Shell surface treatment process and device thereof

A surface treatment device and surface treatment technology, applied in the direction of surface reaction electrolytic coating, manufacturing tools, metal processing equipment, etc., can solve the problem of single color and other problems, and achieve the effect of improving single color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

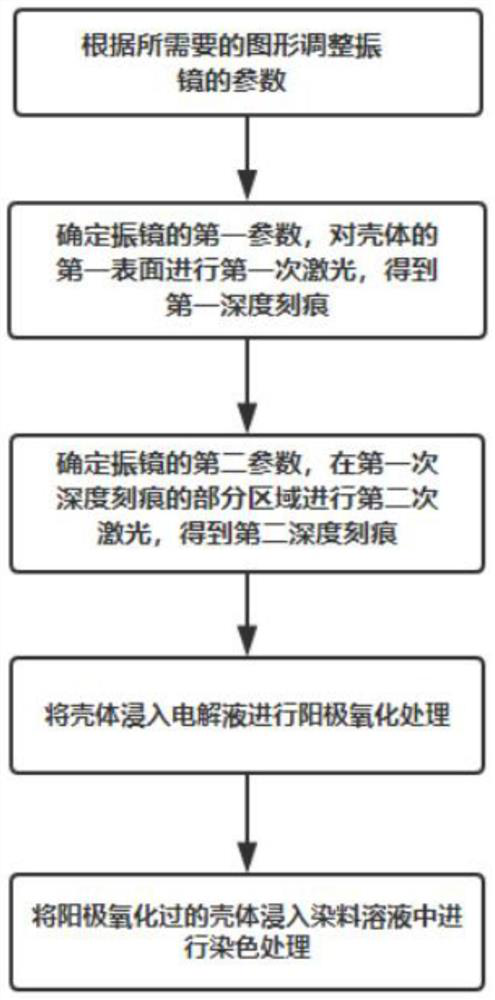

[0050] Such as figure 1 As shown, the present invention provides a shell surface treatment process, comprising the steps of:

[0051] (1) Adjust the engraving parameters of the vibrating mirror according to the required graphics;

[0052] (2) Determine the first engraving parameters of the vibrating mirror, and perform the first laser on the first surface of the housing along the first engraving track to obtain the first depth notch;

[0053] (3) Determine the second engraving parameters of the vibrating mirror, and perform a second laser along the first engraving track in the partial area of the first depth notch to obtain the second depth notch;

[0054] (4) Immerse the shell in the electrolyte for anodic oxidation treatment;

[0055] (5) Dip the anodized casing into a dye solution for dyeing treatment;

[0056] (6) Carry out sealing treatment on the shell after dyeing treatment.

[0057] Wherein, the engraving parameter provided by the present invention refers to powe...

Embodiment 2

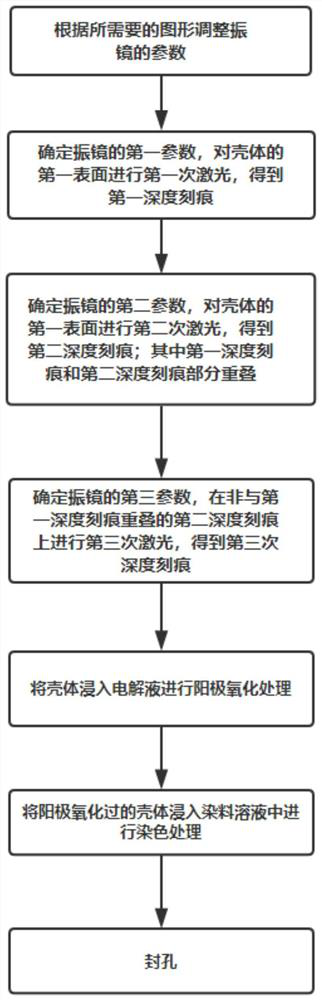

[0067] The invention provides a shell surface treatment process, comprising the following steps:

[0068] (1) Adjust the parameters of the galvanometer according to the required graphics;

[0069] (2) Determine the first engraving parameters of the vibrating mirror, and perform the first laser on the first surface of the housing along the first engraving track to obtain the first depth notch;

[0070] (3) Determine the second engraving parameters of the galvanometer, and perform a second laser on the first surface of the housing along the second engraving track to obtain a second depth notch; wherein the first depth notch and the second depth notch partial overlap;

[0071] (4) Determine the third engraving parameters of the galvanometer, and perform a third laser on the area of the second depth notch that does not overlap with the first depth notch along the third engraving track to obtain the third depth notch;

[0072] (5) Immerse the shell in the electrolyte for anodic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com