Selective nickel and gold plating method, PCB and device

A PCB board and electro-nickel-gold technology, which is applied in the field of selective electro-nickel-gold, can solve the problems such as the difficulty of electroplating nickel-gold on PCB boards, and achieve the effect of improving the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

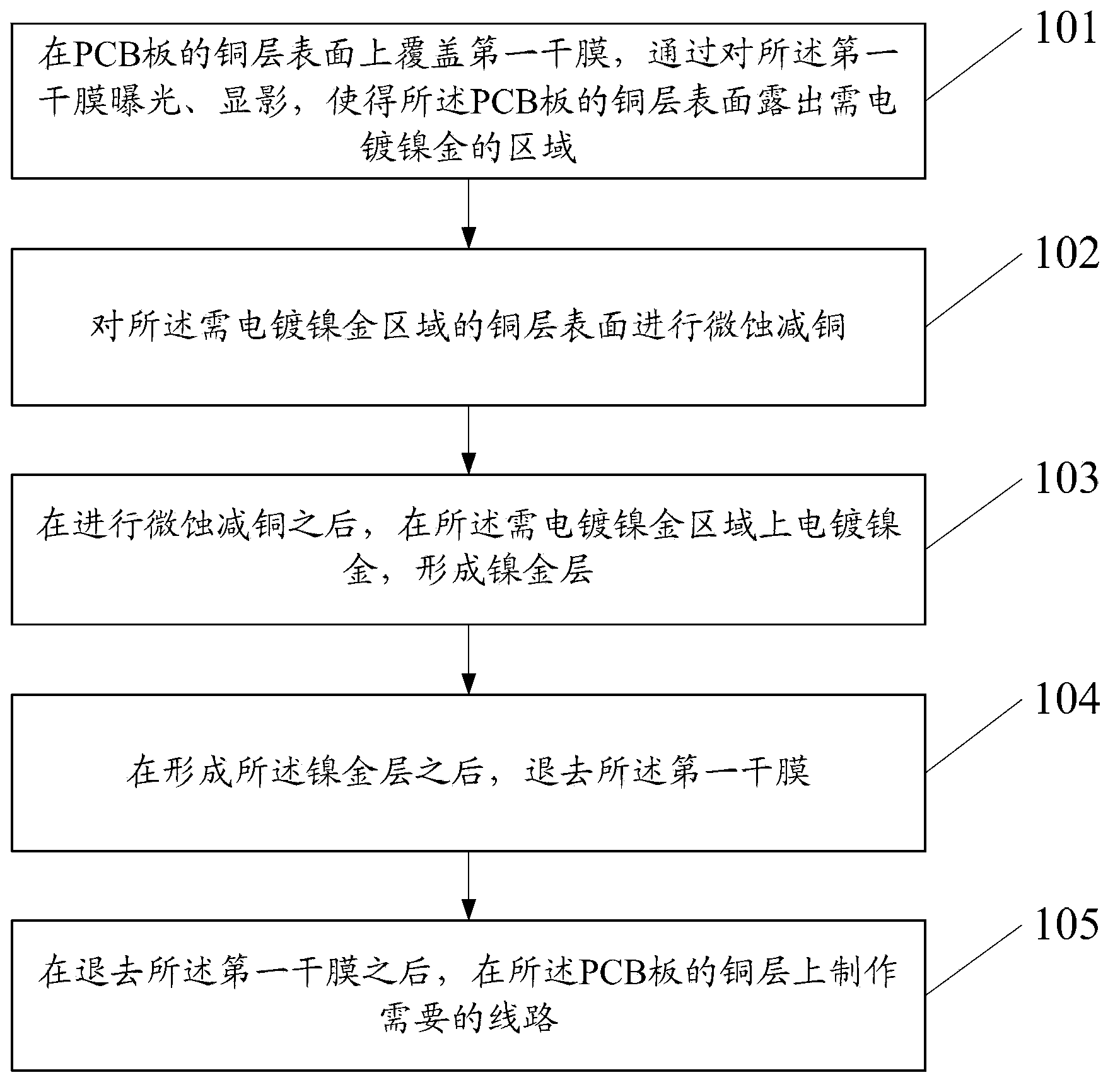

[0035] Such as figure 1 As shown, embodiment 1 of the present invention provides a kind of method of selective electric nickel gold, comprising:

