Chemical nickel palladium gold production line and production technology

A production process, chemical nickel technology, applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of rising production costs and labor costs, production lines that cannot be produced at the same time, and circuit boards that are prone to scratches , to achieve the effect of saving manpower, shortening the production line, avoiding pollution and scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

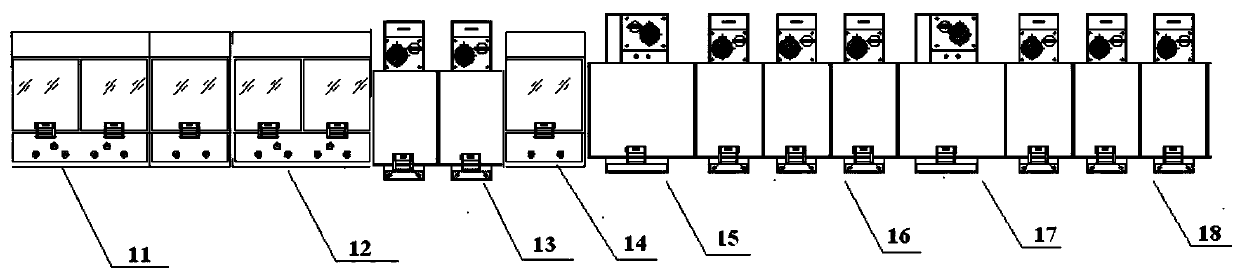

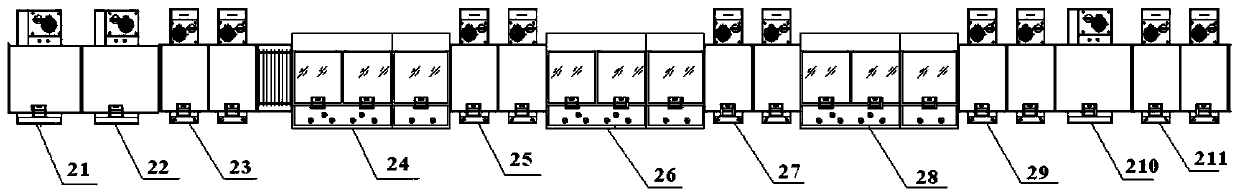

[0119] The structural representation of the electroless nickel-plating palladium-gold production line that the present embodiment provides is as figure 1 , figure 2 , image 3 with Figure 4 as shown, figure 1 The structural representation of the chemical nickel-palladium-gold production line provided by the present invention includes:

[0120] Conveyor mechanism (not shown in the figure), comprises: the pretreatment area horizontal conveying device that is used for horizontally conveying plating piece, the chemical nickel palladium gold zone horizontal conveying device that is used for horizontally conveying plating piece, is used for the back of horizontal conveying plated piece The horizontal conveying device in the treatment area; the first vertical conveying device, the first vertical conveying device is used to vertically lift the plated parts from the horizontal conveying device in the chemical nickel palladium gold area and immerse them in the chemical nickel tank ...

Embodiment 2

[0127] Adopt the electroless nickel-palladium-gold production line in embodiment 1 to carry out chemical nickel-palladium-gold process production:

[0128] Put the plated parts into the production line in order: sandblasting, grinding, primary cleaning, degreasing, micro-etching, secondary cleaning, pickling and three pre-cleaning treatments;

[0129] Then directly carry out pre-soaking, activation, four times of cleaning, nickel plating, five times of cleaning, palladium plating, six times of cleaning, gold plating, seven times of cleaning, gold surface sealing and eight times of chemical nickel palladium gold treatment;

[0130] Finally, it is directly processed after drying.

[0131] During chemical nickel palladium gold treatment:

[0132] The plating solution formula for hard plate electroless nickel plating is: nickel sulfate 10g / L, sodium hypophosphite 25g / L, lactic acid 10g / L, ammonia water 10g / L, ethylenediamine tetramethylene phosphonate sodium (EDTMPS) 20g / L, Hydr...

Embodiment 3

[0150] Carry out chemical nickel-palladium-gold process production according to the method for embodiment 2, and the difference of embodiment 2 is:

[0151] Plating solution formula for hard plate electroless nickel plating: nickel sulfate 10g / L, sodium hypophosphite 25g / L, lactic acid 8g / L, ammonia water 10g / L, sodium ethylenediamine tetramethylene phosphonate (EDTMPS) 30g / L, hydroxyl Ethylidene diphosphonic acid (HEDP) 15g / L, ammonium chloride 15g / L, glycine 10g / L, praseodymium sulfate 91ppm, yttrium sulfate 13ppm.

[0152] The plating solution formula for electroless nickel plating on flexible boards is: nickel sulfate 10g / L, sodium hypophosphite 25 / L, lactic acid 10g / L, malic acid 10g / L, ammonia water 10g / L, glycine 10g / L, lead acetate 10ppm, OP -10 15g / L, saccharin 10g / L, diazolidinyl urea 5g / L.

[0153] Plating solution formula for chemical reduction palladium plating: palladium sulfate 1g / L, sodium hypophosphite 10g / L, ethylenediamine 10g / L, triammonium citrate 10g / L, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com