Patents

Literature

32results about How to "Enhanced condensation heat transfer capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

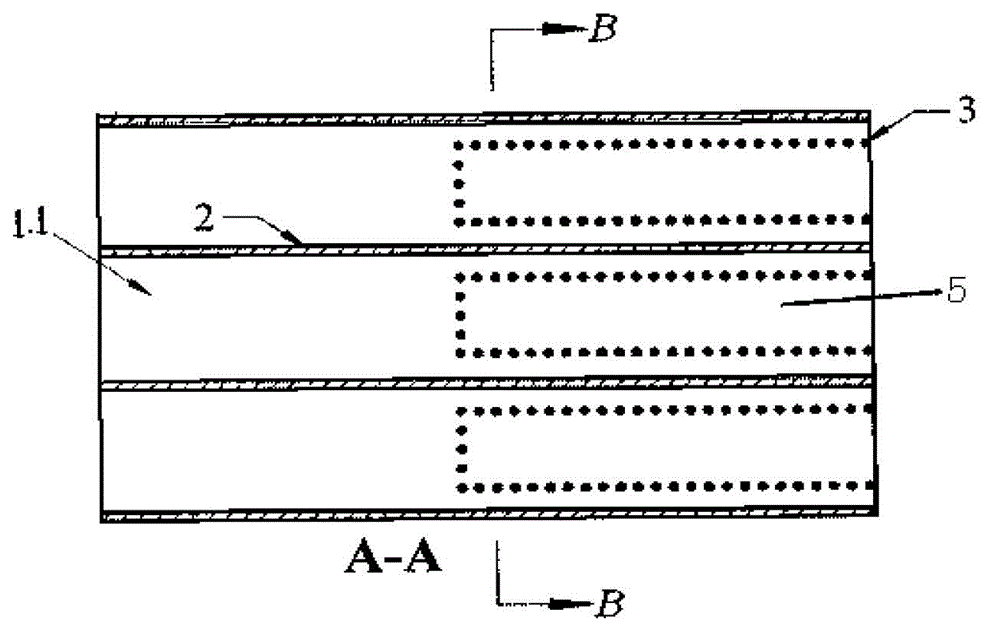

Gravity assisted heat pipe device and preparation method

InactiveCN105973044AEnhanced condensation heat transfer capacityReduce condensation thermal resistanceIndirect heat exchangersMicro structureNano structuring

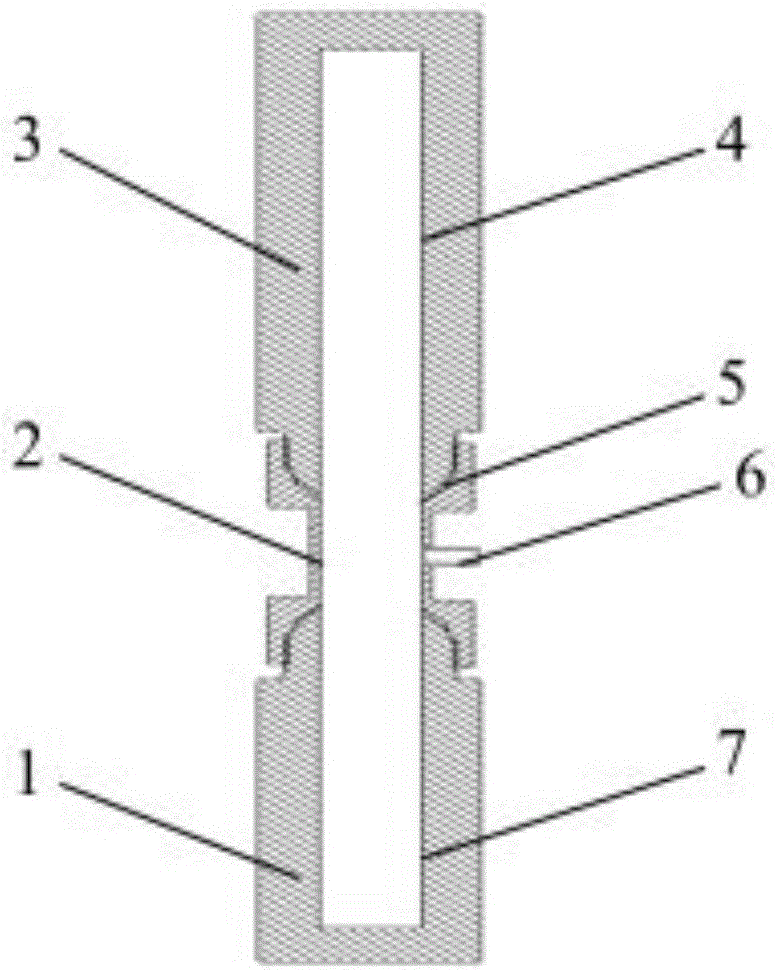

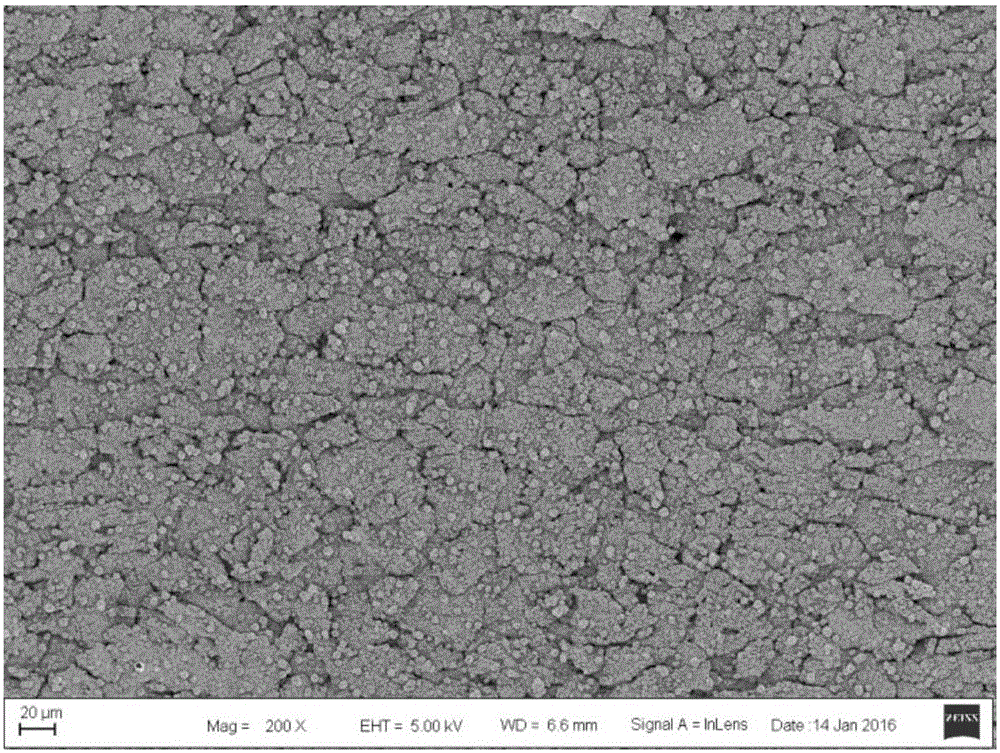

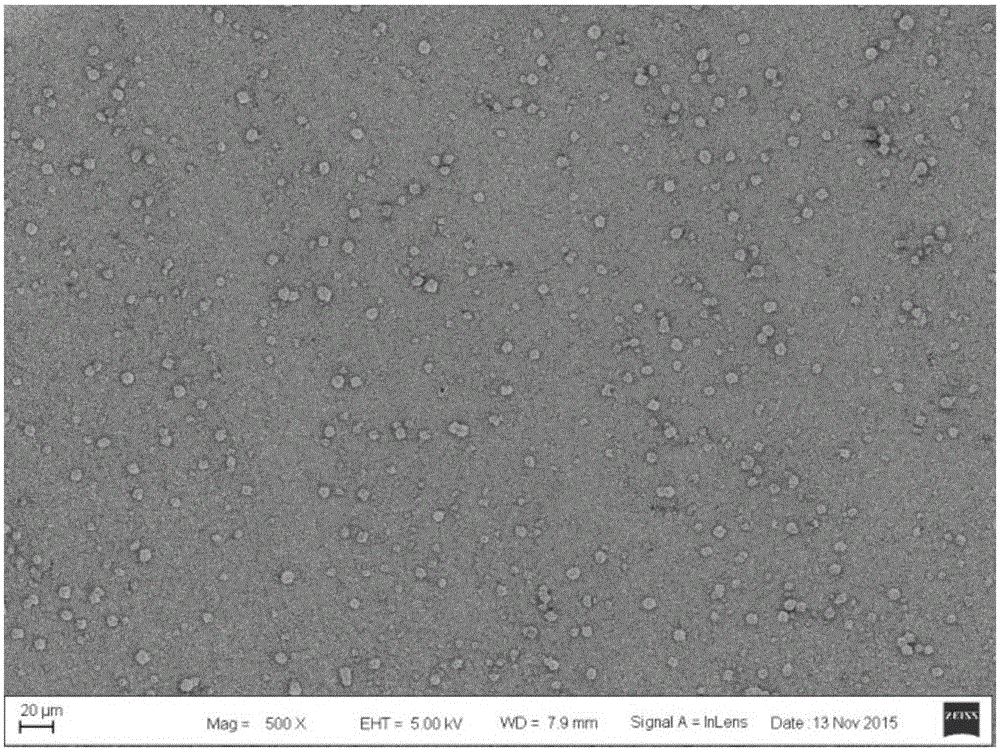

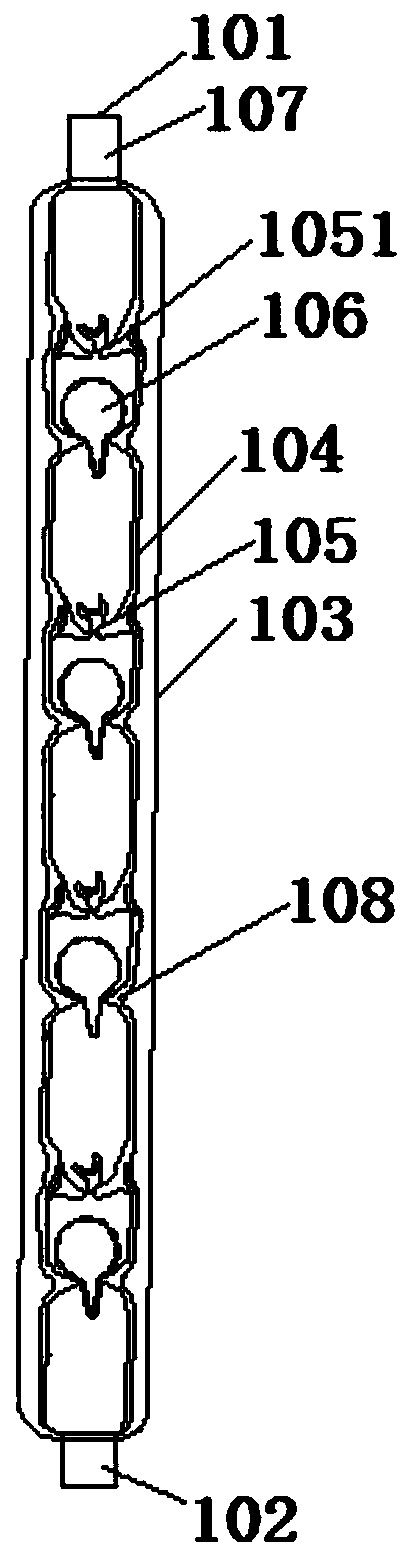

The invention discloses a gravity assisted heat pipe device which comprises an evaporator, a heat insulation segment and a condenser. The evaporator and the condenser are in sealed connection with the heat insulation segment. The inner surface of the evaporator is a super-hydrophilic surface. The inner surface of the condenser is a smooth lubricant implanted porous surface (SLIPS). Lubricant on the SLIPS and a charged working medium cannot be mixed. A super-hydrophilic surface of a nano-micro structure is arranged on the inner wall of the evaporator, the working medium can completely moisten the wall face, a liquid film evaporates in the heating process, the evaporation intensity is improved, and the SLIPS of the condenser is formed by compounding the super-hydrophilic of a nano structure with implanted fluorine-containing lubricant or silicone oil or ionic liquid. Condensed liquid drops float on the SLIPS, are combined, fast fall off the SLIPS and sweep small liquid drops on the path of the condensed liquid drops, a condensation surface is provided for secondary condensation, and the condensation and heat exchange effect is remarkably improved. According to the gravity assisted heat pipe device, heat pipe heat resistance can be effectively reduced, the heat exchange performance of the device is improved, and wide application prospects are achieved.

Owner:SHANGHAI JIAO TONG UNIV

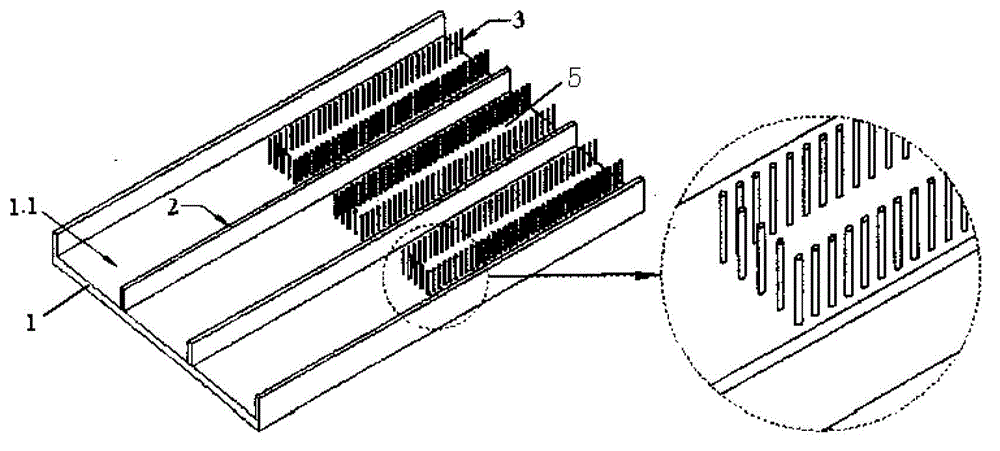

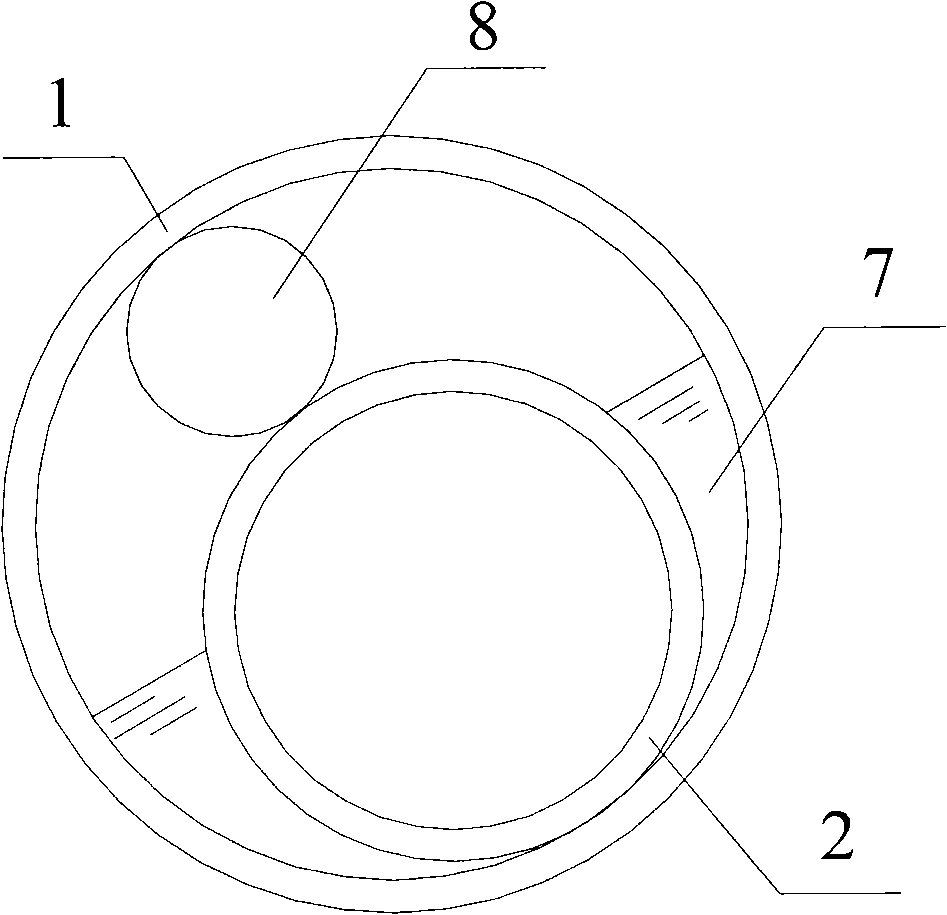

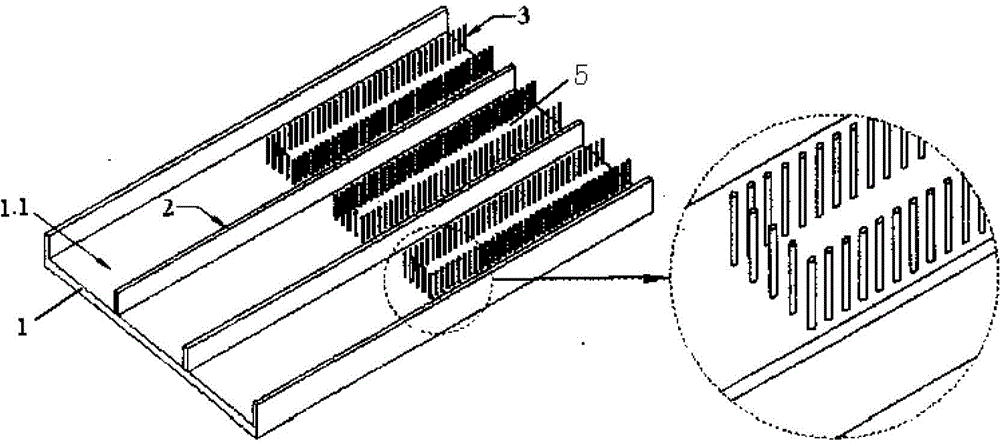

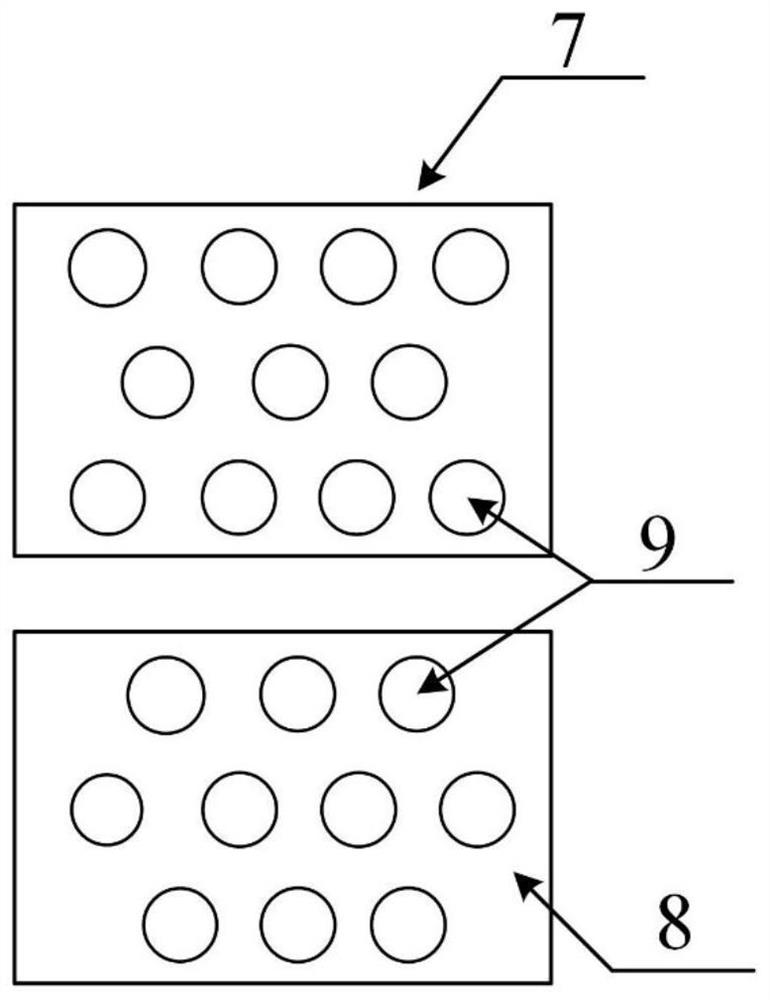

Phase separation micro-channel condenser

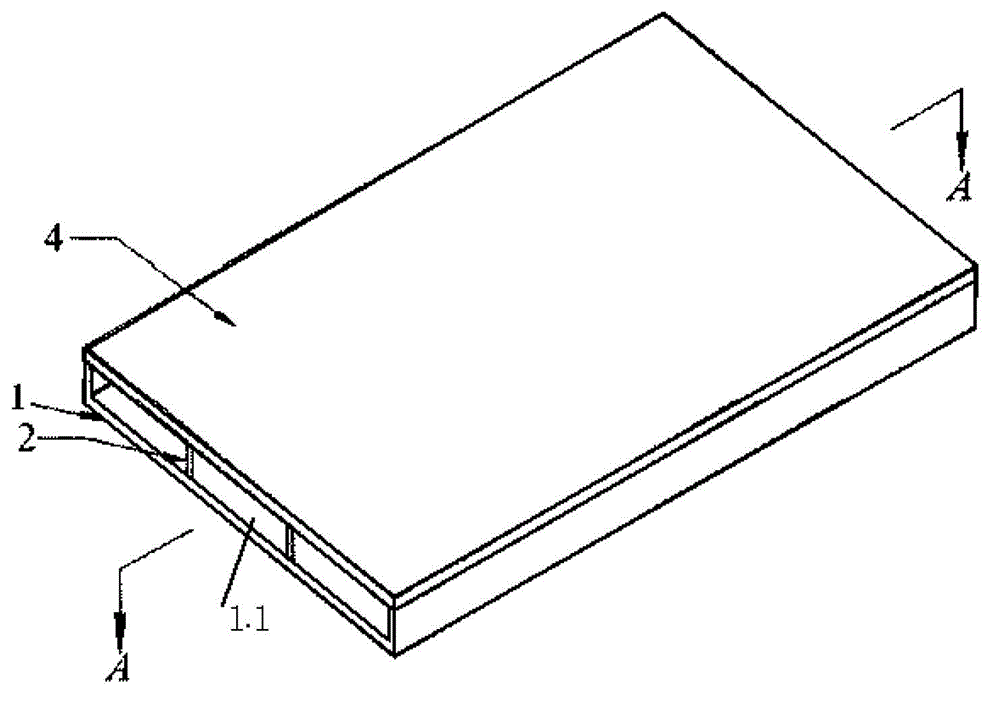

ActiveCN103335549AOvercome the disadvantage of being unable to control the two-phase flow patternReduce thicknessIndirect heat exchangersCooling/ventilation/heating modificationsEngineeringSilicon

The invention discloses a phase separation micro-channel condenser and belongs to the field of the heat transfer enhancement technology. A plurality of parallel micro-channels are etched on a silicon substrate and are separated by rib sheets. A plurality of rib strips are etched in the downstream area of each micro-channel. The rib strips of each micro-channel form, in an enclosing mode, a rib strip net with an opening toward the downstream. A cover plate packages on the micro-channels. The phase separation micro-channel condenser overcomes the defect that a traditional micro-channel condenser can not modulate a two phase flow pattern. Different from other reinforcing condensing heat conduction devices, due to the fact that an air phase and a liquid phase flow in branch paths after flow pattern modulation, the phase separation micro-channel condenser can greatly reduce the thickness of a liquid film, improve condensing heat exchange performance, reduce flow resistance and flow instability, and be applied to an electronic element heat-sink cooling system.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

