binary eutectic alloy welding powder takes the mass percent of 10 to 20 percent. The lead-free soldering paste keeps the peak value temperature between 210 to 220 DEG C in reflow soldering process, greatly reducing the peak value temperature and the possibility for damaging a breadboard and an element device.

Owner:CHANGSHA TAIHUI NETWORK TECH

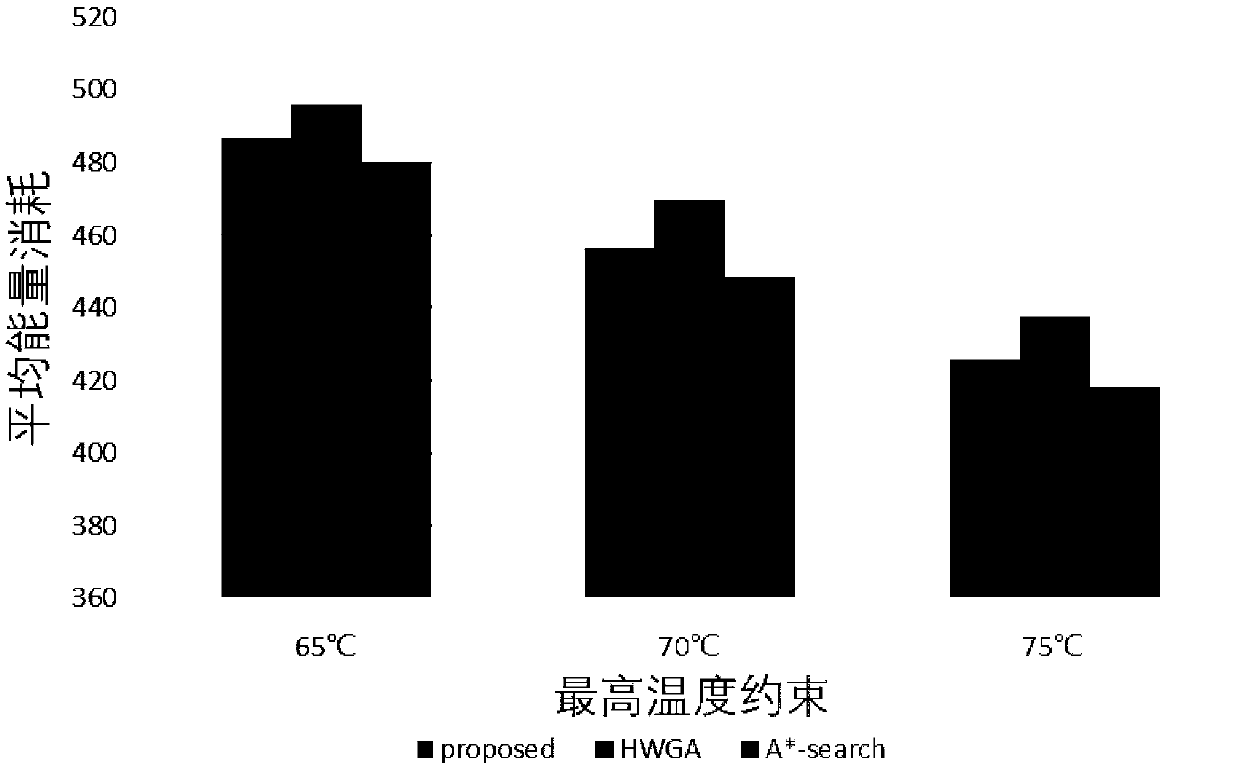

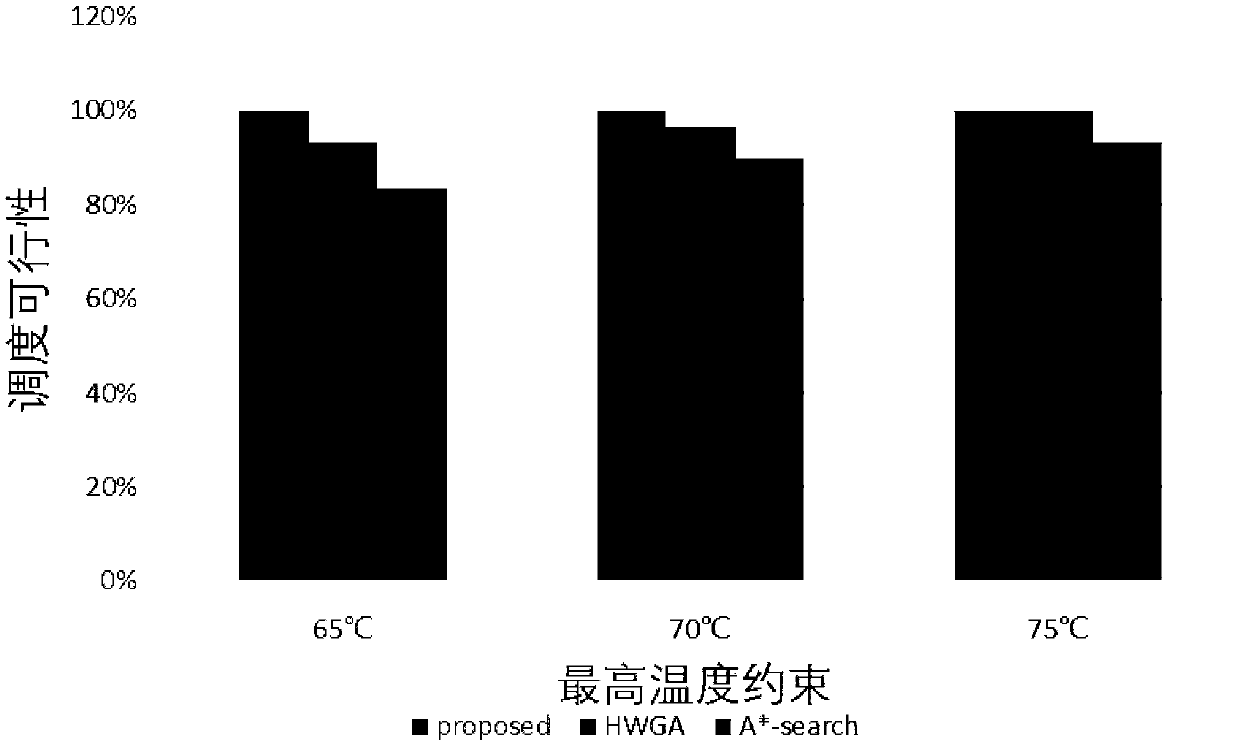

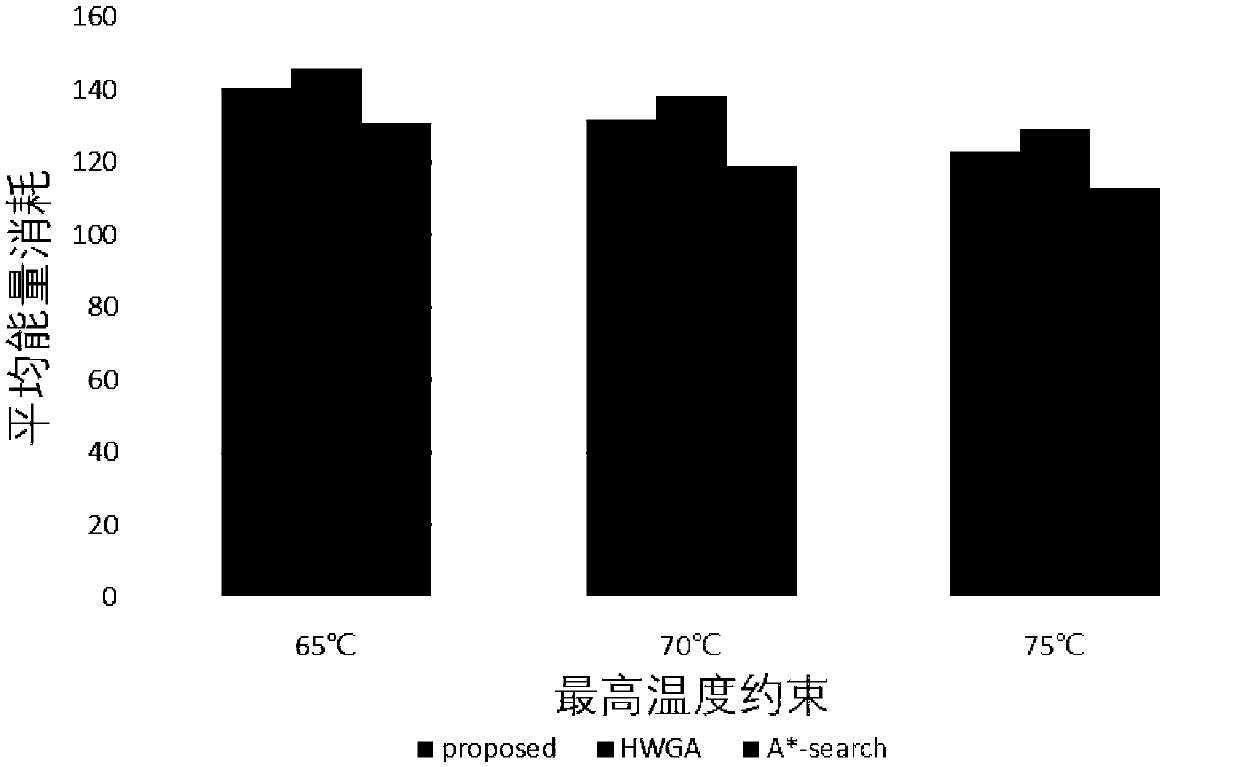

Thermal-sensing and low-energy consumption task scheduling method oriented to heterogeneous MPSoC system

ActiveCN108733491ALower peak temperatureReduce energy consumptionResource allocationPower supply for data processingMulti processorTask dependency

The invention discloses a thermal-sensing and low-energy consumption task scheduling method oriented to a heterogeneous MPSoC system. The method comprises the following steps: converting a heterogeneous multi-processor supporting multiple frequencies into a virtual multi-processor model only supporting a fixed frequency; distributing the task with the dependency relation to the virtual processor by using a heuristic algorithm; computing peak temperature of the system under the current task distribution; computing the accomplishment time of the task under the current task distribution; verifying this task distribution satisfies a constraint condition of the time and the task dependency relation; and updating a undistributed task queue, the task queue distributed to each virtual processor, and the task execution time of each virtual processor. Under the constraint of the task expiration deadline, the task priority and the chip peak temperature, the system energy consumption is optimizedthrough the thermal-sensing energy-saving scheduling algorithm; the algorithm determines the task distributed to each processor and the working efficiency of each task, thereby effectively computing the low energy-consumption task scheduling solution.

