Method of micro cantilever beam sensor using functional carbon nano tubes as sensitive materials

A carbon nanotube and micro-cantilever technology, which is applied in the field of micro-nano sensors, can solve the problem that research on changes has not been reported, and achieves the effects of advanced methods, low cost and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

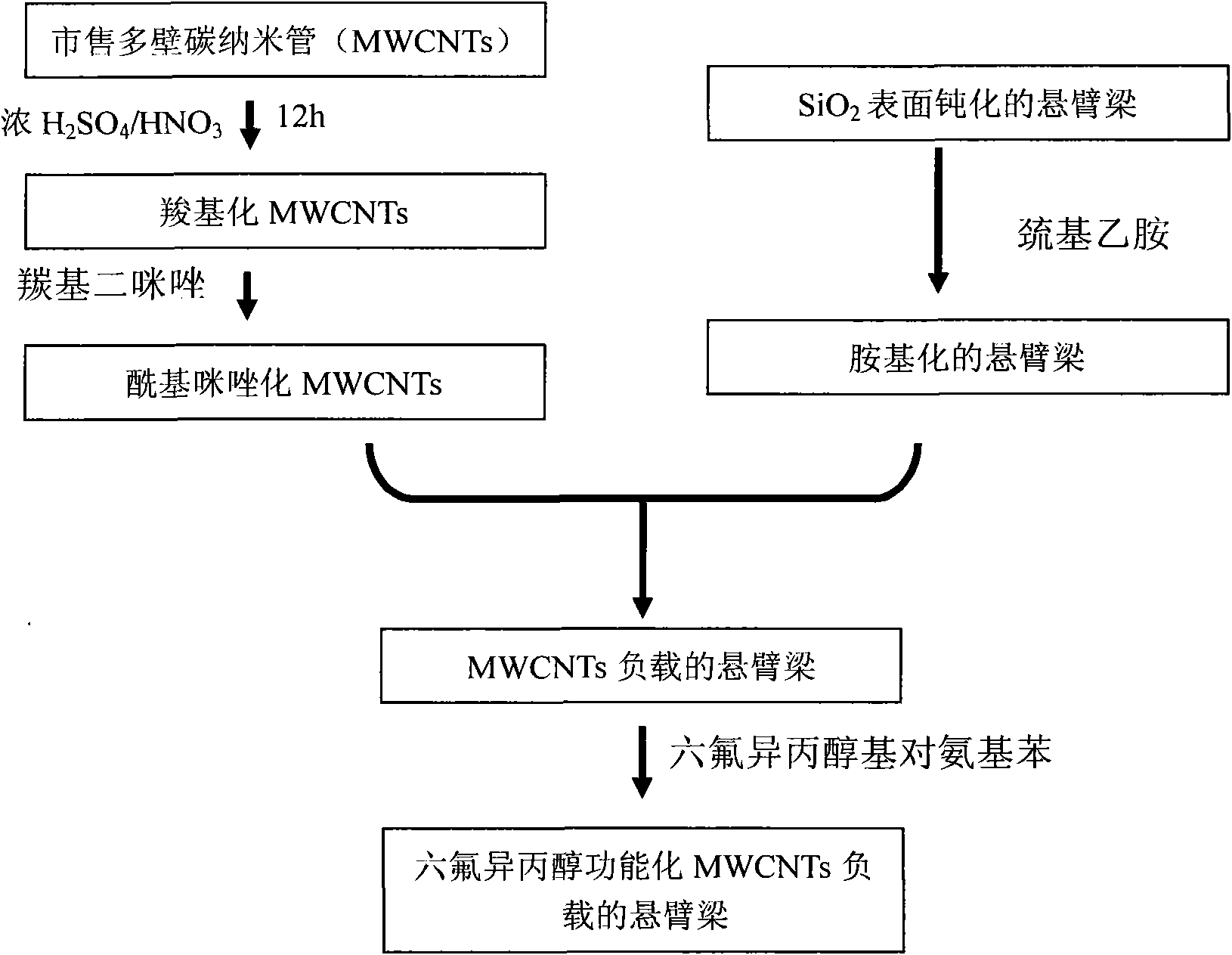

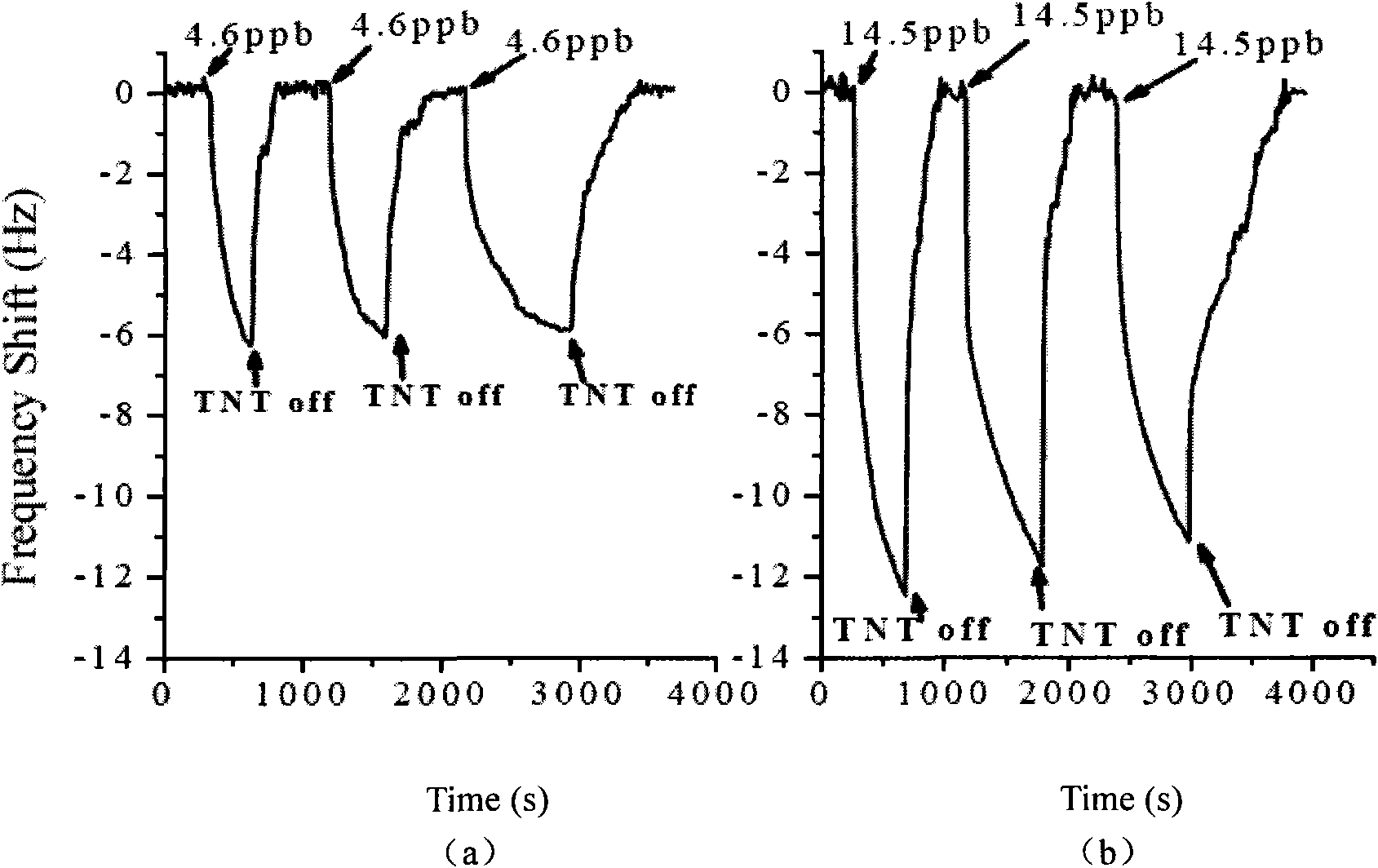

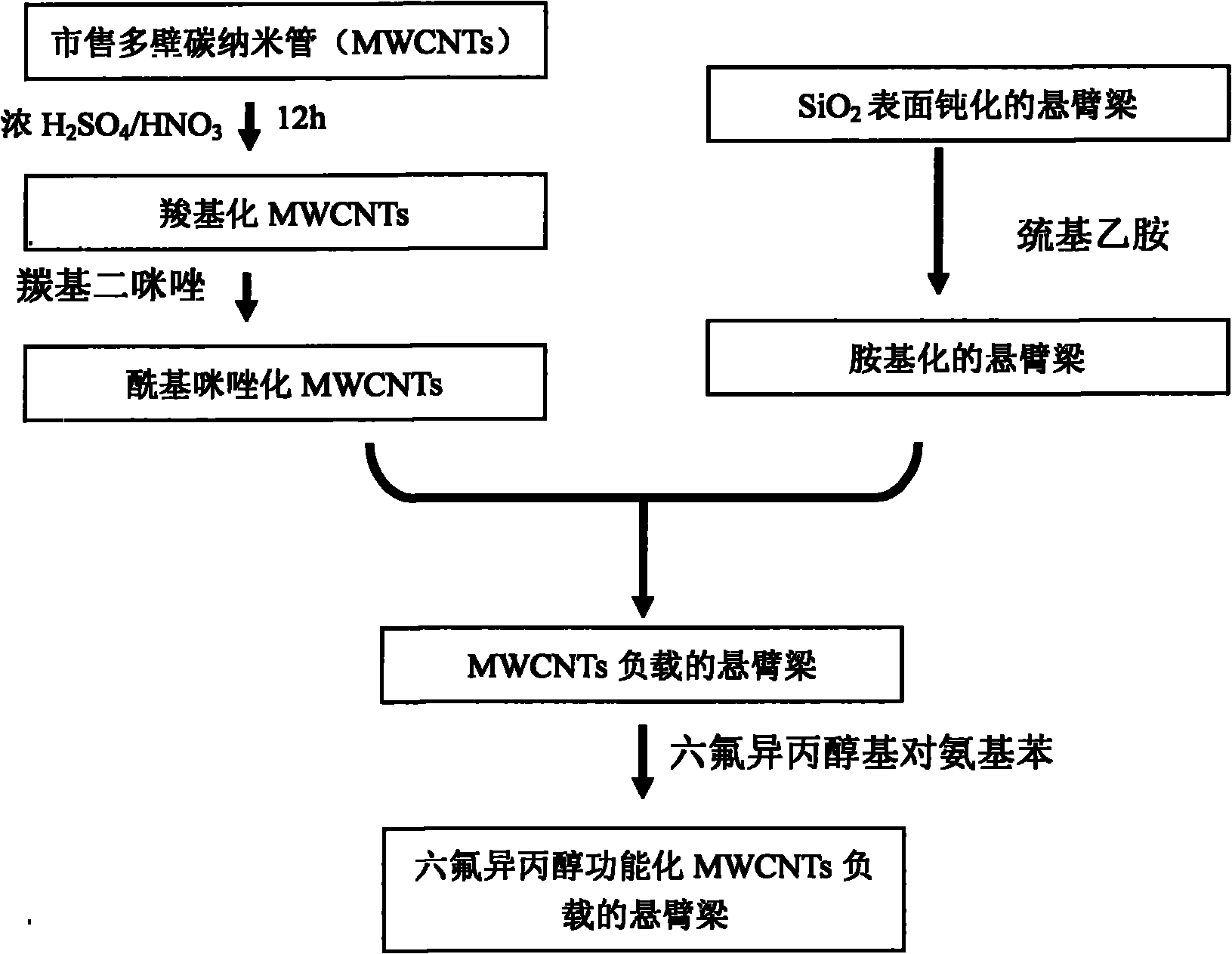

[0017] Embodiment 1: in combination with figure 1 with 2 The manufacturing method and detection characteristics of the MEMS sensor based on functionalized carbon nanotubes that can be used for ppb (that is, the volume ratio is one billionth) level TNT vapor detection are described in detail.