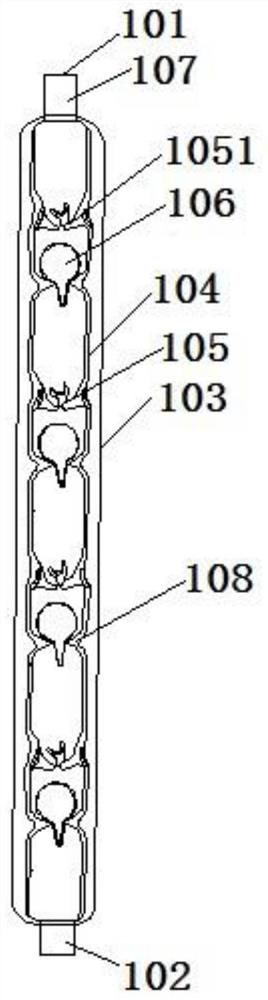

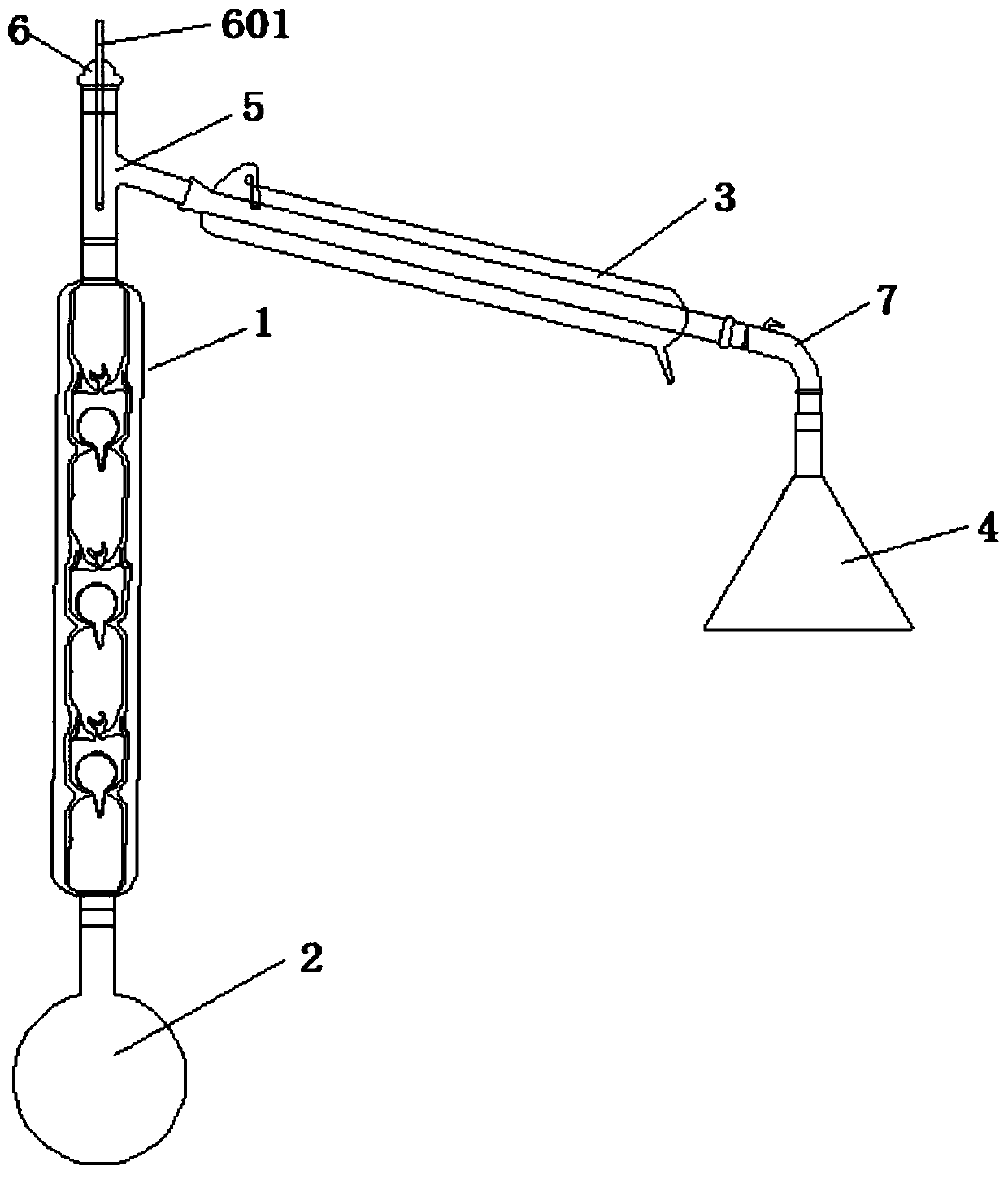

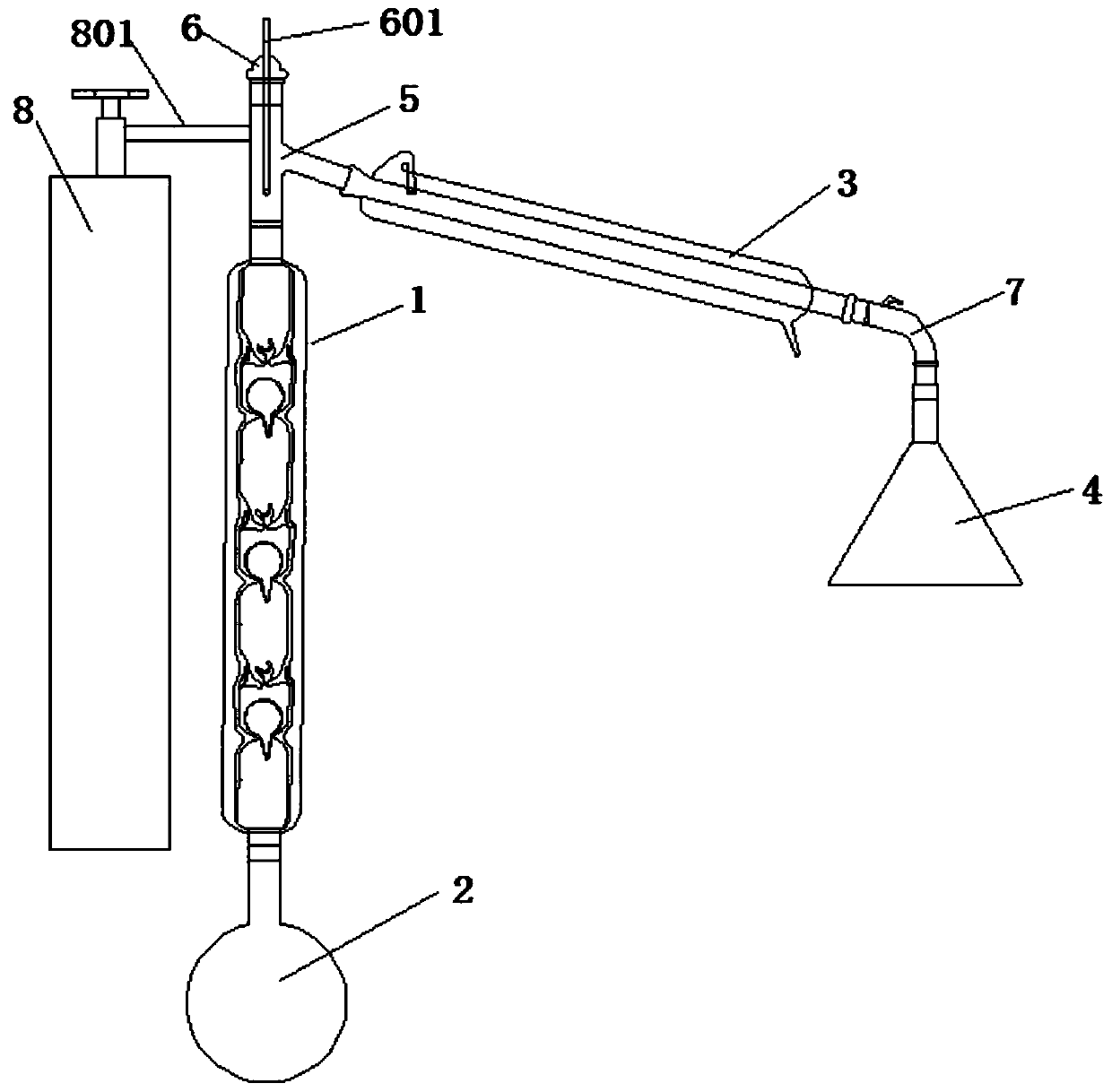

A kind of method for measuring coal tar three mixed naphthalene oil

ActiveCN110196202BImprove extraction efficiencyImprove extraction qualityWeighing by removing componentThermodynamicsDistillation

The invention relates to a method for measuring coal tar trimixed naphthalene oil, comprising the following steps: (1) weighing the dehydrated coal tar whose quality is X; (2) putting the coal tar into a distillation bottle of a fractionation device, and The fractionation device is connected and assembled; (3) start heating the retort in step (2), cut off the distillate segment with a temperature of 180-250°C and weigh the weight X1 of the distillate and measure the purity Z; (4) continue to reheat the retort The coal tar in the heating is heated until crystallization occurs in the distillate, and the heating is stopped, the temperature at this time is recorded, and the weight X2 of the distillate in the receiver at this time is weighed; (5) according to step (3) and step (4 ) fraction weight calculation of the content Y1 of naphthalene in coal tar and the content Y2 of three mixed naphthalene oils. The method for measuring coal tar trimixed naphthalene oil predicts the yield of trimixed naphthalene oil in actual production, can reduce the content of anthracene oil in the trimixed naphthalene oil, and improves the purity of the trimixed naphthalene oil, which can be used to guide practice Production.

Owner:马钢奥瑟亚化工有限公司

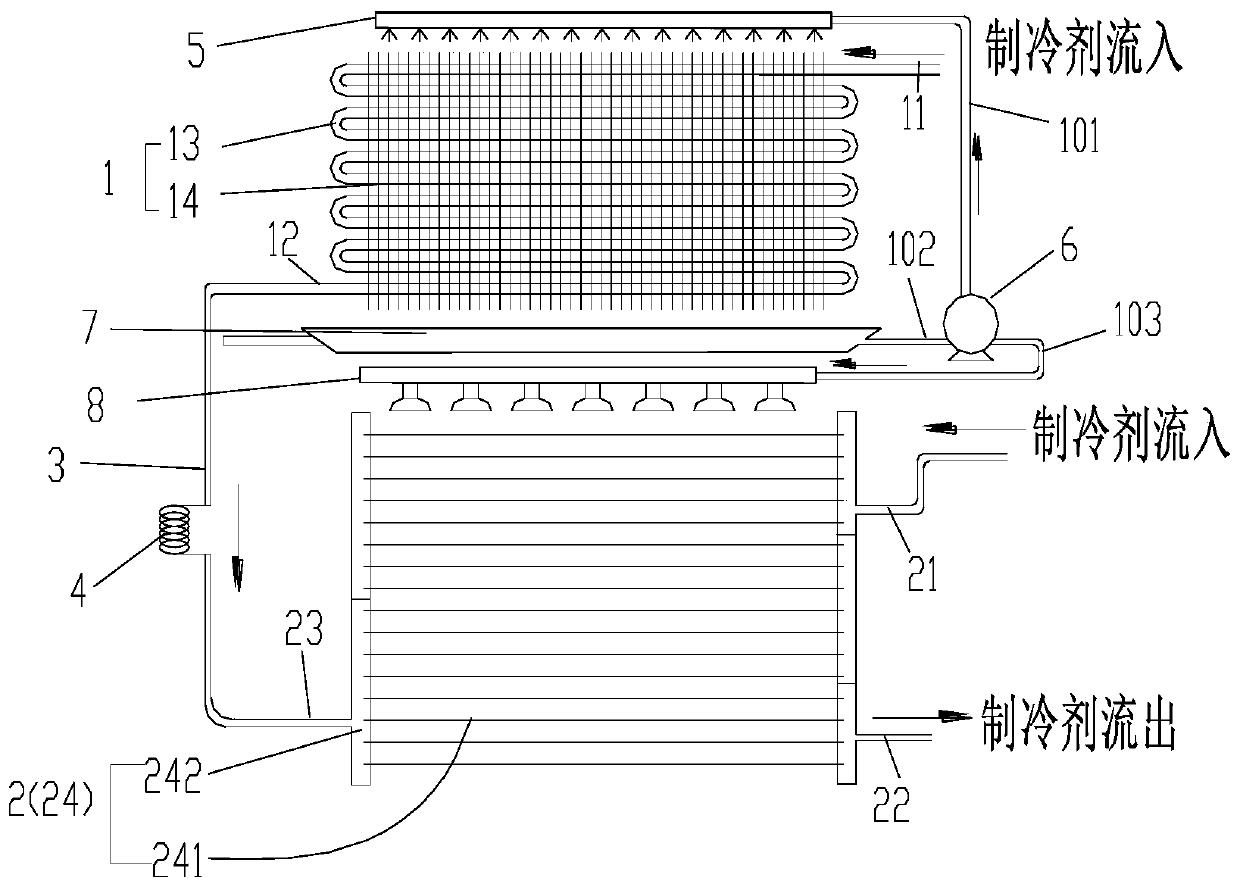

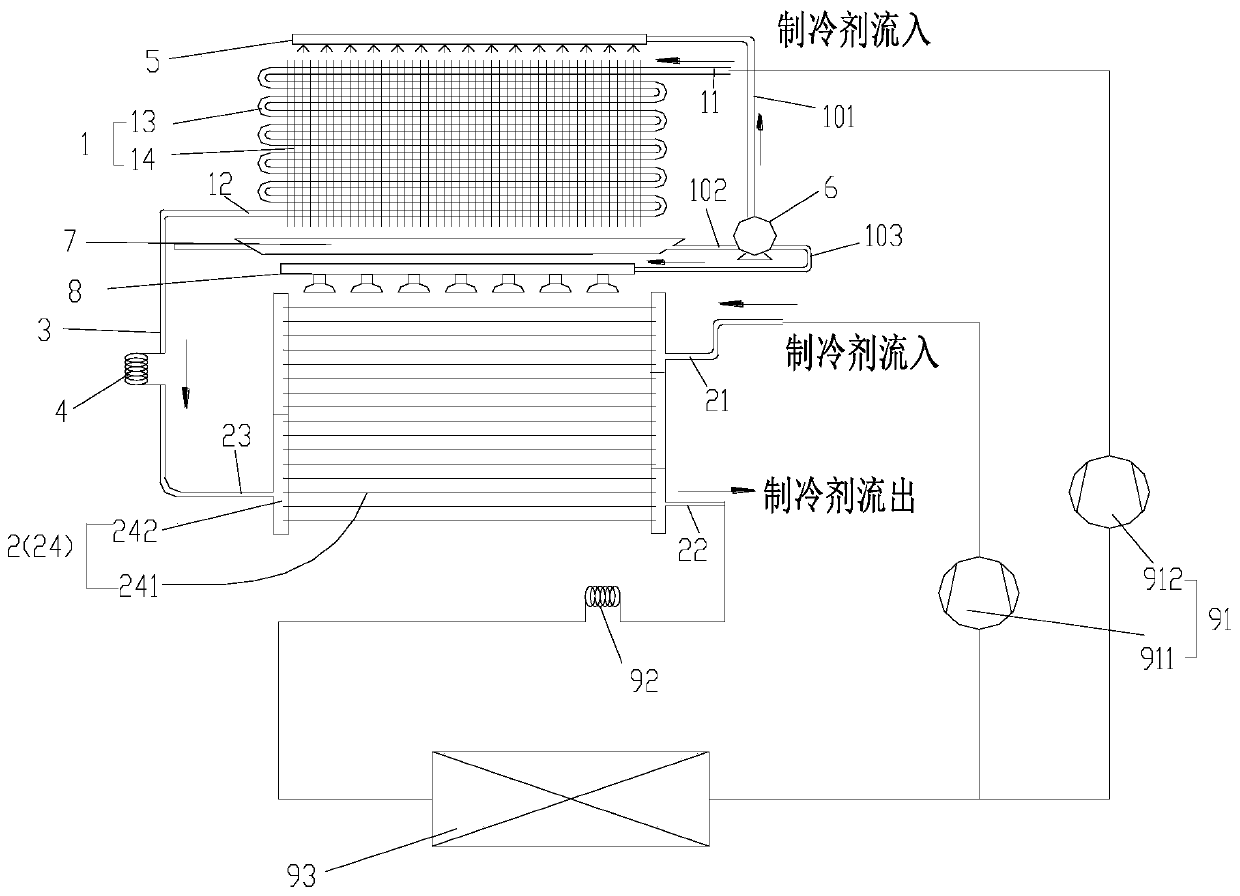

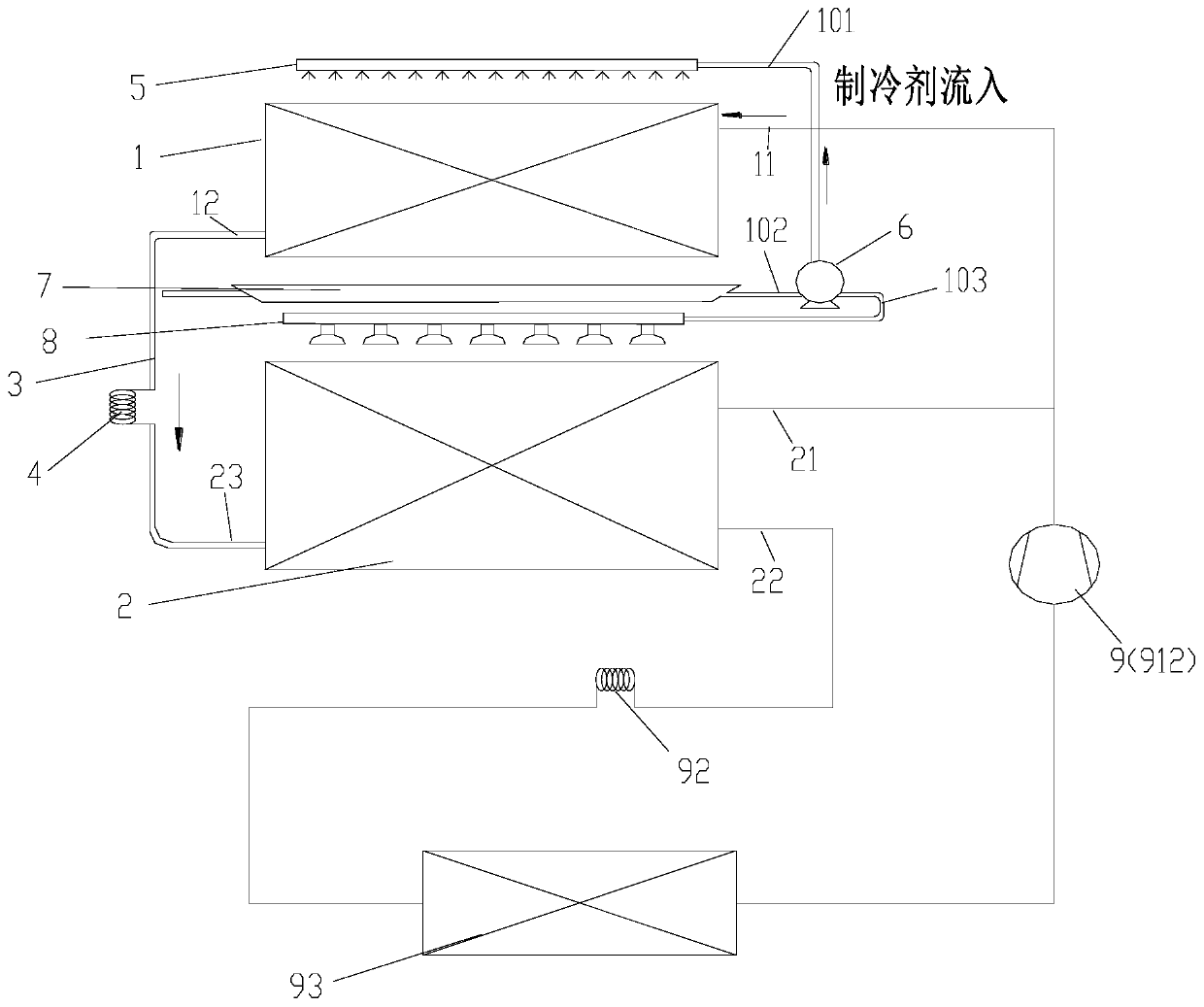

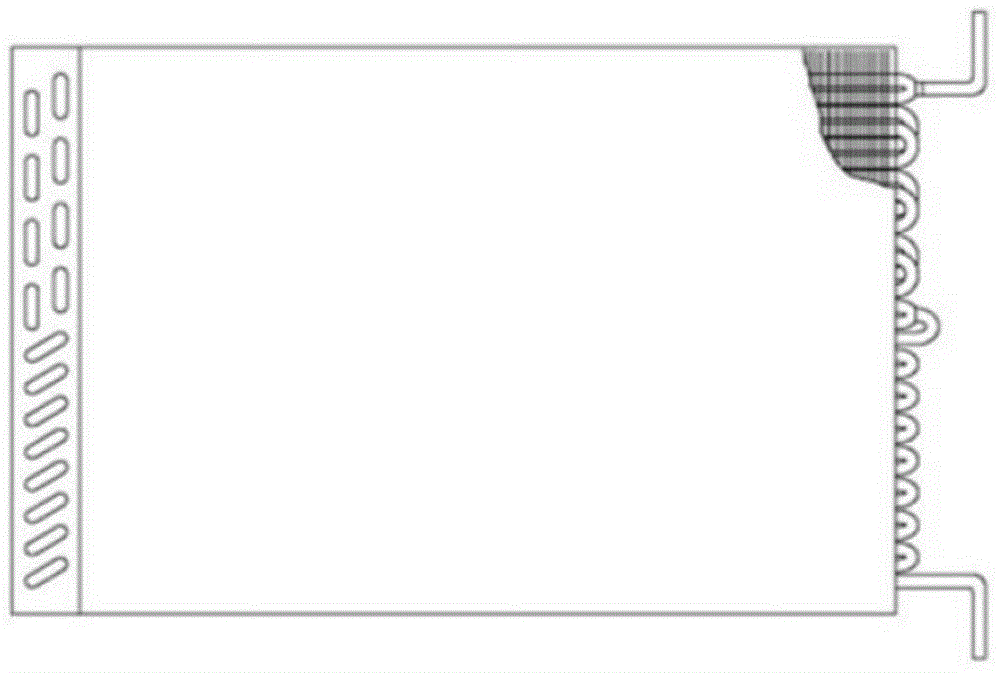

Condensing device and air conditioning system with same

PendingCN111059802AImprove heat transfer effectIncrease flow rateCompressorEvaporators/condensersEngineeringAir conditioning

The invention provides a condensing device and an air conditioning system with the same. The condensing device comprises a first heat exchanger and a second heat exchanger, the first heat exchanger isprovided with a first inlet allowing refrigerant to enter and a first outlet allowing the refrigerant to flow out after cooling and heat exchange, and the second heat exchanger is provided with a second inlet allowing the refrigerant to enter and a second outlet allowing the refrigerant to flow out after cooling and heat exchange; and a supercooling section of the second heat exchanger is provided with a third inlet which can communicate with the first outlet, the third inlet communicates with the first outlet through a middle pipe, so that fluid sequentially flows to the second heat exchanger from the first outlet, the middle pipe and the third inlet, and the pipe diameter of a first heat exchange pipe of the first heat exchanger is larger than the pipe diameter of a second heat exchangepipe of the second heat exchanger. According to the condensing device and the air conditioning system with the same, the flow speed of the refrigerant in a supercooling section heat exchange pipe isincreased, liquid film refrigerant on the wall face is rapidly taken away, the condensation heat exchange effect is effectively enhanced, the heat exchange amount is increased, and the filling amountof the refrigerant in a condenser is further reduced.

Owner:GREE ELECTRIC APPLIANCES INC

High-efficiency evaporation and condensation casing heat exchanger

InactiveCN101303184AReduce resistanceMeet condensationEvaporators/condensersEngineeringAir conditioning

The invention discloses a highly effective heat exchanger of evaporation-condensation sheathed tube type, which comprises two tubes with different diameters; an inner tube adopts an externally-finned nickel brass tube or a copper tube, and the two tubes are able to transmit heat by enforcement; an outer tube adopts a smooth cooper tube or a steel tube; the small section of a capillary tube is padded between the inner tube and the outer tube at different positions along length direction and on different angles along circumferential direction; when the sheathed tube is bent into serpentine tubes with different diameters according to the requirements; the capillary tube on the inner tube has a function of supporting the outer tube; two ends of the inner tube and the outer tube are welded. The highly effective heat exchanger of the invention is characterized by simple process, small resistance of refrigerant and water side, overcoming the defect of the existing sheathed tube type heat exchanger being unable to have both good condensing heat exchange effect and evaporating heat exchange effect, realizing the enforcement of condensing heat exchange as well as evaporating heat exchange, thus meeting the double high efficiency requirement of condensation and evaporation heat exchange of a sheathed tube type heat exchanger for a small-sized air-water air-conditioning heat pump unit.

