Patents

Literature

64results about How to "Improve soldering effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Halogen-free tin-bismuth-copper soldering paste and preparation method thereof

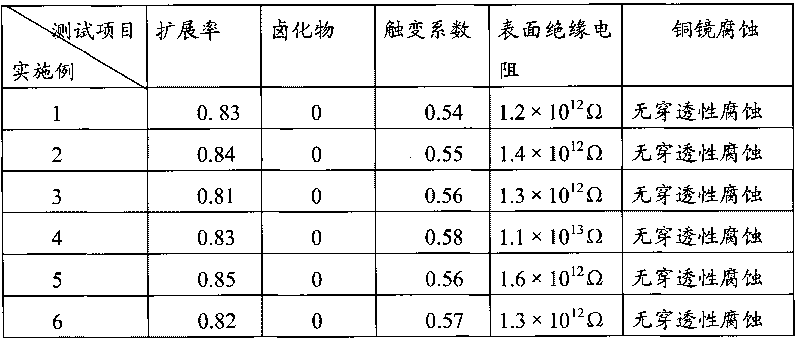

InactiveCN101695794AExtended shelf lifeExtended service lifeWelding/cutting media/materialsSoldering mediaAntioxidantExpansion rate

The invention relates to the technical field of soldering pastes, in particular to a halogen-free tin-bismuth-copper soldering paste and a preparation method thereof. A soldering flux of the halogen-free tin-bismuth-copper soldering paste consists of the following components in percentage by weight: 20 to 40 percent of polymerized rosin, 1 to 6 percent of rosin amine, 4 to 8 percent of thixotropic agent, 5 to 10 percent of organic acid, 5 to 10 percent of organic amine, 1 to 5 percent of antioxidant, 0.5 to 3 percent of surfactant and an organic solvent. The halogen-free tin-bismuth-copper soldering paste is mainly characterized by adopting the organic acid and the organic amine serving as activating agents and comprising no halogens at all, so not only the solderability is not reduced, but also the expansion rate and the insulation resistance value of the soldering paste are improved, and simultaneously the corrosivity of residues after soldering to a base material is reduced and the service life of the soldering paste is prolonged; and particularly, the peak temperature of the soldering paste during soldering is lower in favor of reducing the thermal damages to electronic components.

Owner:东莞市特尔佳电子有限公司

Al and Al alloy soft braze welding metal displaced type unleaded welding soldering flux

InactiveCN101204762AWith corrosion protectionImprove matchWelding/cutting media/materialsSoldering mediaSurface-active agentsSolder paste

The invention discloses a soldering metal replacement no lead welding scaling powder for aluminum and aluminum alloy, which is composed of the following weight proportions: 5 to 50 percent of metal salt that can be reduced by the aluminum, 10 to 15 percent of stripper, 3 to 40 percent of wetting agent, 3 to 20 percent of activating agent, 1 to 15 percent of surface active agent, 2 to 20 percent of inhibiter and a carrier with the rest percent. The invention has an extremely excellent matching effect with a lead-free solder in the welding temperature and is suitable for being made into a welding stick or a welding paste with the lead-free solder. After welding, the invention has a high welding intensity and a good expansion rate, belongs to an environment protection scaling powder, and has the function of inhibition protection on the aluminum and aluminum alloy as well as a simple and practical preparing method. Undoubtedly, the embodiment can also be used for the no lead soldering on the materials like stainless steel, galvanized iron, copper and copper alloy, etc., and bear the same effects as well.

