Patents

Literature

43 results about "Gold production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This is a list of countries by gold production in 2018.. For many years until 2006, South Africa was the world's dominant gold producer, but recently other countries have surpassed South Africa: China, Russia, Canada, the United States, Peru and Australia. Albeit, none of these countries have approached South Africa's peak production which occurred in the apartheid-era 1970s.

Novel chemical nickel gold production process and chemical nickel plating liquid

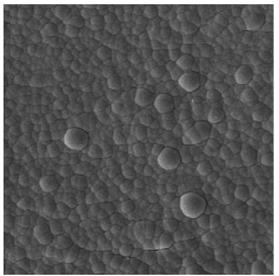

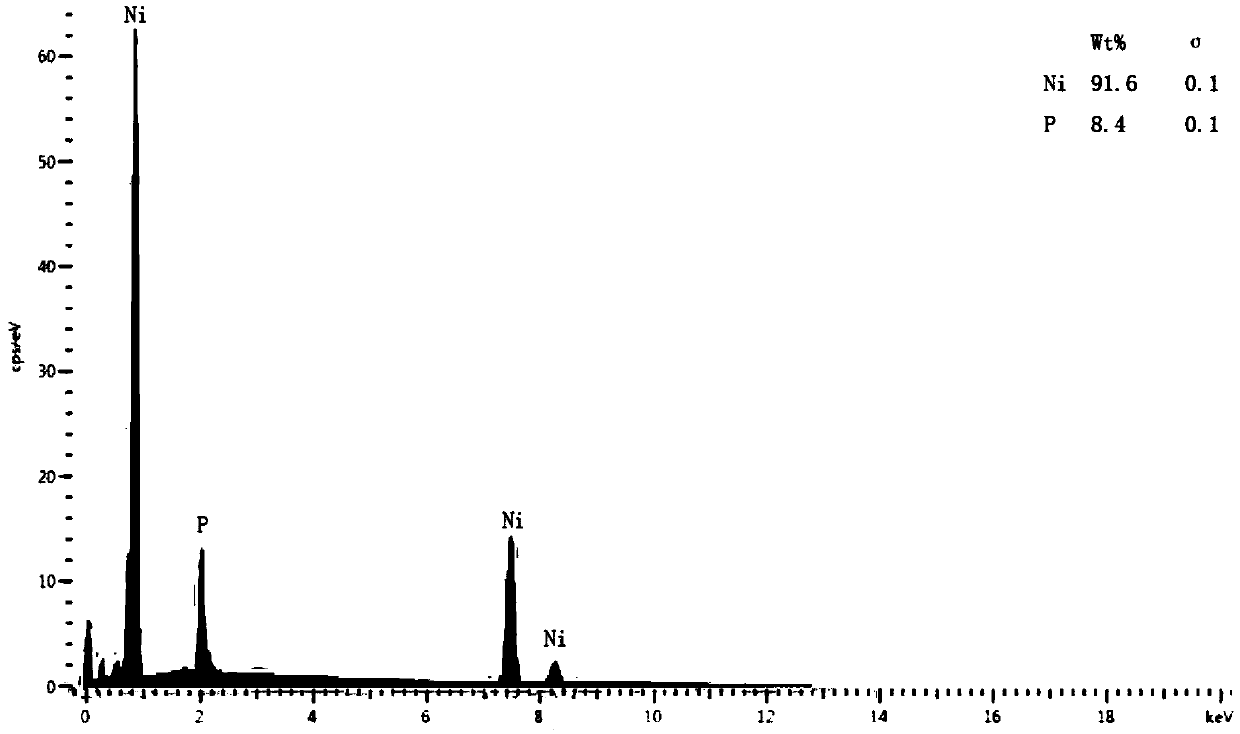

InactiveCN109628913AFast deposition rateSolve the difficulty of levelingLiquid/solution decomposition chemical coatingEtchingNickel deposition

The invention discloses a PCB or package substrate chemical nickel gold production new process. The new process comprises the steps of chemical gold pretreatment, deoiling, micro-etching, activation,alkaline chemical nickel, nickel activation, acid chemical nickel, chemical gold, gold surface hole sealing and chemical gold aftertreatment. The invention further provides novel chemical nickel plating liquid. The process is low in nickel cylinder temperature and high in chemical nickel deposition speed; nickel simple substances are difficultly separated out from the wall of a chemical nickel plating liquid stabilizing tank; the horizontal production of chemical nickel gold can be realized; a production line is shortened; the emission of waste water is reduced; and the comprehensive production cost of the production line is reduced. In the novel chemical nickel plating liquid, through adjustment of types of complexing agents and stabilizing agents in the chemical nickel plating liquid, even if under the conditions of higher PH and higher deposition speed, higher P content is achieved to meet various performance requirements of existing chemical nickel gold for the surface treatment ofPCBs and package substrates.

Owner:湖南互连微电子材料有限公司

One-step producing technique for high-purity gold

InactiveCN101122032AReduce thickness differencePhotography auxillary processesProcess efficiency improvementElectrolysisProcessing cost

A one-step high purity gold production process includes four procedures, namely gold electrolyte making, gold electrolyte preparation, high purity gold electrolysis and finished product treatment. The one-step high purity gold production process of the invention well solves the problems of cathode verticality and smoothness, so the high purity gold produced in appropriately adjusted proportion of electrolyte has even surface, with thickness difference less than 0.1mm; meanwhile, the physical specification of the electrolyzed gold can be well controlled and the quality high purity gold (containing 99.999percent gold) can be produced one step by simple means of controlling the electrolyzing time and current density, etc, with the recovery rate up to 99.95percent and the processing cost of only 0.1 to 0.12yuan / g.

Owner:JIANGXI COPPER CORP

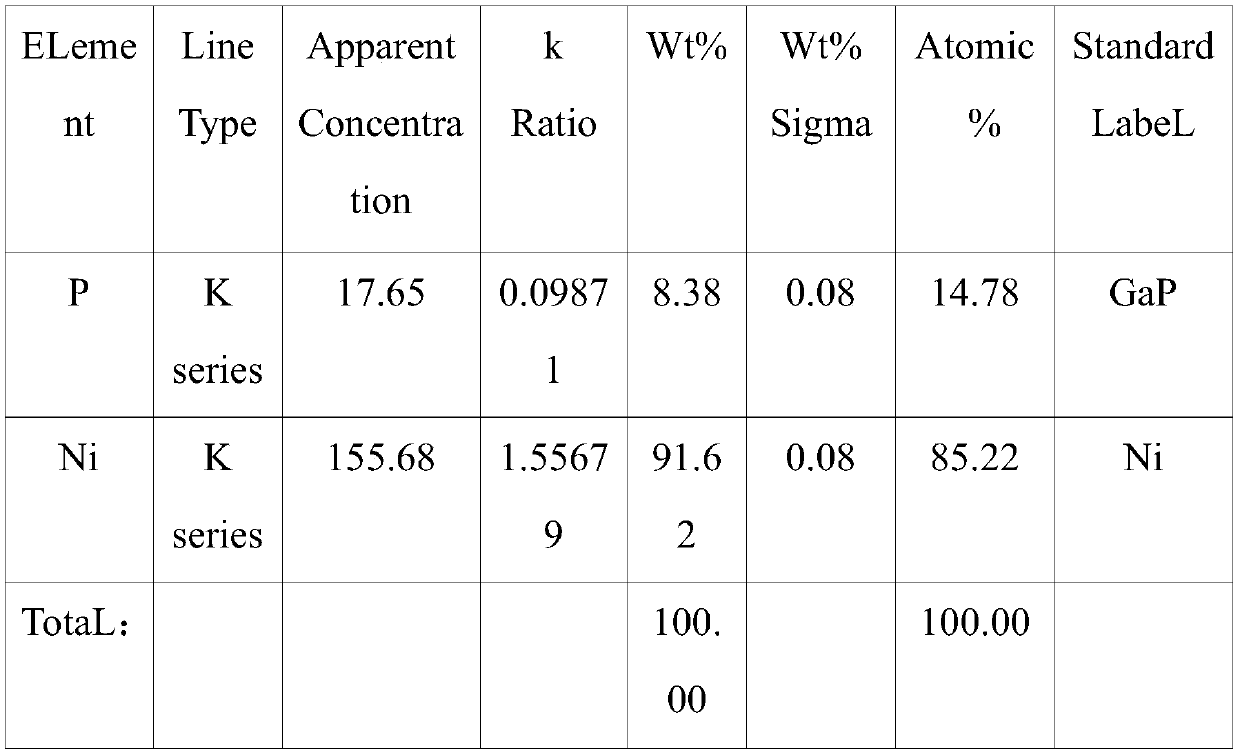

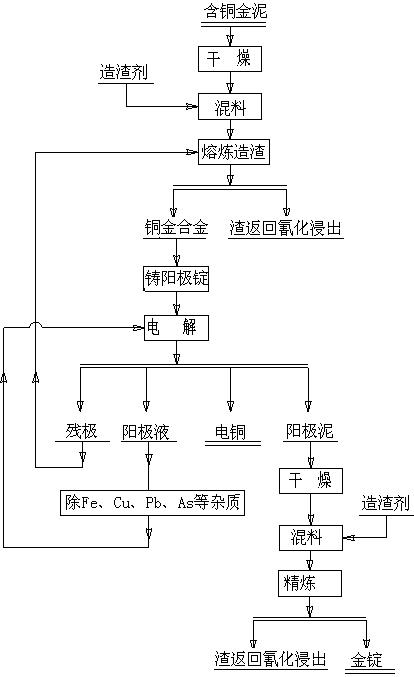

A kind of processing method of copper-containing gold mud

ActiveCN102286663AReduce consumptionIncrease the link of electrolytic copper removalPhotography auxillary processesProcess efficiency improvementElectrolysisSlag

The invention discloses a method for processing copper-contained gold mud, relating to a comprehensive recovering and processing method of copper-contained gold (silver or gold and silver) mud, in particular to copper-contained gold (silver or gold and silver) mud obtained by zinc powder replacement in the gold production process. The method is characterized by comprising the following steps in the processing process: (1) after the copper-contained gold mud is dried, smelting to obtain copper and gold copper and smelting slag; (2) casting the copper alloy obtained by smelting into an anode for electrolysis, and electrolyzing to obtain cathode copper; (3) after smelting to obtain smelted slag ore grinding, carrying out cyaniding leaching to recover gold and silver; (4) drying the anode mudobtained in step (2); adding slagging constituent to smelt to obtain a gold ingot and smelting slag; and (5) after carrying out ore grinding to the smelting slag obtained by smelting, recovering goldand silver by cyaniding leaching. With the method, the step of dissolving and removing copper by acid in the high copper-contained gold mud processing process is omitted by integrated innovation. Meanwhile, a link of electrolytic copper removal is added to realize zero wastewater emission and consume no medicines, such as sulfuric acid and the like, and meanwhile the electrolytic copper and the gold ingot can be obtained.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

Cyanide waste water recovery treatment method

ActiveCN104445750AImprove processing efficiencyEasy to handleWater contaminantsWaste water treatment from metallurgical processParticulatesTreatment effect

The invention discloses a cyanide waste water recovery treatment method. The method is composed of a resin adsorption method, an advanced oxidation process, a coagulant-sedimentation method and an active carbon adsorption method. When cyanide waste water is treated, firstly, resin is selected and used for adsorbing and recovering cyanide in the waste water, an oxidizing agent and a catalyst are added to the adsorbed waste water for advanced oxidation treatment, coagulant-sedimentation is conducted on the oxidized waste water so as to remove pollutants such as suspended particulate matter and heavy metal ions in the waste water, active carbon adsorption is conducted on supernate obtained after sedimentation, and therefore remaining pollutants in the waste water are removed. According to the characteristics that the concentration of cyanide in the cyanide waste water generated in the gold production process is high, pollutant types are complex, and the pollutants are difficult to treat, the resin adsorption method, the advanced oxidation process, the coagulant-sedimentation method and the active carbon adsorption method are combined together to collaboratively conduct deep treatment on the cyanide waste water, the cyanide waste water recovery treatment method has the advantages of being good in treatment effect, high in treatment efficiency, stable in system operation, simple in technological process, capable of facilitating industrial application and the like, and the treated waste water can return to the production technological process and serve as reuse water to be used or can be drained when reaching the standard.

