Novel chemical nickel gold production process and chemical nickel plating liquid

An electroless nickel plating solution and electroless nickel-gold technology, applied in liquid electroless plating, metal material coating process, coating, etc., can solve the problems of high equipment cost, high temperature of electroless nickel cylinder, scratched board surface, etc. Achieve the effect of reducing manufacturing cost and production cost, shortening treatment process and reducing sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

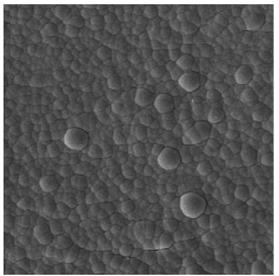

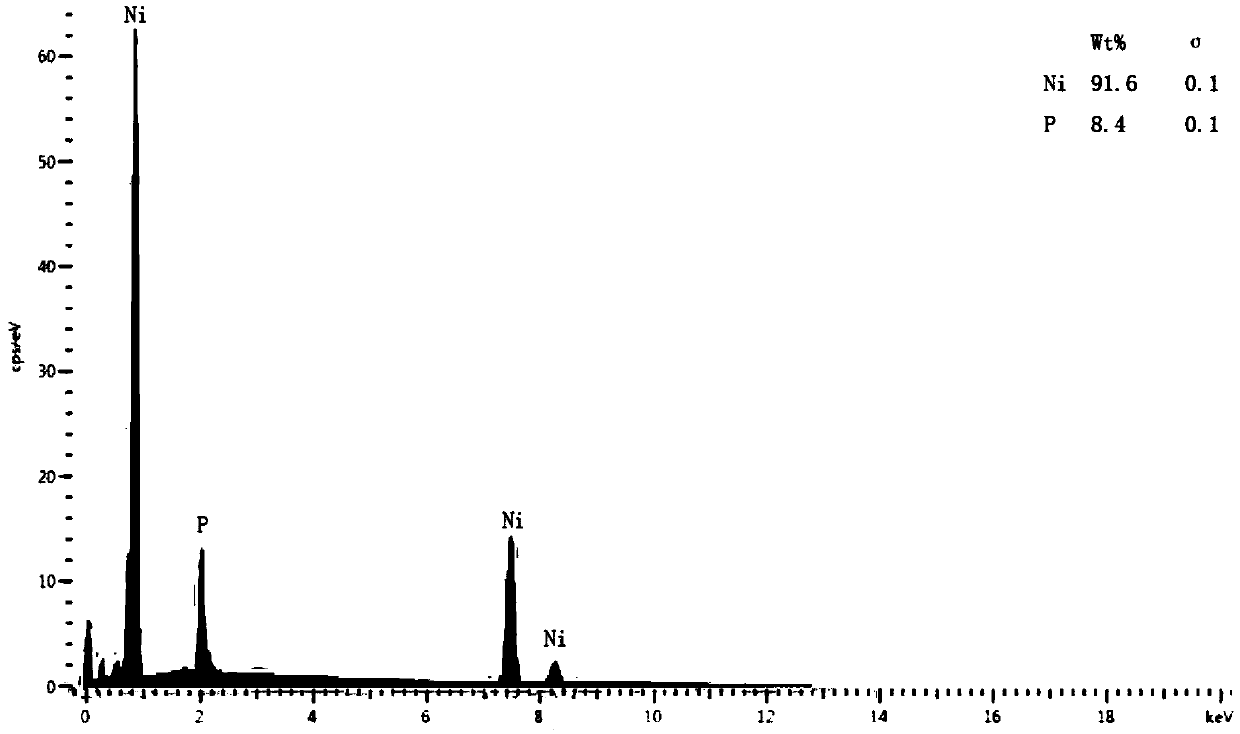

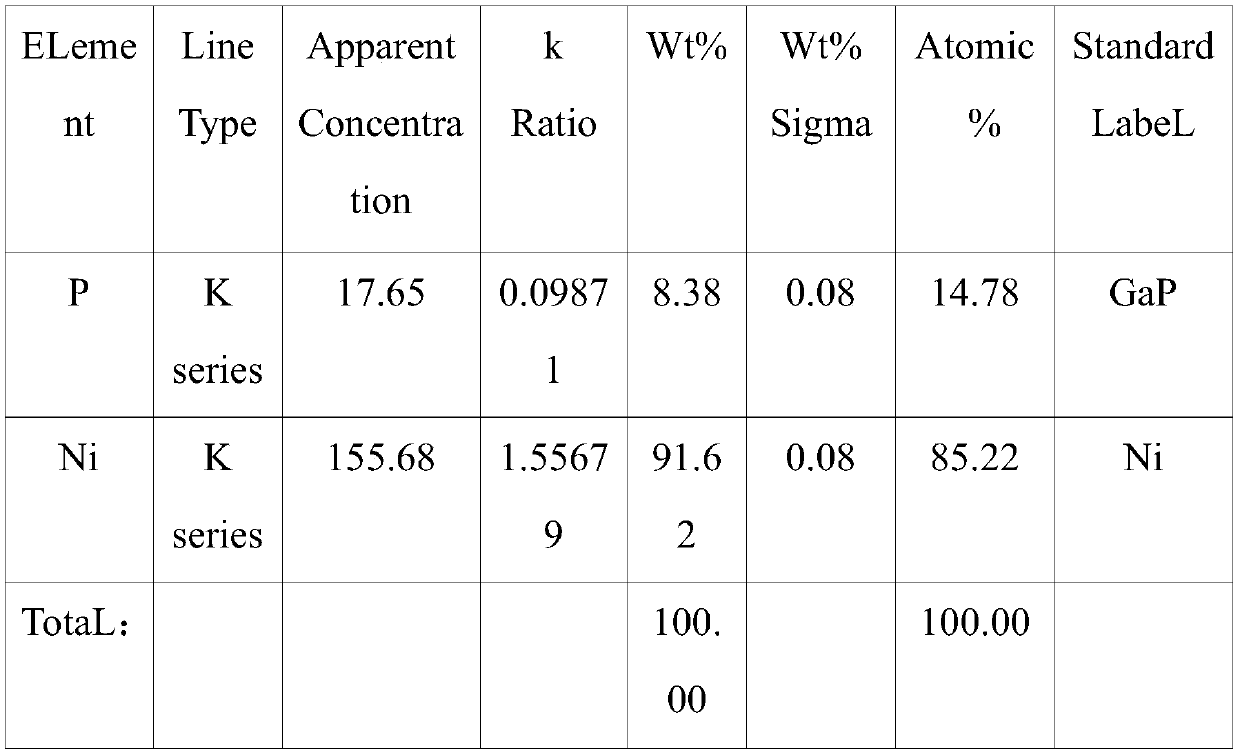

[0055] In this embodiment, chemical nickel-gold is carried out on the copper surface, and the experiment is carried out according to the steps described. Wherein, the alkaline electroless nickel plating solution in step 6 comprises: nickel sulfate 10g / L, sodium hypophosphite 22g / L, lactic acid 10g / L, ammoniacal liquor 40g / L, succinic acid 10g / L, glycine 10g / L, Ammonium chloride 15g / L, citric acid 10g / L. Wherein, the nickel activator composition in step 7 includes: citric acid 10g / L.

[0056] The acidic electroless nickel plating solution in the step 8 comprises: nickel sulfate 10g / L, sodium hypophosphite 30g / L, lactic acid 10g / L, ammoniacal liquor 10g / L, sodium ethylenediamine tetramethylene phosphonate (EDTMPS) 20g / L , Hydroxyethylidene diphosphonic acid (HEDP) 10g / L, ammonium chloride 15g / L, glycine 10g / L, praseodymium sulfate 70ppm, yttrium sulfate 10ppm.

[0057] The composition of the chemical gold immersion solution in step 9 includes: potassium aurous cyanide 1g / L, ED...

Embodiment 2