Owner:昆山成利焊锡制造有限公司

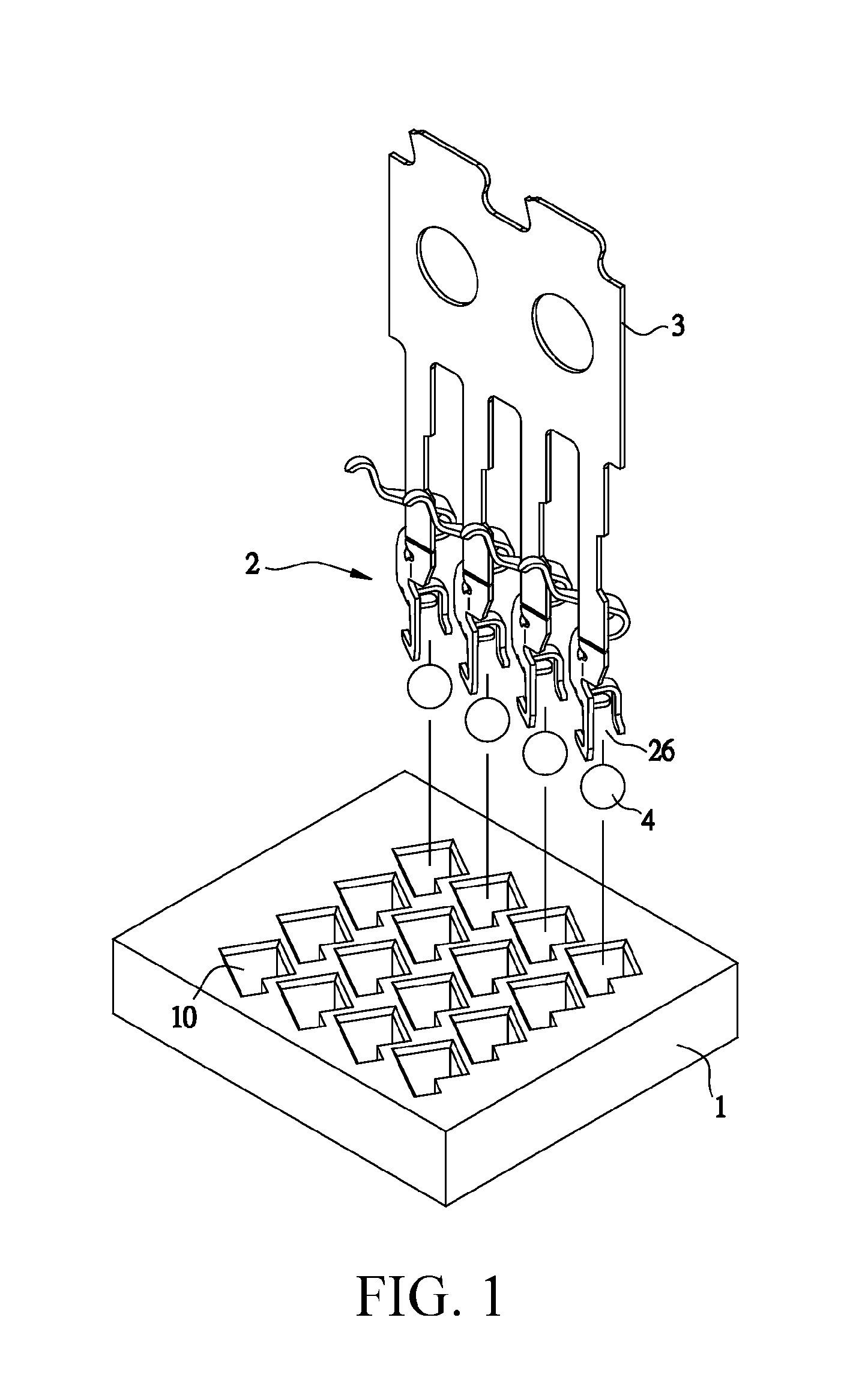

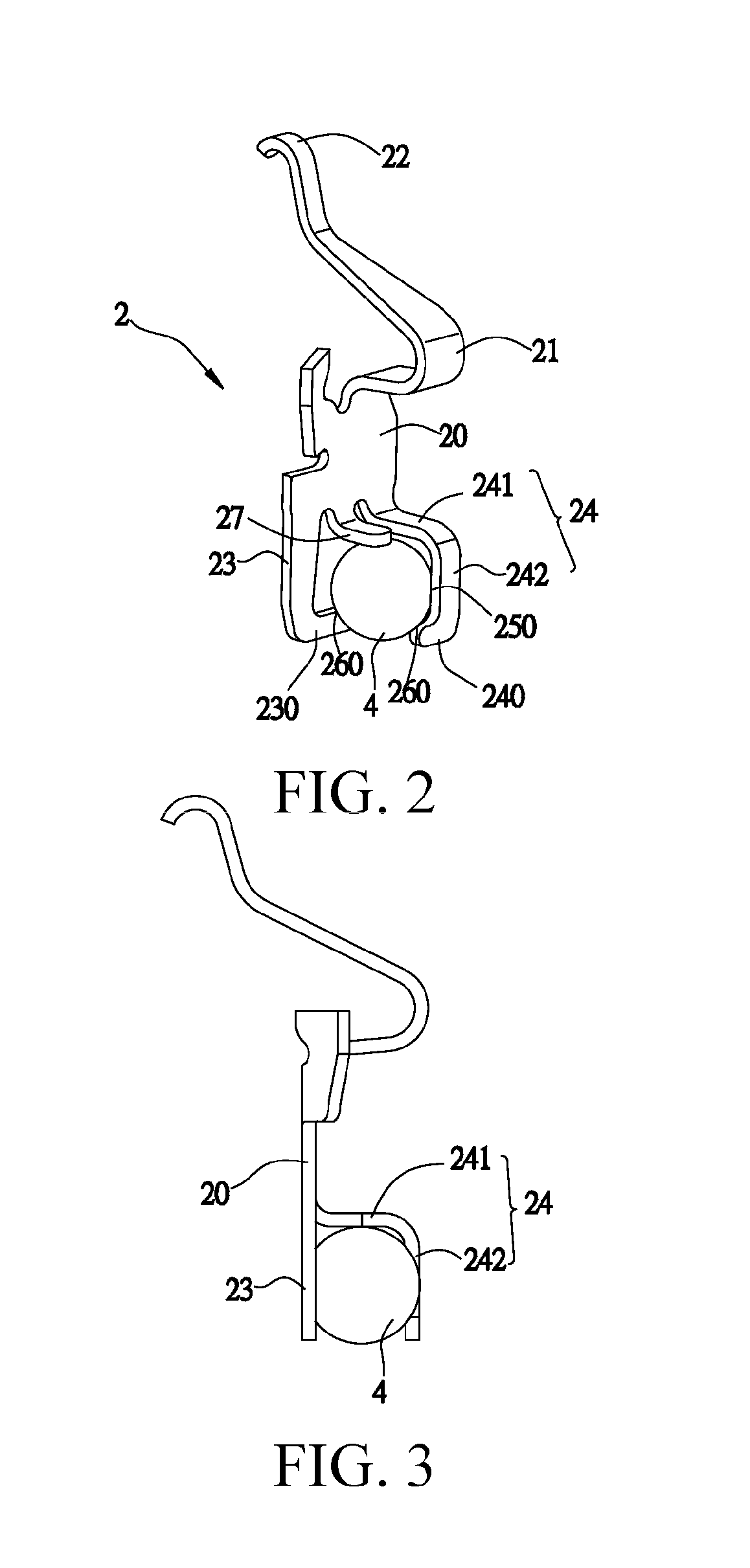

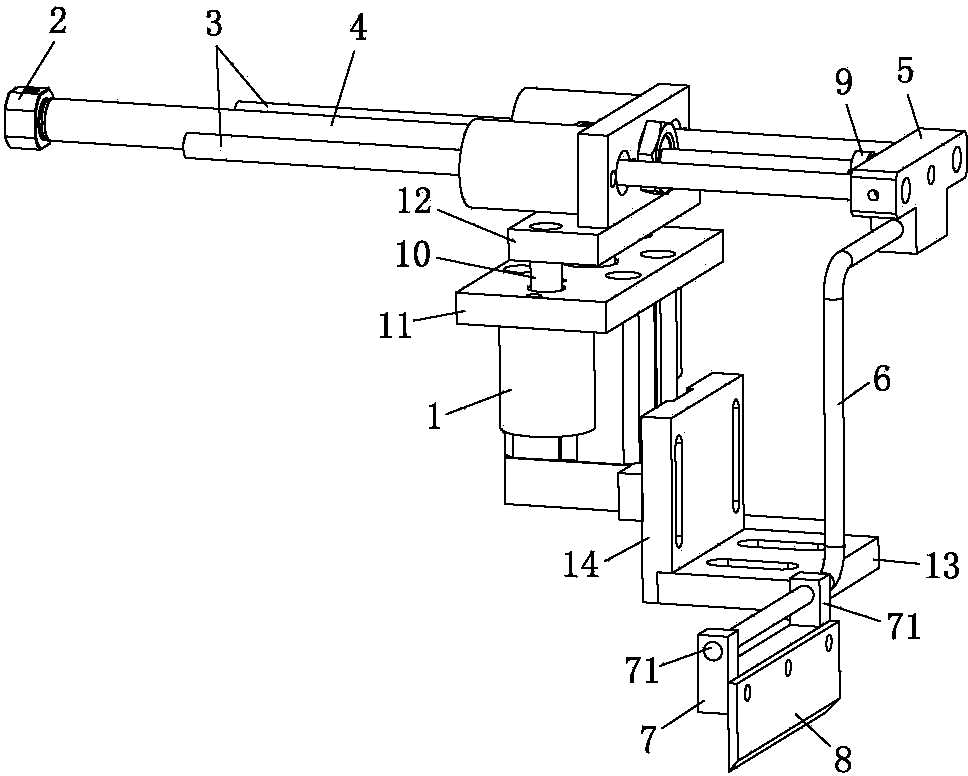

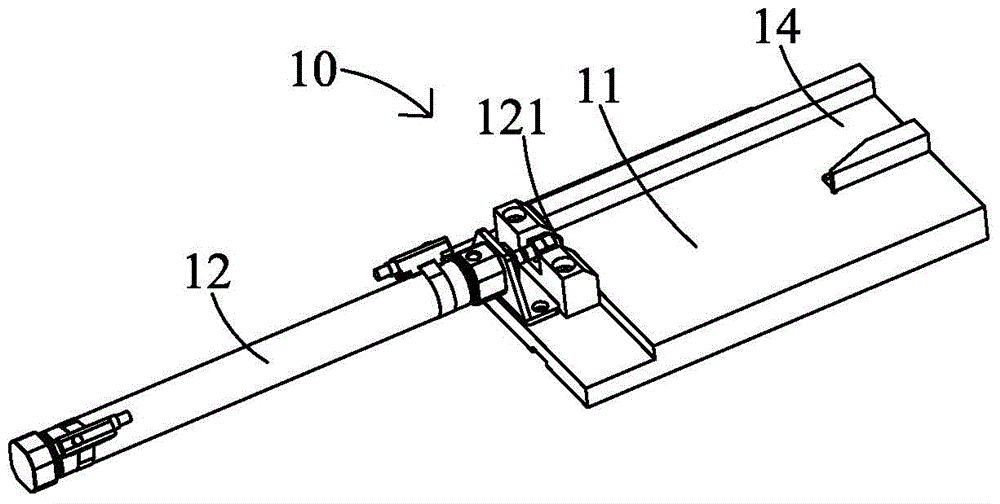

Terminal for electrical connector

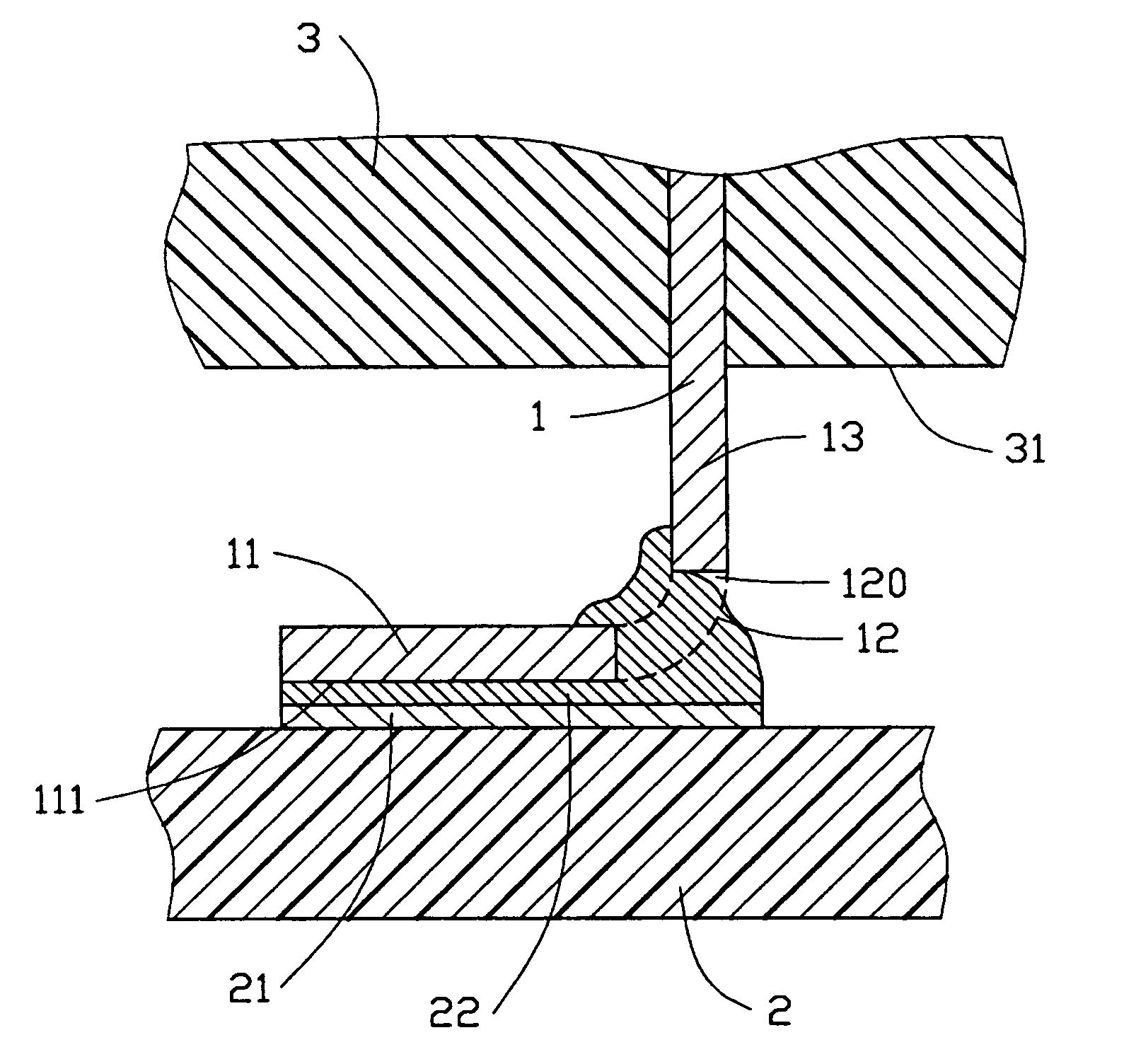

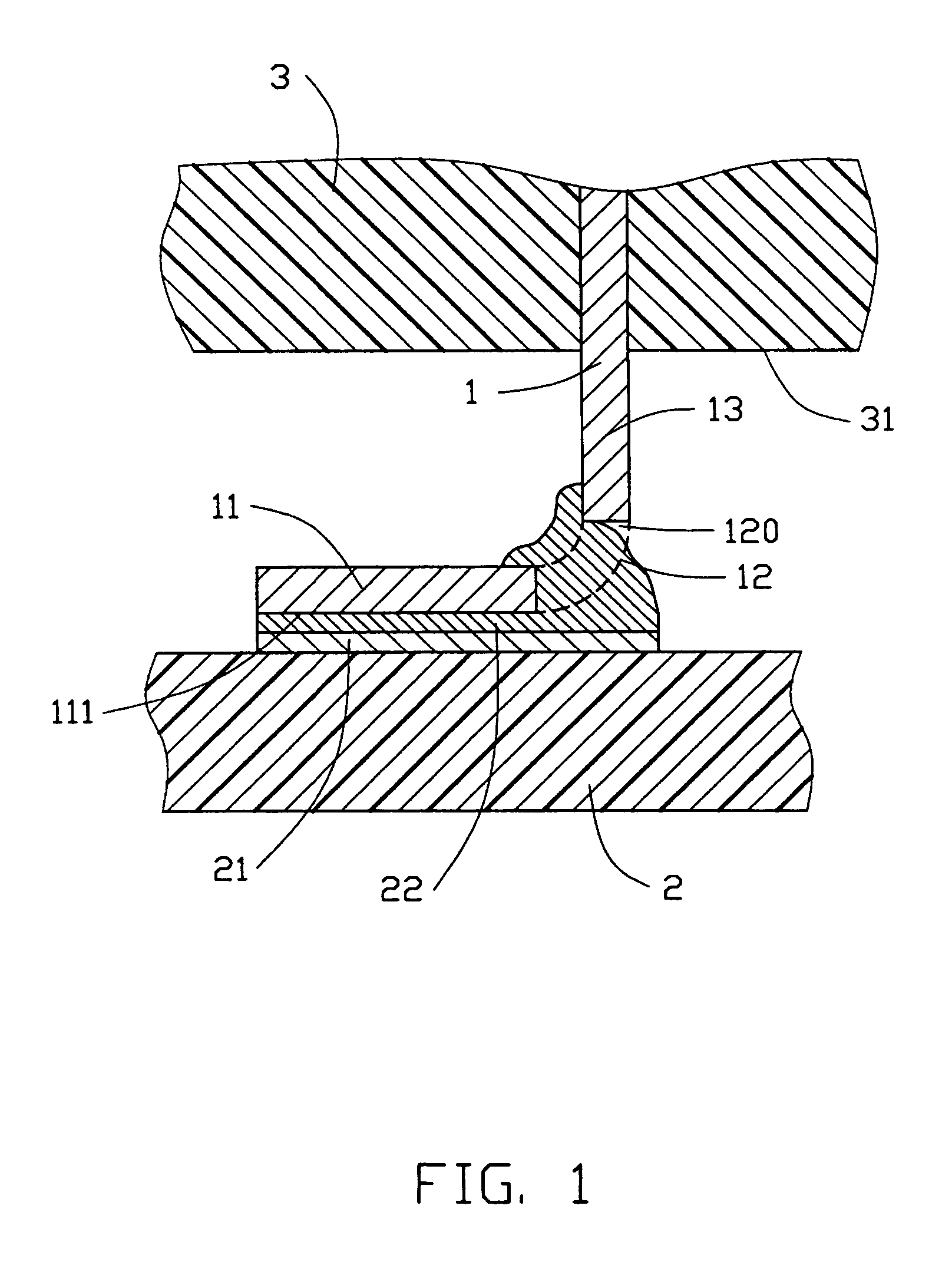

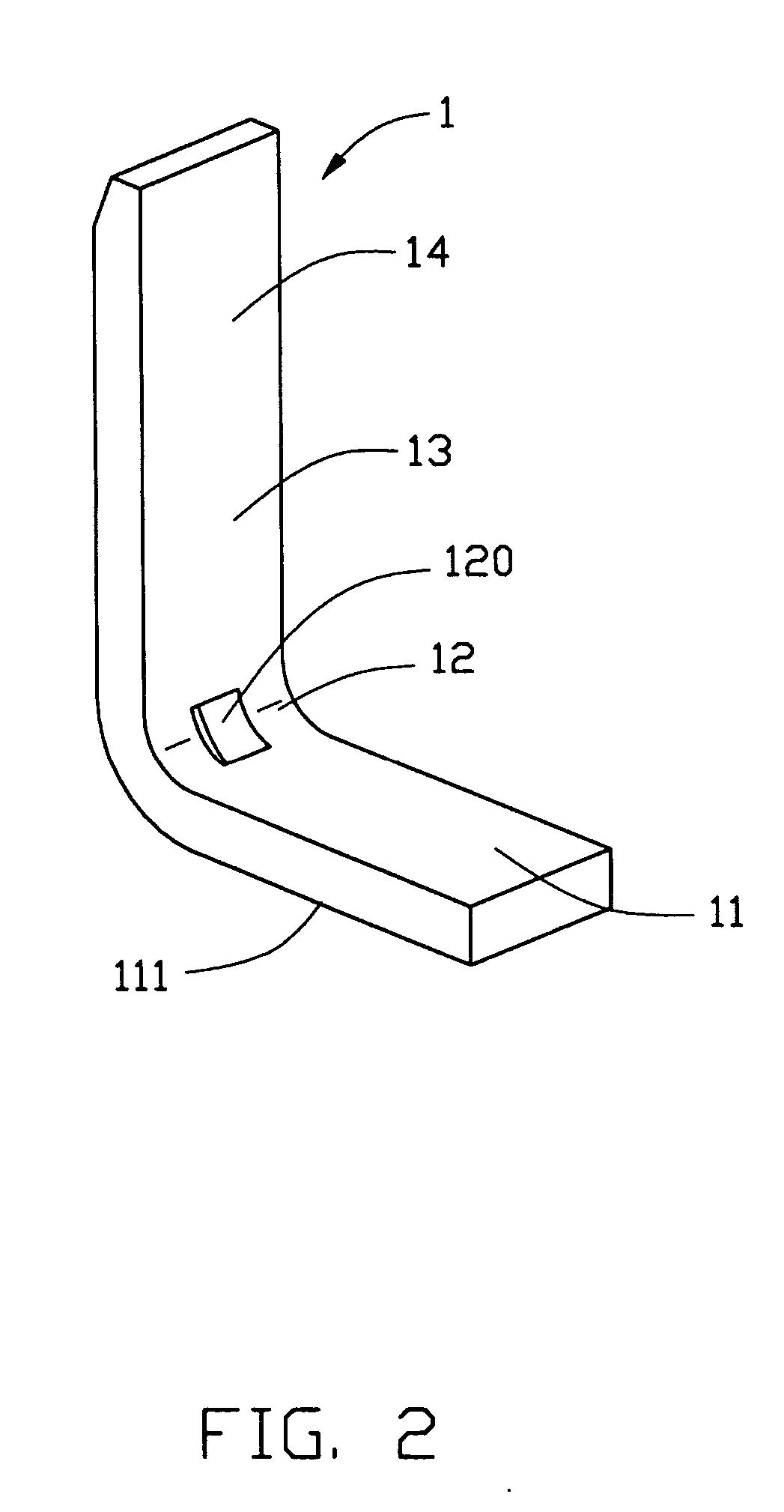

InactiveUS20050064745A1Improve soldering effectFirmly connectedPrinted circuit assemblingContact member manufacturingElectrical connectionEngineering

A terminal (1) for an electrical connector includes a flat soldering portion (11), a flexed portion (12) extending from the soldering portion, and a contacting portion (14) extending upwardly from the flexed portion. The soldering portion has a soldering face (111) and the connecting portion extends away from the soldering face. A rectangular overflowing aperture (120) extends through a centre of the flexed portion. Thus, the terminal is securely soldered on a printed circuit board to thereby achieve a reliable electrical connection between the terminal and the printed circuit board.

Owner:HON HAI PRECISION IND CO LTD

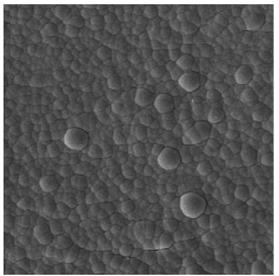

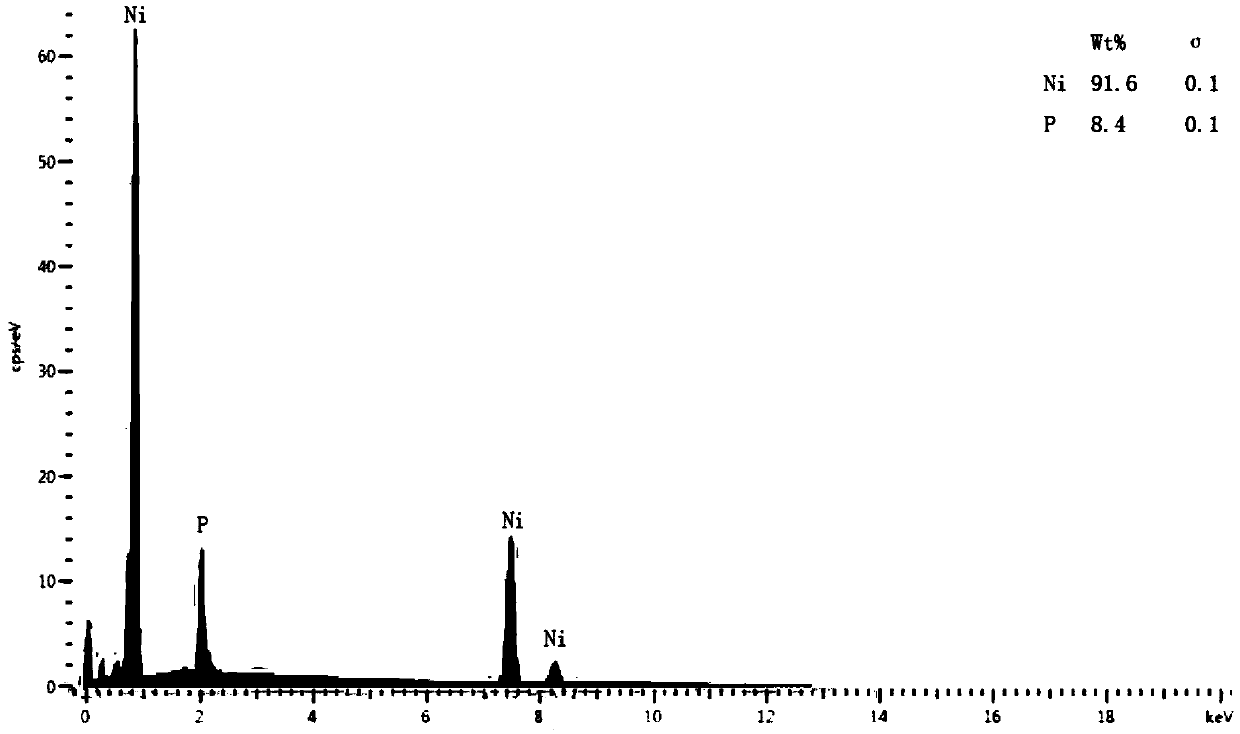

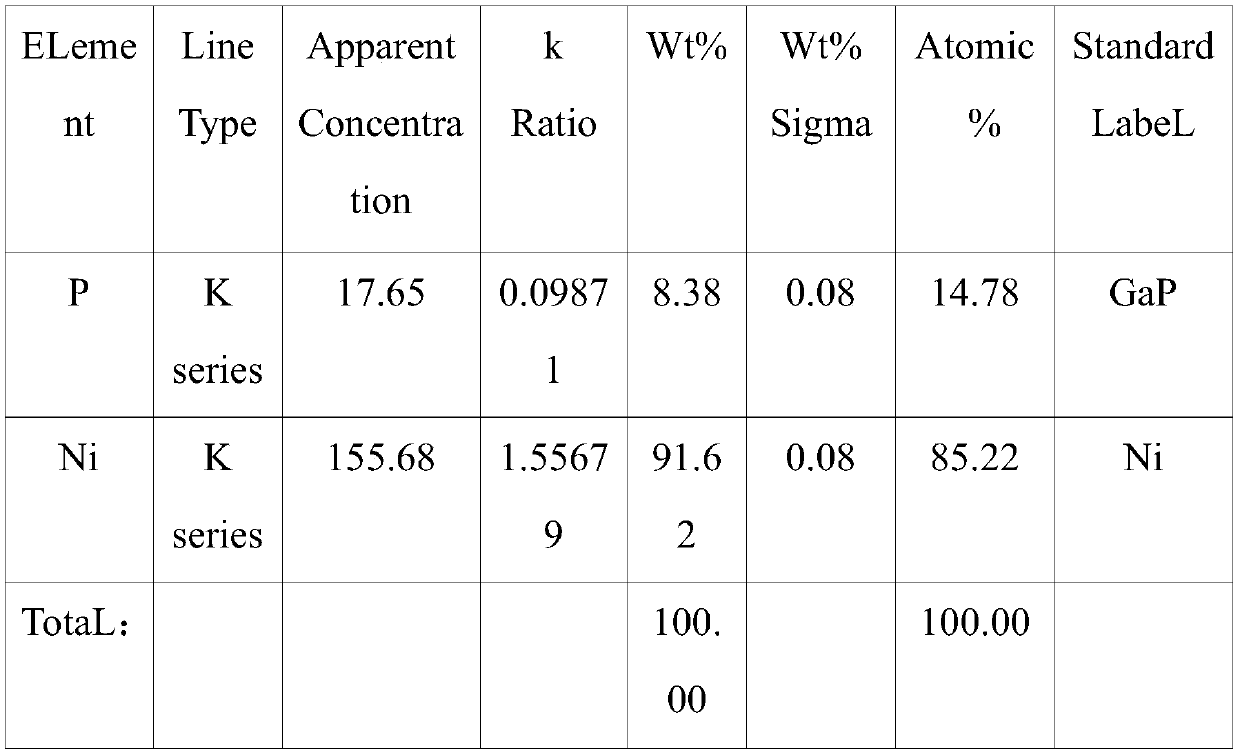

Novel chemical nickel gold production process and chemical nickel plating liquid

InactiveCN109628913AFast deposition rateSolve the difficulty of levelingLiquid/solution decomposition chemical coatingEtchingNickel deposition

The invention discloses a PCB or package substrate chemical nickel gold production new process. The new process comprises the steps of chemical gold pretreatment, deoiling, micro-etching, activation,alkaline chemical nickel, nickel activation, acid chemical nickel, chemical gold, gold surface hole sealing and chemical gold aftertreatment. The invention further provides novel chemical nickel plating liquid. The process is low in nickel cylinder temperature and high in chemical nickel deposition speed; nickel simple substances are difficultly separated out from the wall of a chemical nickel plating liquid stabilizing tank; the horizontal production of chemical nickel gold can be realized; a production line is shortened; the emission of waste water is reduced; and the comprehensive production cost of the production line is reduced. In the novel chemical nickel plating liquid, through adjustment of types of complexing agents and stabilizing agents in the chemical nickel plating liquid, even if under the conditions of higher PH and higher deposition speed, higher P content is achieved to meet various performance requirements of existing chemical nickel gold for the surface treatment ofPCBs and package substrates.

Owner:湖南互连微电子材料有限公司

Lead-free environmentally friendly soldering flux and preparation method thereof

InactiveCN101972906AReduce manufacturing costIncrease productivityWelding/cutting media/materialsSoldering mediaSolventRosin

The invention relates to a lead-free environmentally friendly soldering flux and a preparation method thereof. The method comprises the following steps of: mixing synthetic organic acid, an activating agent and a mixed alcohol solvent at normal temperature according to a component formula; pouring an obtained mixture into a stainless steel container, and then adding modified rosin particles; stirring materials in the container until the rosins are all dissolved, and then stopping stirring; and standing still, filtering and hermetically packaging to obtain a soldering flux product. The lead-free environmentally friendly soldering flux is a no-clean soldering flux with low solid content, less rosin and no halide, has the characteristics of quick dry, bright and firm welding spot, uniform spreading, full structure, no corrosivity, excellent solderability, good soldering wetting, stable property, and the like, conforms to the property requirements of various electrical appliances and is suitable for soldering computers and peripheral equipment or high-precision multilayer board electronic assemblies. When in use, the soldering flux product has the advantages of low smoke, no pollution to working environment, no influence on the human health, no pollution to tracks and clamps of a tinning furnace, higher insulating impedance, good environment friendly performance and stronger market competitiveness.

Owner:DANFENG RONGYI ELECTRONICS

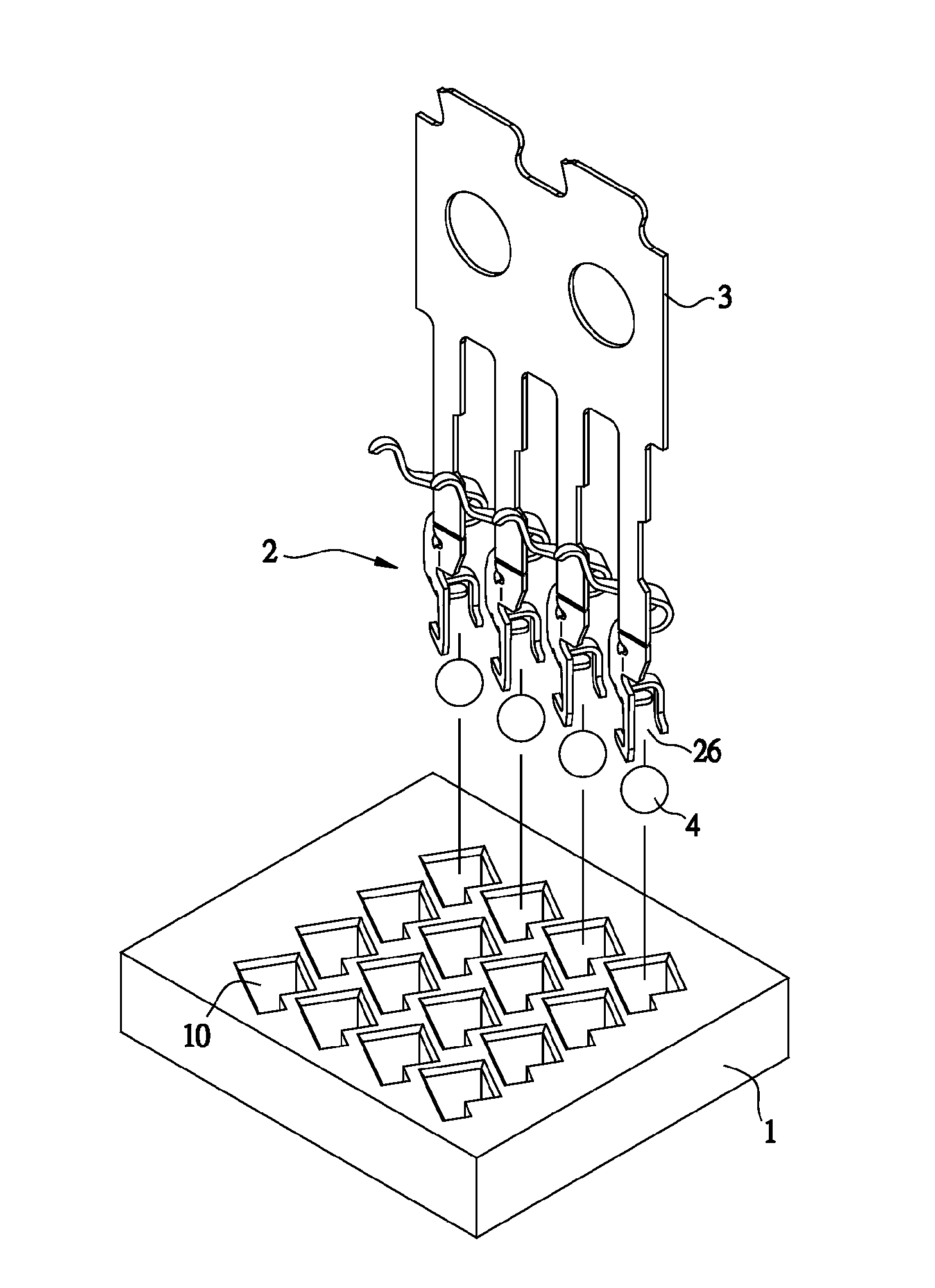

Electrical connector

ActiveUS20120178306A1Low production costSimplified assembly stepsElectric discharge tubesTwo-part coupling devicesSolder ballEngineering

An electrical connector that includes: an insulating body, having a plurality of receiving holes disposed thereon, a plurality of solder balls, respectively received in one of the receiving holes, a plurality of terminals, in which each terminal has a base correspondingly received in one of the receiving holes, a first extending portion and a second extending portion extend downwards from the base, a first hook extends laterally from an end of the first extending portion, a second hook extends laterally from an end of the second extending portion, and the first hook and the second hook respectively hook a periphery of the solder ball under a horizontal center line of the solder ball.