Owner:EAST CHINA NORMAL UNIV

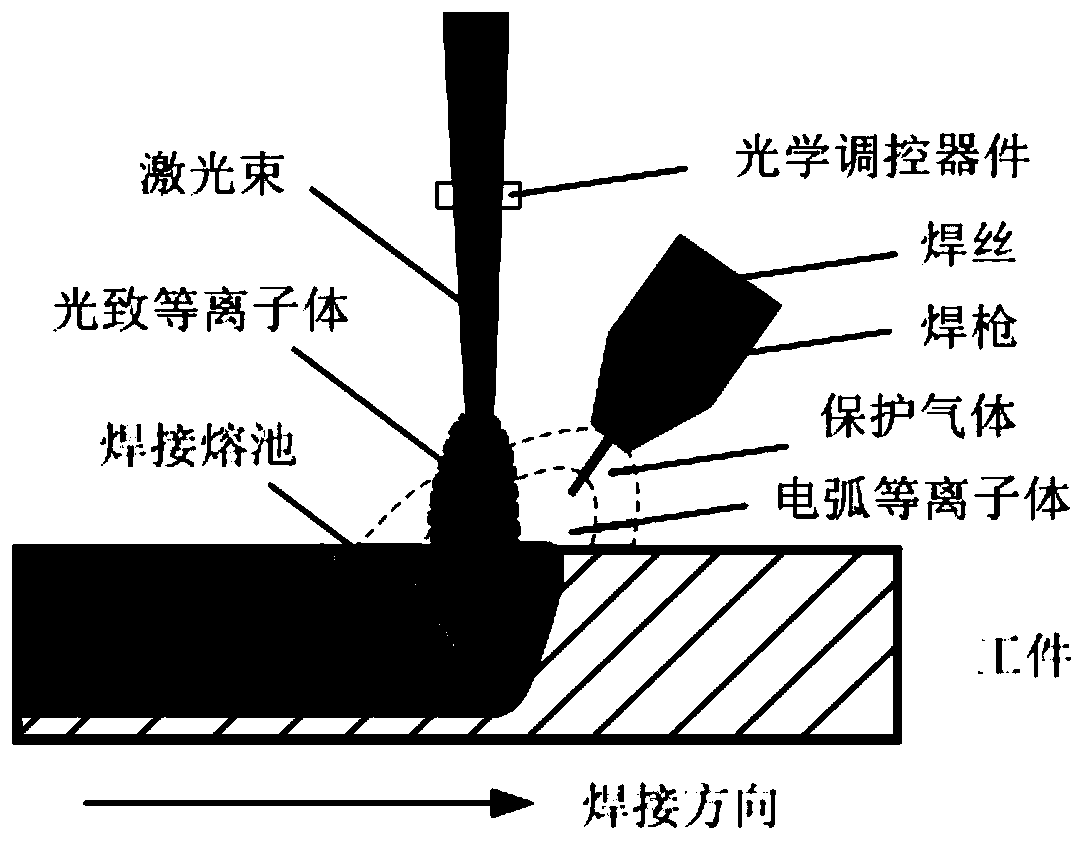

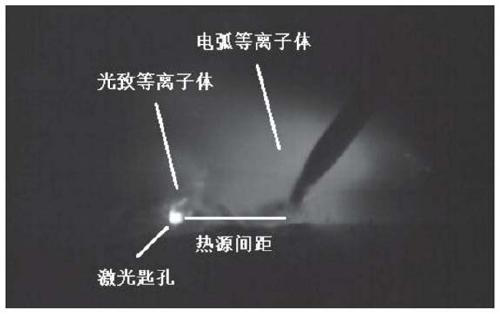

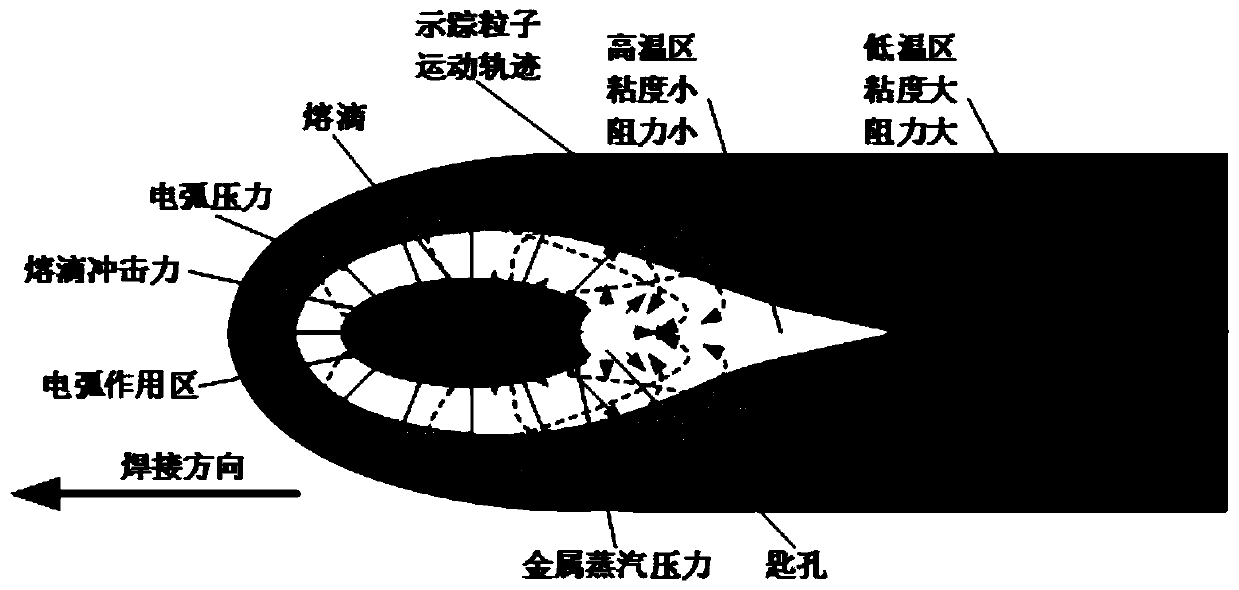

Laser-electric arc two-heat source weak coupling welding method for high-nitrogen steel

ActiveCN111515542AImprove the coupling effectIncrease energy densityLaser beam welding apparatusWeld seamLiquid metal

The invention relates to a laser-electric arc two-heat source weak coupling welding method for high-nitrogen steel. Firstly, energy density of laser beams is reduced by means of an optical regulationand control technology; then, the energy density of a composite heat source is reduced by means of two-heat source weak coupling effect; and more importantly, the weak coupling effect is capable of changing the flowing speed and direction of a molten pool and reducing the peak temperature of the molten pool, so that nitrogen precipitation of base metal is reduced, reabsorption of molten pool liquid metal on precipitated nitrogen is improved, discharge of redundant nitrogen is accelerated, and pore-free welding seams are formed finally. The comprehensive mechanical property of splice is improved, and the problems that the welding pores of the high-nitrogen steel are difficult to inhibit and the consistency of the performance of the splice is poor in the prior art are solved. The method hasthe advantages of high welding speed and good welding seam quality and the production efficiency and product quality are improved; and the problems of multiple welding seam pores, poor comprehensive performance and complex welding process in the related art are solved, the product quality is improved, the production cost is reduced, the welding process is simple, and high automation degree is achieved.

Owner:CHANGCHUN UNIV OF SCI & TECH

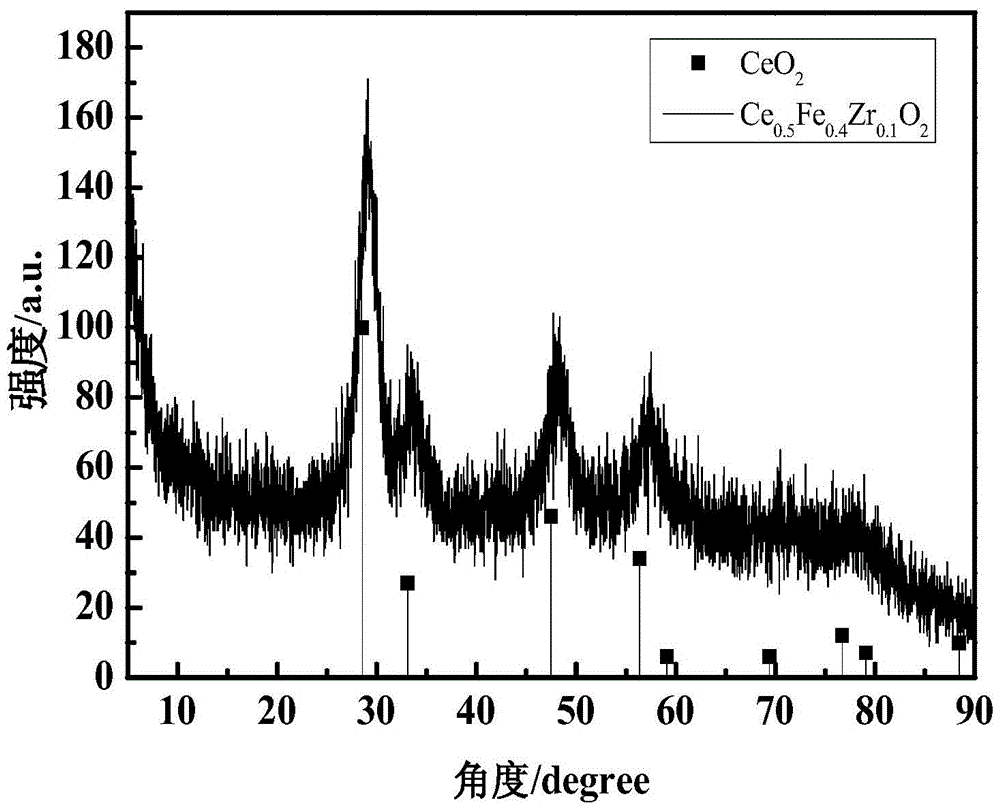

Three-dimensional composite oxide catalyst for removing NO and coal smoke particles simultaneously and preparation method and application thereof

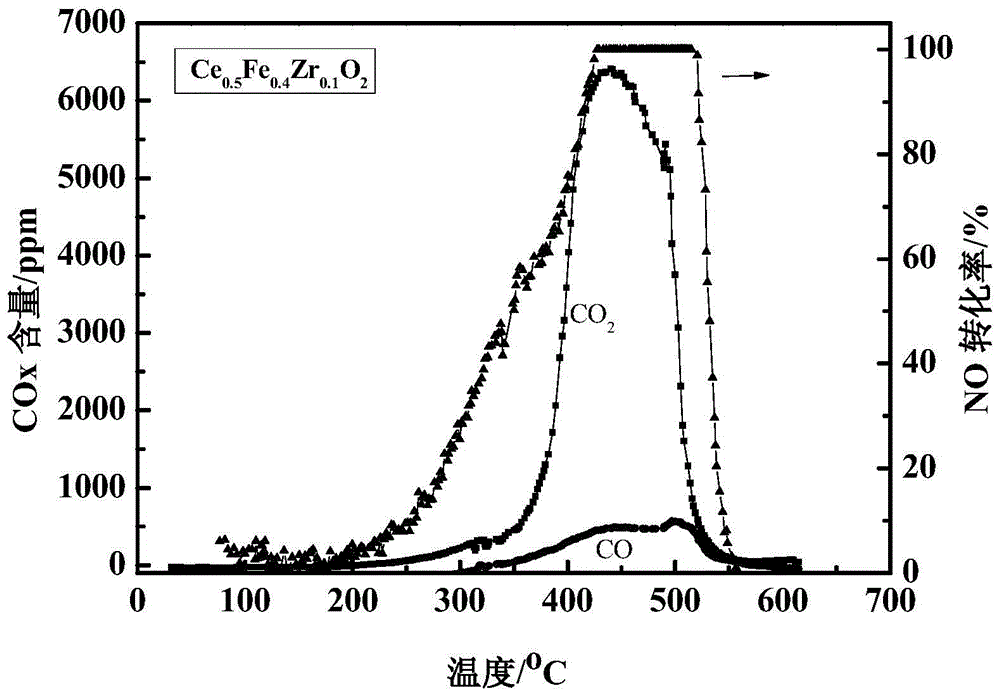

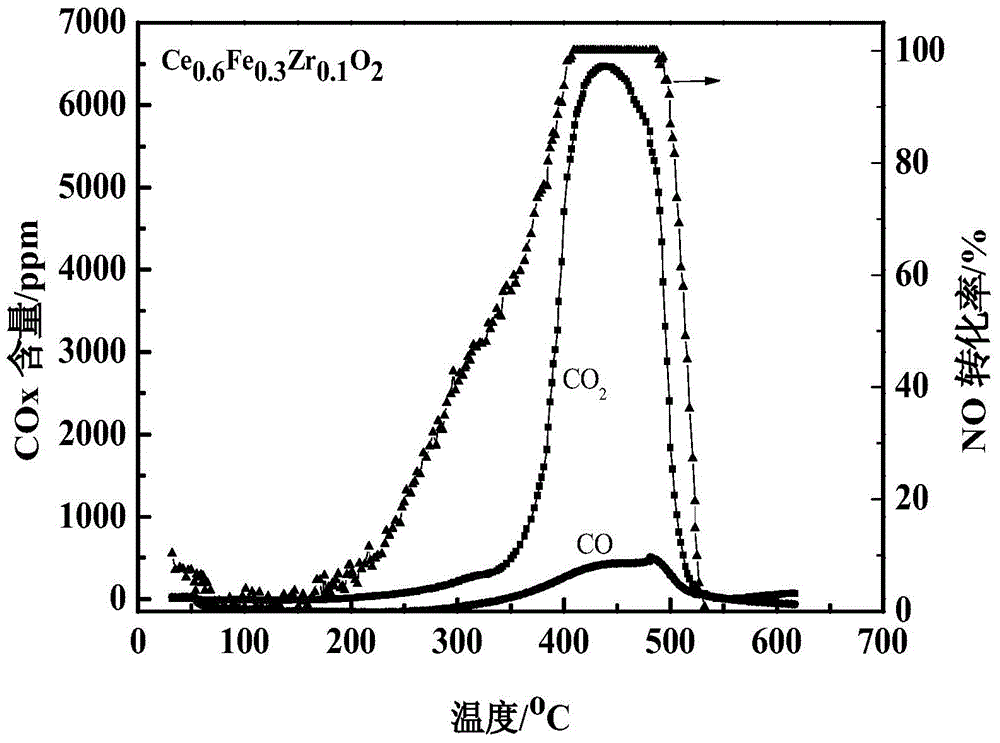

InactiveCN105727964AHigh activityUniform pore sizeHeterogenous catalyst chemical elementsDispersed particle separationComposite oxideOxide

