Transverse electric field liquid crystal display device picture element, and its substrate and picture element process

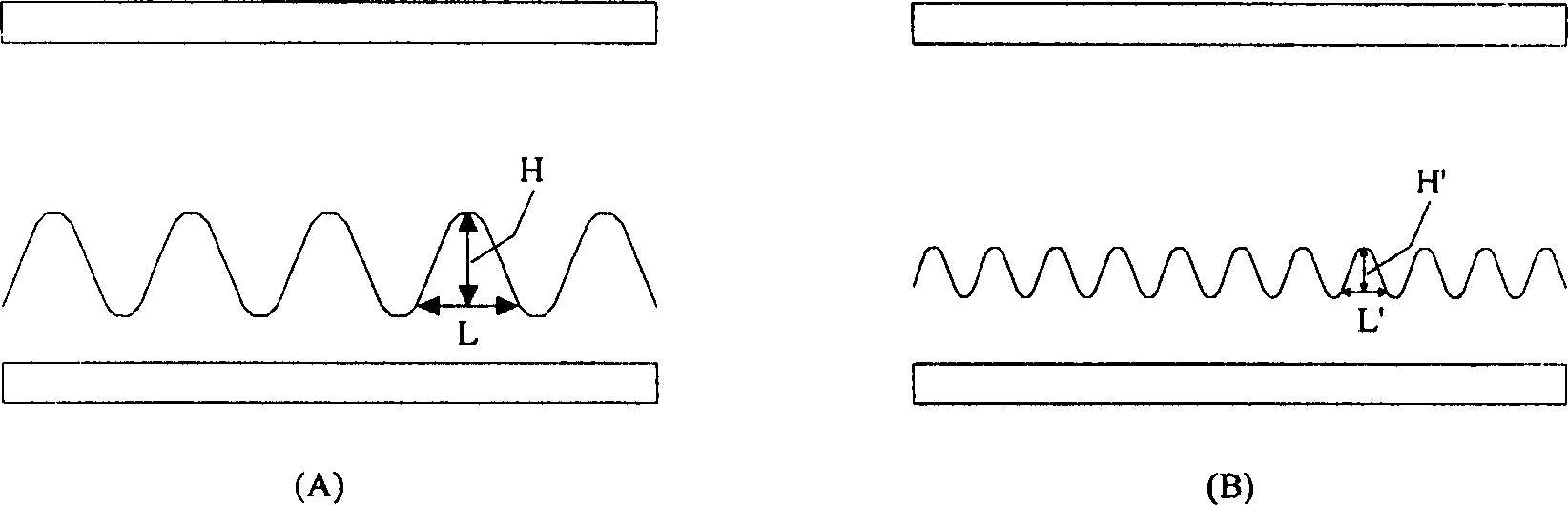

A technology of liquid crystal display and transverse electric field, which is applied in the direction of instruments, transistors, optics, etc. It can solve the problems of reducing contrast, large height difference on rough surface, narrow viewing angle, etc., and achieves reducing gap changes, good anti-glare effect, and large scatter The effect of the angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

