Patents

Literature

305 results about "Gold surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Devices and techniques for treating glaucoma

InactiveUS6989007B2Improve facilitiesGood mannersLaser surgeryDiagnosticsOpen angle glaucomaAqueous outflow

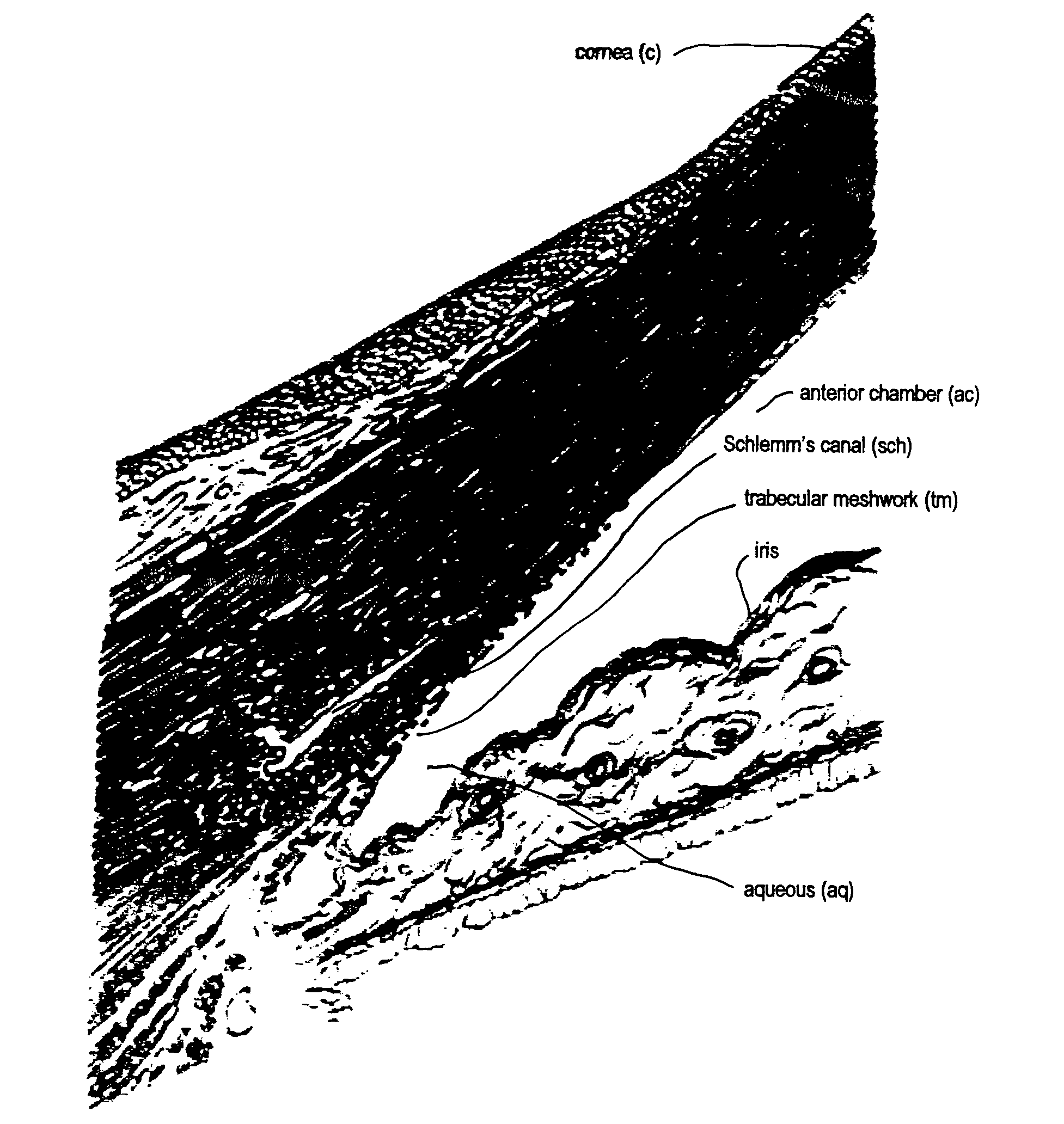

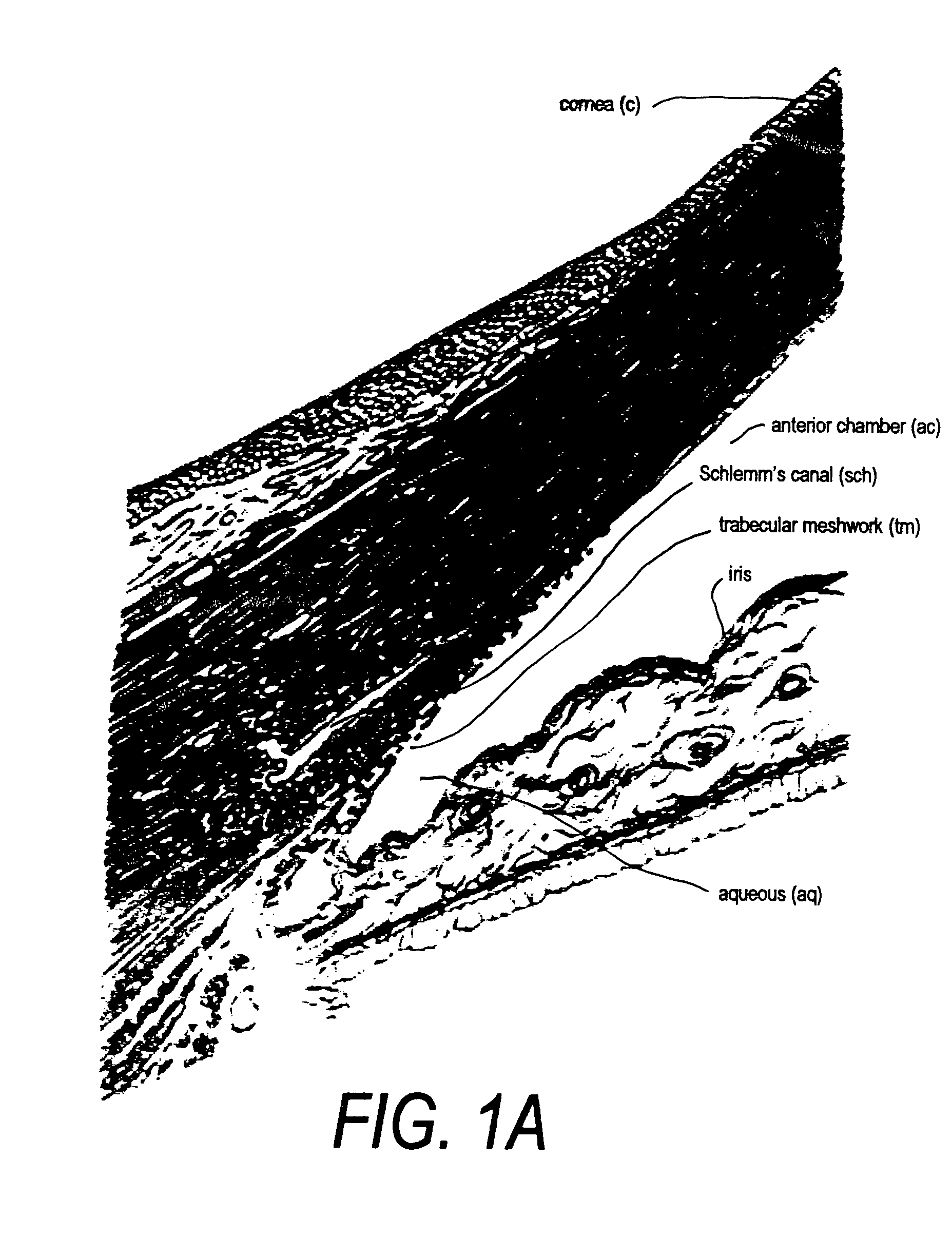

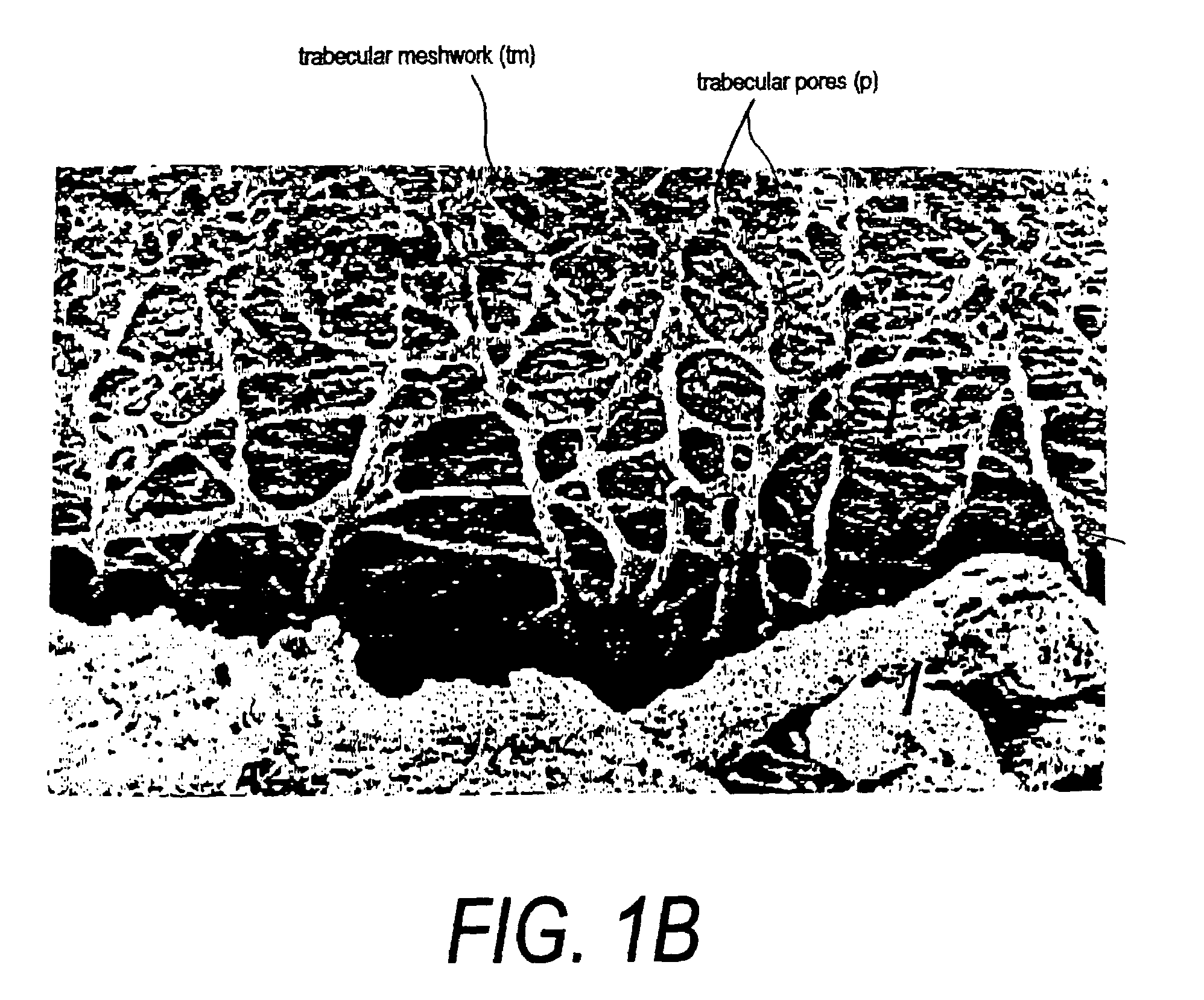

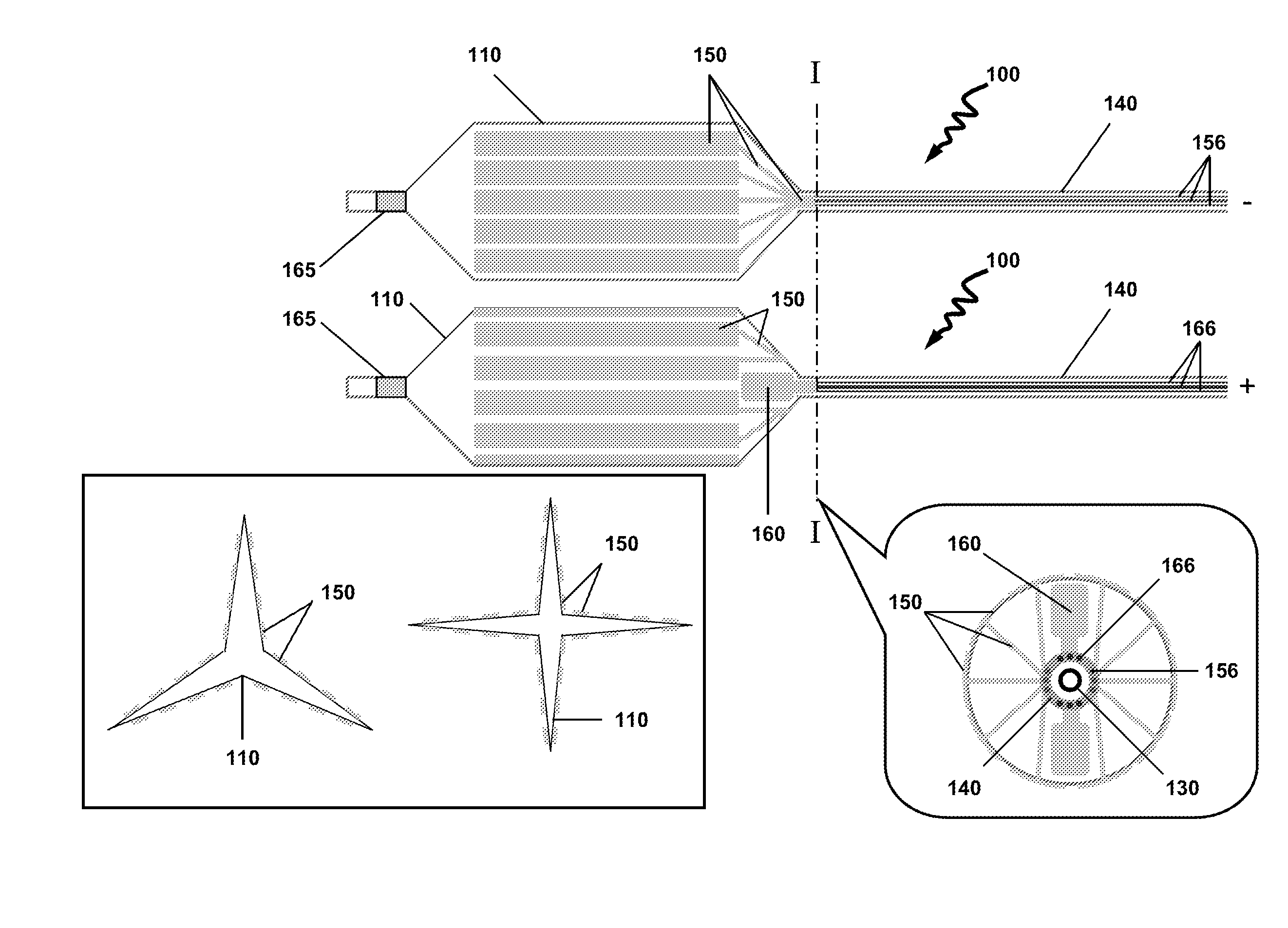

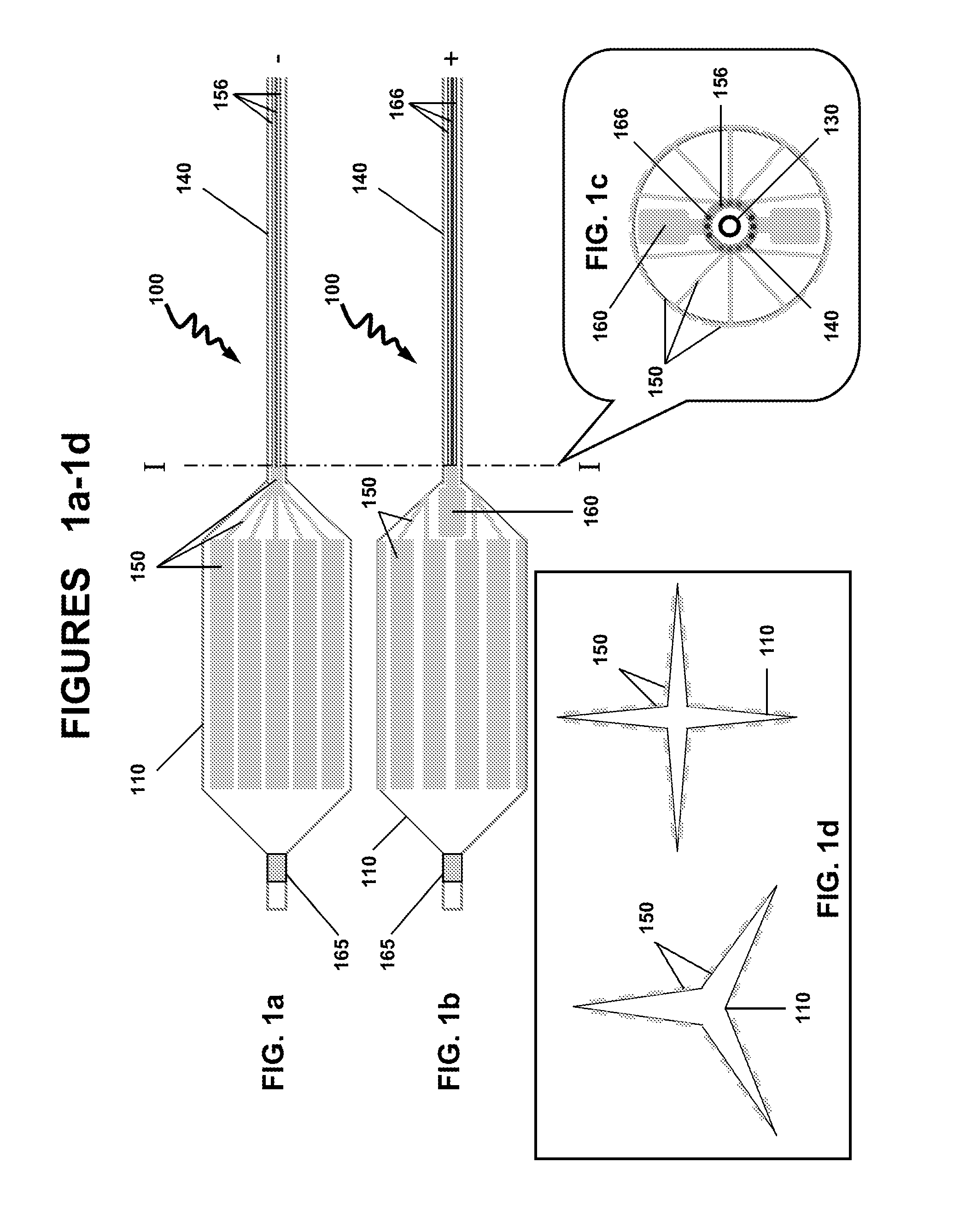

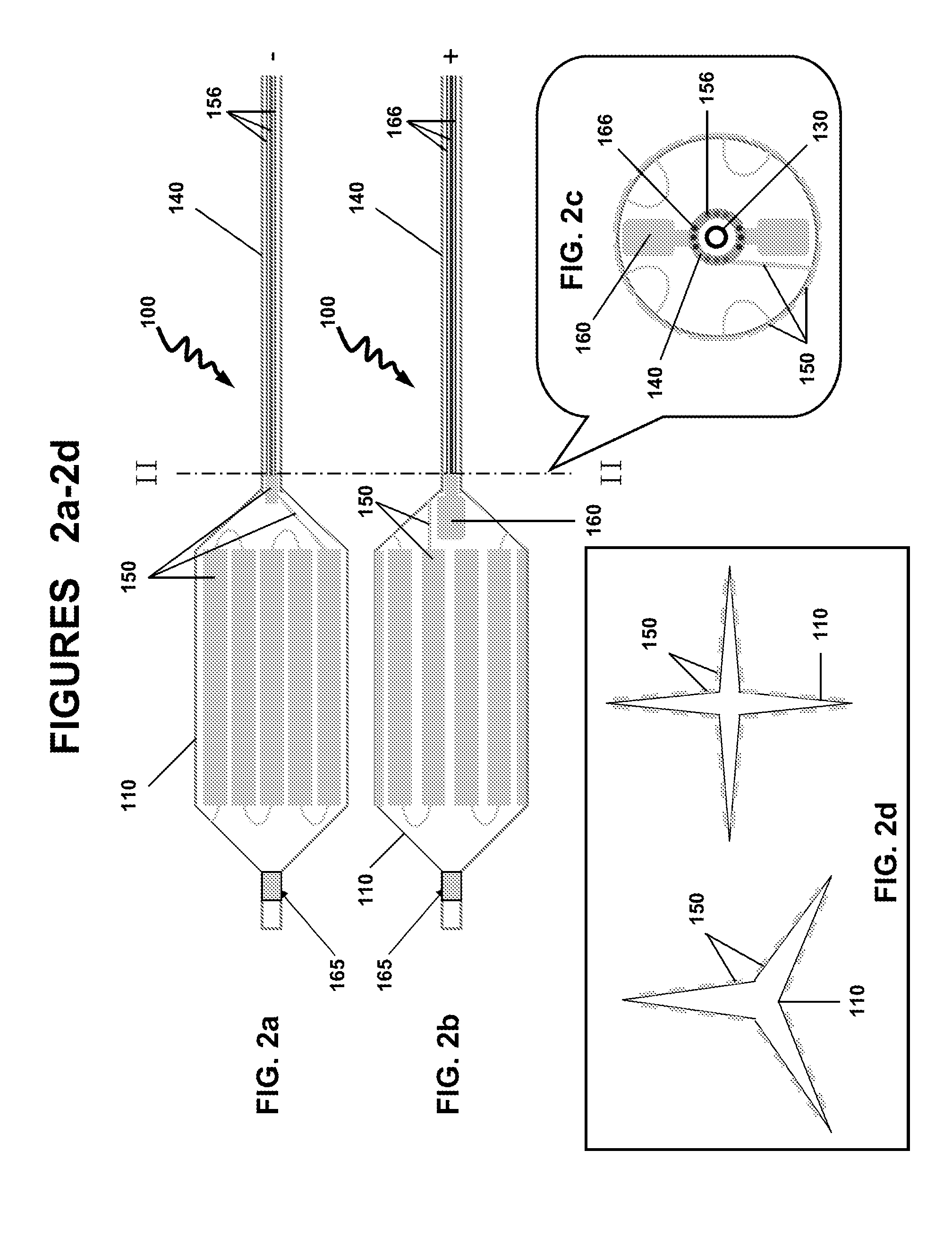

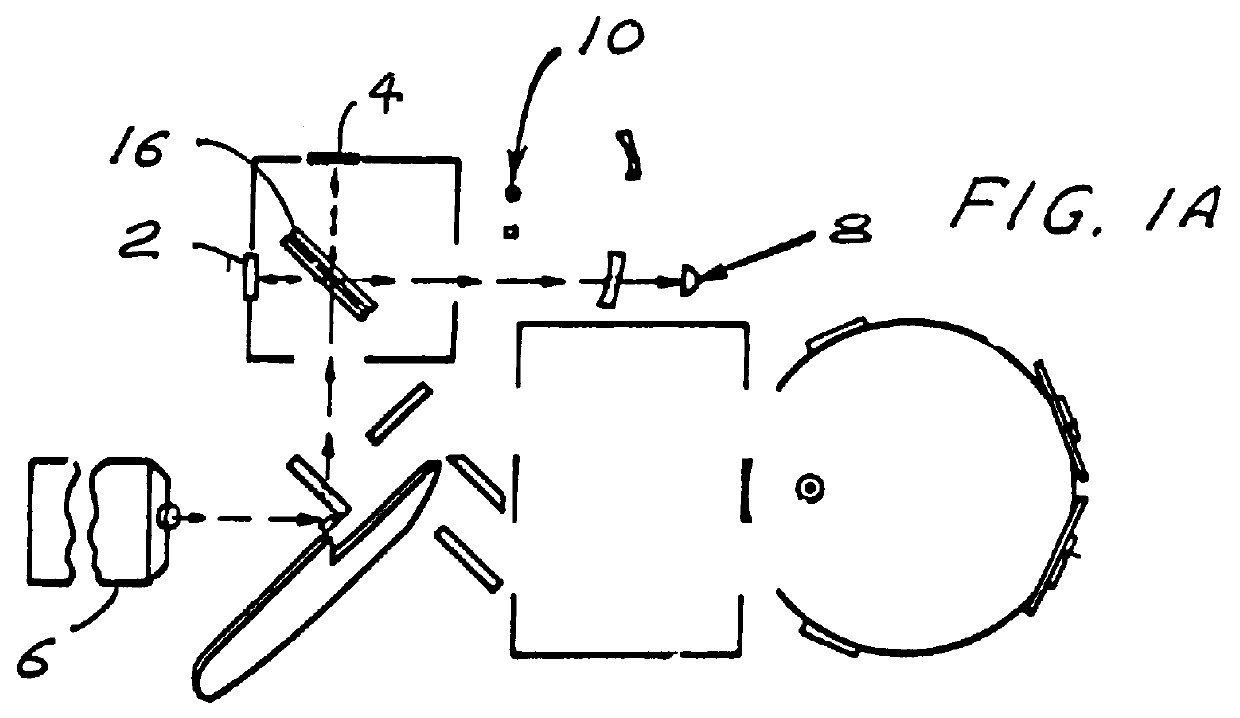

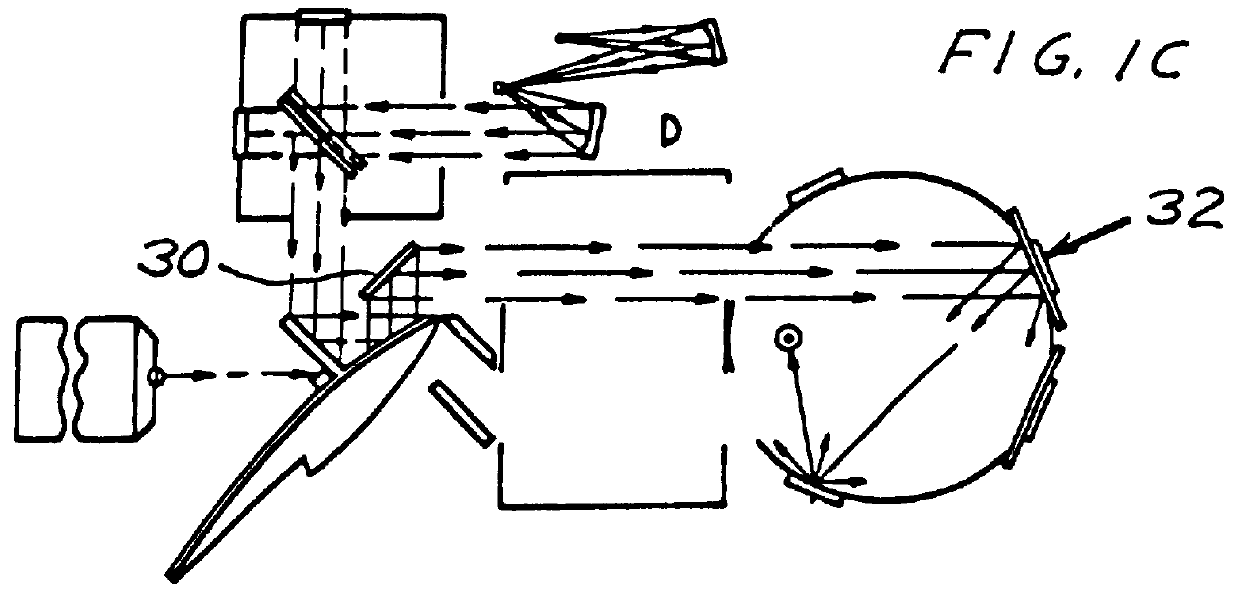

A system for non-invasive treatment of a patient's trabecular meshwork to treat primary open-angle glaucoma. The system and technique applies energy directly to media within clogged spaces in a patient's trabecular meshwork to increase aqueous outflow facility by (i) localization of microimplantable bodies carrying a selected exogenous chromophore, such as particles with a gold surface, in deeper regions of the trabecular meshwork, and (ii) irradiation of the microimplantables with a selected coherent wavelength having a power level and pulse duration that is strongly absorbed by the surfaces of the microimplantables.

Owner:OCCULOGIX CORP

Device for local intraluminal transport of a biologically and physiologically active agent

Provided herein is a drug delivery device and the method of us for the intraluminal controlled delivery of a biologically active agent comprising a dilating member comprising a proximal end and a distal end, and an inner surface and an outer surface, wherein a part of the outer surface of the dilating member is coated with a gold surface layer; a biodegradable substrate comprising the biologically active agent, wherein the substrate is covalently bonded to the gold surface layer by a gold-sulfur (Au—S—) bond; an electrical lead having a first end and a second end, the first end connected to the gold surface layer, wherein the electrical lead is configured to pass an electrical current to the gold surface layer; and wherein the controlled delivery and release of the sub strate comprising the biologically active agent is initiated by an electrical current reduction and cleavage of the Au—S bond.