The invention provides a three-dimensional composite oxide catalyst for removing NO and coal smoke particles simultaneously and a preparation method and application thereof.The preparation method comprises the steps that under the stirring condition, a cerium source, an iron source and a zirconium source are dissolved in an organic solvent, the mixture is stirred to be uniform at the temperature of 20 DEG C to 45 DEG C, and a precursor solution is formed; a template agent is weighed and added to the precursor solution to be dipped, and then suction filtration and drying are carried out; solids obtained through drying are heated in a heating furnace for the first time and heat preservation is carried out, and then the solids obtained through drying are heated for the second time and heat preservation is carried out, and the three-dimensional composite oxide catalyst is obtained.The three-dimensional composite oxide catalyst is a cerium, iron and zirconium composite oxide, and the composition of the catalyst is Ce0.9-xFexZr0.1O2, wherein x ranges from 0.1 to 0.4.According to the catalyst, the temperature at which the coal smoke particles are combusted to be converted into CO2 and the temperature for NO conversion can be reduced to the same range, meanwhile, the NO conversion rate is increased, and the activity of catalytic coal smoke combustion is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

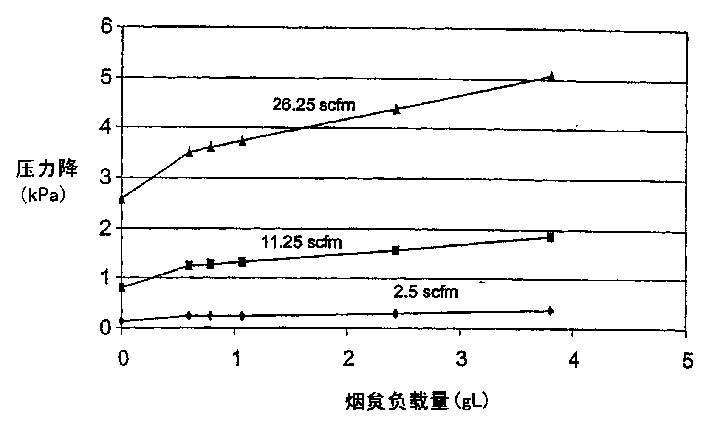

Quench protection apparatus for superconducting magnet system

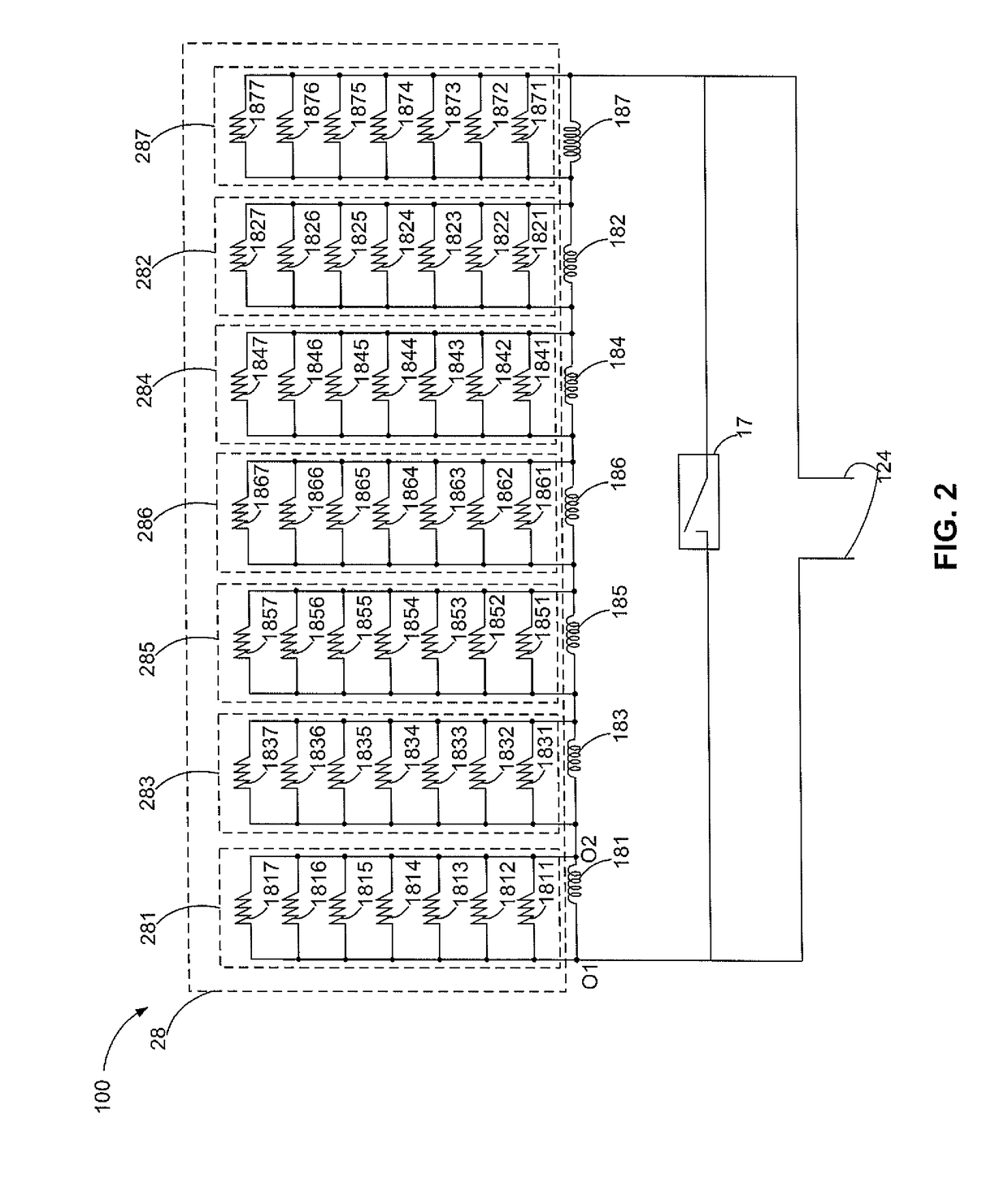

ActiveUS20170250018A1Protect from damageReduce voltageMagnetic measurementsSuperconducting magnets/coilsPhysicsSuperconducting Coils

A quench protection apparatus includes a number N of superconducting coils and a heater matrix. The number N of superconducting coils are electrically coupled in series. The heater matrix module includes the number N of heater units. The number N of heater units is electrically coupled in parallel with the number N of superconducting coils respectively. A number M of the heater units each includes at least the number N of heaters. Each superconducting coil is thermally coupled with at least one heater of each of the number M of the heater units. The number of N-M of the heater units each includes at least one heater. Each of the number M of superconducting coils correspondingly coupled with the number M of the heater units is thermally coupled with at least one heater of each of the number N-M of the heater units. A superconducting magnet system protected by above quench protection apparatus is also provided.