Owner:上海源知电器有限公司

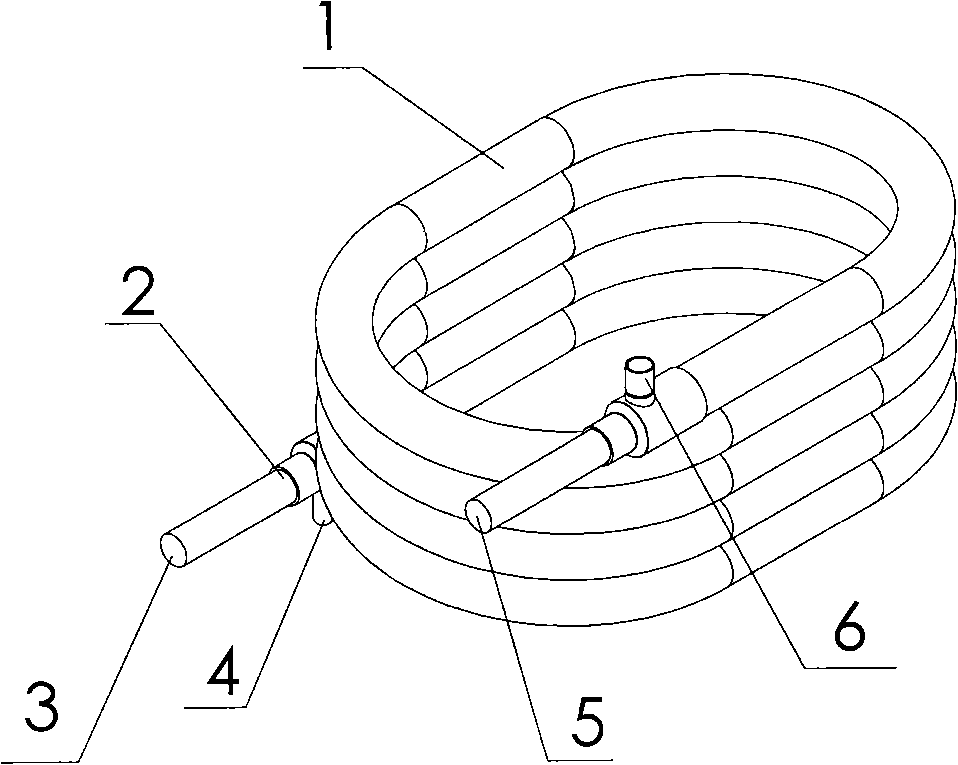

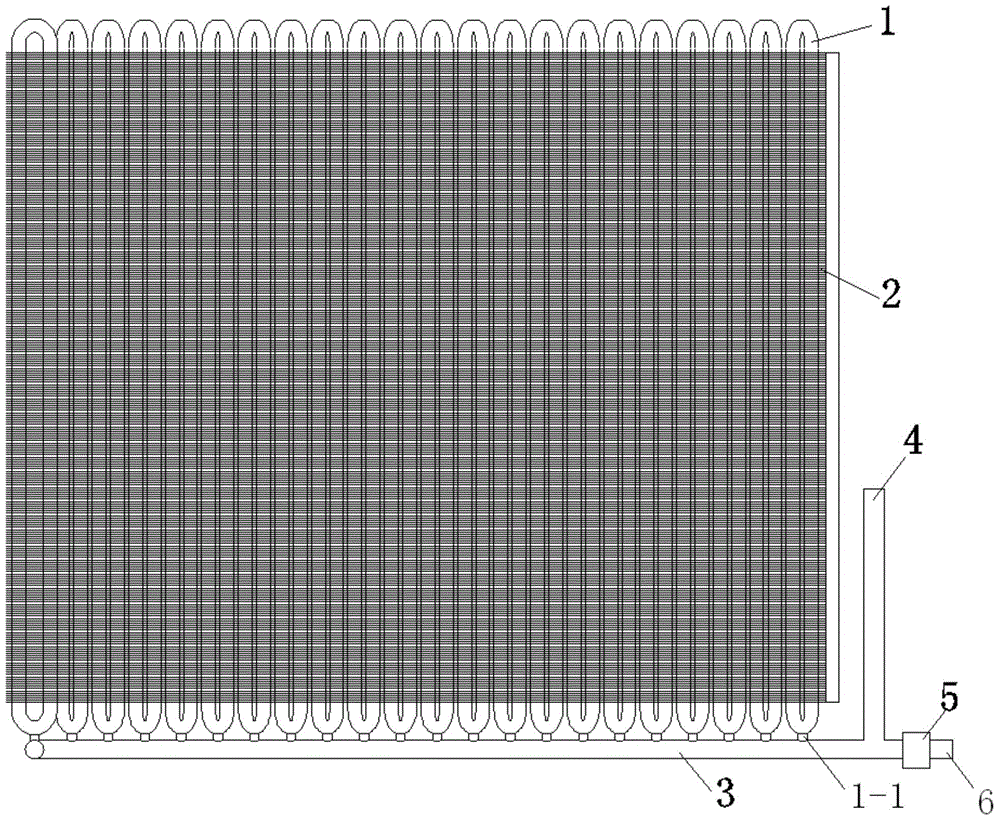

Micro channel heat exchanger and heat pump water heater

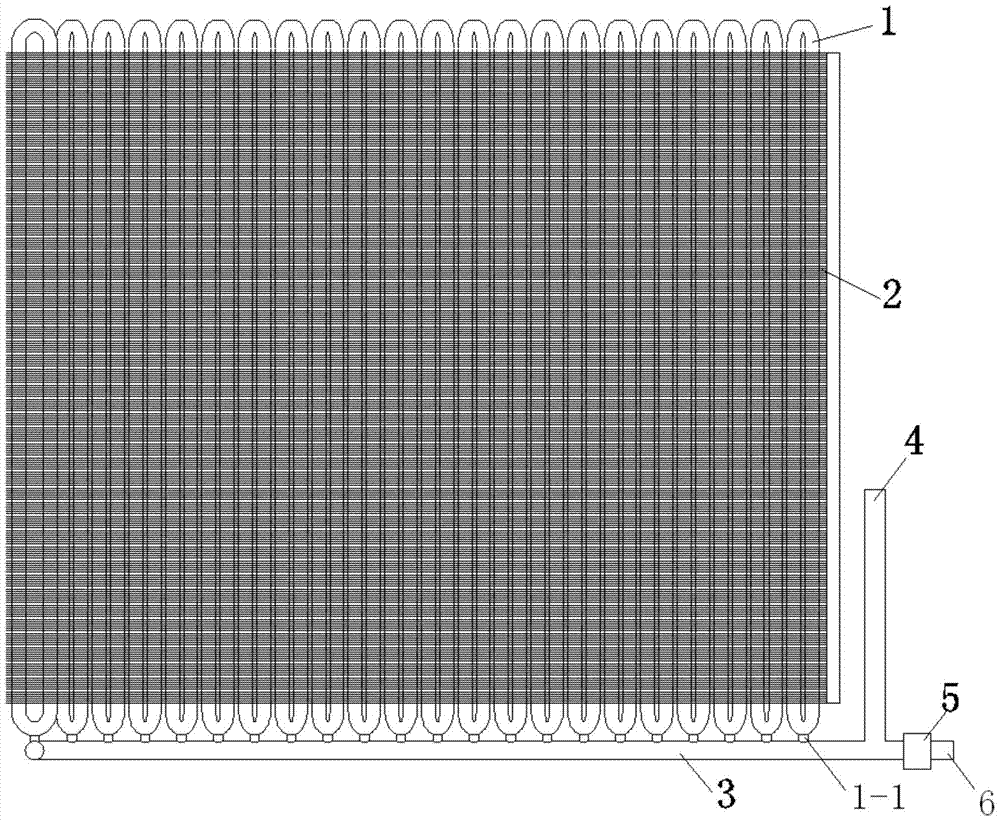

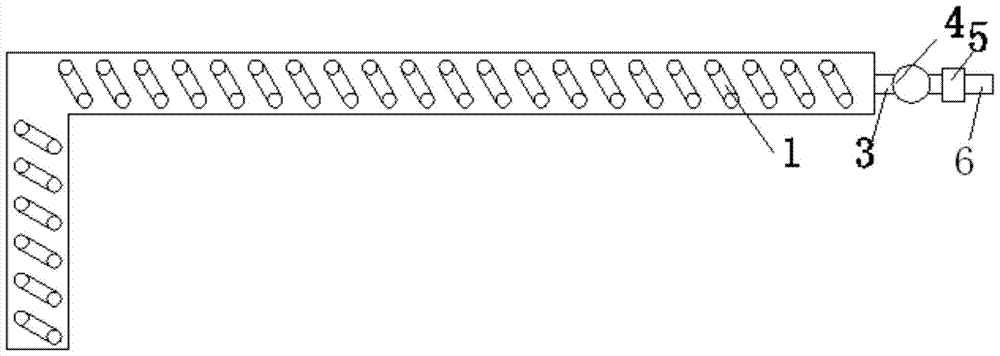

PendingCN106969545AEnhanced condensation heat transfer capacityReduce heat transferFluid heatersEvaporators/condensersEngineeringMechanical engineering

A micro channel heat exchanger of the invention relates to the technical field of heat exchange, and aims to provide the micro heat exchanger being simple in structure, high-efficiency in heat exchange and safe and reliable and a heat pump water heater. The micro channel heat exchanger comprises a first collecting pipe, a second collecting pipe, a third collecting pipe and a plurality of flat pipes, and a first connecting port, a second connecting port and a third connecting port which communicate with a system pipeline are formed in the first collecting pipe, the second collecting pipe and the third collecting pipe correspondingly; the third collecting pipe is arranged between the first collecting pipe and the second collecting pipe, the flat pipes are used for enabling the first collecting pipe and the third collecting pipe to communicate and enabling the second collecting pipe and the third collecting pipe to communicate; and directions of refrigerant in and out at the first connecting port and the second connecting port are identical and are both opposite to directions of refrigerant in and out at the third connecting port, a first flowing route is formed by the first collecting pipe, the third collecting pipe and the flat pipes between the first collecting pipe and the third collecting pipe, and a second flowing route is formed by the second collecting pipe, the third collecting pipe and the flat pipes between the second collecting pipe and the third collecting pipe.