Owner:CHANGCHUN GOLD RES INST

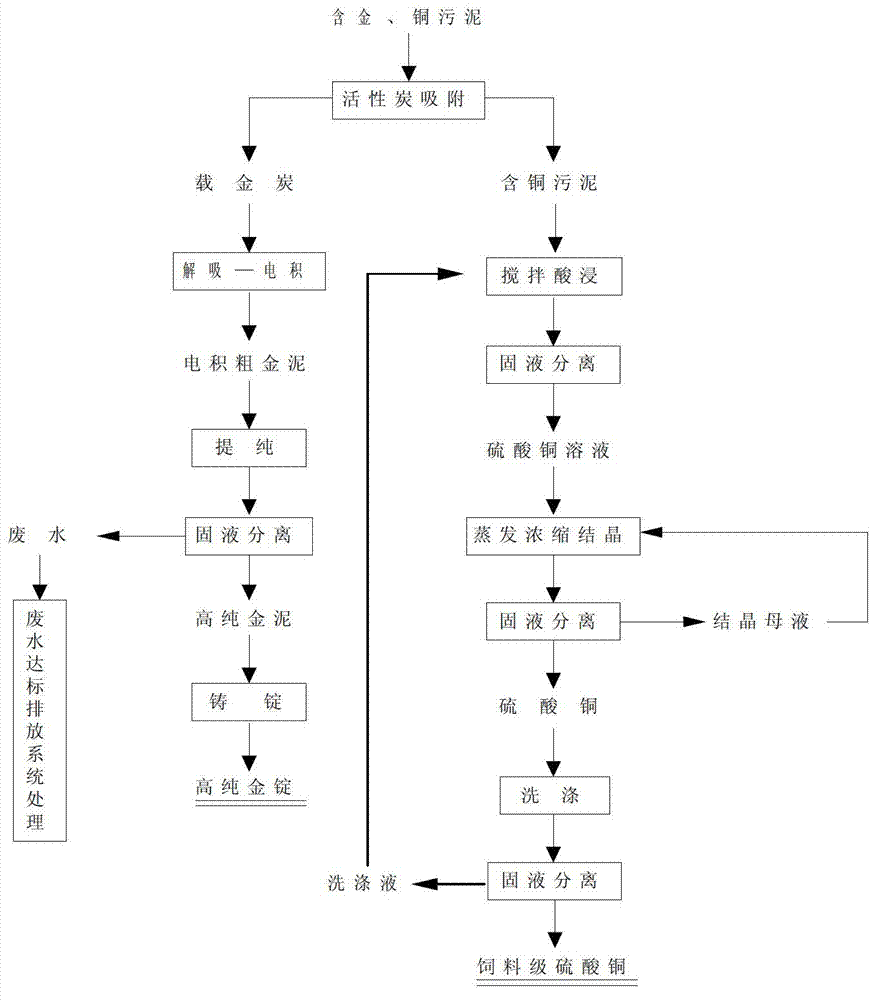

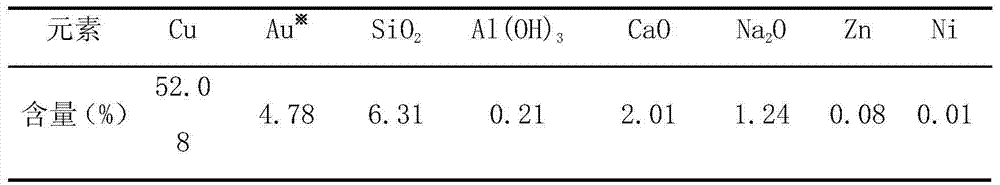

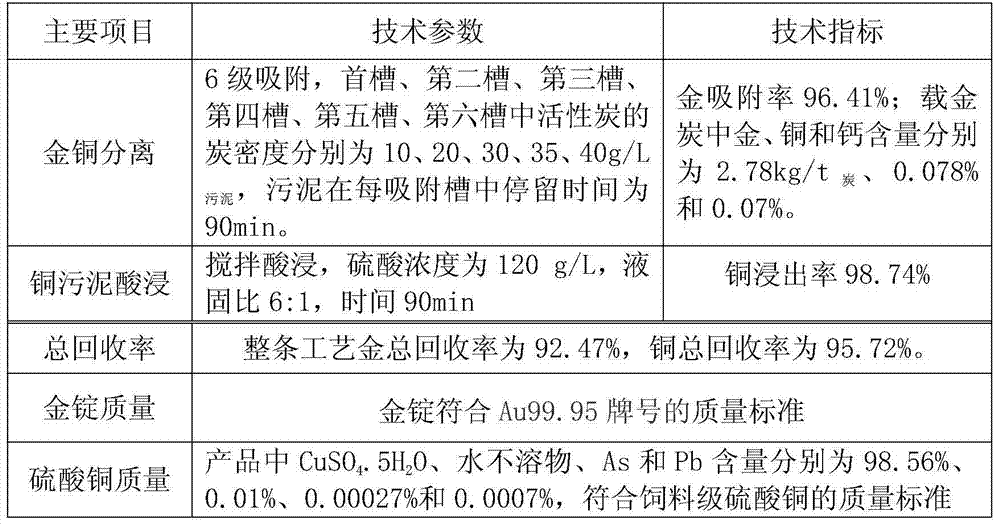

Method for producing high-purity gold and copper sulphate from gold-bearing copper sludge

ActiveCN103397190AEfficient separationAchieve reductionPhotography auxillary processesProcess efficiency improvementSludgeDesorption

The invention relates to a method for producing high-purity gold and copper sulphate from gold-bearing copper sludge. The method comprises the process steps of gold-copper separation, high-purity gold production and feed-grade copper sulphate production; in the gold-copper separation, cyanided pregnant solution generated through cyanide leaching of copper-bearing gold ores or carbon adsorption barren solution is fed to a carbon absorption system by virtue of gold-bearing and copper-bearing sludge which has a water content of 90-98% and is generated during an oxidative cyanogen removal process, gold is absorbed by active carbon and finally gold and copper are separated; in the high-purity gold production, a finished gold ingot is mainly prepared by the steps of gold-bearing carbon desorption-electrodeposition, electrodeposition gold sludge purification and ingot casting; and in the feed-grade copper sulphate production, feed-grade copper sulphate and washing solution are prepared by the working procedures of stirring and acid-leaching, evaporation and concentration and crystallization, and copper sulphate impurity removal. The method has the advantages of low treatment cost, strong adaptability, environmental friendliness, capability of realizing reduced, resourceful and harmless treatment on the gold-bearing and copper-bearing sludge, and the like, and is applicable to process of copper-bearing gold ores of which the cyanide soluble copper content is 0.04-0.1%.

Owner:ZIJIN MINING GROUP

Cyanide-containing waste water recovery and treatment method

ActiveCN104445843AImprove processing efficiencyEasy to handleTreatment using aerobic processesWater contaminantsParticulatesBiological filter

The invention discloses a cyanide-containing waste water recovery and treatment method. A resin adsorption method, a chemical oxidation method, a coagulating sedimentation method and a biological filter treatment system are included in the method. When cyanide-containing waste water is treated, resin is firstly selected to carry out adsorption and recovery on cyanide in the waste water, an oxidizing agent and a catalyst are added to the waste water after adsorption to carry out oxidation treatment, suspended particulate matter, heavy metal ions and other pollutants in the oxidized waste water are removed through coagulating sedimentation, and pollutants remaining in the waste water are removed through supernate obtained after sedimentation by adopting the multi-stage biological filter treatment system. According to the characteristics that the cyanide-containing waste water generated in the gold production process is high in cyanide concentration, complex in pollutant kind and hard to treat, the resin adsorption method, the chemical oxidation method, the coagulating sedimentation method and the biological filter treatment technology are combined together, deep treatment is carried out on the cyanide-containing waste water collaboratively, the advantages of being good in treatment effect, high in treatment efficiency, stable in system running and simple in technological process and facilitating industrial application implementation are achieved, and the treated waste water can return to the production technological process to be used as reuse water or drained after reaching the standard.

Owner:CHANGCHUN GOLD RES INST

Method for treating gold production sewage

InactiveCN103253800ALow costEasy to operateWaste water treatment from metallurgical processMultistage water/sewage treatmentFiltrationClean water

The invention relates to a method for treating gold production sewage. The method comprises the following steps of: performing filtration pretreatment on wastewater produced in a gold production process; mixing the pretreated wastewater, then adjusting the pH of the mixed liquid to 6.7-7.2, then enabling the mixed liquid to flow into a transverse flow settling tank, and separating the mixed liquid to be preliminary wastewater and transverse flow precipitates; measuring the pH value of the preliminary wastewater, adjusting the pH of the preliminary wastewater to 6.7-7.2 by acid or alkaline, then enabling the preliminary wastewater to flow into an upright flow settling tank, and separating the preliminary wastewater into secondary wastewater and upright flow precipitates; discharging the secondary wastewater into an electric flocculation device for flocculation to obtain third wastewater containing flocculates; enabling the third wastewater containing flocculates to flow into an inclined pipe settling tank to obtain clean water subjected to flocculation settling and treatment. By a combined technology for discharging cyanide by sodium metabisulfite and removing heavy metals by electric flocculation, various gold production wastewater can be treated at the same time, and noble metal such as gold, silver and copper in the wastewater can be effectively recycled; the cost for treating the wastewater is lower; and the operation technology is simple.

Owner:招金矿业股份有限公司金翅岭金矿

Cyanide waste water comprehensive recovery treatment method

ActiveCN104445842AImprove processing efficiencyEasy to handleMultistage water/sewage treatmentParticulatesBiological filter

The invention discloses a cyanide waste water comprehensive recovery treatment method. The method is composed of a resin adsorption method, an ozone oxidation method, a coagulant-sedimentation method and the biological filter treatment technology. When cyanide waste water is treated, firstly, resin is selected and used for adsorbing and recovering cyanide in the waste water, ozone is delivered to the adsorbed waste water for oxidation treatment, coagulant-sedimentation is conducted on the oxidized waste water so as to remove pollutants such as suspended particulate matter and heavy metal ions in the waste water, supernate obtained after sedimentation is treated through a biological filter treatment system, and therefore remaining pollutants in the waste water are removed. According to the characteristics that the concentration of cyanide in the cyanide waste water generated in the gold production process is high, pollutant types are complex, and the pollutants are difficult to treat, the resin adsorption method, the ozone oxidation method, the coagulant-sedimentation method and the biological filter treatment technology are combined together to collaboratively conduct deep treatment on the cyanide waste water of a gold production enterprise, the cyanide waste water comprehensive recovery treatment method has the advantages of being good in treatment effect, high in treatment efficiency, stable in system operation, simple in technological process, capable of facilitating industrial application and the like, and the treated waste water can return to the production technological process and serve as reuse water to be used or can be drained when reaching the standard.

Owner:CHANGCHUN GOLD RES INST

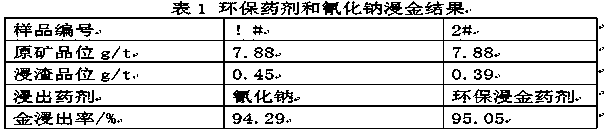

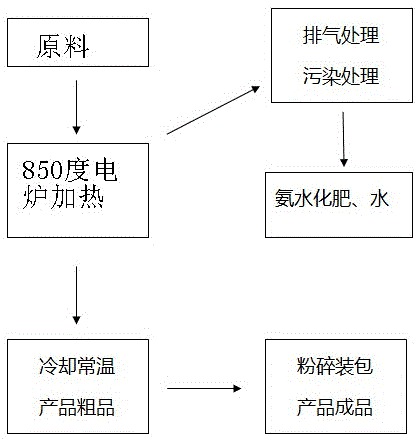

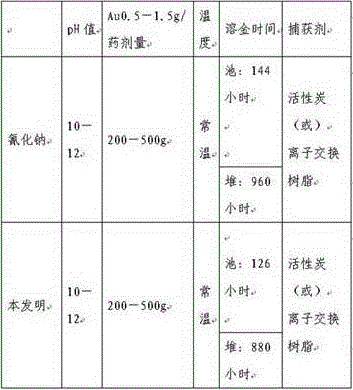

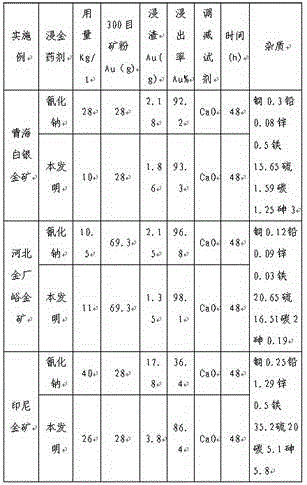

Environment-friendly gold extraction agent and preparation method thereof

InactiveCN108441648AReduce manufacturing costSimple production methodAdditive ingredientSodium thiocyanate