Owner:TERUMO KK

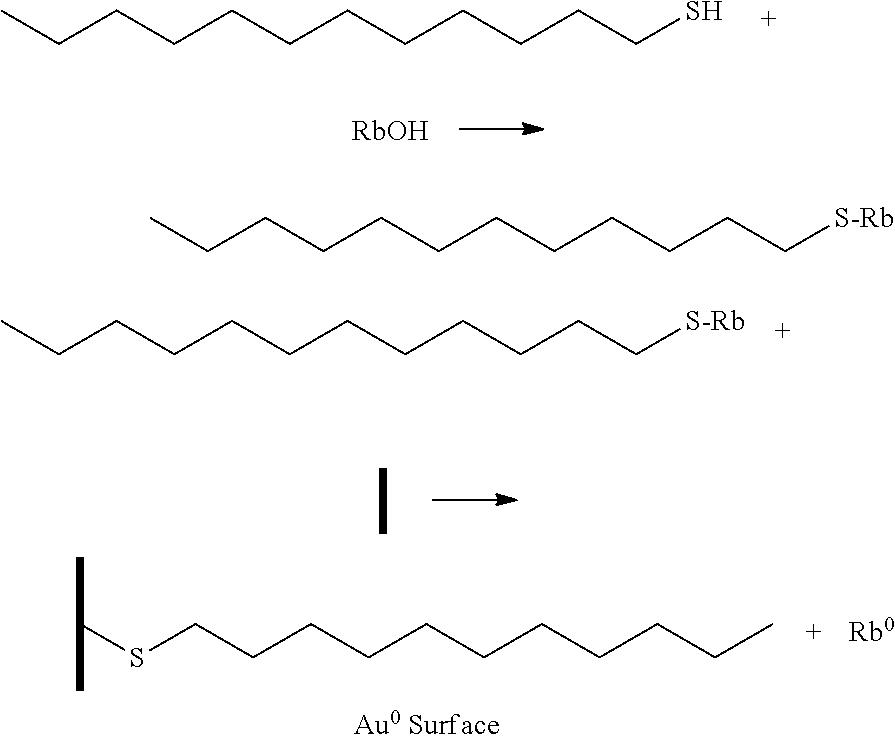

Dispensing of alkali metals mediated by zero oxidation state gold surfaces

ActiveUS20200056263A1Electrodynamic magnetometersMagnetic field measurement using magneto-optic devicesSulfurPhysical chemistry

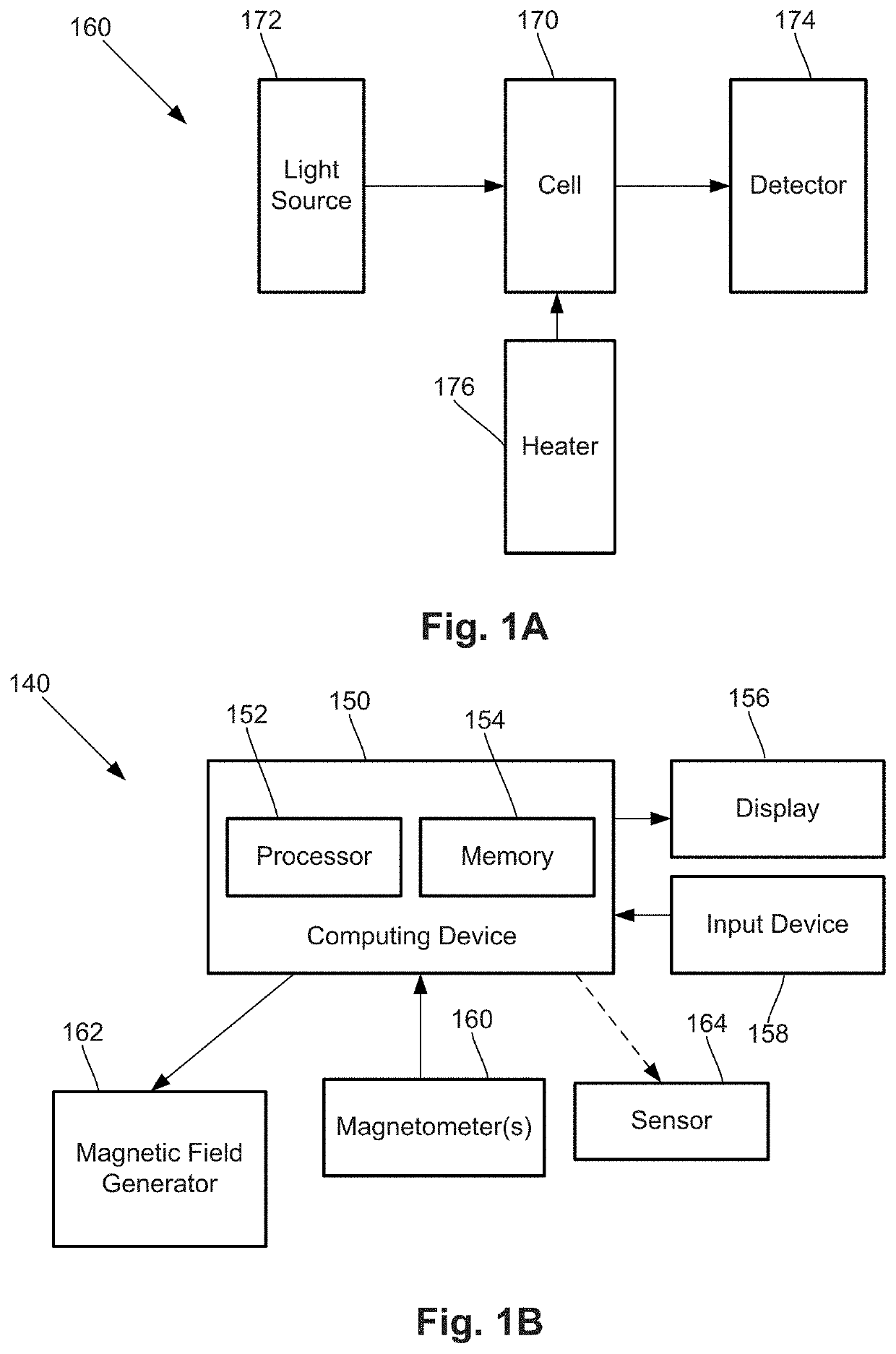

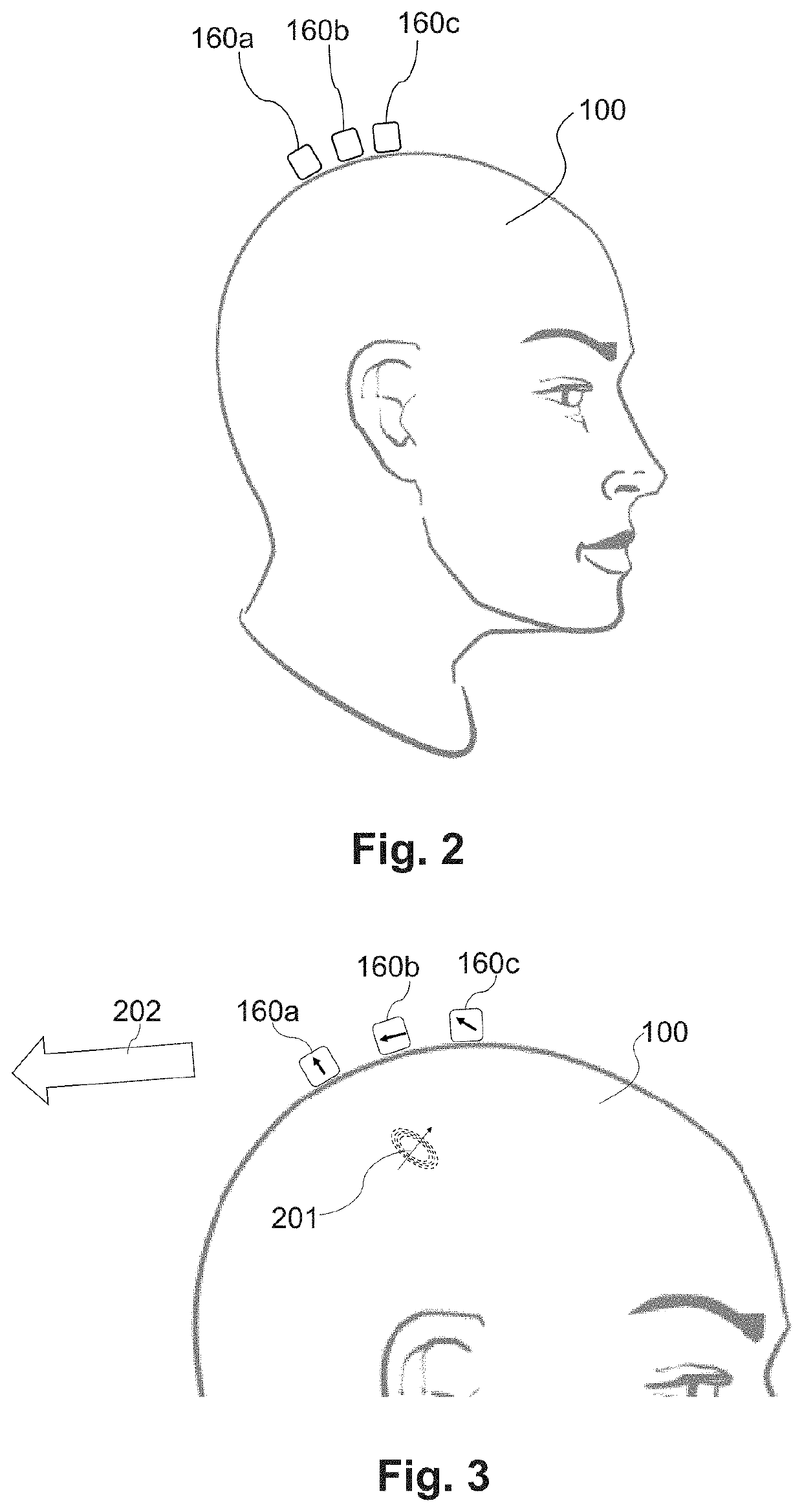

A method for generating alkali metal in a zero oxidation state includes reacting an alkali metal compound having a —S-M substituent, where M is an alkali metal and S is sulfur, with gold in a zero oxidation state to release the alkali metal in the zero oxidation state. For example, an alkali metal alkylthiolate can be reacted with a gold in a zero oxidation state to release the alkali metal in the zero oxidation state. As another example, an alkali metal sulfide can be reacted with gold in a zero oxidation state to release the alkali metal in the zero oxidation state. The alkali metal may be used in various applications including vapor cells, magnetometers, and magnetic field measurement systems.

Owner:HI LLC

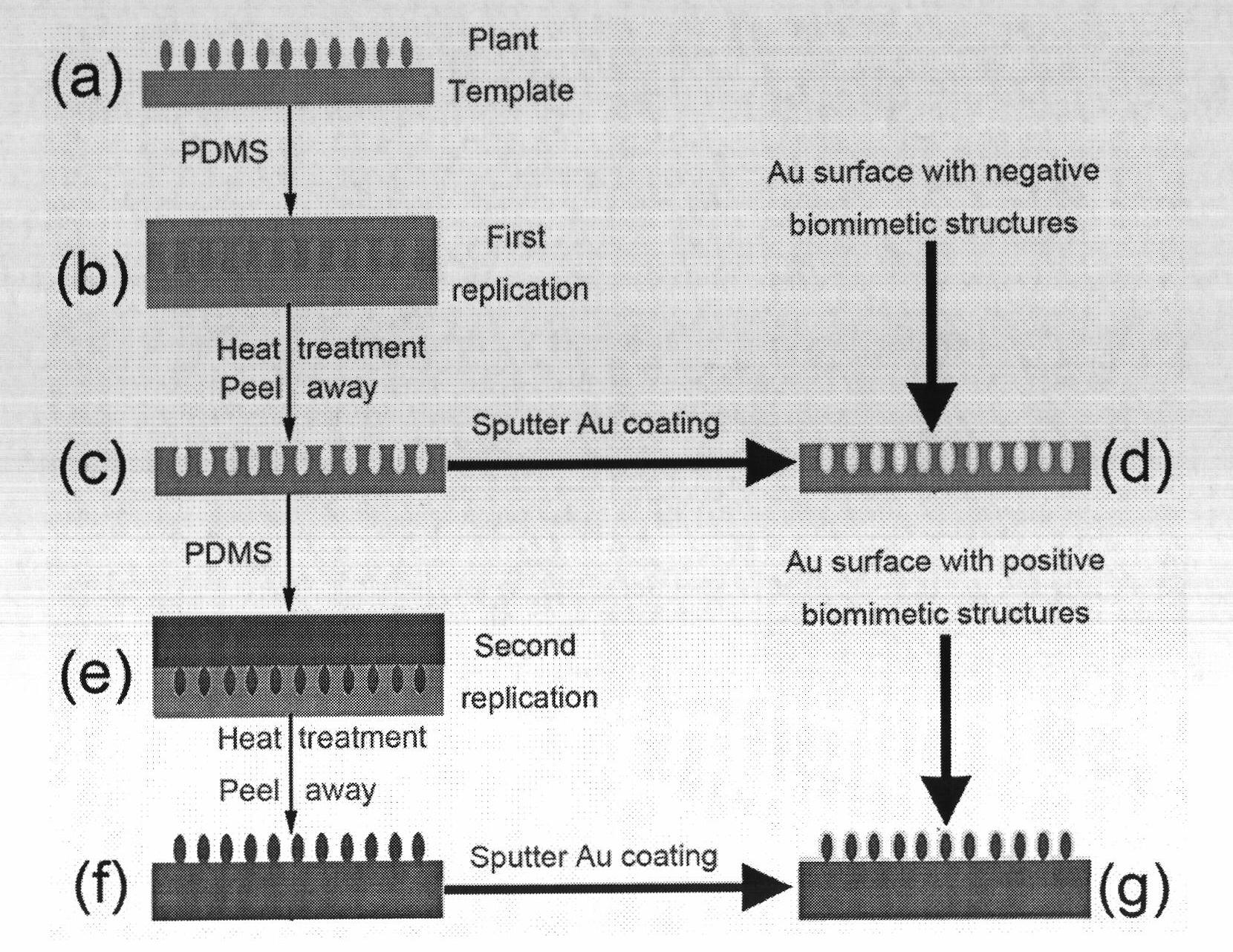

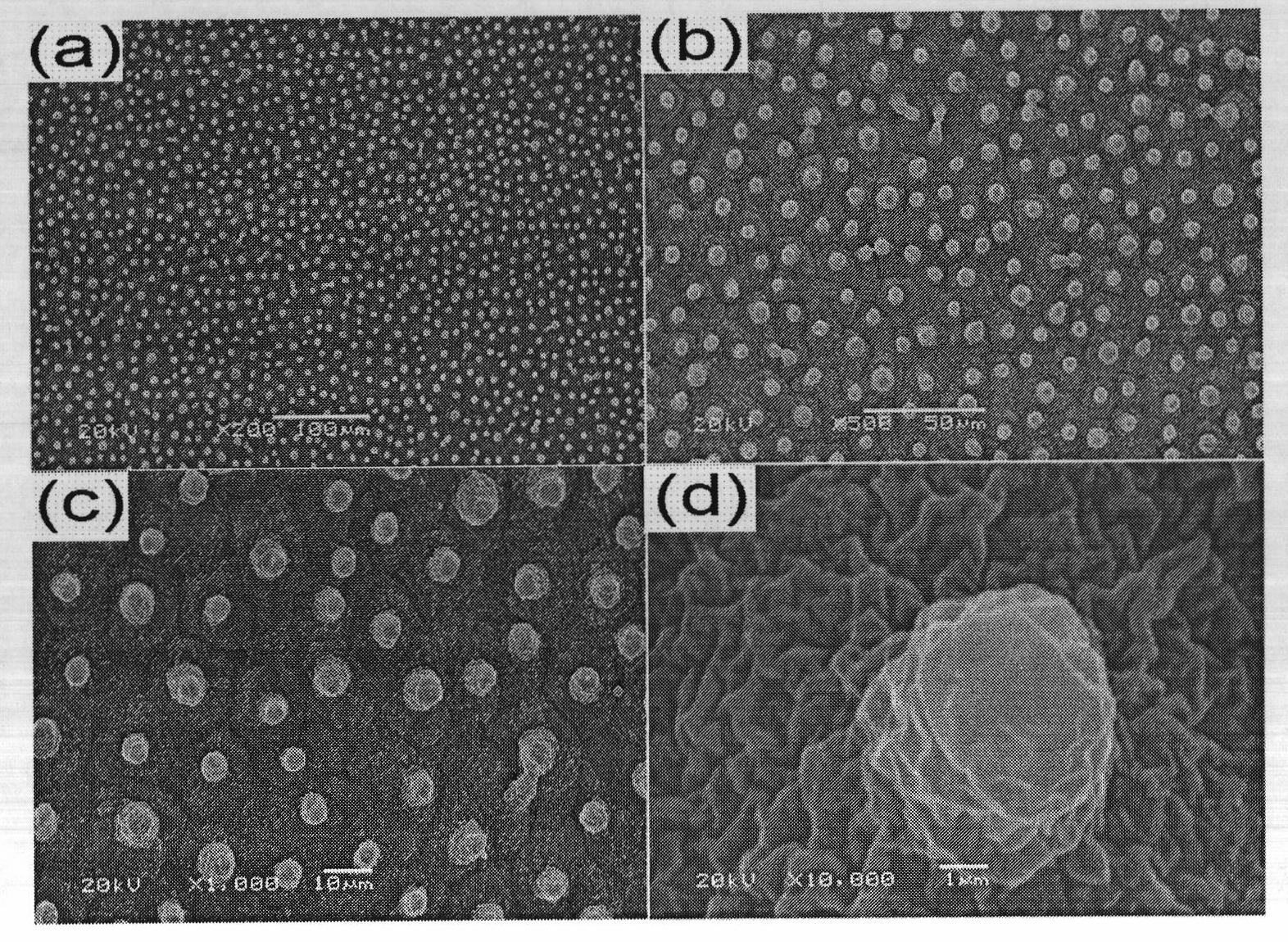

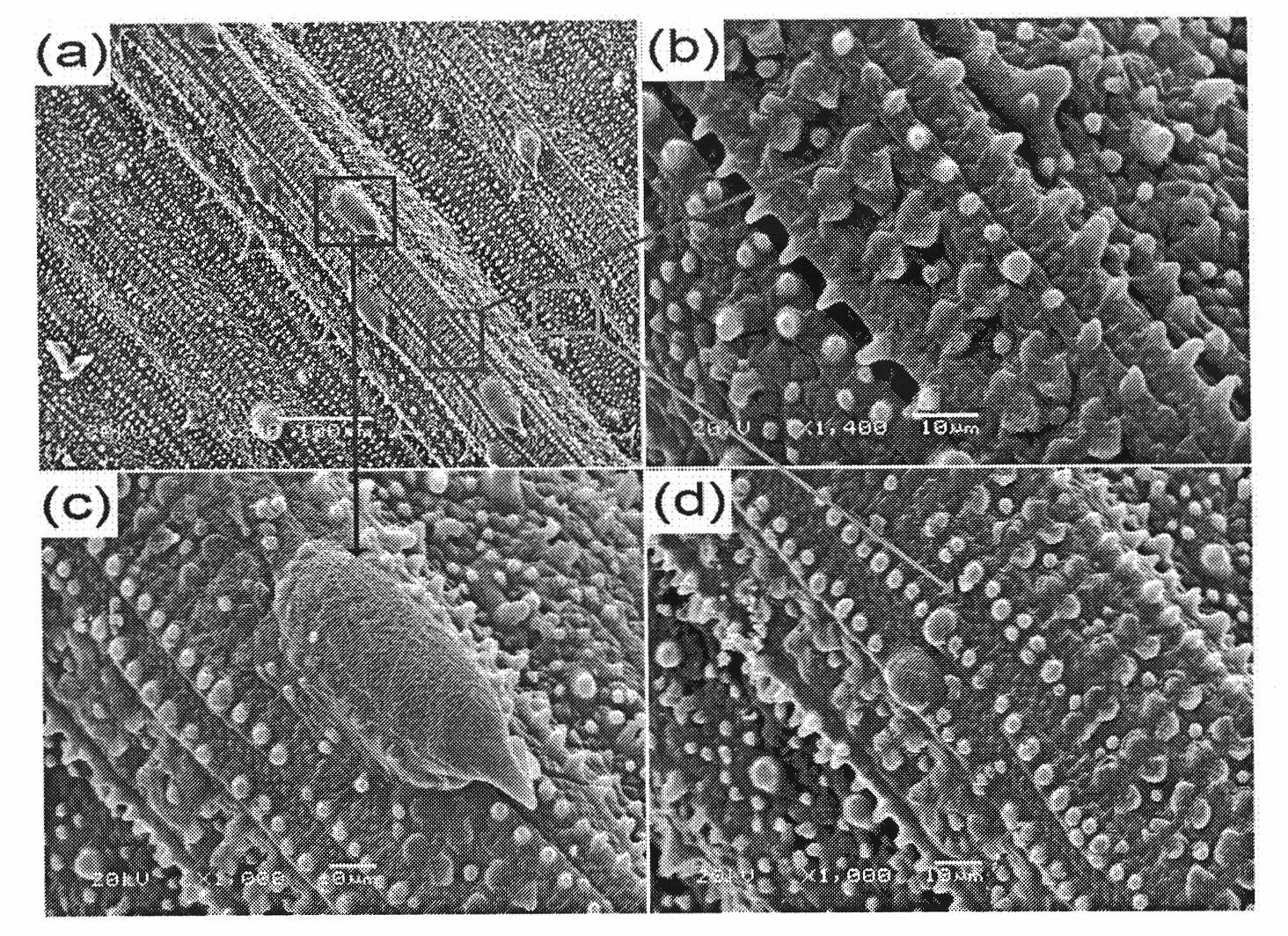

Preparation method of bionic controllable adhesive hydrophobic gold surface

ActiveCN101942638AControlled AdhesionSimple preparation processVacuum evaporation coatingSputtering coatingAdhesivePipette

The invention relates to a preparation method of a bionic controllable-adhesiveness hydrophobic gold surface. The method comprises the following steps: using a biological material in the natural world as a template, and preparing the controllable-adhesiveness hydrophobic gold surface with the same surface micro texture of the biological prototype by using the soft seal technology and surface chemical modification method. The surface micro texture is a typical micro / nano dualistic structure. The micro / nano dualistic structure gold surface with front and back patterns of lotus leaves and rice leaves is obtained. The gold surfaces with different bionic micro / nano textures have different adhesiveness for water drops, and can be used for design of engineering, biorobots and the like. The gold surface with front pattern micro texture has rolling property and hydrophobicity, and the gold surface with back pattern has adhesiveness and hydrophobicity; and the gold surface can be used as a manipulator to realize nondestructive transportation of micro drops, liquid-carried materials, biological micro solution pipettes and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing surface enhanced Raman substrate

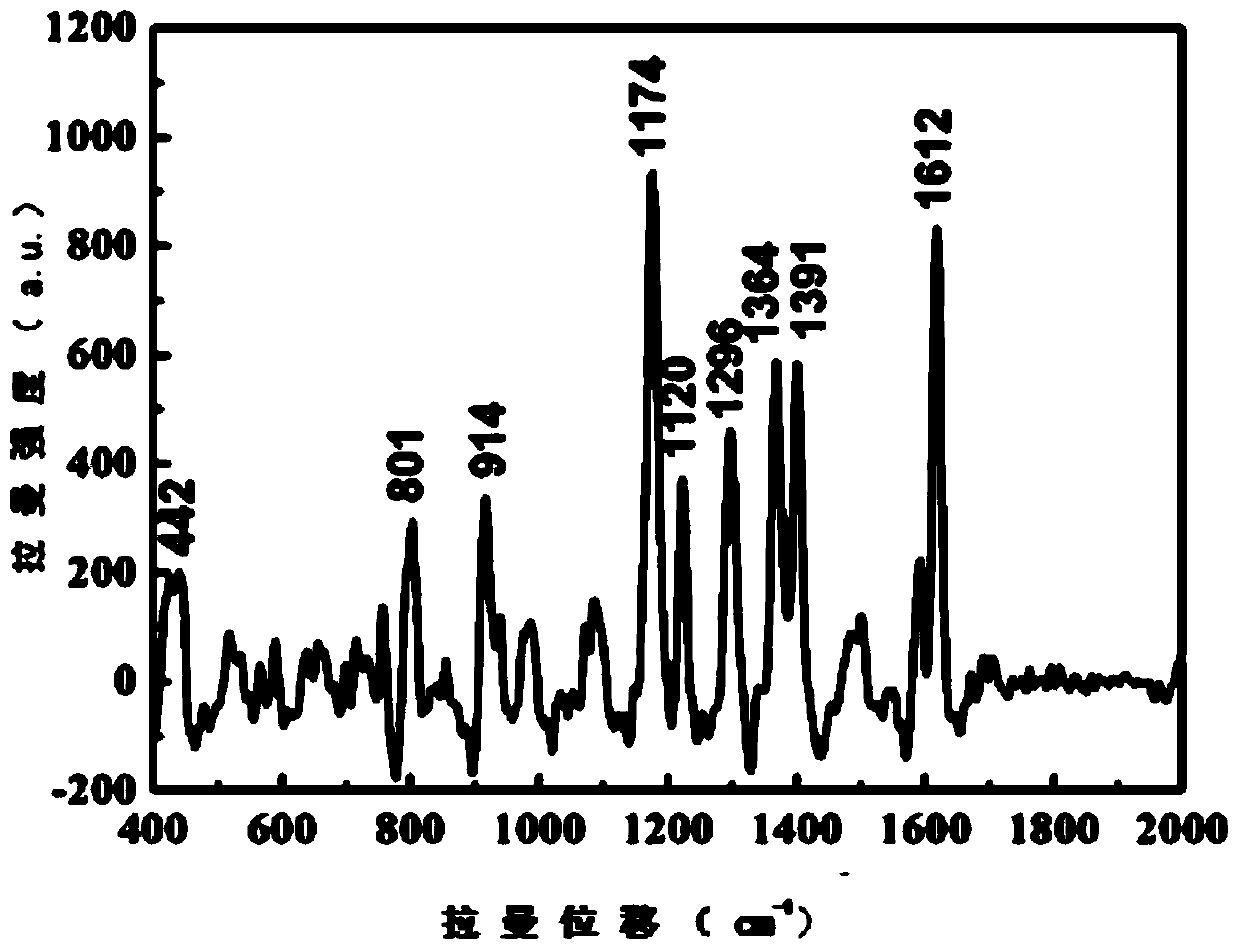

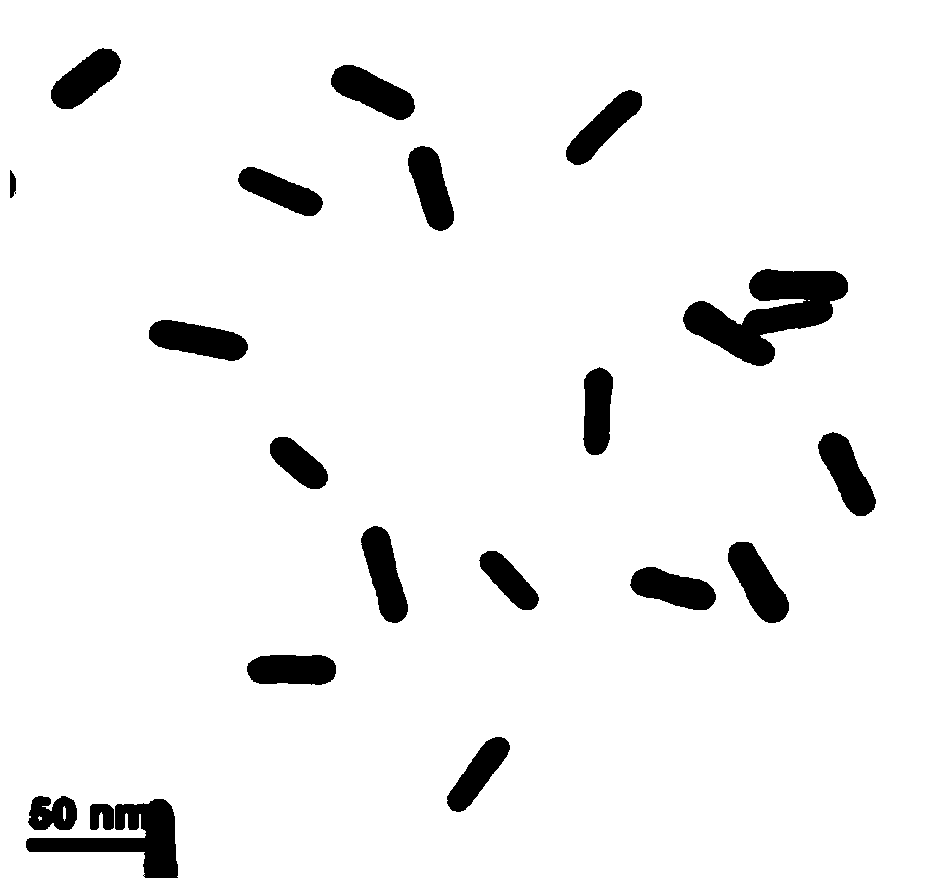

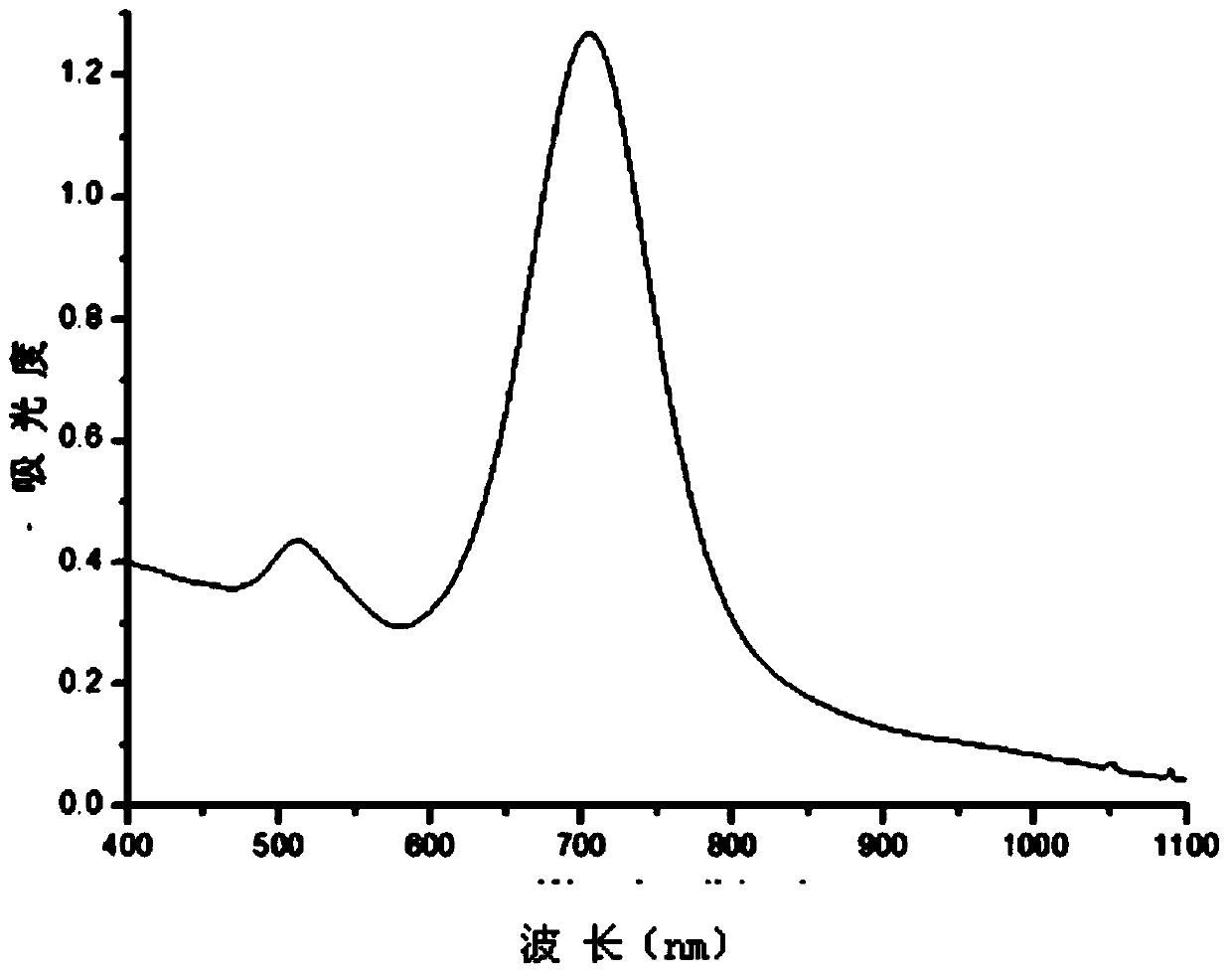

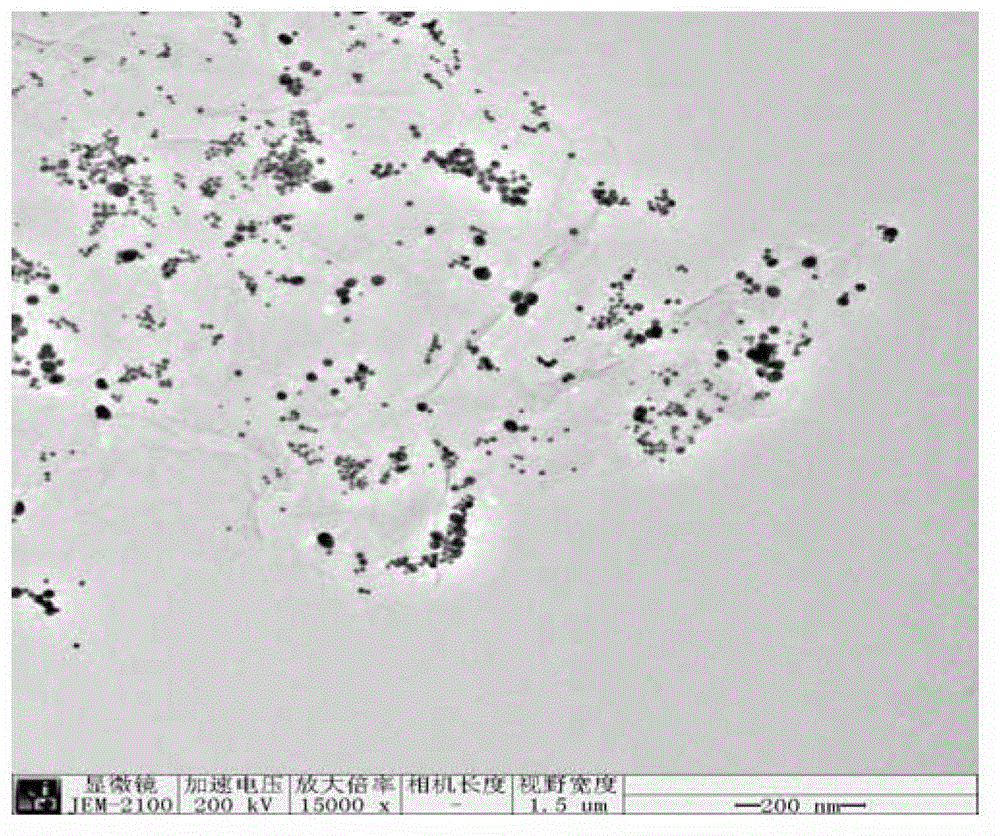

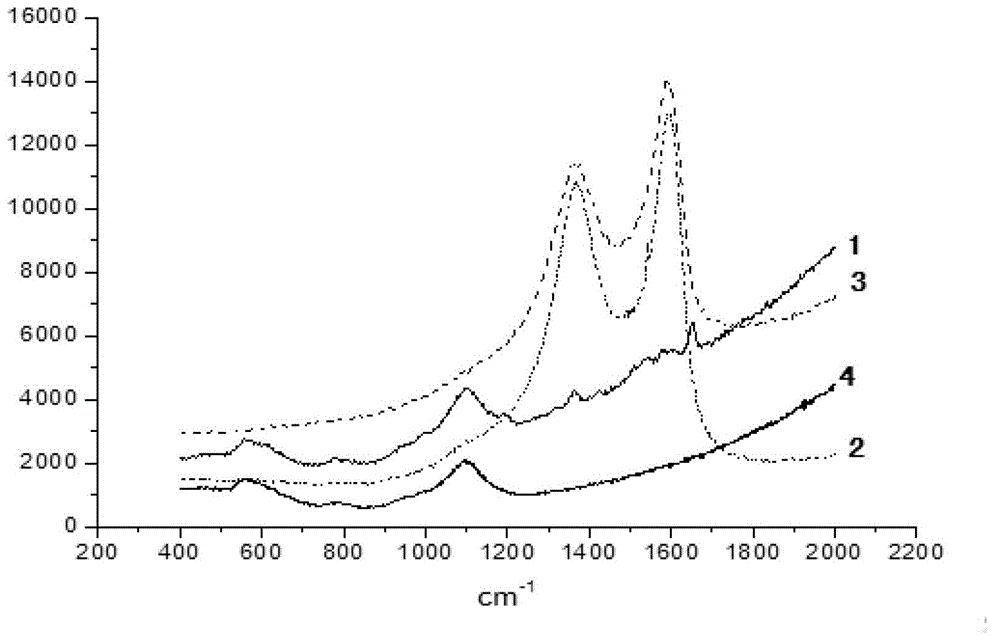

InactiveCN103990812AHigh detection sensitivityGood biocompatibilityRaman scatteringGold nanorodSignalling molecules

The invention provides a method for preparing surface enhanced Raman substrate, and relates to Raman spectrums. The method comprises the steps that a seed crystal growing method is used for synthetizing a gold nanorod solution, wherein gold nano seeds are synthetized first, then a growing solution is added, silver nitrate is used for adjusting the slenderness ratio of gold nanorods until reaction is completed, the needed gold nanorod solution is obtained, then centrifuging is conducted to remove supernatant liquor, signal molecules are added to be connected to a gold surface, then a polyethylene glycol dressing agent is added to induce the gold nanorods to conduct self-assembling, then a processed nano particle solution is stirred, a TEOS methanol solution is added for reacting, silicon dioxide layers are wrapped on the surfaces of the self-assembled gold nanorods, and the surface enhanced Raman substrate is obtained. Detecting can be directly conducted in the solution, due to self-assembling and the coupling effect of plasma on the surfaces of adjacent nano particles, the electromagnetic field between the nano particles is obviously enhanced, the Raman signals at the position are amplified in a quantity level mode, accordingly, the detecting sensitivity of surface enhanced Raman is greatly improved, and the stability is high.