Owner:GENERAL ELECTRIC CO

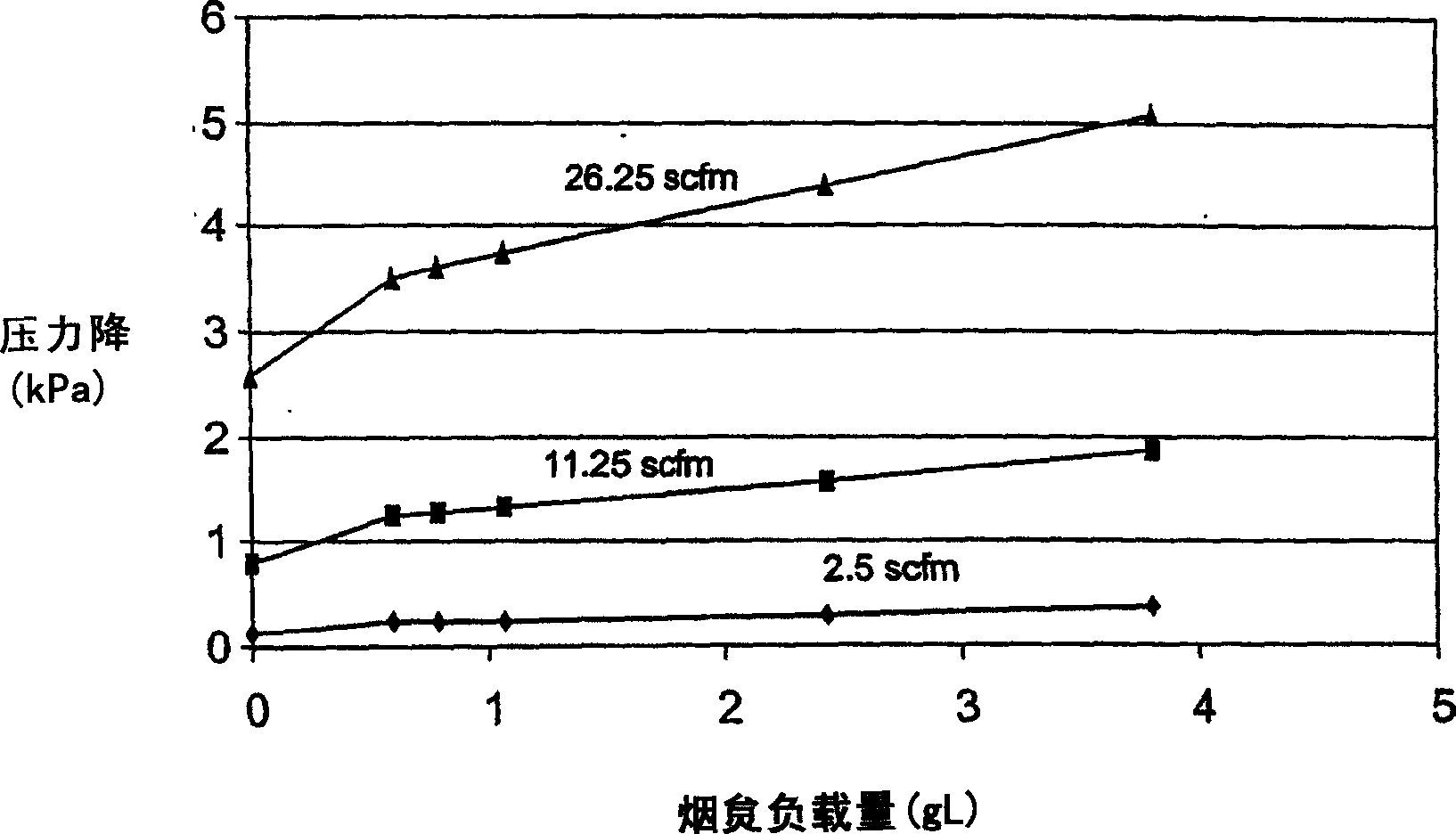

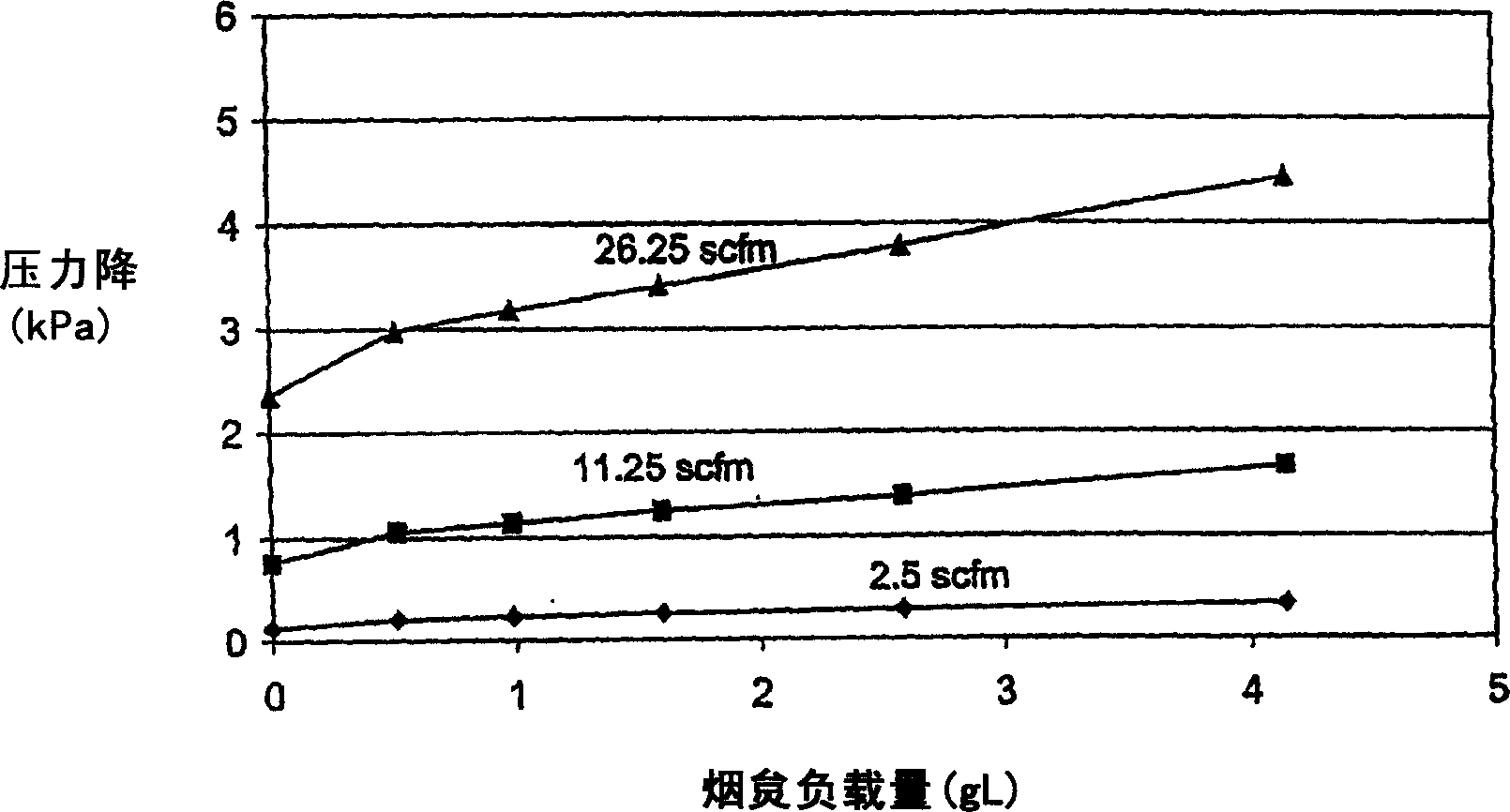

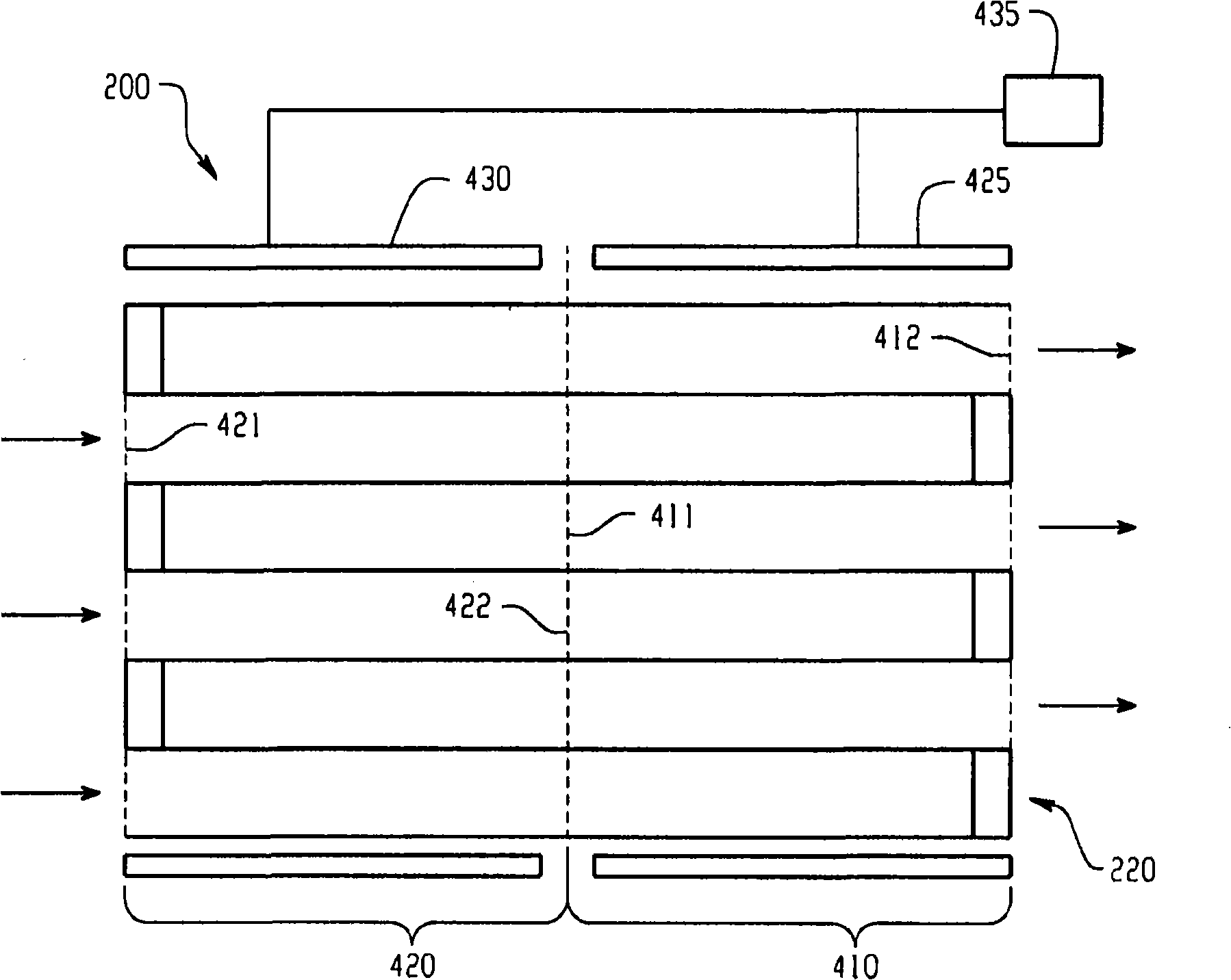

Exhaust particulate filter

InactiveCN101300059AReduce thermal stressLower peak temperatureDispersed particle filtrationFiltrationProcess engineering

A particulate filter for an exhaust system configured to receive an exhaust flow is disclosed. The filter includes a wall-flow filtration element having a first regeneration zone and a second regeneration zone, the first zone being downstream of the second zone, and a heat source disposed at the first regeneration zone. In response to demand for regeneration, the wall-filtration element regenerates according to a staged regeneration such that the first zone initiates regeneration ahead of the second zone, and each zone regenerates in the direction of the exhaust flow.

Owner:GM GLOBAL TECH OPERATIONS LLC

Wheat having new starch and method for producing it

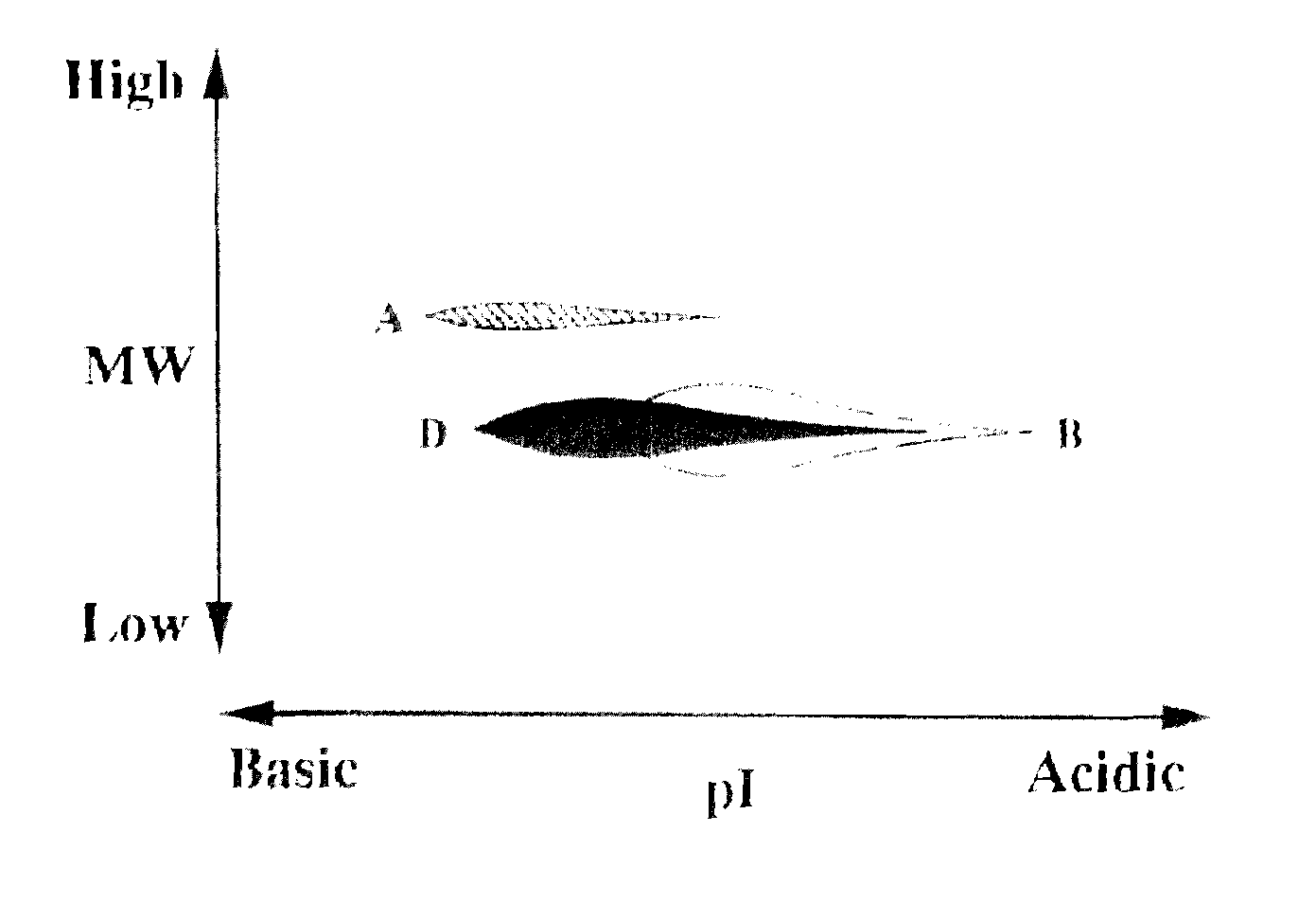

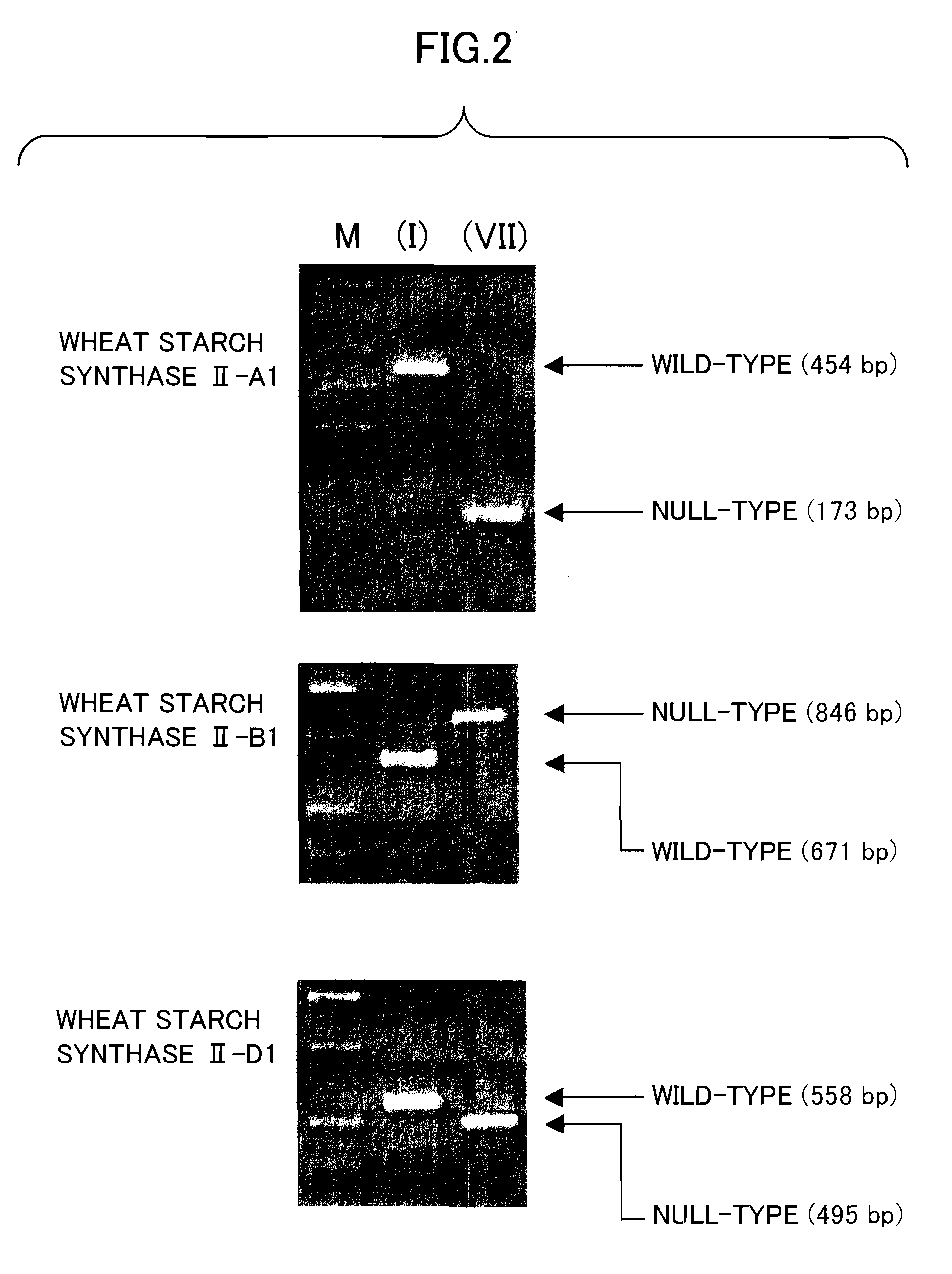

ActiveUS20090285960A1Retrogradation tolerance of gelatinized starch is improvedRaise the peak temperatureDough treatmentBaking mixturesBiotechnologyGranule-Bound Starch Synthase