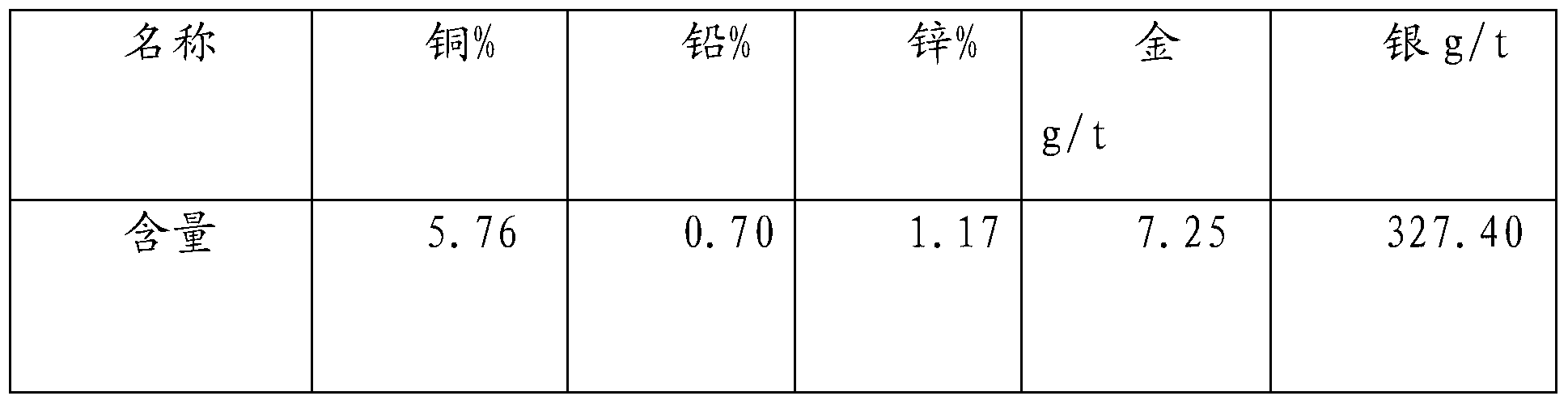

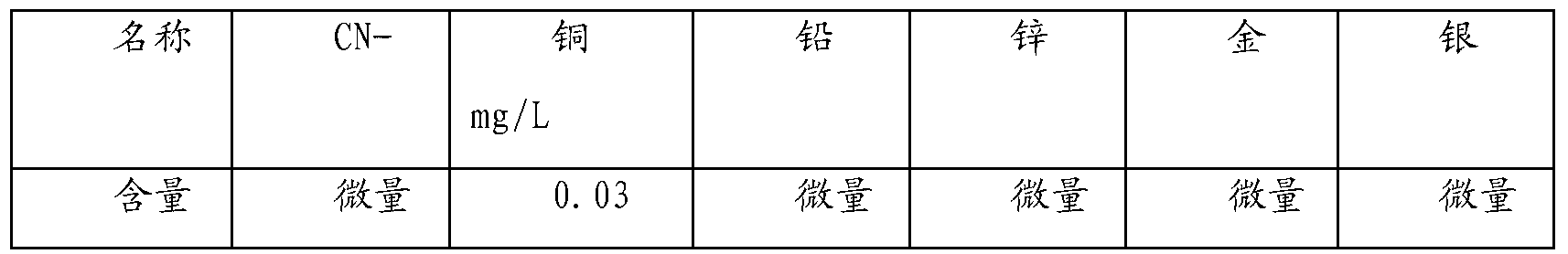

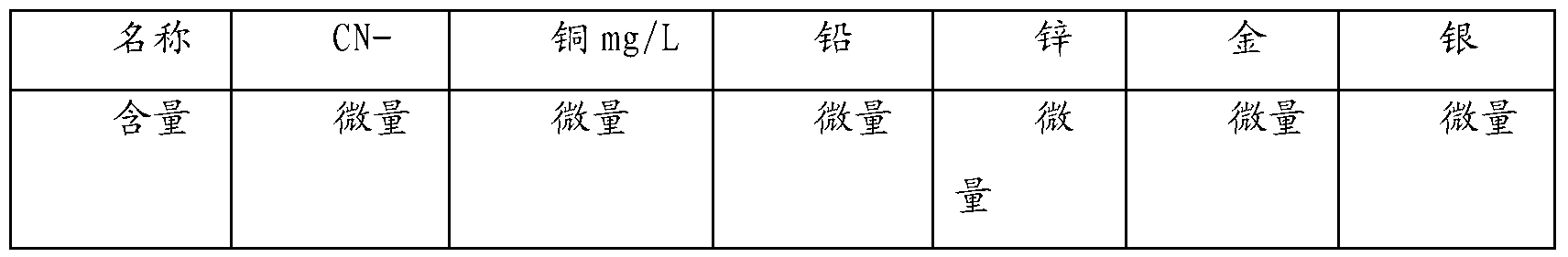

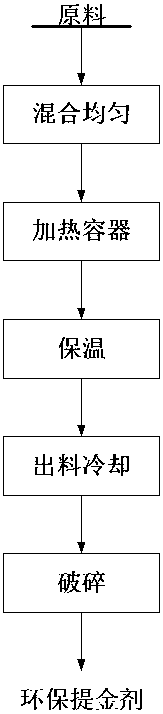

The invention relates to an environment-friendly gold extraction agent and a preparation method for the environment-friendly gold extraction agent and belongs to the technical field of gold production. The technical scheme of the environment-friendly gold extraction agent and the preparation method for the environment-friendly gold extraction agent is that the environment-friendly gold extractionagent is compounded of sodium carbonate, carbamide, sodium chloride, sodium sulphide, iodine, potassium ferricyanide, sodium thiocyanate, sodium bromide and sodium thiosulfate by thermal reaction, themass ratio of all the ingredients is 20-50% of sodium carbonate, 10-50% of carbamide, 1-10% of sodium chloride, 1-5% of sodium sulphide, 1-5% of iodine, 1-5% of potassium ferricyanide, 1-5% of sodiumthiocyanate, 1-5% of sodium bromide and 1-5% of sodium thiosulfate, the ingredients are heated to 700-800 DEG C in an airtight container to perform thermal reaction after being mixed evenly by a mixer, heat preservation is performed for 1-5 h, and the product after reaction is poured out to an open container and cooled to room temperature naturally to form the environment-friendly gold extractionagent. The environment-friendly gold extraction agent and the preparation method for the environment-friendly gold extraction agent have the positive effects that the environment-friendly gold extraction agent can completely replace sodium cyanide and is suitable for recovery and utilization of gold in gold-bearing oxidized ore and gold-bearing tail ore, and compared with other agents, the environment-friendly gold extraction agent has the characteristics of being low in production cost, simple in production method, high in applicability, environmental friendly, good in economic benefit and the like.

Owner:韩志永

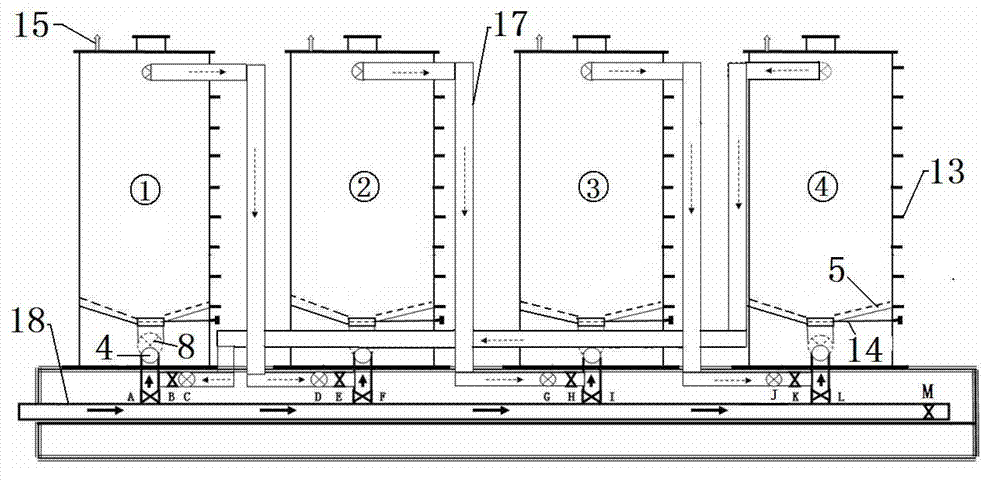

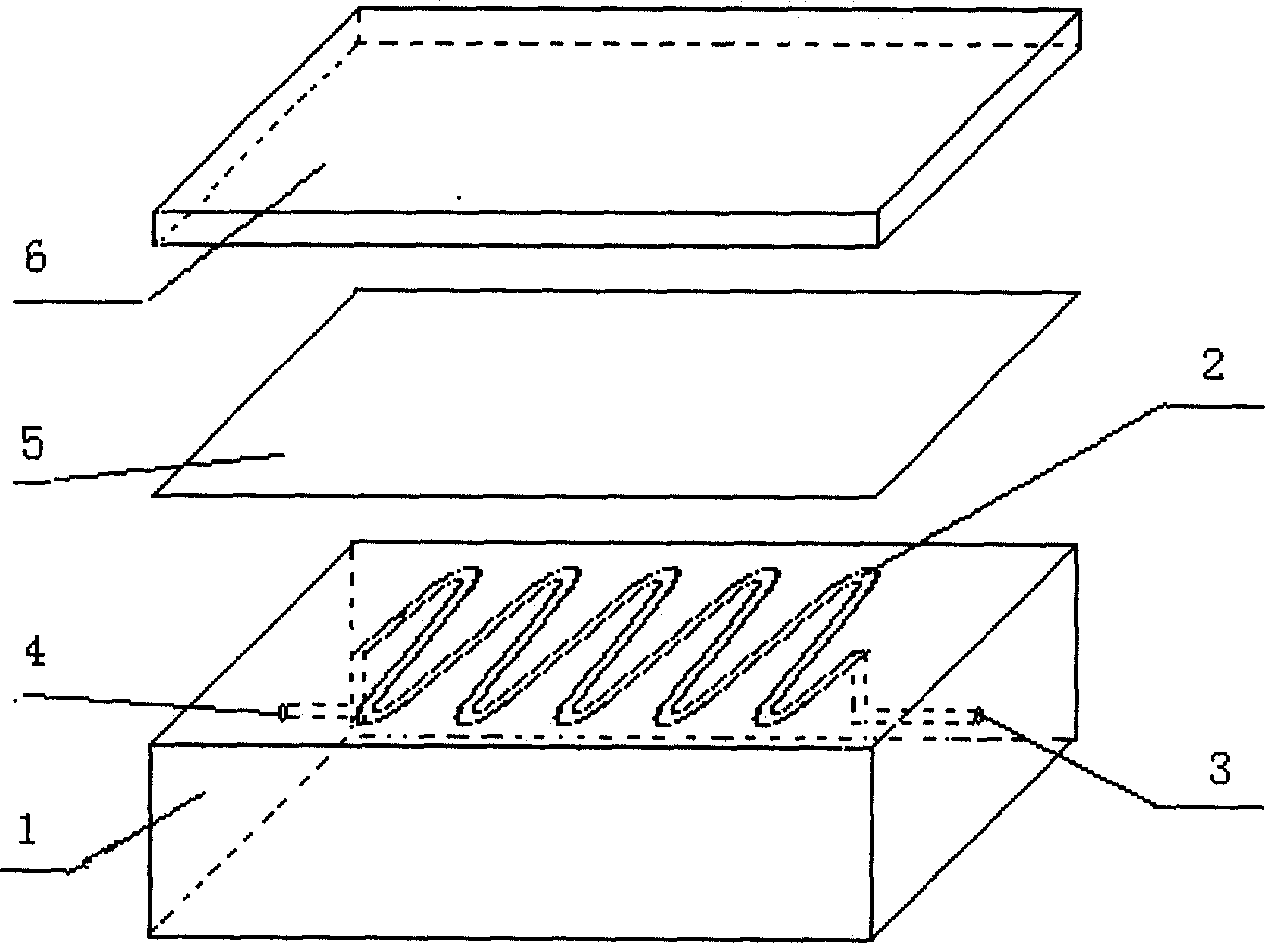

Closed circulation active carbon adsorption system

InactiveCN102732721AHigh recovery rateIncrease gold loading capacityProcess efficiency improvementActivated carbonEconomic benefits

The present invention discloses a closed circulation active carbon adsorption system, wherein a closed active carbon adsorption column is adopted as a basic adsorption unit, and a plurality of the basic adsorption units are connected in series to form a closed circulation, which is provided for recovery of gold from a gold-containing solution. According to the system, the system can not be affected by landform and is especially suitable for a flatland layout, and no adsorption cascade table is required to be specially arranged, such that the cascade preparation manner of the traditional adsorption column is completely changed; the counter current carbon series connection manner is changed, and change of inlet and outlet manners of the extracted gold pregnant solution can be achieved only by adopting adjustment of control of valve opening and valve closing in a system pipeline. With application of the system of the present invention, quality and adsorption rate of gold loaded carbon in gold production can be completely improved, the cascade counter current carbon series connection manner in production can be changed, the adsorption operation manner without carbon series connection can be achieved, the labor intensity of workers can be effectively reduced, the process can be simplified, the gold recovery rate can be improved, the whole economic benefits of the mine can be improved, and the production cost can be reduced. In addition, the system has characteristics of safety, reliability, easy preparation, flexible operation and variable scale.

Owner:广西地博矿业集团股份有限公司

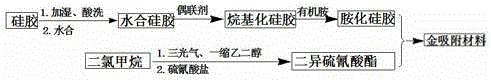

Material with double functional groups, namely silica gel-supported chelating amine and thiourea, and preparation method of material

InactiveCN104437379AImprove adsorption capacityExcellent gold desorption performanceOther chemical processesProcess efficiency improvementPregnant leach solutionThiourea

The invention discloses an adsorption material with double functional groups, namely silica gel-supported chelating amine and thiourea, and a preparation method of the adsorption material. An organic / inorganic composite adsorption material with the double functional groups, namely chelating amine and thiourea, is obtained by taking porous silica gel as an inorganic rigid framework and performing the steps of pickling, hydrating, alkylating and bonding the double functional groups, namely chelating amine and thiourea. The prepared double functional group / silica gel composite material has excellent gold adsorption performance, and can be used for separating, enriching, concentrating and extracting gold from a gold leaching solution and a gold tail solution, thereby realizing development of a gold production technology to a pollution-free direction; and simultaneously, after the material is regenerated, the material can be recycled for many times. The gold adsorption material is simple in preparation process, extensive in raw material sources and easy to realize industrialization.