Owner:LOTES

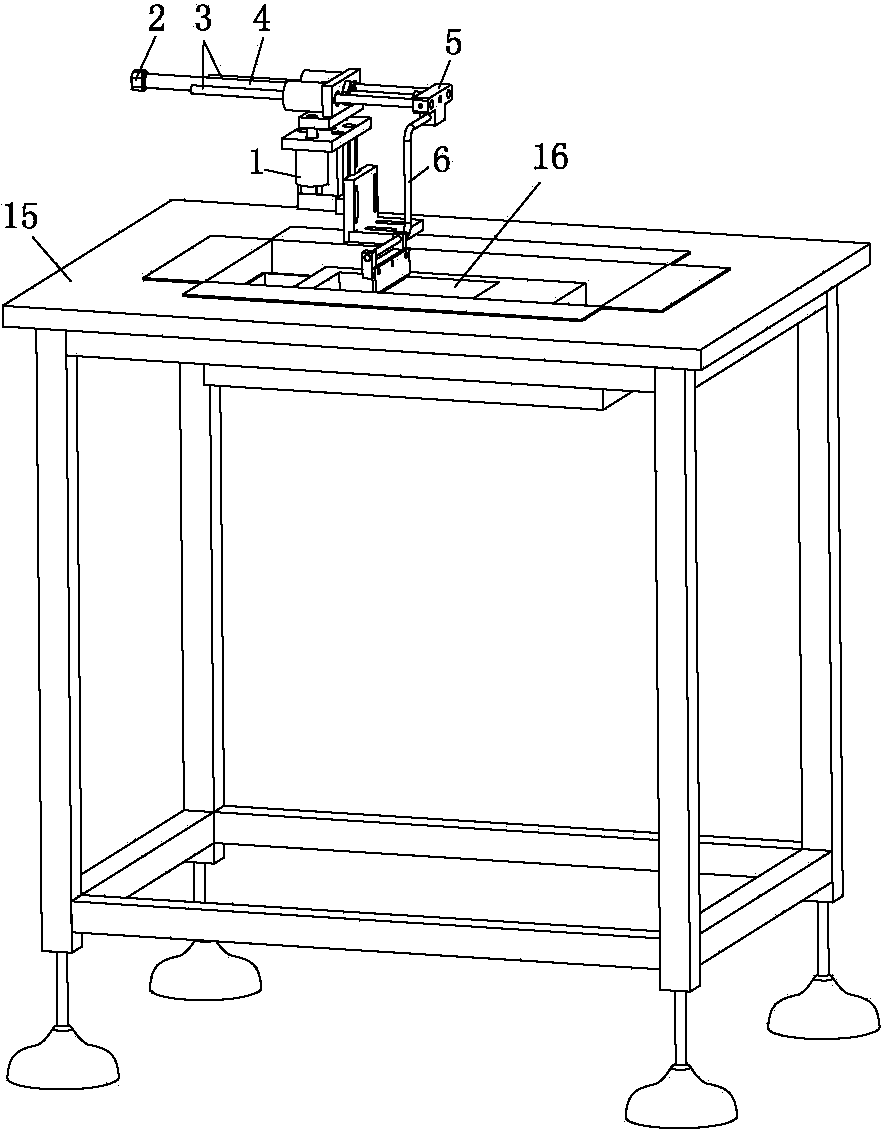

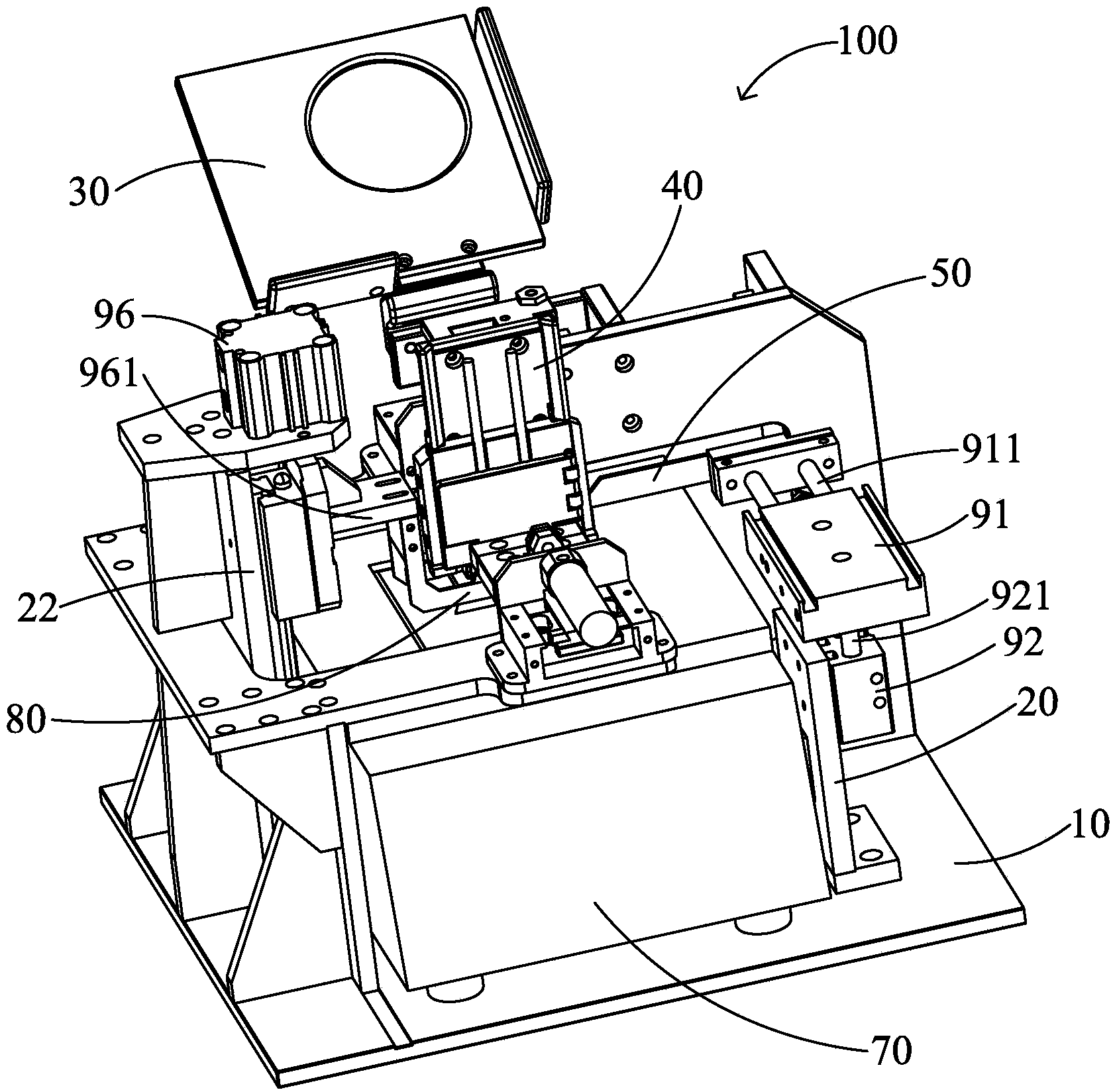

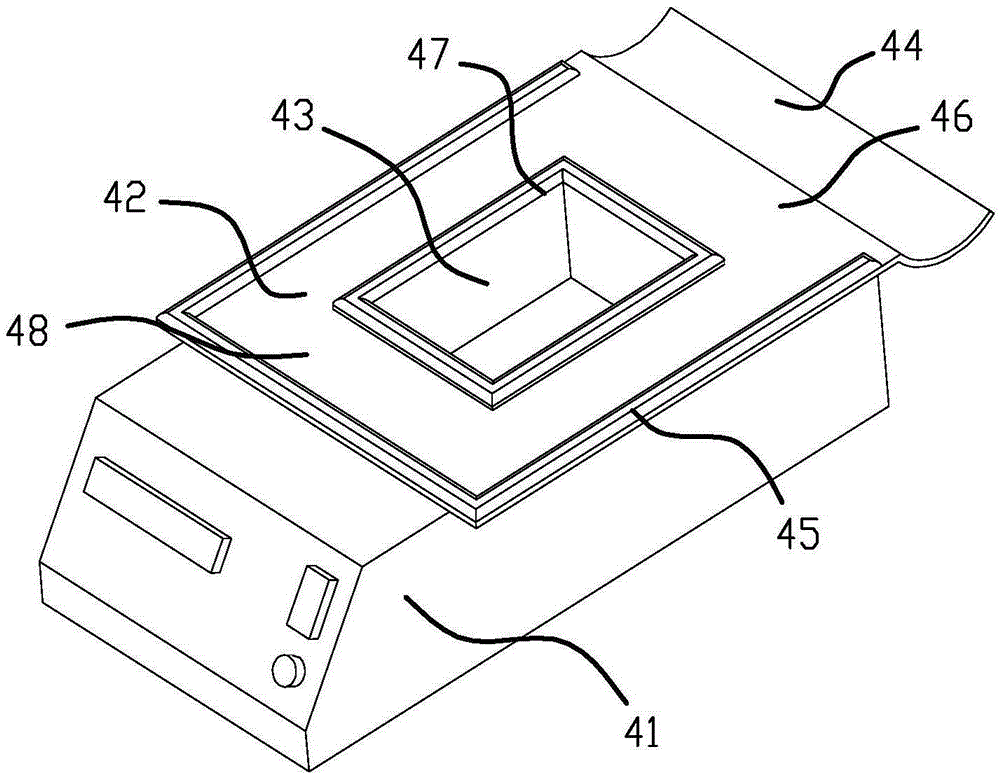

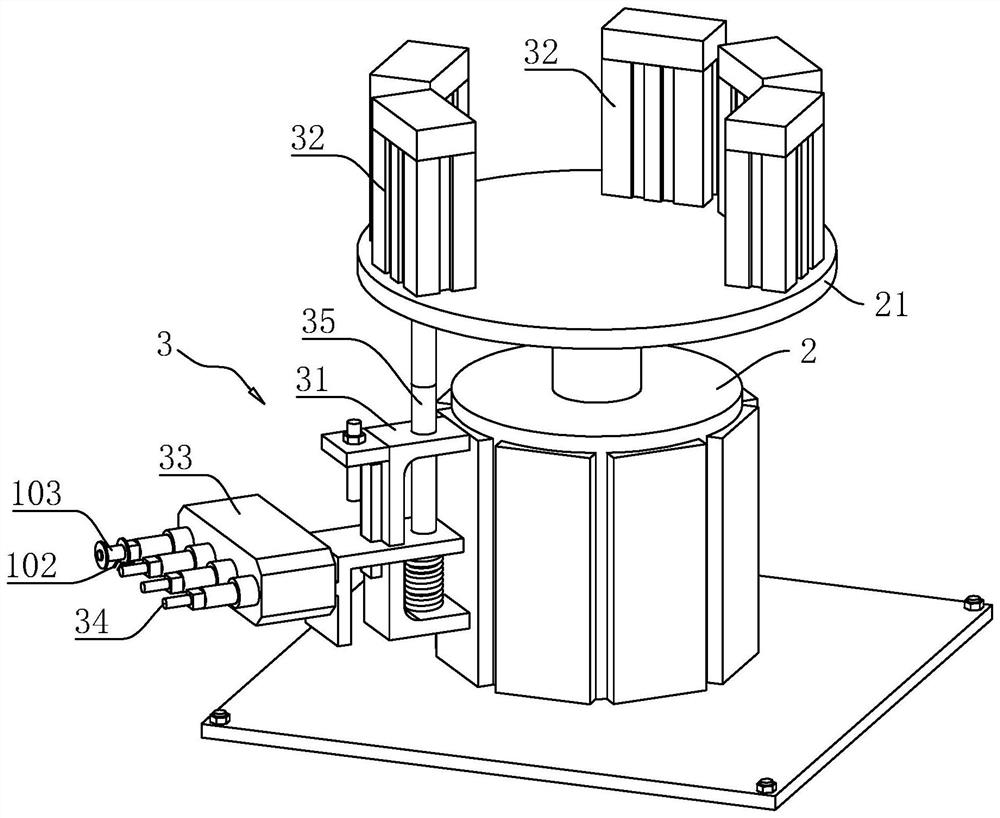

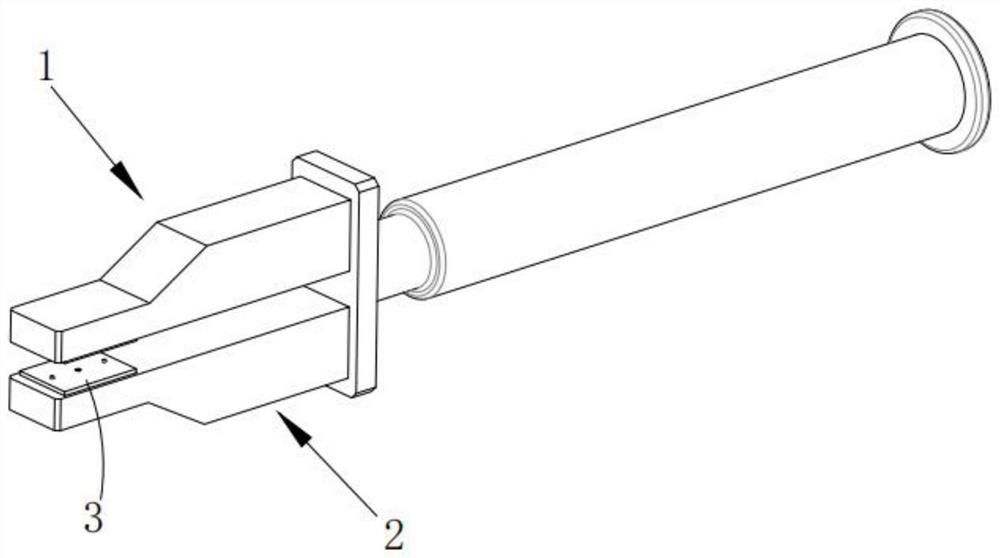

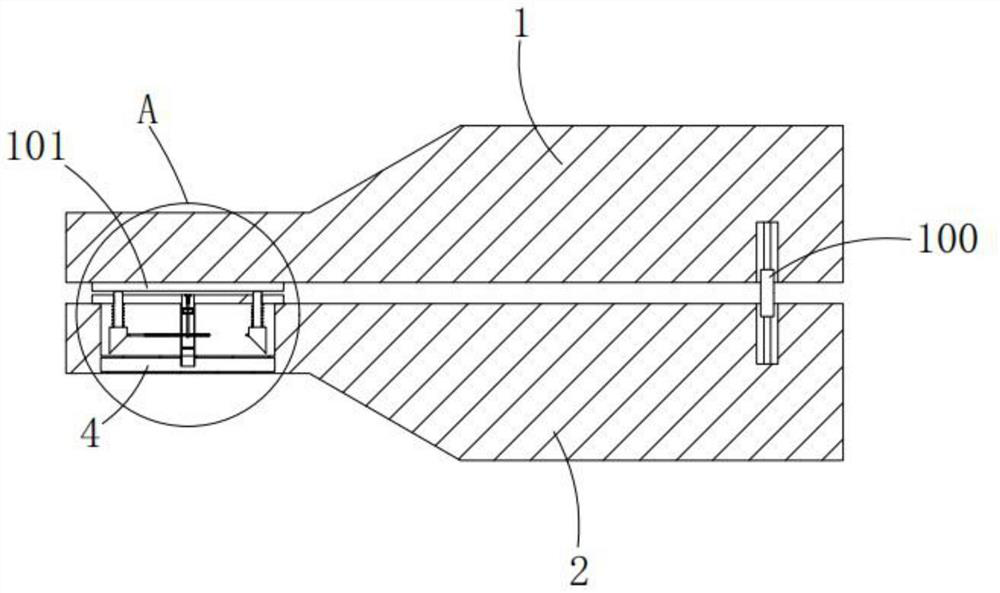

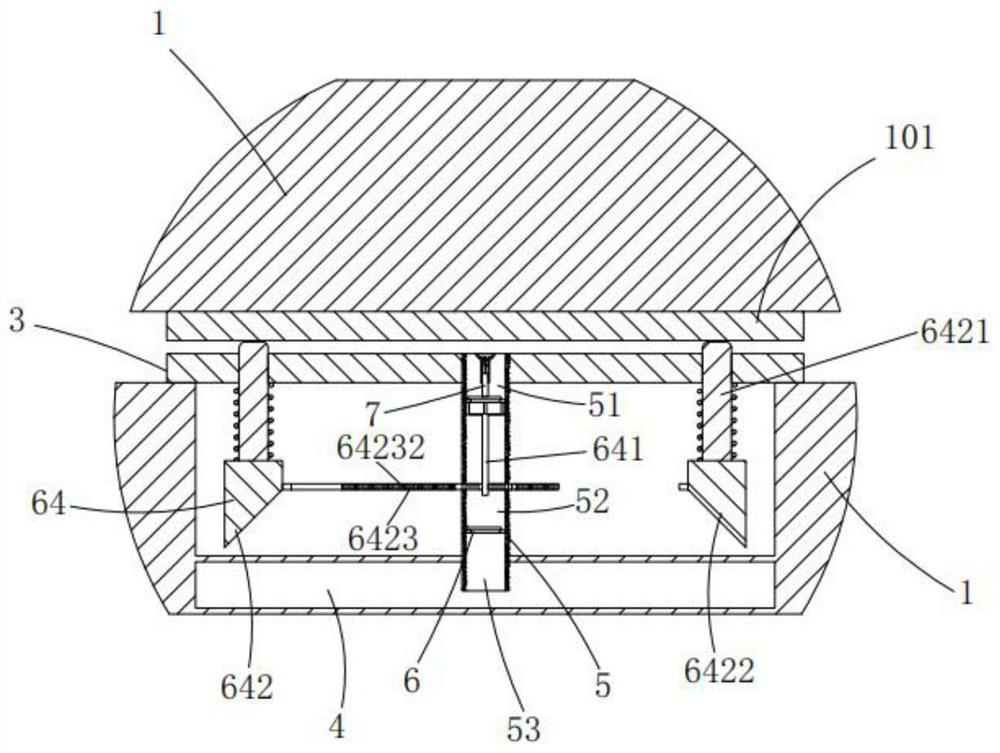

Automatic tin scraping machine and tin soldering device

InactiveCN104191062AScraping action standardReduce labor intensityMetal working apparatusSolder feeding devicesSolderingEngineering

The invention relates to the technical field of transformer production, in particular to an automatic tin scraping machine and a tin soldering device. The automatic tin scraping machine structurally comprises a time relay, a first air cylinder, a second air cylinder and a tin scraping mechanism, wherein the first air cylinder and the second air cylinder are controlled by the time relay, and the tin scraping mechanism is connected with the second air cylinder in a driving mode. The first air cylinder is connected with the second air cylinder in a driving mode and enables the second air cylinder to do lifting motion to drive the tin scraping mechanism to do lifting motion. The second air cylinder is provided with a second air cylinder rod and a second air cylinder plain shaft, and the second air cylinder rod and the second air cylinder plain shaft are connected with the tin scraping mechanism and enable the tin scraping mechanism to do horizontal motion. The tin soldering device comprises a machine frame, a tin smelting furnace arranged on the machine frame and the automatic tin scraping machine. The automatic tin scraping machine has the advantages that the tin scrapping movement is standard, the labor intensity is low, the tin scrapping effect is ideal and the production efficiency is high. The tin soldering device has the advantages that the tin soldering time and the tin soldering height are standard and the tin scrapping effect is good.

