Long-term firm durable hydrophobic coating as well as preparation method and application thereof

A hydrophobic coating and durable technology, applied in the field of hydrophobic coating and its preparation, can solve the problems of insufficient stability, poor film-base binding force and mechanical properties, easy wear, etc., and achieve good film-base binding force and adhesion Good, fast deposition rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

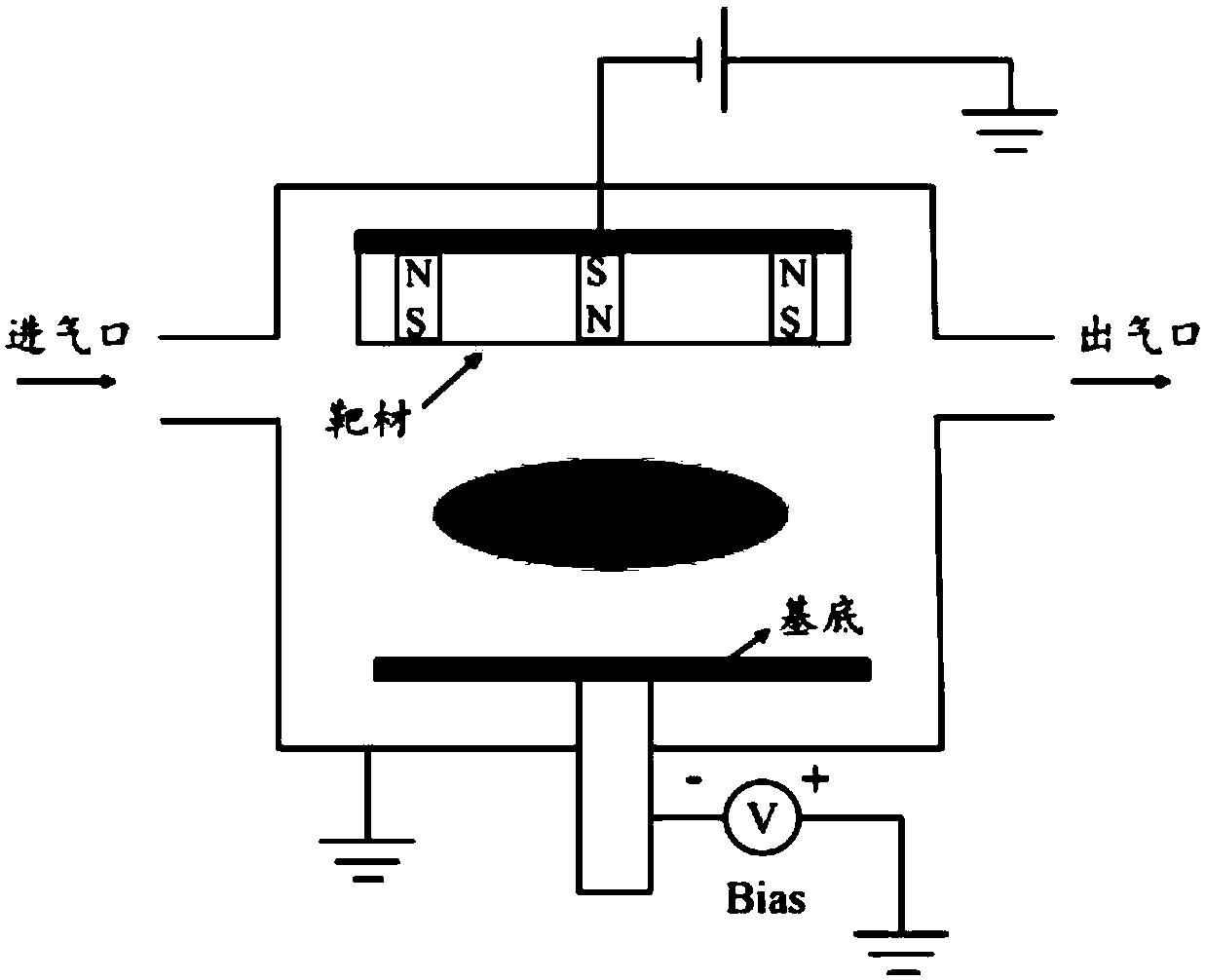

[0039] Embodiment 1 Utilizes the magnetron sputtering device system to deposit a cerium oxide hydrophobic coating on a 316 stainless steel substrate:

[0040] (1) Before being placed in the plasma deposition chamber, the 316 stainless steel substrate was ultrasonically cleaned with acetone, ethanol, and deionized water in order to remove pollutants on the substrate. Place the stainless steel substrate in the chamber of the plasma device and evacuate to 5.0×10 -4 Pa, turn on the DC power supply, set the bias voltage to –450V, and use argon plasma to activate and clean the substrate surface for 20 minutes;

