Precious metal product with plating layer on surface and preparation method thereof

A technology of precious metals and products, which is applied in the field of precious metal products with coating on the surface and its preparation, and can solve the problems of weak bonding between the film layer and the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

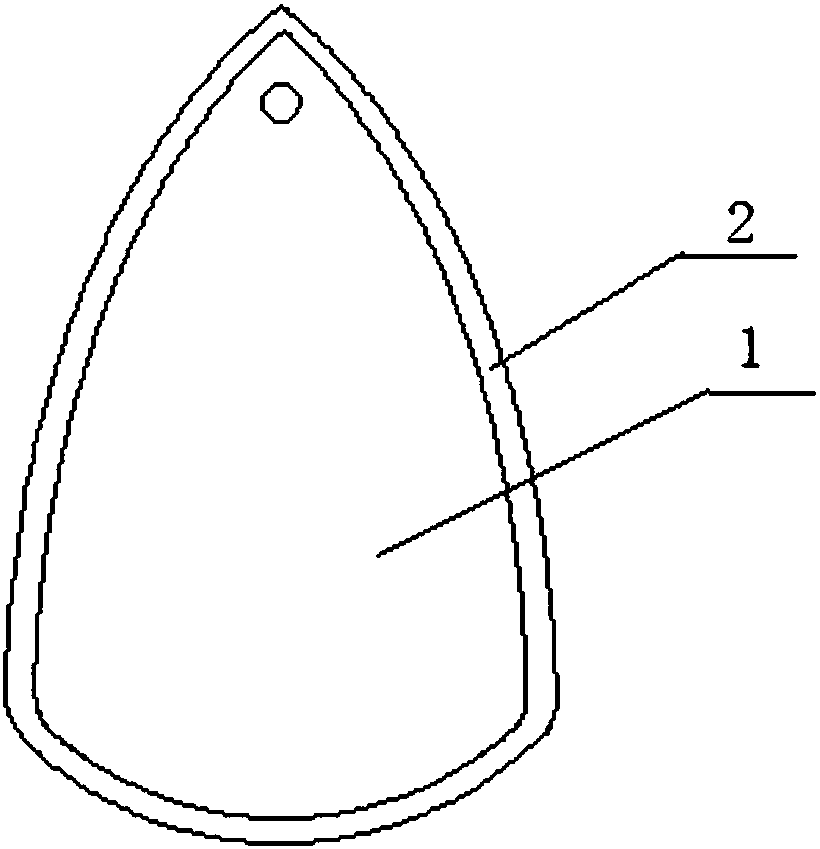

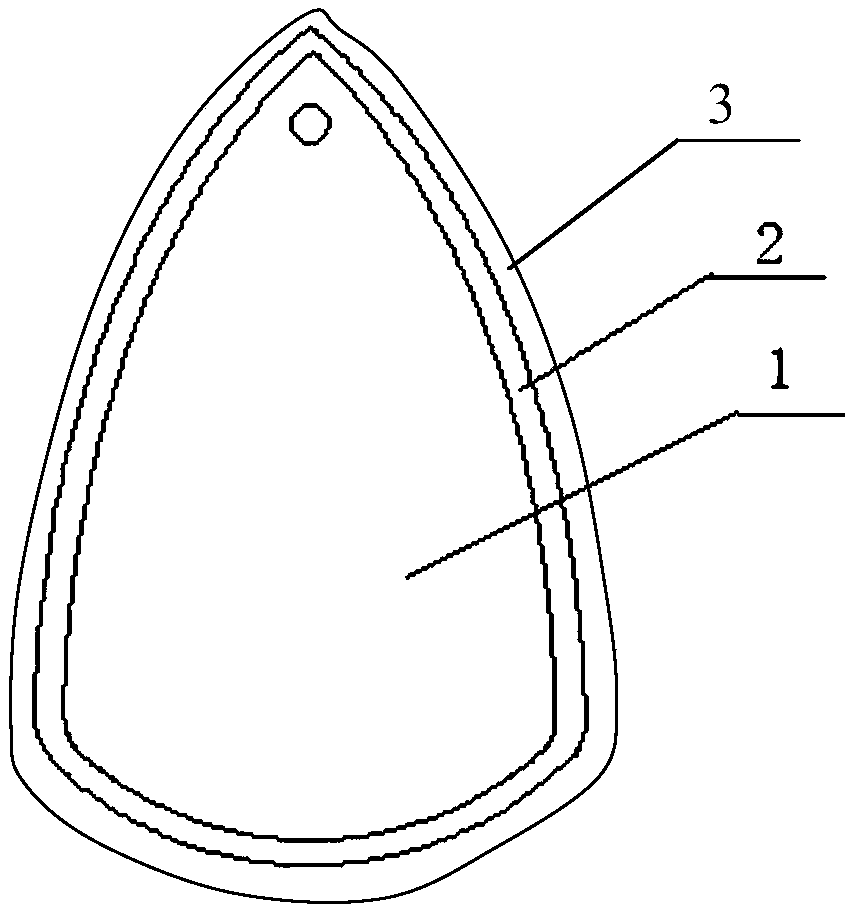

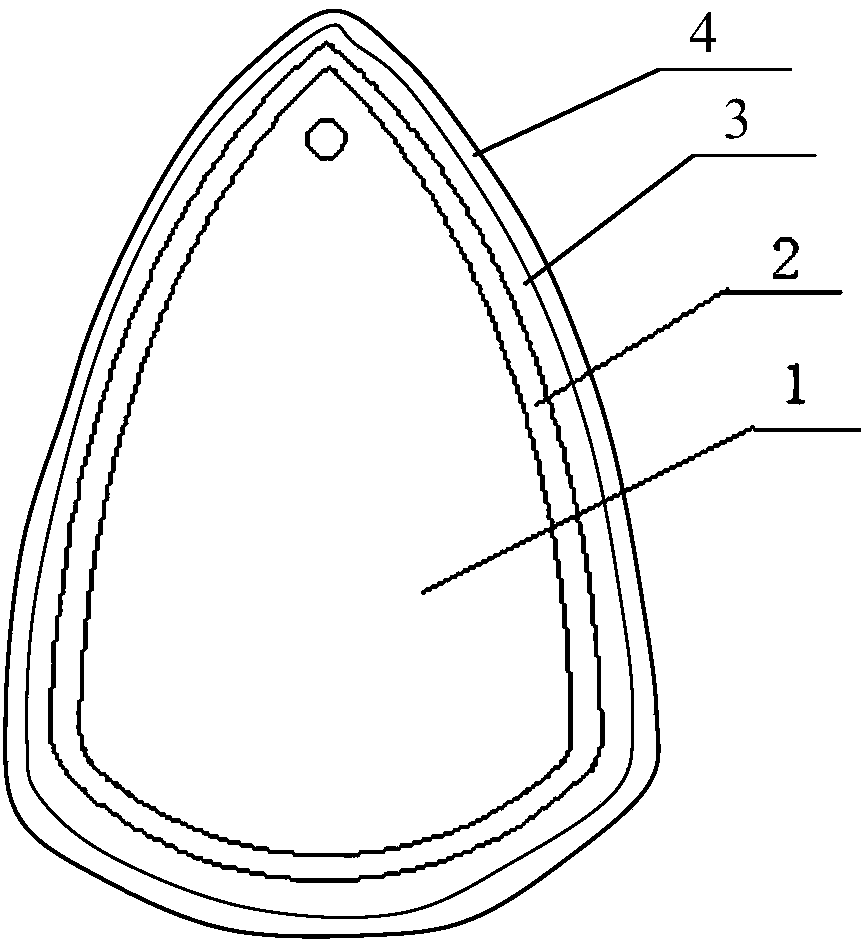

[0034] The second aspect of the present invention provides a method for preparing a noble metal product, the method comprising: attaching a physical vapor deposition layer 2 on the surface of a noble metal substrate 1 by means of physical vapor deposition.

[0035] According to the present invention, the condition of physical vapor deposition makes the thickness of physical vapor deposition layer 2 be 10nm-50μm (such as 10nm, 20nm, 30nm, 50nm, 80nm, 0.1μm, 0.15μm, 0.2μm, 0.25μm, 0.3μm, 0.5μm , 0.8 μm, 1 μm, 2 μm, 10 μm, 30 μm, 50 μm or any value between the aforementioned values), preferably 0.04 μm-2 μm.

[0036] The method of physical vapor deposition has no special requirements, and it can be vacuum evaporation coating, vacuum sputtering coating or vacuum ion coating, preferably vacuum ion coating.

[0037] If vacuum evaporation coating is adopted, the vacuum evaporation system is used, the precious metal substrate 1 and the metal to be plated are placed in the vacuum evapo...

Embodiment 1

[0072] The present embodiment is to adopt the method of the present invention to prepare the pure gold gold product of brown TiAlN film plating, its structure is as figure 1 shown.

[0073] (1) Pretreatment