Owner:DONGGUAN DAZHONG ELECTRONICS

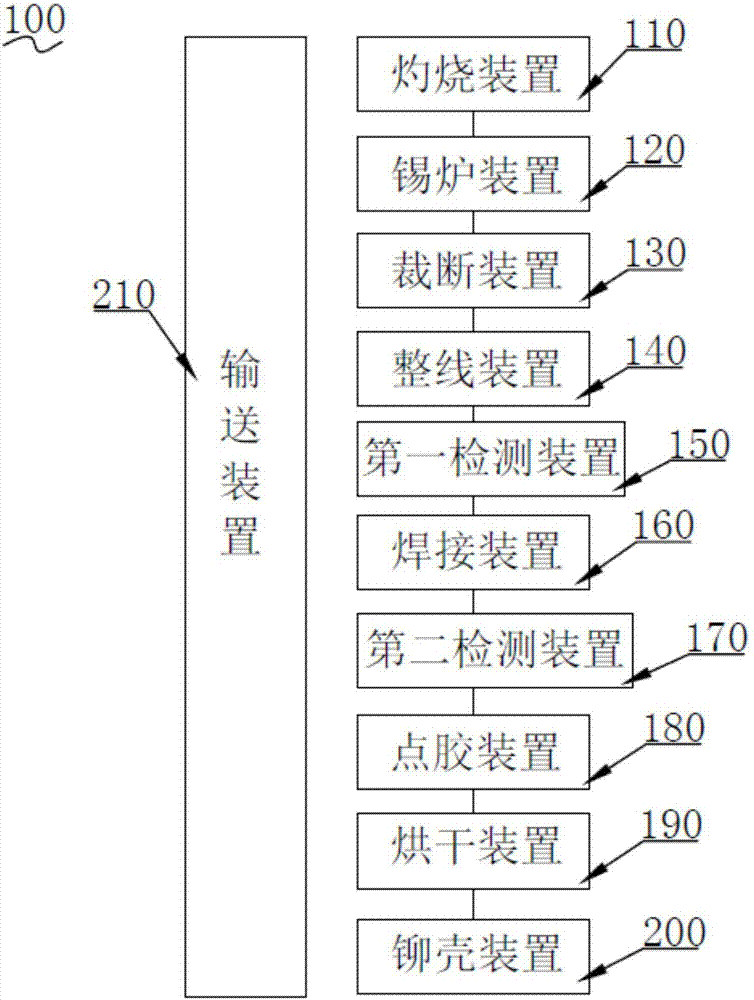

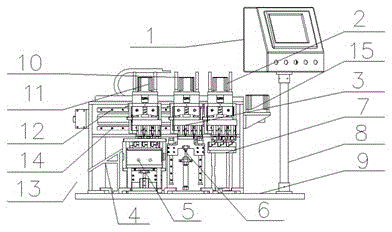

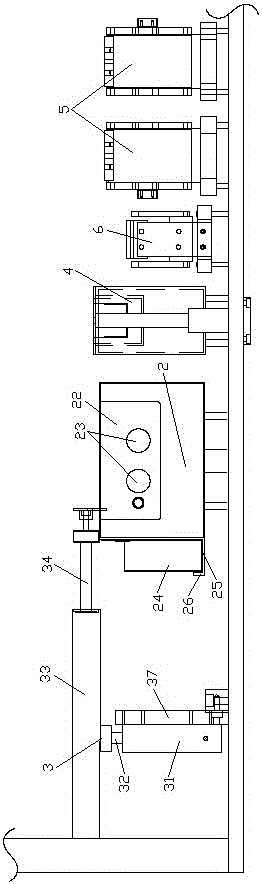

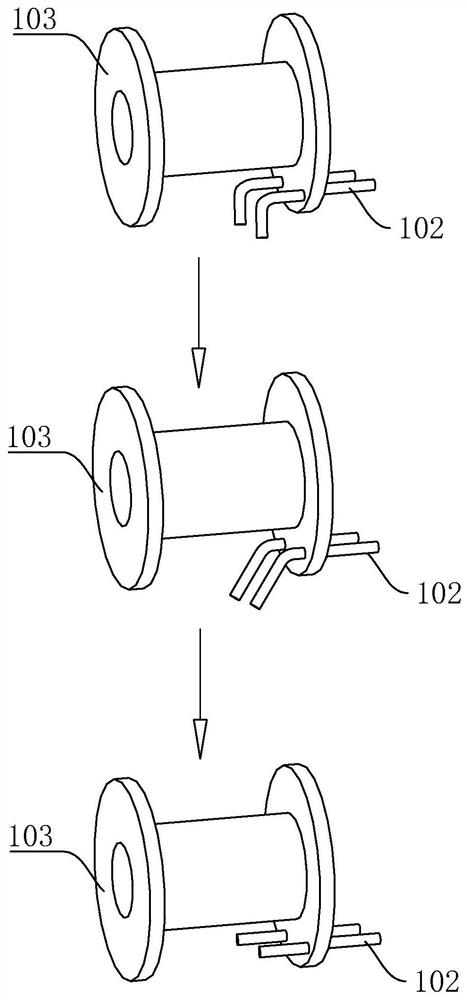

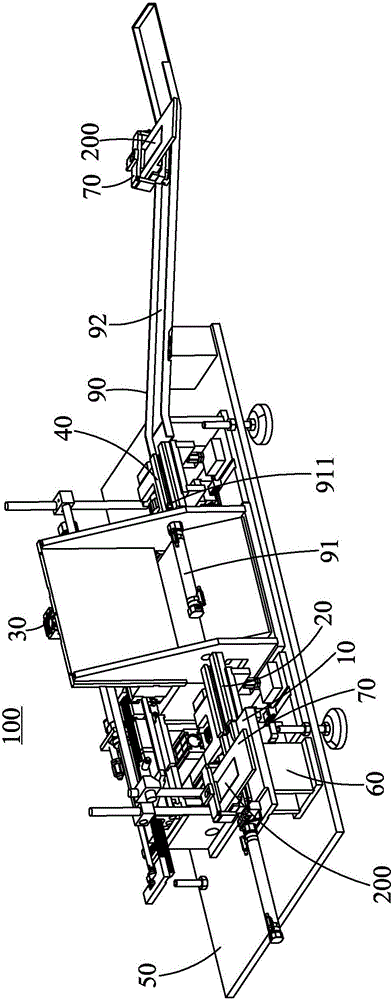

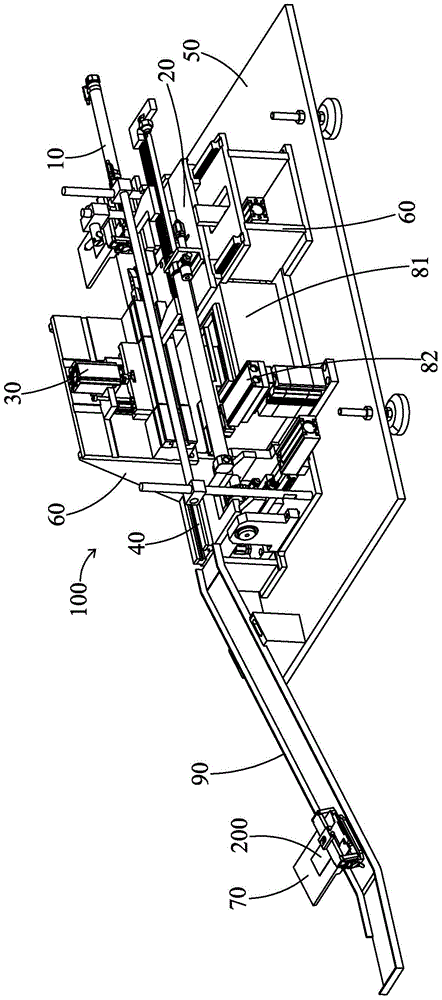

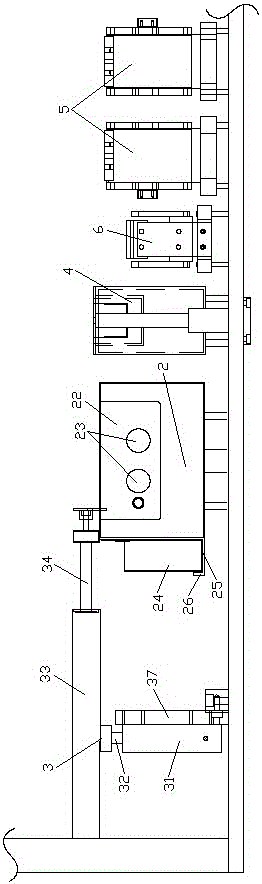

Dip soldering welding system for enamelled wire and operating method thereof

PendingCN107350589AImprove soldering effectUniform weldingMetal working apparatusSoldering auxillary devicesProduction lineDip soldering

The invention relates to the technical field of dip soldering welding of enamelled wires and in particular relates to a dip soldering welding system for enamelled wire and an operating method thereof. The system comprises a firing device for removing skin of the enamelled wire, a solder machine device for dipping tin of the enamelled wire, a cut-off device for cutting, a wire neatening device for neatening, a first detection device for detecting the enamelled wire, a welding device for welding, a second detection device for detection, a dispensing device for dispensing, a drying device for drying and a riveting cover device for riveting. The cost of manual detection can be effectively reduced. The operating method comprises the following steps: removing non-metal substances on the surface; immersing the enamelled wire into the solder machine device; cutting off the enamelled wire; neatening the enamelled wire; performing primary detection; welding a connector; performing secondary detection; performing dispersing; performing drying; and performing riveting forming. The cost of manual detection can be effectively lowered. Compared with an existing production line, the work efficiency can be increased by more than 3 times. The production efficiency is high. By immersing the enamelled wire into the solder machine to dip tin, tin is uniformly dipped, the production precision is high and the work efficiency is high.

Owner:DONGGUAN YINGTONG WIRE

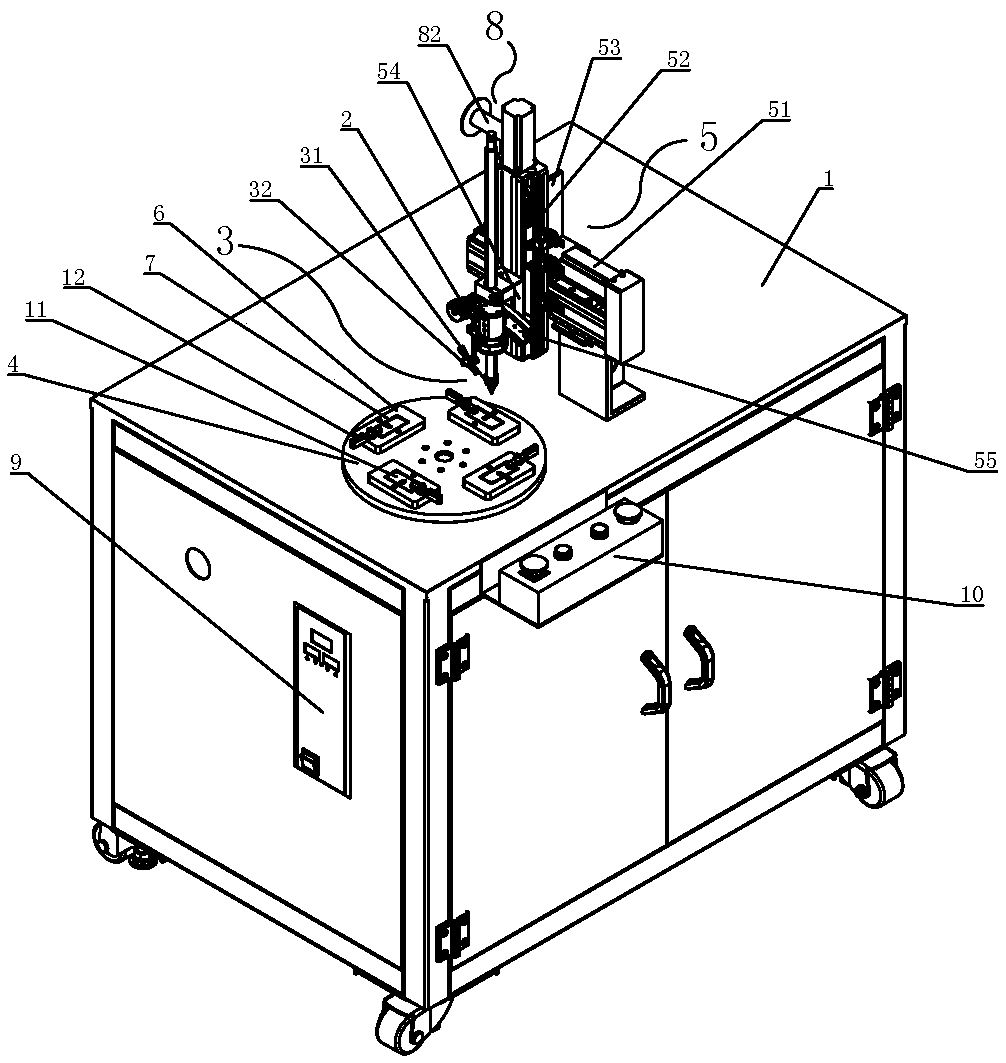

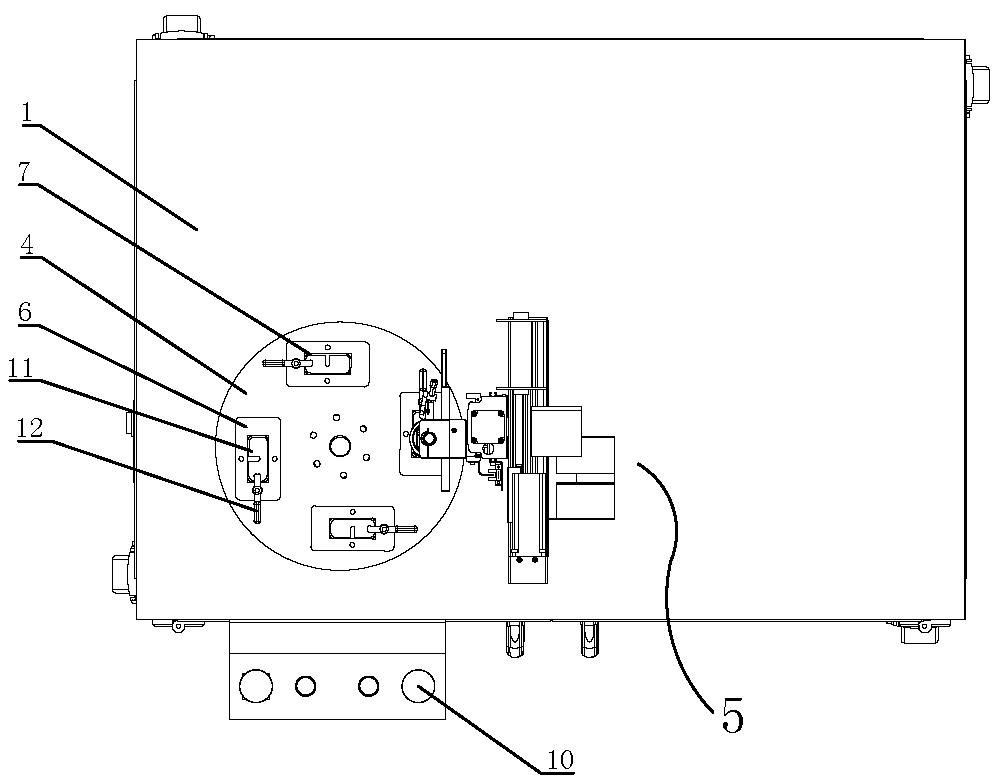

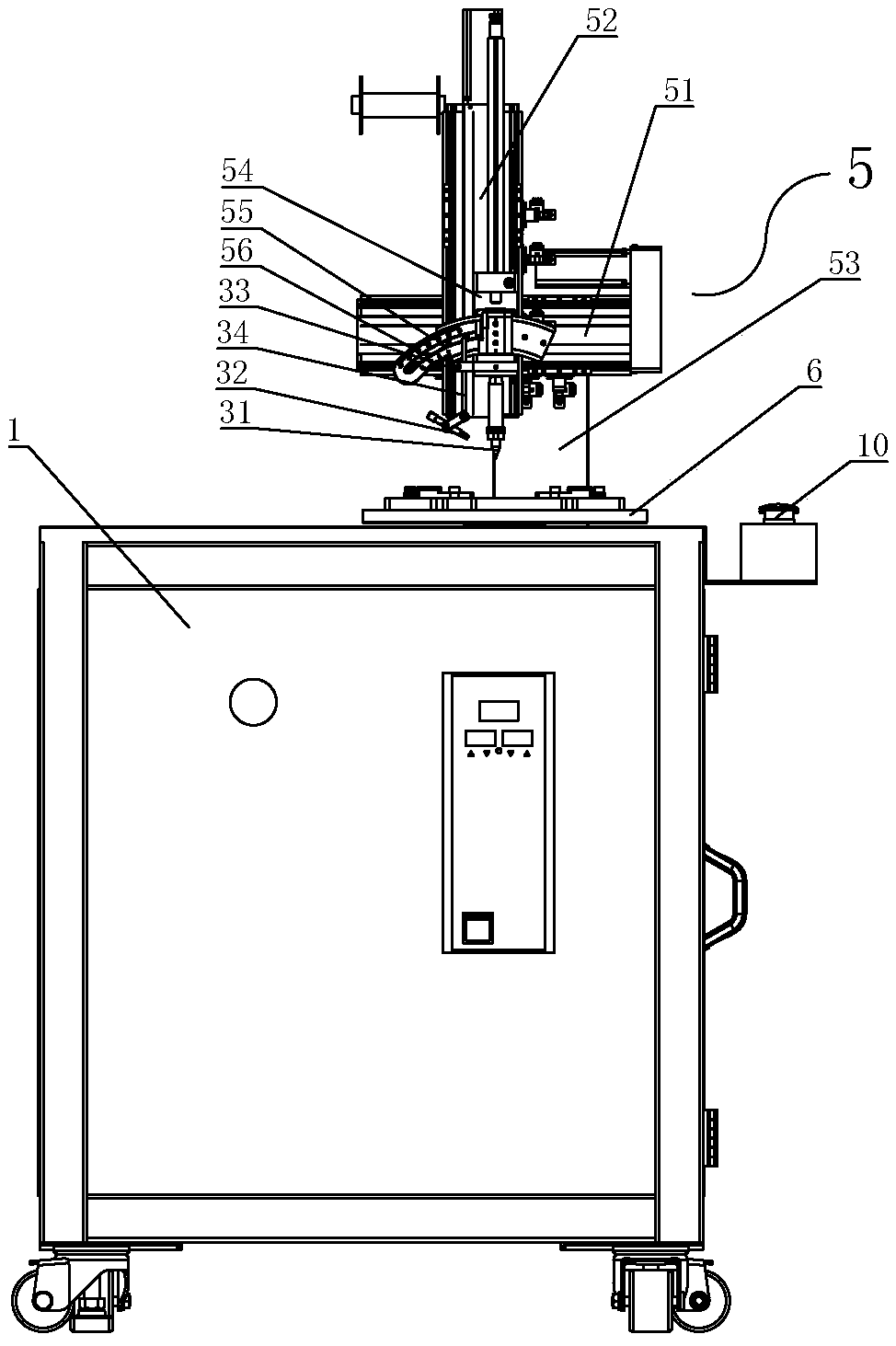

Tin soldering machine

InactiveCN108015375ARealize automatic positioningHigh soldering precisionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSlide plate

The invention provides an automatic tin soldering machine capable of conducting automatic angle adjusting and positioning on a soldering iron mechanism and high in soldering precision. The tin soldering machine comprises a workbench. The soldering iron mechanism is arranged on the workbench and comprises soldering iron arranged on a soldering iron support. A rotation disc is correspondingly arranged below the soldering iron and provided with product carriers. A tin feeding mechanism is arranged on one side of the soldering iron support. The soldering iron support is composed of a first moduleand a second module which are perpendicular in the vertical direction and the longitudinal direction. The first module is arranged at the top end of a supporting plate, and the second module is movably arranged on the first module through a sliding block. The first module and the second module are provided with drive devices connected with a circuit control device. A guide rail of the second module is provided with a sliding plate capable of sliding in the longitudinal direction, and the sliding plate is provided with an arc dividing ruler rotation disc, and an arc through hole corresponding to a dividing ruler is formed in the middle part of the sliding plate. A tin soldering head is movably arranged in the through hole through a clamping piece.