[0018] Weigh 100mg of commercial multi-walled carbon nanotubes (abbreviated as MWCNTs, purchased from Shenzhen Nanometer Port), put it into a 125ml glass bottle, add 60ml of concentrated sulfuric acid (98% by mass) and 20ml of concentrated nitric acid (98% by mass) 70%), sonicated for 12 hours to generate carboxyl sites available for modification on the surface of MWCNTs. Dilute the above-mentioned mixed acid solution containing MWCNTs to 1000ml with deionized water, then settle for 12 hours, and remove the supernatant. The deposited MWCNTs were collected, diluted with deionized water, and the diluted solution was filtered with a polytetrafluoroethylene membrane with a pore size of 1 m...

Embodiment 2

[0022] Embodiment 2: NH that can be used for ppm level based on functionalized carbon nanotubes 3 Detection of MEMS sensors

[0023] The pretreatment of MWCNTs and its fixation on the gold surface of MEMS devices are the same as in Example 1. During detection, a certain amount of p-Aminobenzoic acid (PABA) was firstly weighed and dissolved in deionized water to prepare a solution with a concentration of 1 mg / ml. The gold surface modified with MWCNTs is immersed in the solution, and the acyl imidazoles on the side walls of MWCNTs can react with the amino groups of PABA. Finally, the MEMS device is rinsed with deionized water and dried with nitrogen, which can be used for the NH3 test on the order of ppm (that is, the volume ratio is one millionth). Its detection result is similar to embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com