PCB production line IoT (Internet of Things) system based on cloud computing platform

An Internet of Things system and cloud computing platform technology, which is applied in the field of PCB production line Internet of Things system, can solve the problems of long chemical gold production line and rising product defective rate, and achieve the effects of high degree of automation, improved product quality, and easy monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

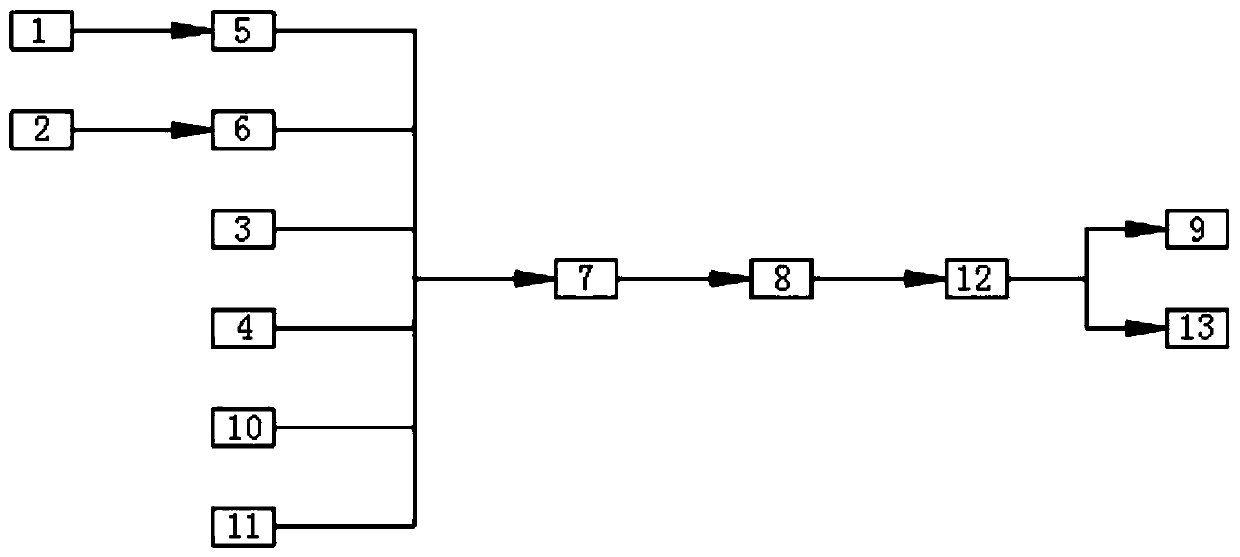

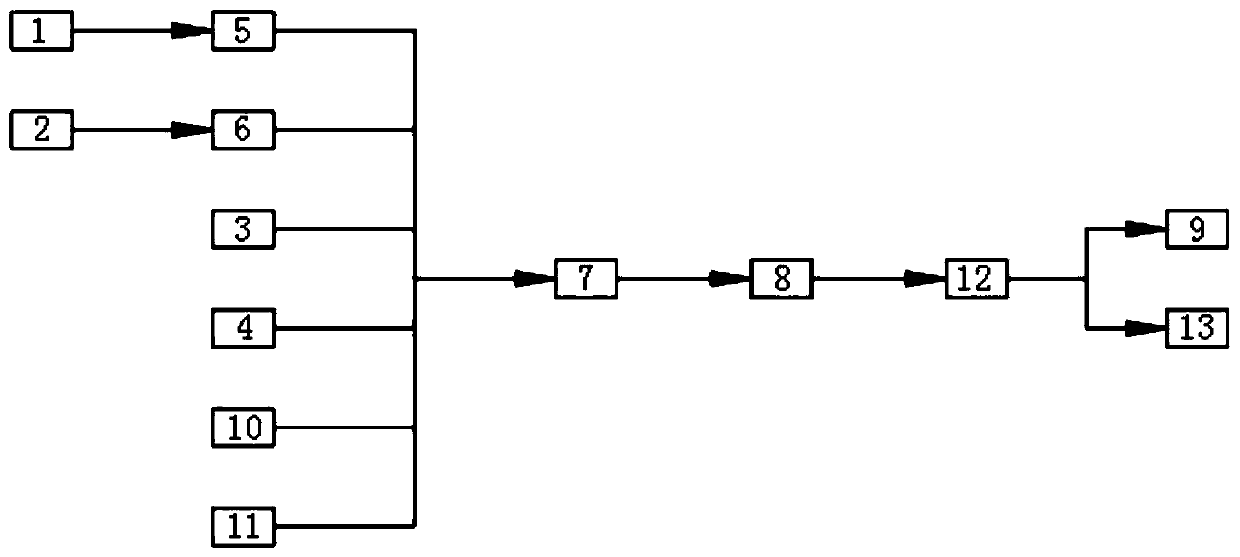

[0024] Example: A PCB production line IoT system based on a cloud computing platform, such as figure 1 As shown, it includes a potion tank and a water washing tank. A rocking square steel is provided above the potion tank and the water washing tank. A flying target base, an electric vibration motor 1 and an air vibration motor 2 are provided on the rocking square steel. The flying target base is provided with a flying target matching it, and the lower surface of the flying target is in conflict with the output shaft of the electric vibration motor 1;

[0025] The medicine tank includes a degreasing tank, a micro-etching tank, an activation tank, a nickel tank, a gold tank and a gold recovery tank, the degreasing tank, the micro-etching tank, the activation tank, the nickel tank, the gold tank , The gold recovery tank and several of the washing tanks are equipped with liquid level sensors 3, and the degreasing tank, the micro-etching tank, the activation tank, the nickel tank and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com