Owner:WUXI CHANGZHISHENG MACHINERY MFG CO LTD

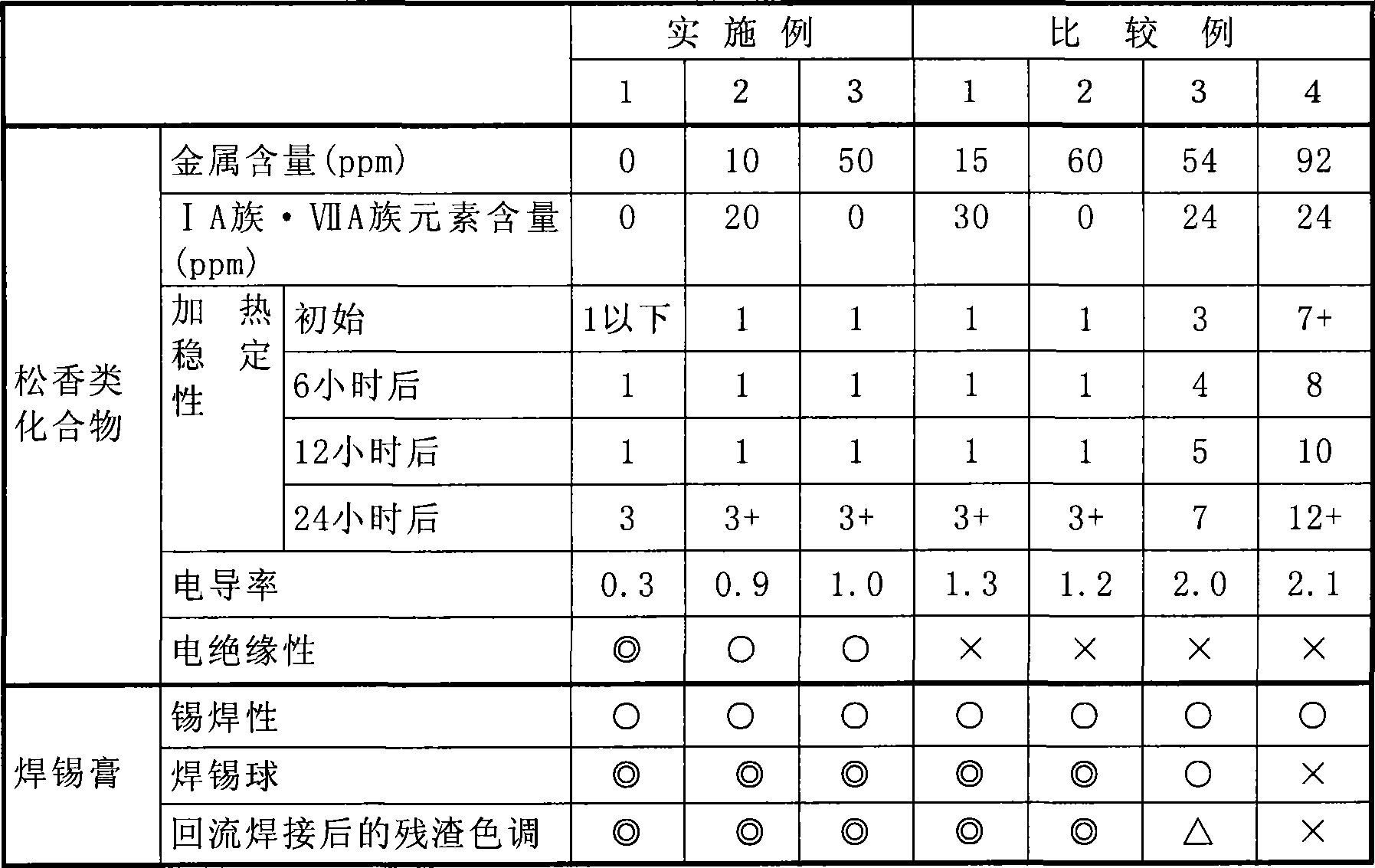

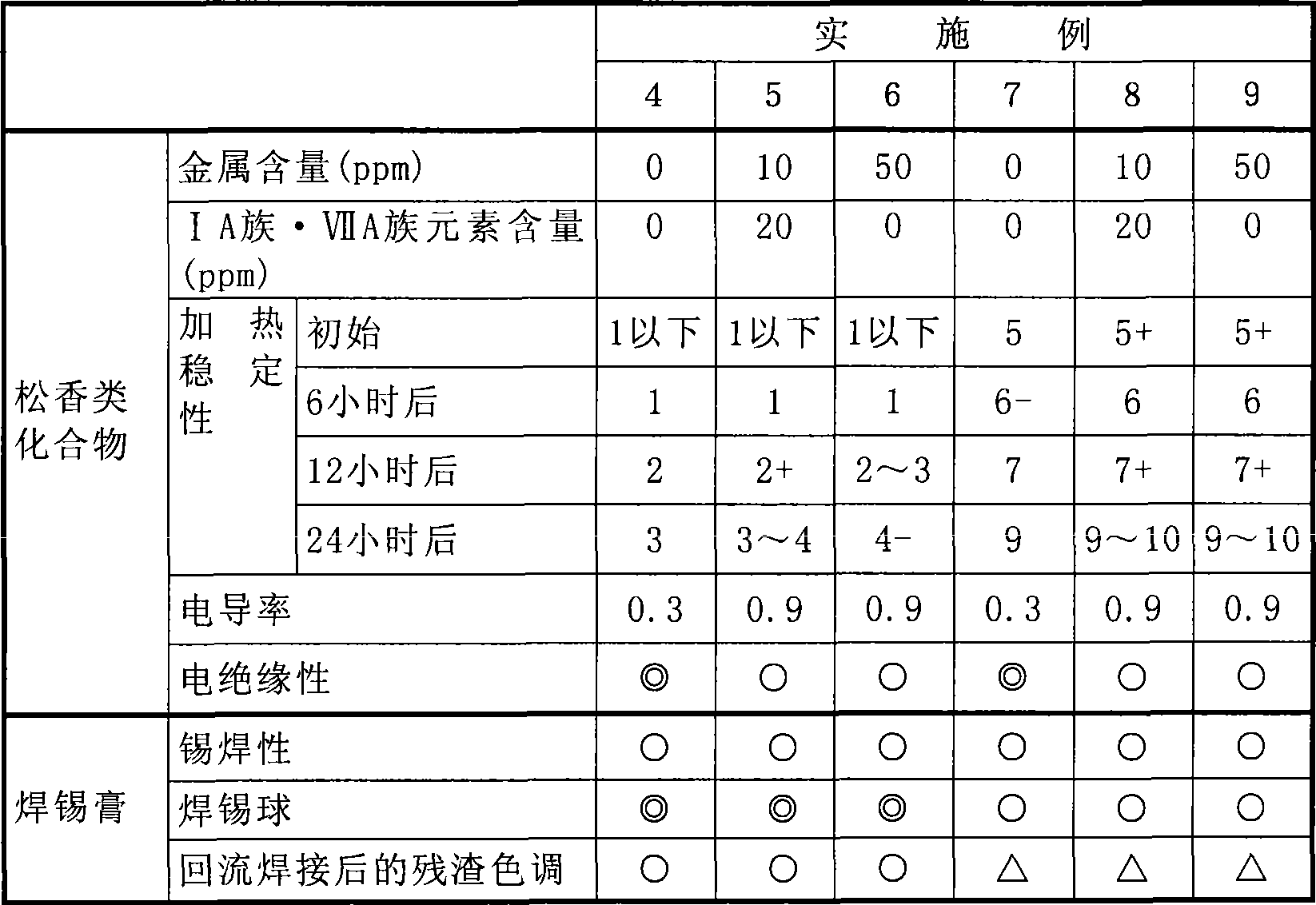

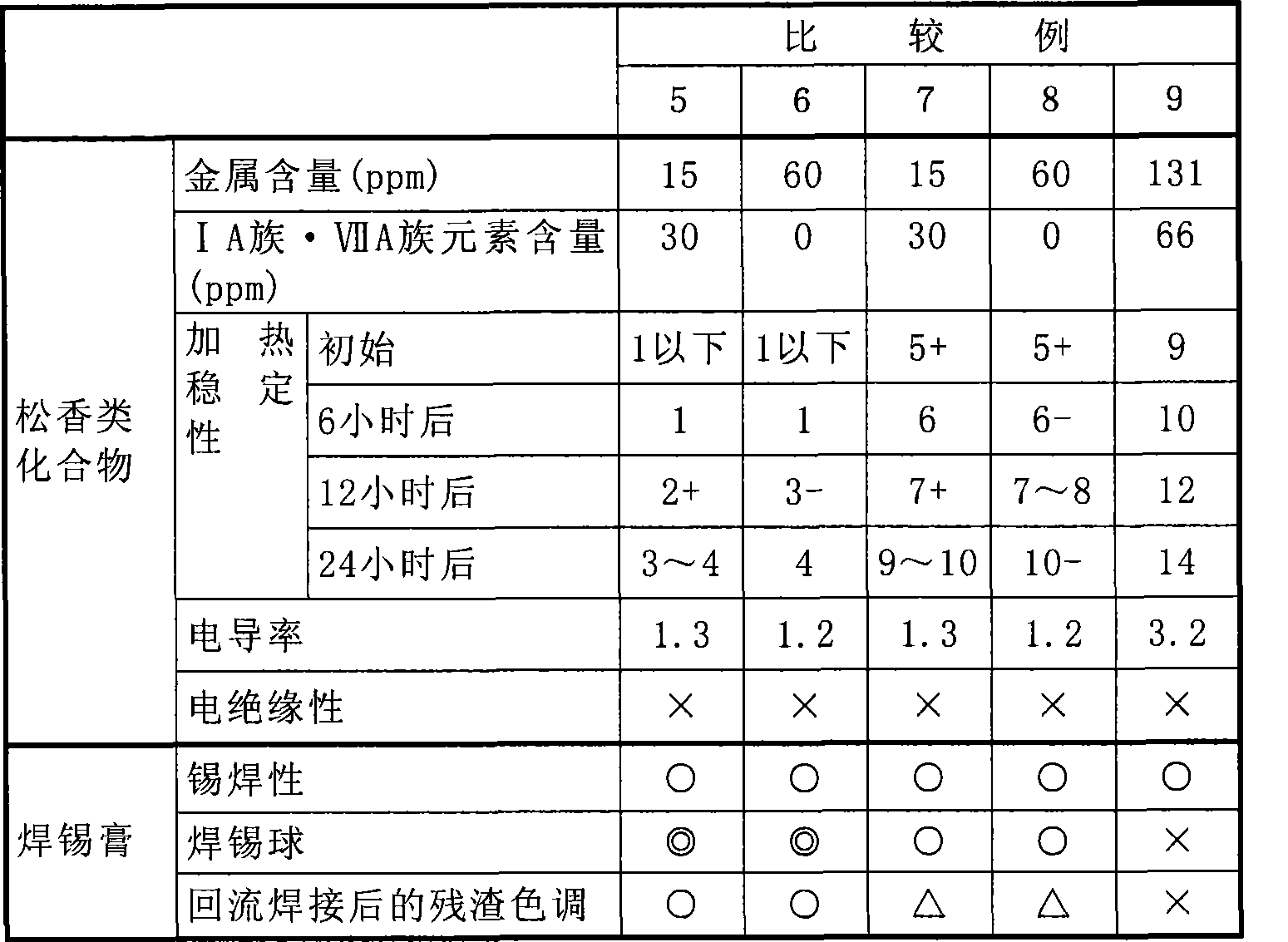

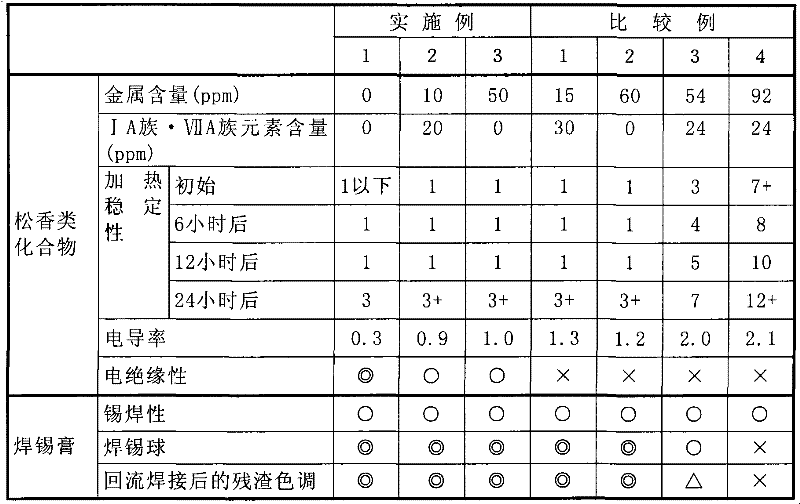

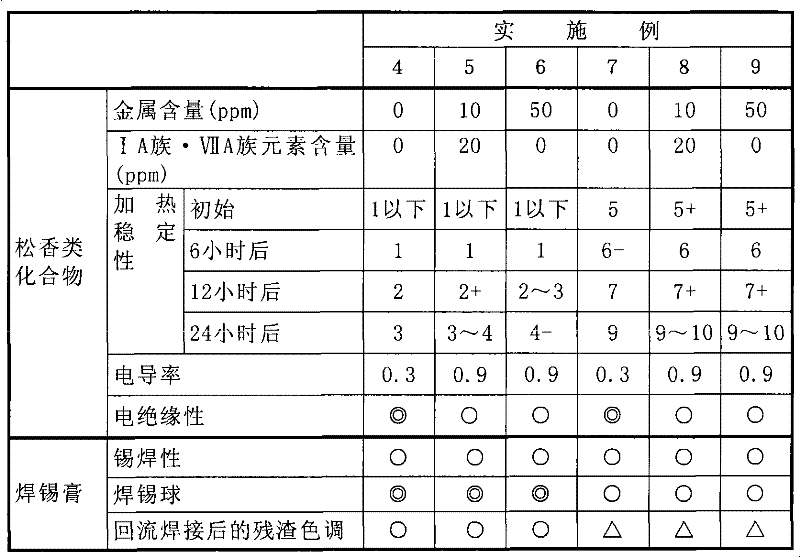

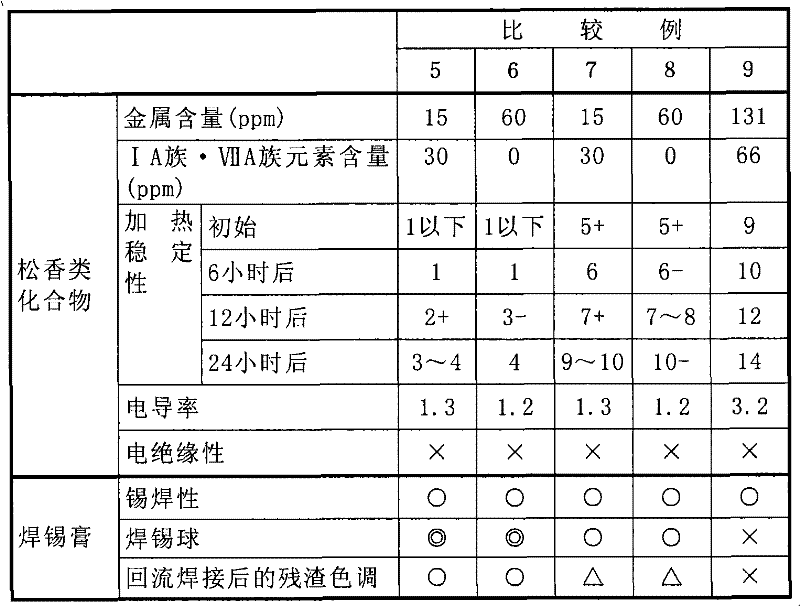

Soldering flux and soldering paste

ActiveCN101497155AImprove thermal stabilityReduce generationWelding/cutting media/materialsSoldering mediaSolderingElectrical resistivity and conductivity

Owner:ARAKAWA CHEM IND LTD

No-clean soldering flux and preparation method of no-clean soldering flux

InactiveCN103801857AReduce surface tensionEnhance surface wettingWelding/cutting media/materialsSoldering mediaOrganic acidRosin

The invention provides no-clean soldering flux which comprises, by mass, 1%-4% of organic acid activating agents, 0.5%-3% of non-ionic surface active agents, 0.1%-3% of antioxidants, 0.005%-0.02% of modified rosin and the balanced organic solvents. The invention further provides a preparation method of the no-clean soldering flux. The preparation method includes the steps of melting the modified rosin, sequentially adding the organic acid activating agents, the non-ionic surface active agents, the antioxidants and the organic solvents, evenly stirring the mixture, naturally cooling the mixture, filtering the mixture, and obtaining the no-clean soldering flux. According to the no-clean soldering flux, dilution and dilution control are not required, direct use can be achieved, heavy metal is not contained, and residues do not exist. The no-clean soldering flux has the advantages of being high in drying speed, bright and firm in soldering point, even in spreading, full in structure, free of corrosiveness, excellent in solderability, good in soldering smoothing performance, stable in performance and the like.

Owner:THE NORTHWEST MACHINE

Method for producing environment-friendly lead-free electroless nickel immersion gold

InactiveCN102877044ANo solder defect occursWon't decomposeLiquid/solution decomposition chemical coatingElectroless nickel immersion goldSolder mask

The invention provides a method for producing environment-friendly lead-free electroless nickel immersion gold. The method comprises the following steps of: etching a line, and treating a circuit board by using solder mask ink; performing pretreatment, namely polishing and brushing or blasting sand; placing the circuit board in an oil removal trough and treating for 5 minutes; washing by using tap water and conveying into a microetching trough for 2 minutes; washing by using deionized water, and feeding into a preimpregnation trough for 1 minute; directly feeding into an activation trough and treating for 1 minute; washing by using the deionized water, and treating in chemical nickel at the temperature of 80 DEG C for 20 minutes; and washing by using the deionized water, and treating in immersion gold which is prepared from 10 percent KOZO 806 and citric acid gold with density of 2g / L. By the method, the technical problem that the conventional production method is not environment-friendly can be solved; lead in the chemical nickel is replaced and is totally environment-friendly; and the condition that tin is not soldered well can be avoided. The toxic potassium aurous cyanide in the immersion gold is replaced, and the immersion gold is totally environment-friendly; and a solution is stable and is prevented from being decomposed.

Owner:湖南领湃科技股份有限公司

Bromide soldering flux for copper-aluminum soldering

InactiveCN102218625AImprove pass rateFast consumptionWelding/cutting media/materialsSoldering mediaZinc bromideSodium fluoride

The invention discloses a bromide soldering flux for copper-aluminum soldering. The bromide soldering flux comprises a substrate, a solvent and a film removal agent; according to weight percentage, zinc bromide (ZnBr2) serving as the substrate accounts for about 24 to 25 percent, ammonium bromide (NH4Br) serving as the solvent accounts for about 74 to 75 percent, and sodium fluoride serving as the film removal agent accounts for about 1 to 2 percent. The prepared bromide soldering flux has the characteristics of fast consumption in a soldering process and low postwelding residue, and can avoid corrosion of a copper-aluminum joint caused by the residual soldering flux after welding. Moreover, the service life of the copper-aluminum soldering joint prepared from stannum, zinc and copper soldering flux reaches more than 14 years, and the bromide soldering flux is applicable for the environment of an air conditioner refrigeration pipeline.

Owner:GUANGDONG HANGJI METAL PRODUCT INDUSTRIES CO LTD

Soldering machine for manganese-copper terminals

InactiveCN105057831AEasy to operateReasonable structural designMetal working apparatusSolder feeding devicesElectric machineManganese

The invention discloses a soldering machine for manganese-copper terminals. The soldering machine for the manganese-copper terminals comprises a body which comprises a control box, a base, a first transfer motor and a second transfer motor. The base is arranged under the body; the control box is arranged on the surface of the base, and a rosin feeding work table is arranged on the left side of the control box; a manual discharging table is arranged on the right side of the rosin feeding work table; the first transfer motor is arranged above the rosin feeding work table; the second transfer motor and a third transfer motor are arranged on the left side of the first transfer motor; the output portions of the first transfer motor, the second transfer motor and the third transfer motor are connected with a transfer mechanism; a soldering furnace is arranged on the left side of the rosin feeding work table; buffering rails are arranged on the upper portion of the soldering furnace and comprise the first buffering rail and the second buffering rail; and a discharging rail is arranged on the left side of the soldering furnace. The soldering machine for the manganese-copper terminals has the advantages of being reasonable in structural design, convenient to use, good in soldering effect and the like.

Owner:MINGGUANG WANJIA LIANZHONG ELECTRONICS

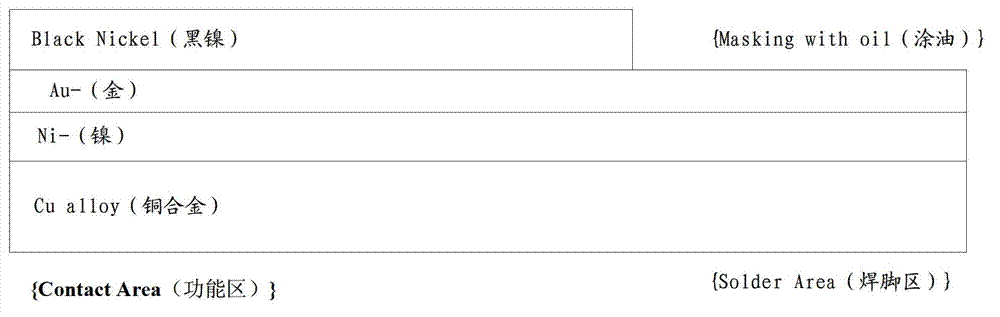

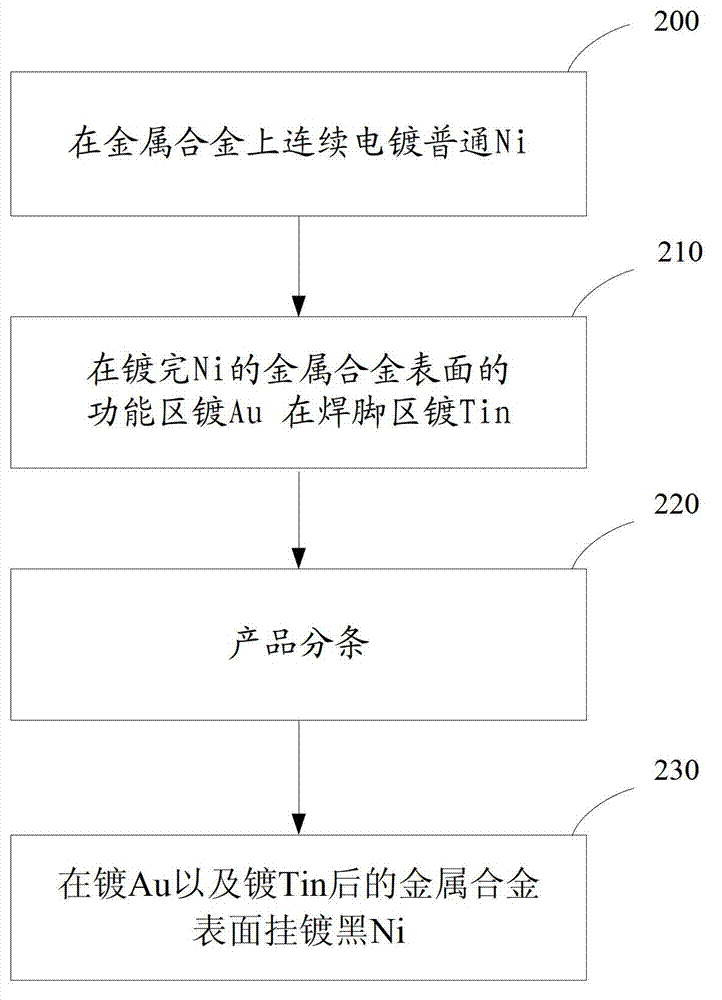

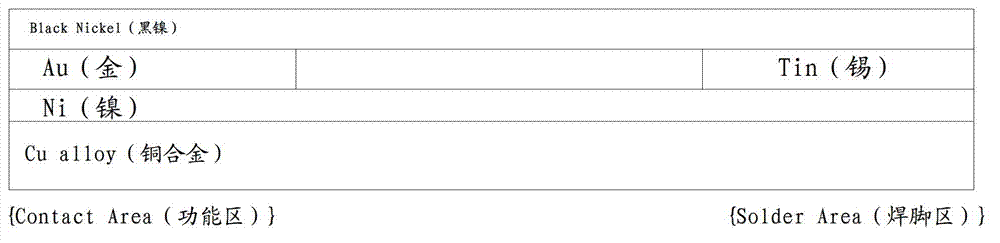

Production method and products of metal exposed terminals

ActiveCN102851714AImprove soldering effectLow priceElectrically conductive connectionsNickelMetal alloy

The invention discloses a production method and products of metal exposed terminals. The production method includes: making the metal exposed terminals by new manufacturing process, namely plating a functional area of metal alloy with Au, plating a weld leg area with metal for enhancing solderability. In other words, the metal for enhancing solderability replaces part of plated Au, and a layer of black Ni is plated on the surface of the metal alloy plated with the Au and the metal for enhancing solderability by rack plating. Therefore the function and appearance requirements of the metal exposed terminals are met, production efficiency of the metal exposed terminals is improved, the cost is lowered, and benefit is created. According to related production and applications, the treatment cost of the metal exposed terminals can be reduced by about 50% by improving the production efficiency and saving precious metals.

Owner:XIAOMI INC

Cable weaving tin dipping device and method

ActiveCN104002006ASame lengthImprove soldering effectLine/current collector detailsSolder feeding devicesEngineeringMechanical engineering

The invention relates to a cable weaving tin dipping device which comprises a base, a support, a tray, a location carrier, a tin furnace and a plurality of cylinders. The support is installed on the base, the tin furnace is arranged on the base and used for containing a tin material, the tray is installed on the support and used for placing a cable, the location carrier is located under the tray and used for clamping and fixing the cable, the tail of the cable stretches downwards out of the location carrier, and the weaving portion on the tail is exposed to the outer portion. The device is characterized by further comprising a tin spoon located above the tin furnace and connected with one cylinder, the tin spoon is located in a tin material in the tin furnace, the tin spoon can move upwards out of the tin furnace under the driving of the cylinder, the location carrier is connected with another cylinder, the cylinder can drive the location carrier to move downwards to drive the tail portion of the cable to be immersed into the tin material of the tin spoon and then move upwards out of the tin spoon, the tin spoon contains the tin material of identical quantity every time, and the tin dipping length of the front and the back of the cable is consistent.