Owner:XIAMEN UNIV

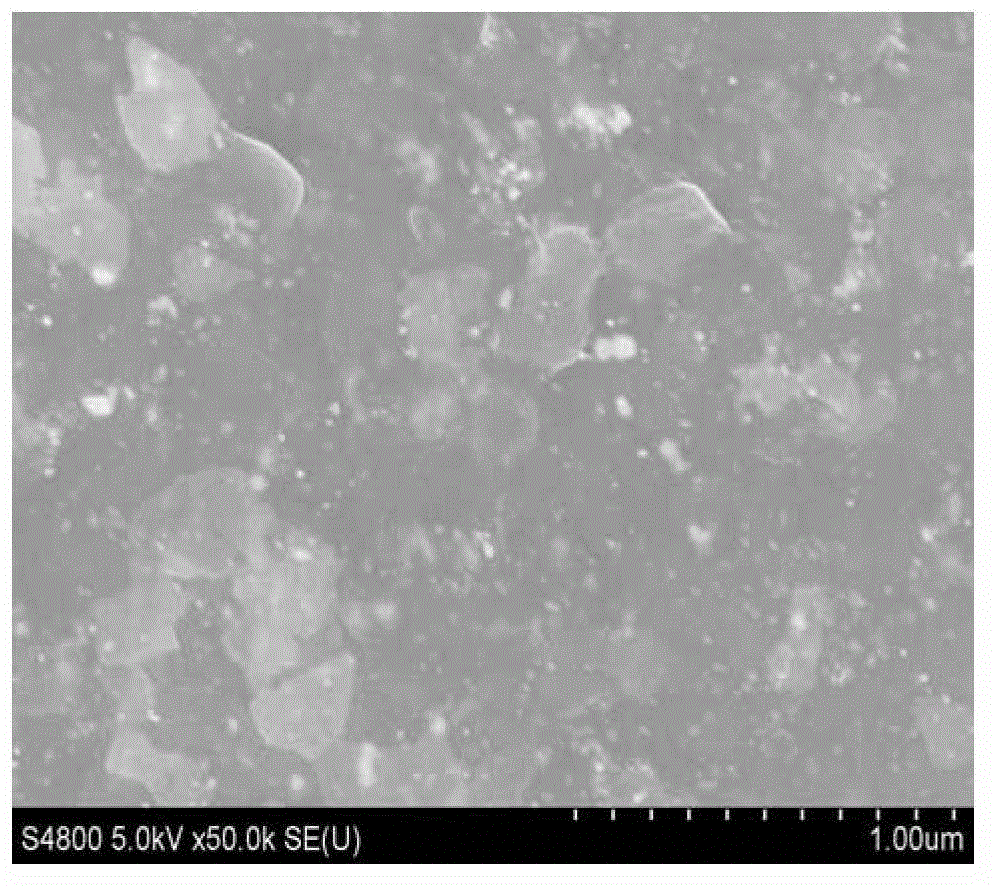

Method for manufacturing graphene/gold surface-enhanced Raman spectrum substrate

InactiveCN102914500AHigh reusabilityLow costRaman scatteringChemical industrySurface-enhanced Raman spectroscopy

The invention discloses a method for manufacturing a graphene / gold surface-enhanced Raman spectrum substrate and relates to a method for manufacturing a surface-enhanced Raman spectrum substrate. The problems that gold nanoparticles of the conventional precious metal surface-enhanced Raman spectrum substrate are not fully utilized and precious metal substrates are insufficient are solved. The method comprises the following steps of: 1, preparing a graphene oxide aqueous solution; 2, preparing a hydrogen tetrachloroaurate hydrate aqueous solution, a sodium citrate aqueous solution and a silver nitrate solution; 3, preparing a graphene / gold composite material; 4, preparing a graphene / gold composite material suspension; and 5, erecting the treated substrate in the graphene / gold composite material suspension, and obtaining the graphene / gold surface-enhanced Raman spectrum substrate after the reaction is finished. According to the graphene / gold surface-enhanced Raman spectrum substrate, the repeated utilization of gold nanoparticles is improved, so that the cost is reduced, and the substrate has high enhancement of the surface Raman spectrum; and moreover, the method is applied to the field of chemical industry.

Owner:HEILONGJIANG UNIV

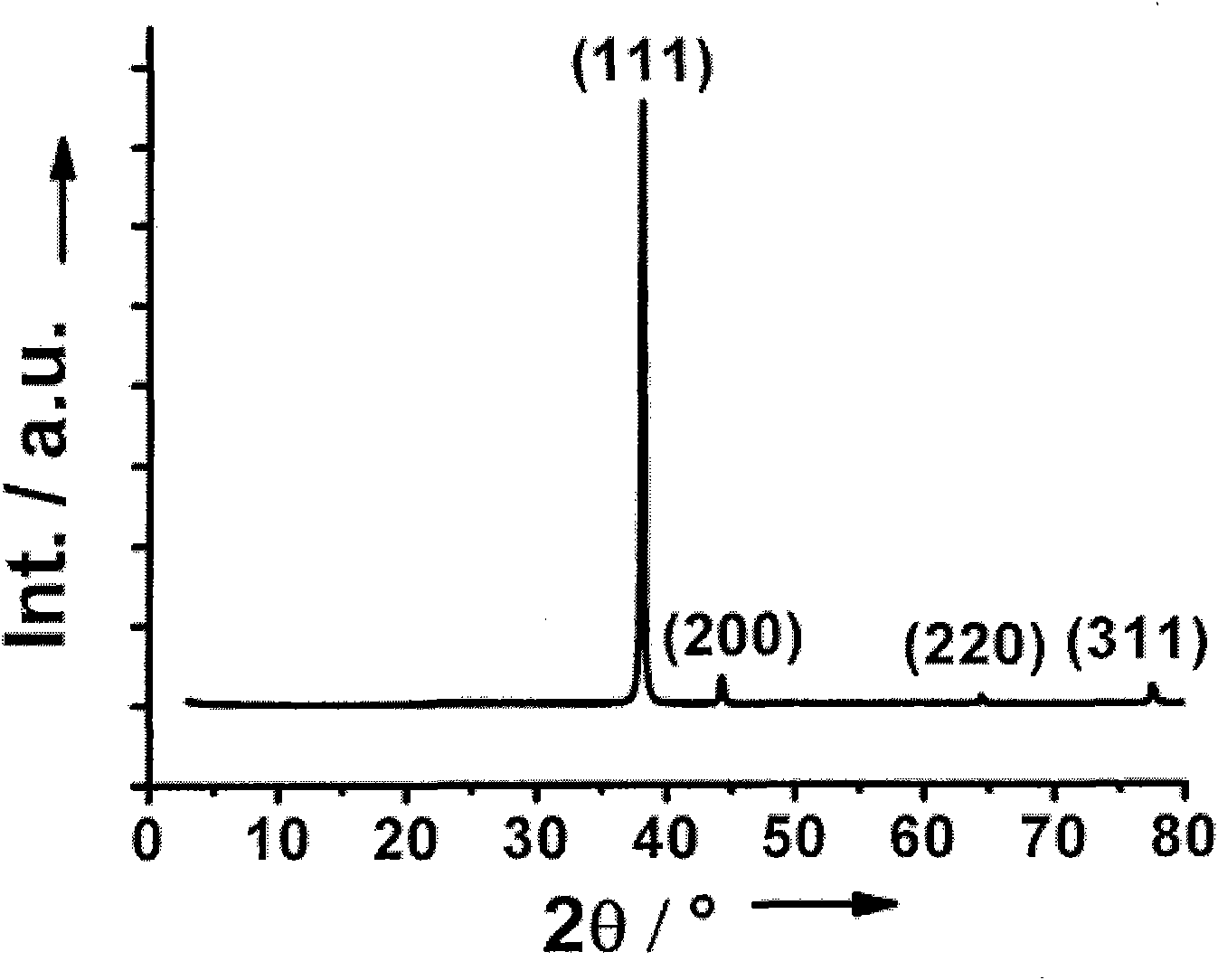

Method for coating noble metal on nano porous gold and prepared catalyst

InactiveCN101332438AIncrease profitModified implementationCell electrodesCatalyst activation/preparationAlloyRadical ion

The invention discloses a method for finishing a noble metal coating of a porous gold and the method comprises the following steps: the nanoporous gold is made by corroding gold-silver alloy; the nanoporous gold is soaked into a certain concentration of a solution containing chloroplatinic acid radical ions (or chloroplatinous acid radical ions, or chloropalladic acid radical ions, or chloropalladic acid radical ions, or the mixture) for an appropriate time to cause the surface of the nanoporous gold to absorb some noble metal ions, the other noble metal ions except for the noble metal ions absorbed on the surface of the nanoporous gold are washed clean, and the noble metal ions absorbed are reduced to a noble metal simple substance under proper electrochemical conditions, and the noble metal simple substance is tightly bonded on the pore wall of the nanoporous gold. The method of the invention can be used for preparing a catalyst which combines porous metals with ultra-low content of noble metals and can be applied in the catalytic fields of fuel cells and the like.

Owner:SHANDONG UNIV

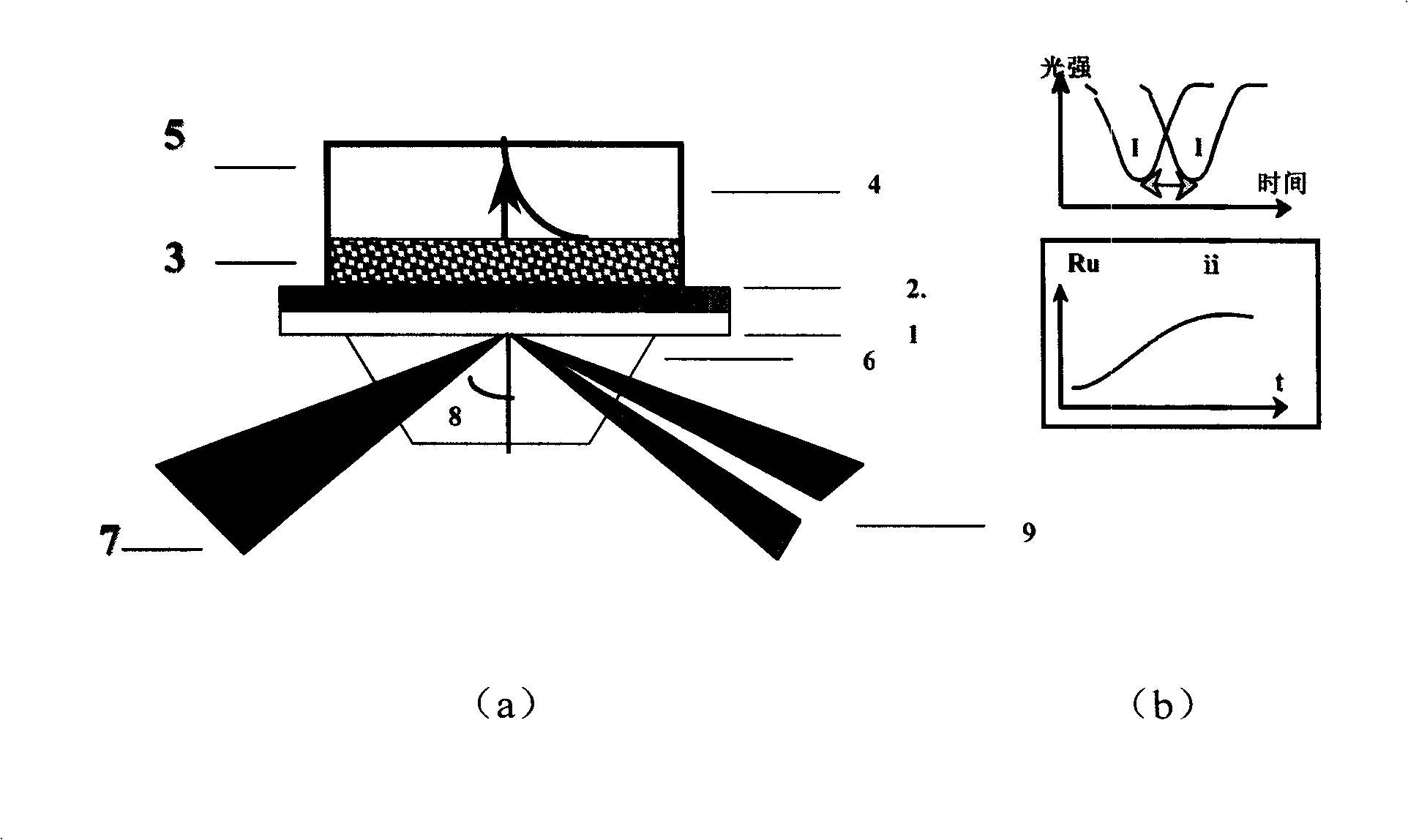

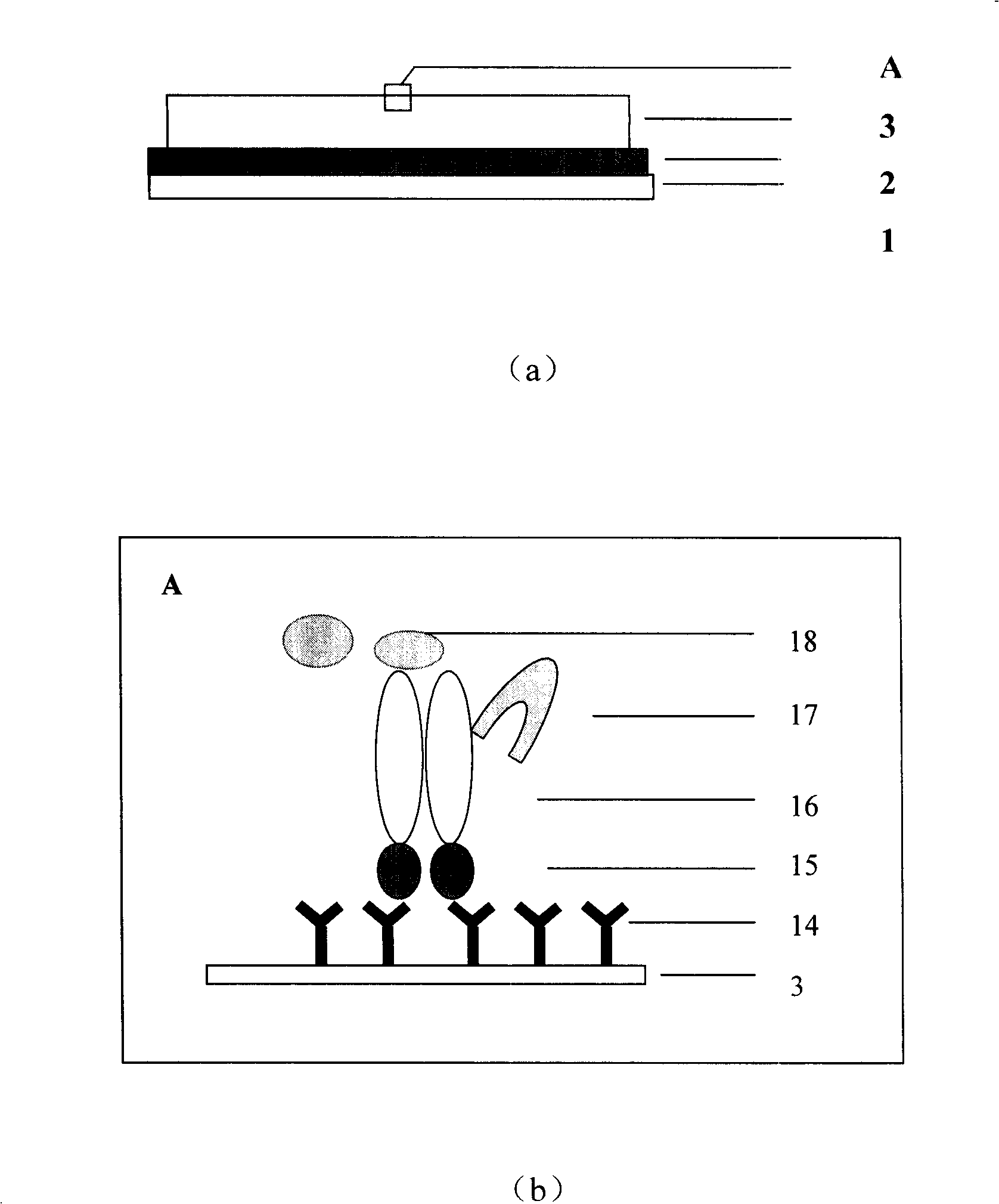

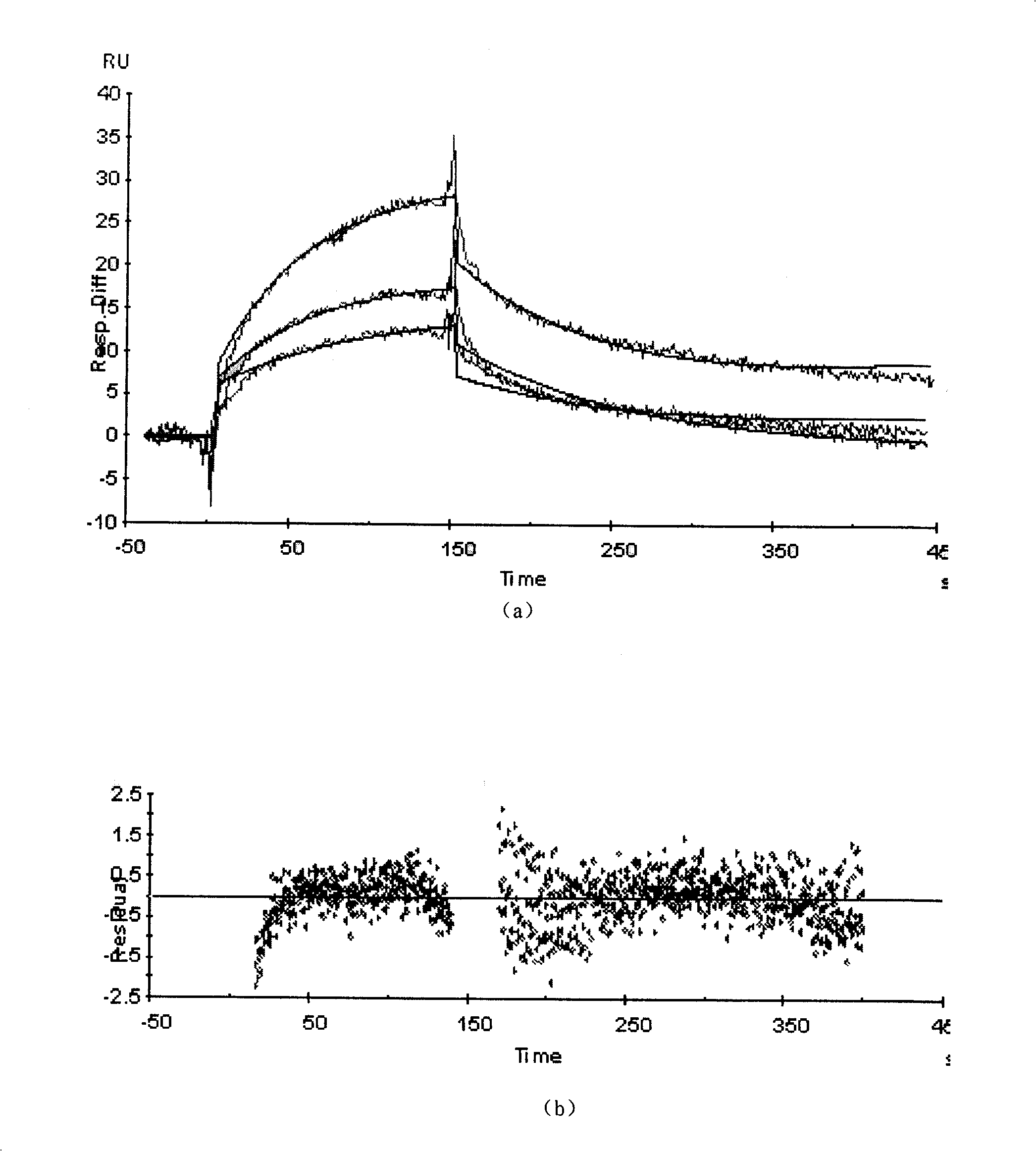

Biological chips of surface plasma resonating biological sensor, preparation and application

The invention relates to a cell surface receptor biochip based on a surface plasmon resonance biosensor, a preparation method and application thereof. The biochip is characterized in that the chip is provided with a gold surface coating at a glass substrate and the gold surface is fixed with a sephadex layer which is fixed with the monoclonal antibody of the Beta subunit of the receptors of anti para-insulin and surface receptors are fixed by antibody capture. The preparation method includes that the monoclonal antibody of the Beta subunit of the receptors of anti para-insulin adopts the method of antibody capture and is fixed on the surface of CM5 chip based on the surface plasmon resonance biosensor, so as to produce the protein chip of para-insulin receptors which is applicable to the mutual action between IGF-1R and IRS-1, SHC, PI3K or GRB2 and hopeful to be applied to screening cancer-fighting drugs.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI +1

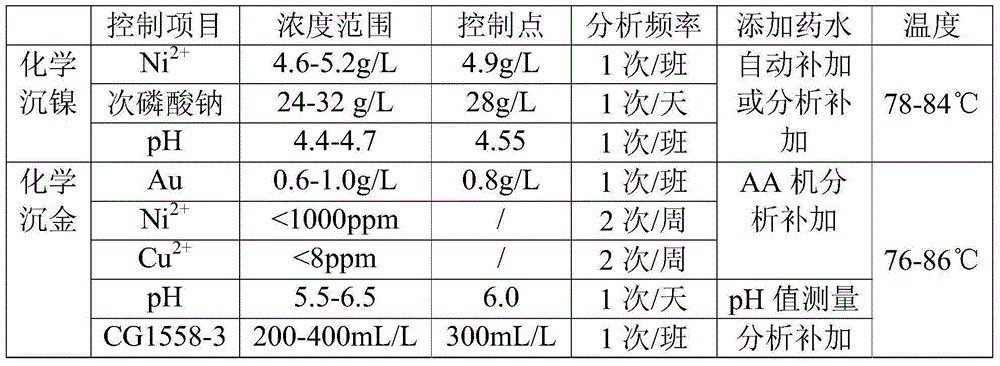

Manufacturing method of PCB integrated with multiple surface processing

ActiveCN104994688APrevent from being platedImprove bindingConductive pattern polishing/cleaningNon-metallic protective coating applicationSolder maskManufacturing technology

The invention relates to the field of a PCB production and manufacturing technology, and specifically relates to a manufacturing method of a PCB integrated with multiple surface processing. Through adjusting the production process of the PCB, electroplating thick gold surface processing which is conventionally carried out only after a solder mask is manufactured is performed in advance before an external-layer line is prepared, corresponding technical parameters are adjusted, the problem of mutual interference of three surface processing is effectively avoided, and three surface processing modes are realized in the same PCB. According to the invention, through adjusting a process sequence and the technical parameters, when antioxidation surface processing is carried out, the gold layer at an electroplating gold position and a nickel gold immersion position is not oxidized and an organic membrane is not formed, such that the effects of various surface processing are ensured. When the external-layer line is prepared, a volcanic ash grinding plate is employed, the bonding force applied to a dry membrane and a plate surface in a positive process can be increased, and the electroplating gold position is prevented from being plated with copper during pattern electroplating.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