Owner:GREE ELECTRIC APPLIANCES INC

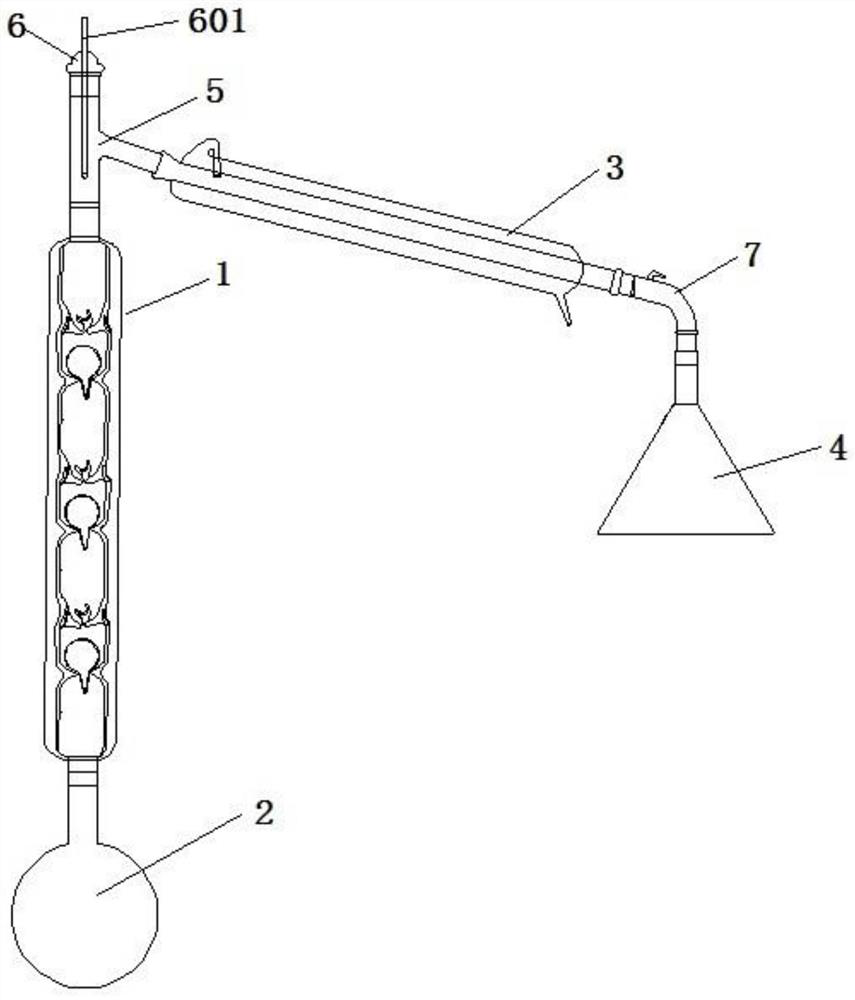

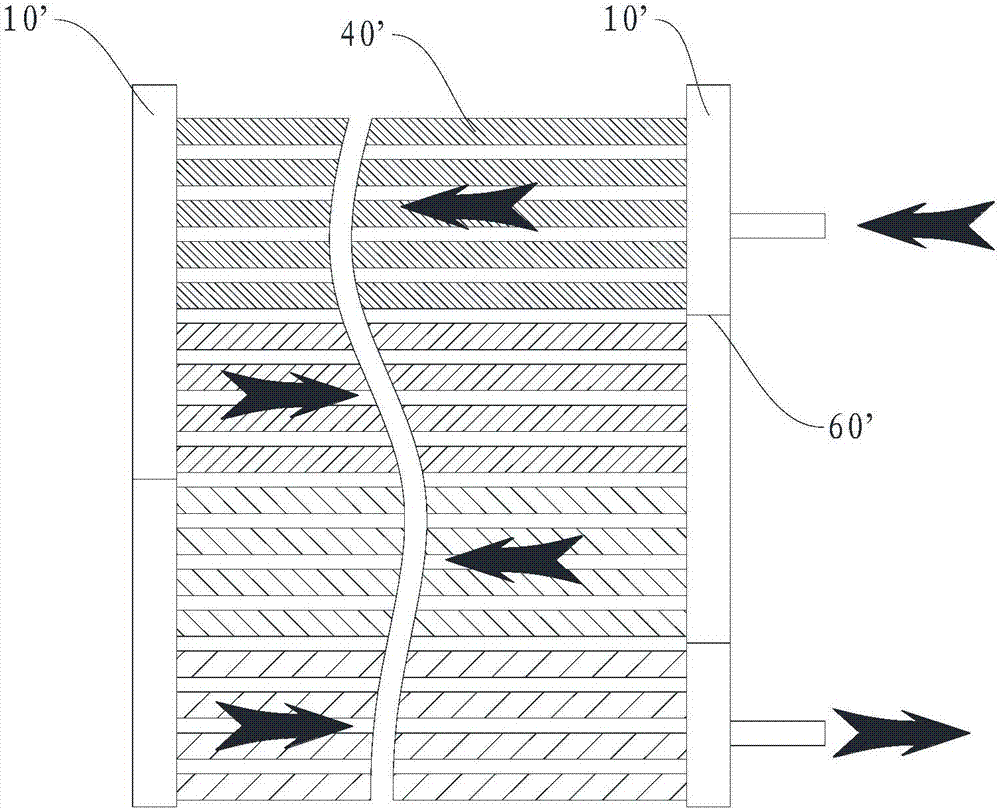

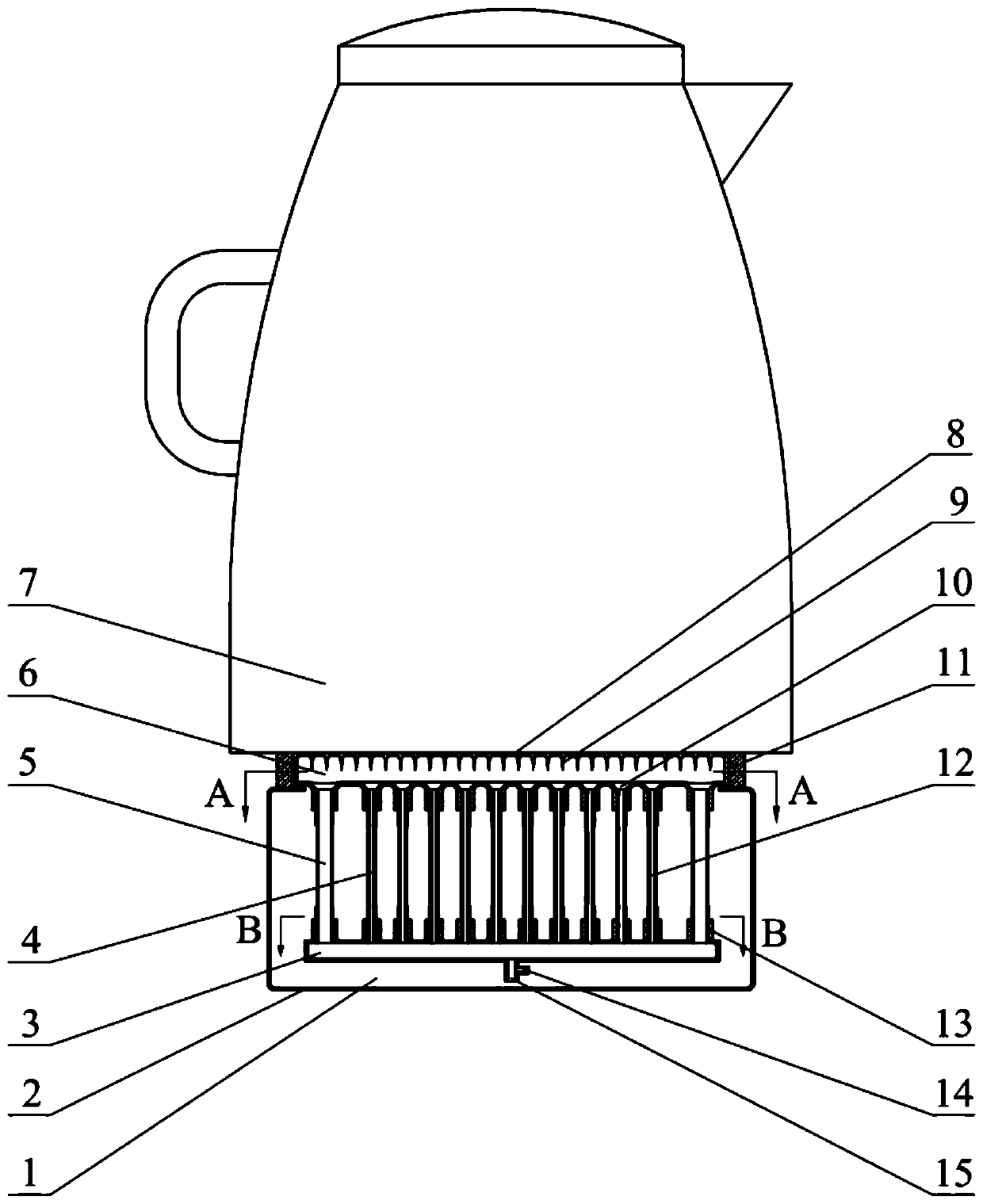

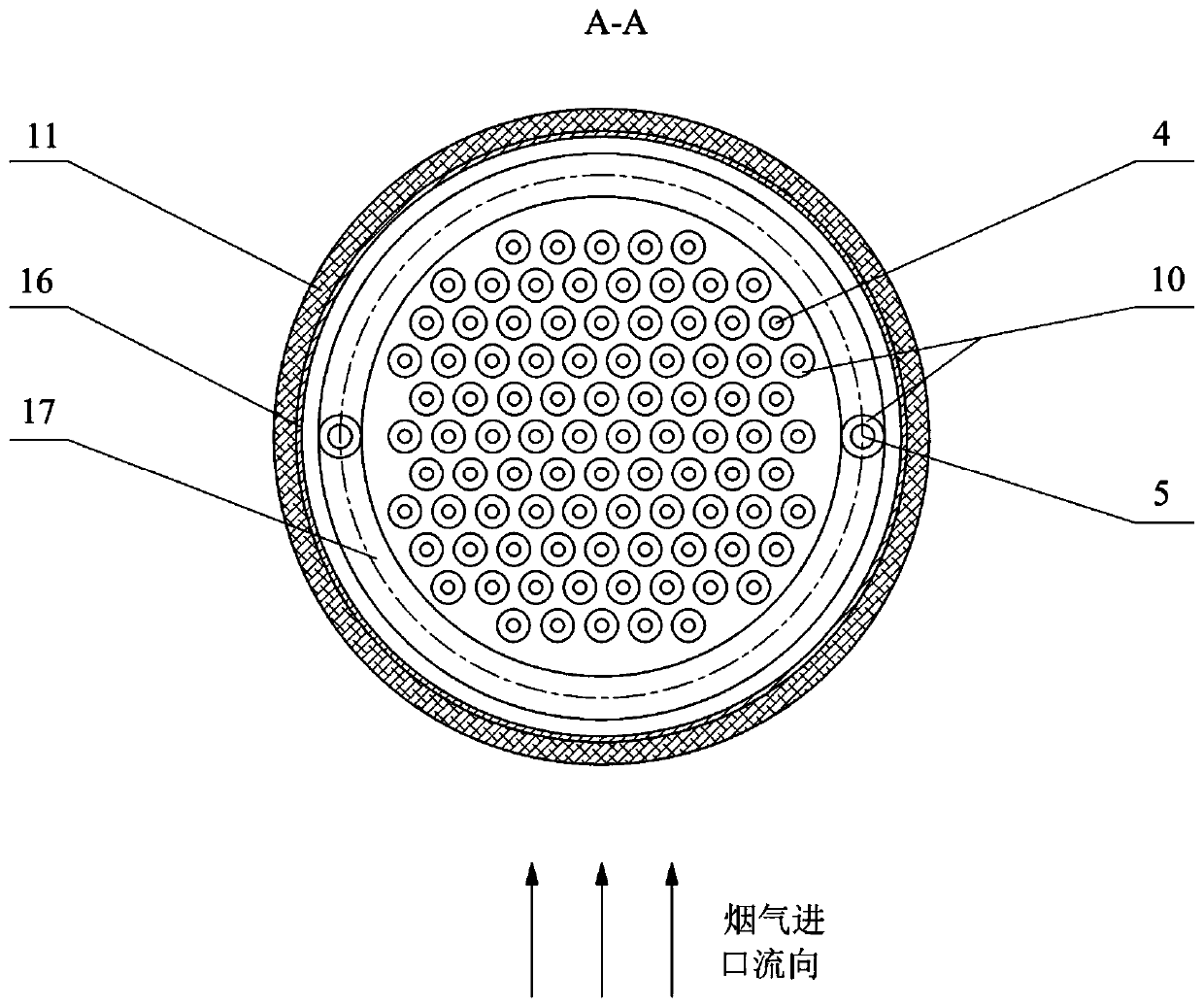

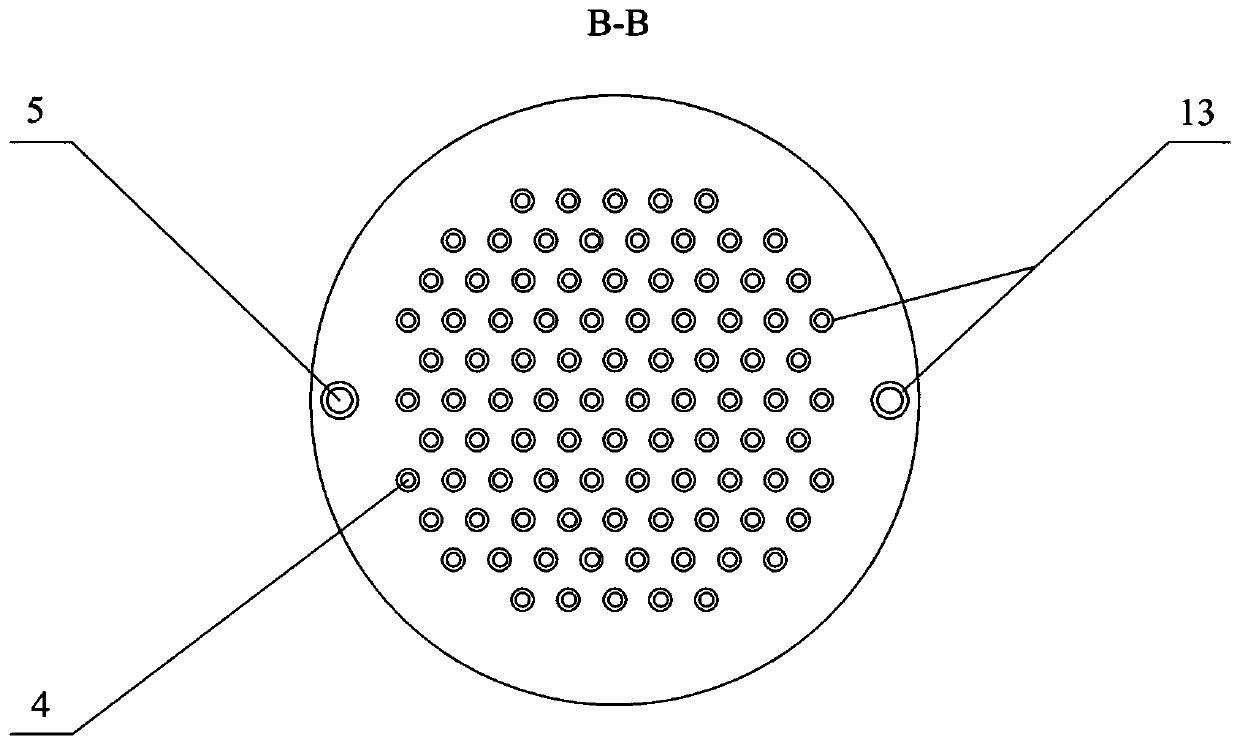

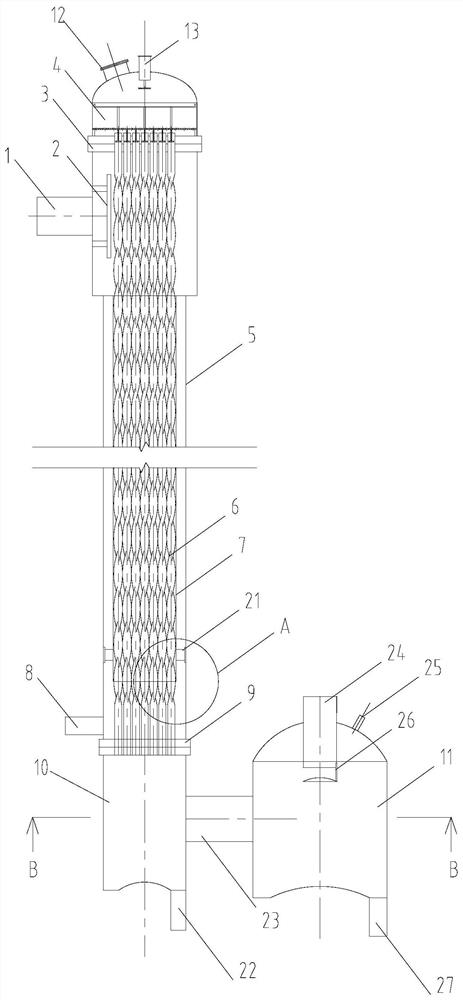

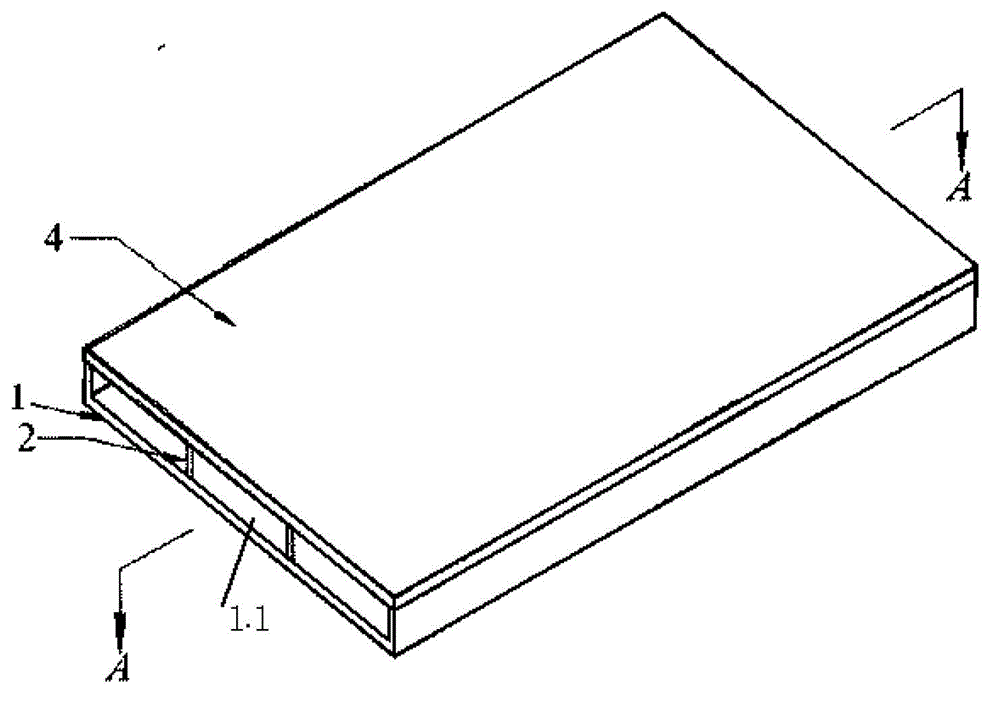

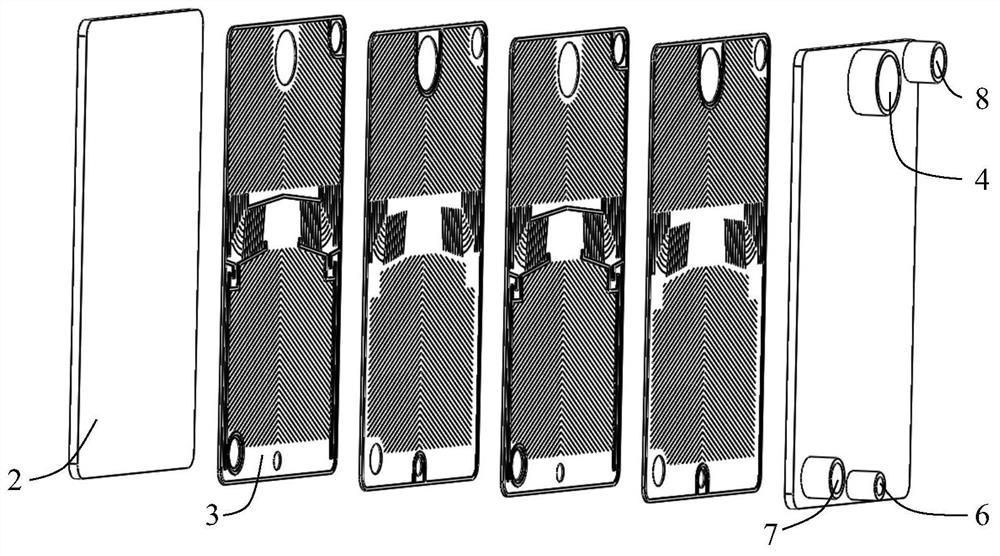

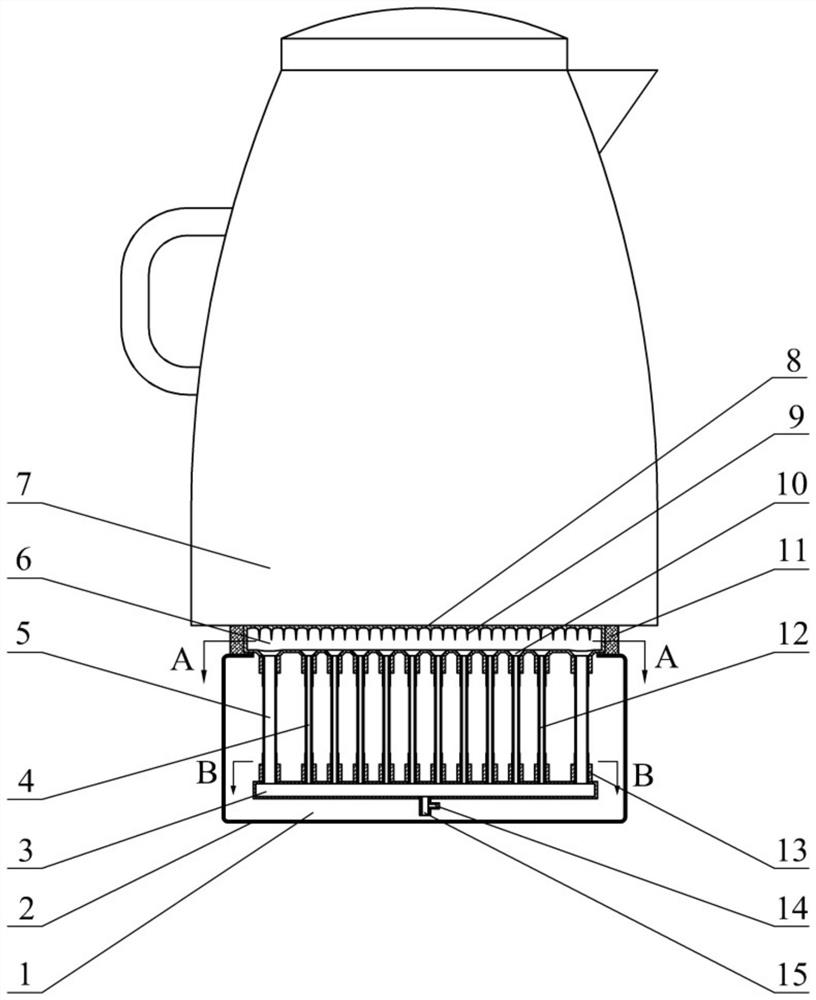

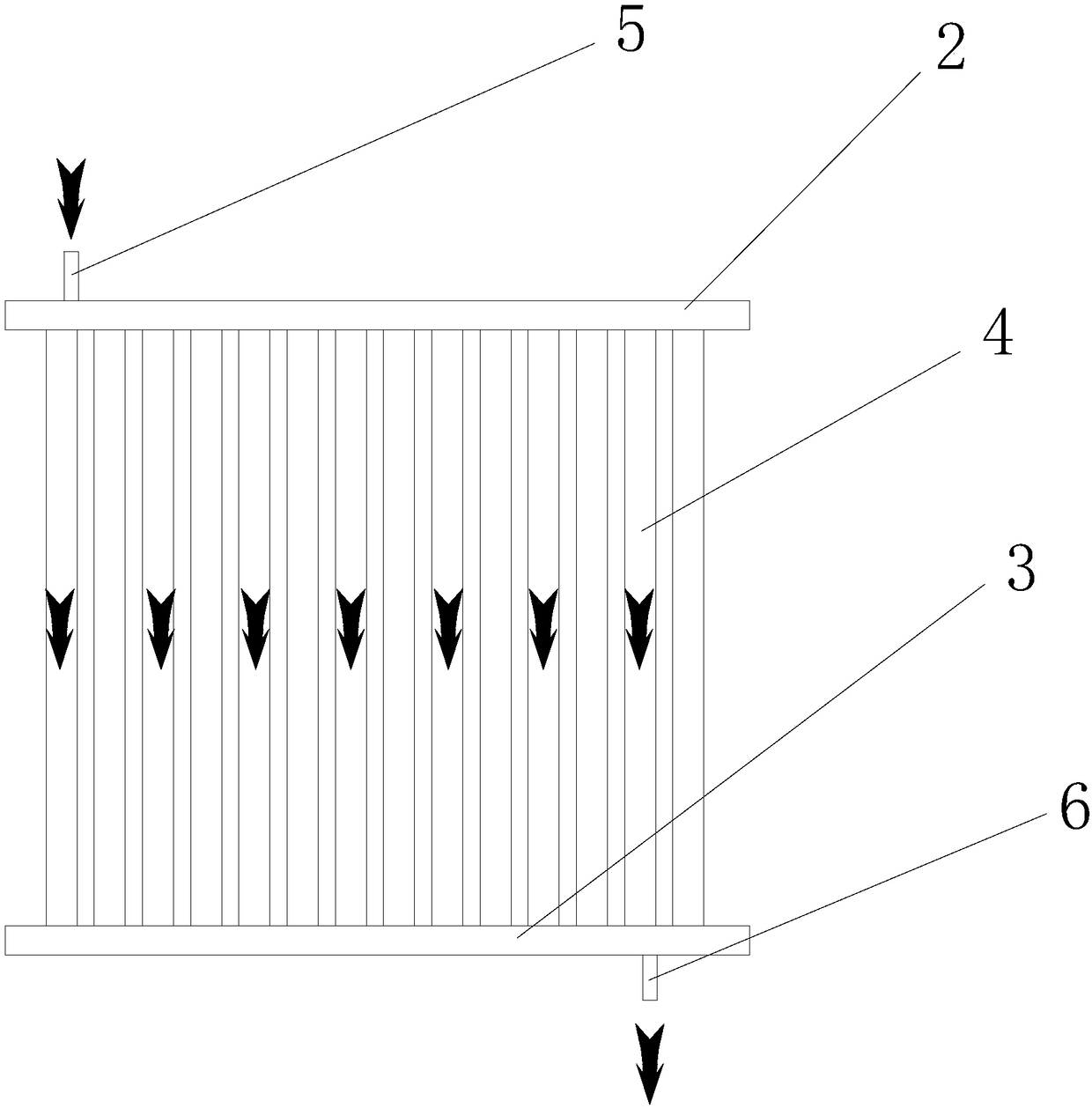

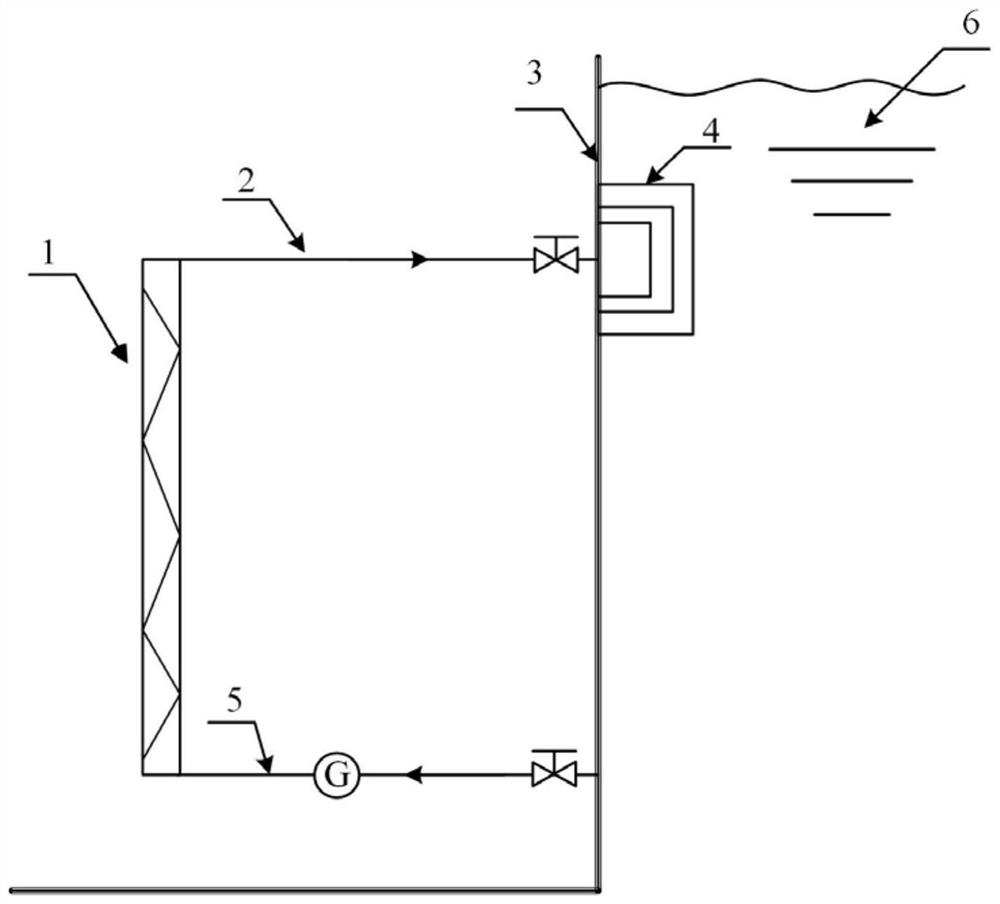

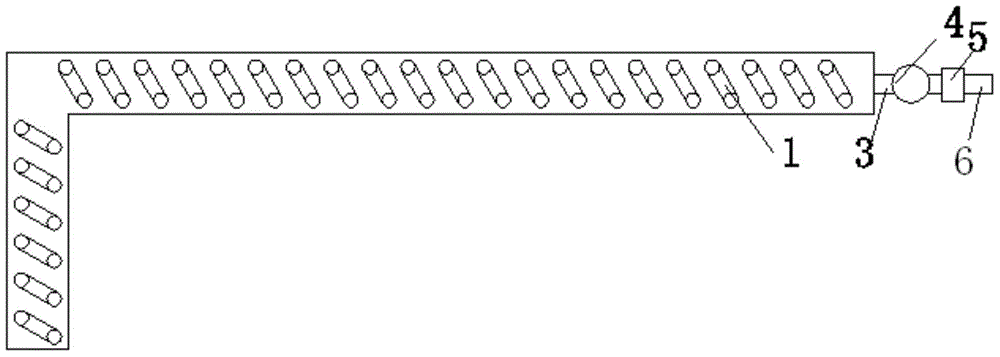

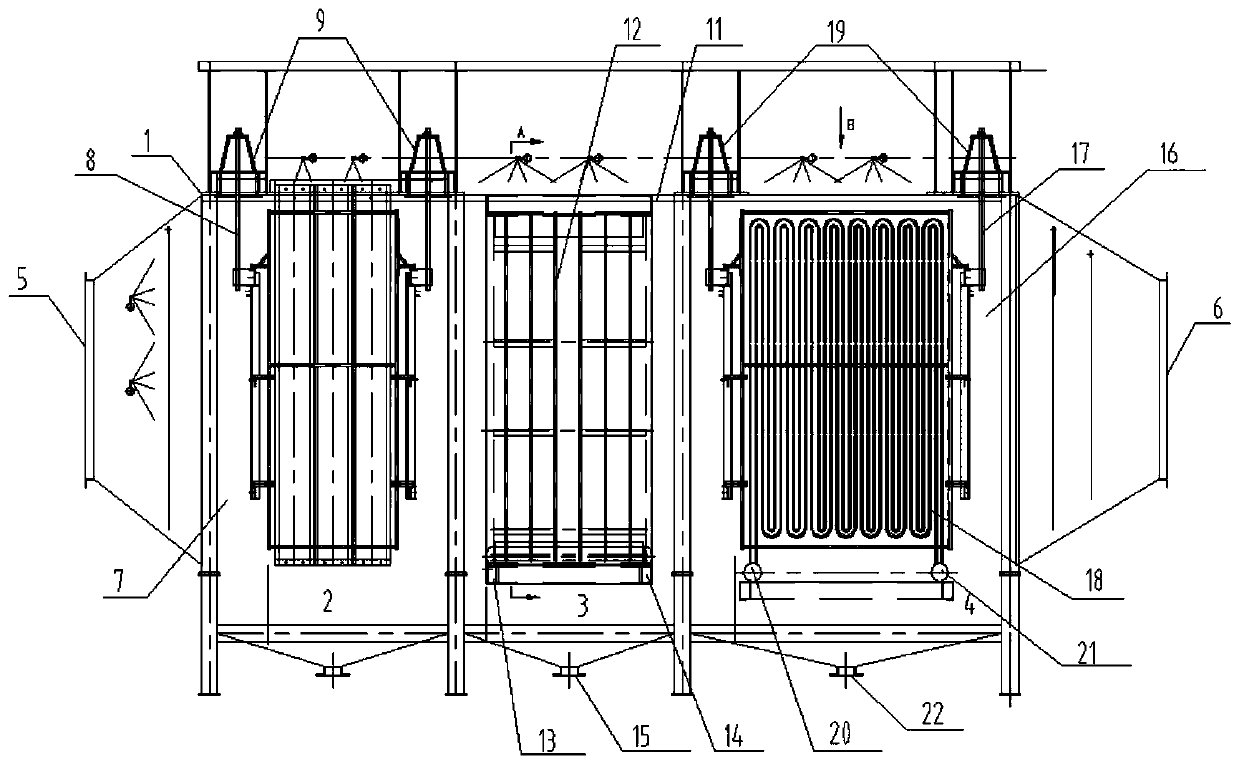

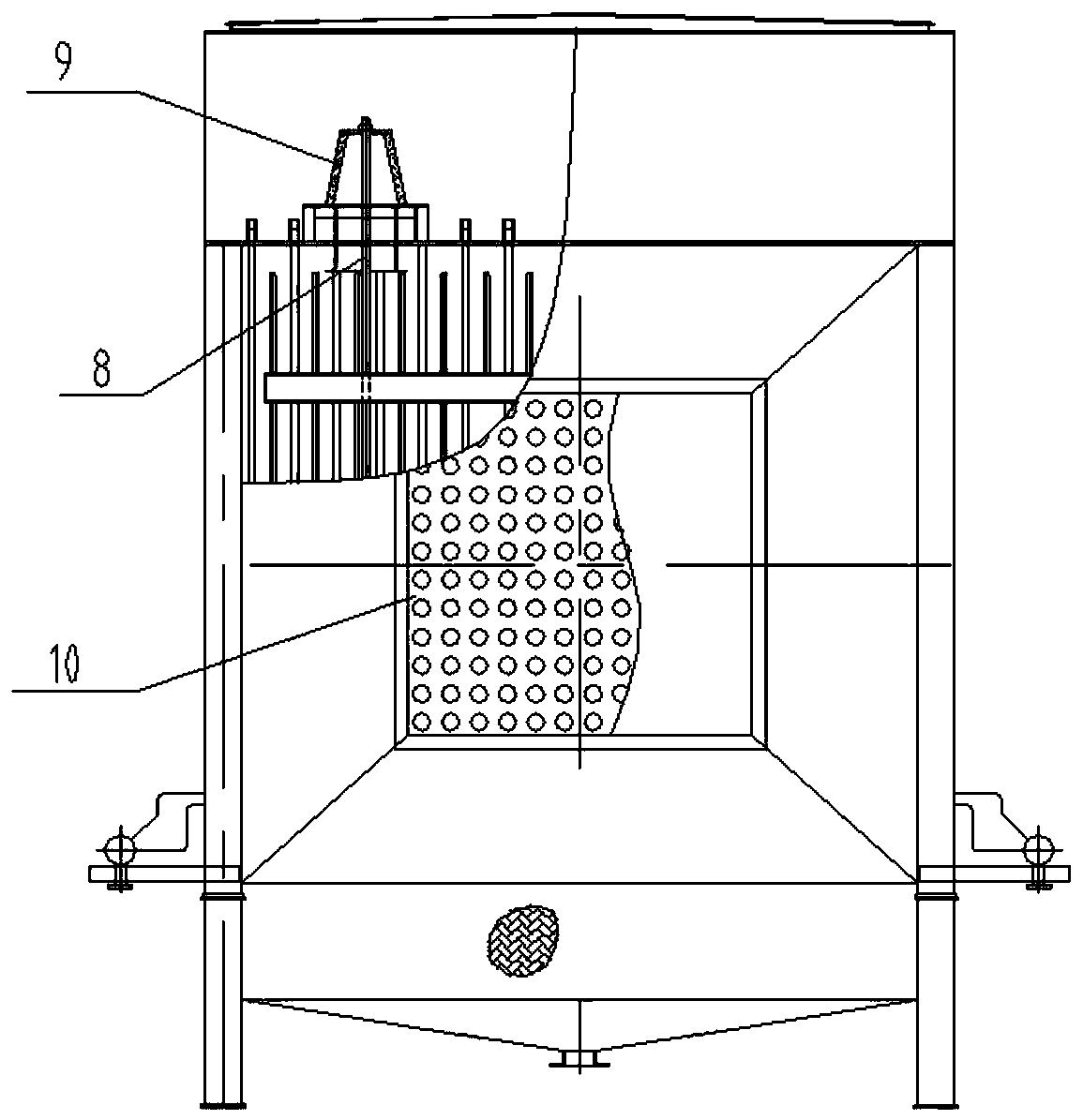

Parallel small diameter heat pipe enhanced heat exchange device for recovering medium and low temperature flue gas waste heat and preparation method thereof

ActiveCN110425510AImprove Primary UtilizationReduce heat pollutionIndirect heat exchangersCombustion technology mitigationExhaust gasProcess engineering

The invention relates to a parallel small diameter heat pipe enhanced heat exchange device for recovering medium and low temperature flue gas waste heat, aims to solve the problem of waste of medium and low temperature flue gas waste heat generated in small combustion equipment primarily, recovers the flue gas waste heat by means of parallel small diameter heat pipes to produce hot water or heat other substances, and is suitable for recovering waste heat of small flow flue gas or a discontinuous small flow heat source. The parallel small diameter heat pipe enhanced heat exchange device is primarily characterized in that the parallel small diameter heat pipe enhanced heat exchange device is good in heat transfer property, compact in structure, small in size, easy to process and low in cost,and can achieve self transfer of heat and efficient recovery of waste heat, so that the exhaust gas temperature is reduced greatly and the integral efficiency of the system is improved. The device isquite suitable for heat recovery of small capacity medium and low temperature flue gas waste heat and discontinuous waste heat resources, and a heating container is taken conveniently.