The object of the present invention is to provide a wheat which accumulates a starch with a novel property by controlling the expression of the enzymes described in claims.The present invention provides a wheat, which does not express any of the following proteins (1)-(6): (1) Wheat Starch Synthase II-A1 Protein encoded by Wheat Starch Synthase II-A1 gene of SEQ ID NO:1, (2) Wheat Starch Synthase II-B1 Protein encoded by Wheat Starch Synthase II-B1 gene of SEQ ID NO:3, (3) Wheat Starch Synthase II-D1 Protein encoded by Wheat Starch Synthase II-D1 gene of SEQ ID NO:5, (4) Granule Bound Starch Synthase A1 Protein encoded by Granule Bound Starch Synthase A1 gene of SEQ ID NO:7, (5) Granule Bound Starch Synthase B1 Protein encoded by Granule Bound Starch Synthase B1 gene of SEQ ID NO:9, and (6) Granule Bound Starch Synthase D1 Protein encoded by Granule Bound Starch Synthase D1 gene of SEQ ID NO:11.

Owner:NIPPON FLOUR MILLS +1

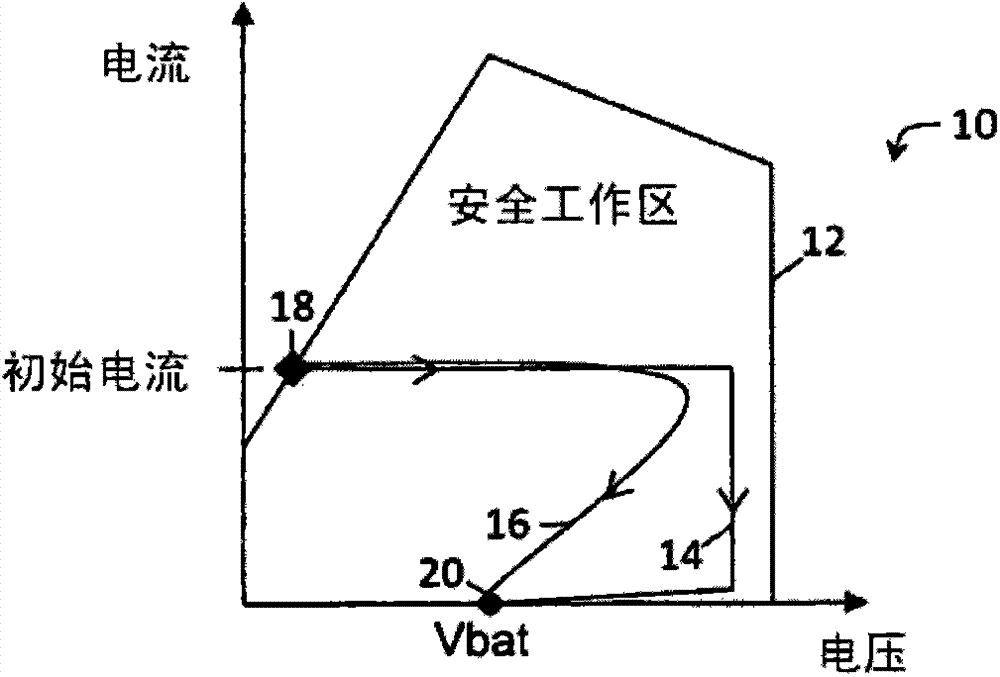

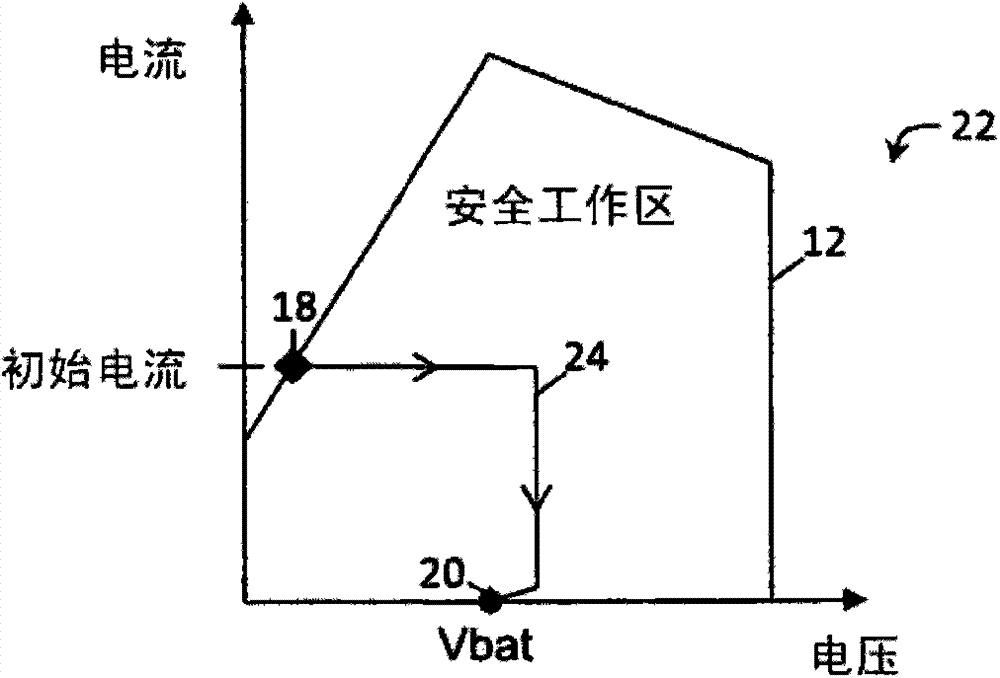

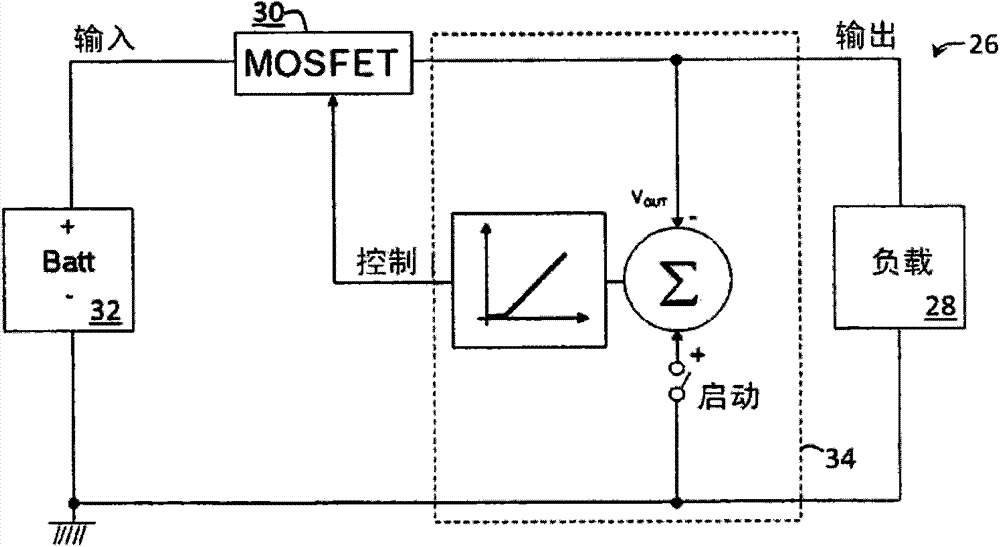

Method of constraining a safe operating area locus for a power semiconductor device

ActiveCN104122921AExtend your lifeLower peak temperatureTransistorSolid-state devicesSafe operating areaEngineering

A method of constraining a Safe Operating Area (SOA) locus for a power semiconductor device during operation of the power semiconductor device placed between a power source and a load, the method including: taking a voltage measurement across the load (VLOAD); selecting a scalar for scaling the voltage measurement taken across the load (VLOAD); and constructing a control voltage for controlling the power semiconductor device with a control circuit according to the voltage measurement taken across the load (VLOAD) multiplied by the scalar so as to constrain an output voltage of the power semiconductor. <filename>

Owner:ROBERT BOSCH AUSTRALIA

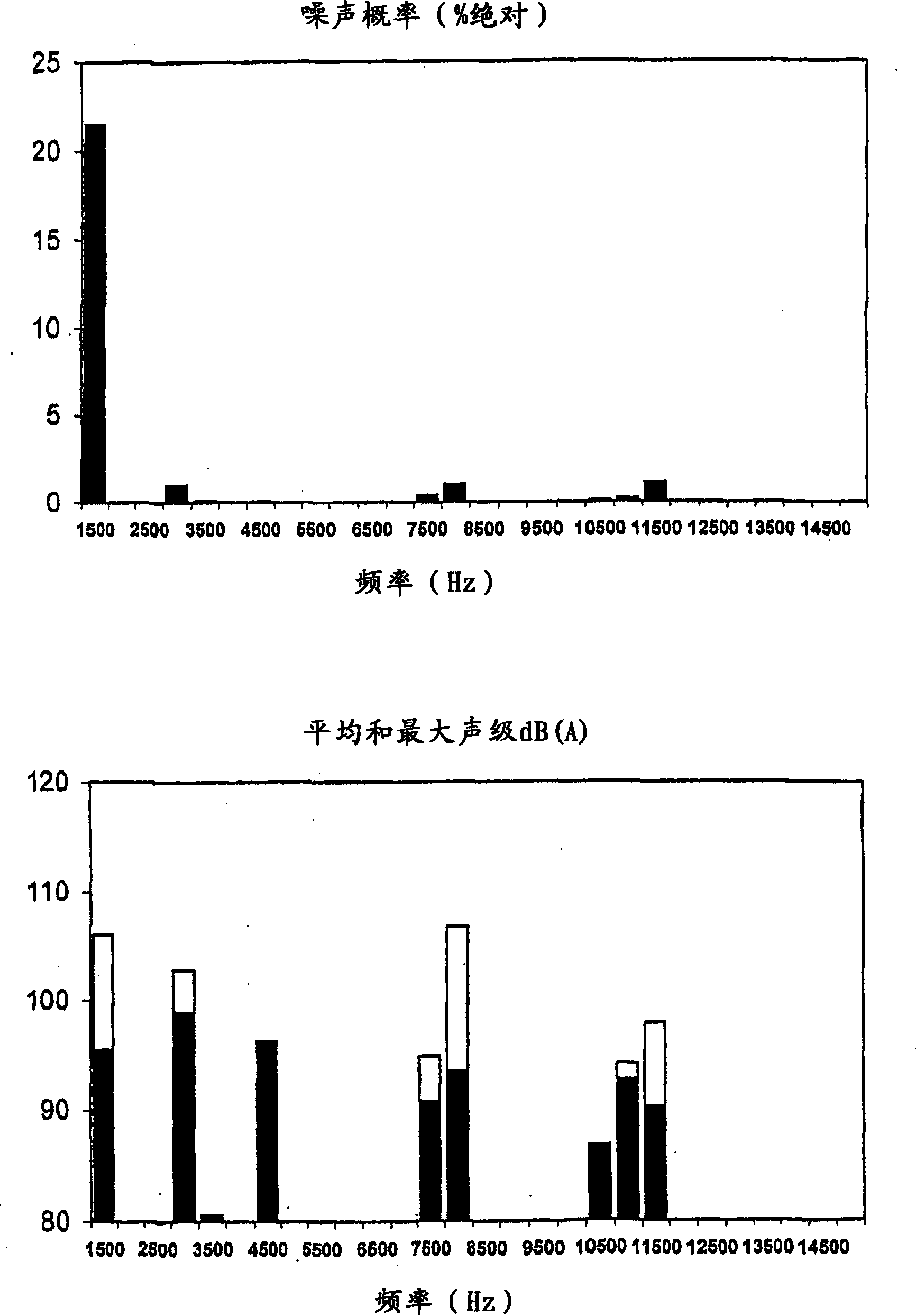

Flameless trapped vortex burner for gas turbine

The invention relates to a flameless trapped vortex burner for a gas turbine, which combines a flameless combustion technology and a trapped vortex combustion technology. By utilizing the advantages of small pressure fluctuation and small noise of the flameless combustion technology, the defect of large noise of the trapped vortex combustion technology is overcome; as on-duty flame, trapped vortex combustion can further reduce the flameout equivalence ratio of the flameless combustion by utilizing the advantages of compact volume and stable combustion of the trapped vortex combustion technology; and generated high-temperature flue gas can be used for diluting and heating fresh mixed gas and broadening the stable combustion scope of the flameless combustion. The burner simultaneously has the advantages of the flameless combustion technology and the trapped vortex combustion technology and has uniform temperature field, low pollutant discharge and good combustion stability.