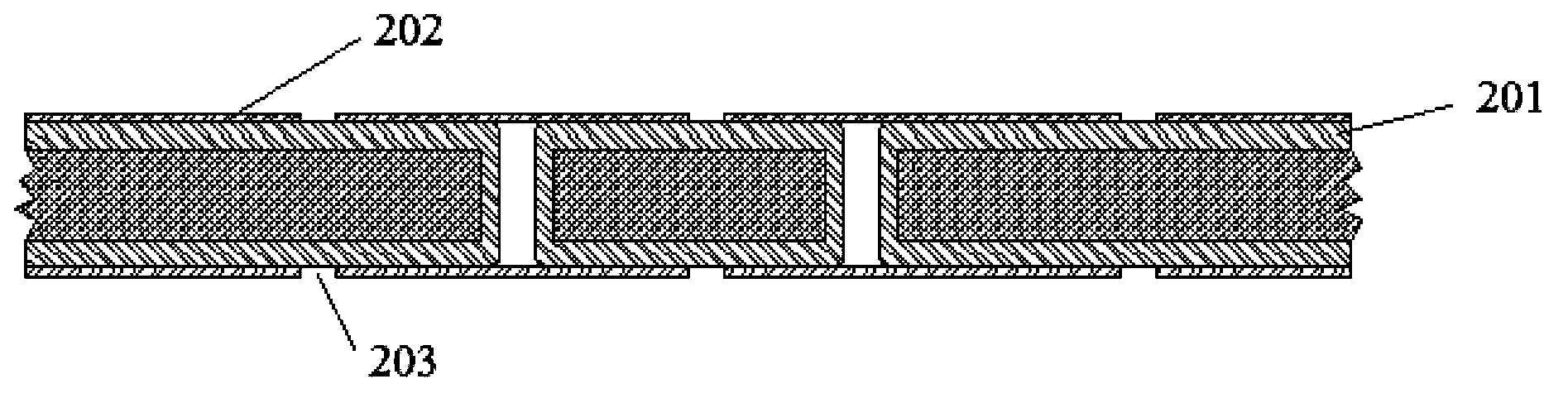

[0036] 101. If Figure 2a As shown, the first dry film 202 is covered on the surface of the copper layer 201 of the PCB board, and by exposing and developing the first dry film 202, the surface of the copper layer 201 of the PCB board exposes the area 203 that needs to be electroplated with nickel and gold. .

[0037] The area to be electroplated with nickel and gold may be a pad area for making inserts or mounting components. Electroplating nickel gold on the surface of the pad can improve the wear resistance and corrosion resistance of the pad surface.

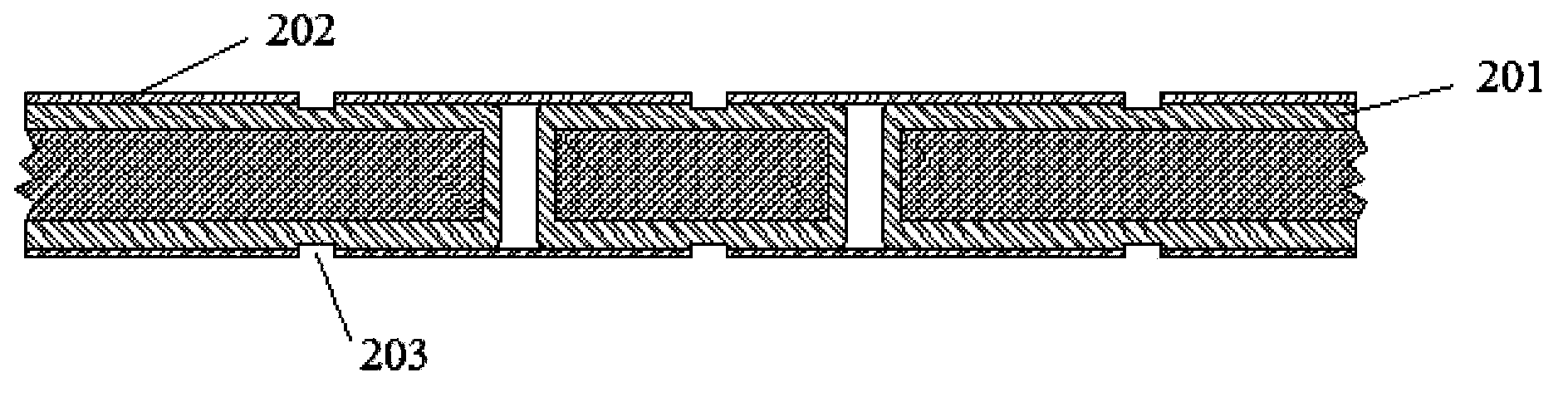

[0038] 102. Perform micro-etching to reduce copper on the surface of the copper layer in the region 203 to be electroplated with nickel and gold.

[0039] Such as Figure 2b As shown, the thickness of the surface of the copper layer in the region 203 to be electroplated with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com