Owner:工信华鑫科技有限公司

Comprehensive utilization method for acid waste liquid containing arsenic

InactiveCN101269890AReduce occupancyTake advantage ofArsenites/arsenatesMultistage water/sewage treatmentArsenateFlue gas

The invention relates to a comprehensive utilization method of arsenious acid waste liquid, which utilizes waste liquid produced during the technical gold production in the treatment of the arsenious aurine mine by a bacterial oxidation technology as the raw material, and has the procedures that the waste liquid is reduced by reducing agent and the pH value range of the waste liquid is more than 2.5 and less than 7 through being adjusted by adding water, so as to realize the separation of FeAsO4, the FeAsO4 filter residue and the FeAsO4 filter liquid are obtained after being filtered. The FeAsO4 filter liquid is concentrated, crystallized, separated, and dried to obtain the green copperas product. The FeAsO4 filter residue is panned, dried, dehydrated, and crushed to obtain the ferric arsenate product. The ferric arsenate product is roasted for 1-2 h, the roasting temperature is 700-1200 DEG C, the flue gas generated by the roasting is cooled and collected to obtain the arsenic trioxide product, and the roasting residue is collected to obtain the ferric oxide product. The process of the invention is simple, and the comprehensive utilization of the waste liquid is realized by less investment, so the effects of energy conservation and carbon emission reduction as well as source scientific utilization are achieved.

Owner:林建忠

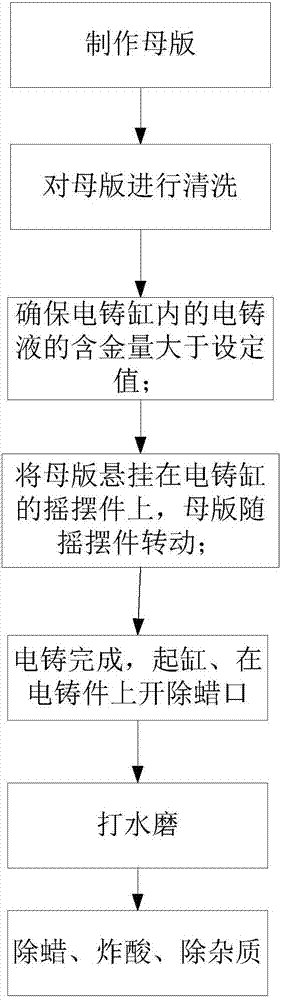

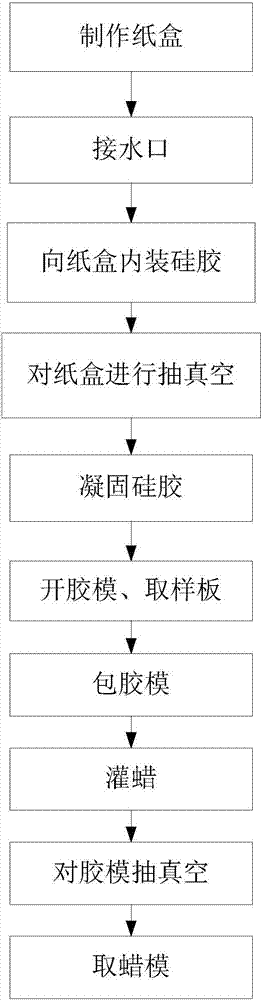

3D hard gold production process

The invention discloses a 3D hard gold production process, comprising: making a master plate; cleaning the master plate; ensuring that the gold content of the electroforming liquid in the electroforming cylinder is greater than a set value; hanging the master plate on the swing of the electroforming cylinder On the piece, the master plate rotates with the swing piece during the electroforming process; after the electroforming is completed, the cylinder is lifted, and the wax port is removed on the electroforming piece; water milling; wax removal, acid frying, and impurity removal. In the 3D hard gold production process of the present invention, before the master plate is put into the cylinder, the master plate is cleaned, thereby avoiding the mixing of impurities into the electroforming layer and improving the purity of the electroforming layer. In addition, in the 3D hard gold process of the present invention, sufficient electroforming liquid is ensured in the electroforming cylinder before electroforming, thereby improving the uniformity of the electroforming part. Secondly, in the process of electroforming, the master plate rotates with the rocker, which not only accelerates the speed of electroforming, but also further improves the uniformity of electroforming.

Owner:DONGGUAN JINLONG JEWELRY CO LTD

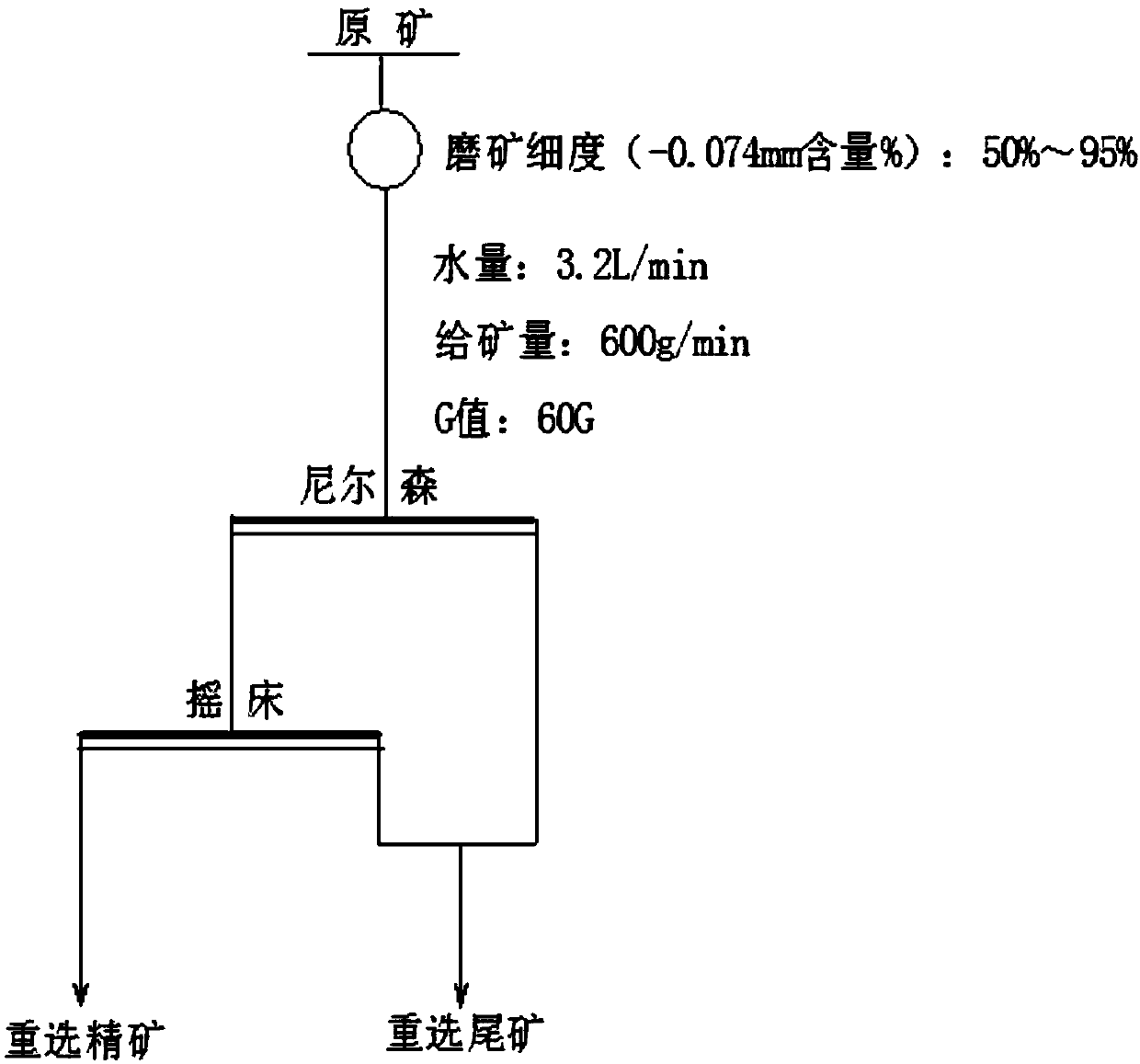

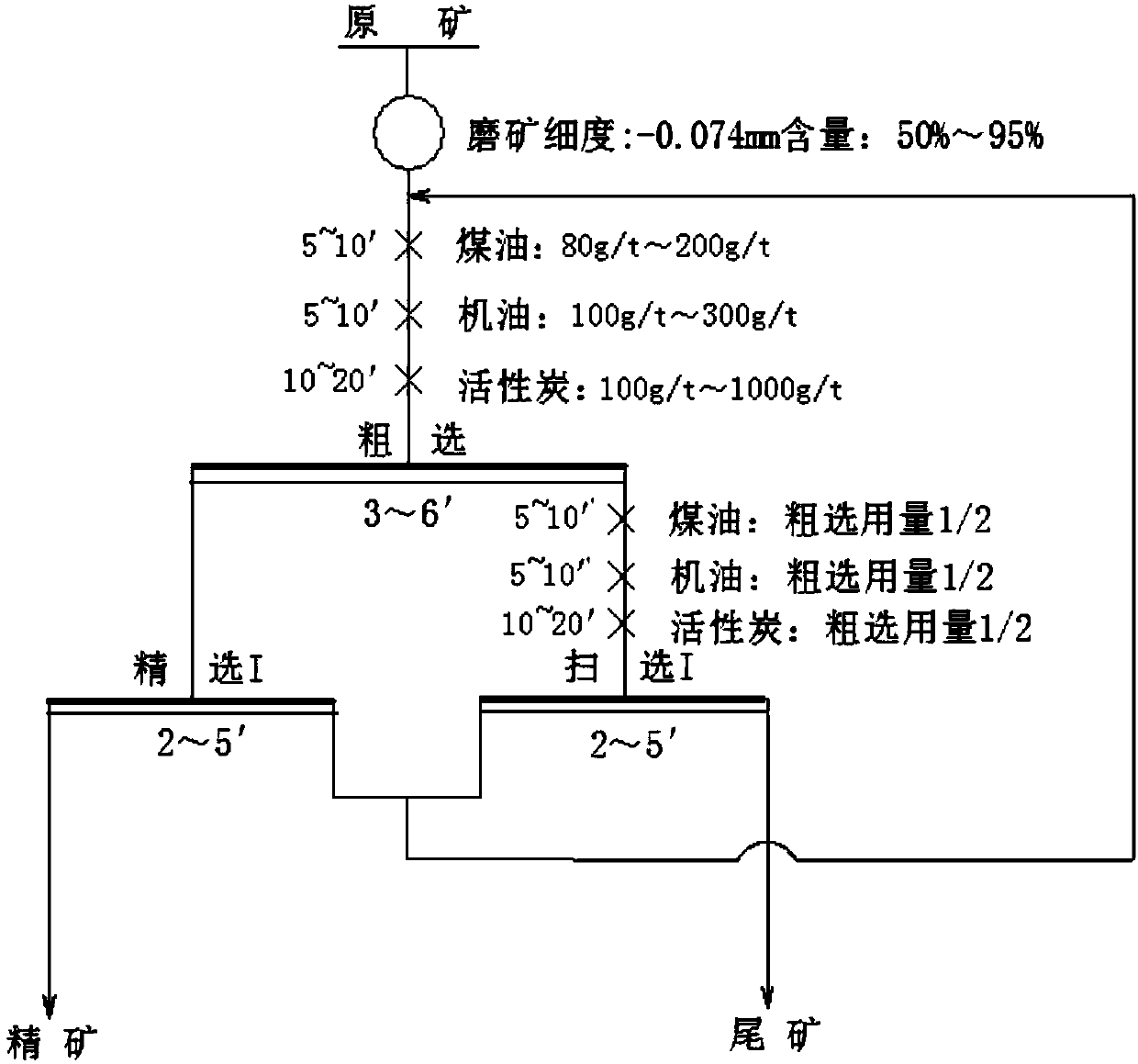

Collecting method for monomer gold particles

The invention belongs to the technical field of mine engineering, and particularly relates to a collecting method for monomer gold particles. According to the method, matching processing equipment issimple, adopted chemicals are free of toxicity, the chemicals are mature and easy to obtain, and the investment of capital construction is low; and the recovering particle grade of the gold particlesis wide, the recovering rate of micro-fine particle monomer gold is high, and gold production in situ can be achieved by carrying out simple ashing treatment on obtained flotation gold concentrate (heavy fraction).