[0061] In this embodiment, chemical nickel-gold is carried out on the copper surface, and the experiment is carried out according to the steps described. Wherein, the alkaline electroless nickel plating solution in step 6 comprises: nickel sulfate 10g / L, sodium hypophosphite 22g / L, lactic acid 10g / L, ammoniacal liquor 40g / L, succinic acid 15g / L glycine 10g / L, chlorine Ammonium chloride 20g / L, citric acid 10g / L. Wherein, the nickel activator composition in step 7 includes: malic acid 10g / L.

[0062] The acidic electroless nickel plating solution in the step 8 comprises: nickel sulfate 10g / L, sodium hypophosphite 30g / L, lactic acid 8g / L, ammoniacal liquor 10g / L, sodium ethylenediamine tetramethylene phosphonate (EDTMPS) 30g / L , Hydroxyethylidene diphosphonic acid (HEDP) 15g / L, ammonium chloride 15g / L, glycine 10g / L praseodymium sulfate 91ppm, yttrium sulfate 13ppm.

[0063] The composition of the chemical gold immersion solution in step 9 includes: potassium aurous cyanide 1g / ...

Embodiment 3

[0067] In this embodiment, chemical nickel-gold is carried out on the copper surface, and the experiment is carried out according to the steps described. Wherein, the alkaline electroless nickel plating solution in step 6 comprises: nickel sulfate 10g / L, sodium hypophosphite 22g / L, lactic acid 10g / L, ammoniacal liquor 40g / L, succinic acid 10g / L glycine 10g / L, chlorine Ammonium chloride 15g / L, citric acid 10g / L. Wherein, the nickel activator composition in step 7 includes: glycine 10g / L.

[0068] The acidic electroless nickel plating solution in the step 8 comprises: nickel sulfate 10g / L, sodium hypophosphite 30g / L, lactic acid 8g / L, ammoniacal liquor 10g / L, sodium ethylenediamine tetramethylene phosphonate (EDTMPS) 30g / L , Hydroxyethylidene diphosphonic acid (HEDP) 15g / L, ammonium chloride 20g / L, glycine 10g / L praseodymium sulfate 91ppm, yttrium sulfate 13ppm.

[0069] The composition of the chemical gold immersion solution in step 9 includes: potassium aurous cyanide 1g / L, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com