Owner:中科合肥中型燃气轮机研究院有限公司

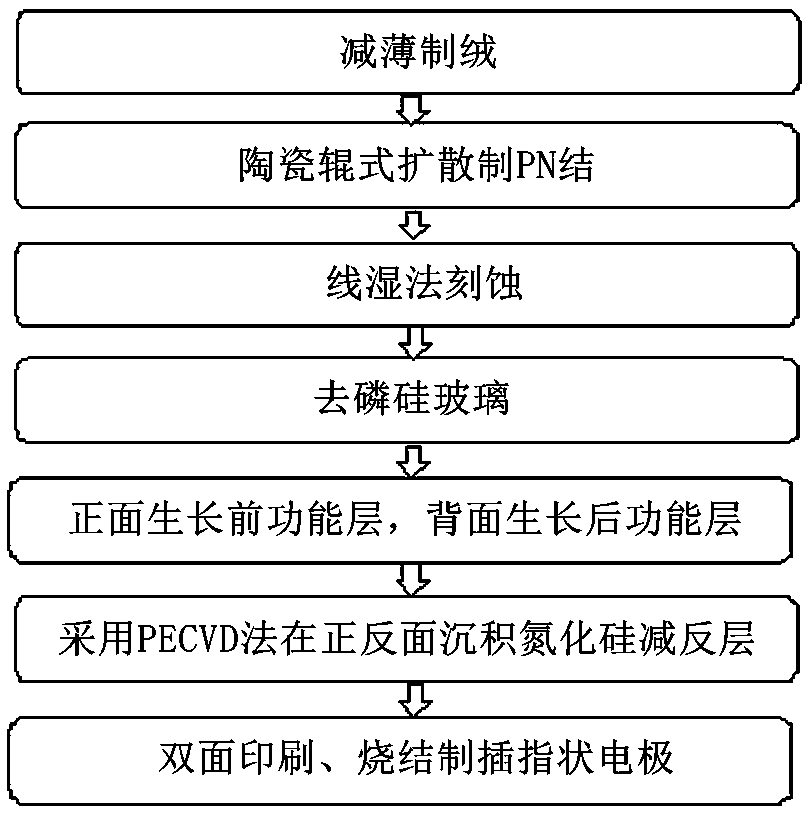

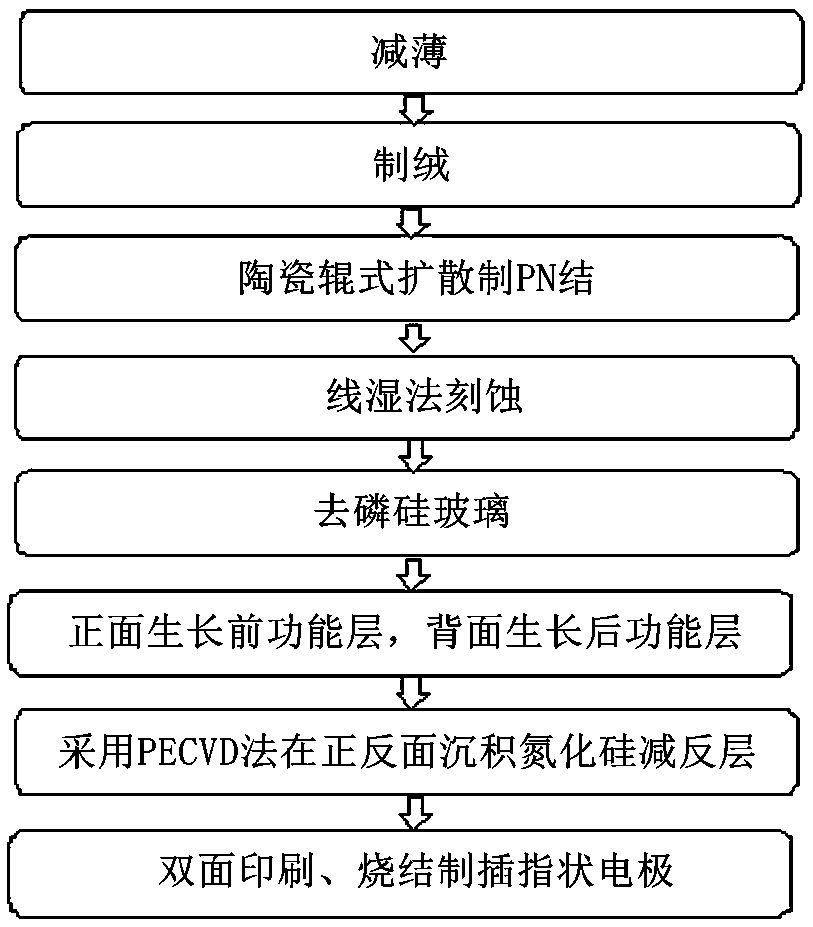

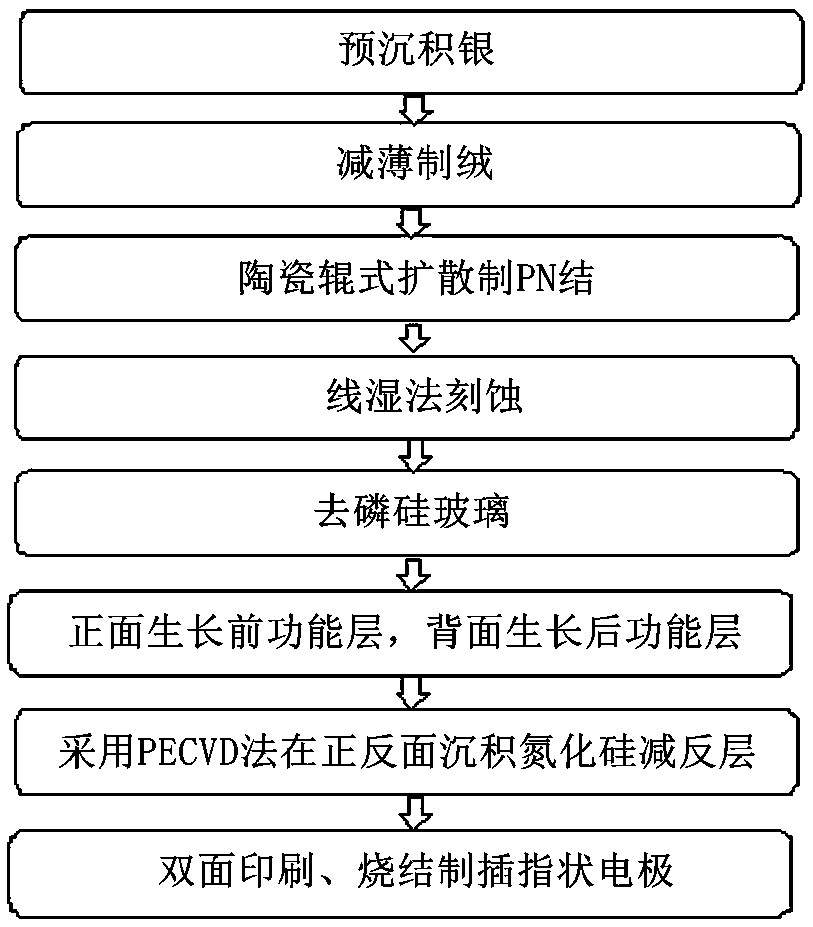

Method for preparing ultrathin crystalline silicon double-sided solar cell

ActiveCN109802009AImprove light energy utilizationIncrease light dwell timeFinal product manufacturePhotovoltaic energy generationPhosphoric acidSilicon nitride

The invention provides a method for preparing ultrathin crystalline silicon double-sided solar cell. The method comprises steps of: firstly thinning a polycrystalline silicon substrate to 90-120[mu]mat 18-25 degrees centigrade for 2000-2300s by using a mixed solution of HF, H2O2 and an additive, wherein a textured structure is formed on the surface of the substrate during the thinning process; preparing a PN junction by roll diffusion, and using ultrasonic atomization of phosphoric acid, thereby being nontoxic and nonpolluting, and achieving a uniform diffusion junction; and disposing siliconnitride antireflection layers on the front and back sides of the substrate; finally forming finger electrodes on the front and back sides by a silk-screen printing and sintering process. The method is suitable for the production technology of polycrystalline silicon 90-120[mu]m thick. Compared with a method for preparing a conventional polycrystalline silicon cell 180[mu]m thick, the method can reduce the thickness of the cell under the premise of ensuring a fragmentation rate, ensures battery efficiency, is simple in process, and low in cost. The method also solves the problem that the thincell is likely to be bent and is fragile, and can be industrialized by experimental verification.