Owner:CHANGCHUN GOLD RES INST

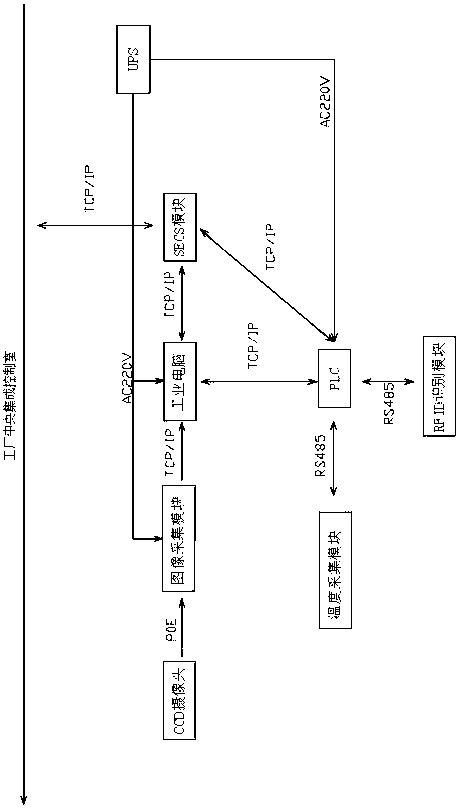

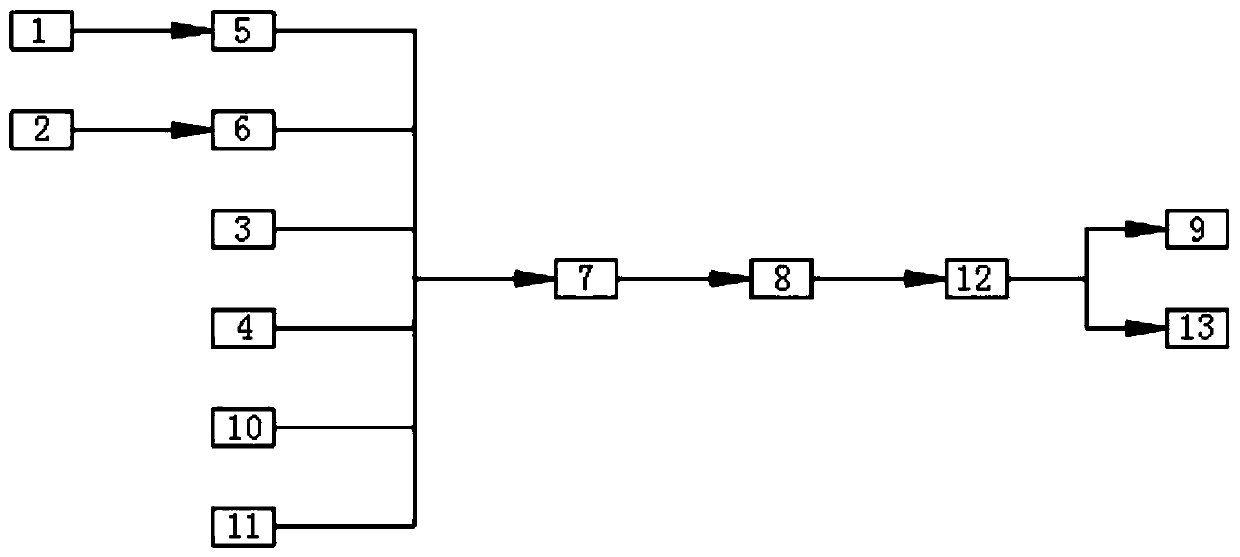

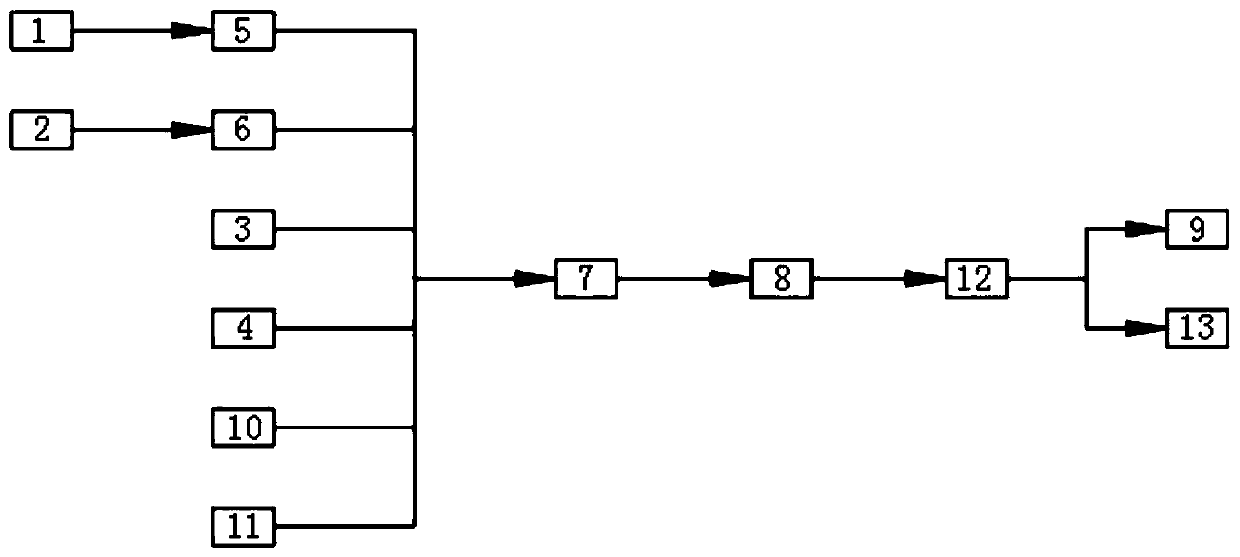

Control system of full-automatic chemical nickel-palladium-gold production equipment

PendingCN110629207AEasy to manageAvoid it happening againLiquid/solution decomposition chemical coatingPrinted circuit manufactureMetallic NickelImage acquisition

The invention discloses a control system of full-automatic chemical nickel-palladium-gold production equipment. The control system is structurally characterized in that an industrial computer is connected with an image acquisition module, a PLC and an SECS; the image acquisition module is connected with a CCD high-definition camera; the PLC is connected with a temperature acquisition module, an RFID identification module and the SECS module; and the SECS module is connected with a central integrated control room of a factory. The control system has the advantages that the CCD high-definition camera can obtain a running picture in a machine in real time, and alarm when any abnormality occurs; the RFID identification module carries out real-time tracking to automatically identify and input process parameters required by a product without manual intervention, and can automatically return incorrect information so as to prevent defects; the SECS module facilitates the management and can monitor production conditions of a production line in time, and save important production data and reports to reduce process errors in order to reduce cost as well as improve product quality, and meanwhile, a senior administrator can coordinate production of the whole workshop more conveniently; and as traceability is increased, the product quality is advantageously improved.

Owner:吉姆西半导体科技(无锡)有限公司

Method for treating cyanided tailing slurry through hot-press oxidized liquid of gold extracting technology in gold industry

InactiveCN108373217AEasy to handleImprove processing efficiencyWaste water treatment from quariesWater contaminantsLiquid wasteOperational costs

The invention belongs to the technical field of pollutant treating methods and specifically relates to a method for treating cyanided tailing slurry through hot-press oxidized liquid of a gold extracting technology in the gold industry. Aiming at the environmental problem of cyanided tailings obtained by an existing treating method, waste slurry and waste liquid generated by a hot-press pre-oxidizing work section of the gold extracting technology of the gold industry are utilized to achieve the purpose of treating waste by waste; enterprises are prevented from purchasing harmless treatment agents, operation cost of gold production enterprises is greatly reduced, and important significance in clean production, energy conservation, emission reduction and sustainable development of the wholegold industry is achieved.