Owner:KUNSHAN XUNTAO PRECISION MACHINERY

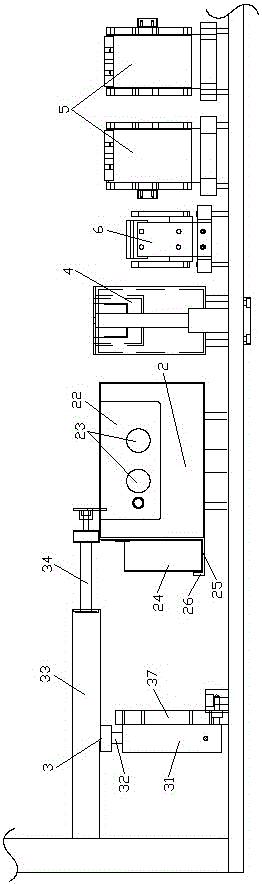

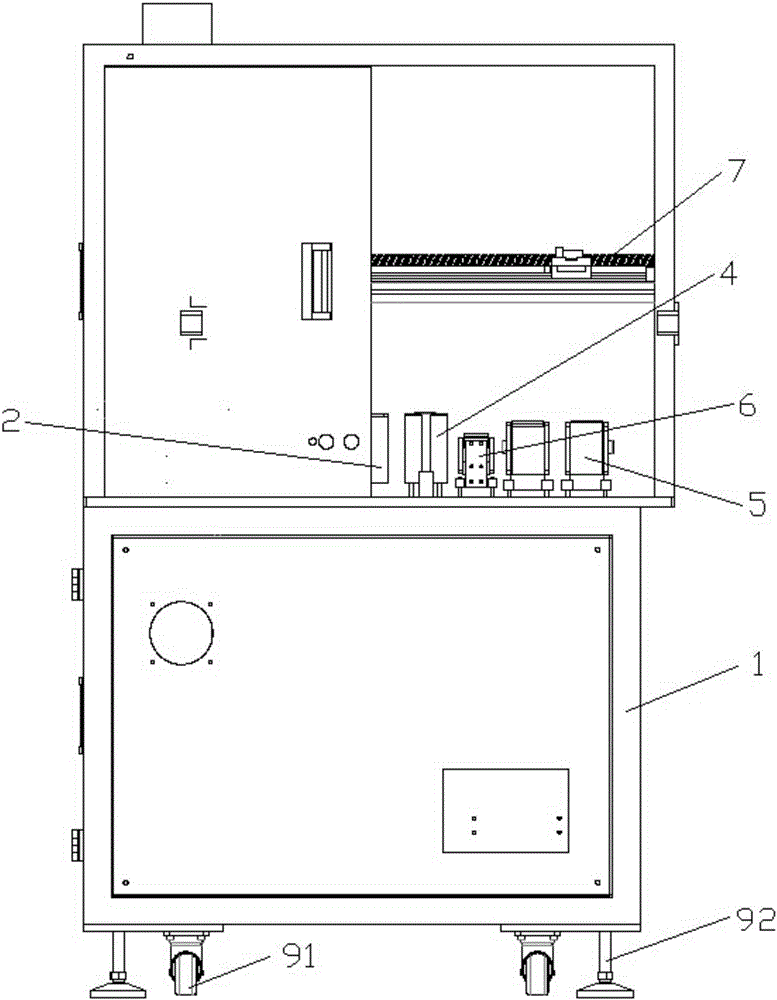

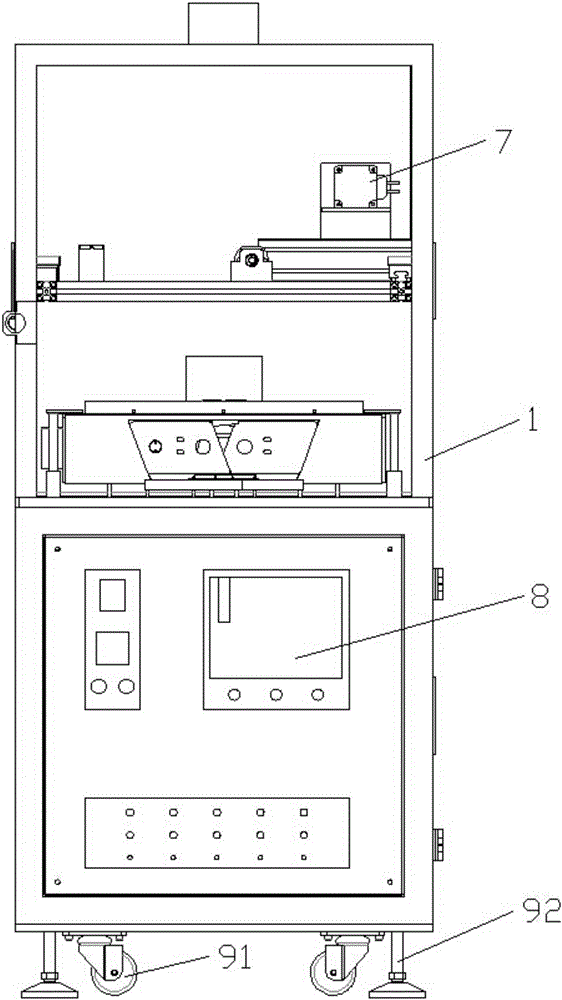

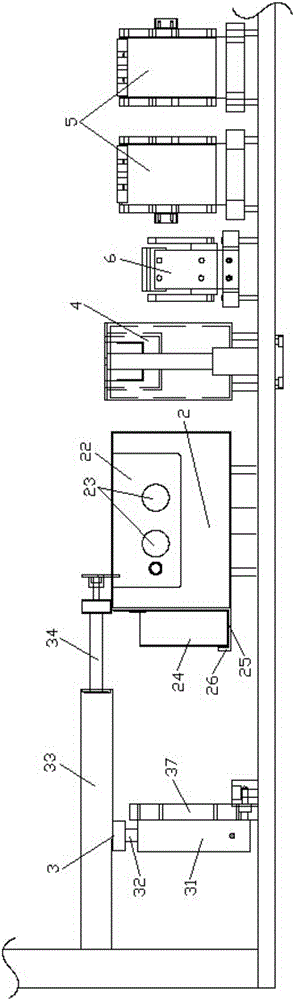

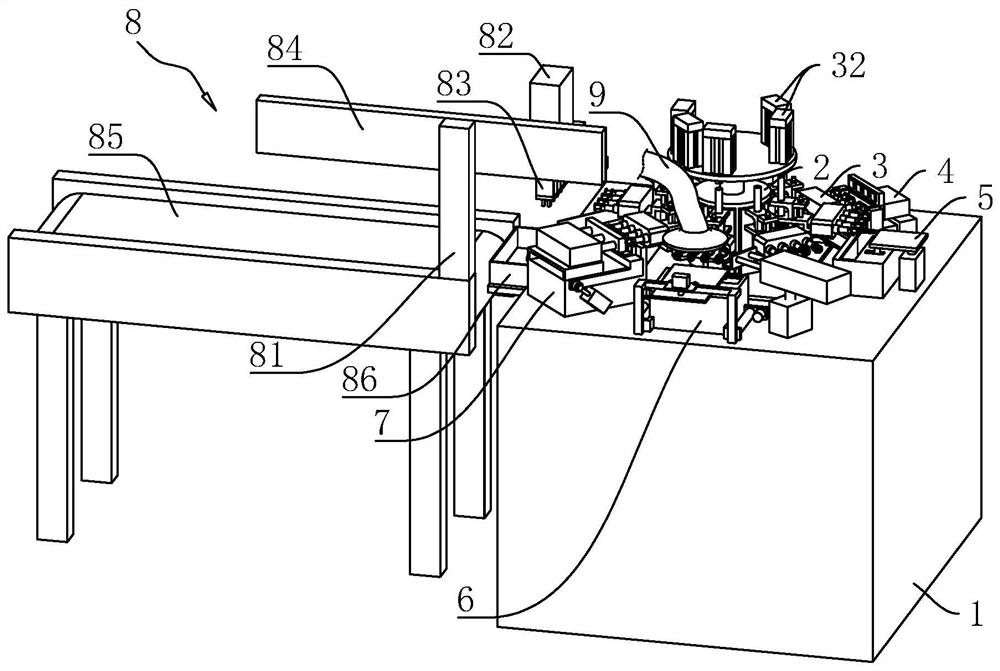

Full-automatic tinning machine used for tinning of induction transformer

InactiveCN105904057AReasonable designDesign scienceWelding/soldering/cutting articlesMetal working apparatusTinningTransformer

The invention relates to a full-automatic tinning machine used for tinning of an induction transformer. Currently, a tinning machine suitable for conducting tinning operation on the induction transformer is unavailable. The full-automatic tinning machine comprises a machine frame, a tin melting device, a tin slag scraping device, a flux containing device, an induction transformer input device, an induction transformer output device and an induction transformer grabbing and tinning device. The full-automatic tinning machine is characterized in that the tin melting device further comprises a tin slag guiding-in piece and a tin slag collecting tank; the upper portion of the tin slag guiding-in piece is fixed to the furnace wall, where a tin slag outlet is formed, of a tin furnace body; the tin slag scraping device comprises a tin slag scraper, a vertical cylinder and a horizontal cylinder; and the tin slag scraping device, the tin melting device, the flux containing device, the induction transformer output device and the induction transformer input device are sequentially arranged in the horizontal direction. By the adoption of the full-automatic tinning machine, the tin slag in a tin melting cavity can be efficiently and thoroughly scraped into the tin slag collecting tank.

Owner:TONGXIANG YAORUN ELECTRONICS

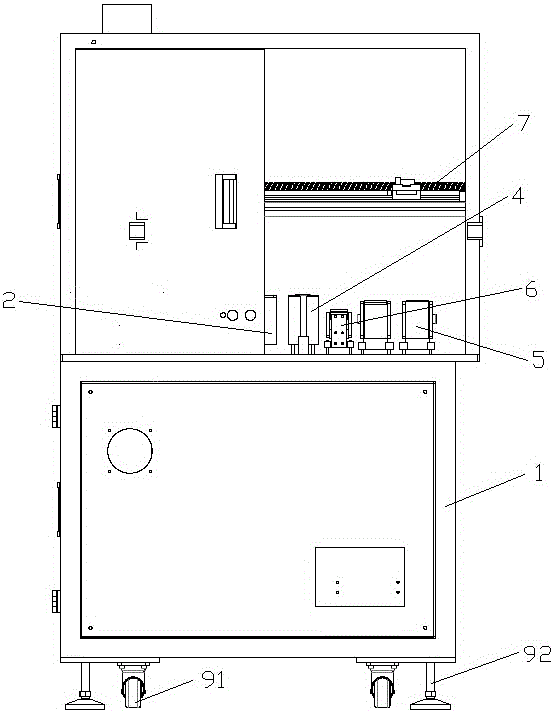

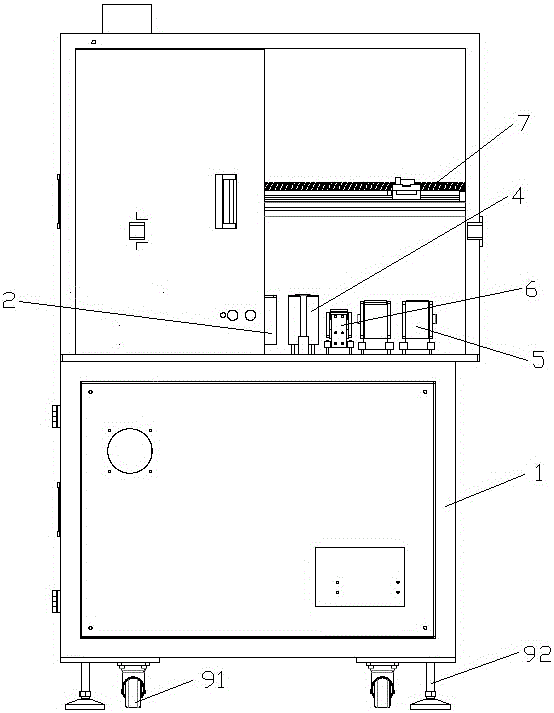

Automatic tinning machine for induction transformer

InactiveCN105904055AReasonable designDesign scienceHeating appliancesWelding/soldering/cutting articlesTinningTransformer

The invention relates to an automatic tinning machine for an induction transformer. Currently, a tinning machine suitable for conducting tinning operation on the induction transformer is unavailable. The automatic tinning machine comprises a machine frame, a tin melting device, a flux containing device, an induction transformer input device, an induction transformer output device and an induction transformer grabbing and tinning device. The tin melting device comprises a tin furnace body and an electric heating pipe. The tin furnace body is provided with a tin melting cavity. The automatic tinning machine is characterized in that the tin melting device further comprises a tin slag collecting tank, a collecting tank supporting platform and a collecting tank limiting bar; the tin furnace body is provided with a tin slag outlet; the length of the tin slag outlet is identical to that of the tin melting cavity; the collecting tank limiting bar is fixed to the collecting tank supporting platform; and the tin melting device, the flux containing device, the induction transformer output device and the induction transformer input device are sequentially arranged in the horizontal direction. By the adoption of the automatic tinning machine, the tin slag in the tin melting cavity can be efficiently, thoroughly and effectively scraped into the tin slag collecting tank.

Owner:TONGXIANG YAORUN ELECTRONICS

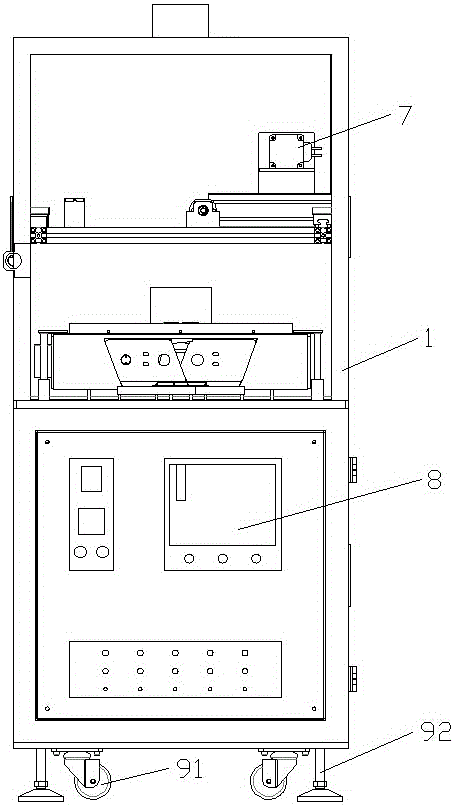

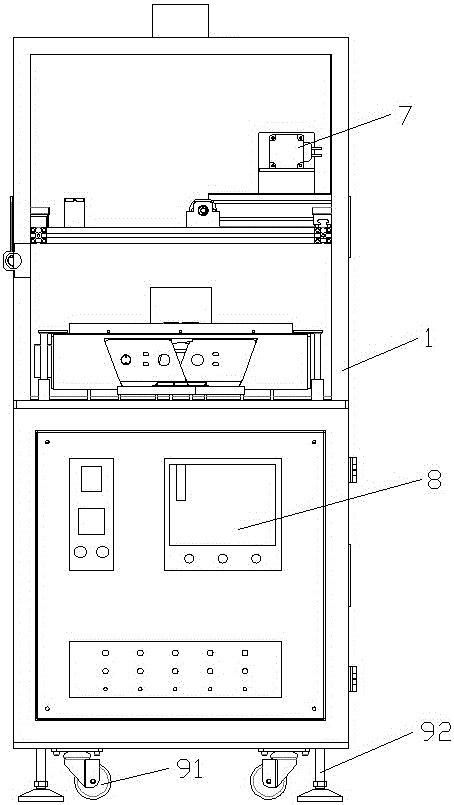

Automatic tin dipping machine used for tin dipping of induction transformer

InactiveCN106112185AReasonable designDesign scienceWelding/soldering/cutting articlesMetal working apparatusSlagTransformer

The invention relates to an automatic tin dipping machine for dipping an inductance transformer. At present, there is no tin dipping machine suitable for dipping inductance transformers. The invention includes a machine frame, a tin melting device, a tin slag scraping device, a flux containing device, an inductance transformer input device, an inductance transformer output device and an inductance transformer grabbing and dipping device, and is characterized in that the tin melting device includes a tin slag importing device The top of a furnace wall of the tin furnace body is provided with a tin slag outlet, and the upper part of the tin slag introducing sheet is fixed on the furnace wall where the tin furnace body is provided with a tin slag outlet; the tin slag scraping device includes a tin The slag scraper, the vertical cylinder and the horizontal cylinder, the tin slag scraper device, the tin melting device, the flux containing device, the inductance transformer output device and the inductance transformer input device are arranged in sequence in the horizontal direction. The invention can efficiently, thoroughly and effectively scrape the tin slag in the tin melting cavity into the tin slag collecting tank.

Owner:TONGXIANG YAORUN ELECTRONICS

Automatic soldering furnace

InactiveCN105401112AEasy to control immersion tin timeDepth is easy to controlHot-dipping/immersion processesSolderingMechanical engineering

The invention provides an automatic soldering furnace, and belongs to the technical field of hot dipping. According to the automatic soldering furnace, the problems that the soldering length is hard to control, and the fluctuation of the tin liquor surface is large are solved in the prior art. The automatic soldering furnace comprises a machine frame, a telescoping mechanism, a mechanical arm and a soldering furnace body. The telescoping mechanism is installed on the machine frame. The mechanical arm is connected to an output shaft of the telescoping mechanism, and a workpiece is clamped onto the mechanical arm. The soldering furnace body is installed on the machine frame, and an open smelting cavity is formed in the soldering furnace body. The telescoping mechanism pushes the mechanical arm to move, and the workpiece moves along with the mechanical arm, so that the tin soldering part of the workpiece is dipped in the smelting cavity. The automatic soldering furnace has the advantages of being good in tin dipping effect and high in production efficiency.