Owner:HEBEI UNIVERSITY

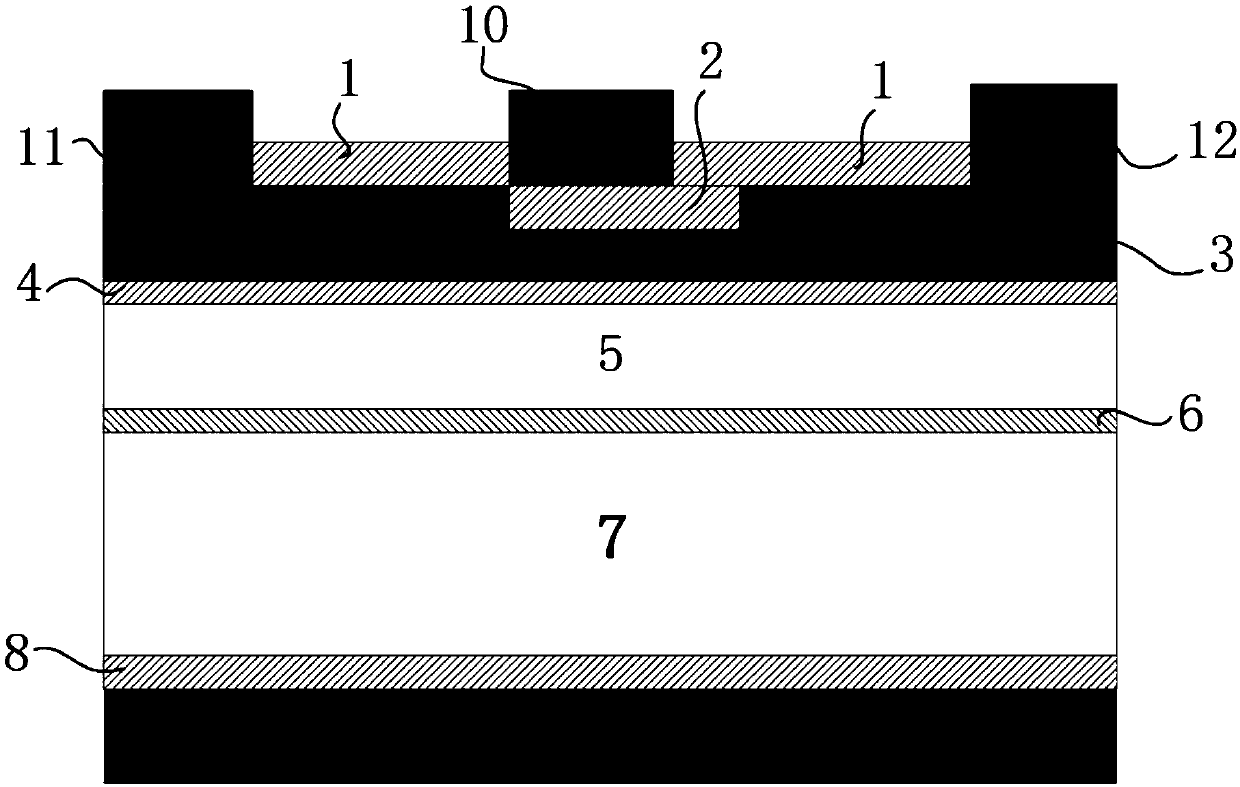

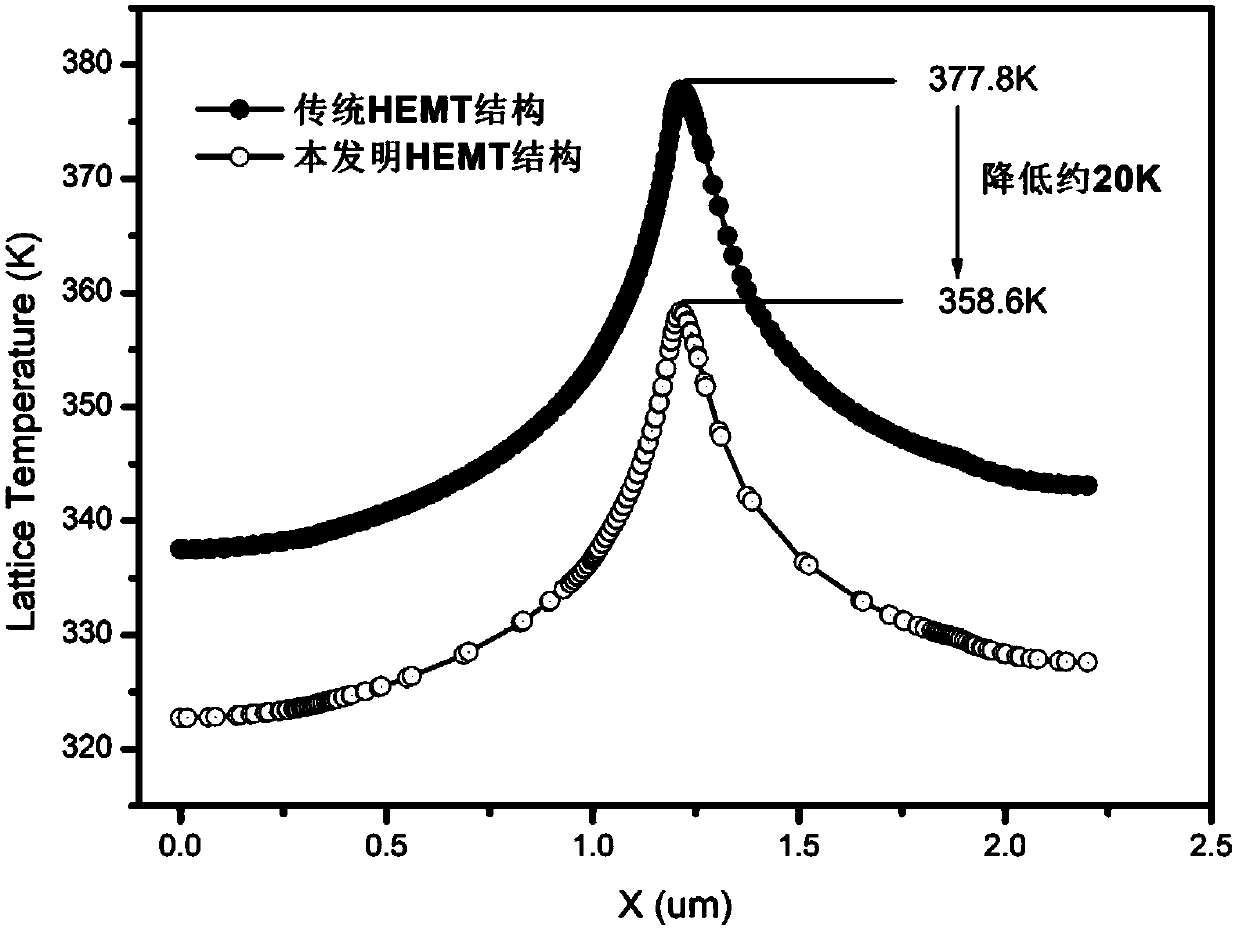

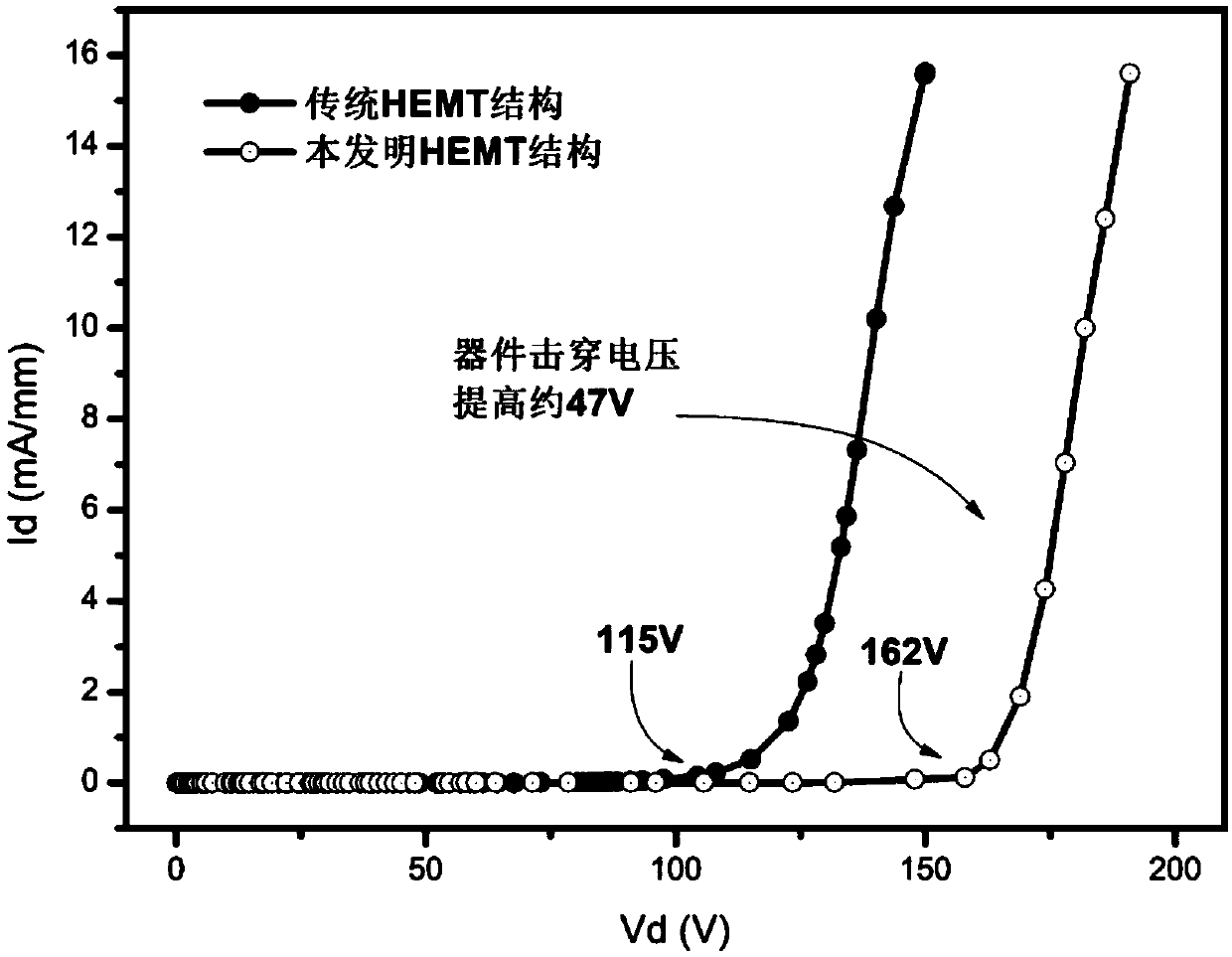

Low-junction-temperature and high-voltage-resistance GaN heterojunction field effect transistor

ActiveCN109671768AImprove efficiencyImprove linearityTransistorSemiconductor/solid-state device detailsHeat conductingJunction temperature

The invention relates to a power semiconductor technology, in particular to a low-junction-temperature and high-voltage-resistance GaN heterojunction field effect transistor. According to the low-junction-temperature and high-voltage-resistance GaN heterojunction field effect transistor provided by the invention, an AlN region is mainly inserted into a barrier layer to reduce a channel peak valveelectric field, so that the aims of increasing the voltage resistance and reducing the heat dissipation are realized. Furthermore, AlN with a good heat-conducting property is used as a passivation layer of a device, so that the current collapse is favorably inhibited and the effect of accelerating heat dissipation is also realized. The low-junction-temperature and high-voltage-resistance GaN heterojunction field effect transistor has the excellent effects that reverse voltage resistance of the device is improved, output properties of the device are improved and the channel temperature of the device is reduced, so that dangers caused by the current collapse and a self-heating effect are inhibited. The invention is especially applicable to the GaN heterojunction field effect transistor witha high-voltage-resistance capability and low channel temperature.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Reflow soldering method for improving device thermal expansion deformation

ActiveCN109604754ALower peak temperatureReduce the temperatureSolder feeding devicesSoldering auxillary devicesNitrogenThermal expansion

The invention discloses a reflow soldering method for improving device thermal expansion deformation. The reflow soldering method comprises the following steps: an SMT steel net is prepared, solder paste is printed for a PCB through the SMT steel net, and the PCB printed with the solder paste is sent into a placement machine to be subjected to SMT placement; the PCB subjected to placement is put into a reflow furnace, and heated nitrogen is introduced into the reflow furnace; primary heating is conducted, and the heating speed is smaller than or equal to 2 DEG C / s; heat preservation is conducted, the rotating speed of a fan at an upper air opening is increased, and the rotating speed of a fan at a lower air opening keeps unchanged; secondary heating is conducted, and the heating speed is smaller than or equal to 2 DEG C / s; reflow soldering is conducted; temperature decreasing for cooling is conducted, and soldering is completed; and subsequent detecting is conducted. The peak value temperature of reflow soldering can be lowered, thus the process window index (PWI) is increased, the good soldering hot melting effect is generated, the temperature difference between components and thePCB is reduced, and the problems of pseudo soldering and deformation caused by the too large temperature difference are avoided.