Owner:NANJING UNIV OF TECH +1

MVR falling film evaporator

PendingCN112933627AFull Coverage GuaranteedEasy to updateEvaporation with vapour compressionEvaporator accessoriesThermodynamicsMechanical engineering

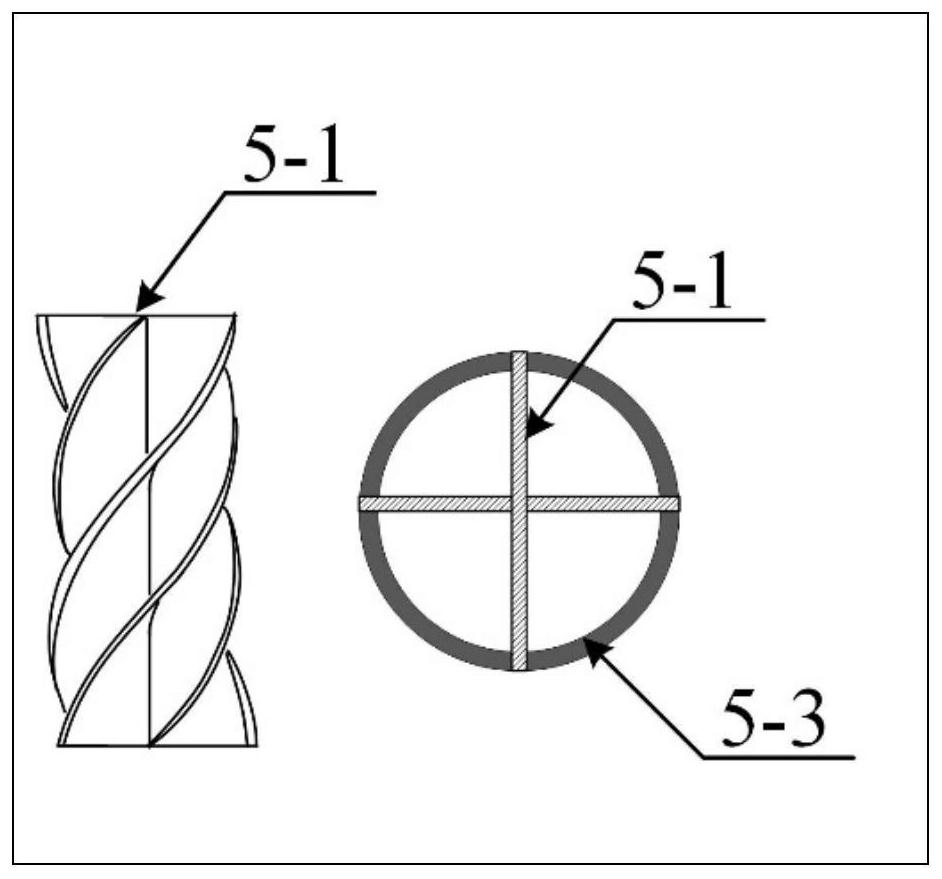

The invention discloses an MVR falling film evaporator. The evaporator comprises a steam inlet pipe, an upper pipe plate, a film distributor, a barrel, a spiral distortion heat exchange pipe, a condensate outlet pipe, a lower pipe plate, a confluence chamber and a separation chamber; the film distributor is connected to the upper end of the barrel through the upper pipe plate, the confluence chamber is connected to the lower end of the barrel through the lower pipe plate, the steam inlet pipe is communicated with the upper part of the barrel, the condensate outlet pipe is communicated with the lower part of the barrel, and the side surface of the separation chamber is connected with the confluence chamber through a steam-liquid channel; and the multiple spiral distortion heat exchange pipes are laid in the barrel, and the two ends of each spiral distortion heat exchange pipe are installed on the upper pipe plate and the lower pipe plate correspondingly to form a heat exchange tube bundle communicating the film distributor with the confluence chamber. According to the falling film evaporator, a better film forming effect and a higher Reynolds number of a medium in the tube can be obtained, the processing capacity of the falling film evaporator is improved, the anti-scaling capacity and the anti-vibration capacity are high, a baffle plate is not needed, and the power consumption of the MVR compressor for overcoming steam resistance is reduced.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

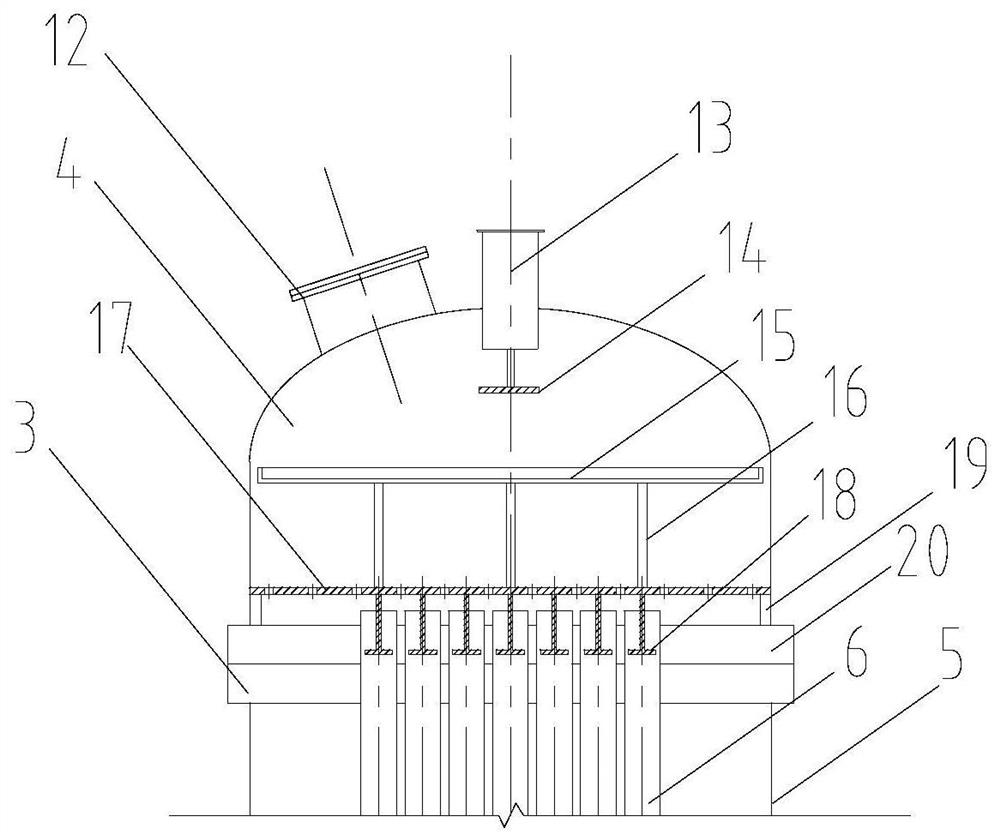

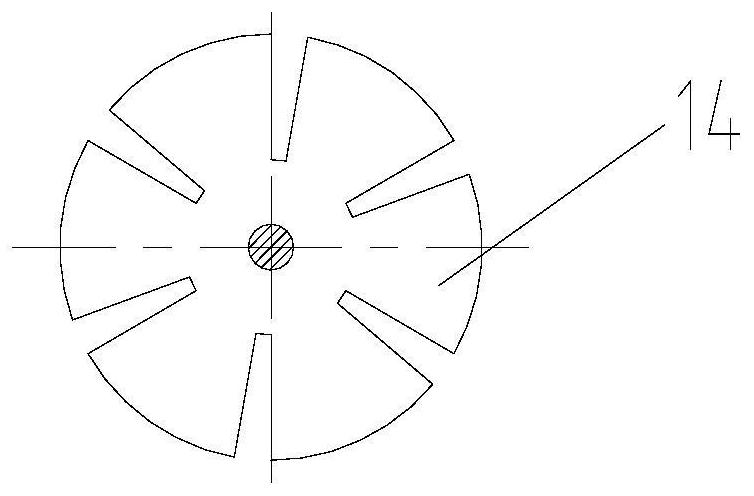

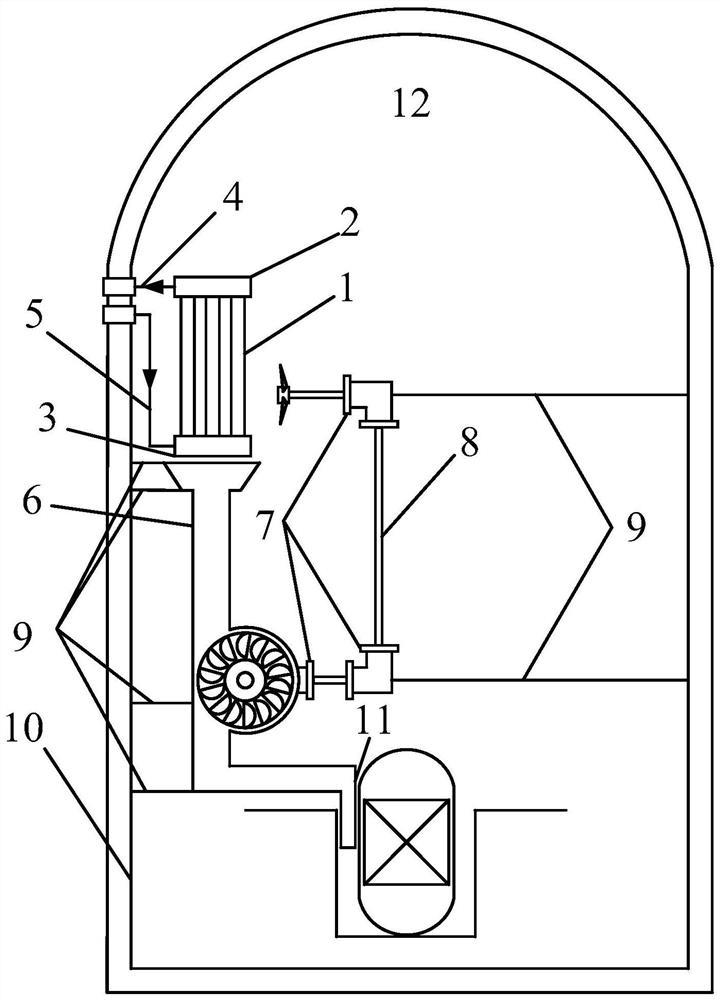

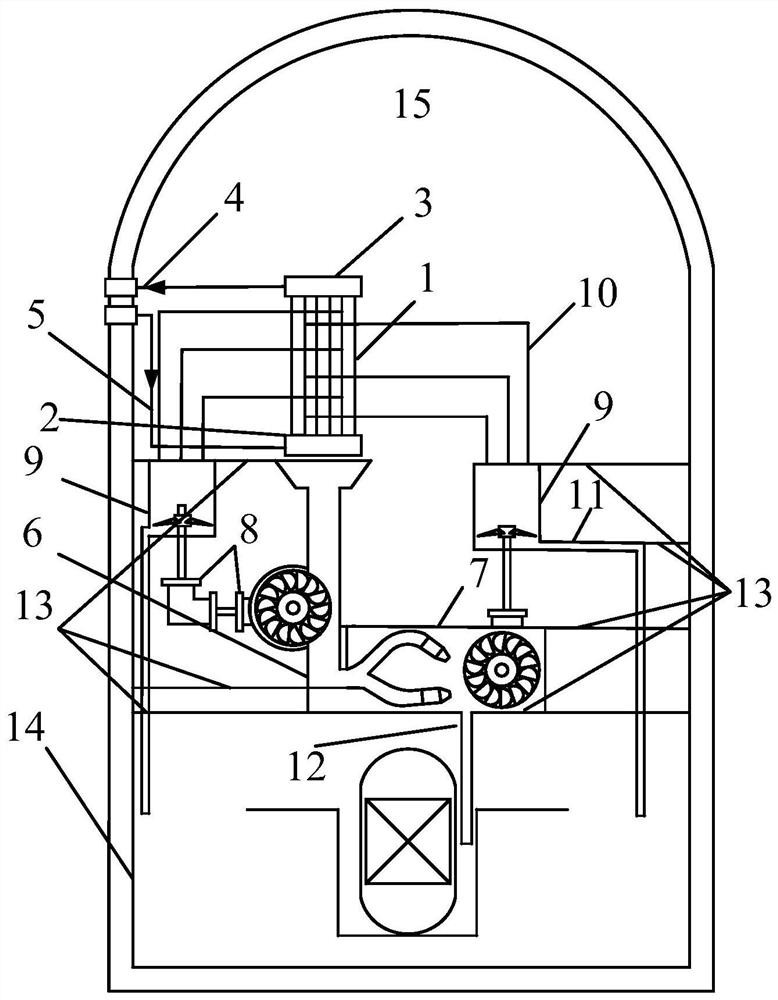

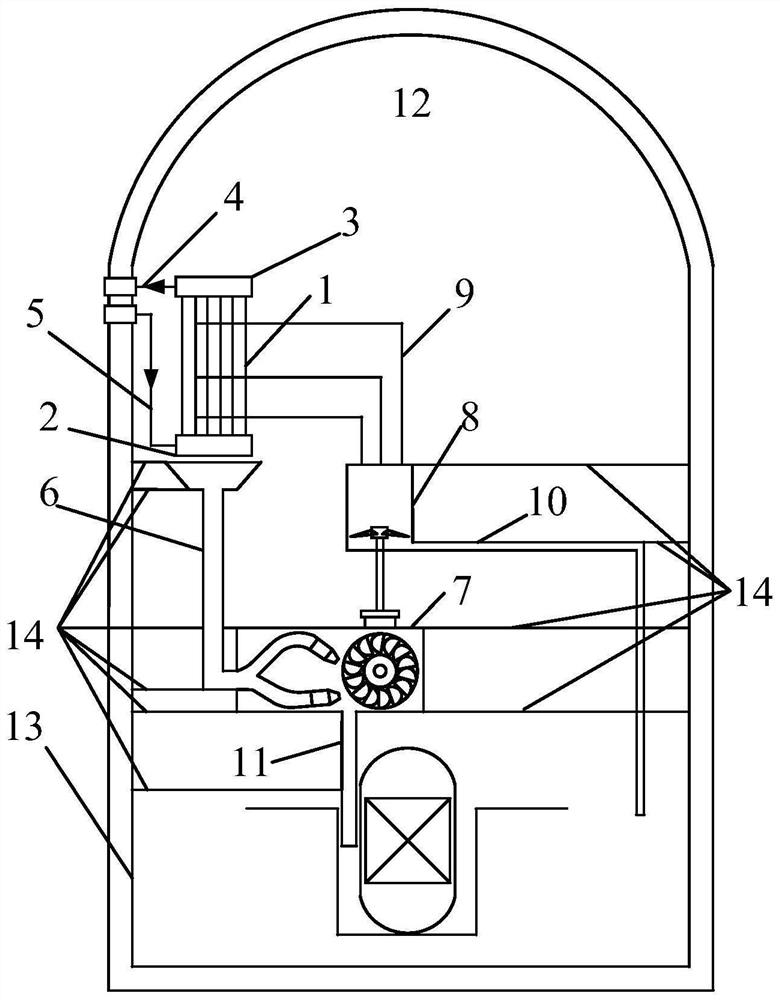

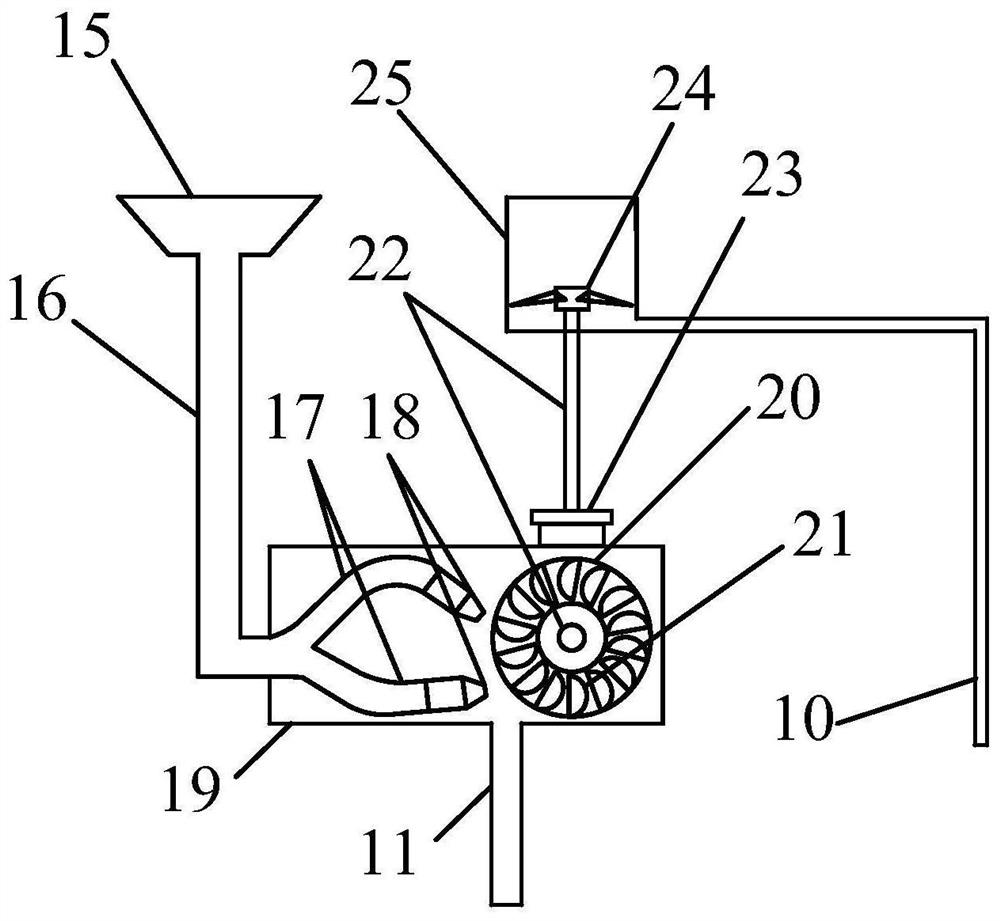

Containment built-in efficient heat exchanger adopting double-wheel double-blade hybrid power blowing

PendingCN113035396AEnhanced condensation heat transfer capacityIncrease contactNuclear energy generationCooling arrangementImpellerSteam condensation

The invention provides a containment built-in efficient heat exchanger adopting double-wheel double-blade hybrid power blowing. A self-flowing type blowing system comprises a water conveying structure, a water bucket type water wheel, a blowing structure, an exhaust pipe and a gear steering box. A cutting type air blowing system comprises a water conveying structure, a jet flow structure, an air blowing structure, a drainage pipe and an exhaust pipe. The two air blowing systems are arranged on the upper portion and the lower portion respectively to form a hybrid power air blowing system, potential energy of water flow generated by steam condensation can be converted into jet flow kinetic energy, air blowing impellers are driven to rotate, and therefore a non-condensable gas film near a heat exchange pipe is blown away, and steam is made to condense and exchange heat on the outer surface of the heat exchange pipe better. The composite blowing system can effectively thin a non-condensable gas film, enhance the contact between steam and a pipe bundle, realize efficient heat transfer, ensure efficient temperature and pressure reduction in the containment vessel under accident conditions, enhance the safety of the containment vessel and provide a feasible scheme for reducing the construction cost of the containment vessel.

Owner:HARBIN ENG UNIV

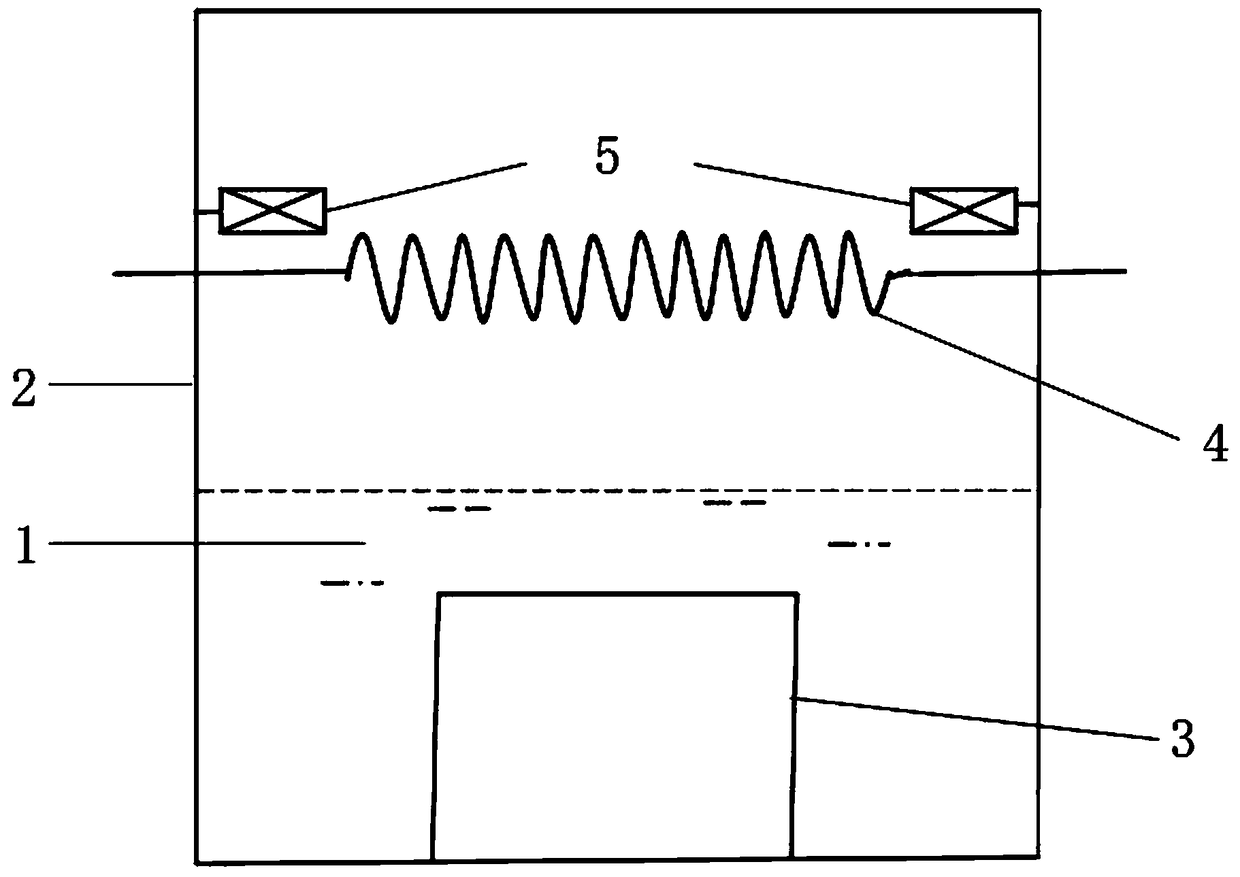

Immersion liquid cooling server, immersion liquid cooling method for server

ActiveCN104597994BImprove heat transfer effectAchieve cycleDigital data processing detailsLiquid cooling systemEvaporation

The invention relates to an immersed liquid cooling server and an immersed liquid cooling method for the server. The immersed liquid cooling server comprises a refrigerant groove, a heating element, a cooling element and a blower or a fan, wherein the refrigerant groove is used for accommodating refrigerants, the heating element is arranged in the refrigerant groove and is soaked by the refrigerants, the cooling element is positioned above the liquid level of the refrigerants, the blower or the fan is arranged above the cooling element, and the direction of airflow blown by the blower or the fan faces the cooling element. The immersed liquid cooling server has the forced condensing heat exchange effect. The immersed liquid cooling method for the server comprises the following steps that the refrigerants absorb heat of the heating element soaked into the refrigerants to form refrigerant steam through evaporation, and the refrigerants upwards flow; the cooling element carries out heat exchange with the upward flowing refrigerant steam, the refrigerant steam is condensed into refrigerant liquid drips, and the refrigerant liquid drips drip back into the refrigerant groove due to gravity effect; the air is downwards blown towards the cooling element through the blower or the fan. The method has the advantage that the condensed heat exchange of an immersed liquid cooling system is enhanced.

Owner:SUGON DATAENERGYBEIJING CO LTD

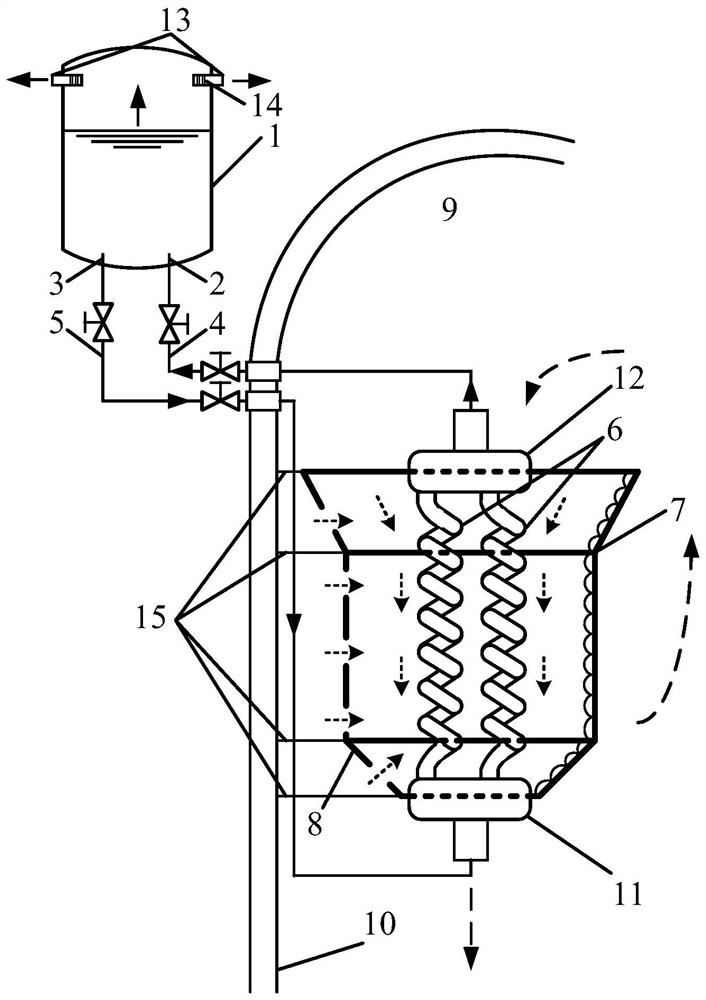

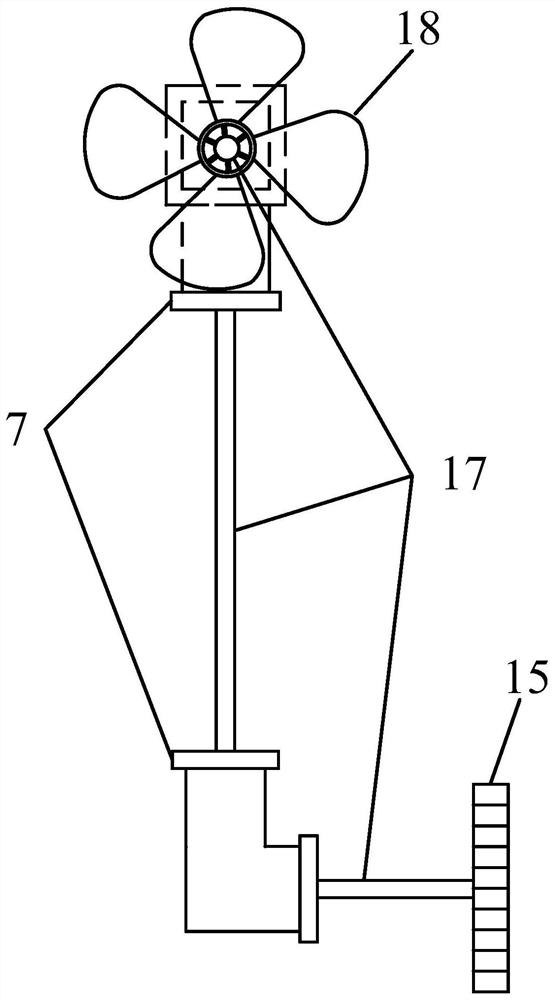

Self-driven drainage type containment built-in efficient heat exchanger

ActiveCN113035399AProtect the borderMaintain structural safetyNuclear energy generationCooling arrangementEngineeringThermal water

The invention provides a self-driven drainage type containment built-in efficient heat exchanger which adopts a spiral pipe enhanced heat exchange pipe, and a plurality of flow gathering plates are arranged on the periphery of the spiral pipe enhanced heat exchange pipe. One end of a containment built-in heat exchanger inlet pipeline is communicated with the outlet pipeline at the bottom of a containment external heat exchange water tank, and the other end extends into a containment and is communicated with a containment built-in heat exchanger inlet header. One end of the containment built-in heat exchanger outlet pipeline is communicated with the bottom inlet pipeline of the containment external heat exchange water tank, and the other end of the containment built-in heat exchanger outlet pipeline extends into the containment and is communicated with the containment built-in heat exchanger outlet header to form a passive containment cooling system. Heat in the containment can be efficiently taken away when a crevasse accident occurs in the containment, passive air natural circulation can be increased through the funnel-shaped structure formed by splicing the multiple flow gathering plates, efficient heat transfer is achieved, potential hazards caused by hydrogen blast to the containment and the heat exchanger can be restrained, and the integrity of the containment is guaranteed.