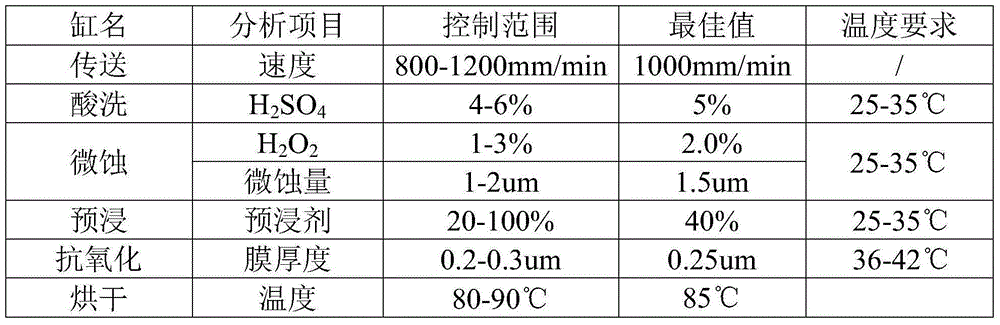

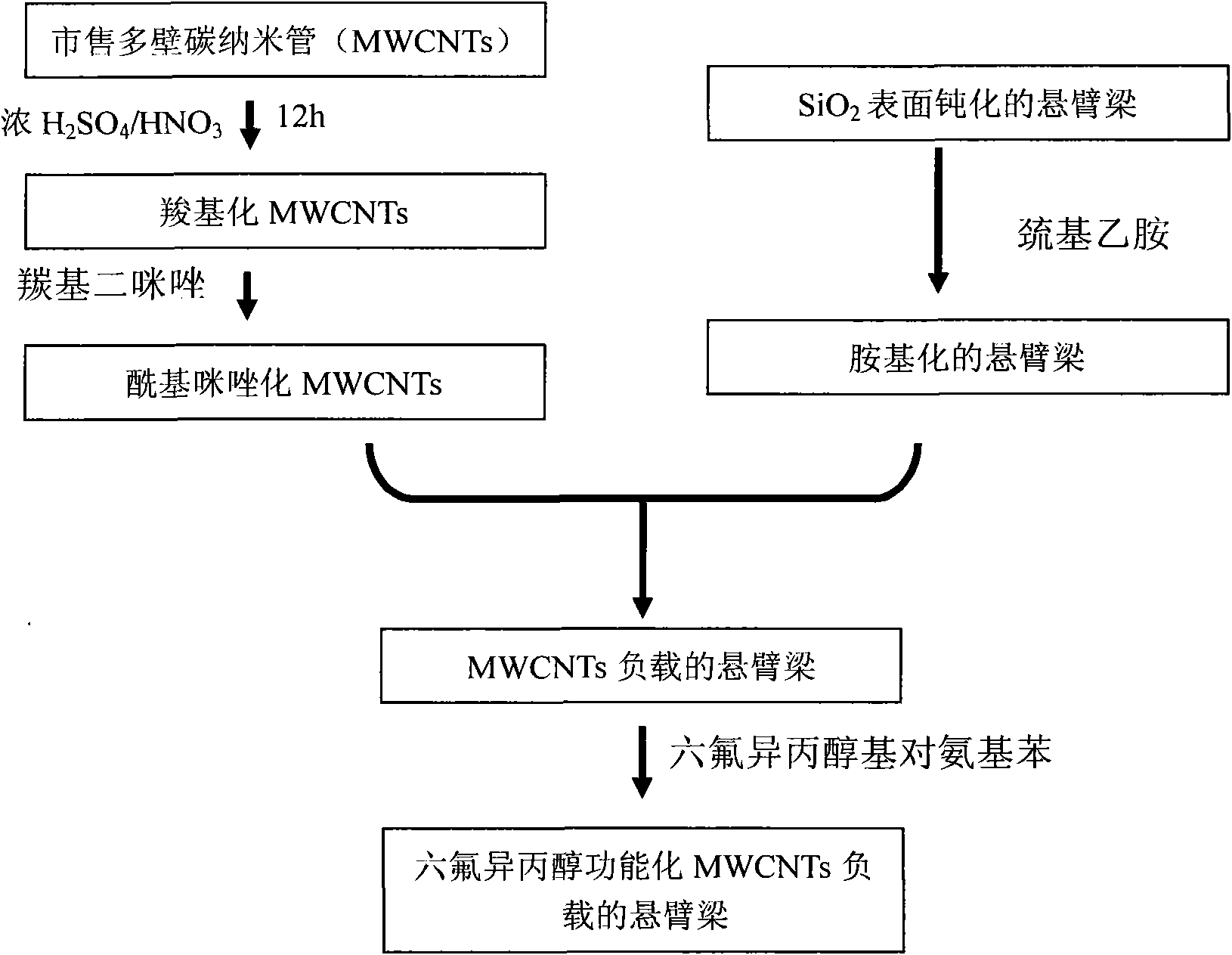

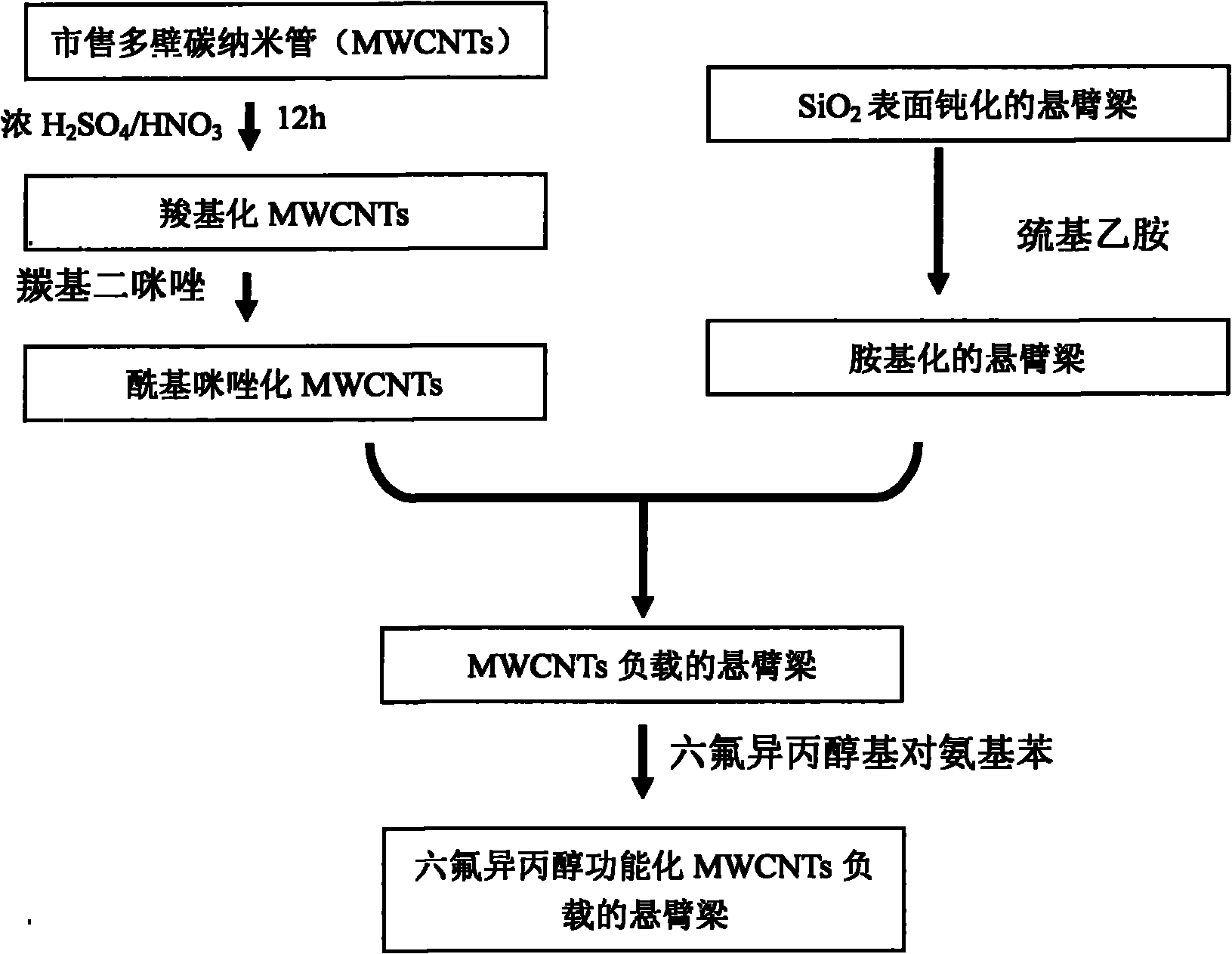

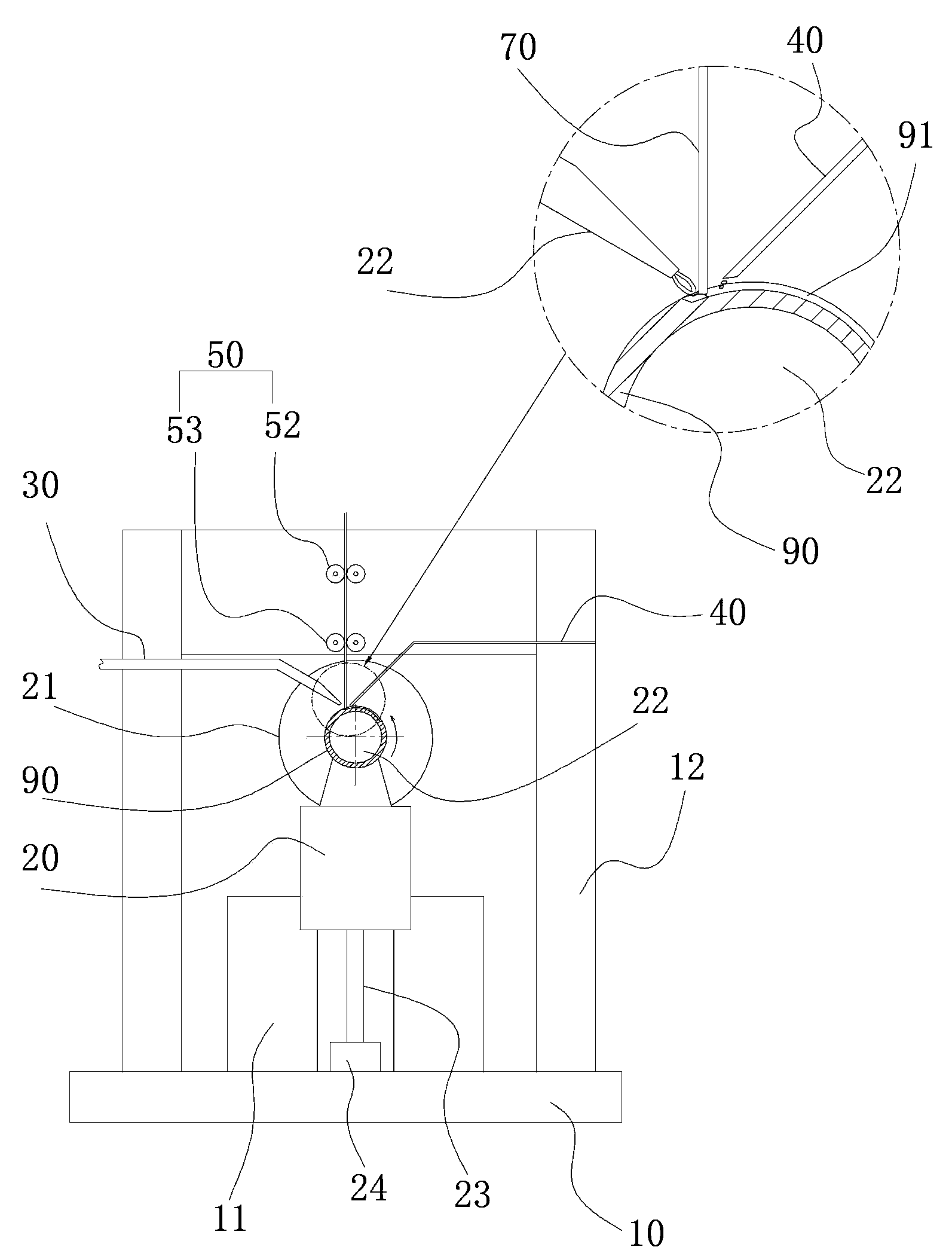

Method of micro cantilever beam sensor using functional carbon nano tubes as sensitive materials

ActiveCN101935008AEasy to operateLow costDecorative surface effectsFuel testingStrong acidsMems sensors

The invention relates to a manufacturing method of a micro cantilever beam sensor using functional carbon nano tubes as sensitive materials, belonging to the field of a micro-nano sensor. The method is characterized by comprising the following steps: using multi-walled carbon nano tubes as manufacturing materials of the sensor, and pretreating with strong acid to form reaction-active points which can be functionally modified on the surfaces of the multi-walled carbon nano tubes; then, fixing the multi-walled carbon nano tubes onto the gold surface of the MEMS sensor according to the molecular self-assembly technology; and finally, carrying out functional group modification again on the carbon nano tubes fixed on the gold surface of the MEMS sensor according to chemical properties of target gas to be detected (for example, a certain hydrogen bonding effect and the like exist between ammonia gas and carboxyl as well as formaldehyde and amino group) based on the molecular design, and enabling the sensor to be used for the detection of special target gas.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

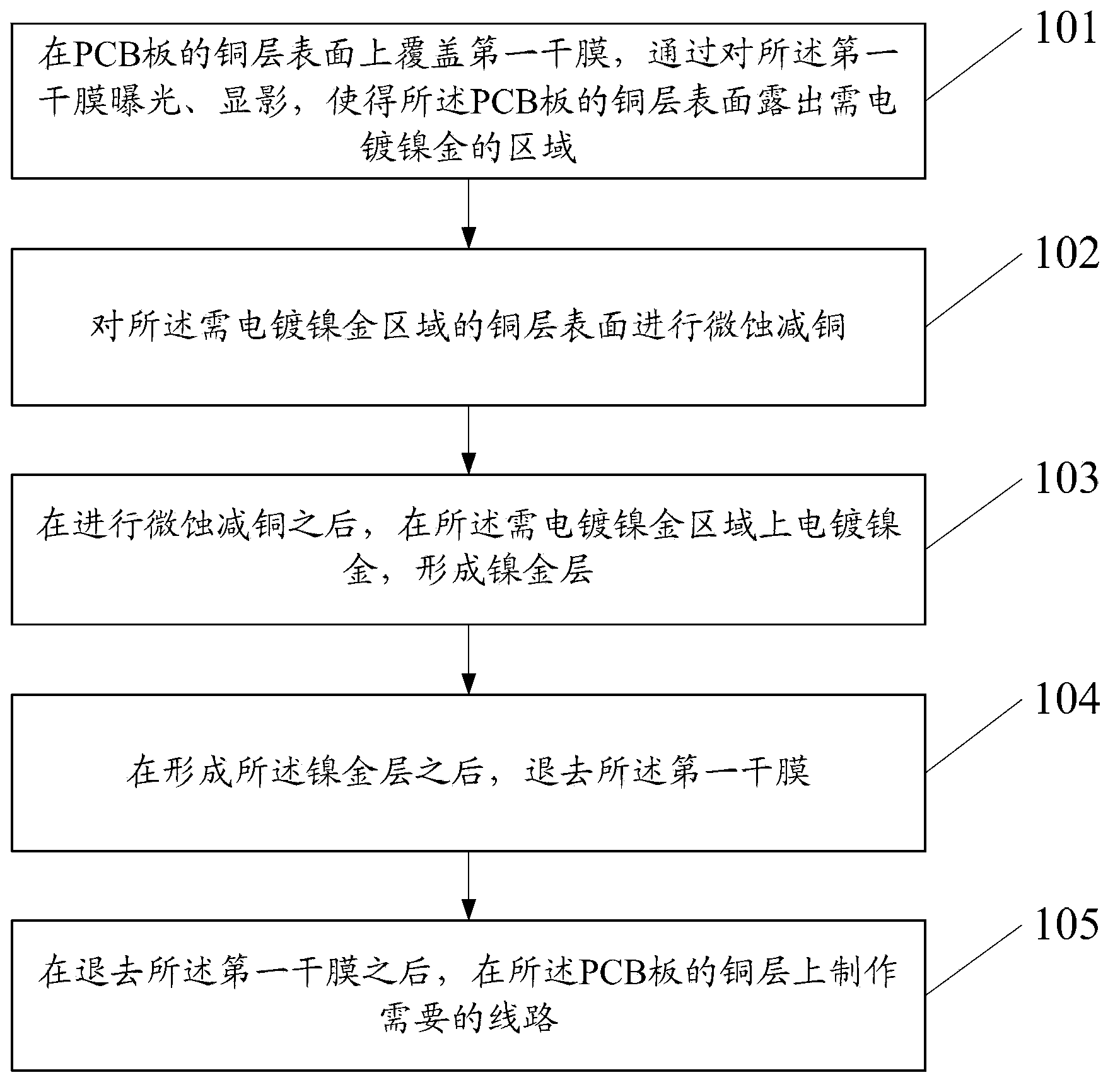

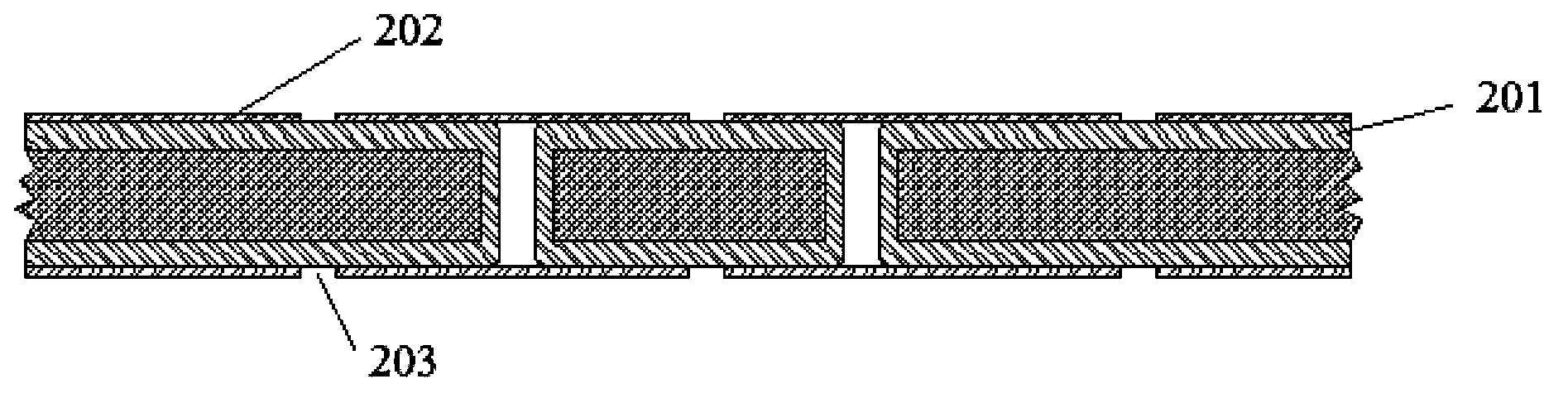

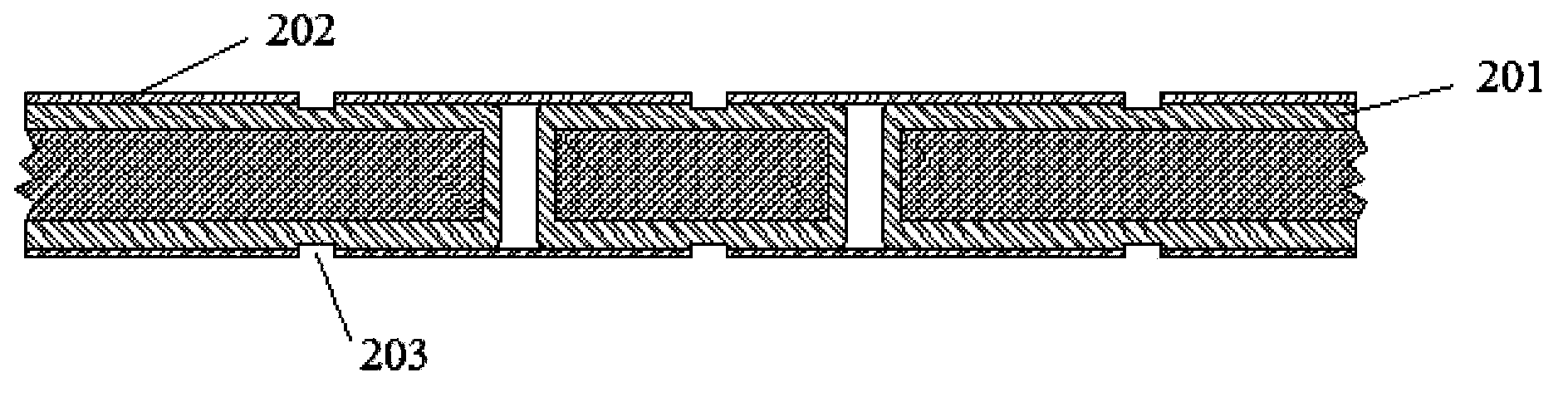

Selective nickel and gold plating method, PCB and device

ActiveCN104105350AReduce height differenceImprove bindingConductive material chemical/electrolytical removalConductive pattern reinforcementEtchingHeight difference

The invention discloses a selective nickel and gold plating method comprising the steps that a first dry film is covered on the surface of a copper layer of a PCB, and a area requiring nickel and gold plating is exposed out of the surface of the copper layer of the PBC via exposure and development; micro-etching and copper reduction are performed on the copper layer of the area requiring nickel and gold plating; and then nickel and gold are plated on the copper layer of the area requiring nickel and gold plating, then the first dry film is removed, and a required line is manufactured on the copper layer of the PCB. According to the method, nickel and gold are firstly plated on the surface of the copper layer of the PCB, and then the line is manufactured so that a lead wire for plating does not need to be manufactured in the overall implement process, and a problem of difficulty in nickel and gold plating on the PCB caused by the fact that the lead wire for plating cannot be manufactured on the PCB is solved. Besides, micro-etching and copper reduction are performed on the copper layer of the area requiring nickel and gold plating so that height difference between the nickel and gold surface of the nickel and gold area and the surface of the line without nickel and gold plating is reduced, and thus combination force of the dry film and the surface of the PCB in the subsequent dry film covering technology is enhanced.