Owner:NINGBO NEW GUANLIAN MOTOR ELECTRONICS

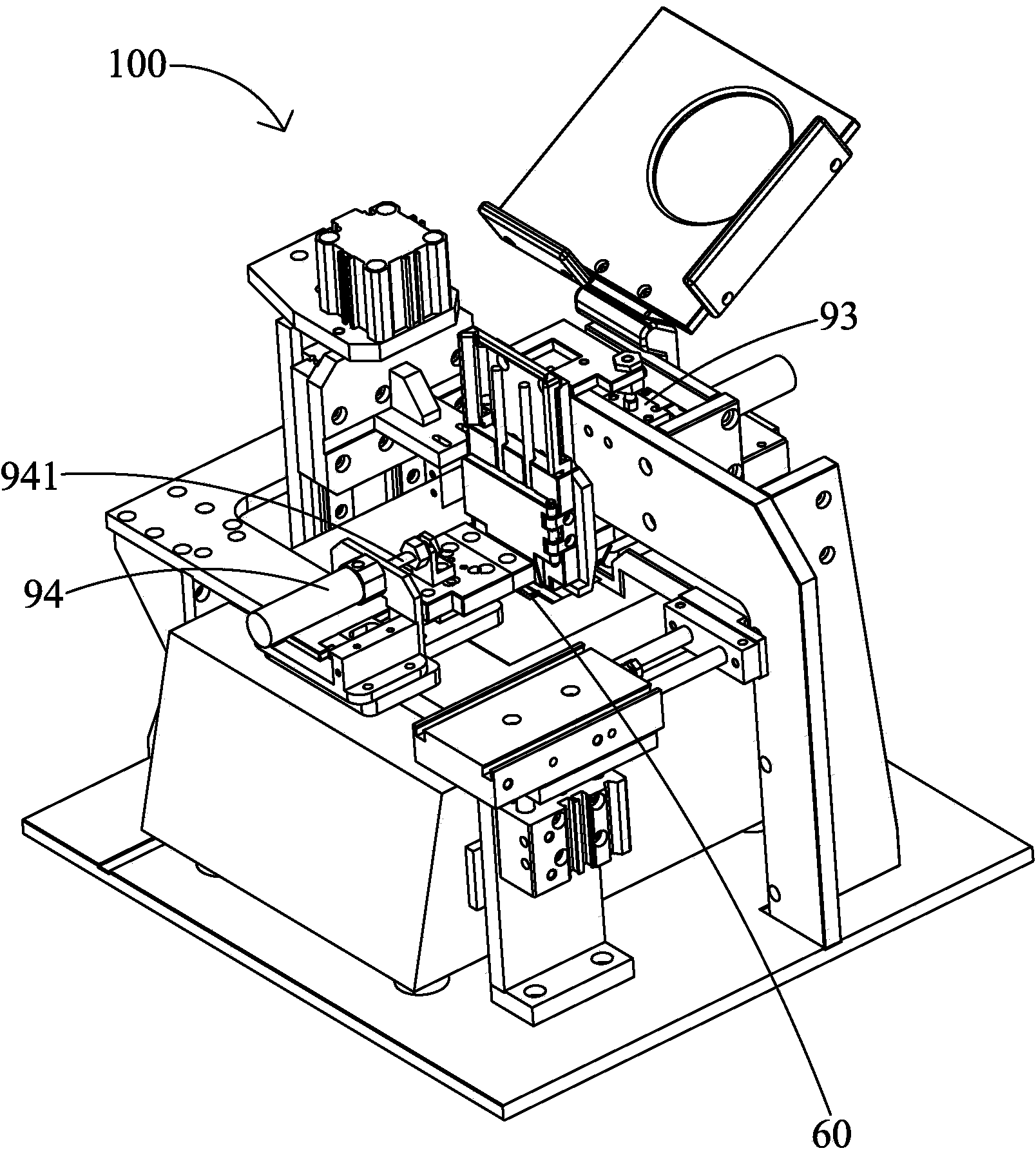

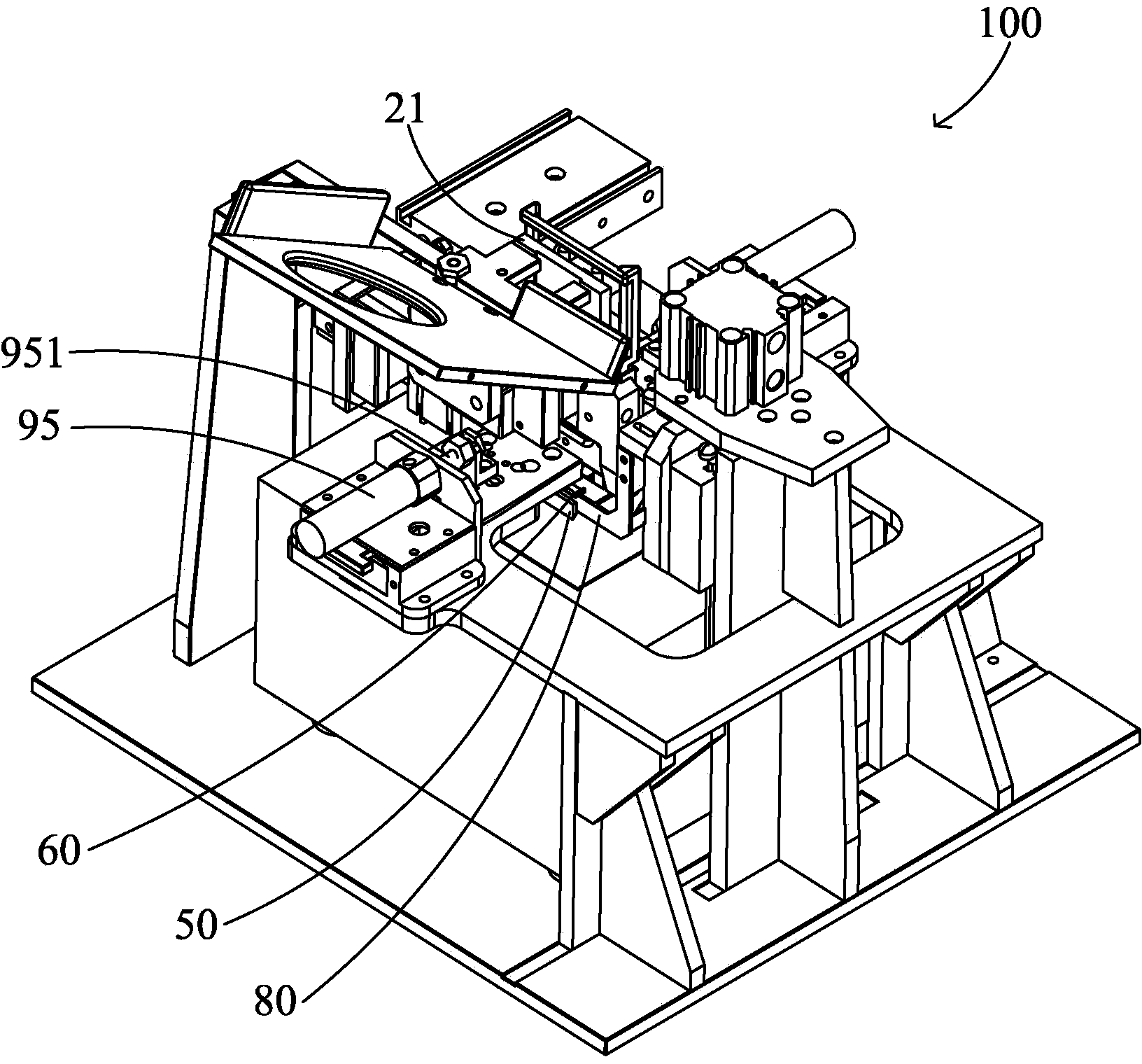

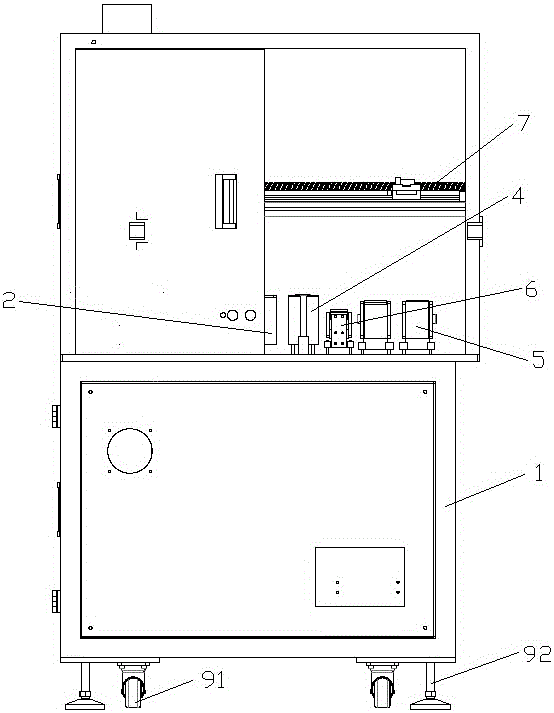

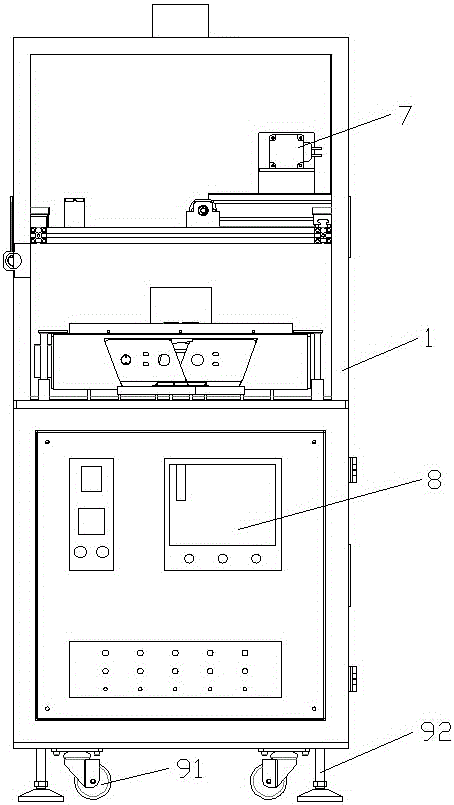

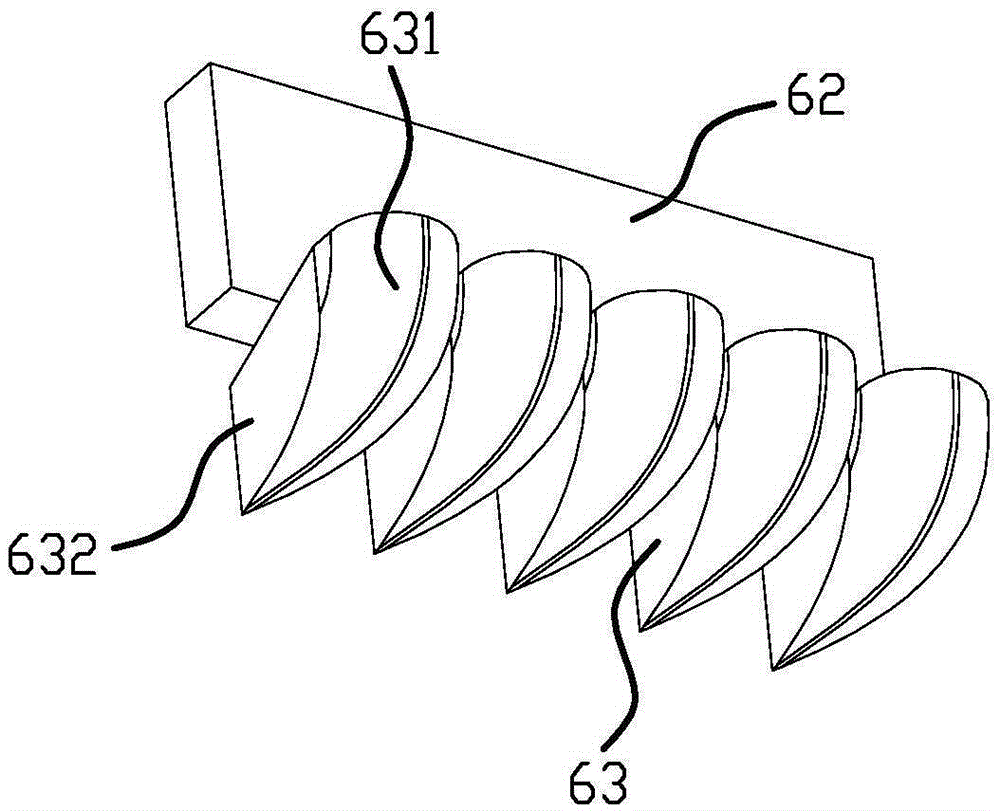

Welding system of relay coil processing device

ActiveCN113070684AImprove yield rateImprove soldering effectOther manufacturing equipments/toolsSolder feeding devicesMechanical engineeringPhysics

The invention relates to a welding system of a relay coil processing device, and relates to the field of relay production equipment. The welding system of the relay coil processing device comprises a rack, wherein a rotating shaft is rotatably assembled on the rack; multiple clamping mechanisms are arranged on the rotating shaft at intervals in the circumferential direction; a semi-bending mechanism, a soldering flux dipping mechanism, a tinning mechanism, a flattening mechanism and a discharging detection mechanism are sequentially arranged on the periphery of the rotating shaft of the rack; the semi-bending mechanism comprises a first base, a first abutting plate, bending rollers, a plate power piece and a roller power piece; the first base is arranged on the rack; the plate power piece is arranged on the first base; the first abutting plate is arranged at the output end of the plate power piece so as to be driven to abut against coils on the clamping mechanisms; the roller power piece is arranged on the first base; the bending rollers are arranged at the output end of the roller power piece so as to be driven to bend pins on the coils into a half-bent state; and the pins are bent flatly in two times and are not prone to being broken, so that the welding system of the relay coil processing device has the effect of being high in yield of coil production.

Owner:WANGRONG ELECTRONICS SHENZHEN

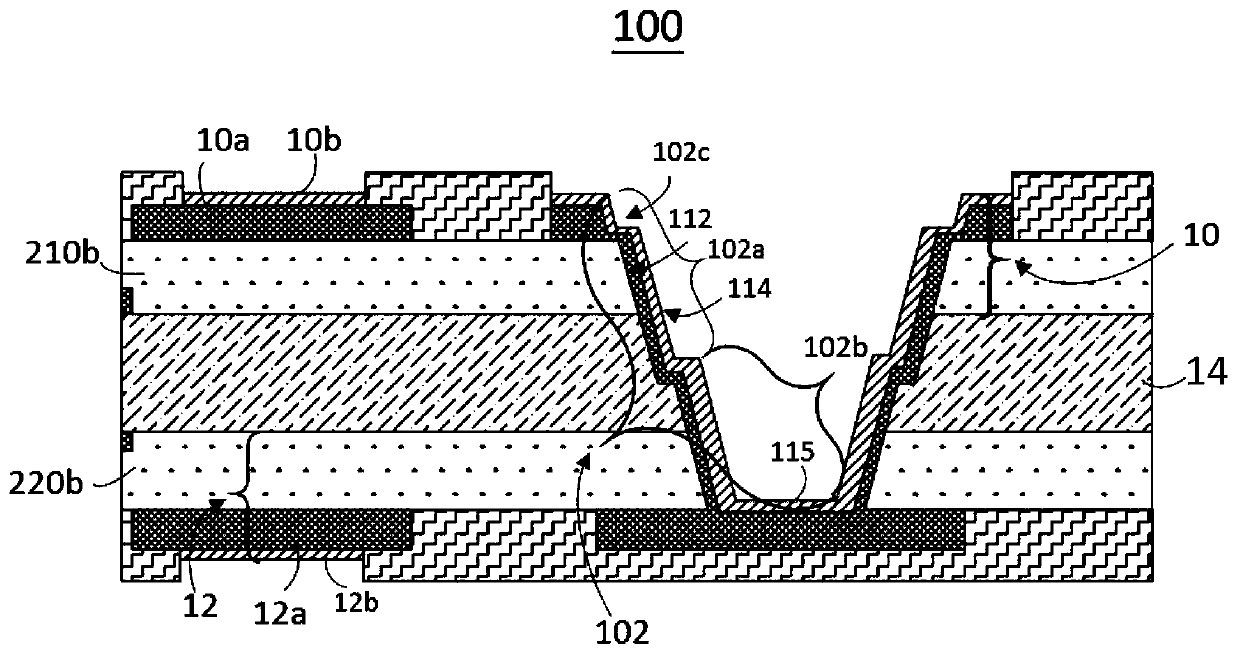

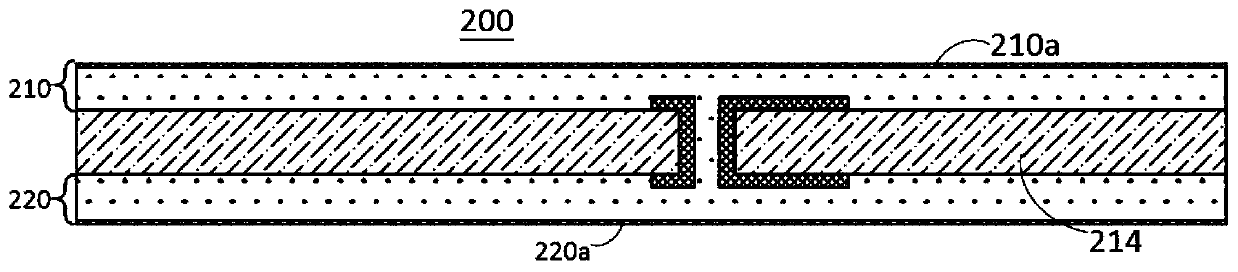

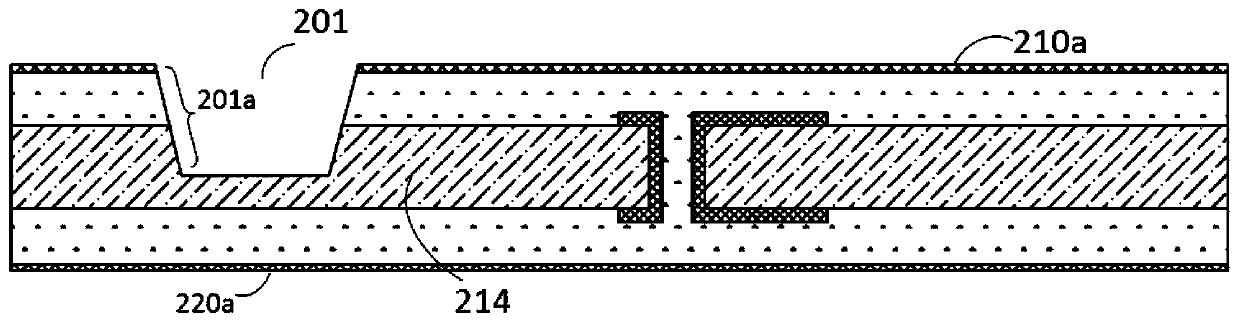

Packaging substrate and manufacturing method thereof

PendingCN111199948AWith solder visibilityImprove soldering effectSemiconductor/solid-state device detailsSolid-state devicesEngineeringMaterials science

The embodiment of the invention relates to a packaging substrate and a manufacturing method thereof. According to the packaging substrate in one embodiment, the packaging substrate comprises a circuittop layer, a circuit bottom layer, a first insulating layer and at least one stepped inclined side surface, wherein the first insulating layer is located between the circuit top layer and the circuitbottom layer; and the stepped inclined side surface is provided with a first stepped inclined side surface extending from the circuit top layer to the first insulating layer and a second stepped inclined side surface extending from the first insulating layer to the circuit bottom layer. According to the packaging substrate and the manufacturing method thereof provided by the embodiment of the invention, the soldering tin performance of the packaging substrate can be effectively evaluated from the appearance.

Owner:ASE SHANGHAI +1

Cable tinning equipment

ActiveCN105014176BSame lengthImprove soldering effectWelding/soldering/cutting articlesMetal working apparatusTinningEngineering

The invention relates to a cable dipping tinning device, which includes first, second, third, and fourth feeding mechanisms, a base, a bracket, a carrier, a tin furnace, and a receiving mechanism. The first feeding mechanism includes a horizontal A first pallet and a first pen-shaped cylinder, the carrier is positioned on the first pallet, the first pallet is provided with a first guide groove, and the first pen-shaped cylinder is provided with a ballast bearing With a push rod that moves backwards, the second feeding mechanism includes a horizontal second pallet, a first cylinder, a clamping mechanism, a second cylinder and a second pen-shaped cylinder, the second support The plate is provided with a second guide groove, and the third feeding mechanism includes a third supporting plate and a third cylinder that are upright, the third supporting plate is provided with a third guiding groove, and the tin furnace is located in the third Below the pallet, the fourth feeding mechanism includes a fourth pallet and a fourth cylinder that are upright, the fourth pallet is provided with a fourth guide groove, and the receiving mechanism includes a third pen-shaped cylinder and receiving channel.

Owner:LUXSHARE PRECISION INDUSTRY (CHUZHOU) CO LTD

Lead-free environmentally friendly soldering flux and preparation method thereof

InactiveCN101972906BDoes not cause failure problemsLow solidsWelding/cutting media/materialsSoldering mediaEnvironmental resistanceTinning

The invention relates to a lead-free environmentally friendly soldering flux and a preparation method thereof. The method comprises the following steps of: mixing synthetic organic acid, an activating agent and a mixed alcohol solvent at normal temperature according to a component formula; pouring an obtained mixture into a stainless steel container, and then adding modified rosin particles; stirring materials in the container until the rosins are all dissolved, and then stopping stirring; and standing still, filtering and hermetically packaging to obtain a soldering flux product. The lead-free environmentally friendly soldering flux is a no-clean soldering flux with low solid content, less rosin and no halide, has the characteristics of quick dry, bright and firm welding spot, uniform spreading, full structure, no corrosivity, excellent solderability, good soldering wetting, stable property, and the like, conforms to the property requirements of various electrical appliances and is suitable for soldering computers and peripheral equipment or high-precision multilayer board electronic assemblies. When in use, the soldering flux product has the advantages of low smoke, no pollutionto working environment, no influence on the human health, no pollution to tracks and clamps of a tinning furnace, higher insulating impedance, good environment friendly performance and stronger market competitiveness.

Owner:DANFENG RONGYI ELECTRONICS

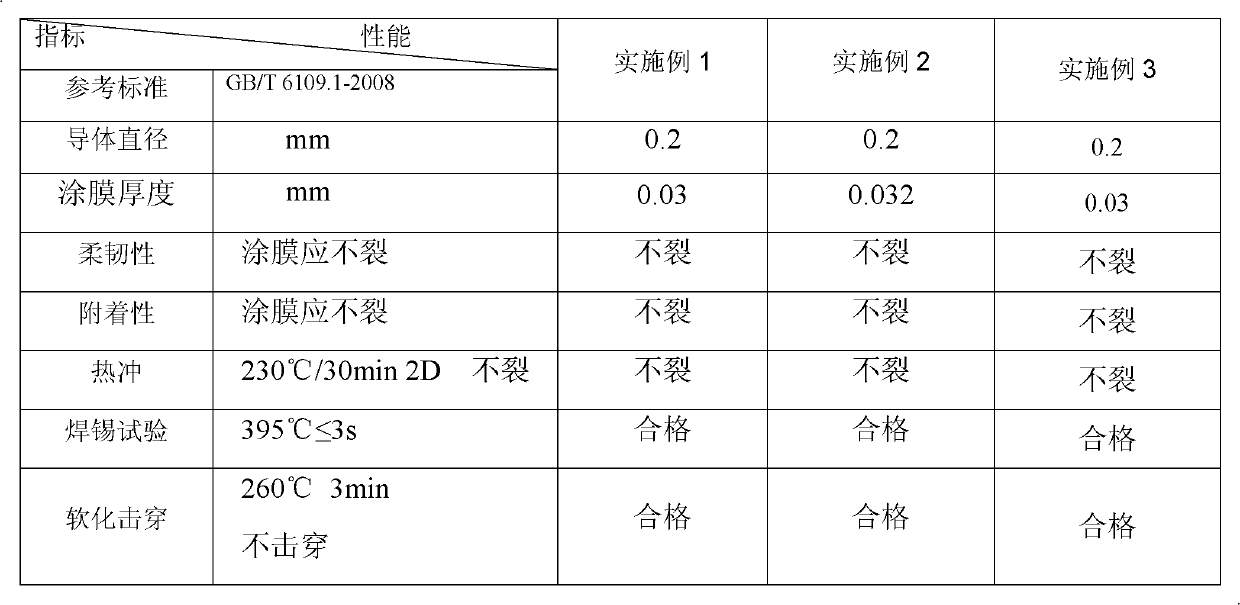

Method for synthesizing C-level polyurethane wire enamel

ActiveCN102618160BNo pollution in the processSimple processPolyurea/polyurethane coatingsPolyesterDiphenylmethane

The invention discloses a method for synthesizing C-level polyurethane wire enamel. The C-level polyurethane wire enamel prepared by the method has high heat-resistant performance and solderability and physical performance, and the heat-resistant level reaches a C level. The method for synthesizing the C-level polyurethane wire enamel mainly comprises the following steps of: synthesizing polyester polyol, synthesizing a diphenylmethane diisocyanate (MDI) tripolymer and preparing polyurethane paint, wherein the polyester polyol is prepared by reacting dimethyl terephthalate, tri-(2-ethoxy) isocyanurate and dihydric alcohol which serve as raw materials under the action of a catalyst; and the dihydric alcohol is N-methyldiethanolamine, and part of dimethyl terephthalate is replaced by adding tetracarboxylic dianhydride for reaction.