Owner:CHANGCHUN GOLD RES INST

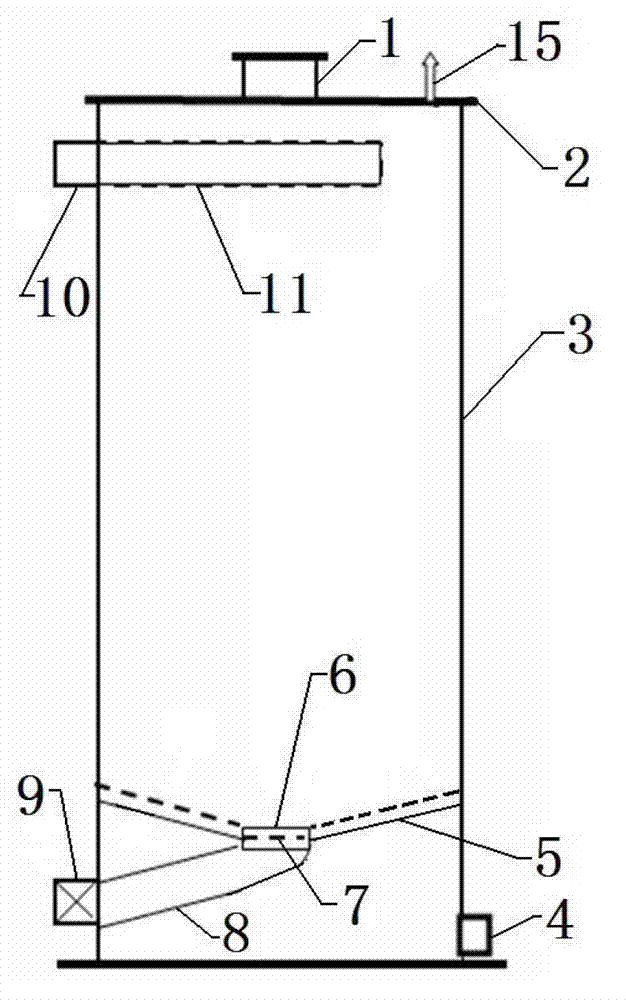

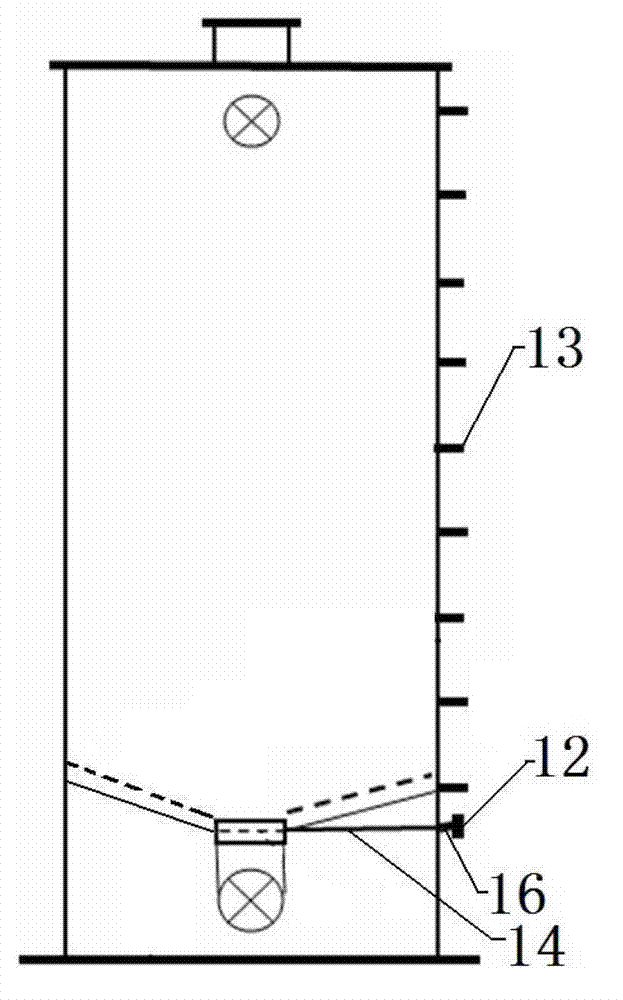

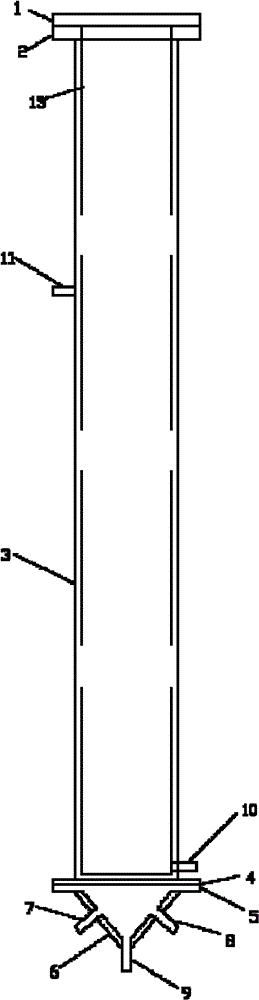

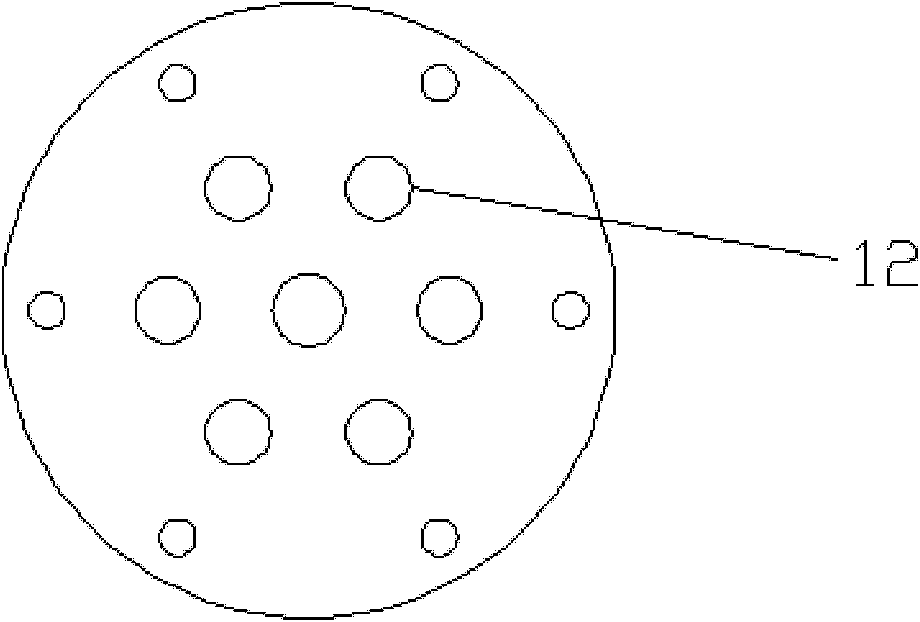

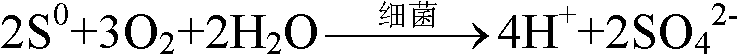

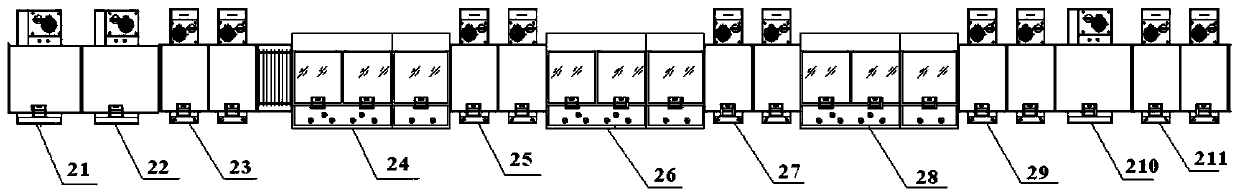

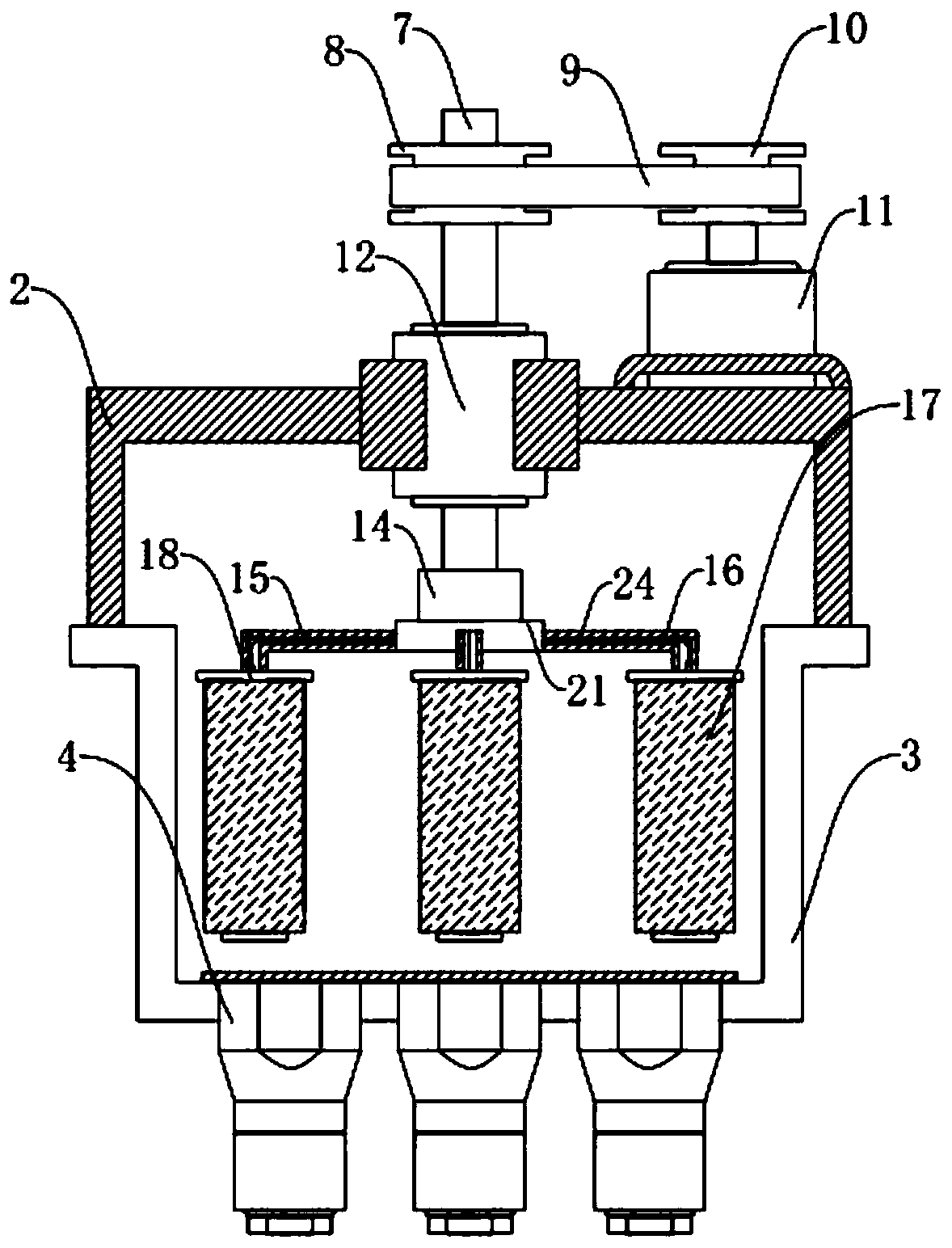

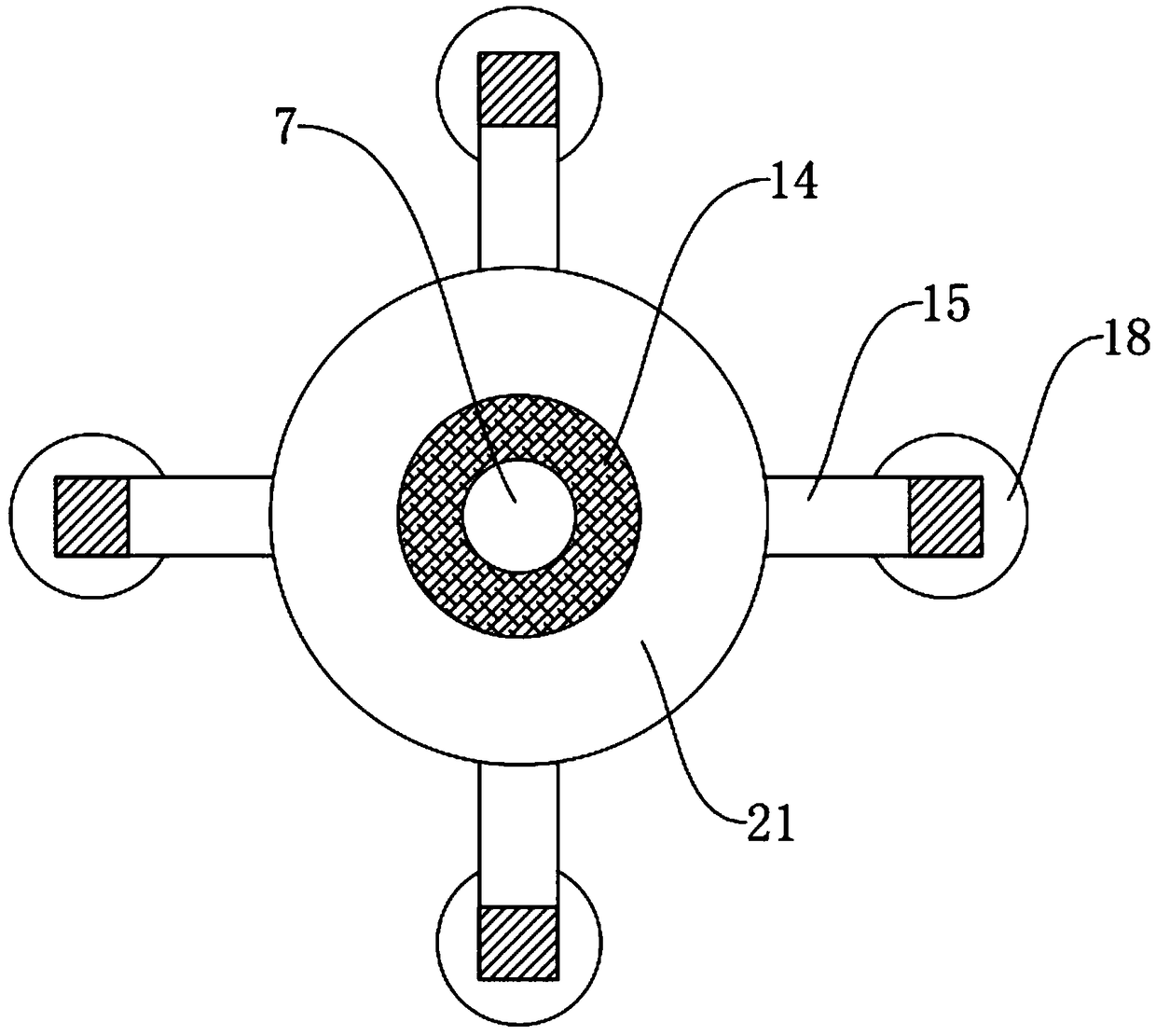

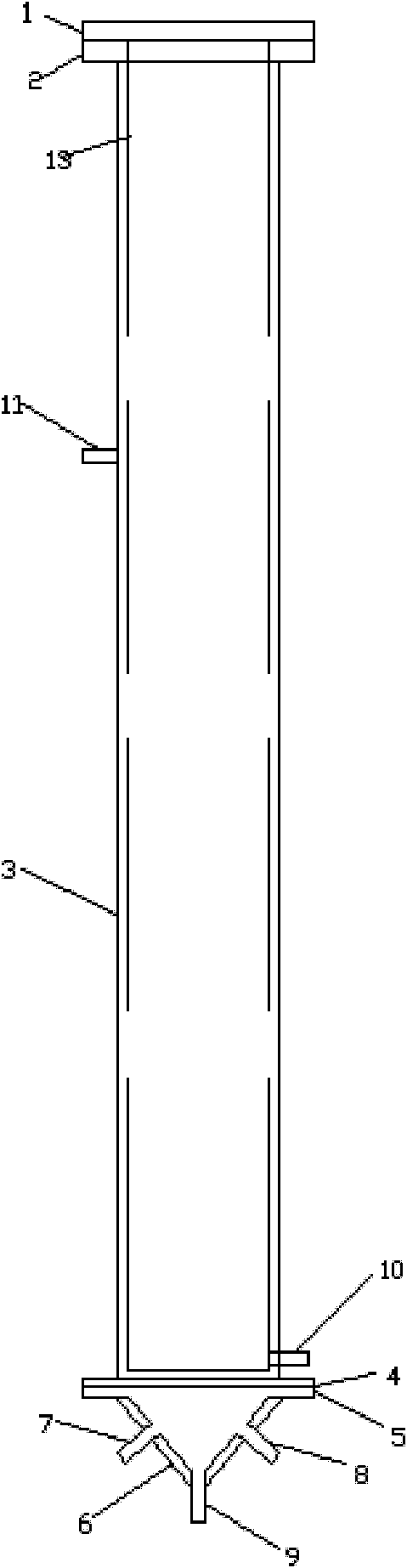

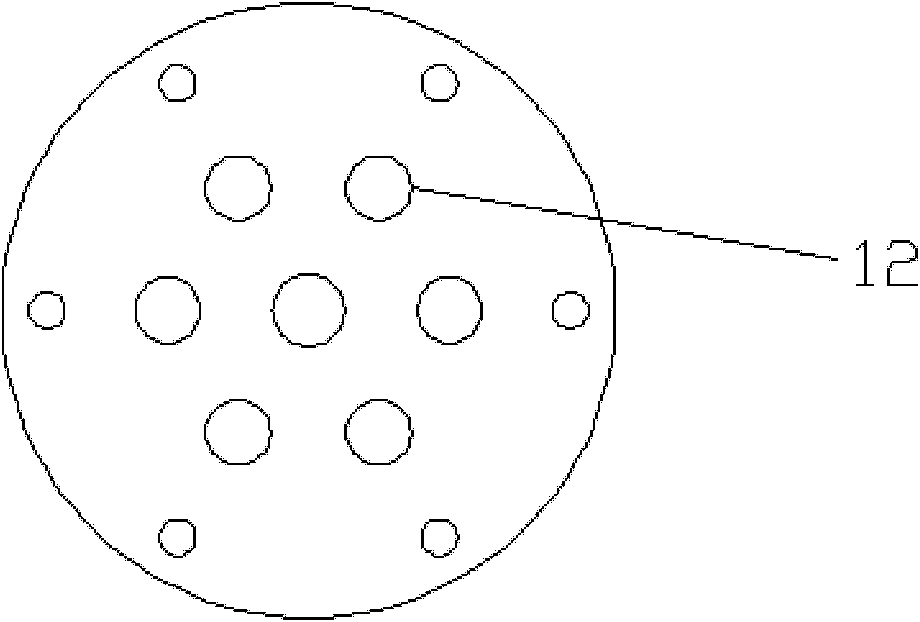

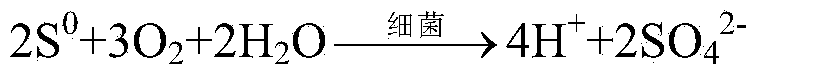

Vertical cell immobilized reactor for producing ferric irons by biological oxidation