Owner:HARBIN ENG UNIV

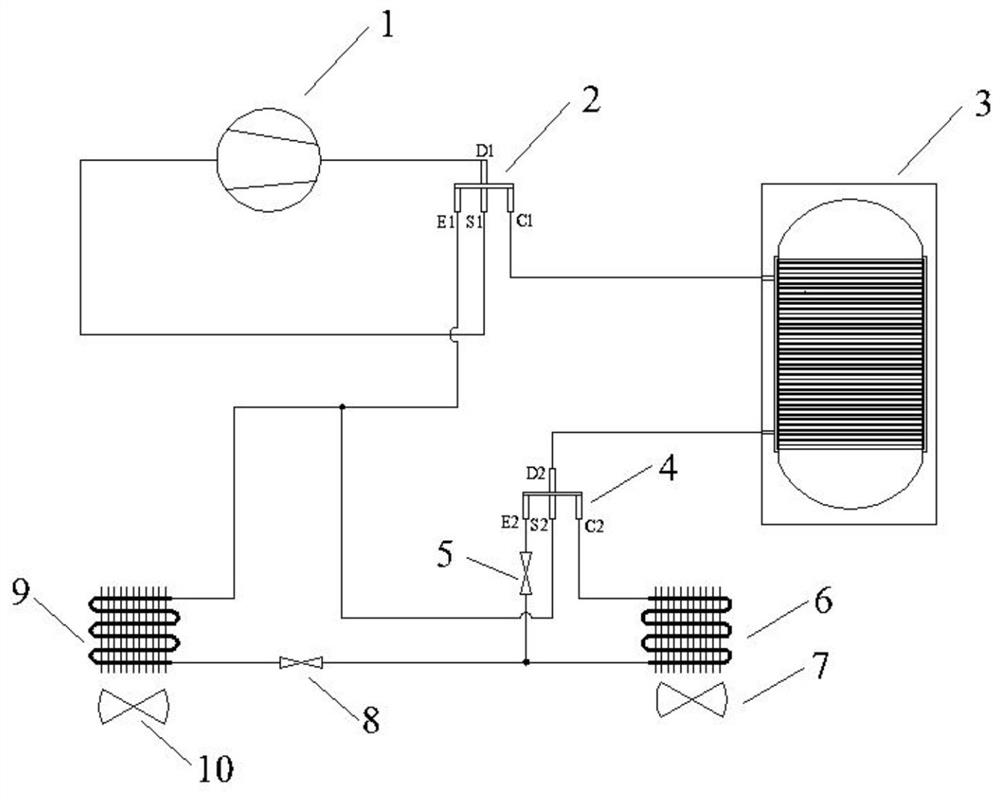

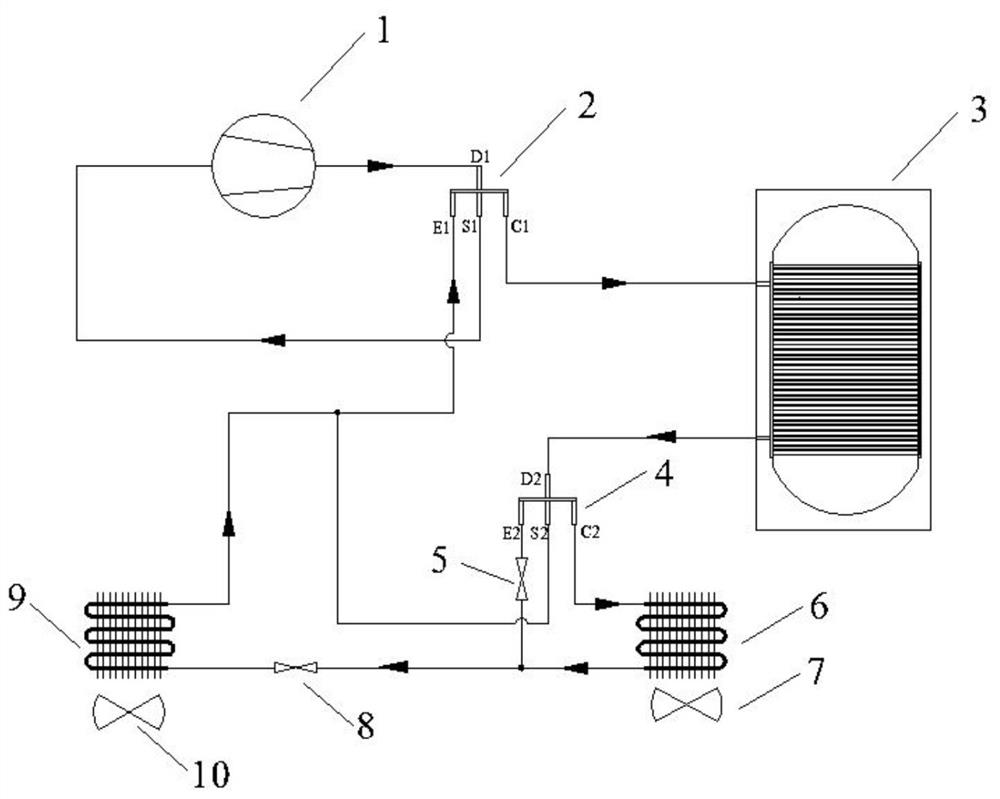

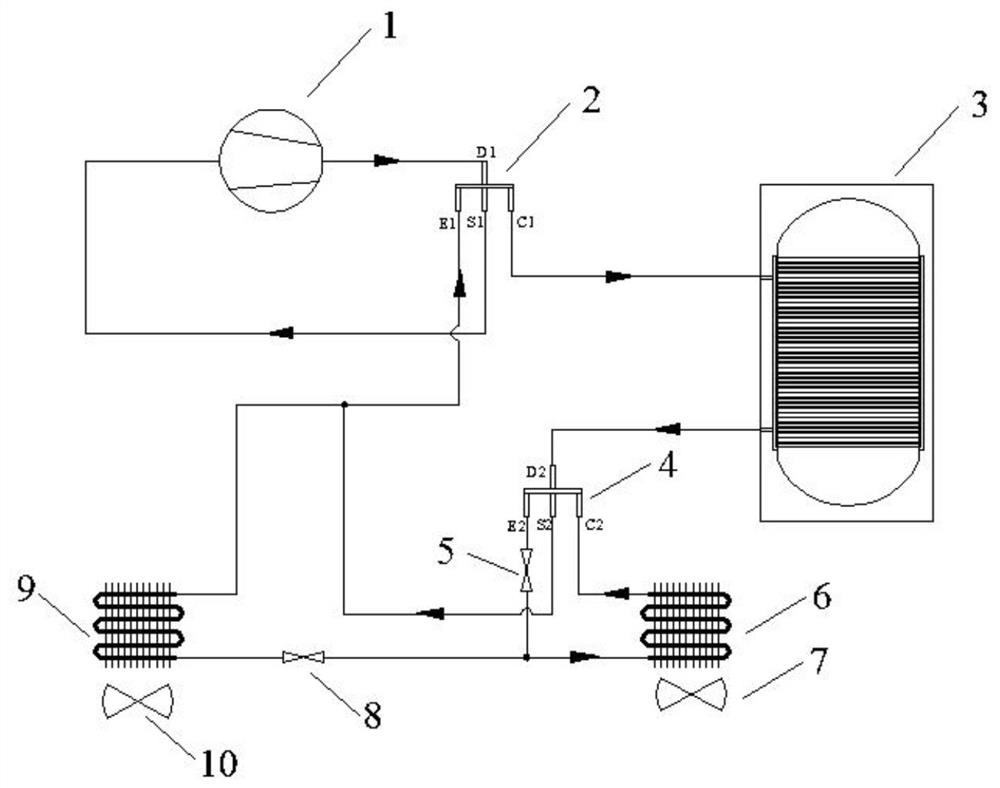

Air conditioner hot water system

PendingCN111735166ARealize condensation heat dissipationAchieve heat recoveryEnergy recovery in ventilation and heatingMechanical apparatusEngineeringThermal water

The invention discloses an air conditioner hot water system. The system comprises a compressor, a first four-way valve, a condenser water tank, a second four-way valve, an outdoor heat exchanger and an indoor heat exchanger, and interfaces D1, E1, S1 and C1 of the first four-way valve are connected with an exhaust port of the compressor, one end of the indoor heat exchanger, an air suction port ofthe compressor and an inlet of the condenser water tank correspondingly; interfaces D2 and C2 of the second four-way valve are respectively connected with the condenser water tank and an outlet at one end of the outdoor heat exchanger, and the other end of the indoor heat exchanger is connected with the other end of the outdoor heat exchanger; the E2 connector and the S2 connector of the second four-way valve are in bypass connection between the indoor heat exchanger and the E1 of the first four-way valve and between the indoor heat exchanger and the outdoor heat exchanger respectively, condensation waste heat of the system can be recycled to produce hot water, and heat recovery is effectively achieved.

Owner:广东高而美制冷设备有限公司

Phase separation micro-channel condenser

ActiveCN103335549BOvercome the disadvantage of being unable to control the two-phase flow patternReduce thicknessIndirect heat exchangersCooling/ventilation/heating modificationsEngineeringHeat sink

The invention discloses a phase separation micro-channel condenser and belongs to the field of the heat transfer enhancement technology. A plurality of parallel micro-channels are etched on a silicon substrate and are separated by rib sheets. A plurality of rib strips are etched in the downstream area of each micro-channel. The rib strips of each micro-channel form, in an enclosing mode, a rib strip net with an opening toward the downstream. A cover plate packages on the micro-channels. The phase separation micro-channel condenser overcomes the defect that a traditional micro-channel condenser can not modulate a two phase flow pattern. Different from other reinforcing condensing heat conduction devices, due to the fact that an air phase and a liquid phase flow in branch paths after flow pattern modulation, the phase separation micro-channel condenser can greatly reduce the thickness of a liquid film, improve condensing heat exchange performance, reduce flow resistance and flow instability, and be applied to an electronic element heat-sink cooling system.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

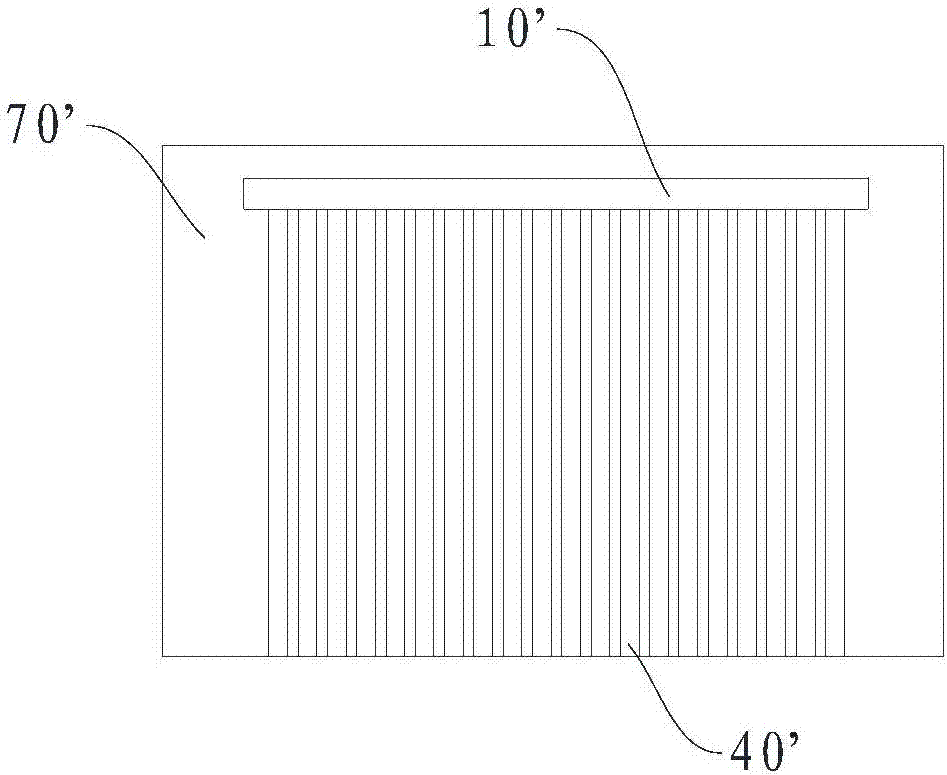

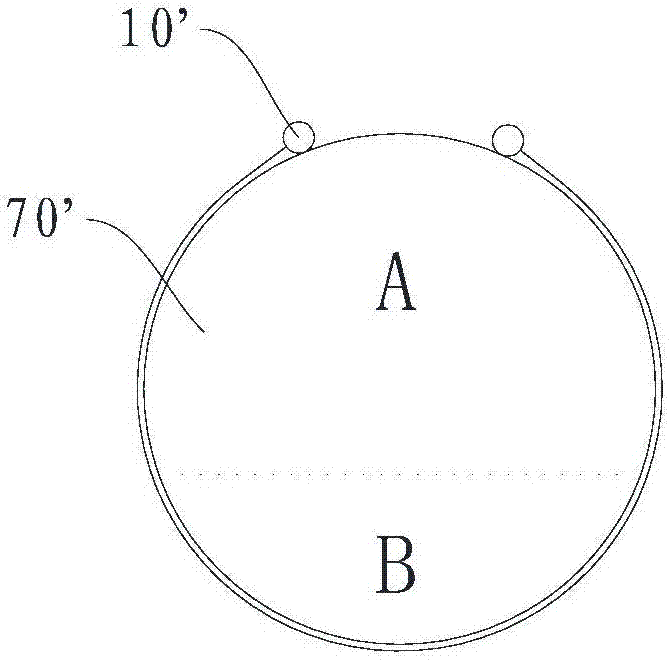

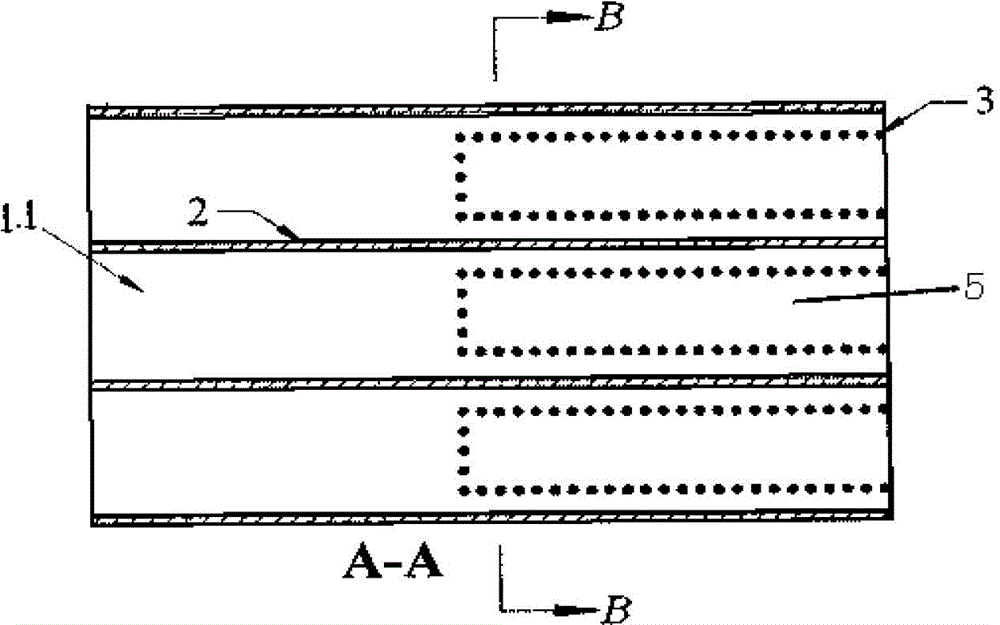

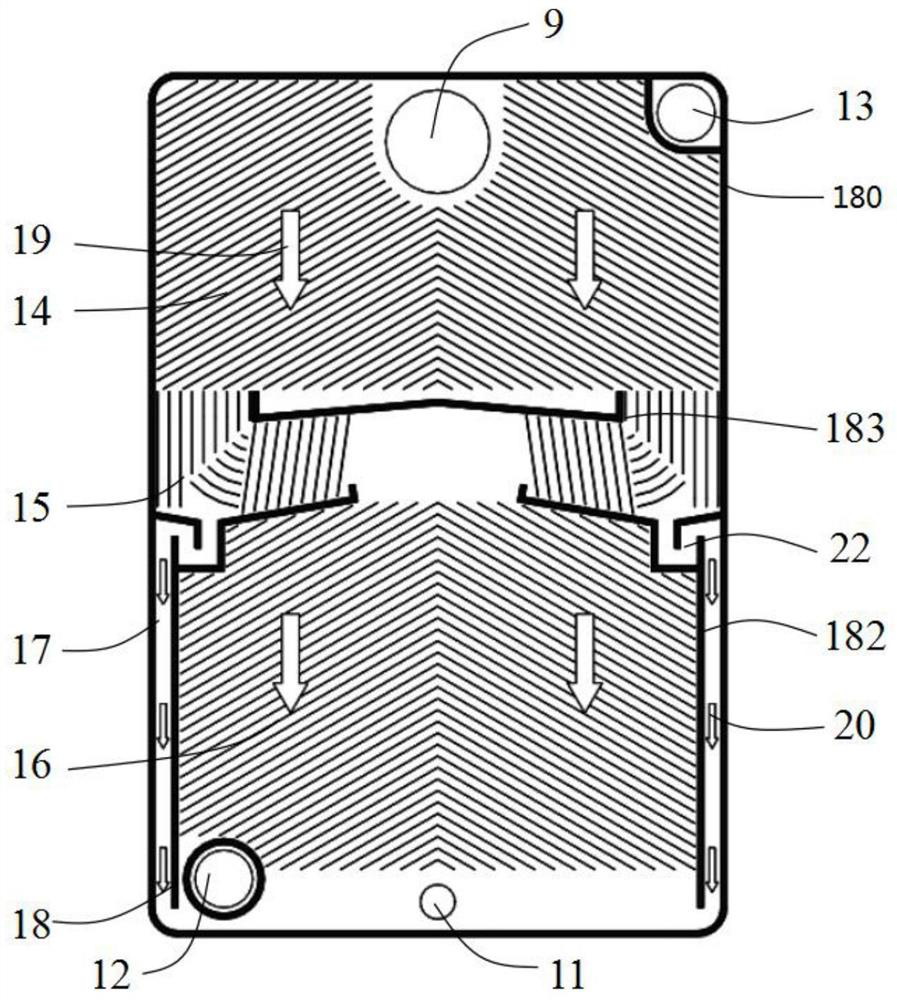

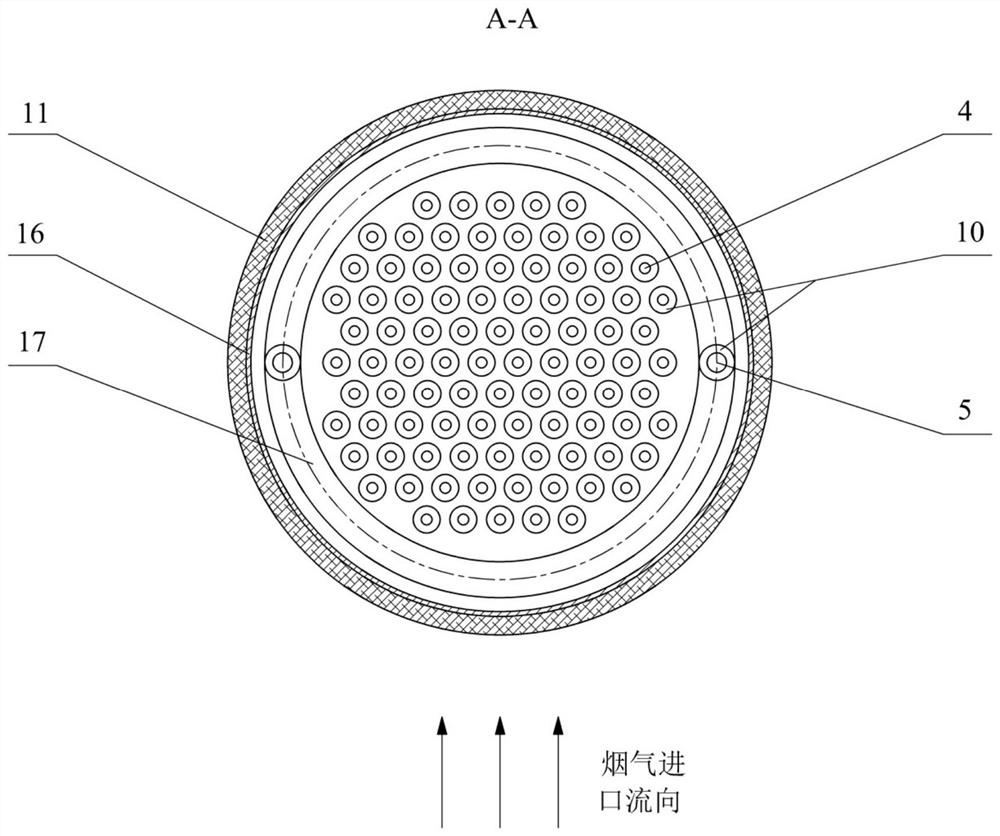

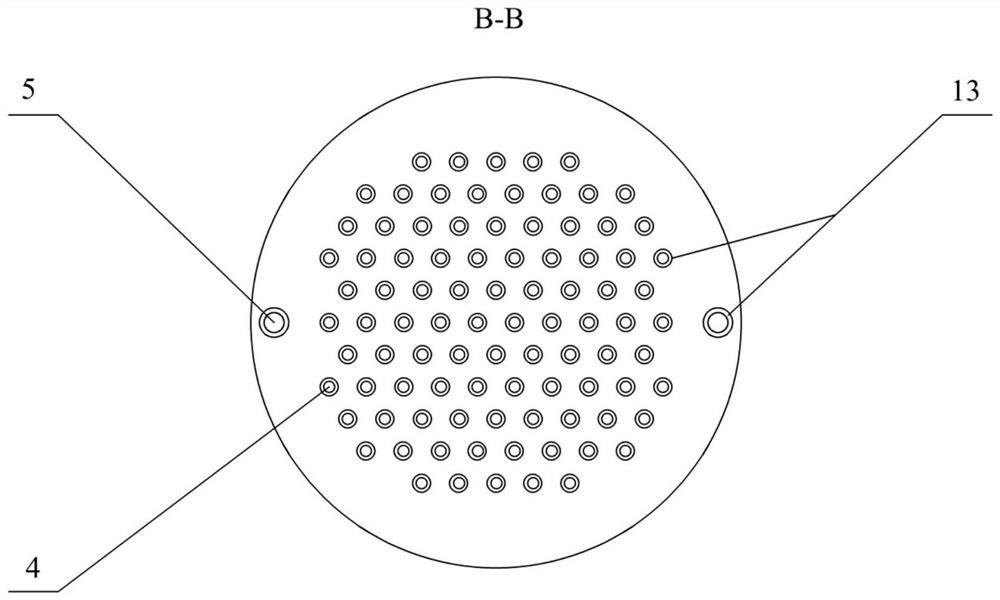

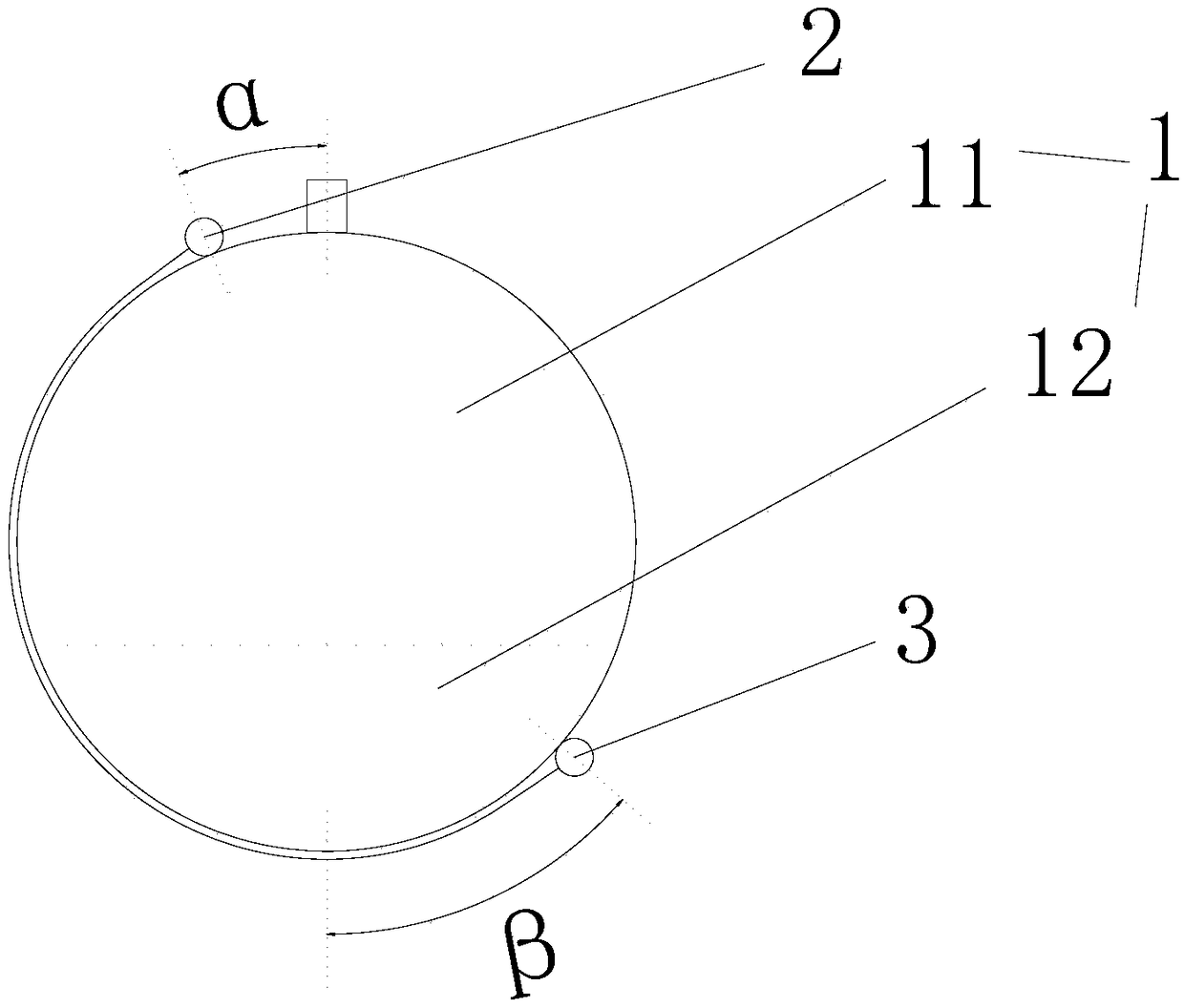

A liquid separation phase change plate heat exchanger and its application

ActiveCN109442806BPrevent scalingReduce thicknessEvaporators/condensersLaminated elementsWorking fluidPlate heat exchanger

A liquid-separating phase-changing plate heat exchanger and an application thereof, comprising a mobile pressing plate (1), a fixed pressing plate (2), at least one heat exchange plate (3) and a plurality of seal gaskets, wherein the heat exchange plates (3) are disposed between the mobile pressing plate (1) and the fixed pressing plate (2); the seal gaskets are disposed between the mobile pressing plate (1) and the heat exchange plates (3) as well as between the fixed pressing plate (2) and the heat exchange plates (3), or directly between adjacent heat exchange plates (3), so as to form passageways; the passageways are working fluid passageways (24) and cold and heat source fluid passageways (25); the working fluid passageways (24) are internally provided with a first heat exchange zone (14), a middle zone (15) and a second heat exchange zone (16); and liquid guide chutes (17) and first U-shaped channels (22) are provided at two sides of the second heat exchange zone (16). When the plate heat exchanger is used as a condenser, the thickness of a condensate film is reduced, the thermal resistance for condensing heat transfer is also reduced, and the condensing heat transfer effect is improved. When the present heat exchanger is used as an evaporator, steam and a liquid working medium may be well mixed, the steam dryness in the first heat exchange zone (14) is reduced, the heat transfer coefficient is raised, and an evaporation heat transfer effect is thus improved.