Owner:SHENNAN CIRCUITS

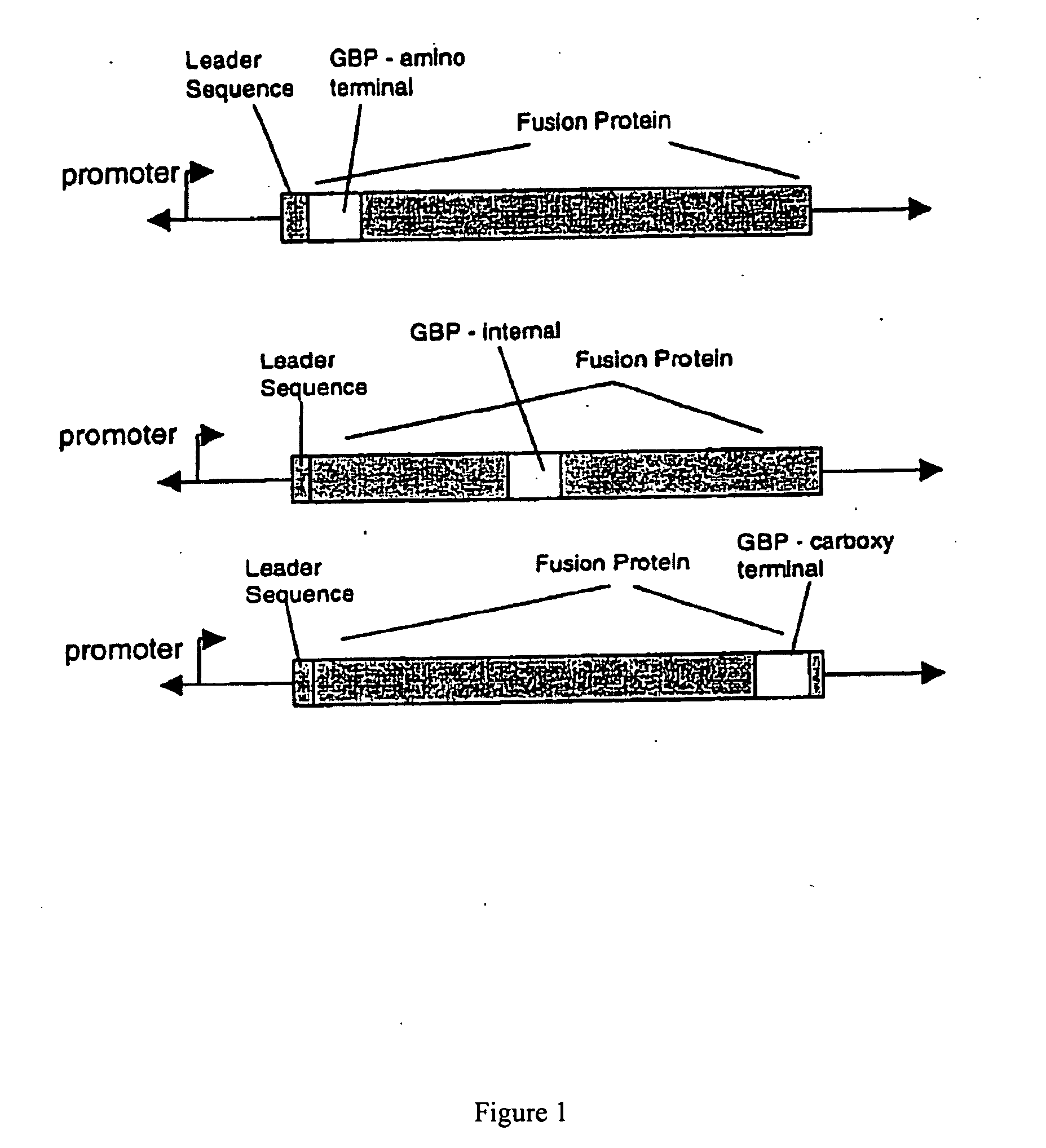

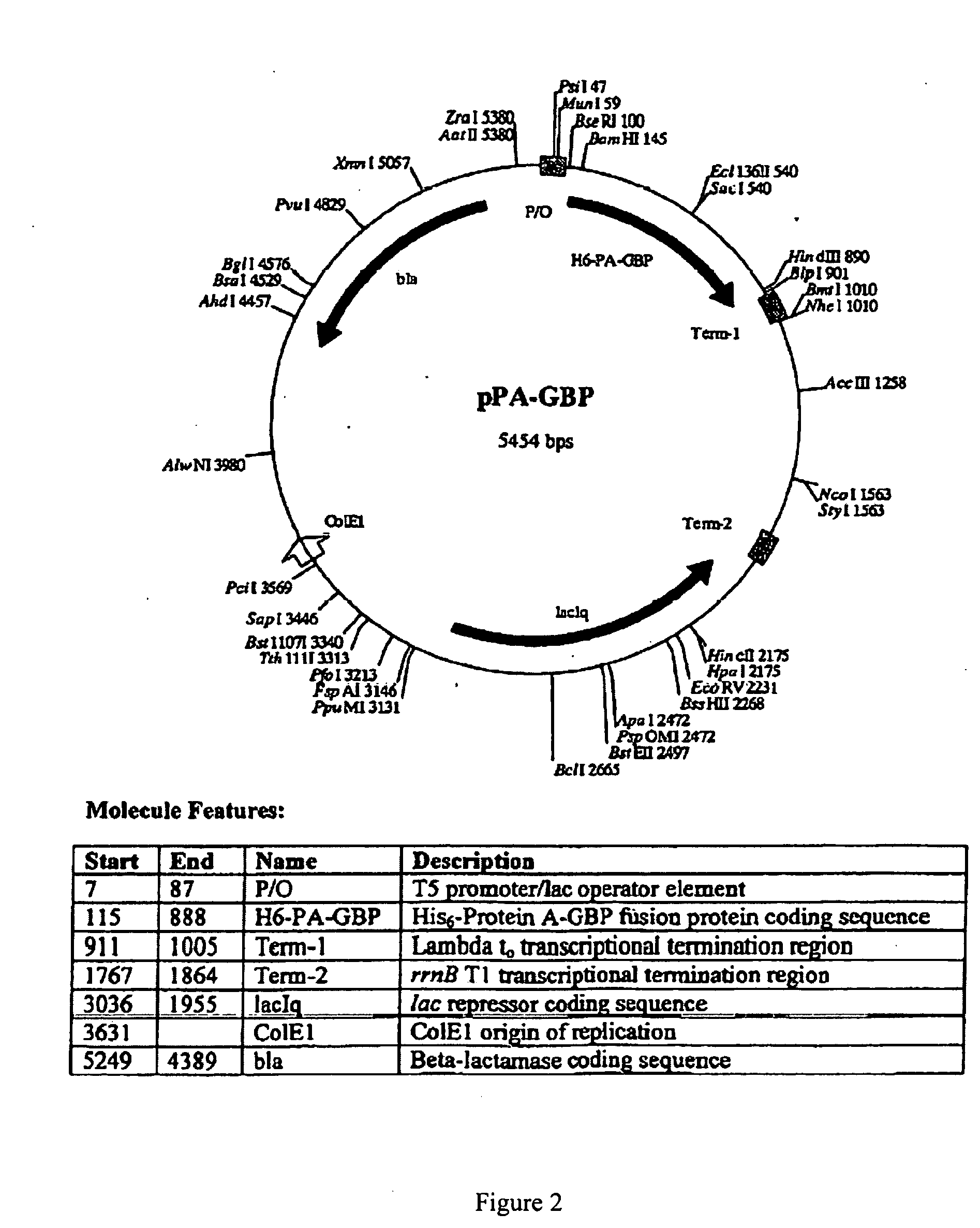

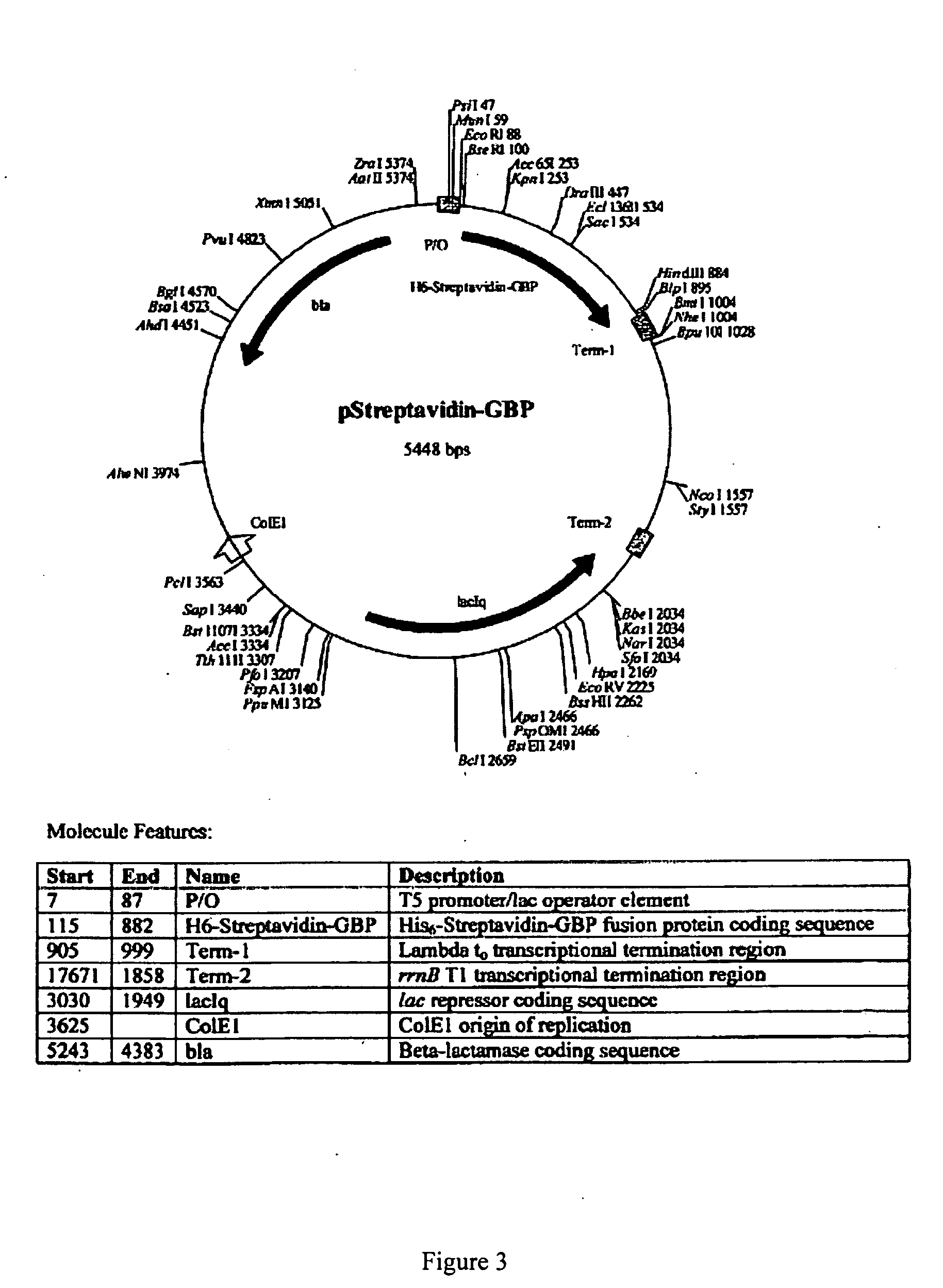

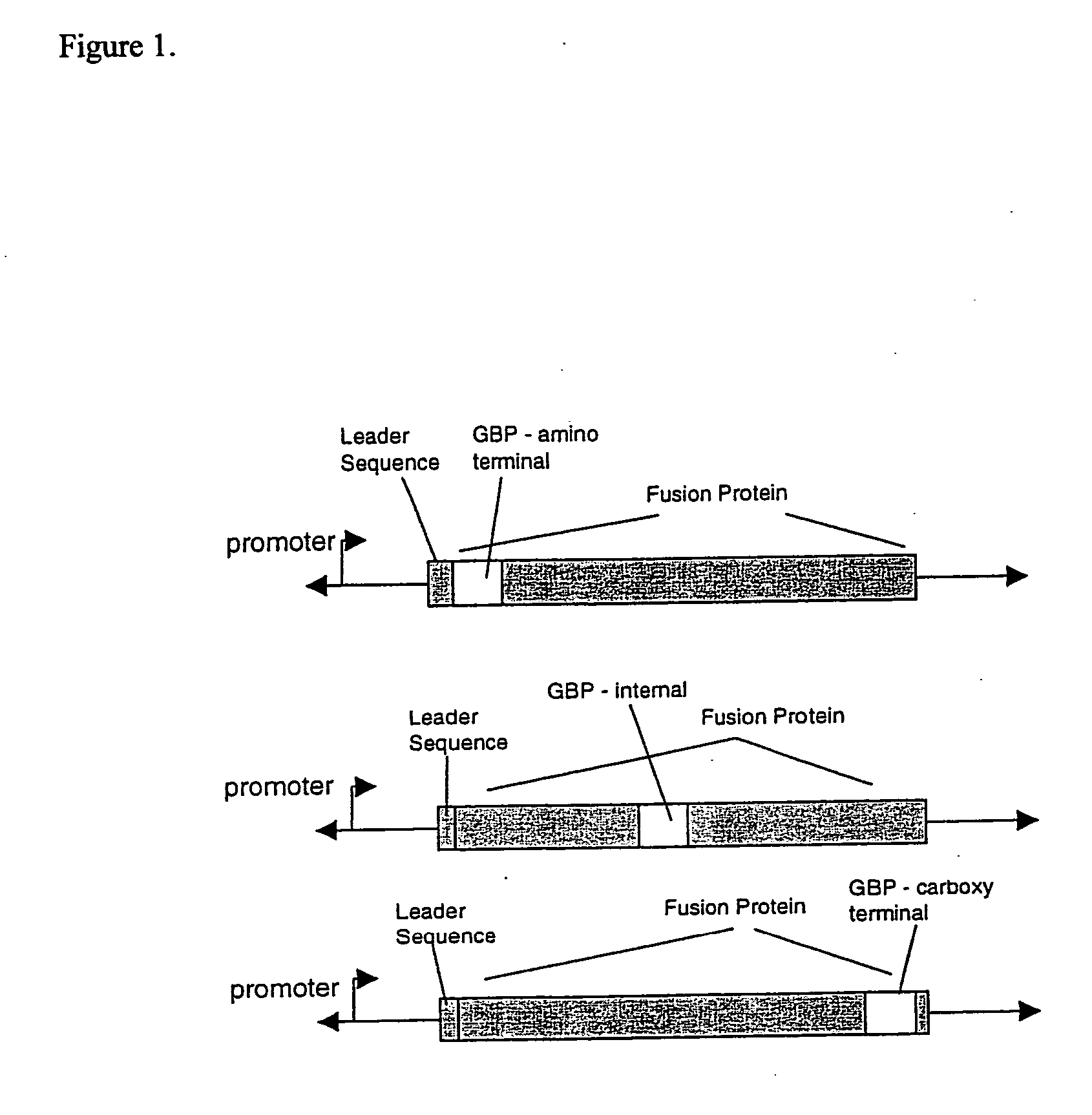

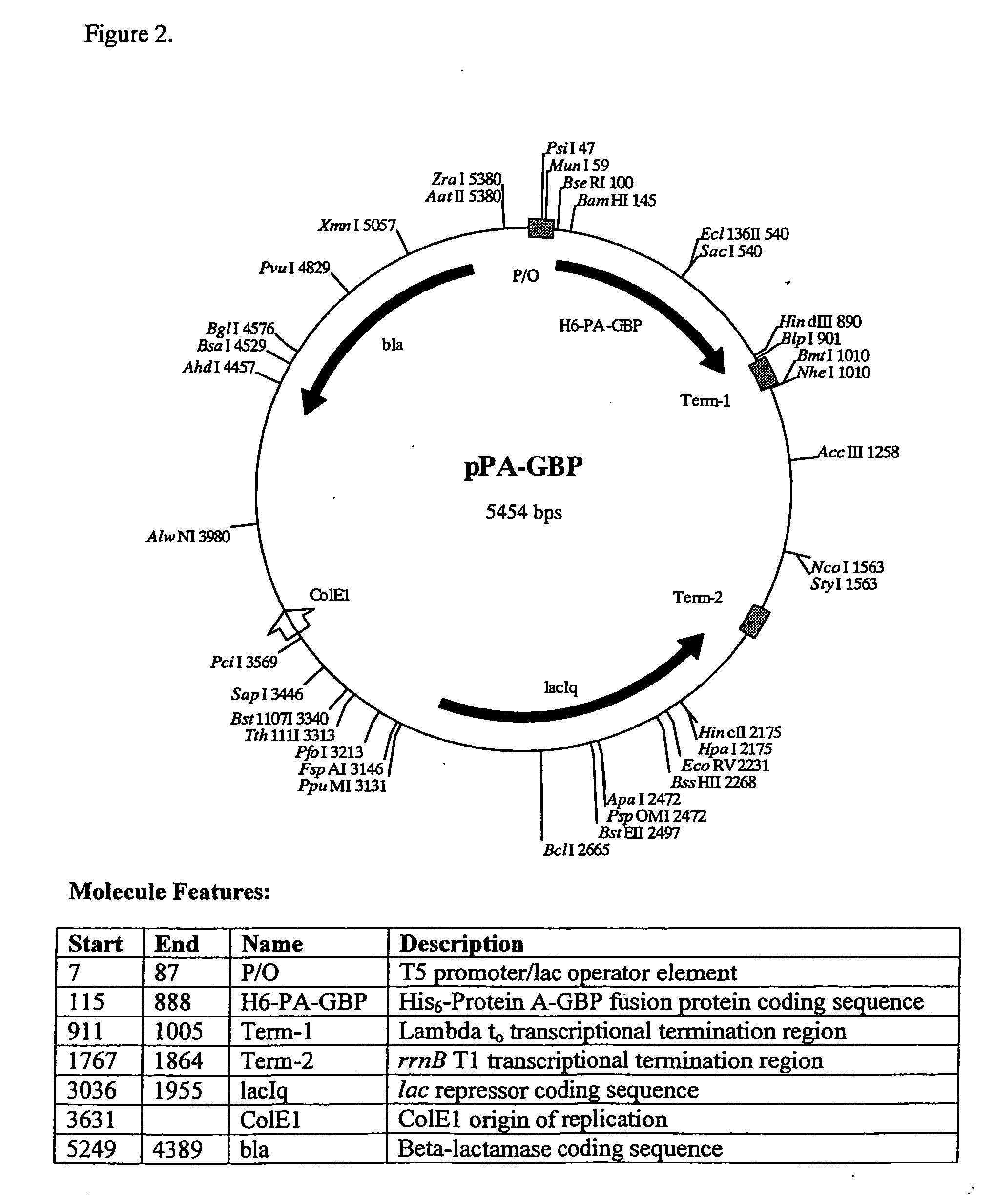

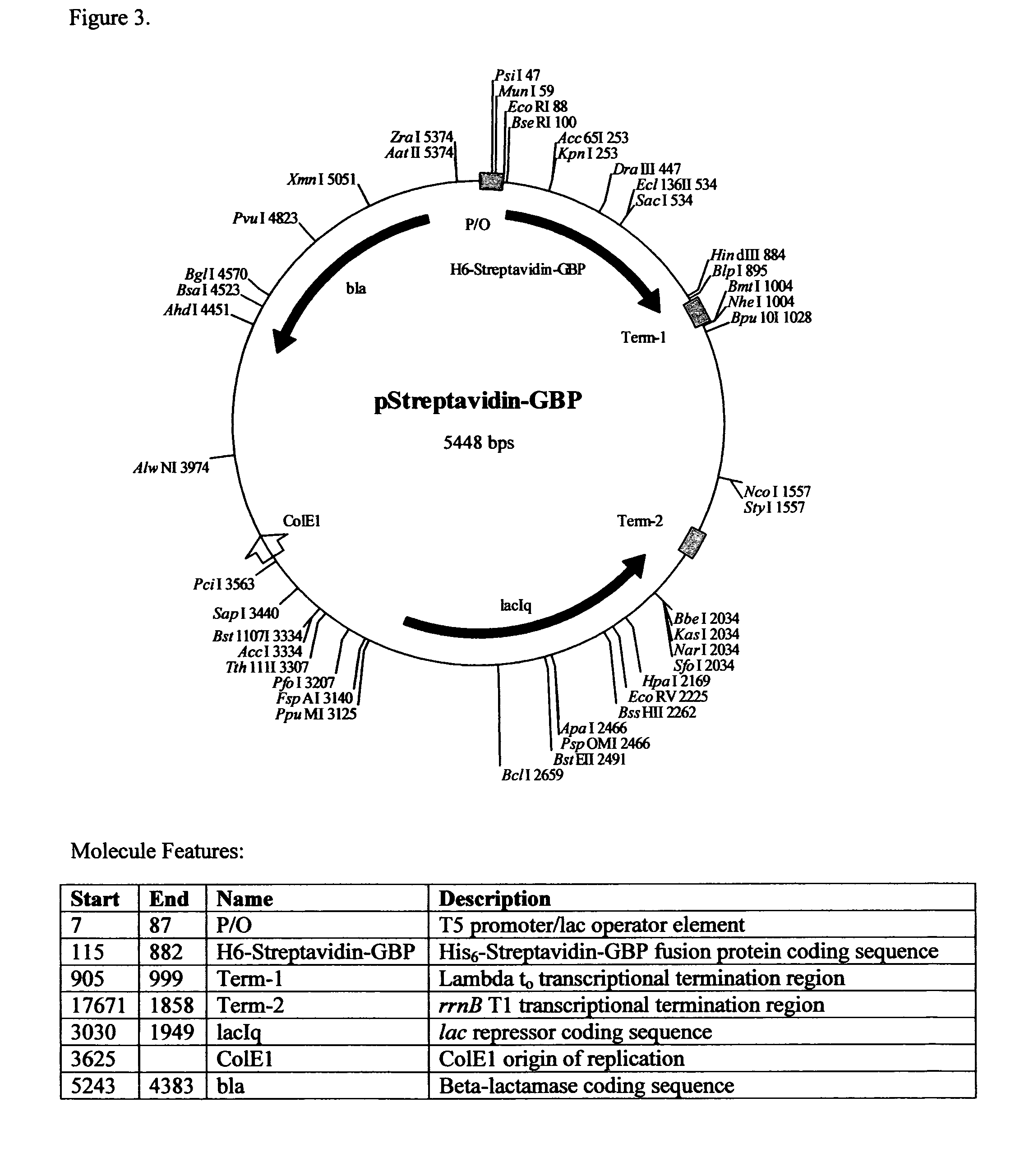

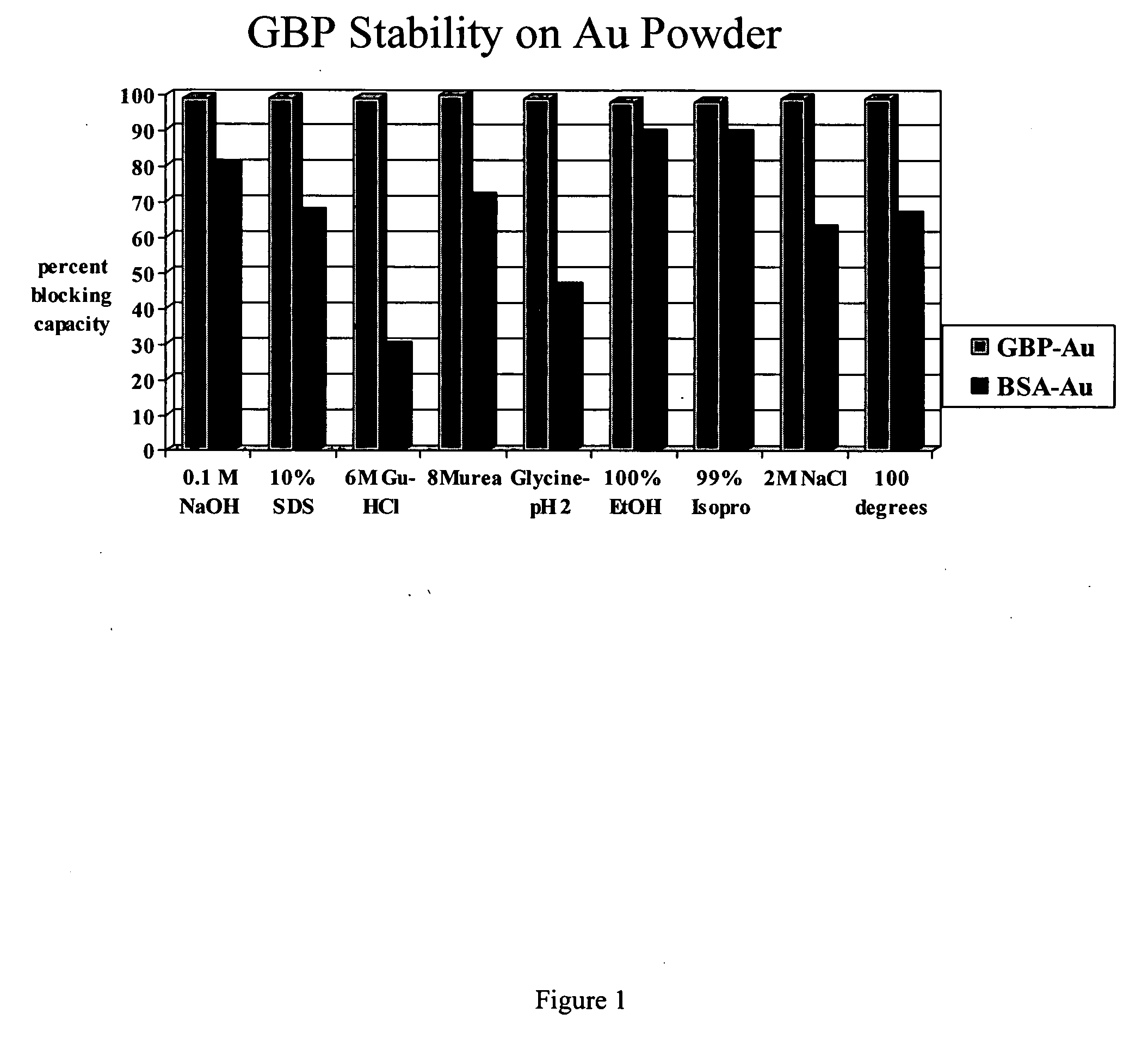

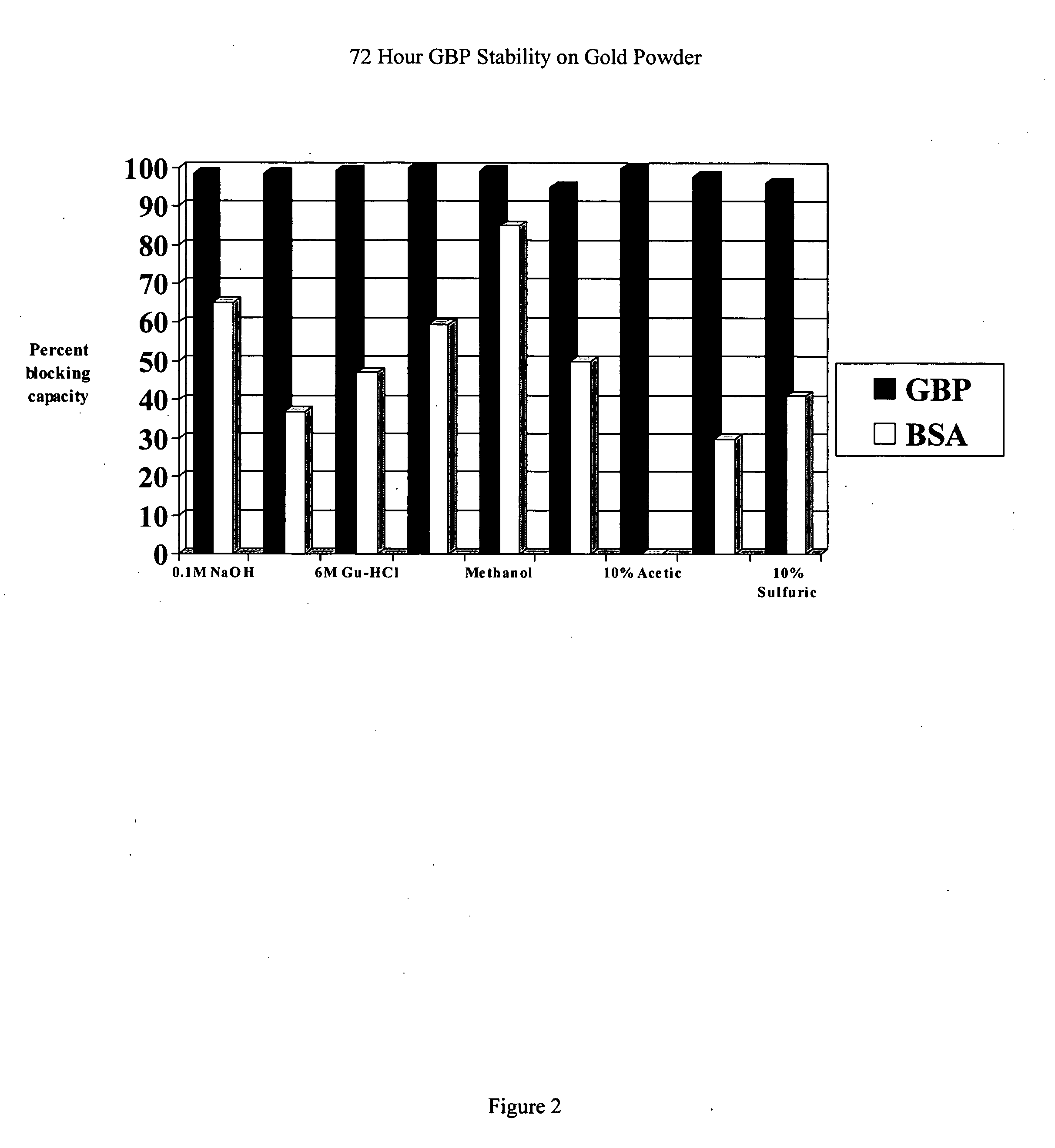

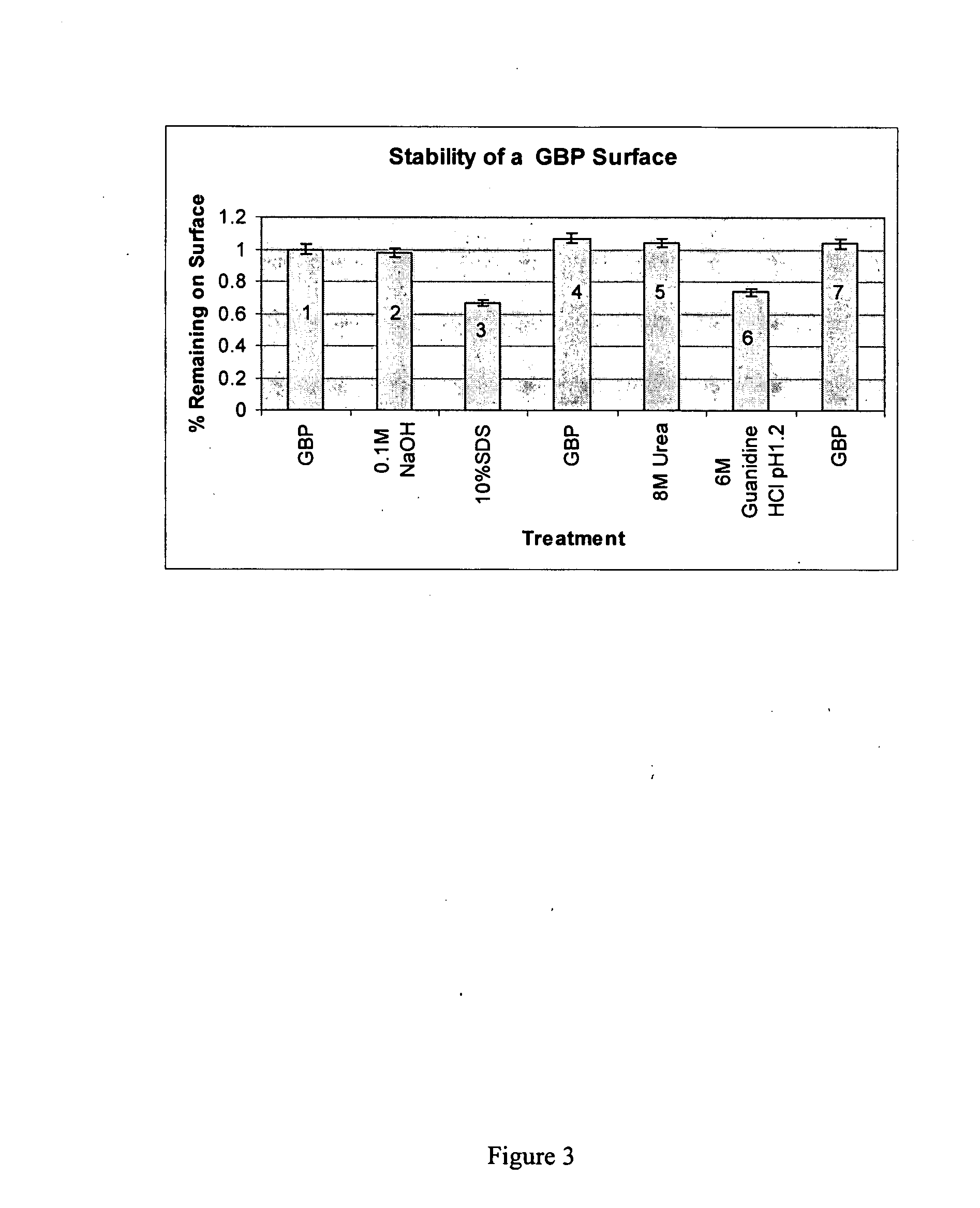

Recombinant fusion proteins with high affinity binding to gold and applications thereof

InactiveUS20060246426A1Robust and efficient immobilizationIncrease the number ofBioreactor/fermenter combinationsBiological substance pretreatmentsBinding peptideAlloy

The present invention provides a method to firmly attach any polypeptide to a gold surface regardless of its intrinsic gold-binding properties. The method describes the production of recombinant fusion proteins consisting of polypeptides of interest and a high affinity gold binding peptide consisting of 1 to 7 repeats of a unique amino acid sequence. By this method, many biologically active polypeptides lacking intrinsic gold-binding properties can be firmly attached to gold surfaces. The disclosure includes evidence that fusion proteins containing the gold-binding sequences provide superior stability and activity compared to similar molecules lacking the tag when used to construct biosensors. The invention provides a method that is a significant improvement over existing chemical and physical adsorption protocols to attach polypeptides to gold and, therefore, can provide benefits to many applications utilizing gold.

Owner:BIOHESION

Novel chemical nickel gold production process and chemical nickel plating liquid

InactiveCN109628913AFast deposition rateSolve the difficulty of levelingLiquid/solution decomposition chemical coatingEtchingNickel deposition

The invention discloses a PCB or package substrate chemical nickel gold production new process. The new process comprises the steps of chemical gold pretreatment, deoiling, micro-etching, activation,alkaline chemical nickel, nickel activation, acid chemical nickel, chemical gold, gold surface hole sealing and chemical gold aftertreatment. The invention further provides novel chemical nickel plating liquid. The process is low in nickel cylinder temperature and high in chemical nickel deposition speed; nickel simple substances are difficultly separated out from the wall of a chemical nickel plating liquid stabilizing tank; the horizontal production of chemical nickel gold can be realized; a production line is shortened; the emission of waste water is reduced; and the comprehensive production cost of the production line is reduced. In the novel chemical nickel plating liquid, through adjustment of types of complexing agents and stabilizing agents in the chemical nickel plating liquid, even if under the conditions of higher PH and higher deposition speed, higher P content is achieved to meet various performance requirements of existing chemical nickel gold for the surface treatment ofPCBs and package substrates.

Owner:湖南互连微电子材料有限公司

Manufacturing method of matted gold line of circuit board

ActiveCN104684266AImprove bindingImprove surface roughnessInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentSurface layerEtching

The invention discloses a manufacturing method of a matted gold line of a circuit board, and belongs to the field of production and manufacturing of the circuit board. The manufacturing method sequentially comprises the following steps: whole board electroplating, surface super-roughening, external line pattern transferring, pattern nickel electroplating, pattern gold electroplating and etching; the step of whole board electroplating is carried out until copper thickness is 3-5microns more than a required thickness; the step of surface super-roughening is carried out by micro-etching a copper layer surface of the circuit board so as to control micro-etching thickness within 0.75 plus / minus 0.25microns; after micro-etching, roughness parameter values of the copper surface are as follows: Ra is 0.3-0.5microns and Rz is 3.0-4.0microns. Through the manufacturing method disclosed by the invention, the circuit board with the matted gold line is researched and developed; the copper surface is roughened by virtue of a super-roughening process and then nickel and gold are electrically matted on the copper surface, therefore through the roughened copper surface and the matted nickel, a gold surface is rougher than a normal gold-electroplated gold surface, so as to achieve required color of matted gold; meanwhile, by roughening the copper surface through the super-roughening process, surface roughness is increased, binding force between the gold surface and the surface layer is enhanced, defects such as plating permeation in the gold electroplating process are overcome, and the reliability of a product is improved.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