[0074] Select precious metal substrate 1: choose pure gold as the precious metal substrate 1, and its surface roughness is 0.02 μm;

[0075] Cleaning: ultrasonically clean the pure gold with distilled water for 10 minutes at 20 kHz, and dry the pure gold after ultrasonic cleaning at 150°C for 30 minutes; then use a dust-free cloth dipped in 98% by weight alcohol to wipe and clean the surface;

[0076] Vacuum in the furnace: put the dried pure gold in the vacuum furnace, adjust the vacuum degree to 3×10 -3 Pa to ensure a clean vacuum environment in the furnace.

[0077] (2) Deposit Physical Vapor Deposition Layer 2

[0078] Glow cleaning: Glow cleaning is performed under the conditions of argon gas flow rate of 300 sccm, loading bias voltage of 400V, duty cycle of 50%, a...

Embodiment 2

[0081] The present embodiment is to adopt the method of the present invention to prepare the pure gold gold product of gray-black plated CrN film.

[0082] (1) Pretreatment

[0083] Select precious metal substrate 1: choose pure gold as the precious metal substrate 1, and its surface roughness is 0.05 μm;

[0084] Cleaning: Ultrasonic cleaning of pure gold with distilled water for 5 minutes under the condition of 30kHz, and drying the cleaned pure gold at 150°C for 30 minutes; then wipe the surface with 98% alcohol by weight;

[0085] Vacuum in the furnace: put the dried pure gold in the vacuum furnace, adjust the vacuum degree to 3×10 -3 Pa, adjust the temperature in the furnace to 200°C.

[0086] (2) Deposit Physical Vapor Deposition Layer 2

[0087] Glow cleaning: Glow cleaning is performed under the conditions of argon gas flow rate of 300 sccm, loading bias voltage of 400V, duty cycle of 50%, and time of 400s.

[0088] Start the high-purity intermediate frequency chro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com