Owner:GUANGDONG UNIV OF TECH

A kind of gravity heat pipe device and preparation method

InactiveCN105973044BEnhanced condensation heat transfer capacityReduce condensation thermal resistanceIndirect heat exchangersMicro structureNano structuring

The invention discloses a gravity assisted heat pipe device which comprises an evaporator, a heat insulation segment and a condenser. The evaporator and the condenser are in sealed connection with the heat insulation segment. The inner surface of the evaporator is a super-hydrophilic surface. The inner surface of the condenser is a smooth lubricant implanted porous surface (SLIPS). Lubricant on the SLIPS and a charged working medium cannot be mixed. A super-hydrophilic surface of a nano-micro structure is arranged on the inner wall of the evaporator, the working medium can completely moisten the wall face, a liquid film evaporates in the heating process, the evaporation intensity is improved, and the SLIPS of the condenser is formed by compounding the super-hydrophilic of a nano structure with implanted fluorine-containing lubricant or silicone oil or ionic liquid. Condensed liquid drops float on the SLIPS, are combined, fast fall off the SLIPS and sweep small liquid drops on the path of the condensed liquid drops, a condensation surface is provided for secondary condensation, and the condensation and heat exchange effect is remarkably improved. According to the gravity assisted heat pipe device, heat pipe heat resistance can be effectively reduced, the heat exchange performance of the device is improved, and wide application prospects are achieved.

Owner:SHANGHAI JIAO TONG UNIV

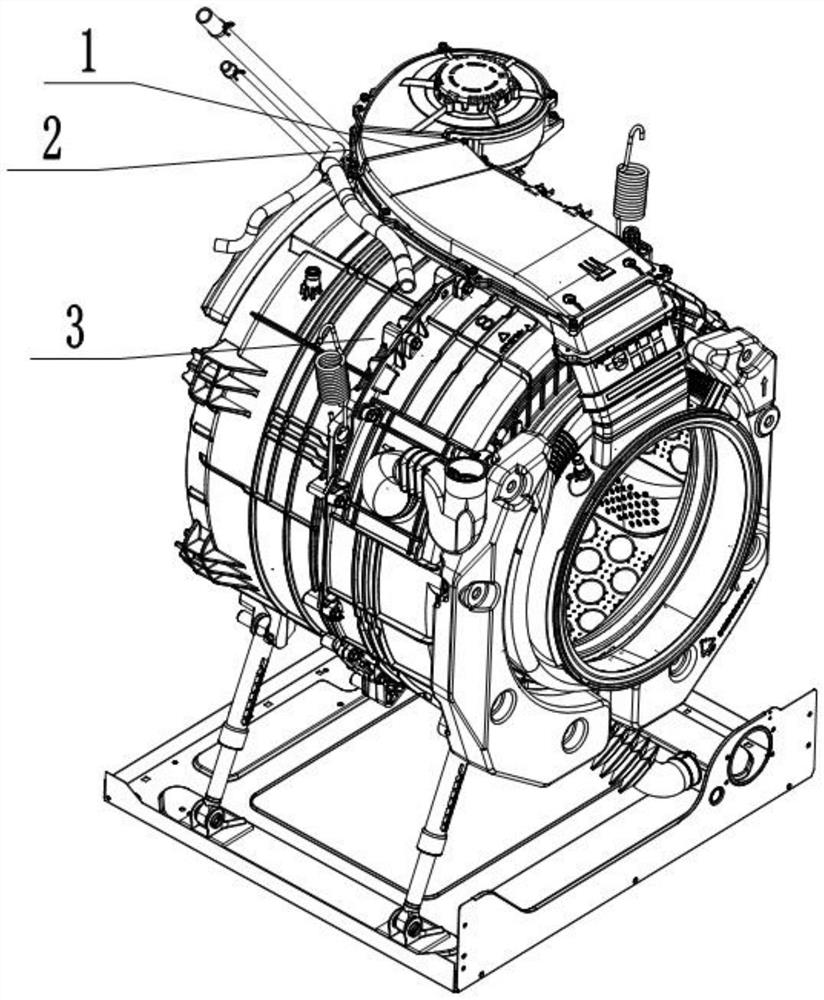

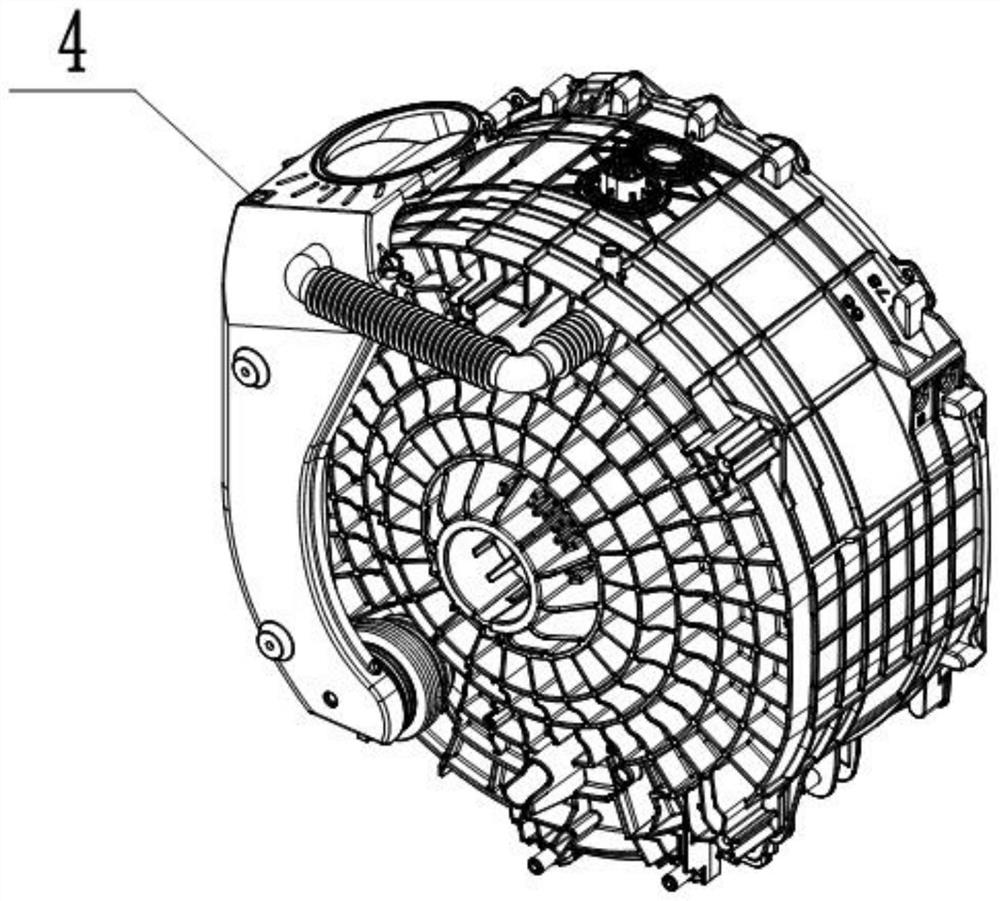

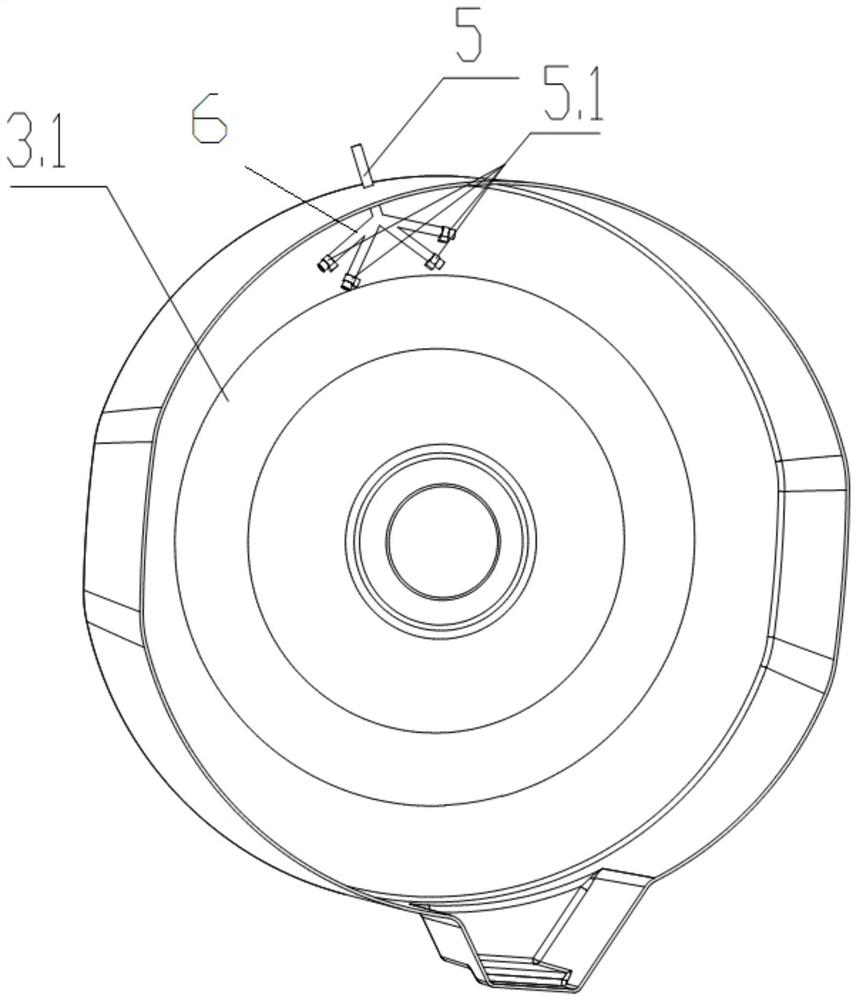

Drying control method of clothes care device and clothes care device

ActiveCN114775225AAvoid damageIncrease the number ofControl devices for washing apparatusWashing machine with receptaclesProcess engineeringDry heat

The invention provides a drying control method of a clothes care device and the clothes care device. The control method comprises the steps that detection is conducted, specifically, the return air temperature of an air duct is detected through a temperature sensor; a judgment step: judging whether the washing and drying machine is at the end of the heating stage or the end stage of the drying stage in the drying process according to the return air temperature; a control step: when the temperature rise stage of the washing and drying machine in the drying process is finished, controlling to increase the number of the opened condensate water branches; and when the washing and drying machine is in the end stage of the drying process, the number of the opened condensate water branches is controlled to be reduced. The condensation heat exchange degree can be adjusted according to the heat exchange degree needed by the clothes, so that it is guaranteed that appropriate energy can be provided, energy waste is avoided, the drying heat exchange effect is reduced in the drying ending stage, damage to the clothes can be effectively reduced, and the use experience of a user can be effectively improved.

Owner:GREE ELECTRIC APPLIANCES INC

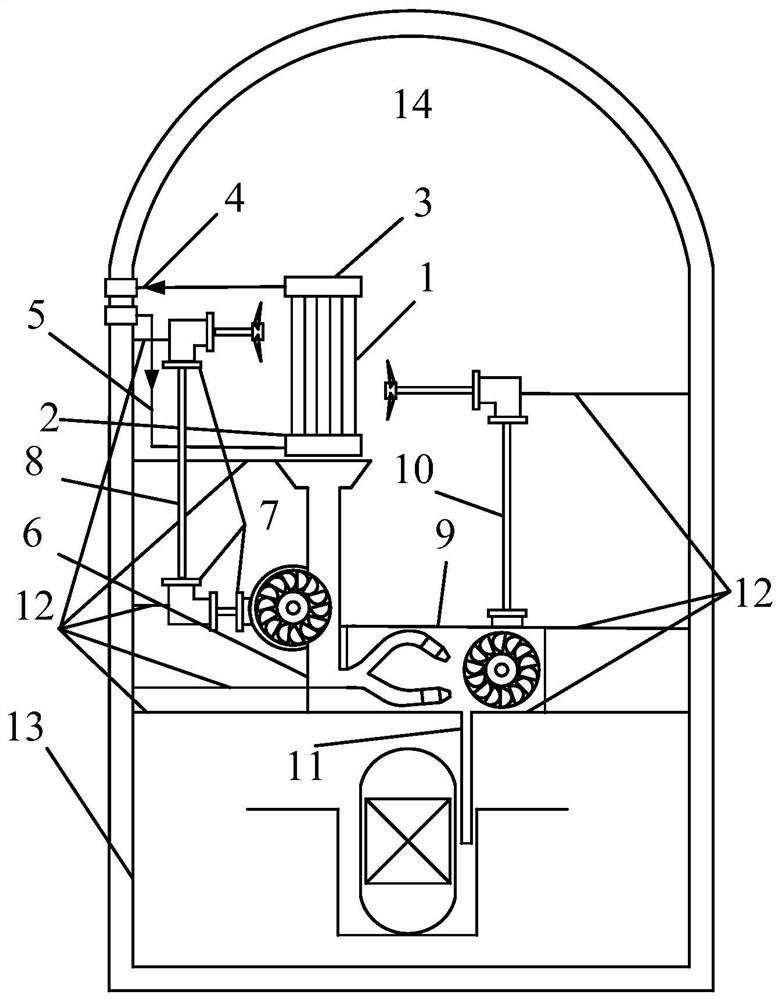

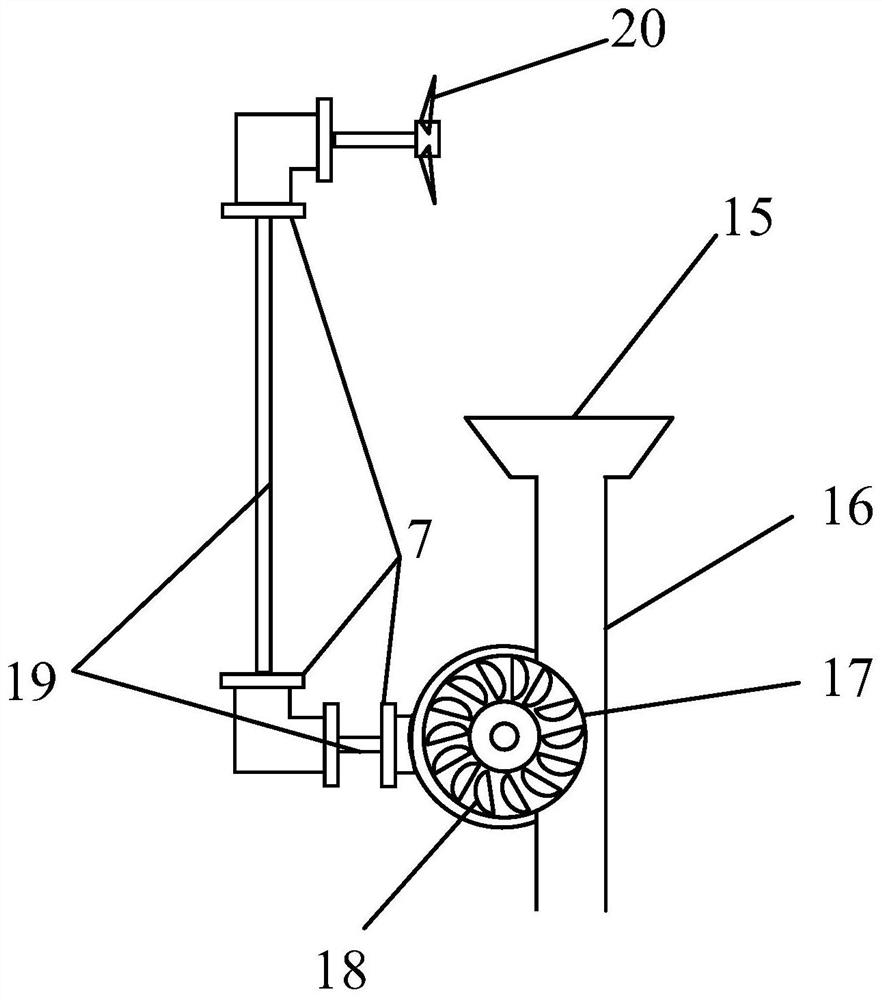

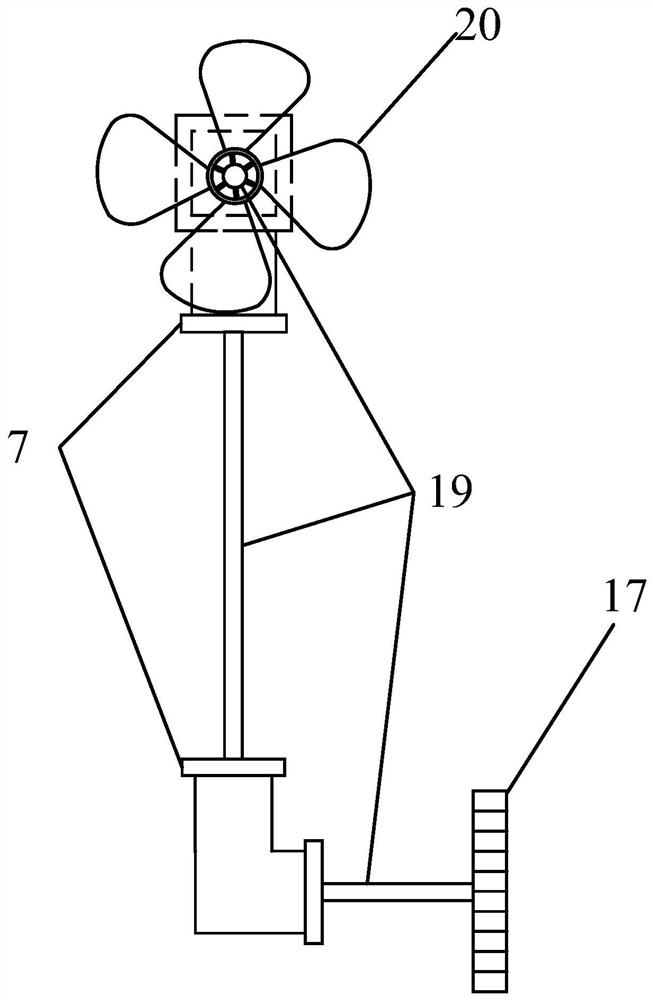

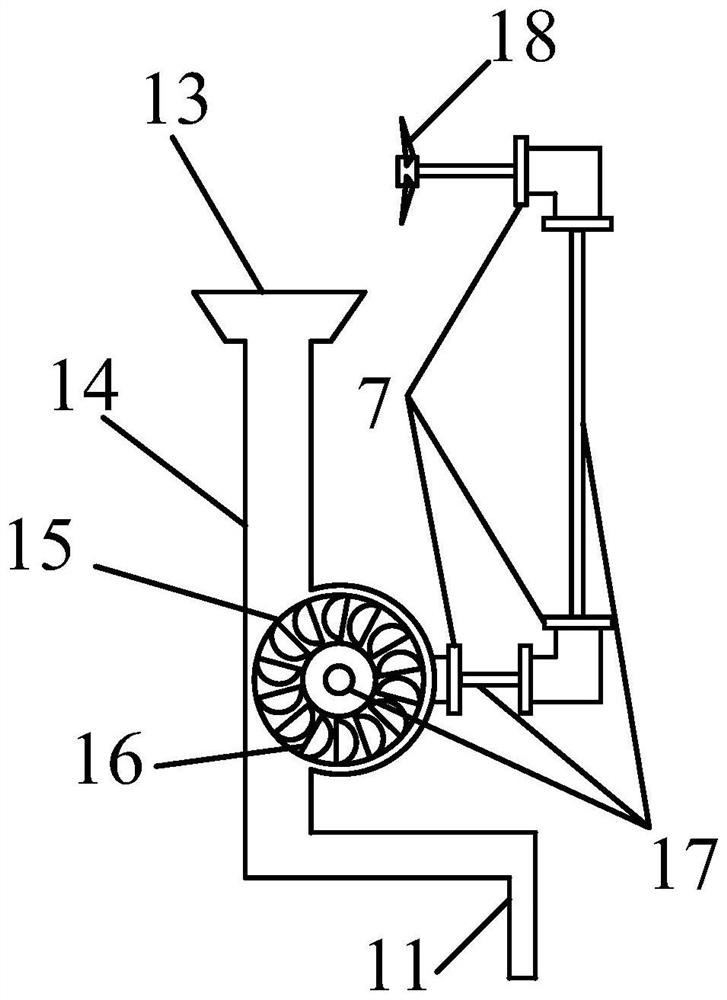

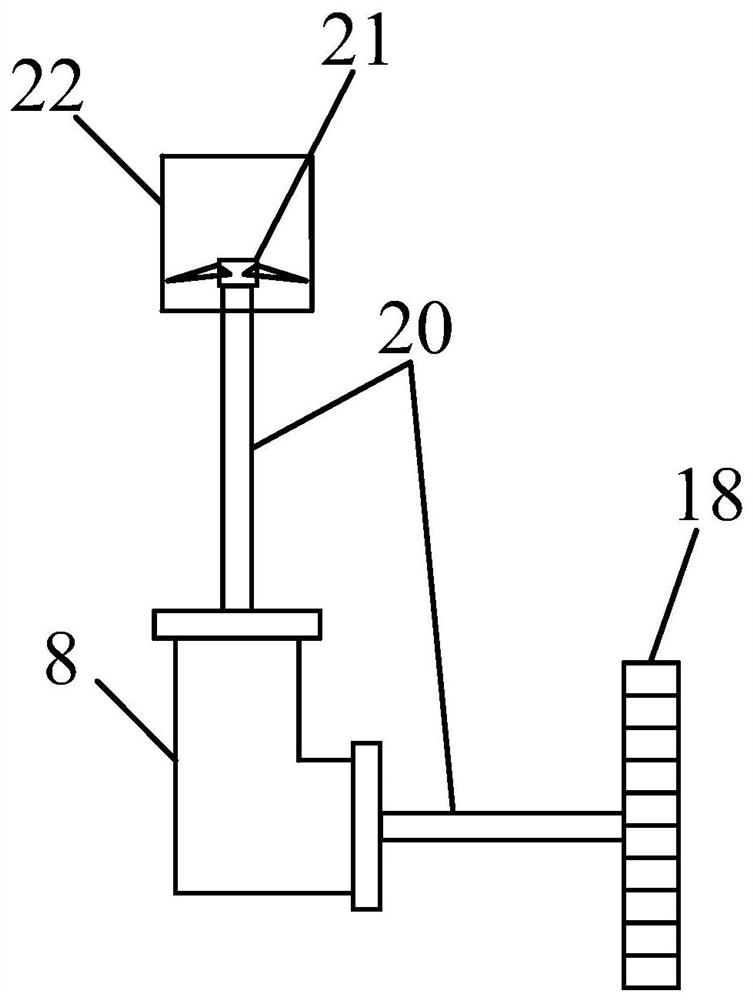

Containment built-in efficient heat exchanger adopting self-flowing type air blowing system

PendingCN113035395AEnhanced condensation heat transfer capacityReduce thicknessNuclear energy generationCooling arrangementImpellerSteam condensation

The invention provides a containment built-in efficient heat exchanger adopting a self-flowing type air blowing system. The containment built-in efficient heat exchanger mainly comprises a heat exchanger inlet header, heat exchange tubes, a heat exchanger outlet header and the self-flowing type air blowing system. The self-flowing type air blowing system comprises a water conveying structure, a water bucket type water wheel, an air blowing structure, a drainage pipe and a gear steering box. The self-flowing type air blowing system can convert potential energy of water flow of steam condensation into jet flow kinetic energy to drive the air blowing impeller to rotate, so that a non-condensable gas film near the heat exchange pipe is blown away, and the steam can be better condensed and exchange heat on the outer surface of the heat exchange pipe. The heat in the containment can be efficiently taken away when a crevasse accident occurs in the containment, a non-condensable gas film can be effectively thinned by utilizing the self-flow blowing system, the contact between steam and a pipe bundle is enhanced, efficient heat transfer is realized, efficient temperature and pressure reduction in the containment under the accident condition can be ensured, and the safety of the containment is ensured. The safety of the containment is enhanced; and a feasible scheme is provided for reducing the construction cost of the containment.