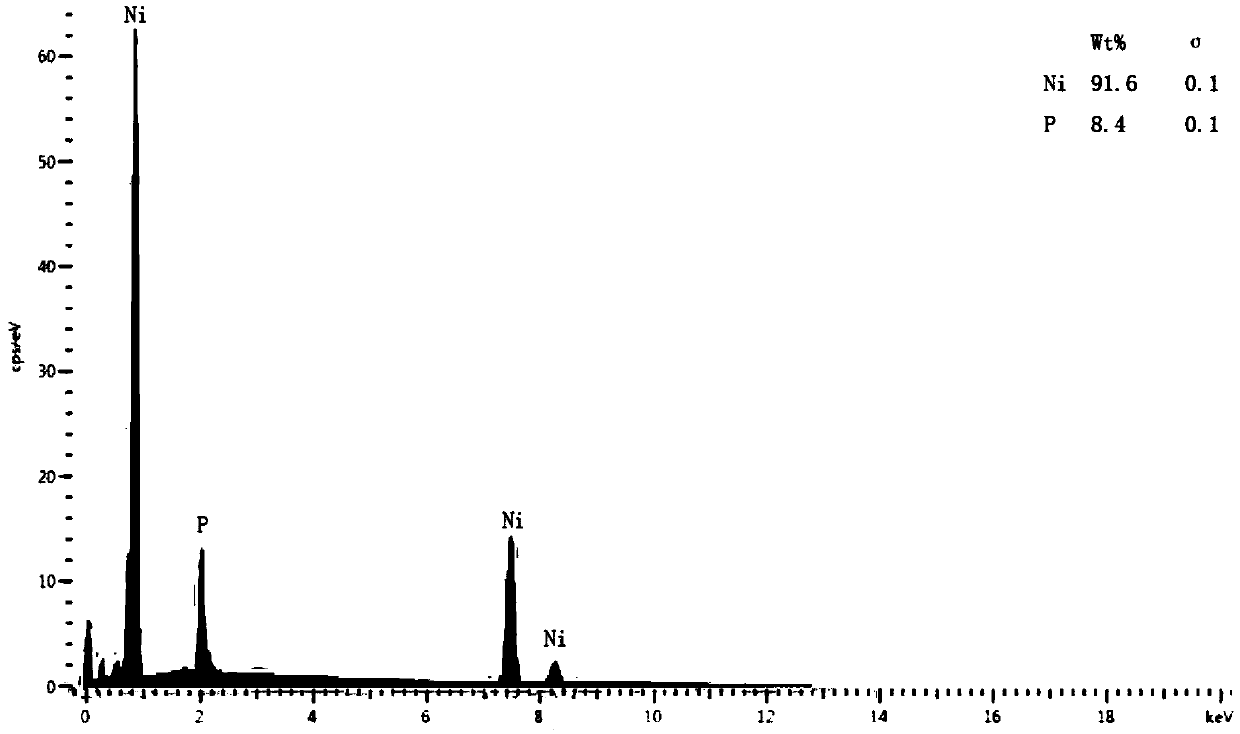

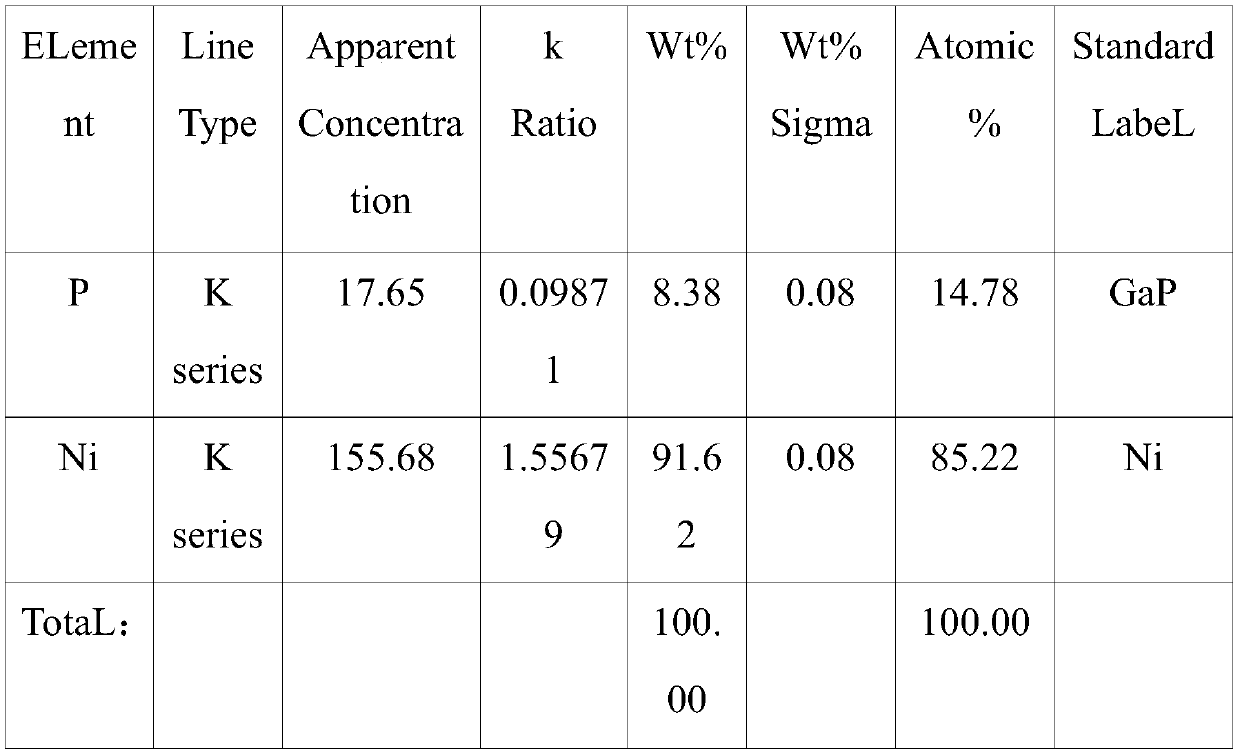

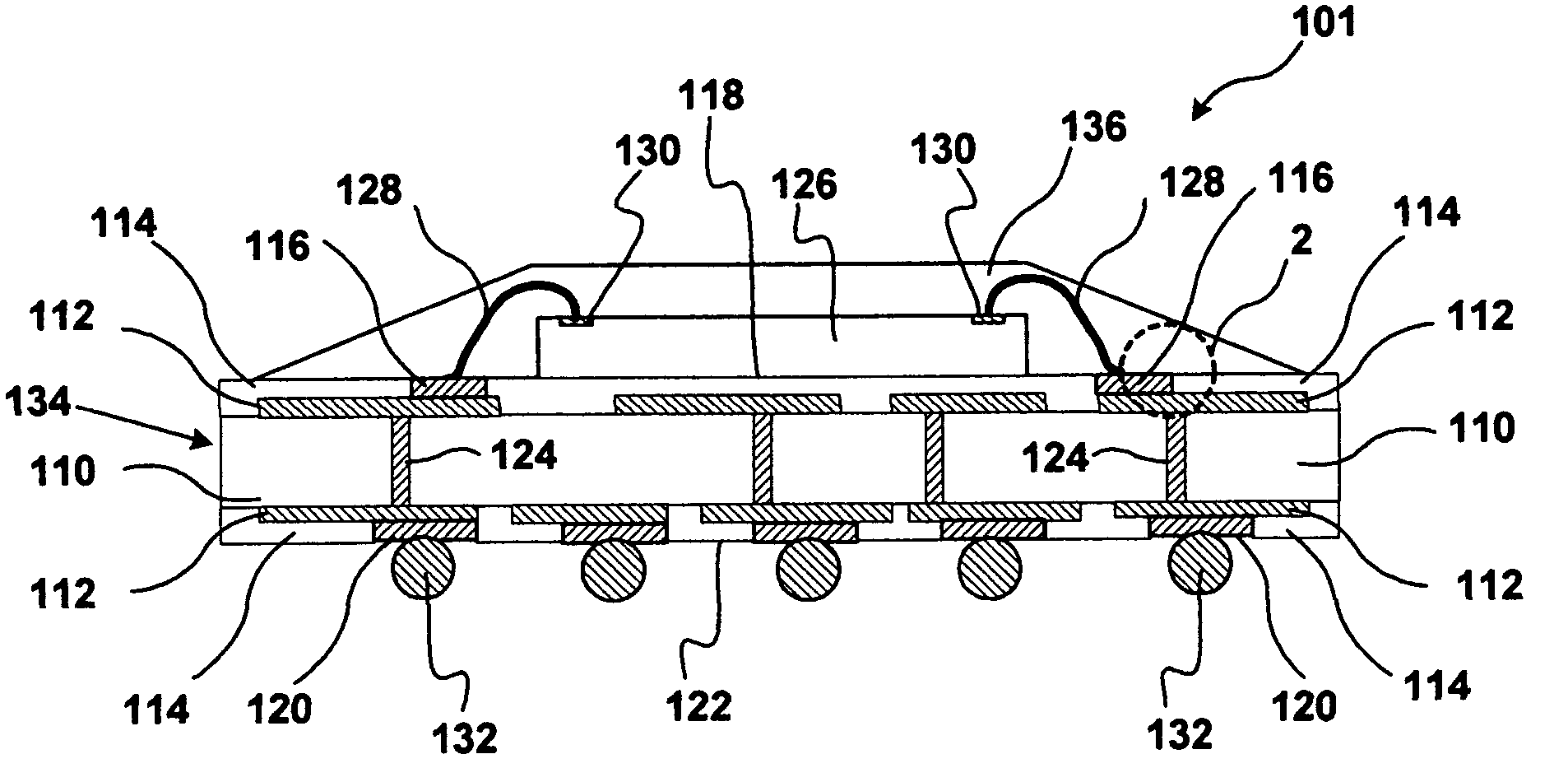

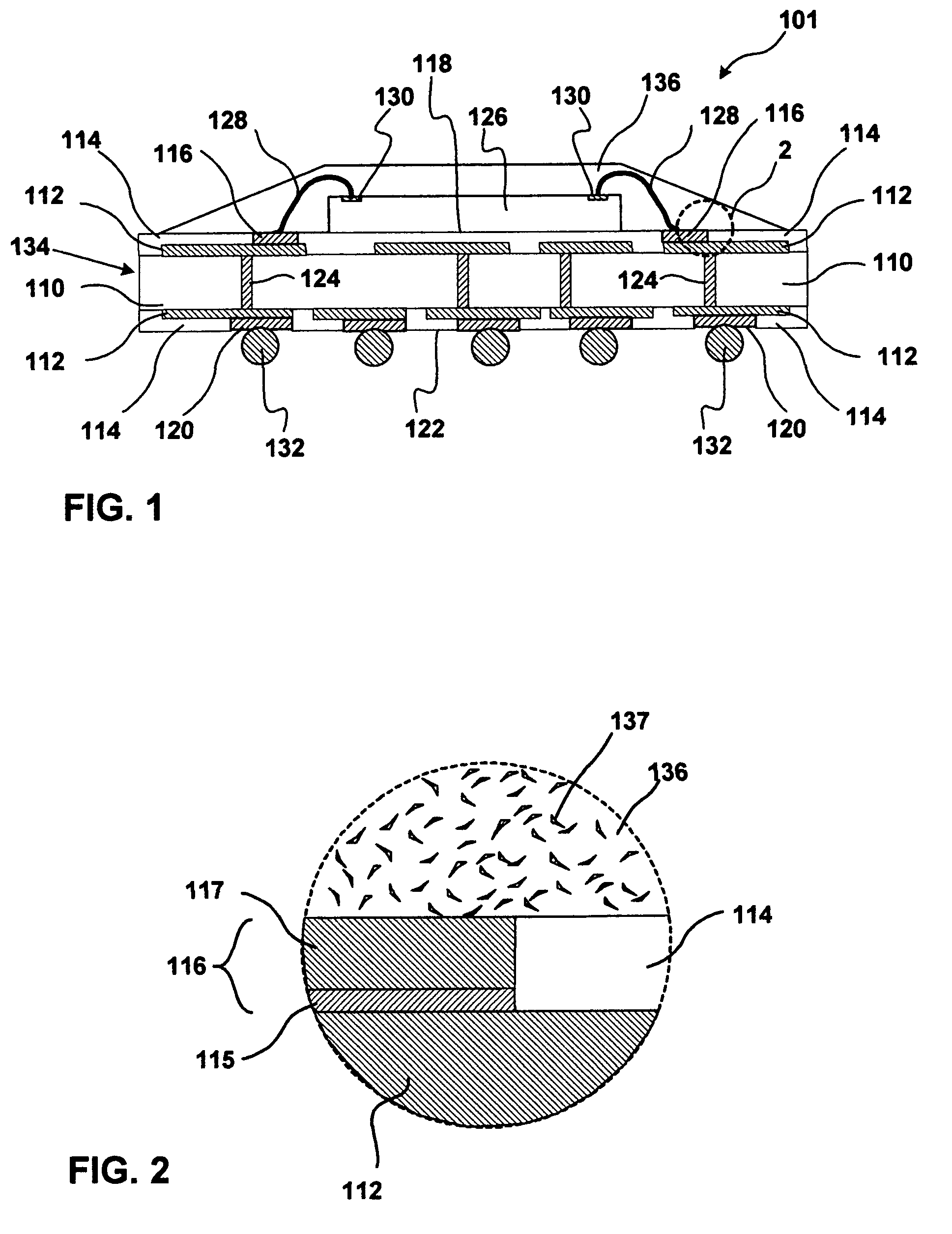

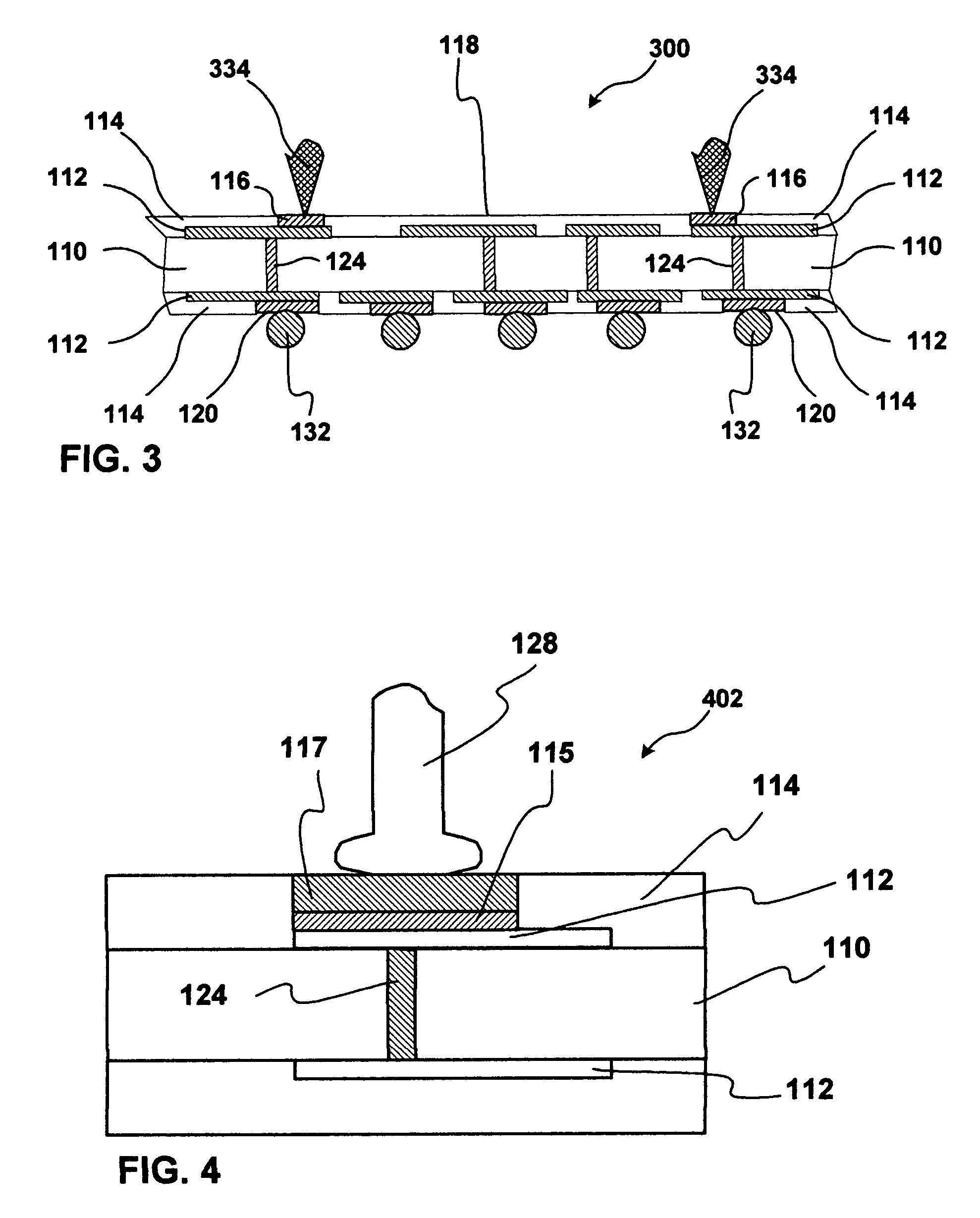

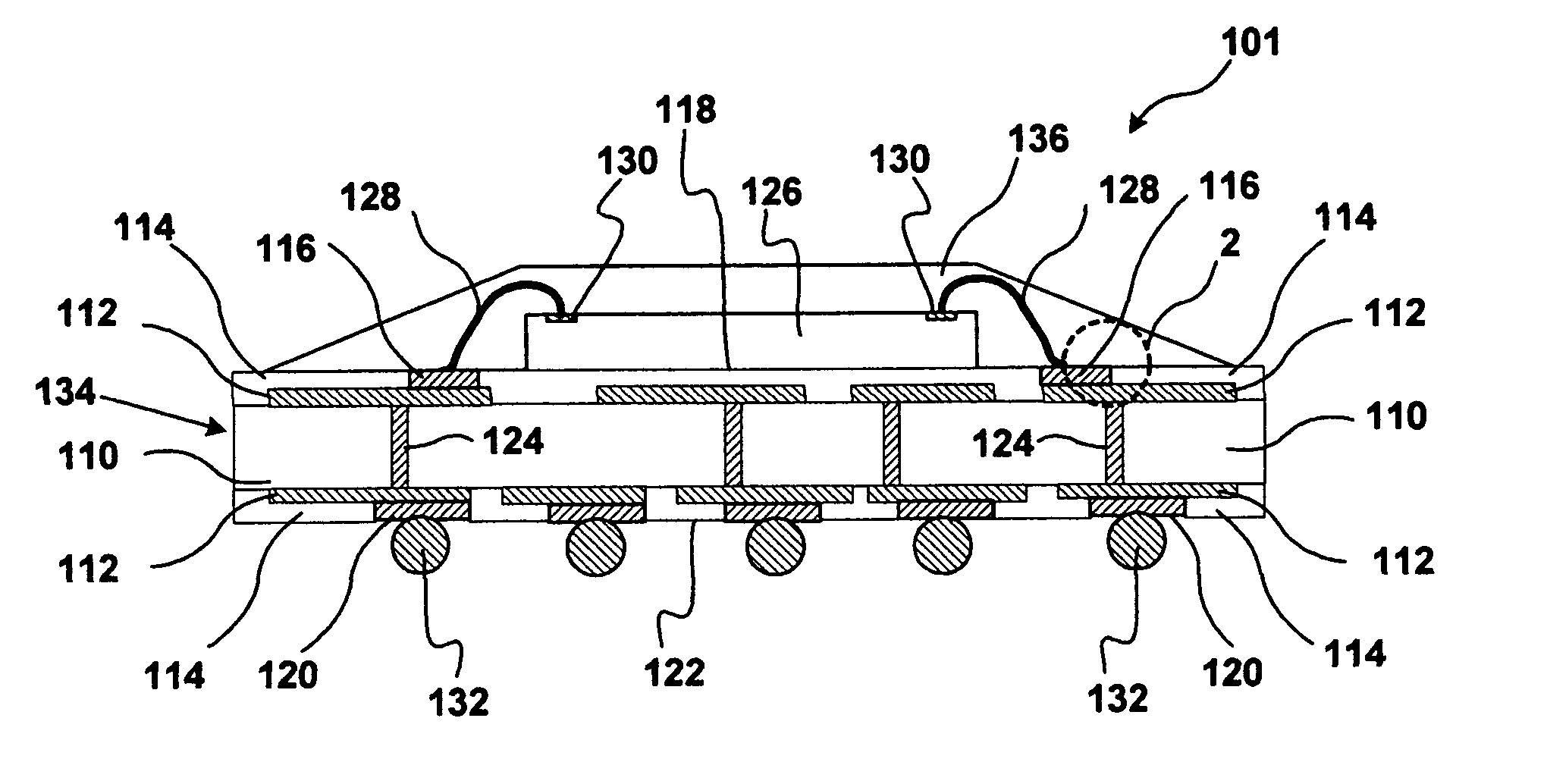

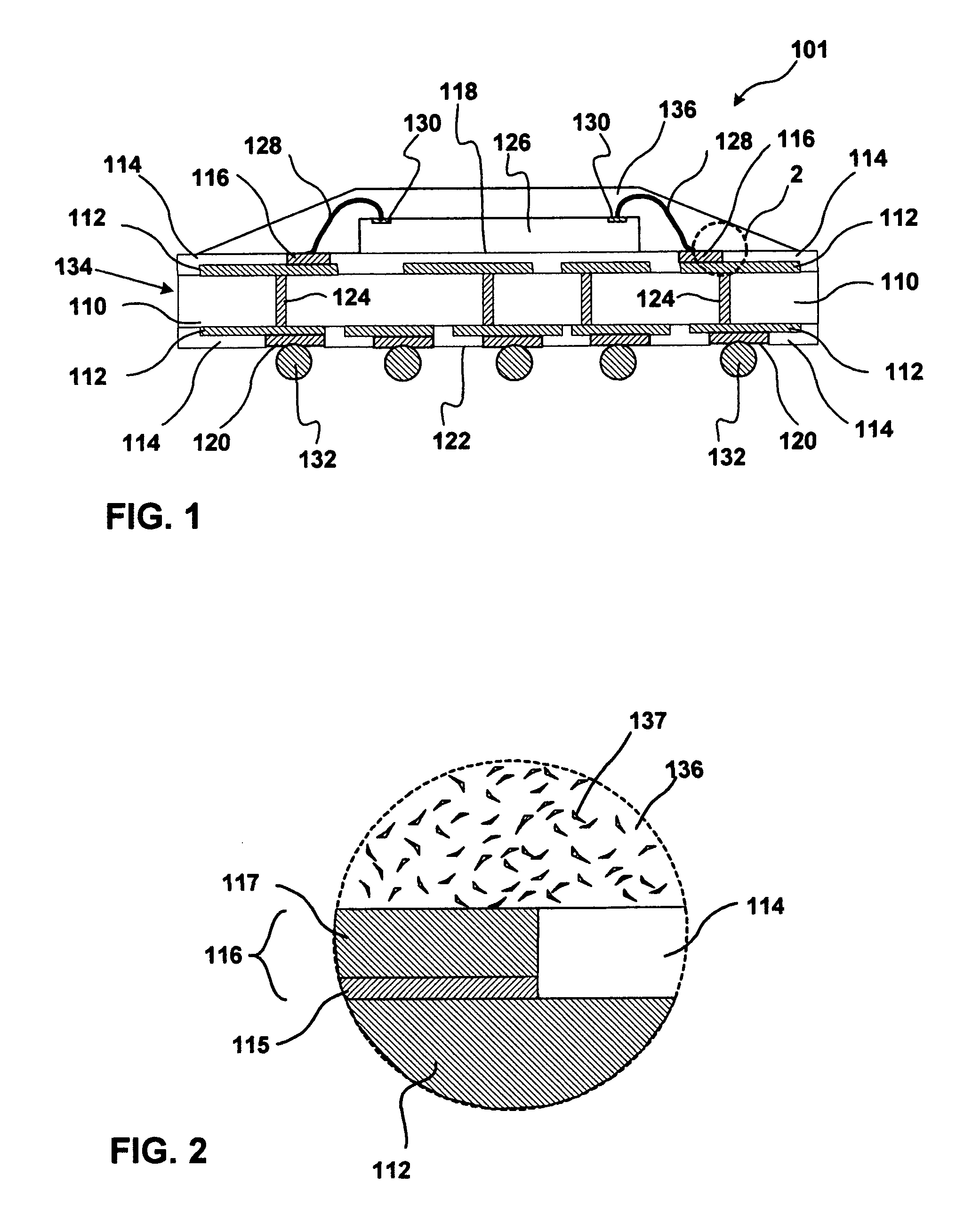

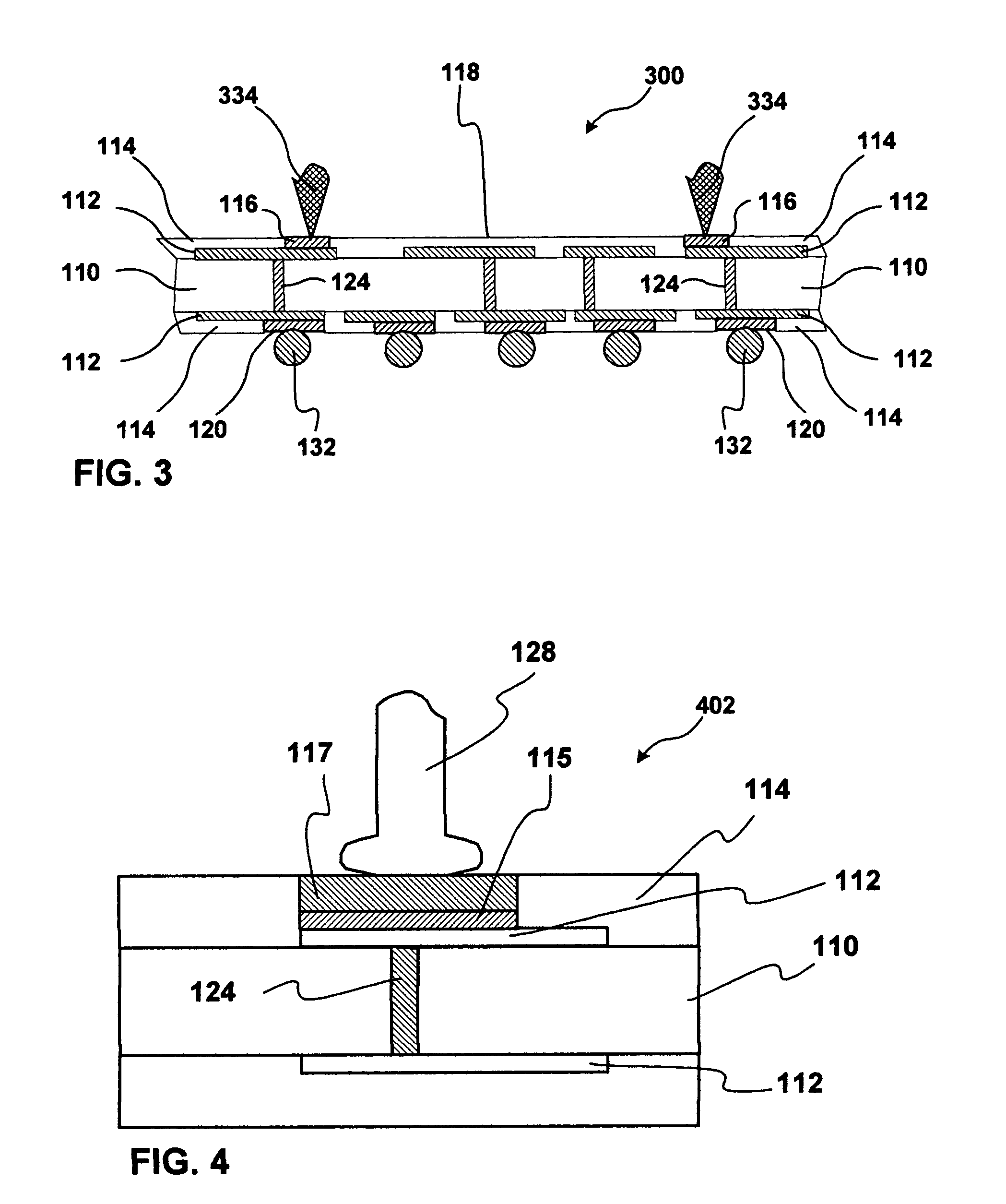

Use of direct gold surface finish on a copper wire-bond substrate, methods of making same, and methods of testing same

InactiveUS6972152B2Semiconductor/solid-state device detailsSolid-state devicesSurface finishCopper wire

A wire-bonding substrate is described. The wire-bonding substrate includes a copper metallization and a gold surface finish disposed above and on the copper metallization. The gold surface finish completes a structure that includes at least one of a bond finger for wire bonding of a first side of the substrate, and a land pad for a ball attach on a second side of the substrate. A process of forming the surface finish is also disclosed. An electronic package is also disclosed that uses the surface finish on the wire-bonding substrate. A method of assembling an electronic package is also disclosed that includes the surface finish on the wire-bonding substrate. A computing system is also described that includes the surface finish on the wire-bonding substrate.

Owner:INTEL CORP

Recombinant fusion proteins with high affinity binding to gold and applications thereof

InactiveUS20050106625A1Solve the complicated productionEasy to purifySugar derivativesPeptide/protein ingredientsBinding peptideBound property

The present invention provides a method to firmly attach any polypeptide to a gold surface regardless of its intrinsic gold-binding properties. The method describes the production of recombinant fusion proteins consisting of polypeptides of interest and a high affinity gold binding peptide consisting of 1 to 7 repeats of a unique amino acid sequence. By this method, many biologically active polypeptides lacking intrinsic gold-binding properties can be firmly attached to gold surfaces. The disclosure includes evidence that fusion proteins containing the gold-binding sequences provide superior stability and activity compared to similar molecules lacking the tag when used to construct biosensors. The invention provides a method that is a significant improvement over existing chemical and physical adsorption protocols to attach polypeptides to gold and, therefore, can provide benefits to many applications utilizing gold.

Owner:BIOHESION

Use of gold surface finish on a copper wire-bond substrate, method of making same, and method of testing same

InactiveUS20050147801A1Semiconductor/solid-state device detailsSolid-state devicesSurface finishCopper wire

A wire-bonding substrate is described. The wire-bonding substrate includes a copper metallization and a gold surface finish disposed above and on the copper metallization. The gold surface finish completes a structure that includes at least one of a bond finger for wire bonding of a first side of the substrate, and a land pad for a ball attach on a second side of the substrate. A process of forming the surface finish is also disclosed. An electronic package is also disclosed that uses the surface finish on the wire-bonding substrate. A method of assembling an electronic package is also disclosed that includes the surface finish on the wire-bonding substrate. A computing system is also described that includes the surface finish on the wire-bonding substrate.

Owner:INTEL CORP

Circuit board production method using immersion gold and electrolytic gold plating combined surface treatment

InactiveCN107041077ASimple processSolve gold seepageConductive material chemical/electrolytical removalEtchingCopper plating

The invention discloses a circuit board production method using immersion gold and electrolytic gold plating combined surface treatment. A substrate is drilled and then subjected to electroless copper deposition panel plating; then the whole copper layer is thickened by pattern plating; then an anti-immersion gold dry film is printed; after exposure and development of the film, a circuit pattern with copper exposed in an open window is formed; immersion gold plating is carried out and the film is stripped off; then an anti-immersion gold dry film is printed; after exposure and development of the film, electrolytic gold plating is carried out and the film is stripped off; the circuit board is subjected to etching, and the exposed copper surface is etched off; an in-process inspection is carried out; solder masking ink is printed and follow-up processes are carried out. The method substantially simplifies the technique and solves the problems of gold infiltration and low consumed time in the prior art. The entire production process has only one etching, so that the entire substrate has the conductive copper surface to complete the electrolytic copper plating before the electrolytic copper plating, thereby reducing the process and improving the quality and production efficiency. According to the invention, the circuit pattern is produced at the same time as an immersion gold surface treatment area, and surface treatment is completed before silk screen and solder masking, so that the process is reduced, the time is saved and the production efficiency of the circuit board is improved.

Owner:广东依顿电子科技股份有限公司

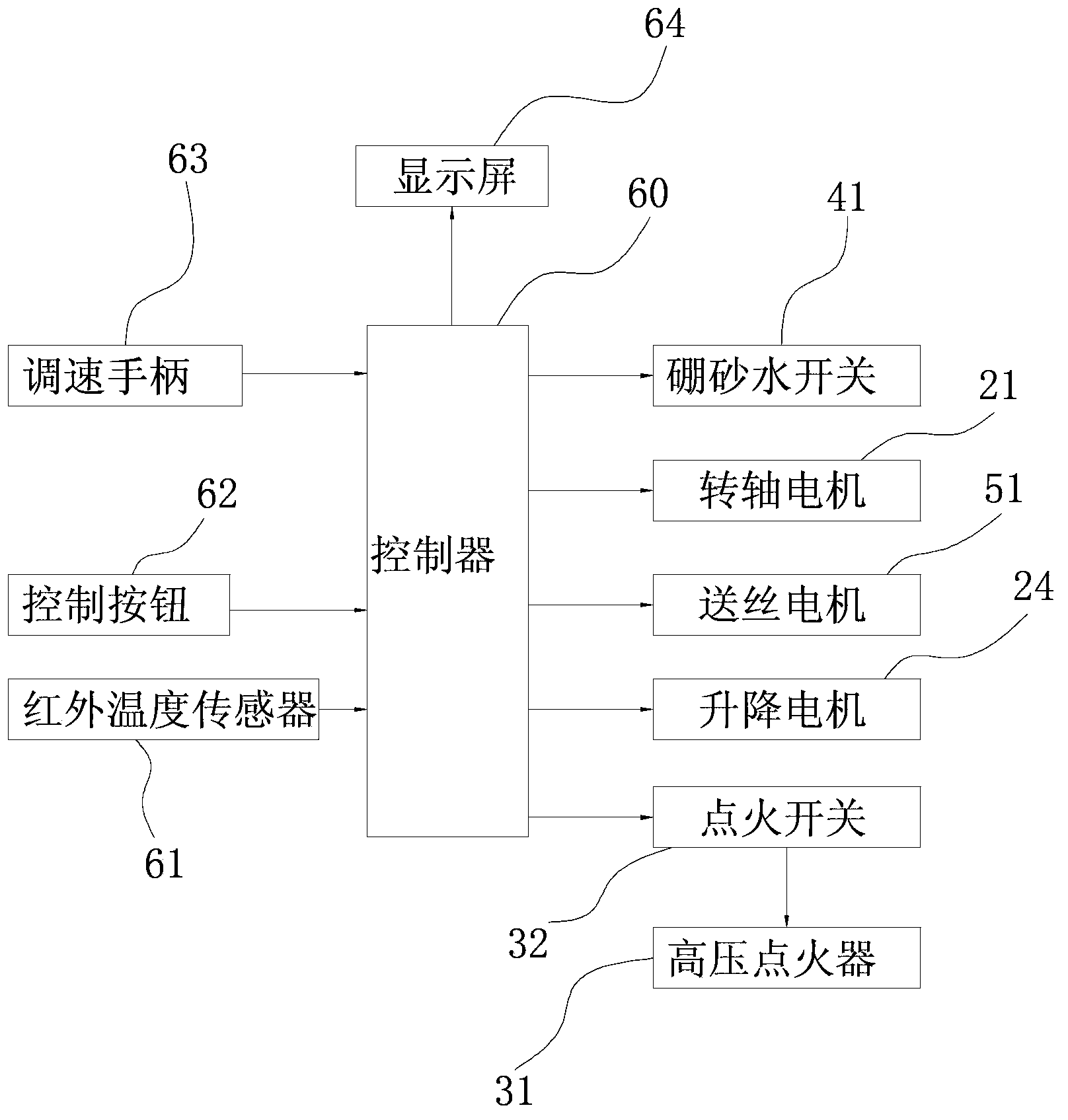

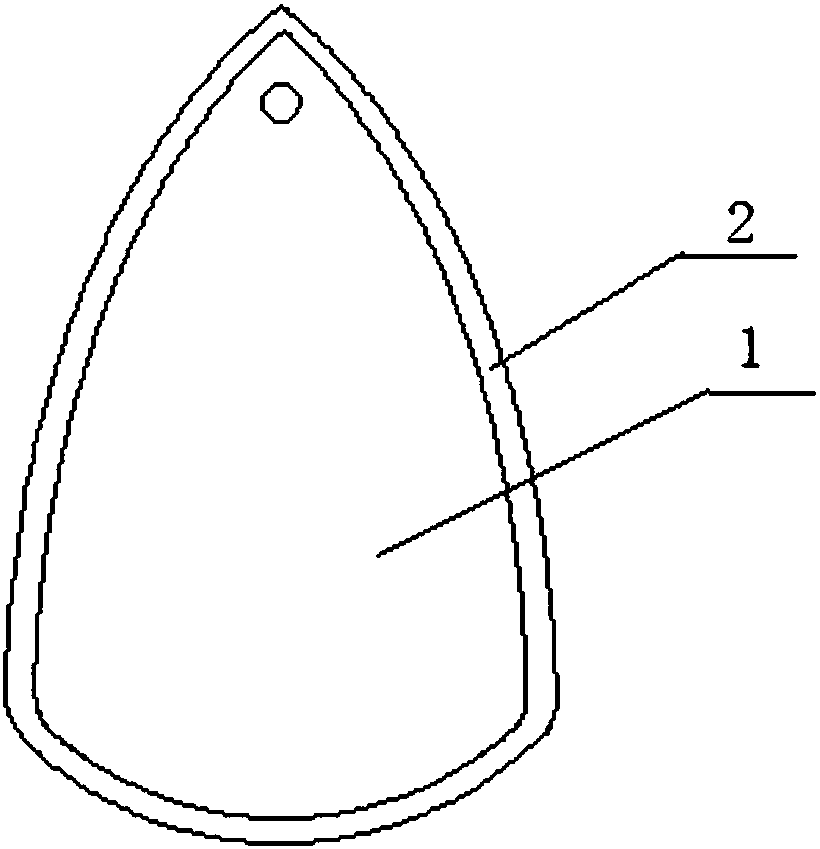

Machining method and device for gold and platinum jewelry and combined type jewelry structure

ActiveCN104337136AReduce labor intensityReduce the difficulty of operationBraceletsWrist-watch strapsPlatinum jewelryAir drying

The invention discloses a machining method and device for a gold and platinum jewelry and a combined type jewelry structure. The machining method for the gold and platinum jewelry includes the following steps: (1) platinum materials are adopted, and a jewelry body is molded through a die or machined through cutting according to a model of the jewelry; (2) at least one groove is machined in the surface of the jewelry body; (3) gold materials are melted at a high temperature into the grooves of the jewelry body; (4) surface polishing is carried out, wherein the surface of the gold and the surface of the platinum are polished; (5) electrolysis and gold plating are carried out on the surface of the jewelry, wherein the surface of the gold is coated with oil firstly, and secondly electrolysis and gold plating are carried out after air drying is carried out; and (6) polishing processing is carried out. According to the machining method, a gold wire rod is heated at a high temperature through a heating gun to be directly melted into the grooves of the jewelry body; as local heating melting is carried out, the production efficiency for melting the gold wire rod and the jewelry body together can be improved, and the production cost can be saved; when heating is carried out, as borax water is contained in the grooves, the effect of removing impurities can be achieved, and the melting intensity can improved.

Owner:SHENZHEN BOFOOK JEWELRY

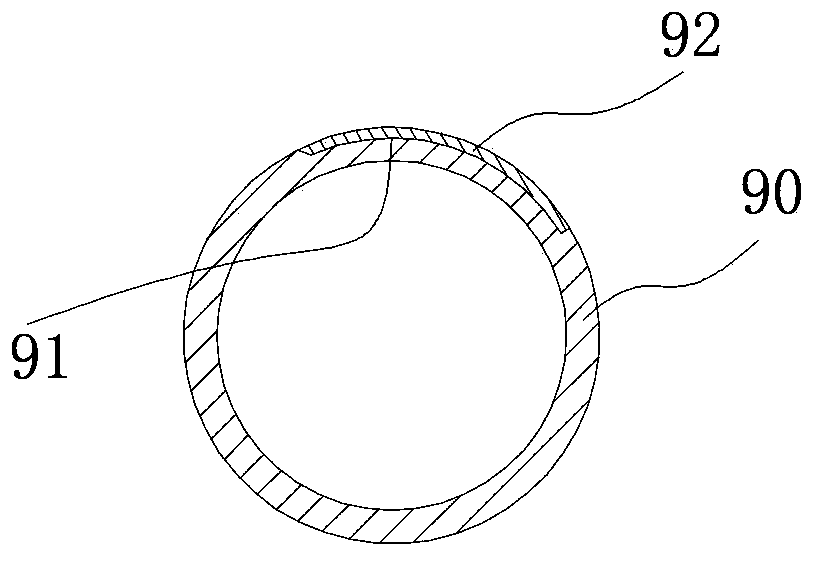

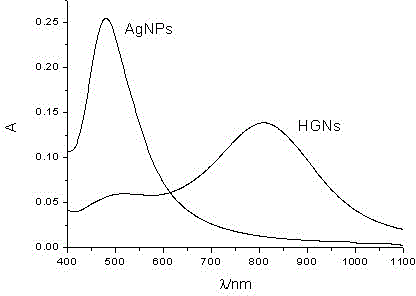

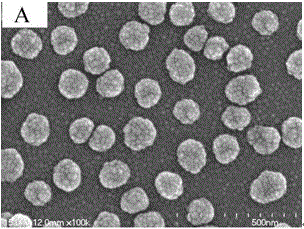

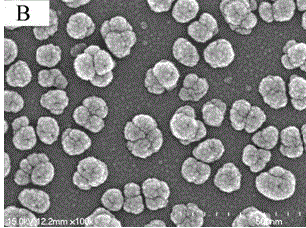

Hollow gold nano particle sensing membrane and preparation method thereof

InactiveCN102914514AImmobilizationEasy to functionalizeColor/spectral properties measurementsResonanceIndium tin oxide

The invention discloses a preparation method of a hollow gold nano particle sensing membrane, and the method comprises the following steps of: (a) adopting an electrochemical method to directly deposit silver nano particles on an ITO (Indium Tin Oxide) conductive glass surface to be used as a template; and (b) adopting HAuCl4 to displace the silver nano particles and depositing gold on the surfaces of the silver nano particles; and meanwhile, dissolving the silver nano particles to obtain the hollow gold nano particle sensing membrane. According to the preparation method disclosed by the invention, a hollow nano gold shell is immobilized on the surface of the transparent conductive glass surface, and any organic stabilizing agent and bonding agent do not need to be added; and the surface is clean and the gold surface is further functionalized to prepare an LSPR (Localized Surface Plasmon Resonance) biosensor.