The invention discloses a vertical cell immobilized reactor for producing ferric irons by biological oxidation. The immobilized reactor is mainly composed of a round top cover (1), an upper flange (2), a reactor cylinder (3), a gas distributor (4), a lower flange (5), an inverted cone pedestal (6), a feeding inlet (7), a waste liquid-discharging port (8), an air vent (9), a sampling outlet (10), a discharging port (11) and an air hole board (12). The immobilized reactor is a cell immobilized reactor for producing the ferric irons which employs moderate thermophilic Siberian influenza bacteria as immobilized bacteria and polyurethane foam as a vector. The immobilized reactor solves the problem of low reaction rate and toxicity by toxic ions in a solution during a process of oxidizing Fe2+ into Fe3+ by bacterial oxidation in a biology process during a preoxidation treatment process of minerals during a gold production process, and can increase the oxidation rate of Fe2+ by the bacteria. The vertical cell immobilized reactor has the advantages of few bacterial contaminations, uniform and sufficient air supply, capacity for continuous operation, high oxidation rate, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Pretreatment method of activated carbon for gold production

ActiveCN106517198AReduce wear rateReduce loss rateCarbon compoundsOther chemical processesActivated carbonPretreatment method

The invention relates to a pretreatment method of activated carbon for gold production, belonging to the field of mineral processing. The method comprises the following steps: preparing ore slurry with the corresponding fineness and mass concentration to the industrial production from ores treated by a carbon-slurry gold extraction process, maintaining activated carbon of which the particle size is greater than 1.0mm and less than 3.35mm, mixing the activated carbon and ore slurry (the mass ratio of the activated carbon to water in the ore slurry is 1:3-1:5), carrying out mechanical stirring and sanding pretreatment for 1-3 hours, screening out fine-particle carbon with the particle size of less than 1.0mm to maintain the activated carbon with the particle size of greater than 1.0mm, washing, filtering out water, and drying. The activated carbon obtained by the activated carbon pretreatment method disclosed by the invention has the advantages of smooth surface and favorable wear resistance, and has lower wear rate of carbon when being used in the carbon-slurry gold extraction process.

Owner:CHANGCHUN GOLD RES INST

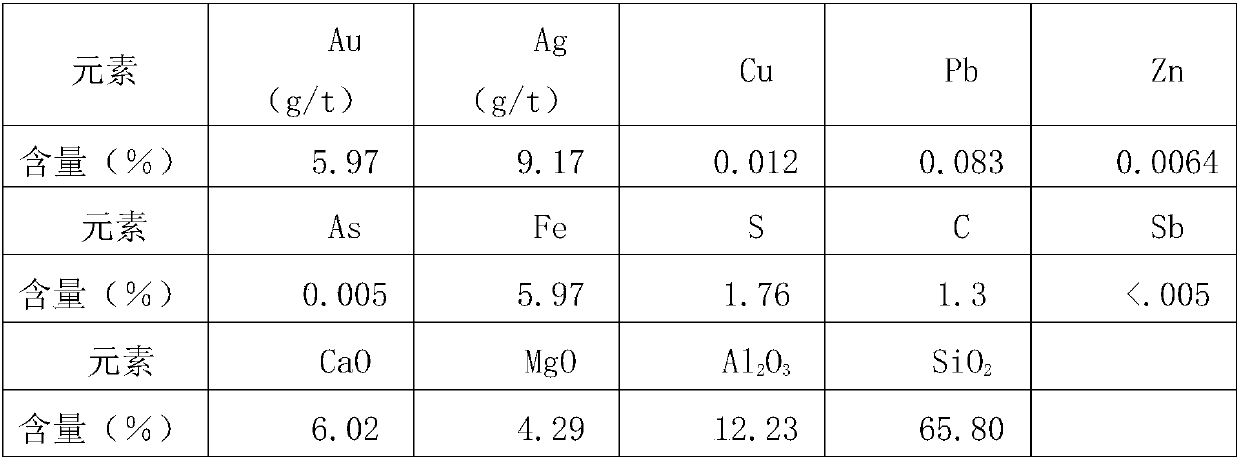

Method for removing impurities in reduced gold powder

ActiveCN110205500AQuality assuranceReduce processing costsProcess efficiency improvementIngotOxidizing agent

The invention relates to a method for removing impurities in reduced gold powder. The method is suitable for removing the impurities such as Ag, Cu, Pb, Fe and the like in the reduced gold powder in agold refining process. The method comprises the steps of adding the reduced gold powder with the impurity exceeding the standard into a hydrochloric acid solution of 3-5 mol / L according to a liquid-solid ratio of 4: 1, and then heating to 60-80 DEG C; adding an oxidant, and reacting for 2-3 hours under strong stirring; filtering the treated reduced gold powder, and washing with hot water to be neutral, specifically the impurity content of Ag, Cu, Pb, Fe and the like in the reduced gold powder can be effectively reduced to be within the scope of the IC-Au 99.99 standard; and obtaining gold ingots meeting the requirements through fusion casting. The method has the advantages of simple process, low cost, short treatment time, good impurity removal effect and the like, and is suitable for application and popularization in the field of gold production and processing.

Owner:山东黄金冶炼有限公司

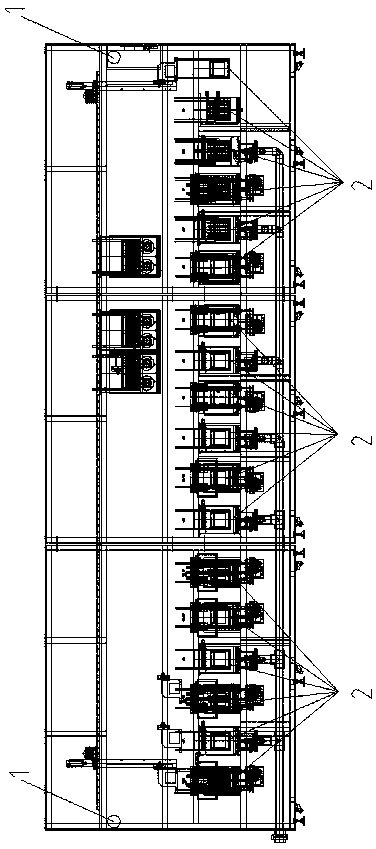

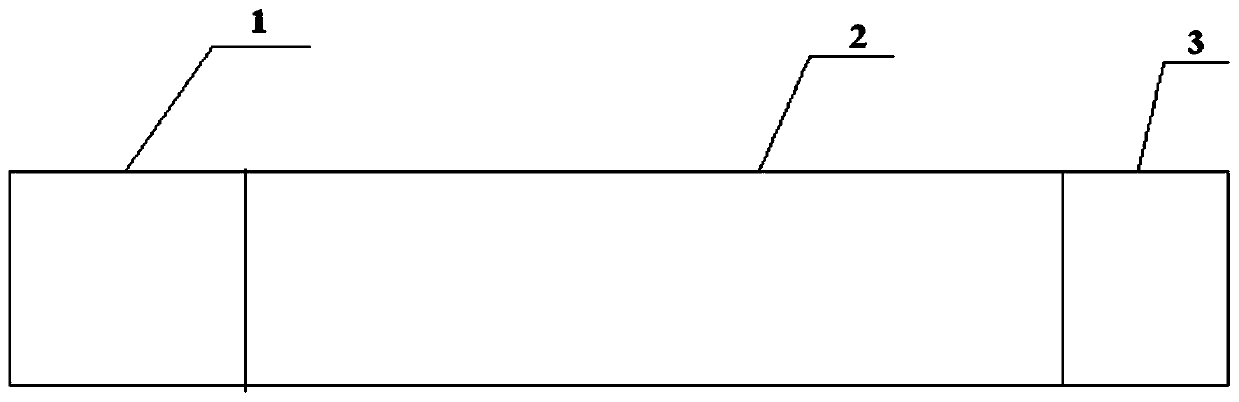

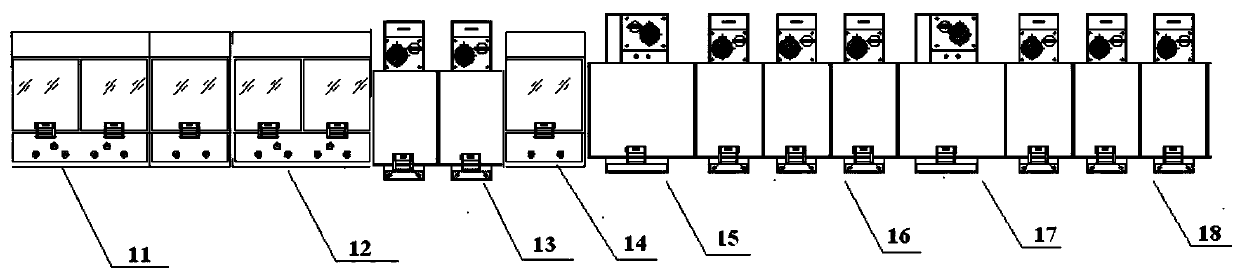

Chemical nickel palladium gold production line and production technology

PendingCN109852951AReduce horizontal space occupiedSmall footprintLiquid/solution decomposition chemical coatingProduction lineManufacturing cost reduction

The invention provides a chemical nickel palladium gold production line. The chemical nickel palladium gold production line comprises a conveying mechanism, a pre-treatment area, a chemical nickel palladium gold area and a post-treatment area, wherein the pre-treatment area, the chemical nickel palladium gold area and the post-treatment area are sequentially adjacently arranged on a moving route of the conveying mechanism. According to the chemical nickel palladium gold production line, the pre-treatment, chemical nickel palladium gold and the post-treatment in chemical nickel palladium gold production are integrated in one production line, so that the labor is saved, and the processes are decreased; in addition, the manufacturing and use cost of the production line are reduced. Additionally, the invention provides a chemical nickel palladium gold technology. The technology involves chemical nickel plating of a soft board, a chemical nickel plating of a hard board, palladium reducing,palladium replacing, gold reducing and gold replacing; and three nickel bathes, three palladium bathes and three gold bathes are formed in the production line. The production line integrates all demands in the chemical nickel palladium gold production technology; and the manufacturing cost and the use coat are decreased.

Owner:深圳互连微电子材料有限公司

Method for treating cyanide-containing wastewater of gold production enterprises

ActiveCN104176888AEasy to handleImprove processing efficiencyMultistage water/sewage treatmentTherapeutic effectElectrochemistry

The invention discloses a method for treating cyanide-containing wastewater of gold production enterprises. The method comprises four steps of electrochemical treatment, coagulating sedimentation treatment, ozonation treatment and biological active carbon treatment. Specifically, the method comprises the following steps: firstly, removing easily treated cyanide by adopting an electrochemical treatment process, and performing coagulating sedimentation on the treated wastewater by adding a zinc sulfate solution and a coagulant to remove metal cyanide complexes and heavy metal ions in the wastewater; secondly, introducing ozone into supernatant liquid, and oxidizing to remove pollutants such as residual difficultly treated cyanide, thiocyanate and the like in the wastewater; finally, removing pollutants difficultly removed by a chemical process in the wastewater by adopting a biological and physical adsorption process through a biological active carbon treatment system. The method is used for deeply treating the cyanide-containing wastewater, has a good treatment effect and is high in treatment efficiency and simple in process; the treated wastewater can return to a production process to be used as recycled water or to be discharged by standard.