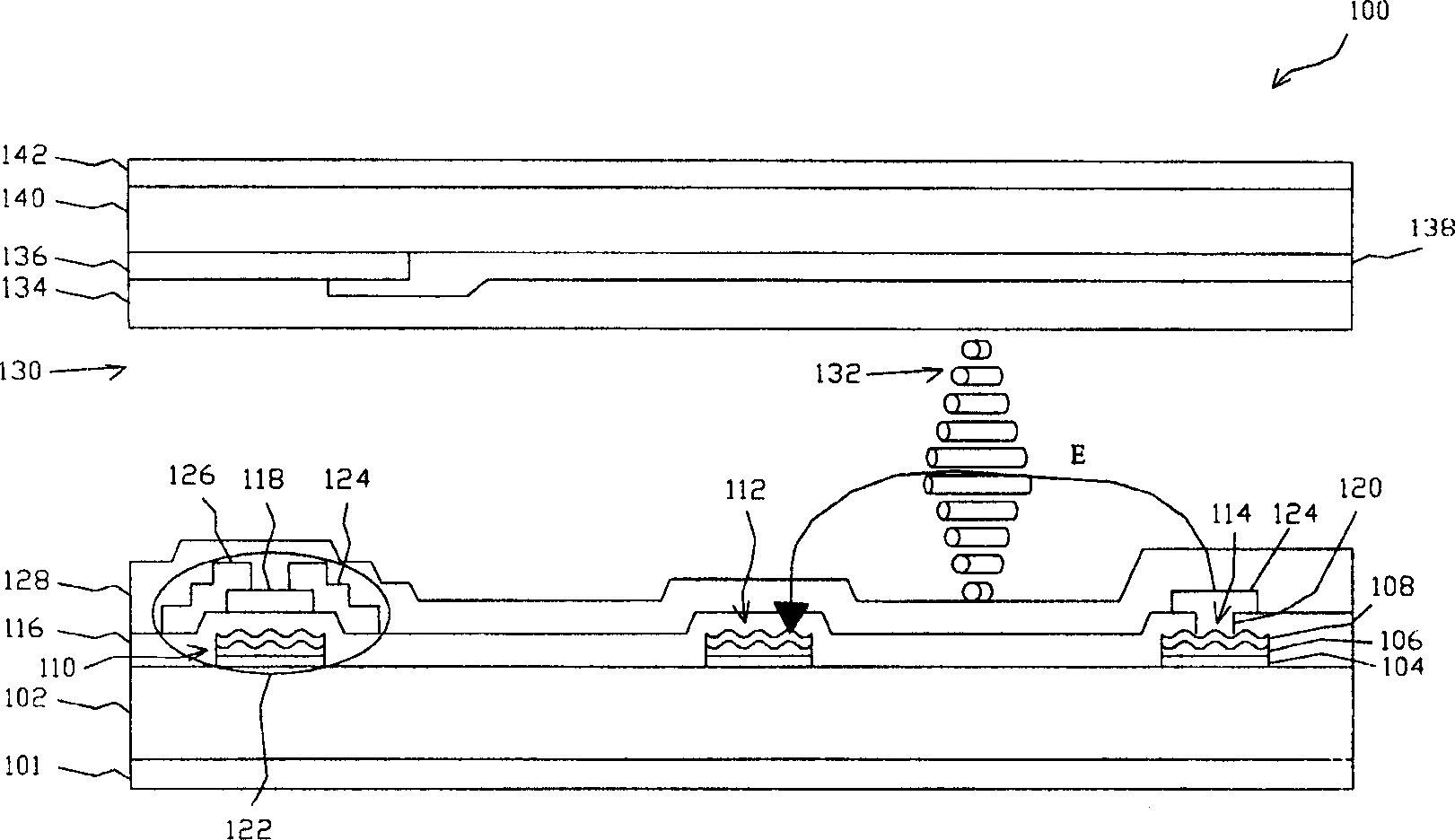

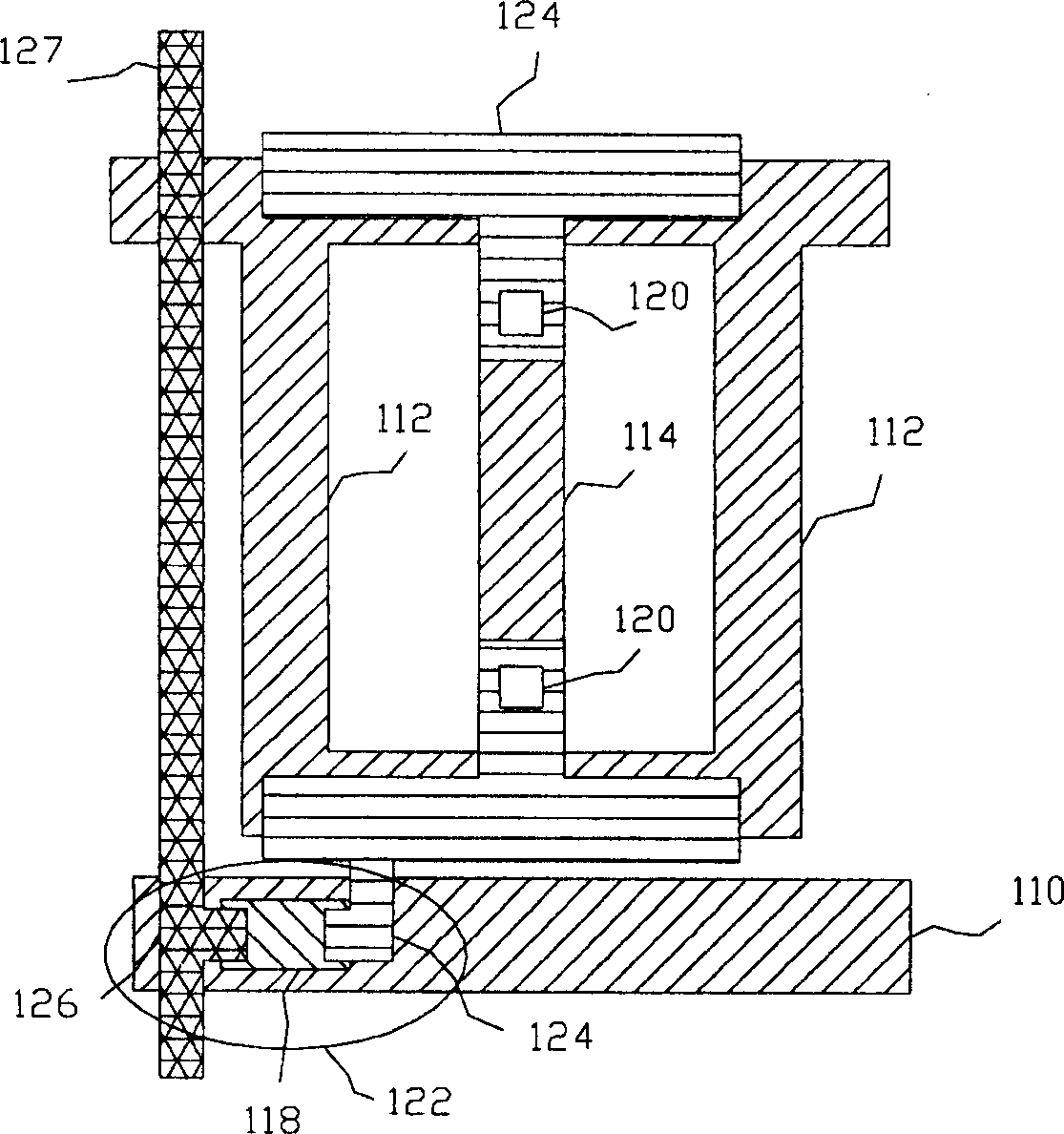

[0040] figure 1 It is an embodiment of the horizontal electric field liquid crystal display pixel structure 100 of the present invention, which is a transflective LCD, including a first structure with a nanoscale rough surface on the substrate 102, the first structure includes a first part and a second Two parts, wherein the first part is the gate electrode 110, and the second part is the reflectors 112 and 114, a protective layer 116 covers the first structure, and a second structure is the protective layer 116 above the gate electrode 110 Above, the second structure includes a drain electrode 124, a source electrode 126 and a channel region formed by an amorphous silicon semiconductor film 118 between the drain electrode 124 and the source electrode 126, the gate electrode 110 and the second structure form a switching element-thin film transistor 122, and the drain electrode 124 is connected to the reflector 114 through the through hole (contact hole) 120 on the protective l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com