Owner:SUZHOU UNIV

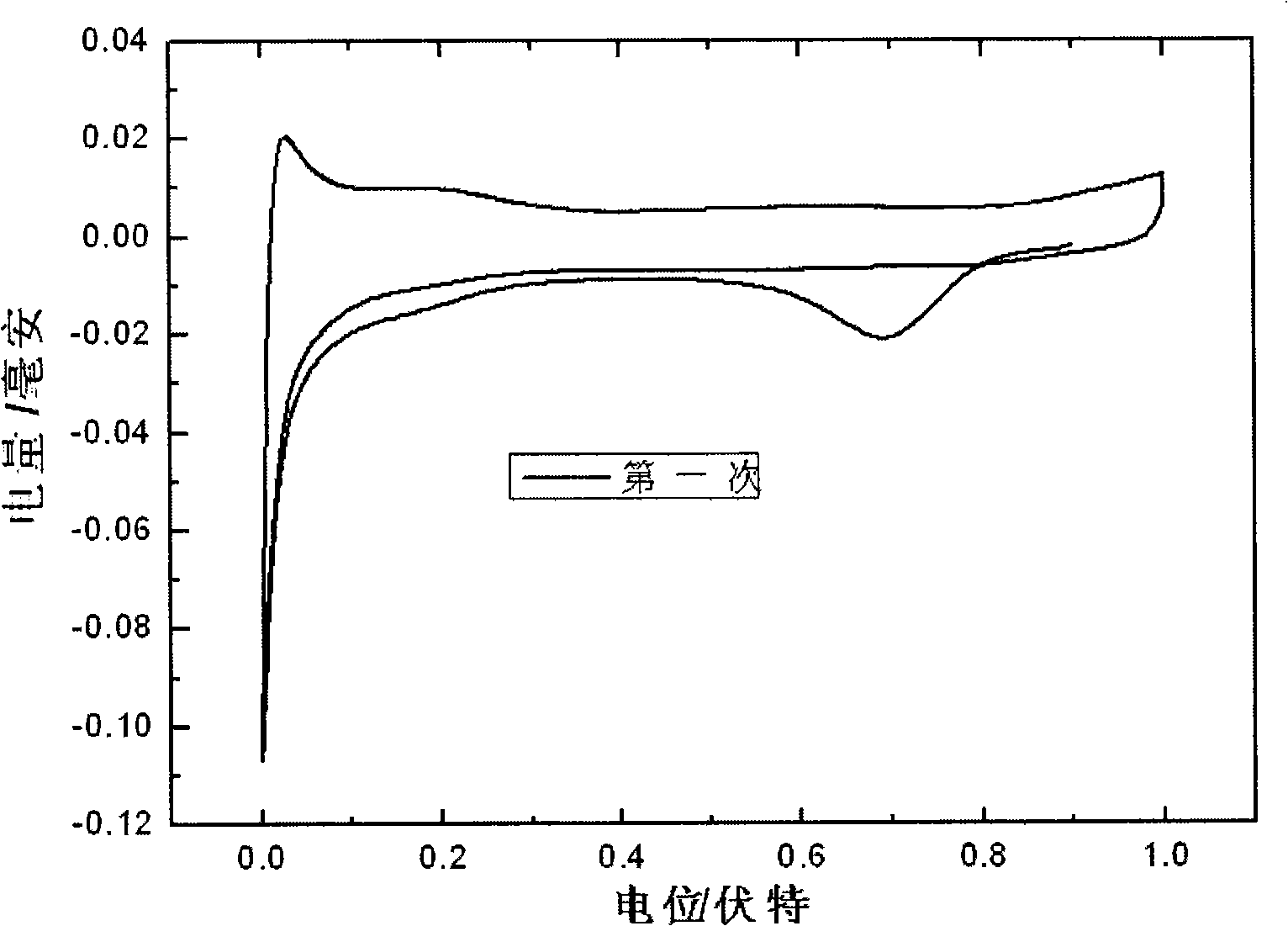

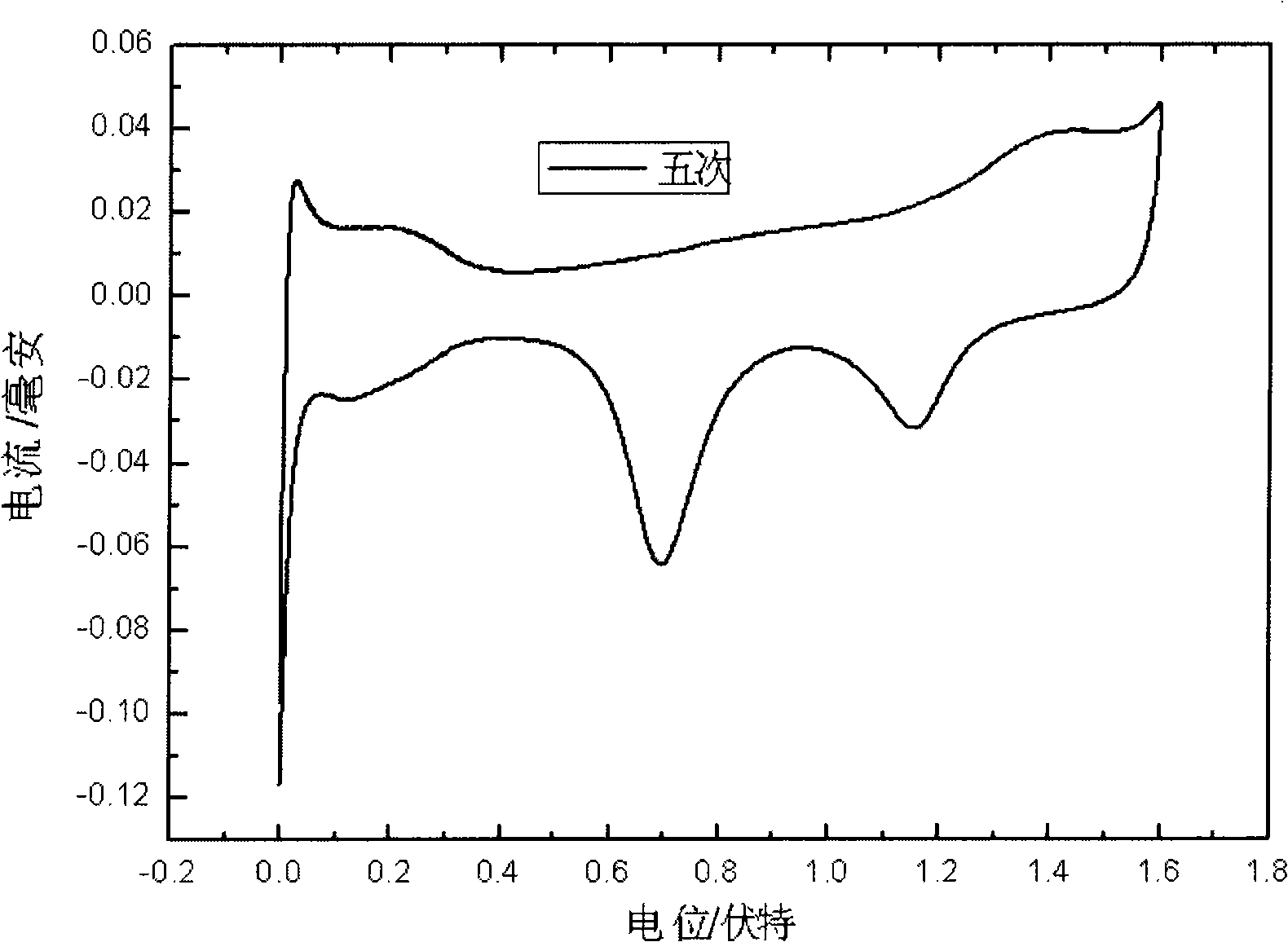

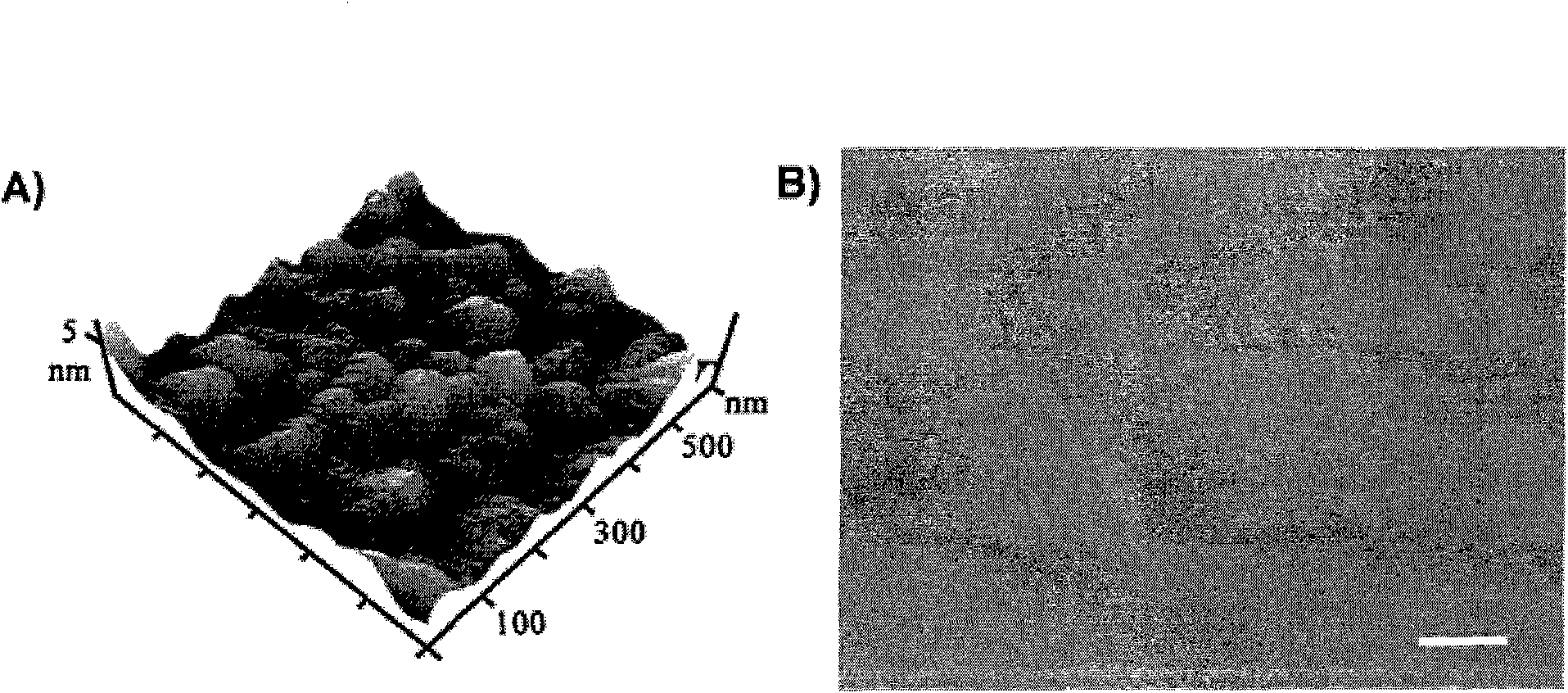

Photoelectrochemistry biosensor and preparation method thereof

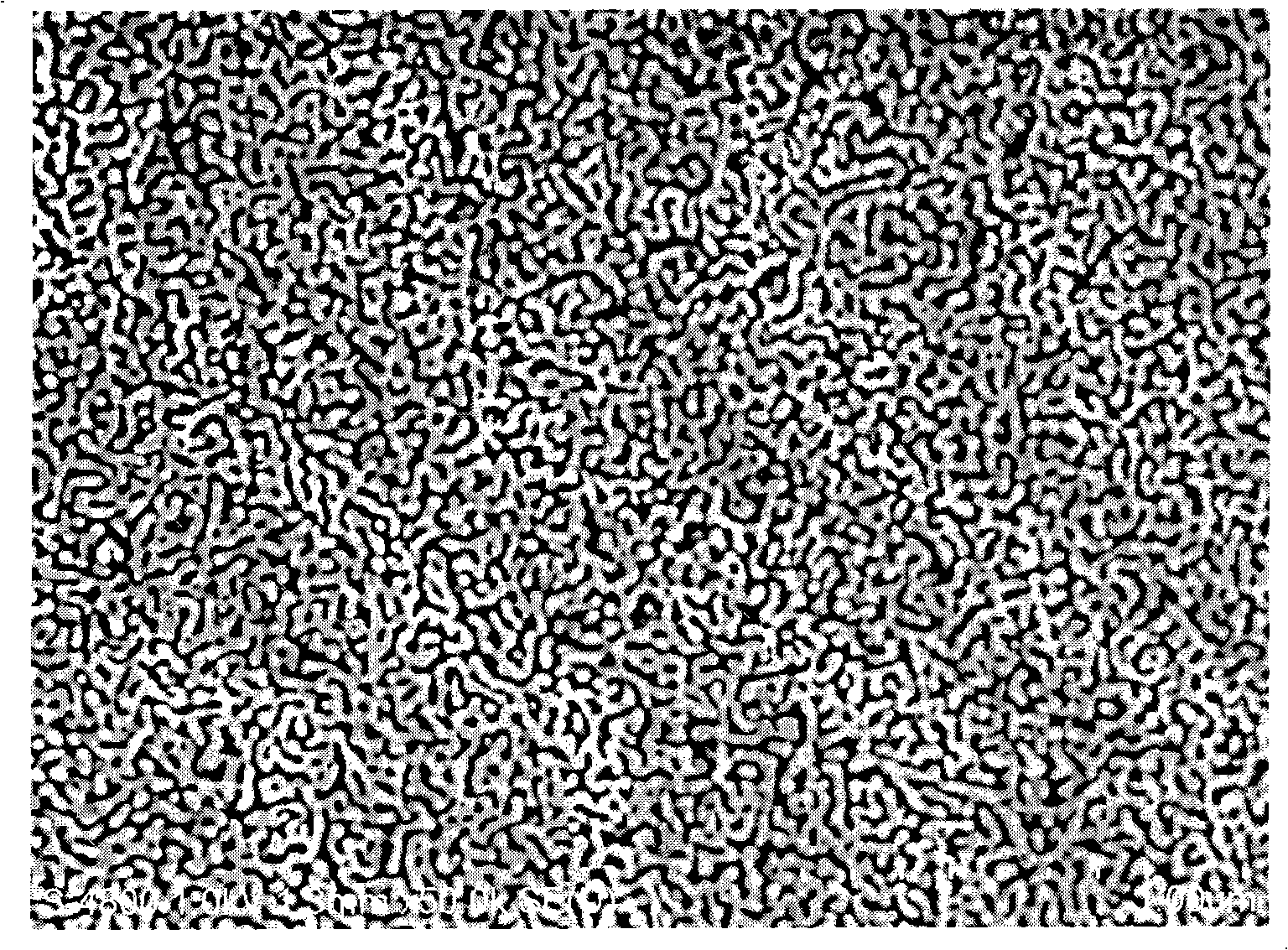

InactiveCN101776637AHigh detection sensitivityImprove production efficiencyMaterial electrochemical variablesRough surfacePhotosensitizer

The invention provides a photoelectrochemistry biosensor and a preparation method thereof. The biosensor uses a gold electrode with a rough surface as a conductive electrode. The surface of the conductive electrode is provided with a photosensitizer. The photosensitizer is a conducting polymer with biomolecule recognition groups, wherein after being compounded with the photosensitizer, i.e. the conducting polymer with the biomolecule recognition groups, the rough gold surface not only is beneficial for capturing light, but also can improves the transmission of a photon-generated carrier of the conducting polymer on the surface of the electrode so as to improve photoelectric conversion rate, strengthen a photoelectric current generated by the system and achieve the effect of improving the detection sensitivity of the photoelectrochemistry biosensor. The preparation method comprises a step of adopting an electrochemical deposition method in which no moulding board and no surface active agent participate to prepare the gold electrode. The method is simple and easy to operate and further improves the preparation efficiency of the photoelectrochemistry biosensor.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

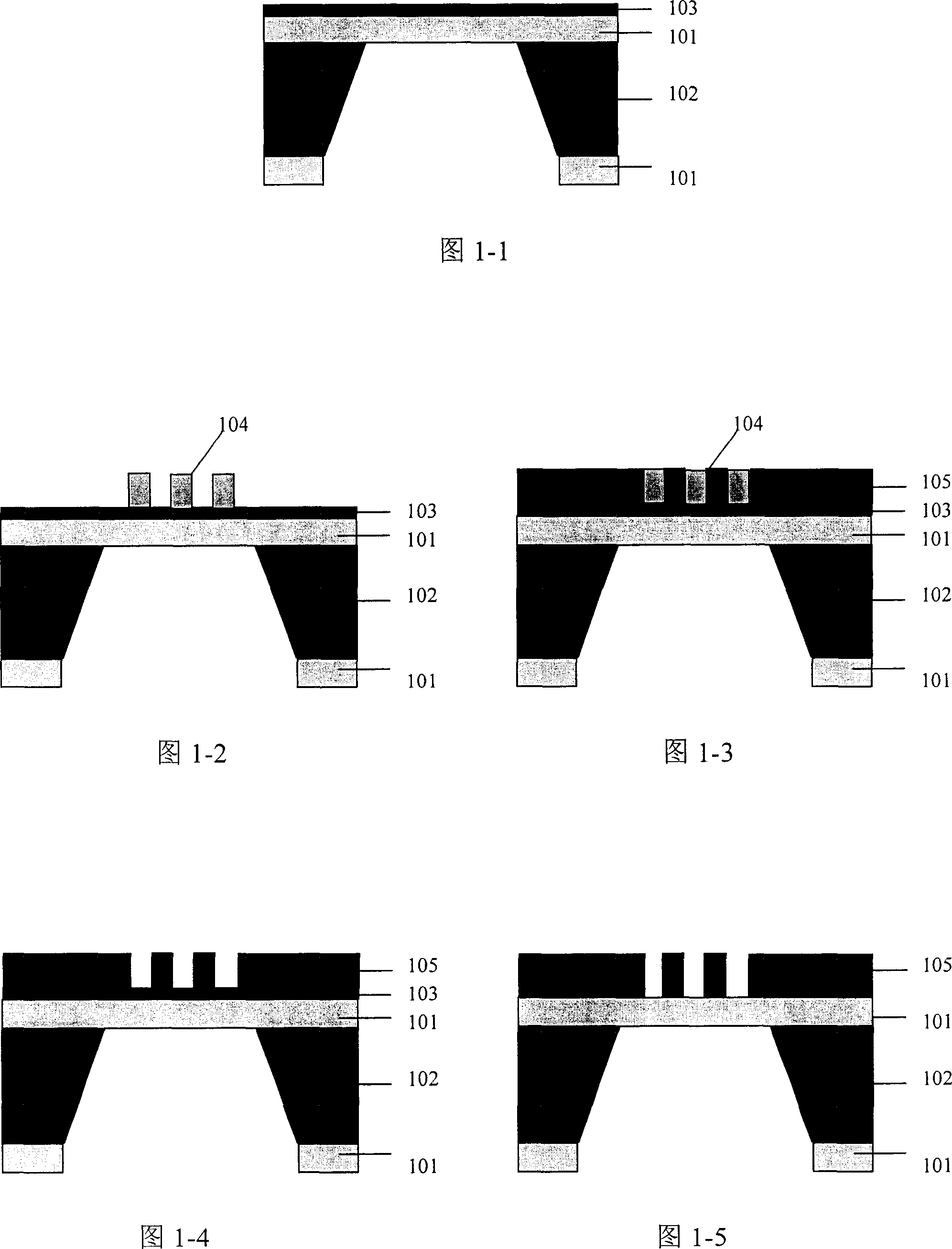

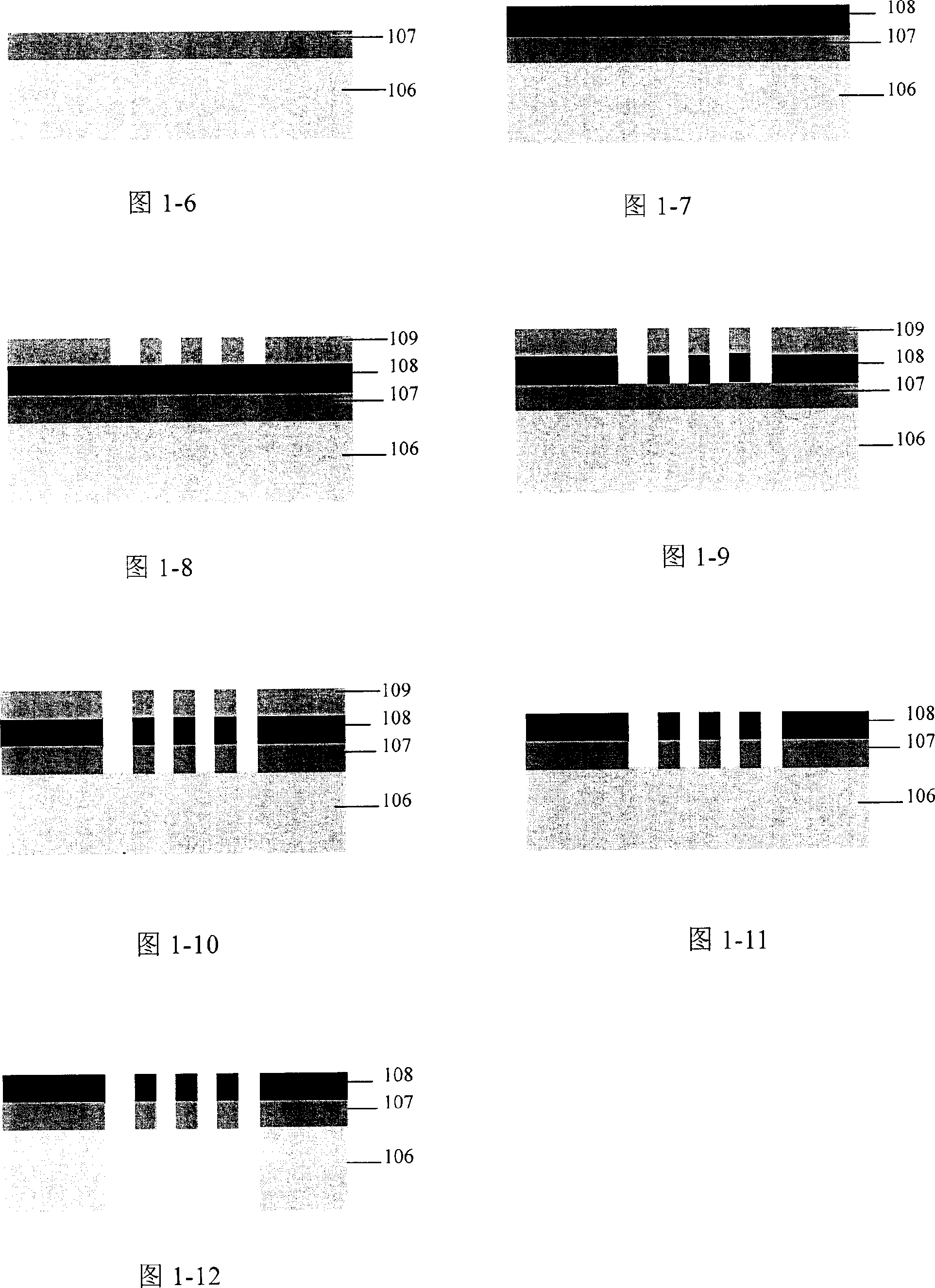

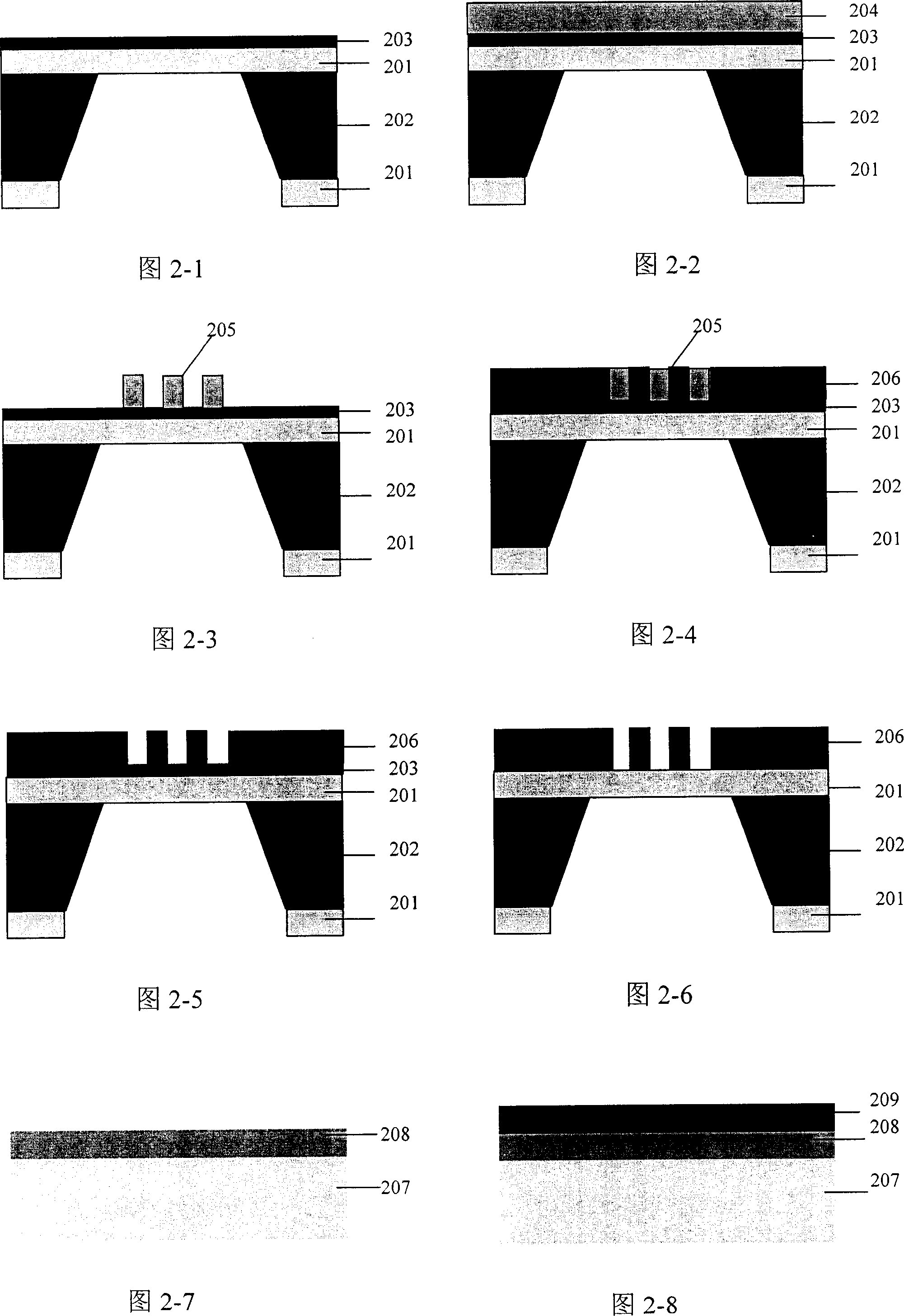

Manufacture method of high resolution self-supporting totally hollowed-out transmission grating

ActiveCN101017214AHigh resolutionIncrease productivitySemiconductor/solid-state device manufacturingDiffraction gratingsGratingX-ray

This invention relates to one X ray infraction optical element high resolution rate self-supportive cast transparent grating, which comprises the following: a, depositing film gold layer to support X ray mask underlay; b, in surface layer etching electron glue to get etch pattern; c, the slice is put to coating liquid for X ray mode absorptive gold pattern; d, the said slice removes electron beam glue; e, then removing electron beam for film of chromium layer; f, coating medlin on glass for fixing; g, depositing gold on its surface; h, coating X ray etch glue on gold surface; I, removing medlin; j, removing etch glue; k, back surface erosion of glass to fulfill the process.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

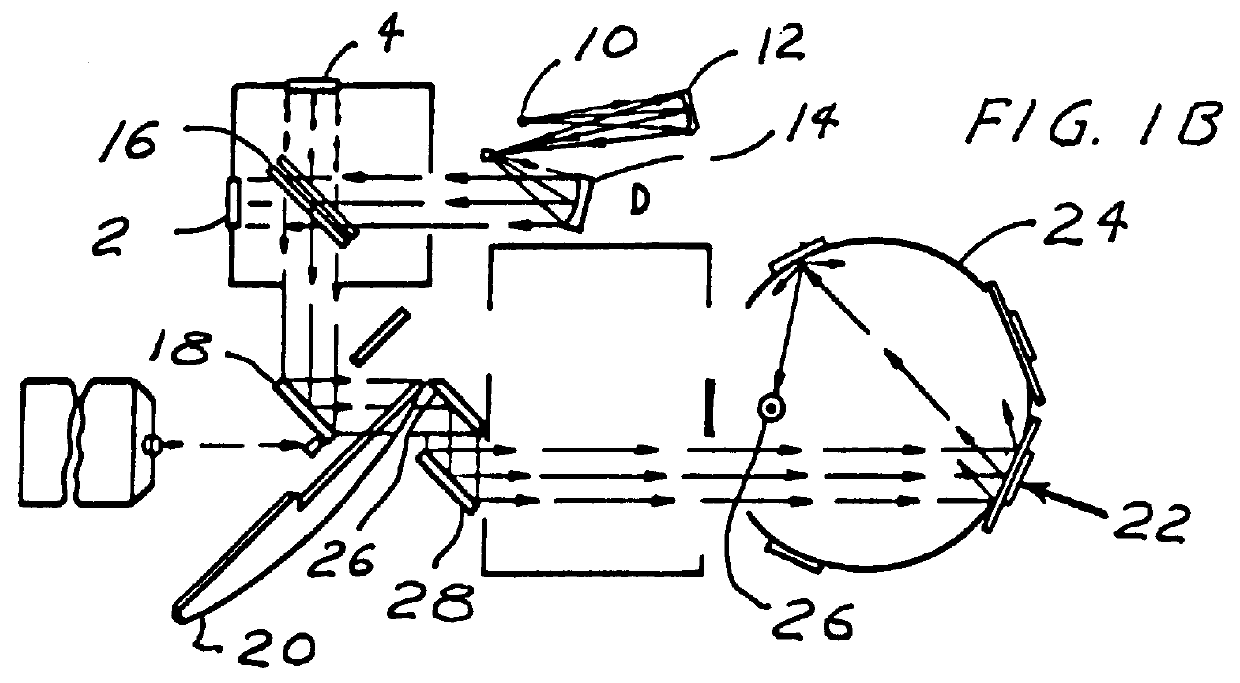

Spectroscopic residue detection system and method

A spectroscopic detection system and method for quantitative measurements of non-volatile residues. A sample to be analyzed is spread out on the inside surface of a cup portion of a unique detector cup. The cup portion mates with a detector portion to create an enclosed reflecting volume. A small port in the detector portion permits entrance of light which diffusely reflects multiple times from the inside surface of the enclosed reflecting volume and which is partially absorbed by the sample depending on the spectral absorption characteristics of the sample. A light detector in the detector portion detects light after multiple reflections from the surfaces of the detector and cup portions and multiple passes through the sample on the surface of the cup portion. Light detected by the light detector is spectrally analyzed to determine the spectral characteristics of the sample. In a preferred embodiment of the present invention the light is infrared light, the diffusely reflecting volume is a sphere, the reflecting surface of the cup is a smooth hemispheric gold surface and the reflecting surface of the detector portion is a rough hemispheric gold surface. In this preferred embodiment light from a broad band infrared light source is directed through an interferometer system prior to entering the detector cup and signals from the light detector are Fourier analyzed along with mirror position data to determine absorption characteristics of the sample.

Owner:SURFACE OPTICS

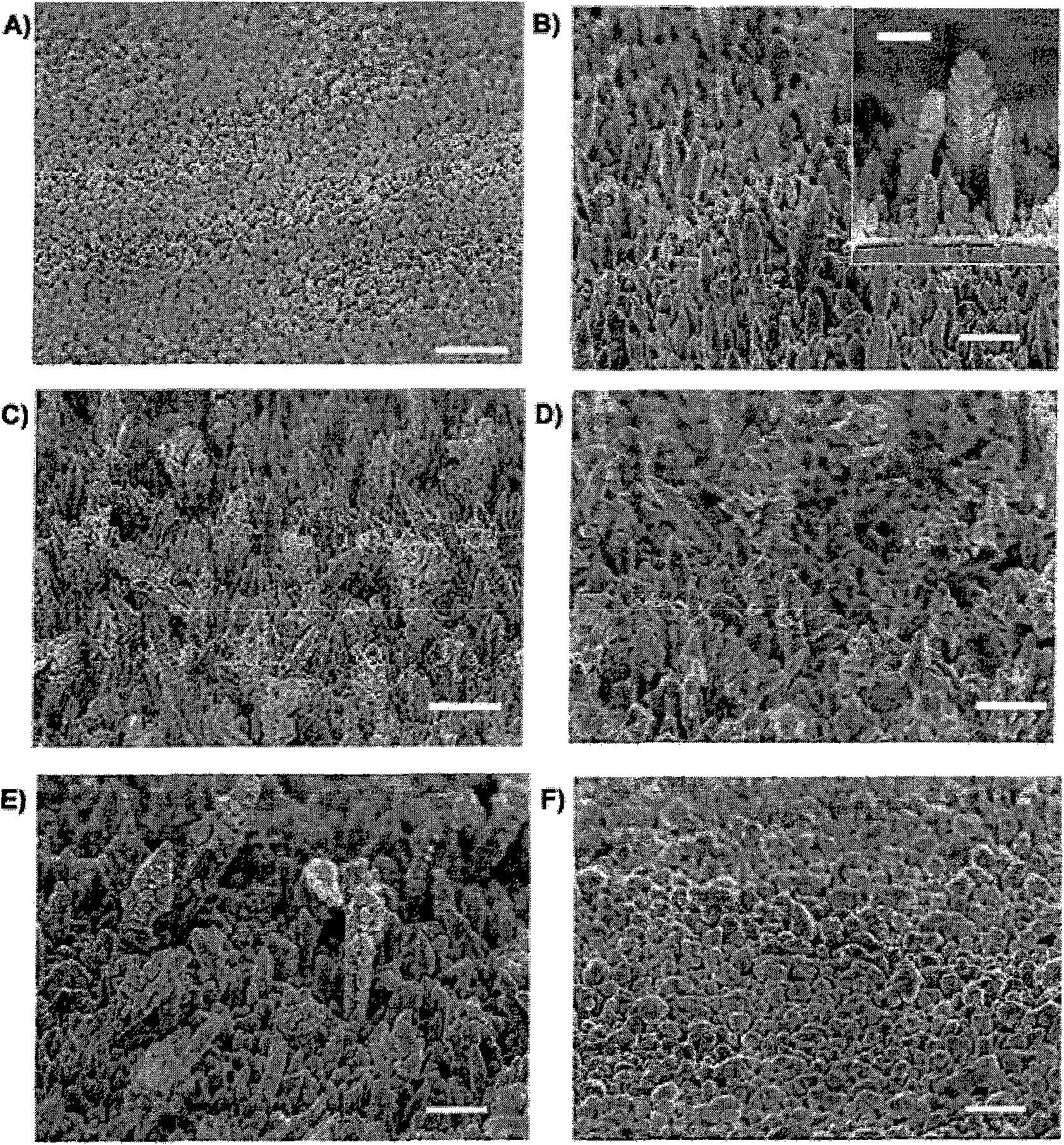

Nano-gold surface-enhanced Raman active substrate with layered three-dimensional structure and method for preparing same

InactiveCN102944545AUniform structureStrong spectral signalDecorative surface effectsRaman scatteringGold particlesSurface-enhanced Raman spectroscopy

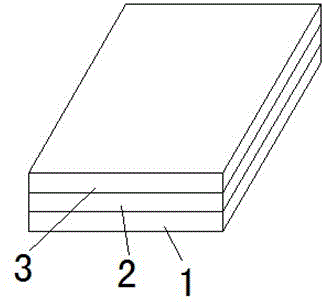

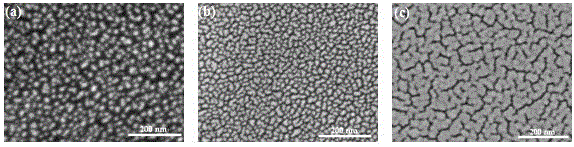

A nano-gold surface-enhanced Raman active substrate with a layered three-dimensional structure and a method for preparing the same relate to the fields of the nanometer materials science, laser Raman and biochemical analysis and detection. The surface-enhanced Raman active substrate is composed of three layers in total: a gold film, a dielectric layer and a two-dimensional array of irregular nano-gold particles arranged orderly from the bottom upwards, wherein the size and shape of the nano-gold particles and the thickness of each layer are adjustable. The method for preparing the substrate provided by the invention is to deposit the layered three-dimensional structure on a commercial glass slide with gold and silicon dioxide as coating materials by the ion beam coating method without using any other method. The nano-gold surface-enhanced Raman active substrate with the layered three-dimensional structure solves the problems of poor signal, low sensitivity, complex preparation process, high cost and the like of the nano-gold surface-enhanced Raman active substrate prepared by the prior art, and can be used for analyzing and detecting low-content compounds.