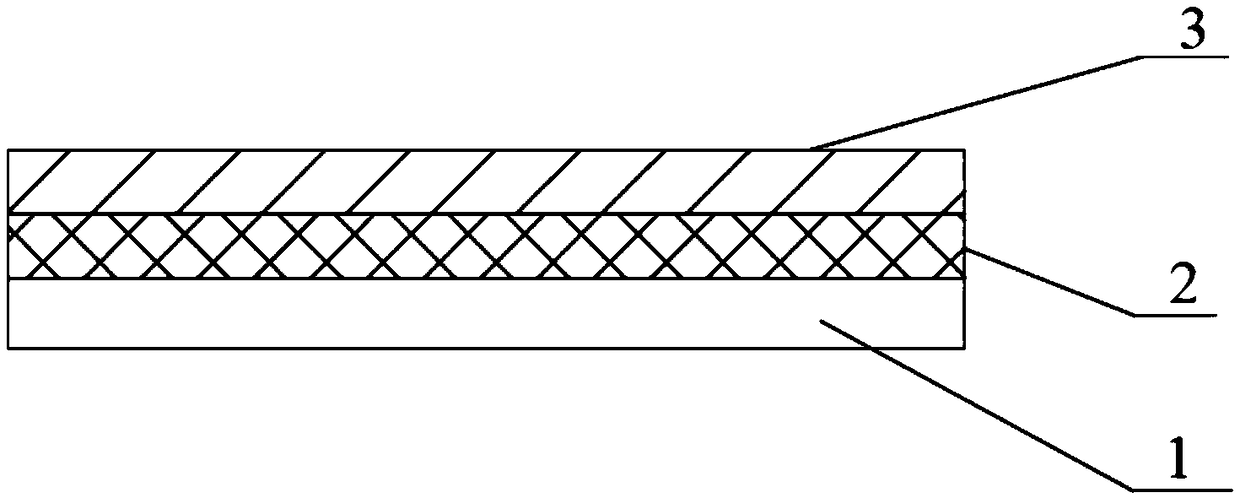

[0041] (2) Carry out the deposition of metal cerium transition layer to strengthen the binding force between cerium oxide and 316 stainless steel substrate: feed the argon gas that mass flow percentage is 100%, under plasma atmosphere, argon ion bombards metal cerium target, The cerium atoms sputtered from the metal cerium target are deposited on the substrate to form a met...

Embodiment 2

[0044] Embodiment 2 Utilizes the magnetron sputtering device system to deposit a cerium oxide hydrophobic coating on a single crystal (100) silicon wafer substrate:

[0045] (1) Before putting into the plasma deposition chamber, the single crystal (100) silicon wafer substrate is ultrasonically cleaned with acetone, ethanol, and deionized water in order to remove pollutants on the single crystal (100) silicon wafer substrate . Place the single crystal (100) silicon wafer substrate in the chamber of the plasma device, and evacuate to 4.0×10 -4 Pa, turn on the DC power supply, set the bias voltage to –450V, and use argon plasma to activate and clean the substrate surface for 20 minutes;

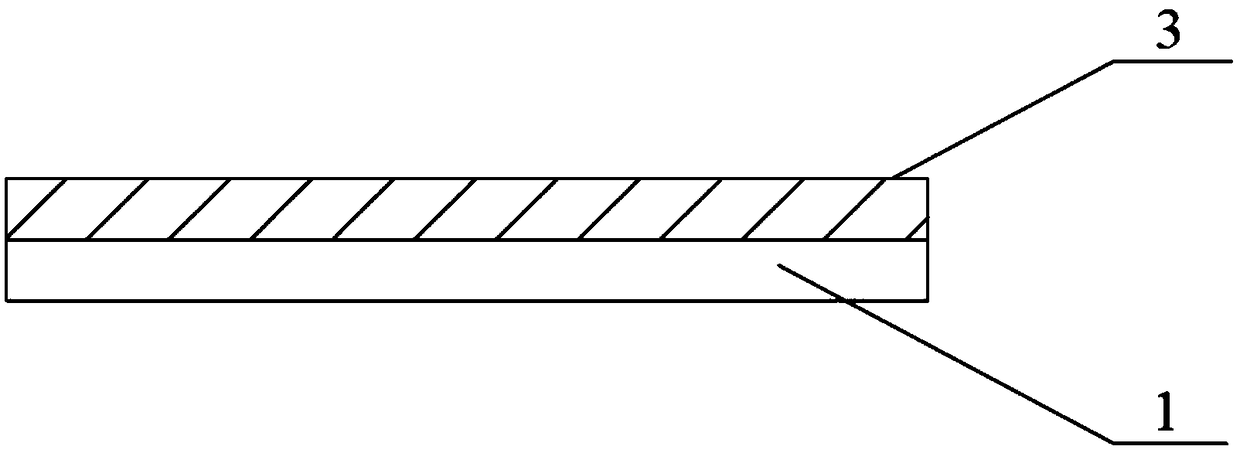

[0046] (2) Deposition of cerium oxide coating: the mass flow percentage of 3% oxygen and the mass flow percentage of argon gas of 97% are introduced respectively. Under the plasma atmosphere, the argon ions bombard the metal cerium target, from the metal cerium target Cerium atoms sputtered o...

Embodiment 3

[0047] Embodiment 3 utilizes magnetron sputtering system to deposit cerium oxide hydrophobic coating on glass substrate:

[0048] (1) Before being put into the plasma deposition chamber, the glass substrate was ultrasonically cleaned with acetone, ethanol, and deionized water in order to remove pollutants on the glass silicon wafer substrate. Place the glass substrate in the chamber of the plasma device and evacuate to 6.0×10 -4 Pa, turn on the DC power supply, set the bias voltage to –450V, and use argon plasma to activate and clean the substrate surface for 20 minutes;

[0049] (2) Carry out the deposition of metal cerium transition layer: pass through the mass flow percentage and be 100% argon gas, under plasma atmosphere, argon ion bombards metal cerium target, the cerium atom sputtered out from metal cerium target deposits on A metal cerium transition layer is formed on the substrate; the deposition bias is set to –60V, the pressure during the deposition process is 0.21P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com