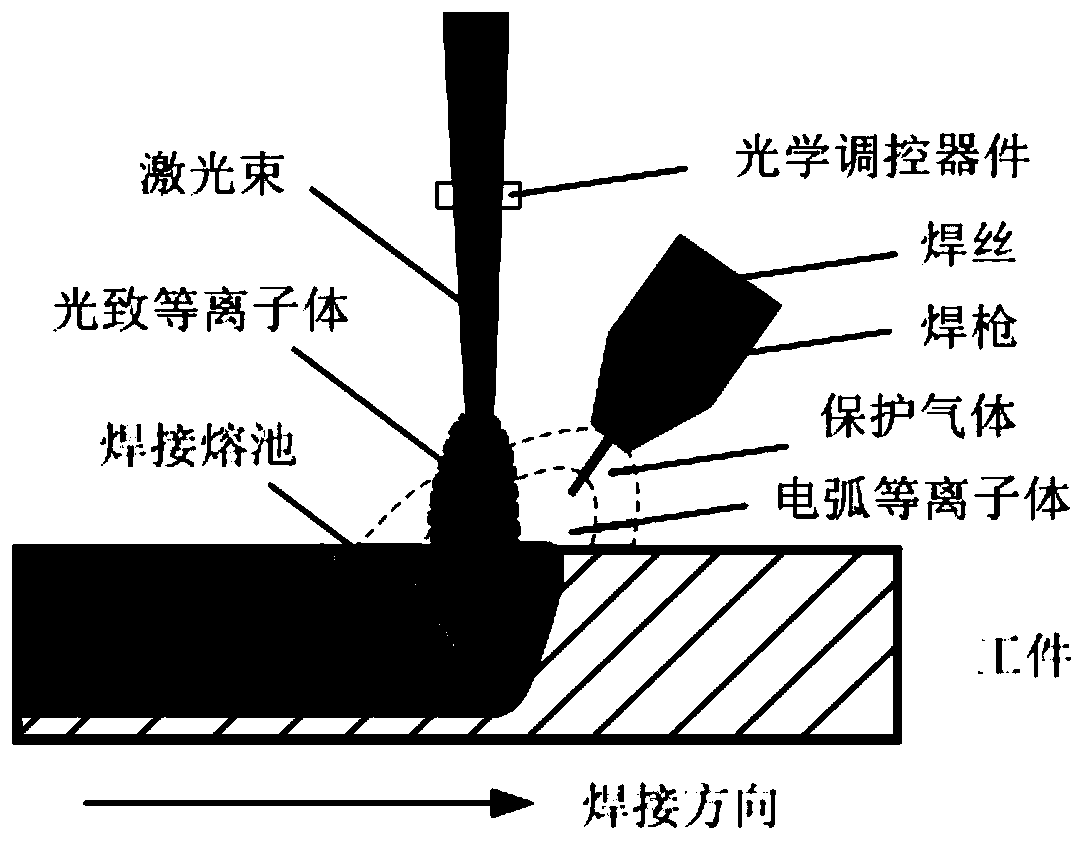

Laser-electric arc two-heat source weak coupling welding method for high-nitrogen steel

A welding method and weak coupling technology, applied in the field of material welding, can solve problems such as failure to completely suppress welding pores, and achieve the effect of enhancing the coupling effect of two heat sources, good technical effect, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