Owner:JIANGXI NORMAL UNIV

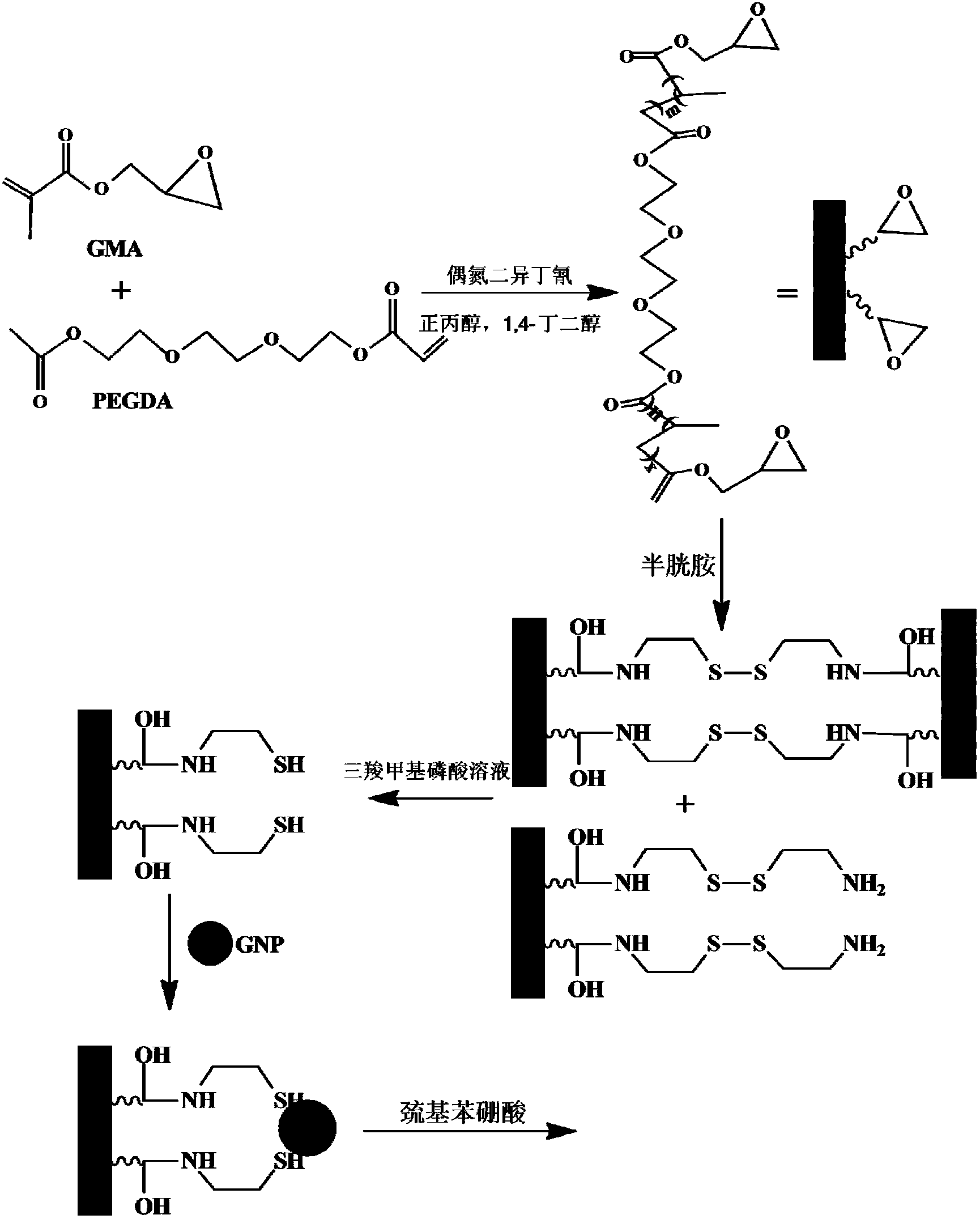

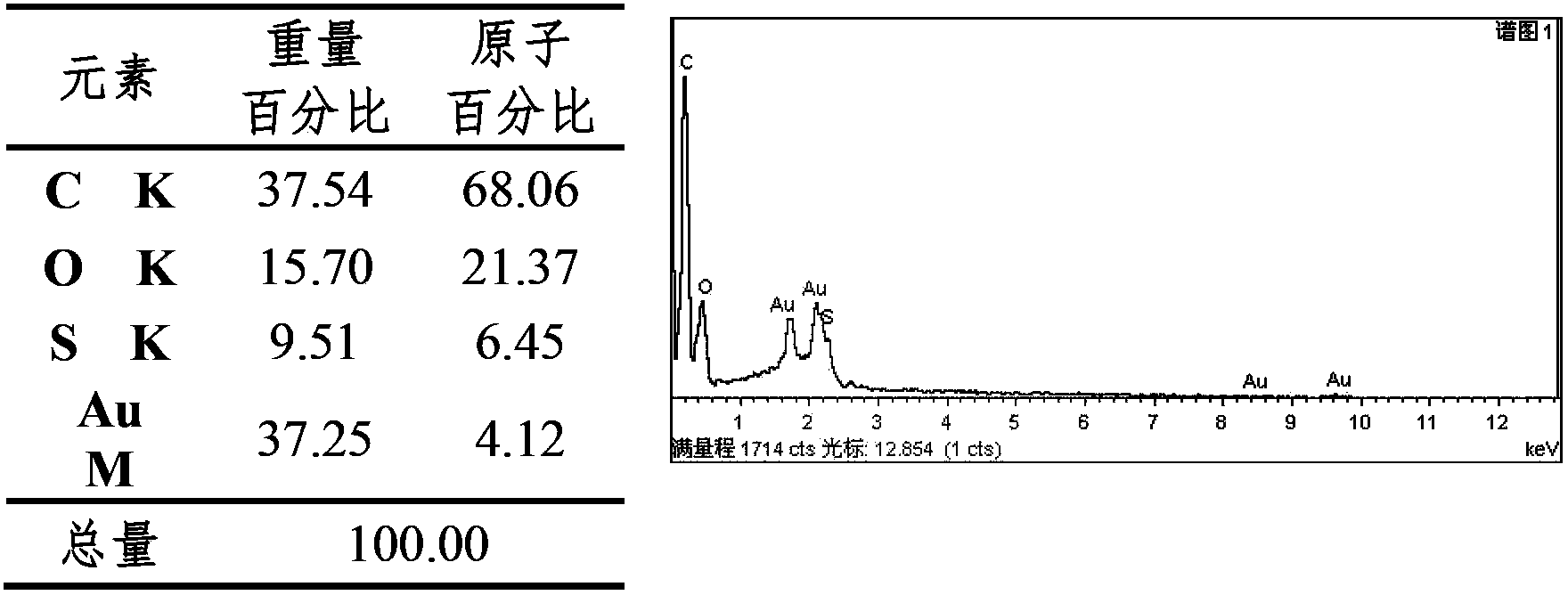

Nano gold doped integral material for enriching glycoprotein and applications thereof

ActiveCN103877949AImprove hydrophilicityReduce non-specific adsorptionOther chemical processesPeptide preparation methodsGlycidyl methacrylateGold particles

The invention relates to a preparation method of a nano gold doped integral material for enriching glycoprotein. The preparation method comprises the following steps: taking glycidyl methacrylate (GMA) and polyethylene glycol diacrylate (PEGDA) as the monomers to synthesize a hydrophilic polymer integral material substrate through an in-situ polymerization method; utilizing the epoxy groups in the substrate surface to enrich the substrate surface with mercapto groups through a chemical derivatization method, then modifying the substrate surface with nano gold particles; finally co-modifying 4-mercaptophenylboronic acid and mercaptoethylamine on the nano gold surfaces on the substrate, and enriching glycoprotein on the basis of phenylboronic acid affinity chromatography. The hydrophilicity of the monomer polyethylene glycol diacrylate (PEGDA) is utilized so as to reduce the non-specific adsorption of substrate on proteins, and thus the enrichment selectivity is improved. At the same time, the high specific surface area of nano particles is utilized at the same time, thus the enrichment capacity is increased, and finally the high-efficient and high-selective enrichment of glycoprotein is achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

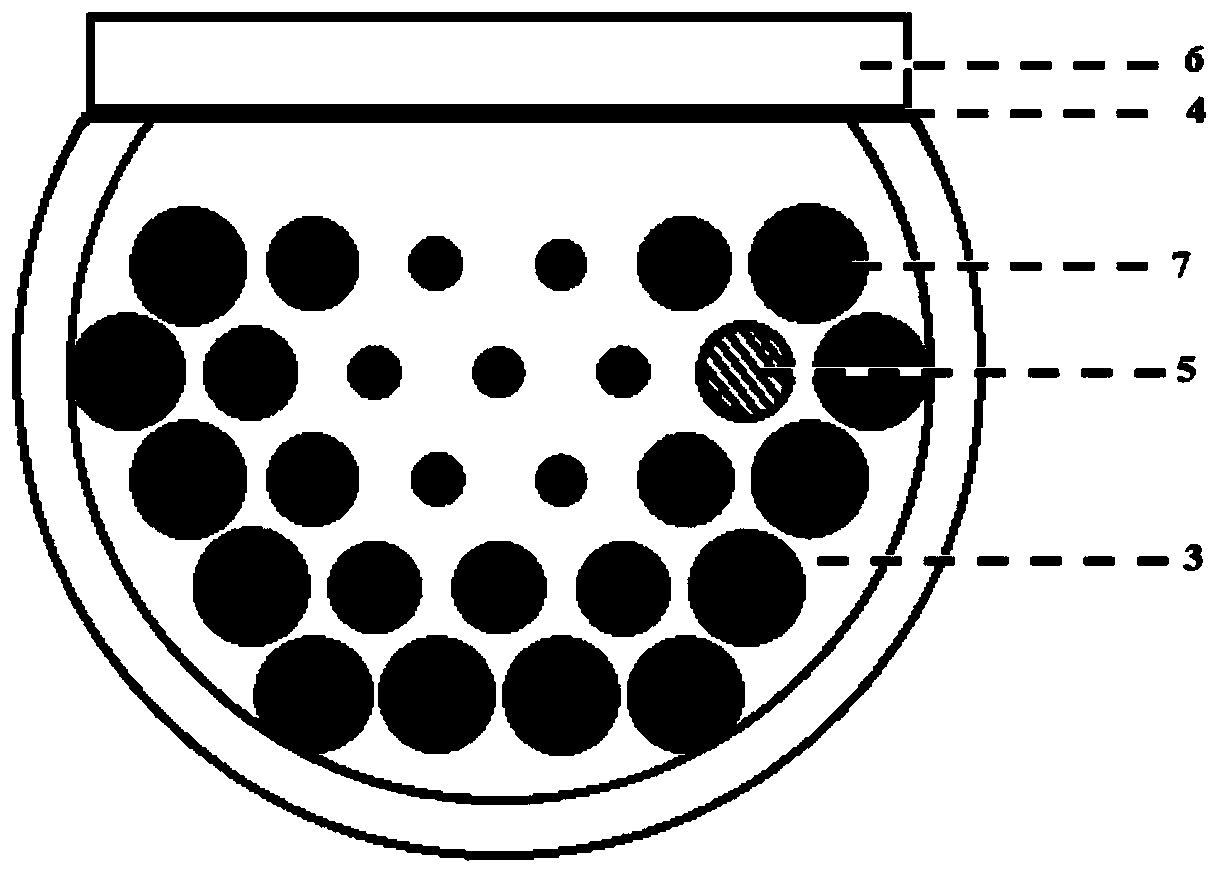

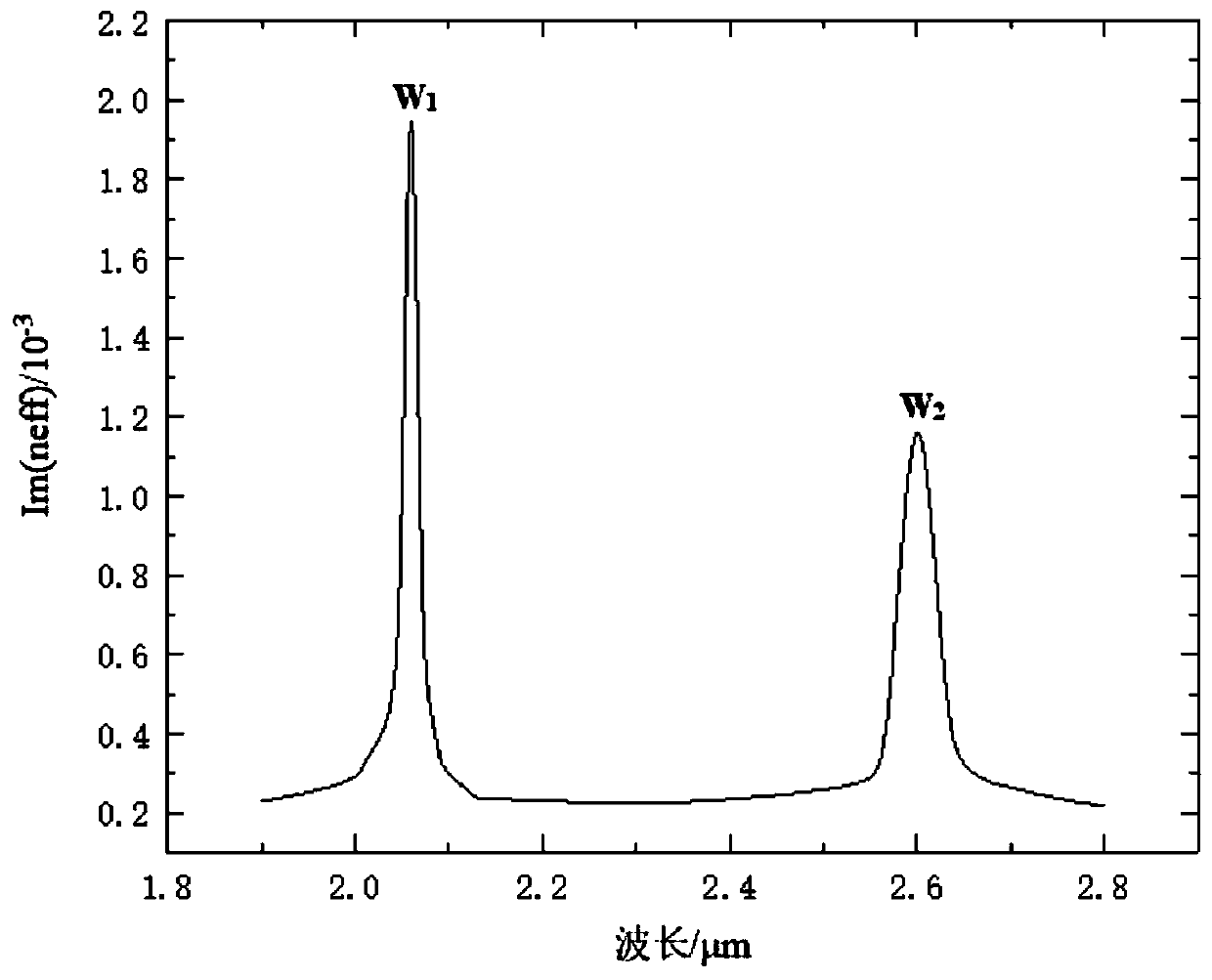

Biological two-parameter sensor based on photonic crystal fiber

InactiveCN110441257ARealize high-sensitivity dual-parameter sensingReduce volumePhase-affecting property measurementsThermometers using physical/chemical changesRefractive indexSurface plasmonic resonance

The invention discloses a biological two-parameter sensor based on a photonic crystal fiber. The biological two-parameter sensor comprises a D type photonic crystal fiber and single mode fibers, wherein the single mode fibers are in fusion welding at the two ends of the D type photonic crystal fiber. The D type photonic crystal fiber comprises a photonic crystal fiber; one side of the photonic crystal fiber is a polishing and grounding surface; a metal layer is plated on the polishing and grinding surface; a plurality of air holes are formed in the photonic crystal fiber; the air holes penetrate through two end surfaces of the photonic crystal fiber; and any one air hole is filled with a temperature-sensitive medium. The film plating gold surface plasma resonance effect is used as a refractive index sensing mechanism; the directional coupling effect and the temperature-sensitive effect of the D type photonic crystal fiber are used as temperature sensing mechanisms; two mutually separated resonance loss peaks are generated in a fiber output spectrum; and the high-sensitivity two-parameter sensing of the concentration and the temperature of biological liquid to be tested is realized.The sensor has higher sensitivity by optimizing the air hole layer number and hole diameter of the photonic crystal fiber and the film plating gold thickness.

Owner:NANJING UNIV OF POSTS & TELECOMM

Precious metal product with plating layer on surface and preparation method thereof

PendingCN108570641AImprove single colorWill not affect the finenessVacuum evaporation coatingSputtering coatingGas phaseShielding gas

The invention relates to the field of gold surface plating and discloses a precious metal product with a plating layer on the surface and a preparation method thereof. The precious metal product comprises a precious metal matrix and a physical vapor deposited layer attached to the surface of the precious metal matrix. The precious metal is gold or silver. The preparation method of the precious metal product comprises ultrasonically treating the precious metal matrix, and depositing a metal nitride, metal carbonitride, metal oxide, metal carbide, metal fluoride, metal sulfide, metal boride or DLC physical vapor deposition layer on the surface of the precious metal matrix by physical vapor deposition. Through synergistic adjustment of the deposited metal, protective gas and a gas flow rate,the precious metal product can exhibit a plurality of colors. The formed film is stable and is not easy to fall off. In detection, the film on the surface of the precious metal product does not influence the color of the precious metal matrix.

Owner:SHENZHEN UNITED BLUEOCEAN TECH DEV

Gold surfaces coated with a thermostable chemically resistant polypeptide layer and applications thereof

InactiveUS20060286142A1Robust and efficient immobilizationRaises number of potentialBioreactor/fermenter combinationsDental implantsBinding peptideBound property

The present invention provides a method for producing biomolecular coatings on devices having gold surfaces. The method describes the production of recombinant fusion proteins consisting of one or more polypeptide domains of interest and a high affinity gold binding peptide consisting of 1 to 7 repeats of a gold binding protein (GBP) sequence. By this method, many biologically active polypeptides lacking intrinsic gold-binding properties can be firmly attached to gold surfaces. By exploiting such gold binding properties, devices are disclosed which comprise such coatings that are useful as prosthetic devices, implants, and tissue interfacing materials. Further, such devices comprising these coatings protect surfaces from fouling and impart various properties to the coated devices.

Owner:BIOHESION

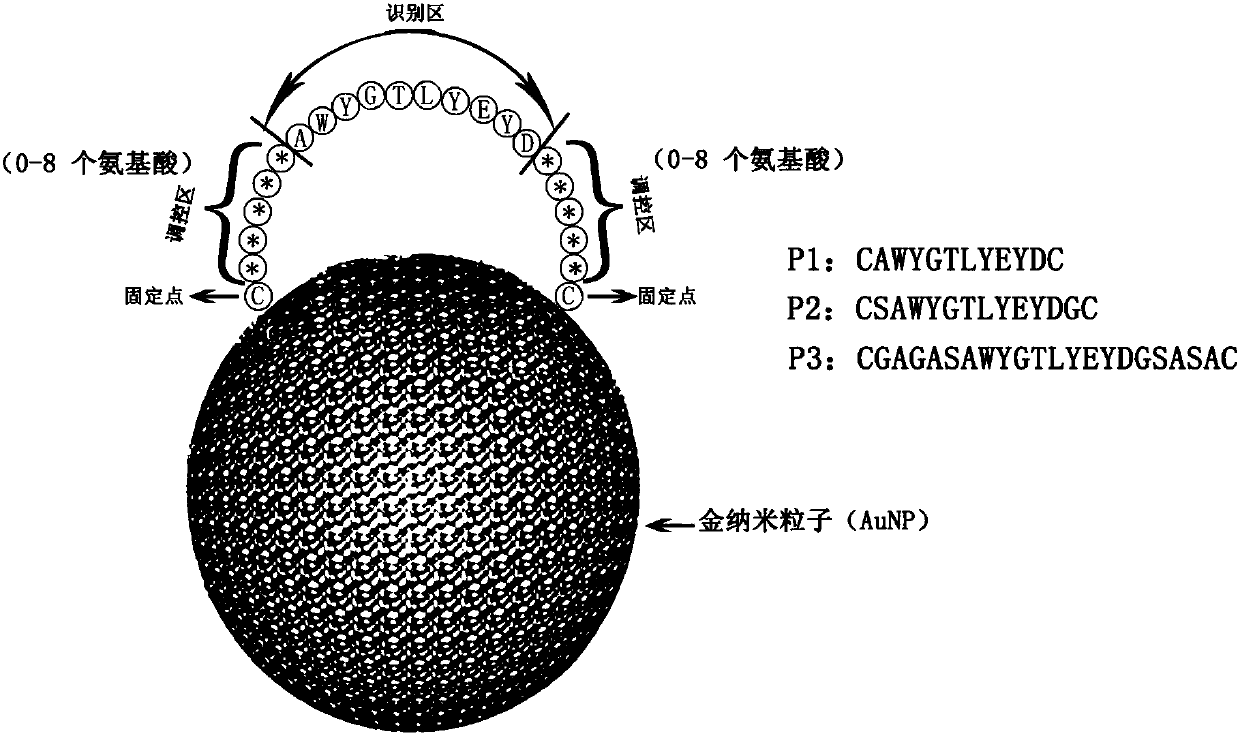

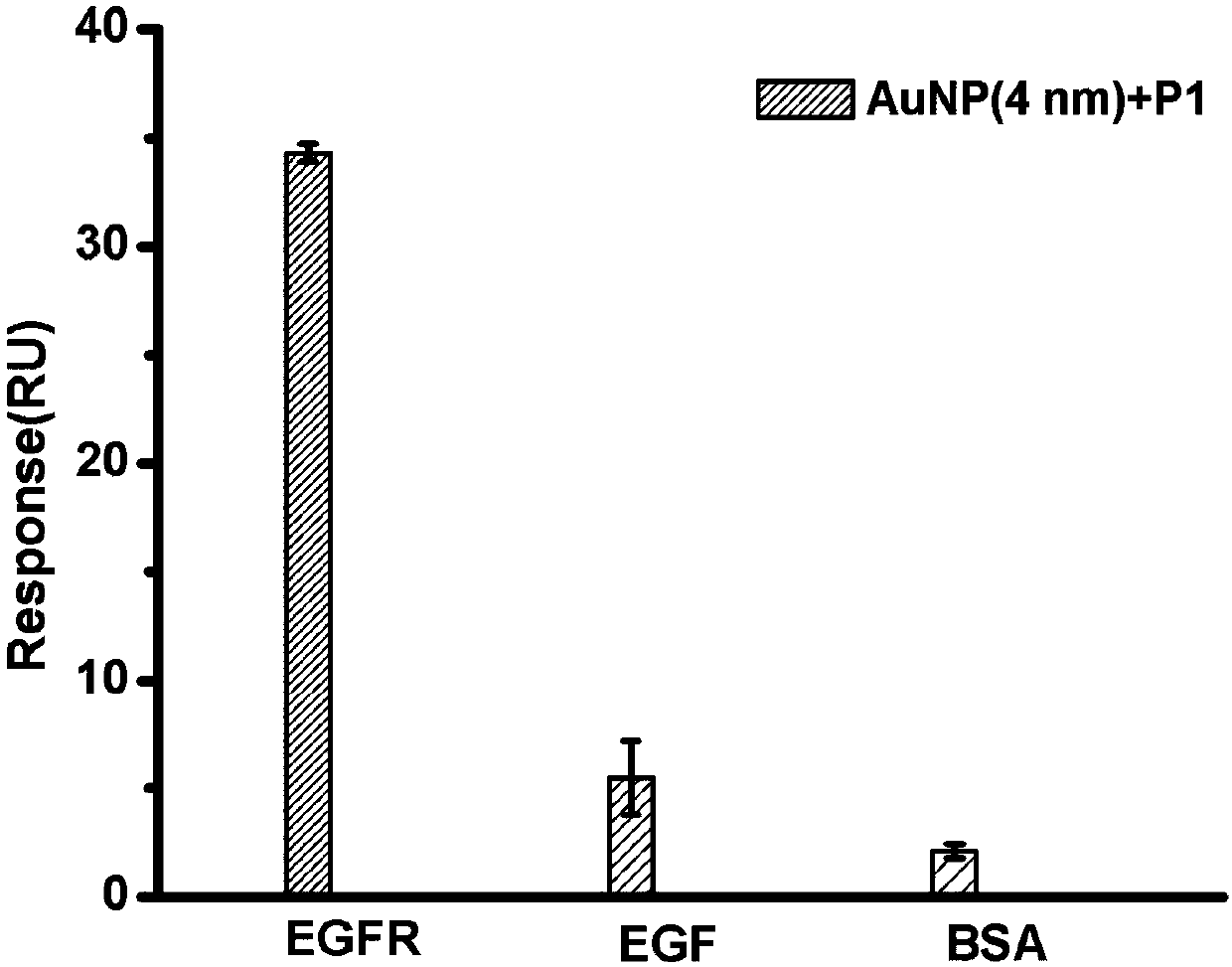

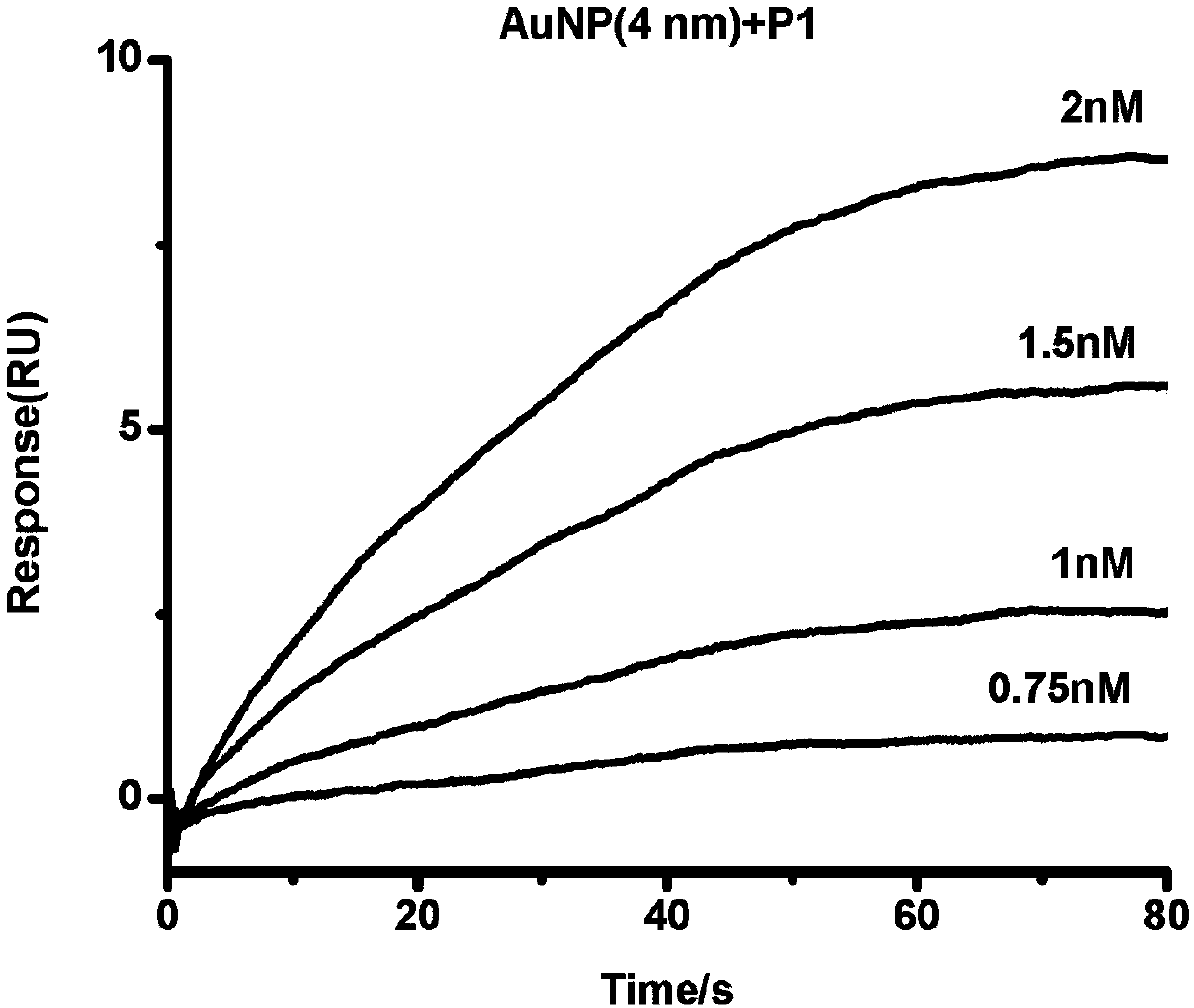

Artificial antibody for targeting EGFR (epidermal growth factor receptor) based on gold nanoparticles and preparation method thereof

ActiveCN106699890AImmunoglobulins against cell receptors/antigens/surface-determinantsNanoparticleHuman epidermal growth factor receptor

The invention relates to an artificial antibody for targeting an EGFR (epidermal growth factor receptor) based on gold nanoparticles and a preparation method thereof. The artificial antibody is characterized by consisting of the gold nanoparticles and a section of designed polypeptide sequence; the conformation of the polypeptide on the nanometer gold surface is reconstructed, so as to prepare the artificial antibody based on the gold nanoparticles. The artificial antibody has the advantages that the property of specifically identifying the EGFR is realized, the bonding ability is strong, and the stability is good; the artificial antibody is used for specially targeting the over-expressed EGFR on the tumor cell surface, and the artificial antibody with the special EGFR identifying function has broad application prospect in the fields of disease diagnosis, targeting therapy, photo-thermal therapy, and medicine carriers.

Owner:SHANGHAI UNIV

Lead wire etching technology with gold fingers with three surfaces wrapped by gold

InactiveCN105282983AReduce chafingImprove pass rateConductive material chemical/electrolytical removalCopperContamination

The invention belongs to the field of circuit board processing and specifically relates to a lead wire etching technology with gold fingers with three surfaces wrapped by gold. The technology comprises successive steps of inner layer, laminating, drilling, copper sinking, whole-plate electroplating, outer-layer pattern (1), pattern plating, etching (1), resistance welding, outer-layer pattern (2), nickel and gold plating, stripping, outer-layer pattern (3), etching (2), stripping, tape pasting, surface processing, and post-operations. The technology optimizes the process of gold fingers with three surfaces wrapped by gold, improves the quality, solves the problem of gold diffusion, reduces finger gold surface scratches, avoids the phenomena that a coating film cannot be attached to a plate surface completely and etching solution seeps into an etching line, reduces the risk of contamination, and has great market prospect and application value.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com