Owner:江苏四达特材科技有限公司 +1

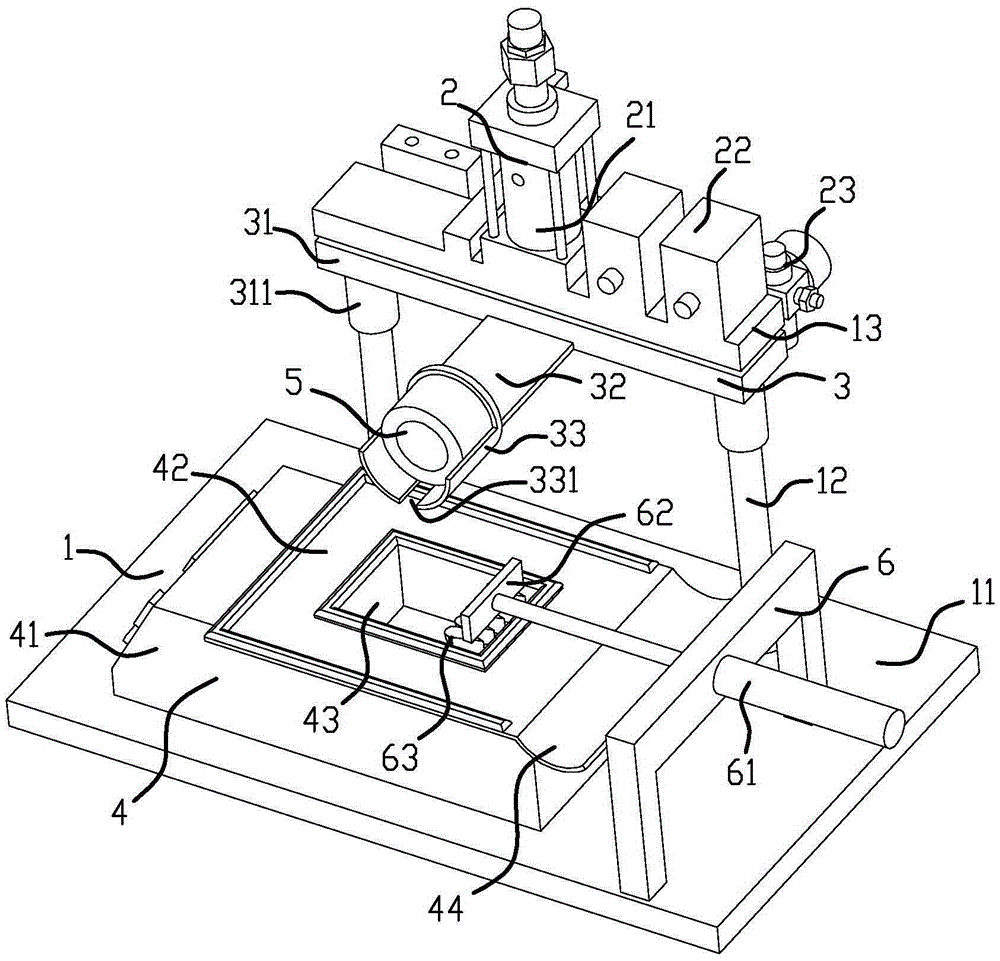

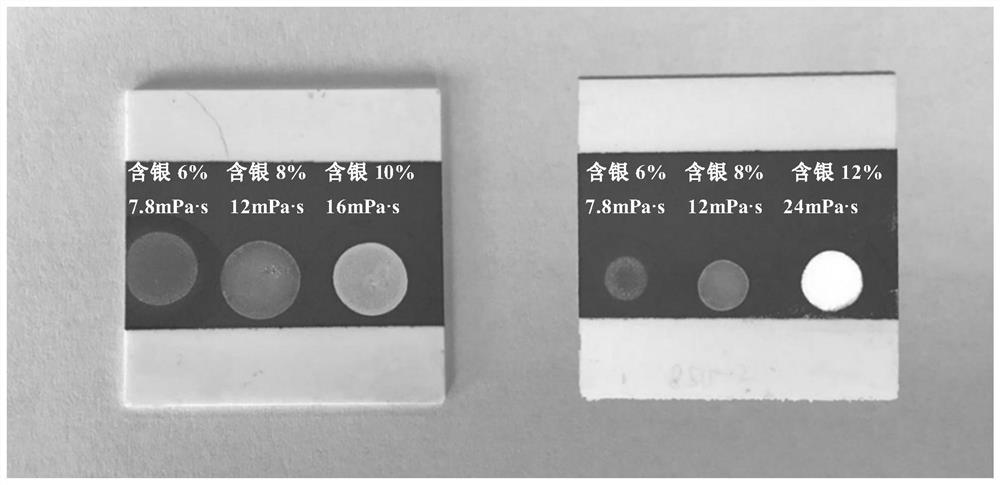

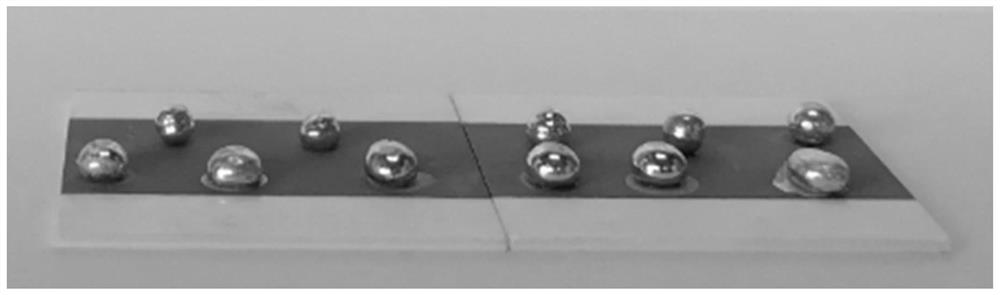

Preparation method of solderable silver-coated nickel conductive layer and automatic screen printing silver-coated device

ActiveCN109365825BImprove adhesionImprove soldering effectTransportation and packagingScreen printersSilver pasteScreen printing

The invention provides a preparation method of a solderable silver-coated nickel conductive layer and an automatic screen printing silver-coated device, wherein the preparation method is: dripping nano-silver paste on the printed nickel conductive pattern, and then drying and co-sintering to obtain a solderable silver-coated nickel conductive layer; wherein, the nano-silver paste has a silver content of 5-15%, a glass phase content of 0.5-1.5%, and a viscosity of 5-30mPa·s. By adopting the technical solution of the present invention, no special flux and solder materials are needed, and only one co-sintering method is required to obtain a nickel conductive layer with better soldering effect and solder bonding force, and the operation is simple and convenient , the consistency and stability of the production products are good, the discharge of three wastes is not increased, the product is green and environmentally friendly, and is suitable for industrial production.

Owner:深圳原驰三维技术有限公司

Soldering flux and soldering paste

ActiveCN101497155BImprove thermal stabilityReduce generationWelding/cutting media/materialsSoldering mediaSolderingElectrical resistivity and conductivity

Owner:ARAKAWA CHEM IND LTD

Automatic tin soaking machine special for tin soaking of induction transformer

InactiveCN105904059AReasonable designDesign scienceHeating appliancesWelding/soldering/cutting articlesTransformerSlag

The invention relates to an automatic tin soaking machine special for tin soaking of an induction transformer. At present, no tin soaking machine suitable for conducting tin soaking operation on induction transformers exists. The automatic tin soaking machine comprises a machine frame, a tin melting device, a scaling powder holding device, induction transformer input devices, an induction transformer output device and an induction transformer grabbing and tin soaking device. The automatic tin soaking machine is characterized in that the automatic tin soaking machine further comprises a tin slag lead-in piece, a tin slag collecting trough, a collecting trough supporting platform and a collecting trough limiting bar; a tin slag outlet is formed in a tin furnace body, and the upper portion of the tin slag lead-in piece is fixed to the furnace wall, provided with the tin slag outlet, of the tin furnace body; the lower portion of the tin slag lead-in piece makes contact with the inner wall of the tin slag collecting trough; and the tin melting device, the scaling powder holding device, the induction transformer output device and the induction transformer input devices are sequentially arranged in the horizontal direction. The automatic tin soaking machine can efficiently, completely and effectively scrape tin slag in a tin melting cavity into the tin slag collecting trough.

Owner:TONGXIANG YAORUN ELECTRONICS

A high-efficiency LED lamp chip soldering equipment based on digital linear dimming technology

ActiveCN113319398BConvenient and accurate fixationReduce wasteSolder feeding devicesSoldering auxillary devicesSolderingEngineering physics

The invention relates to a high-efficiency LED lamp chip soldering device based on digital linear dimming technology. A tin storage chamber is arranged below, and also includes a tin conveying channel, a conveying device and a tin conveying device. The tin conveying channel runs through the welding table and extends downward to the tin storage chamber; It is divided into a storage section, a temporary storage section and a conveying section. The conveying device makes the tin in the tin storage room enter the storage section through the conveying section and the temporary storage section in turn; the tin feeding device sends the tin in the storage section to the solder joints of the chip. The invention solves the technical problem that the molten tin is difficult to be sent to the welding point in the prior art.

Owner:浙江凯友照明科技有限公司

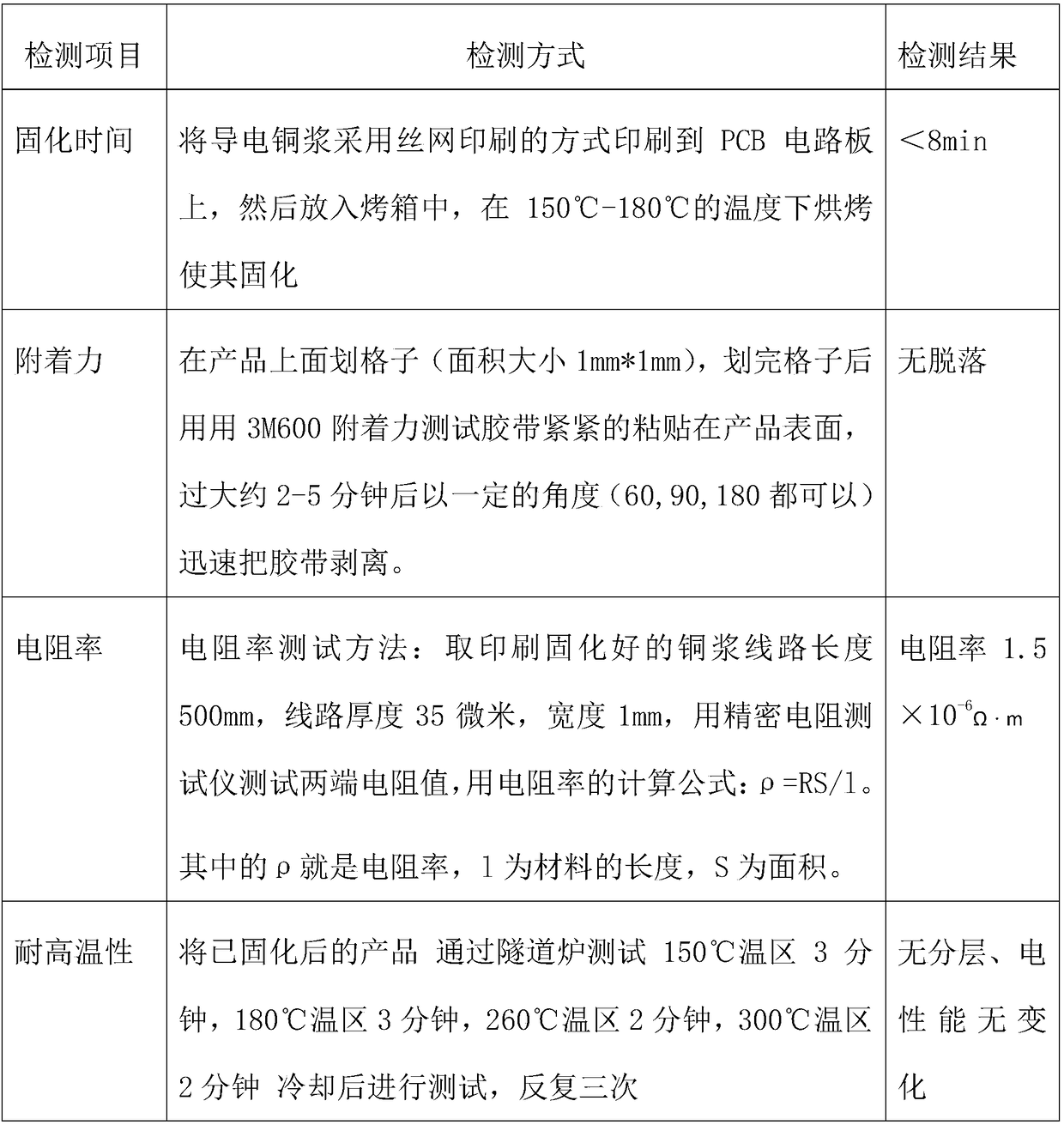

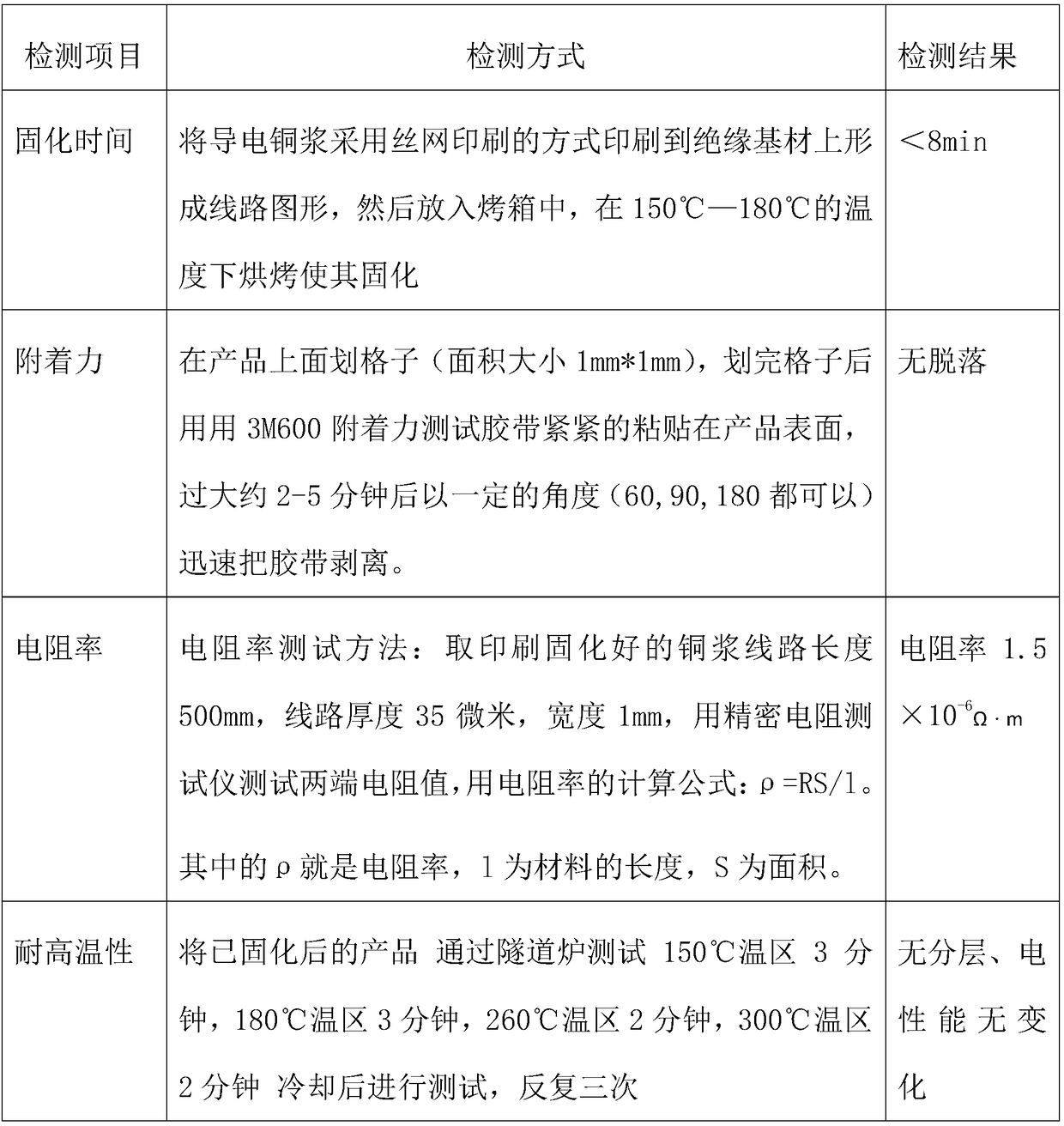

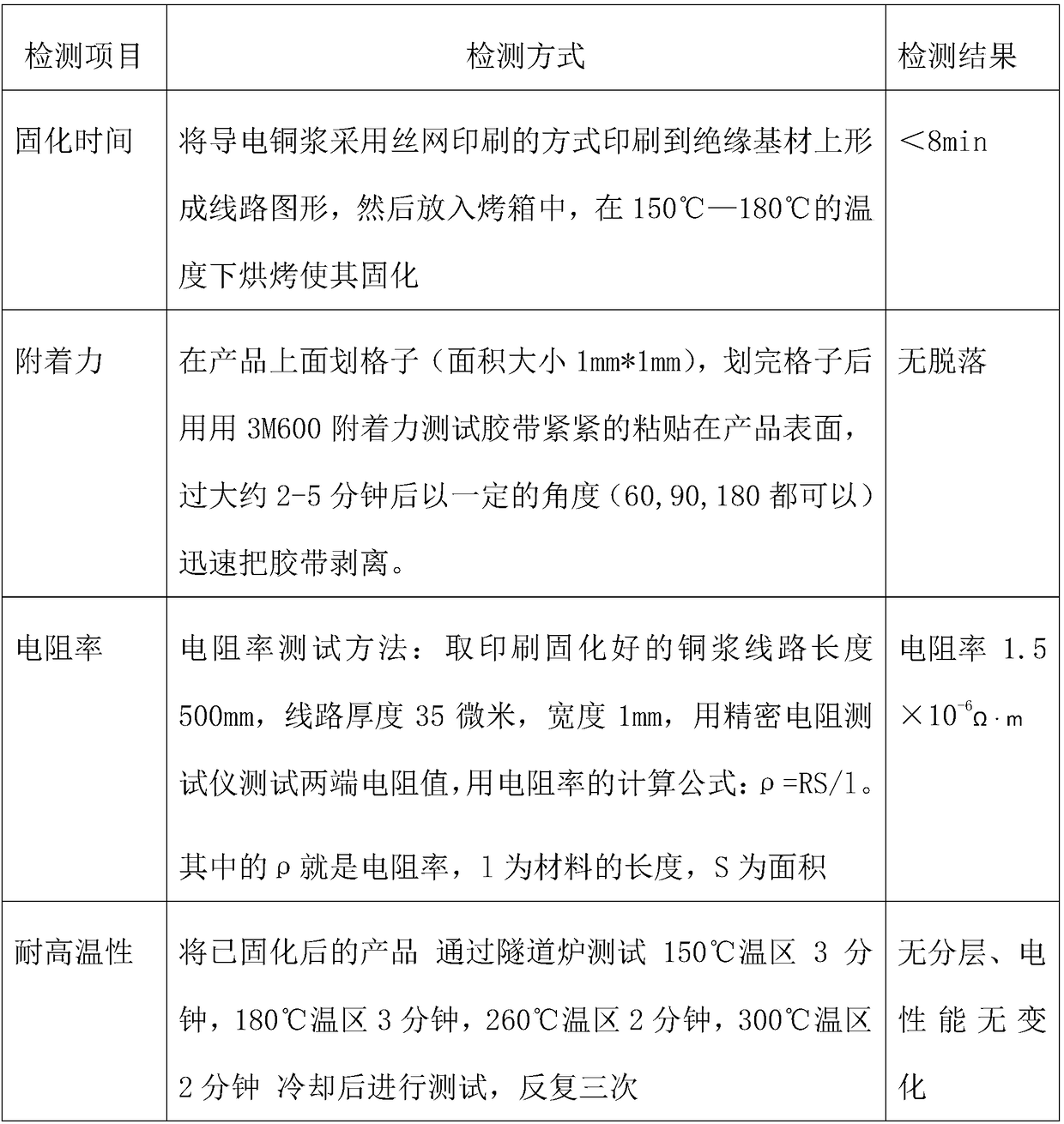

A conductive copper paste and its preparation method

InactiveCN109065218AImprove liquidityGood printabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureAcrylic resinFatty alcohol

The invention discloses a conductive copper paste and a preparation method thereof, belonging to the technical field of electronic paste, wherein the electrically conductive copper paste mainly comprises the following components in parts by weight: 12-16 parts of trimethylolpropane triacrylate, 25-28 parts of N-vinyl pyrrolidone, 8-12 parts of butyl acetate, 3-6 parts of secondary alcohol, 8-12 parts of dimethylformamide, 8-12 parts of divalent acid ester, 1-3 parts of azo initiator, 45-55 parts of epoxy acrylic resin, 2-5 parts of fatty alcohol polyoxyethylene ether, 2-5 parts of curing agentand 240-260 parts of silver-coated copper powder. The conductive copper paste has excellent printing property, short solidification time, strong adhesion, low electrical resistivity, excellent solderability, high temperature resistance, resistance to solder ink corrosion. The preparation method of the conductive copper paste has the advantages of simple process, convenient preparation, high production efficiency, good product quality and low production cost.

Owner:郑胜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com