Owner:CHANGCHUN GOLD RES INST

A method for treating cyanide-containing wastewater from gold cyanide enterprises

ActiveCN104261624BEasy to handleImprove processing efficiencyWater contaminantsWater/sewage treatment by electrochemical methodsTherapeutic effectElectrochemistry

The invention discloses a method for treating cyanide-containing wastewater in gold cyaniding enterprises. The method comprises the four steps of electrochemical treatment, chemical oxidation treatment, coagulating sedimentation treatment and biological activated carbon treatment. When the cyanide-containing wastewater is treated, cyanide is electrolyzed by adopting the electrochemical treatment method; coagulating sedimentation is carried out by adding a coagulating agent, and heavy metal pollutants in wastewater can be removed; precipitated wastewater is oxidized by adding a chemical reagent; and finally, pollutants which are hardly removed from wastewater by a chemical method are removed by adopting a biological and physical adsorption method through a biological activated carbon treatment system. According to the method, the four steps are combined together according to the characteristics of complex and hardly treated pollutants in cyanide-containing wastewater of gold production enterprises, and are synergized to carry out deep treatment on the cyanide-containing wastewater of gold production enterprises. The method has the advantages of good treatment effect, high treatment efficiency, stable system operation and simple process flow, and can easily realize industrial application, and the treated wastewater can be returned to a production process flow to be used as reclaimed water or discharged with standard level.

Owner:CHANGCHUN GOLD RES INST

A kind of pretreatment method of activated carbon for gold production

ActiveCN106517198BReduce wear rateReduce loss rateCarbon compoundsOther chemical processesActivated carbonPretreatment method

The invention relates to a pretreatment method of activated carbon for gold production, belonging to the field of mineral processing. The method comprises the following steps: preparing ore slurry with the corresponding fineness and mass concentration to the industrial production from ores treated by a carbon-slurry gold extraction process, maintaining activated carbon of which the particle size is greater than 1.0mm and less than 3.35mm, mixing the activated carbon and ore slurry (the mass ratio of the activated carbon to water in the ore slurry is 1:3-1:5), carrying out mechanical stirring and sanding pretreatment for 1-3 hours, screening out fine-particle carbon with the particle size of less than 1.0mm to maintain the activated carbon with the particle size of greater than 1.0mm, washing, filtering out water, and drying. The activated carbon obtained by the activated carbon pretreatment method disclosed by the invention has the advantages of smooth surface and favorable wear resistance, and has lower wear rate of carbon when being used in the carbon-slurry gold extraction process.

Owner:CHANGCHUN GOLD RES INST

Trace amount gold separated enriching lumination detection device and method

InactiveCN1664566AReduce dosageRunner is simpleChemiluminescene/bioluminescencePhotomultiplierIon-exchange membranes

The invention relates to a device and method for quantitative analyzing the trace by the chemiluminescence in the gold prospecting, gold production, sea water analysis. The steps: a) setting a beard on the transparent material, an inlet and outlet on the lateral surface; b) covering the amberplex and gland on the beard; c) putting the device in the booth of the multiplier phototube; d) separating and gathering the gold through the adsorption of the amberplex. The device also can be used as chemiluminescence measuring light source, and the amberplex can be used repeatedly.

Owner:JILIN UNIV

Method for extracting gold from gold ore by adopting superconducting effect and quantum cyclotron resonance effect

The invention discloses a novel pollution-free energy-saving gold production method. According to the novel pollution-free energy-saving gold production method, gold particles are selected and collected from gold ore by adopting the superconducting effect and the gold macroscopic quantum cyclotron resonance effect, so that the pollution-free production of gold is realized.

Owner:张庆信 +2

PCB production line IoT (Internet of Things) system based on cloud computing platform

InactiveCN109976293AHigh degree of automationQuality assuranceTotal factory controlProgramme total factory controlProduction lineElectricity

The invention discloses a PCB production line IoT (Internet of Things) system based on a cloud computing platform. The PCB production line IoT system comprises a medicinal liquid tank and rinsing baths; a swinging square steel is arranged above the medicinal liquid tank and the rinsing baths; a skeet base, an electric vibration motor and an air vibration motor are arranged on the swinging square steel; the skeet base is provided with a skeet matched with the skeet base, and the lower surface of the skeet is collided with an output shaft of the electric vibration motor; the medicinal liquid tank comprises a degreasing tank, a micro-etching tank, an activating tank, a nickel tank, a gold tank and a gold recovery tank; the degreasing tank, the micro-etching tank, the activating tank, the nickel tank, the gold tank, the gold recovery tank and a plurality of rinsing baths are all provided with liquid level sensors; the degreasing tank, the micro-etching tank, the activating tank, the nickeltank and the gold tank are all provided with temperature sensors; and both the liquid level sensors and the temperature sensors are electrically connected with a data converter. According to the PCBproduction line IoT system disclosed by the invention, each link of a gold production line is monitored in real time; the automation degree is high; and a field operator is timely reminded to carry out parameter regulation and equipment repair so as to ensure quality of products.

Owner:KUNSHAN HANHUI ELECTRONICS TECH CO LTD

Harmless method for treating cyanide-containing tailing pulp with biological oxidized liquid by gold extraction process in gold industry

ActiveCN108117232AReduce operating costsEasy to handleWater contaminantsTreatment involving filtrationSlagEnergy conservation

The invention relates to a harmless method for treating cyanide-containing tailing pulp with biological oxidized liquid by a gold extraction process in the gold industry, and belongs to the field of environmental protection. The method comprises the following steps: firstly, selecting a closed stirring reactor, introducing hydrogen cyanogen generated in a reaction into a spraying and absorbing device by an air drainage device which is arranged at the upper part of the reactor, and performing absorbing; then, adding biological oxidized liquid into the reactor to remove easily released cyanide and metal cyano complex; performing filter or filter-press process on tailing pulp, and piling the tailing slag which is identified to be conventional industrial solid waste to a tailing bank; adding apH value neutralizing agent into the filtrate, recycling the production process or dosing an advanced treatment agent and catalyst into the filtrate, and draining the filtrate after the filtrate is treated to be in accordance with Integrated Wastewater Discharge Standard GB8978-1996. According to the method, waste is used for treating other wastes, enterprises do not need to purchase harmless treatment agent, the operation cost of gold production enterprises can be greatly reduced, and an important meaning is achieved for clean production, energy conservation, emission reduction and sustainable development of the whole gold industry.

Owner:CHANGCHUN GOLD RES INST

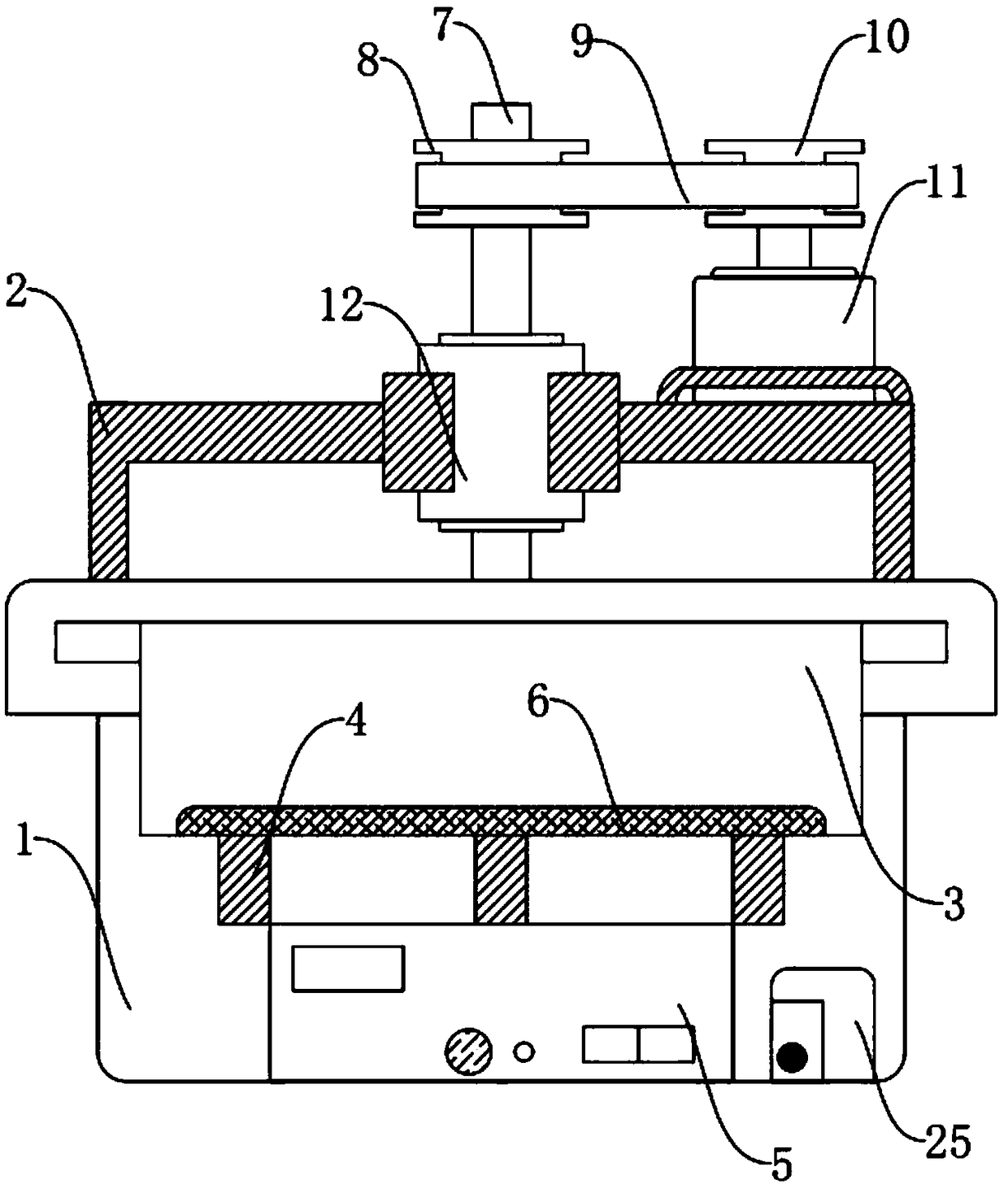

Cleaning machine for K gold production

InactiveCN108941038ASpeed up processingHigh activityCleaning using liquidsTransmission beltMegasonic cleaning

The invention discloses a cleaning machine for K gold production. The cleaning machine for K gold production comprises an outer shell; a cleaning pool is arranged on the inner side of the outer shell;a bearing base is fixedly mounted above the cleaning pool through a bracket; a rotating shaft is rotationally mounted at the middle part of the bearing base; a first belt wheel is fixedly mounted atthe upper end of the rotating shaft; the first belt wheel is in transmission connection with a second belt wheel through a transmission belt; the second belt wheel is rotationally connected with a motor; a turntable is fixedly mounted at the lower end of the rotating shaft; a wire collecting hole is formed in the middle part of the turntable; wire inlet holes are formed around the turntable; an accumulator is arranged at the upper end of the turntable; a mounting frame is fixedly mounted on the outer side of the turntable; the other end of the mounting frame is fixedly connected with an aluminum pipe; an electric heating wire is spirally mounted on the inner side of the aluminum pipe; and a heat conduction insulation rubber is arranged on the inner side of the electric heating wire. The cleaning machine is stable in work, and heats and stirs working liquid to improve the ultrasonic cleaning efficiency.

Owner:深圳市冠华珠宝有限公司

Vertical cell immobilized reactor for producing ferric irons by biological oxidation

The invention discloses a vertical cell immobilized reactor for producing ferric irons by biological oxidation. The immobilized reactor is mainly composed of a round top cover (1), an upper flange (2), a reactor cylinder (3), a gas distributor (4), a lower flange (5), an inverted cone pedestal (6), a feeding inlet (7), a waste liquid-discharging port (8), an air vent (9), a sampling outlet (10), a discharging port (11) and an air hole board (12). The immobilized reactor is a cell immobilized reactor for producing the ferric irons which employs moderate thermophilic Siberian influenza bacteria as immobilized bacteria and polyurethane foam as a vector. The immobilized reactor solves the problem of low reaction rate and toxicity by toxic ions in a solution during a process of oxidizing Fe2+ into Fe3+ by bacterial oxidation in a biology process during a preoxidation treatment process of minerals during a gold production process, and can increase the oxidation rate of Fe2+ by the bacteria. The vertical cell immobilized reactor has the advantages of few bacterial contaminations, uniform and sufficient air supply, capacity for continuous operation, high oxidation rate, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A method for extracting gold from ore and special molten gold mixture

The invention relates to a method for extracting gold from ores and a special gold-melting mixture, belonging to the technical field of gold production. The technical scheme is as follows: the special gold-melting mixture is synthesized by carrying out thermal reaction on the following components in parts by mass: 0.26 part of sodium carbonate, 0.28 part of urea, 0.03 part of sodium bromide, 0.06 part of sodium sulfide, 0.2 part of sodium thiosulfate, 0.05 part of sodium ferrocyanide, 0.06 part of sodium fluoride and 0.06 part of sodium chloride. The method comprises the following steps: mixing the components, and concentrating by carrying out thermal reaction in a sealed stirring furnace at the high temperature of 850 DEG C. The method can completely substitute the sodium cyanide gold extraction mode, is suitable for recovery and utilization of micro-series oxidation, half-oxidation, high-arsenic, high-sulfur and other polymetallic ores, tailings, slag tails and leach residues, is green and environment-friendly, lays stress on the environmental awareness, fully attaches importance to environmental protection, implements environmental protection in deed, and implements green mine and environment-friendly gold melting.

Owner:杨毓华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com