Manufacture method of high resolution self-supporting totally hollowed-out transmission grating

A high-resolution, transmission grating technology, applied in the field of X-ray diffraction optical elements, can solve the problems of low efficiency and inability to produce high aspect ratio graphics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

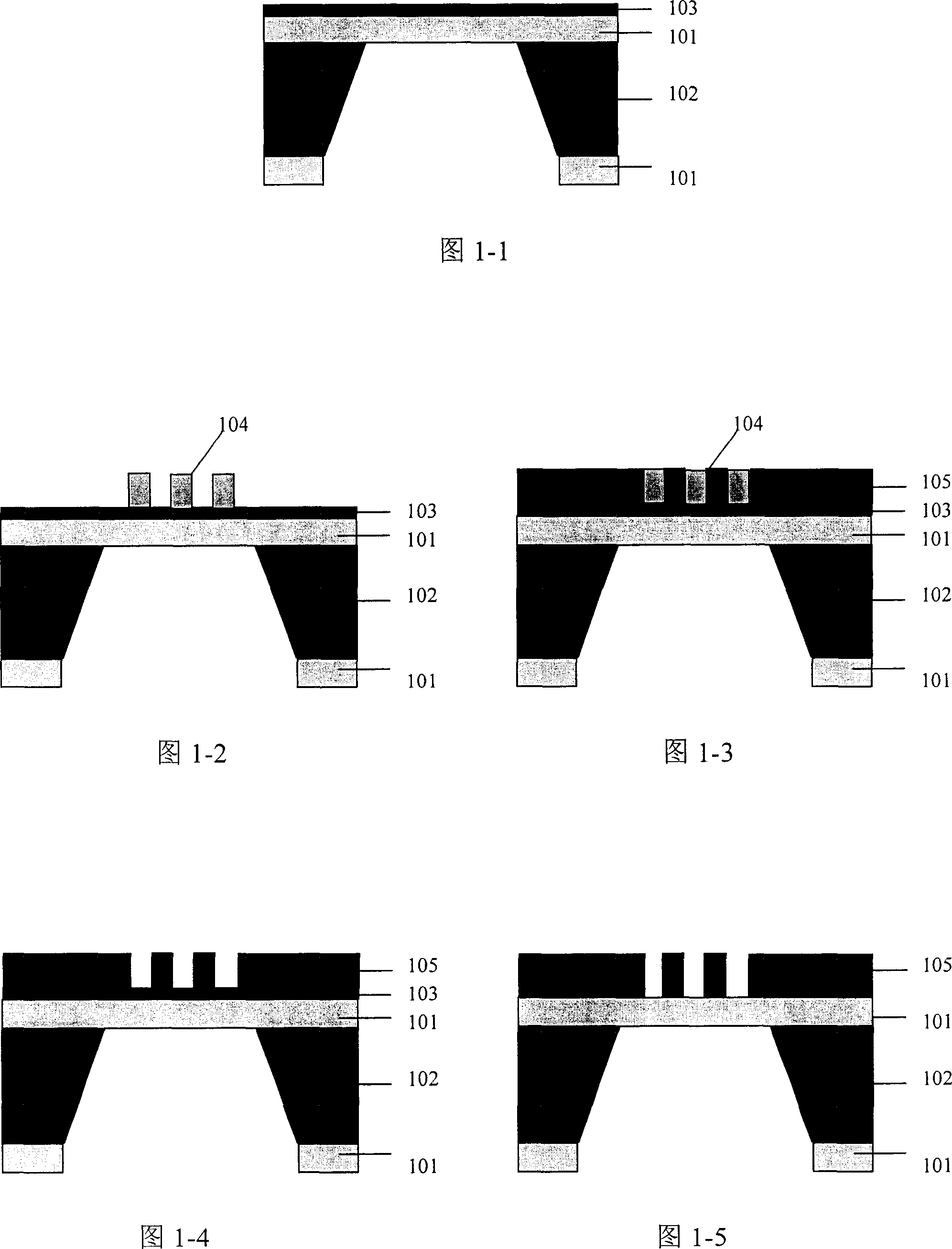

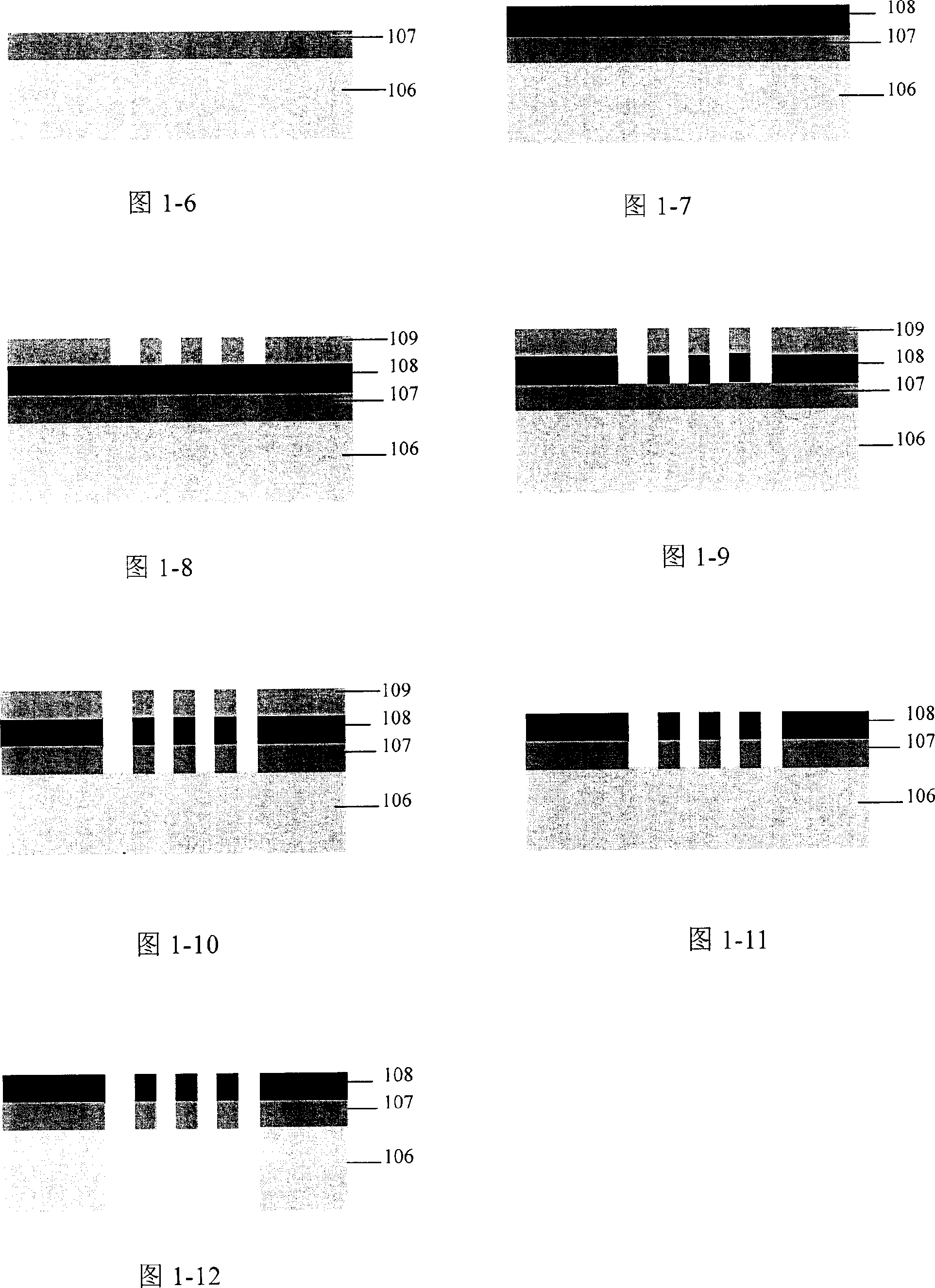

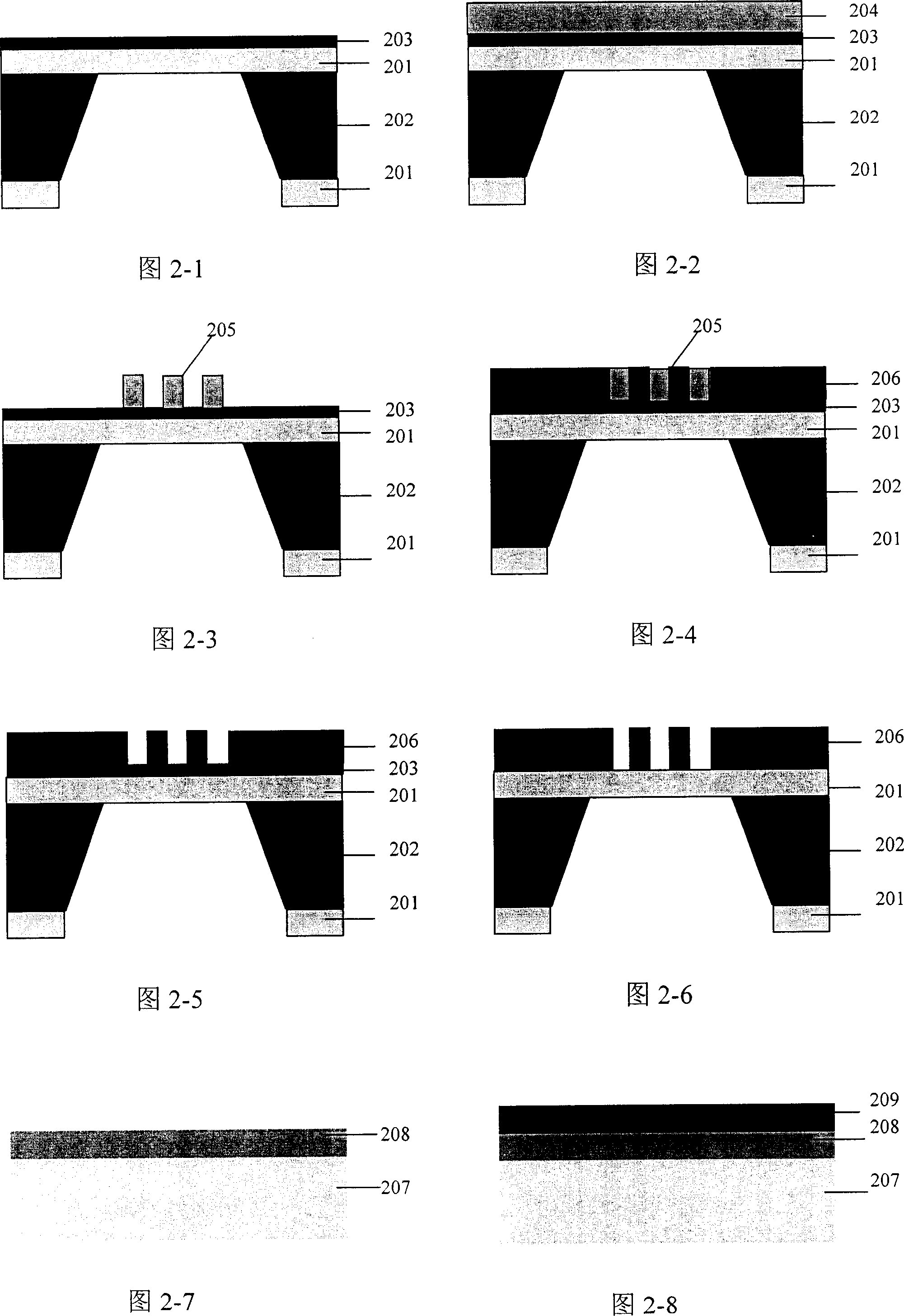

[0034] Black used in the drawings indicates opaque portions, and gray indicates translucent portions. It conforms to the usual representation method in the field of microelectronics technology.

[0035] 1. As shown in Figure 1-1, a thin chromium and thin gold layer 103 is deposited on the self-supporting X-ray mask substrates 101 and 102 as an electroplating substrate; the thickness of the thin chromium and thin gold film 103 is 10 to 30 nm, which is Obtained by electron beam evaporation;

[0036] 2. As shown in Figure 1-2, apply an electron beam photoresist on the surface of the thin chromium and thin gold layer 103, and perform electron beam lithography to obtain a high-resolution grating pattern 104;

[0037] 3. As shown in Figure 1-3, using the grating pattern 104 as the electroplating mold, place the sheet in the gold electroplating solution to electroplate the X-ray mask absorber gold pattern 105;

[0038] 4. As shown in FIG. 1-4, the electron beam photoresist grating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com