Owner:HUIZHOU GUANGHONG TECH CO LTD

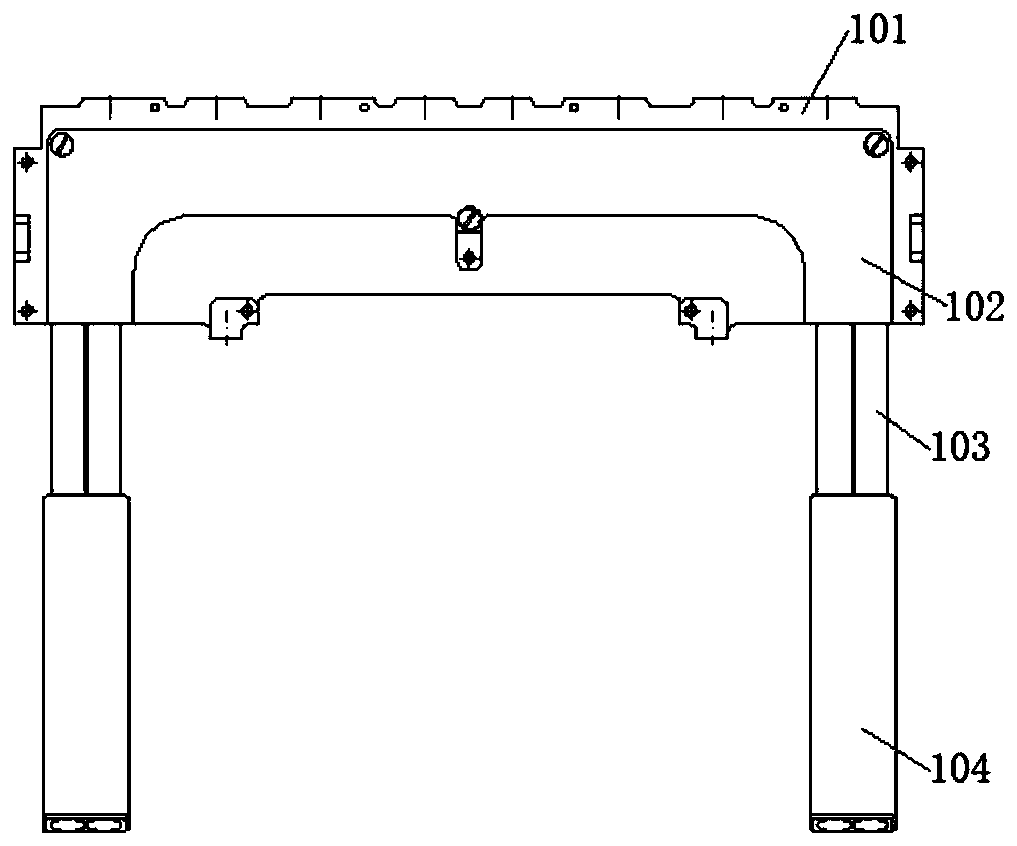

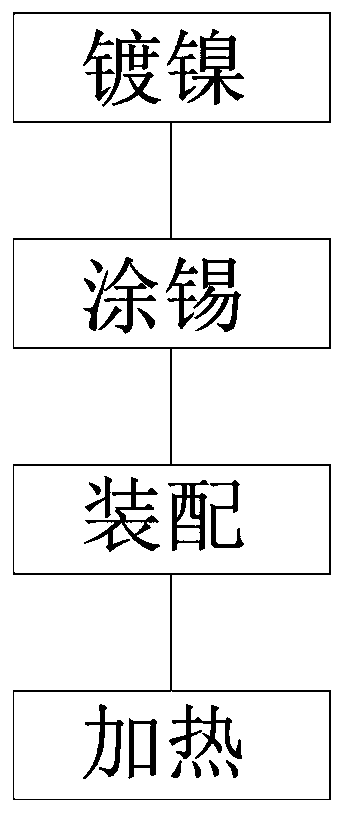

Welding method for cold plate component

ActiveCN110548947APrevent surface oxidationSolve the problem that tin-lead soldering cannot be performedWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCold plate

The invention discloses a welding method for a cold plate component. The cold plate component comprises a cold plate substrate, a cold plate cover, a hot bent pipe, and thermal conductive fingers. Thewelding method comprises the following steps of: step (1). nickel plating, to be specific, plating the interior of a first groove of the cold plate substrate, the interior of a second groove of the cold plate cover, the middle position of the hot bent pipe, each end of the hot bent pipe and each thermal conduction finger with nickel to form nickel layers; step (2). applying tin, to be specific, applying a layer of solder paste to each of the nickel layers in step (1); step (3). assembling, to be specific, inserting the hot bent pipe into the first groove of the cold plate substrate and the second groove of the cold plate cover, respectively embedding the two ends of the hot bent pipe into one thermal conductive finger, thereby forming a cold plate assembly; and step (4). heating, to be specific, putting the cold plate assembly in step 3) into a reflow oven for reflow soldering. The cold plate component is subjected to nickel plating and tin applying surface treatment, so that metal parts on the cold plate component can be soldered by adopting low temperature tin-lead solder to ensure the thermal conductivity and welding quality of the cold plate component.

Owner:HUBEI SANJIANG SPACE XIANFENG ELECTRONICS&INFORMATION CO LTD

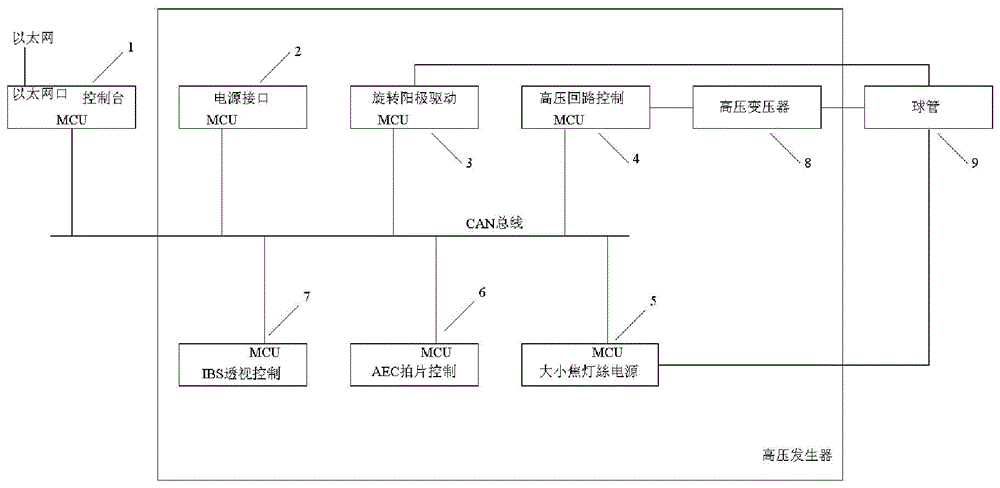

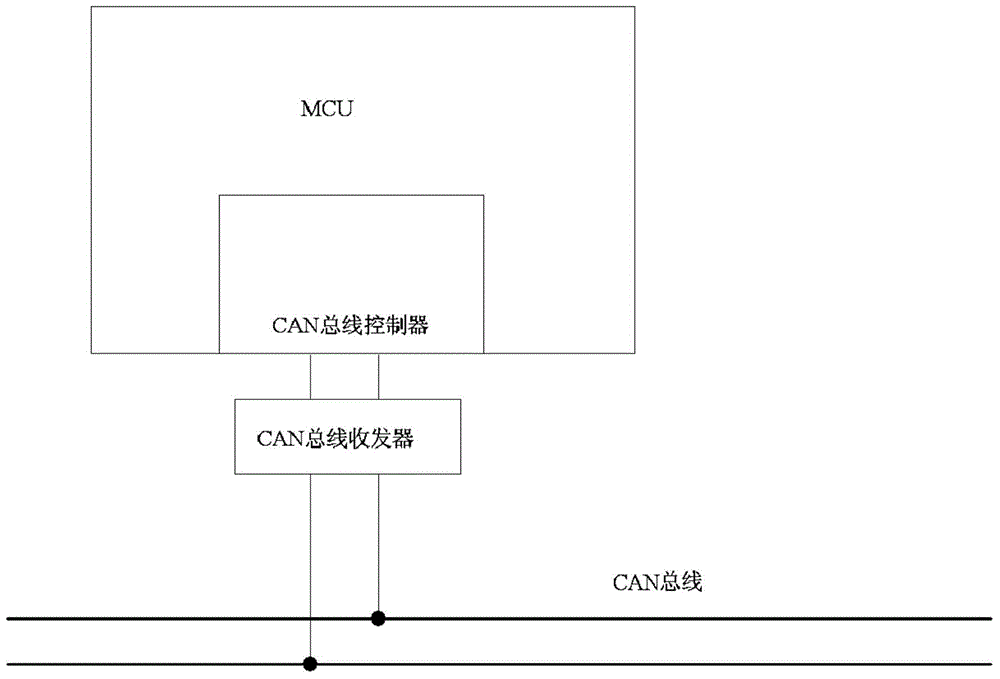

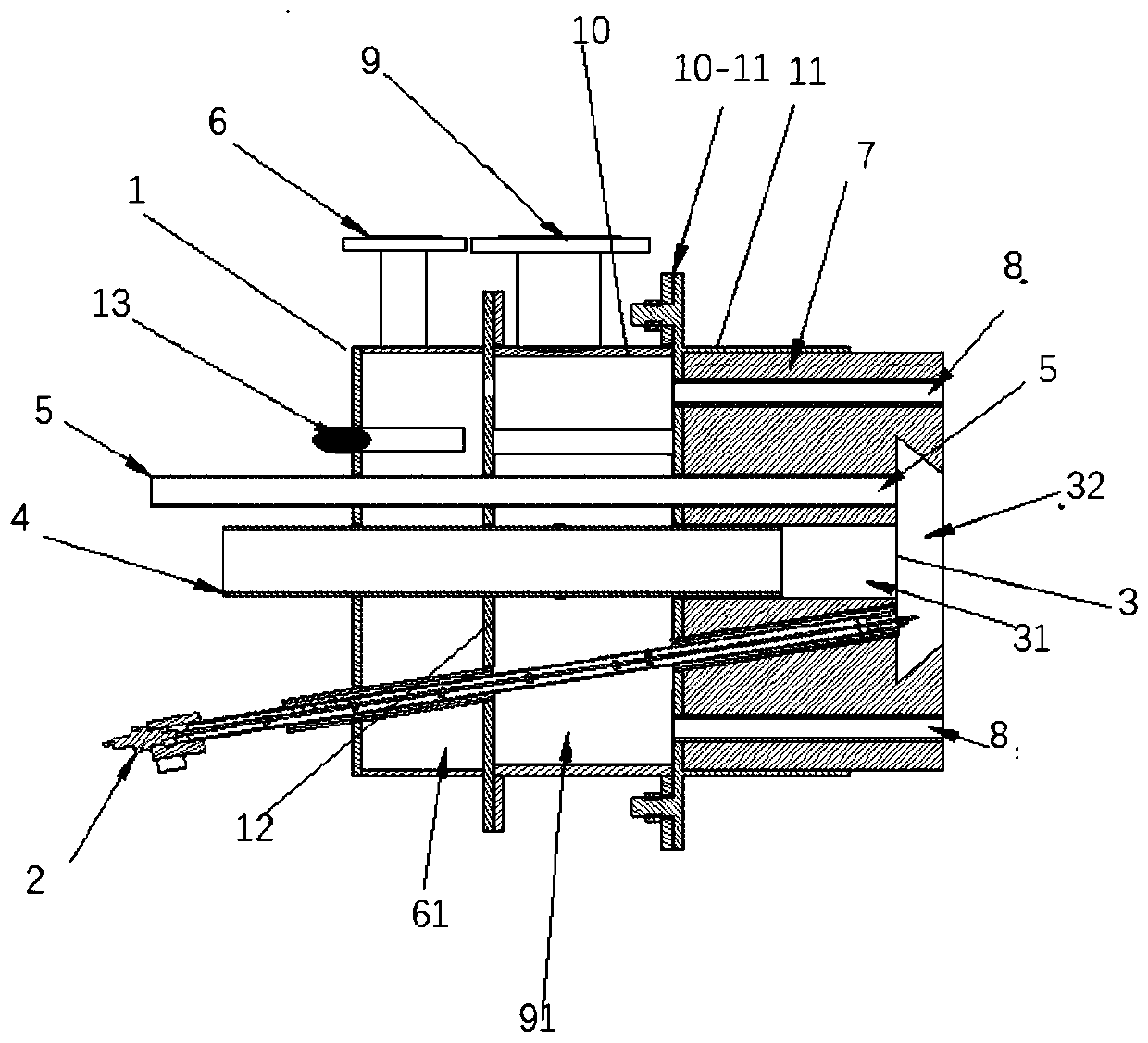

CAN bus-based medical X-ray high voltage generator control system

The invention relates to a CAN bus-based medical X-ray high voltage generator control system, which comprises a console MCU module, a high voltage generator and a bulb tube connected in sequence, wherein the high voltage generator comprises a power interface module, a rotary anode driving module, a high voltage loop control module, a large-small focal filament power module, an AEC shooting control module, an IBS perspective control module, a high voltage inverter and a transformer; the console MCU module, the power interface module, the rotary anode driving module, the high voltage loop control module, the large-small focal filament power module, the AEC shooting control module and the IBS perspective control module are mutually connected via the CAN bus; and the high voltage inverter and the transformer are respectively connected with the high voltage loop control module and the bulb tube. Compared with the prior art, the system has the advantages of flexibility, reliability, low cost, good system performance and the like.

Owner:余幼华

Multistage combustor, molten steel tank preheating equipment and application method thereof

PendingCN110608438AReduce generationEvenly distributedMelt-holding vesselsGaseous fuel burnerCombustion chamberEngineering

The invention relates to the field of molten steel tank preheating equipment, in particular to a multistage combustor, molten steel tank preheating equipment and an application method thereof. The combustor comprises a combustor main body; the combustor main body is provided with an intake pipe for gas feeding; the combustor main body is provided with a combustion chamber for gas and oxygen combustion; the combustion chamber comprises a combustion chamber nozzle; the combustion chamber nozzle communicates with the outer side surface of the combustor main body; and the combustor main body is provided with an ignition gun for ignition. The invention discloses the multistage combustor structure; the structure of the combustor is optimized; and pure oxygen is adopted to replace air as the combustion assisting medium, so that the heat loss caused by participation of nitrogen and inert gas in the air in the heat exchange is reduced, and the system heat efficiency and the molten steel tank heating speed can be greatly improved.

Owner:MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com