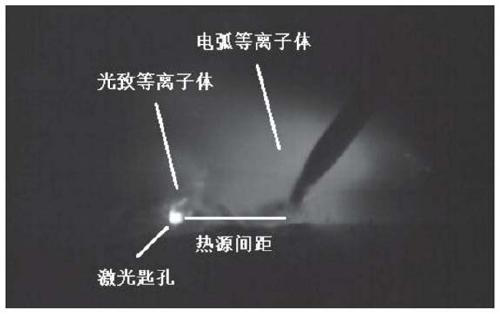

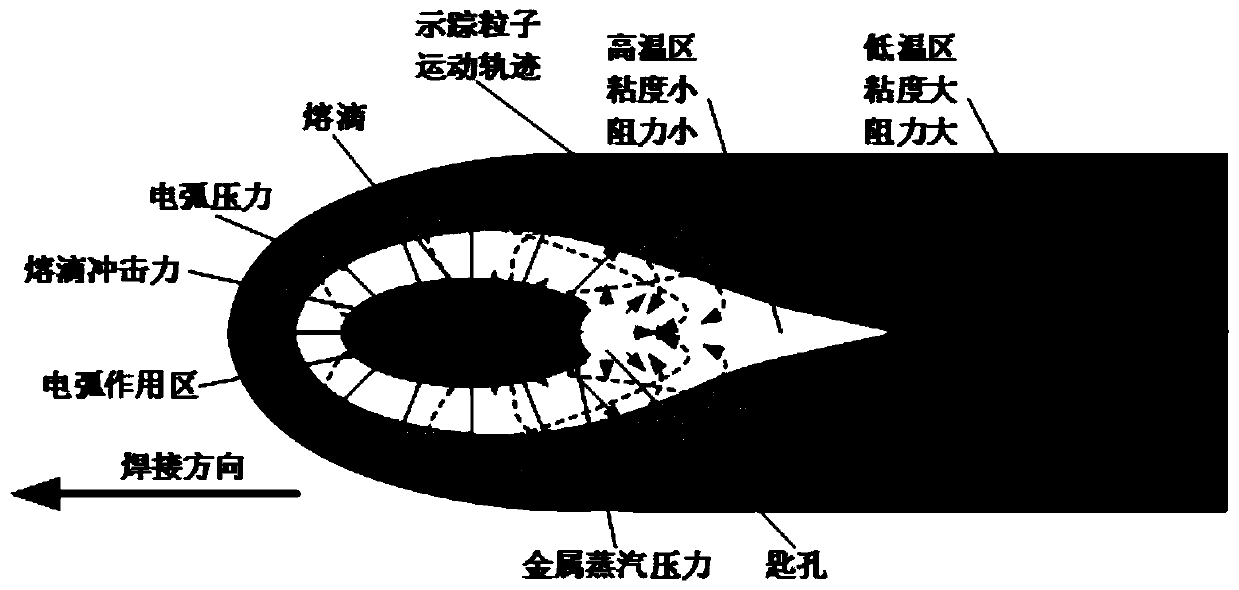

Method used

Image

Examples

Embodiment 1

[0056] Using the above-mentioned welding method of adjusting the heat source distance to realize the weak coupling of the two heat sources, the specific steps are as follows:

[0057] Step 1: Clamp the high-nitrogen steel test plate with a thickness of 8mm and a nitrogen content of 0.5% to 0.7% on the welding platform in a butt joint form. The bevel angle of the test plate is 30°, and the height of the blunt edge of the bevel is 4mm. The gap between the two test plates is 0.8mm.

[0058] Step 2: Regulate the spatial positions of the two heat sources during weak coupling welding. Set the welding process parameters, where the laser power is 2.1kW, the welding current is 220A, the welding speed is 0.8m / min, the defocus is 2mm, and the distance between heat sources is 6mm.

[0059] Step 3: The welding wire used is austenitic stainless steel welding wire, the diameter of the welding wire is 1.2mm, and the shielding gas of the welding torch is 5% N by volume 2 +95% Ar, the flow ra...

Embodiment 2

[0062] Compared with Example 1, only the distance between heat sources is adjusted, specifically according to the following steps:

[0063] Step 1: Clamp the high-nitrogen steel test plate with a thickness of 8mm and a nitrogen content of 0.5% to 0.7% on the welding platform in a butt joint form. The bevel angle of the test plate is 30°, and the height of the blunt edge of the bevel is 4mm. The gap between the two test plates is 0.8mm.

[0064] Step 2: Regulate the spatial positions of the two heat sources during weak coupling welding. Set the welding process parameters, where the laser power is 2.1kW, the welding current is 220A, the welding speed is 0.8m / min, the defocus is 2mm, and the distance between heat sources is 2mm.

[0065] Step 3: The welding wire used is austenitic stainless steel welding wire, the diameter of the welding wire is 1.2mm, and the shielding gas of the welding torch is 5% N by volume 2 +95% Ar, the flow rate is 16L / min. The composite welding head o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com