Owner:HARBIN ENG UNIV

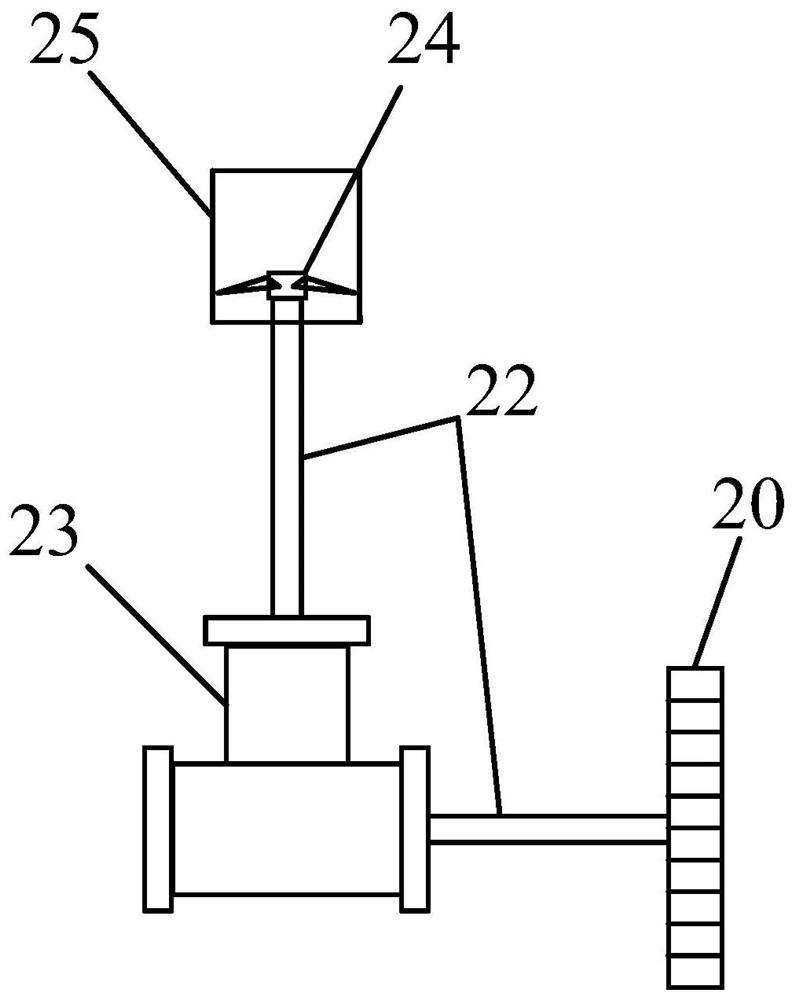

Containment built-in efficient heat exchanger adopting double-wheel double-blade hybrid power air suction

ActiveCN113035386AEnhanced condensation heat transfer capacityIncrease contactNuclear energy generationCooling arrangementSteam condensationSuction force

The invention provides a containment built-in efficient heat exchanger adopting double-wheel double-blade hybrid power air suction, which mainly comprises a heat exchanger inlet header, a heat exchange tube, a heat exchanger outlet header, a self-flowing type air-breathing system and a cutting type air-breathing system. The self-flowing type air suction system comprises a water conveying structure, a water bucket type water wheel, an air suction structure, an exhaust pipe and a gear steering box. The cutting type air suction system comprises a water conveying structure, a jet flow structure, an air suction structure, a drainage pipe and an exhaust pipe. The two air suction systems are arranged on the upper portion and the lower portion respectively to form a hybrid power air suction system, potential energy of water flow generated by steam condensation can be converted into jet flow kinetic energy, an air suction structure is driven to rotate, and suction force is generated, so that a non-condensable gas film near a heat exchange pipe is sucked away, and steam is made to condense and exchange heat on the outer surface of the heat exchange pipe better. When a crevasse accident occurs in the containment, heat in the containment can be efficiently taken away, contact between steam and a pipe bundle is enhanced, and efficient heat transfer is achieved.

Owner:HARBIN ENG UNIV

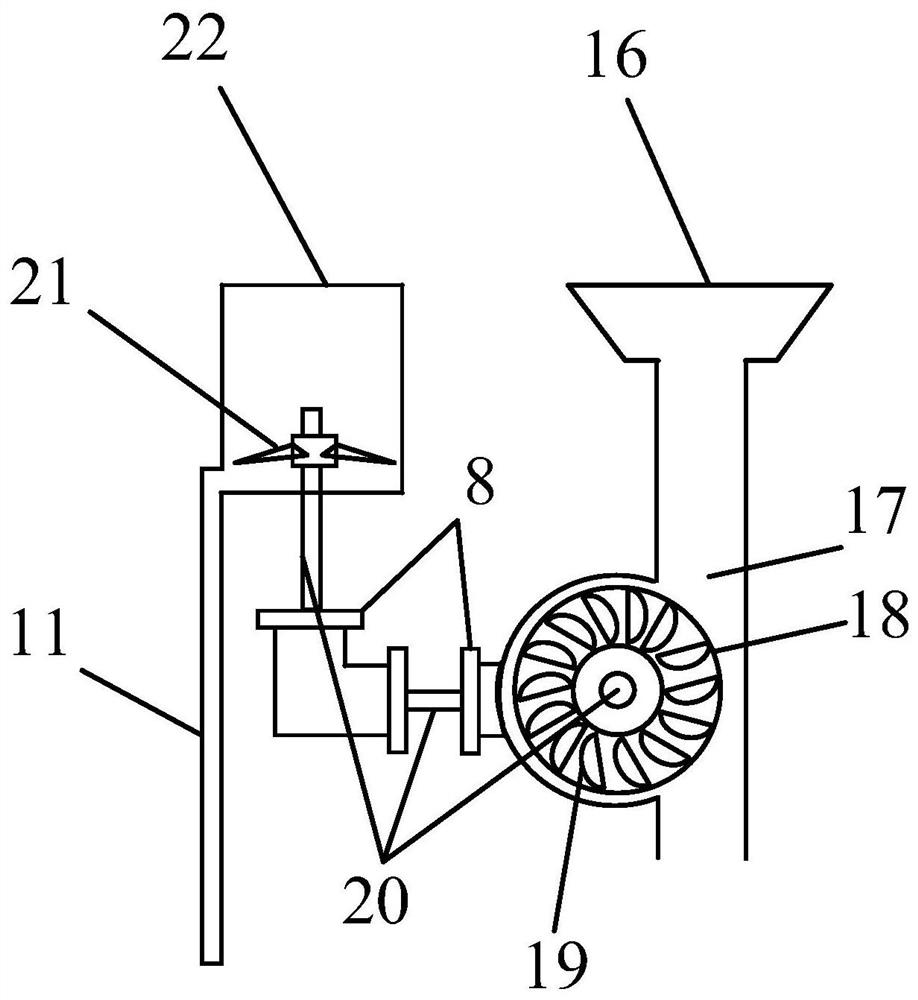

Containment built-in efficient heat exchanger adopting cutting type air suction system

PendingCN113035397AEnhanced condensation heat transfer capacityIncrease contactNuclear energy generationCooling arrangementSteam condensationSuction force

The invention provides a containment built-in efficient heat exchanger adopting a cutting type air suction system. The cutting type air suction system comprises a water conveying structure, a jet flow structure, an air suction structure, a drainage pipe and an exhaust pipe. The cutting type air suction system can convert water flow potential energy of steam condensation into jet flow kinetic energy to drive the air suction structure to rotate to generate suction force, so that a non-condensable gas film near the heat exchange pipe is sucked away, and steam can be better condensed on the outer surface of the heat exchange pipe for heat exchange. The heat in the containment can be efficiently taken away when a crevasse accident occurs in the containment, a non-condensable gas film can be effectively thinned by utilizing the cutting type air suction system, the contact between steam and a pipe bundle is enhanced, efficient heat transfer is realized, efficient temperature and pressure reduction in the containment can be ensured under the accident condition, and the safety of the containment is ensured. The safety of the containment is enhanced; and a feasible scheme is provided for reducing the construction cost of the containment.

Owner:HARBIN ENG UNIV

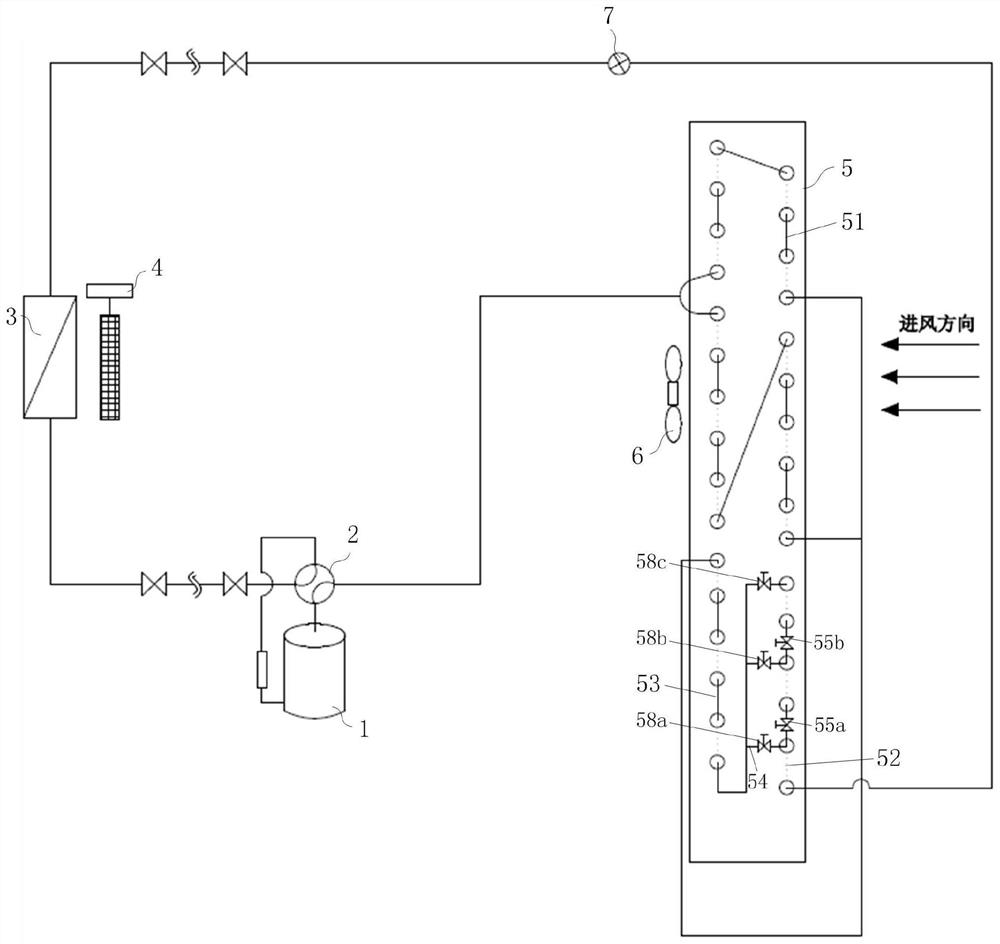

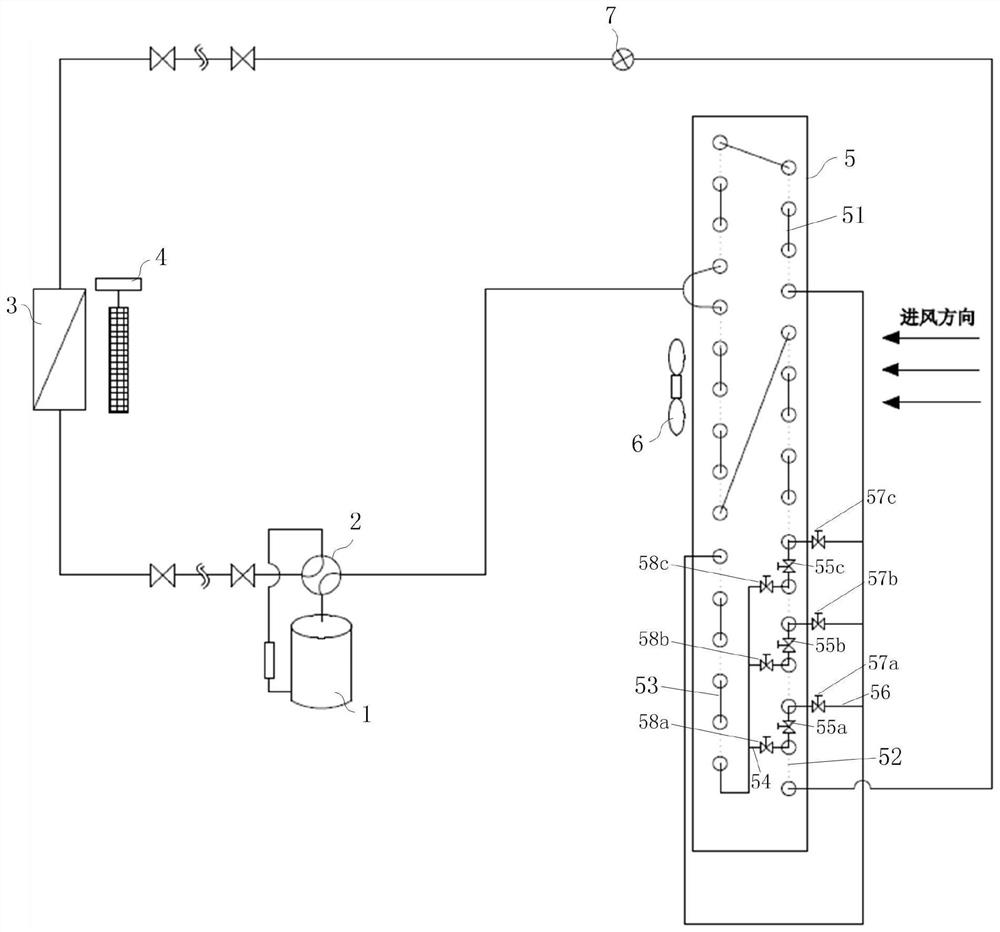

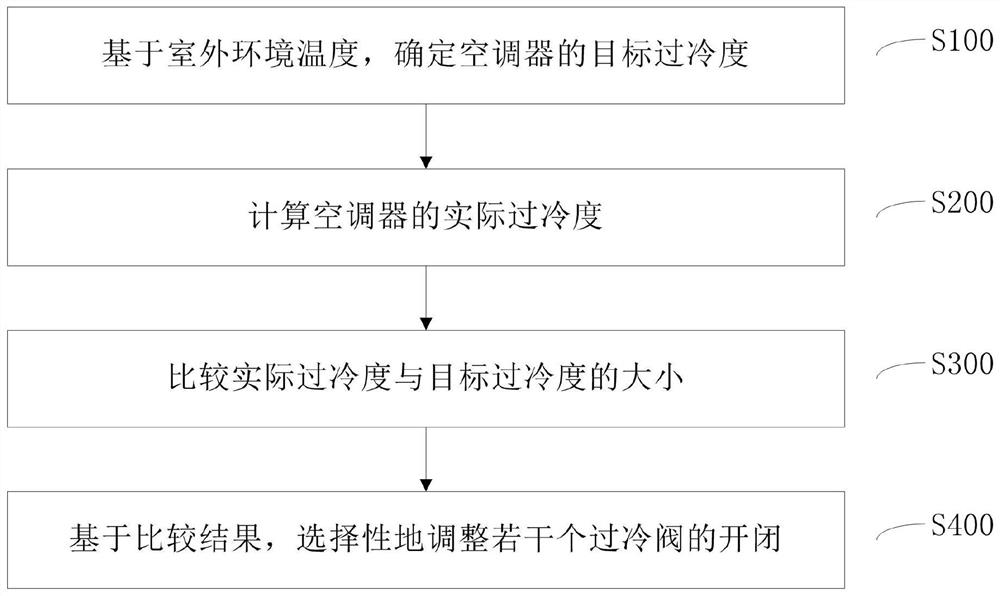

Refrigeration control method of air conditioner and condenser

ActiveCN112539526BImprove cooling energy efficiencyPrecise adjustment of subcoolingMechanical apparatusSpace heating and ventilation safety systemsAir conditioningControl theory

The invention relates to the technical field of air conditioning, in particular to a refrigeration control method of an air conditioner and a condenser. The present invention aims to solve the problem that the existing air conditioner cannot adjust the degree of supercooling. For this purpose, the control method of the present invention includes: determining the target subcooling degree of the air conditioner based on the outdoor ambient temperature; calculating the actual subcooling degree of the air conditioner; comparing the size of the actual subcooling degree and the target subcooling degree; based on the comparison result , and selectively adjust the opening and closing of several subcooling valves to adjust the effective length of the subcooling pipe section. The control method of the present application can adjust the subcooling degree of the air conditioner and improve the refrigeration energy efficiency.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

A parallel small-diameter heat pipe enhanced heat exchange device for recovering waste heat of medium and low temperature flue gas and its preparation method

ActiveCN110425510BImprove Primary UtilizationImprove waste heat recovery efficiencyIndirect heat exchangersCombustion technology mitigationCombustionFlue gas

The invention relates to a parallel small diameter heat pipe enhanced heat exchange device for recovering medium and low temperature flue gas waste heat, aims to solve the problem of waste of medium and low temperature flue gas waste heat generated in small combustion equipment primarily, recovers the flue gas waste heat by means of parallel small diameter heat pipes to produce hot water or heat other substances, and is suitable for recovering waste heat of small flow flue gas or a discontinuous small flow heat source. The parallel small diameter heat pipe enhanced heat exchange device is primarily characterized in that the parallel small diameter heat pipe enhanced heat exchange device is good in heat transfer property, compact in structure, small in size, easy to process and low in cost,and can achieve self transfer of heat and efficient recovery of waste heat, so that the exhaust gas temperature is reduced greatly and the integral efficiency of the system is improved. The device isquite suitable for heat recovery of small capacity medium and low temperature flue gas waste heat and discontinuous waste heat resources, and a heating container is taken conveniently.

Owner:NANJING TECH UNIV +1

Heat exchange water tank and water heater

PendingCN108645029AAvoid heat exchangeEnhanced condensation heat transfer capacityFluid heatersEngineeringWater temperature

The invention provides a heat exchange water tank and a water heater. The heat exchange water tank comprises a liner and a heat exchange part, wherein a first heat exchange area is formed at the upperpart in the liner, and a second heat exchange area is formed at the lower part; and the heat exchange part comprises a first current collecting pipe, a second current collecting pipe and multiple heat exchange pipes. In the heat exchange water tank and the water heater, the first current collecting pipe is arranged in the first heat exchange area, and the second current collecting pipe is arranged in the second heat exchange area; when a refrigerant enters the heat exchange part, the refrigerant exchanges heat with the second heat exchange area after heat exchange with the first heat exchangearea, so that the heat exchange of the refrigerant with the first heat exchange area again after heat exchange with the second heat exchange area can be prevented, and the condensation and heat exchange performance in channel heat exchange is effectively improved; and meanwhile, the first current collecting pipe is arranged on the upper side, and the second current collecting pipe is arranged onthe lower side, so that the flowing direction of the refrigerant and the distribution direction of the water temperature in the liner from low to high are opposite, the countercurrent heat exchange isrealized, and the heat exchange performance is further improved.

Owner:GREE ELECTRIC APPLIANCES INC

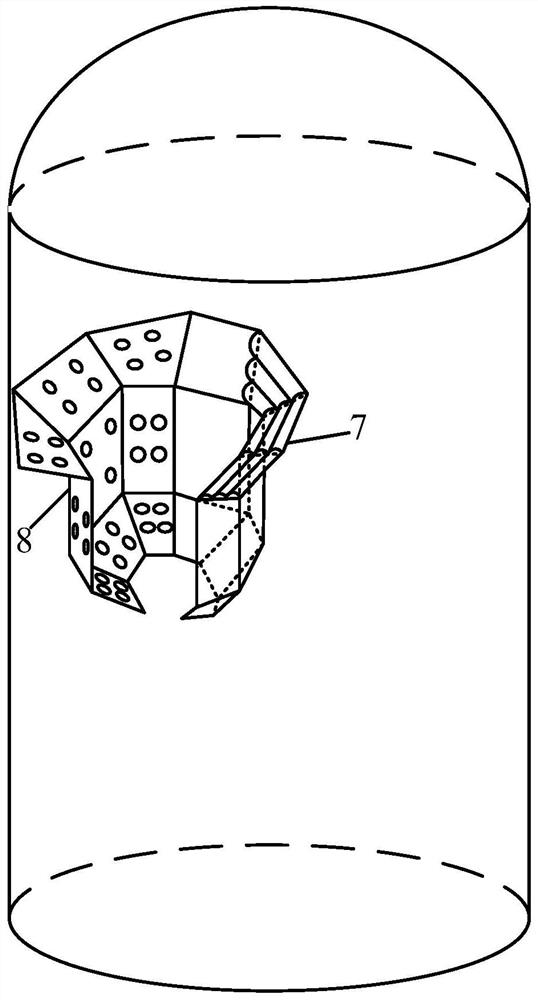

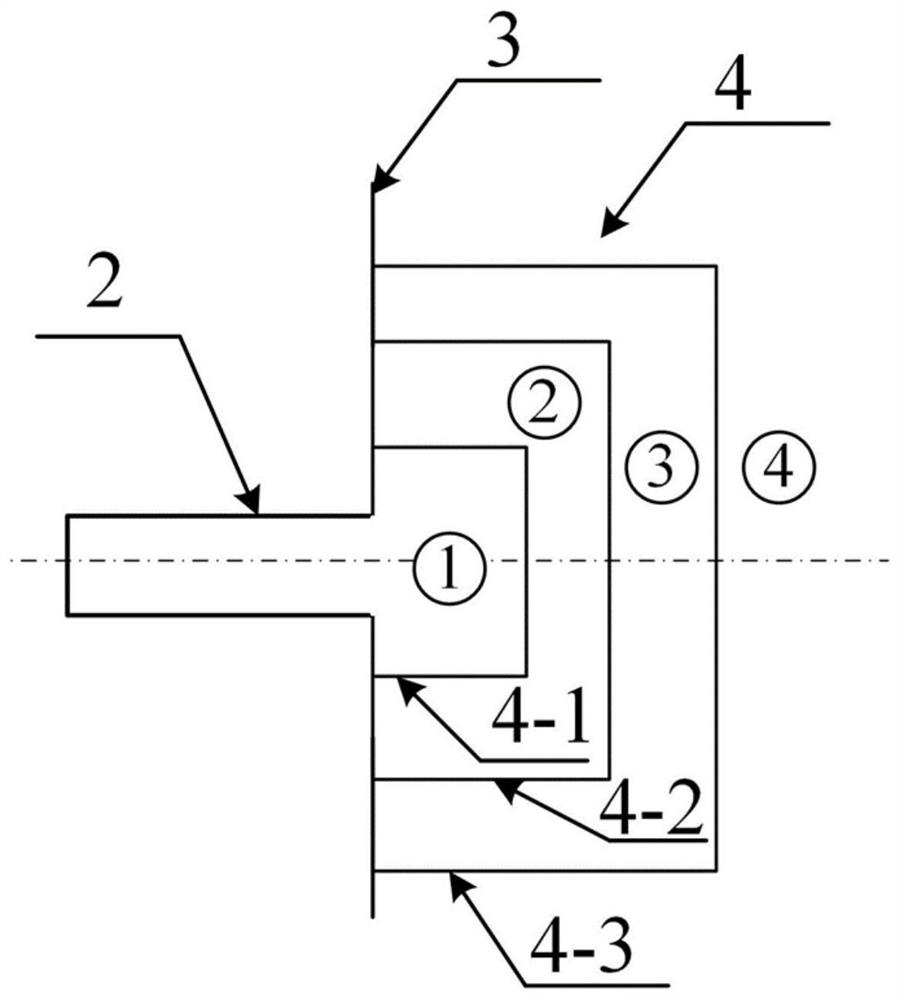

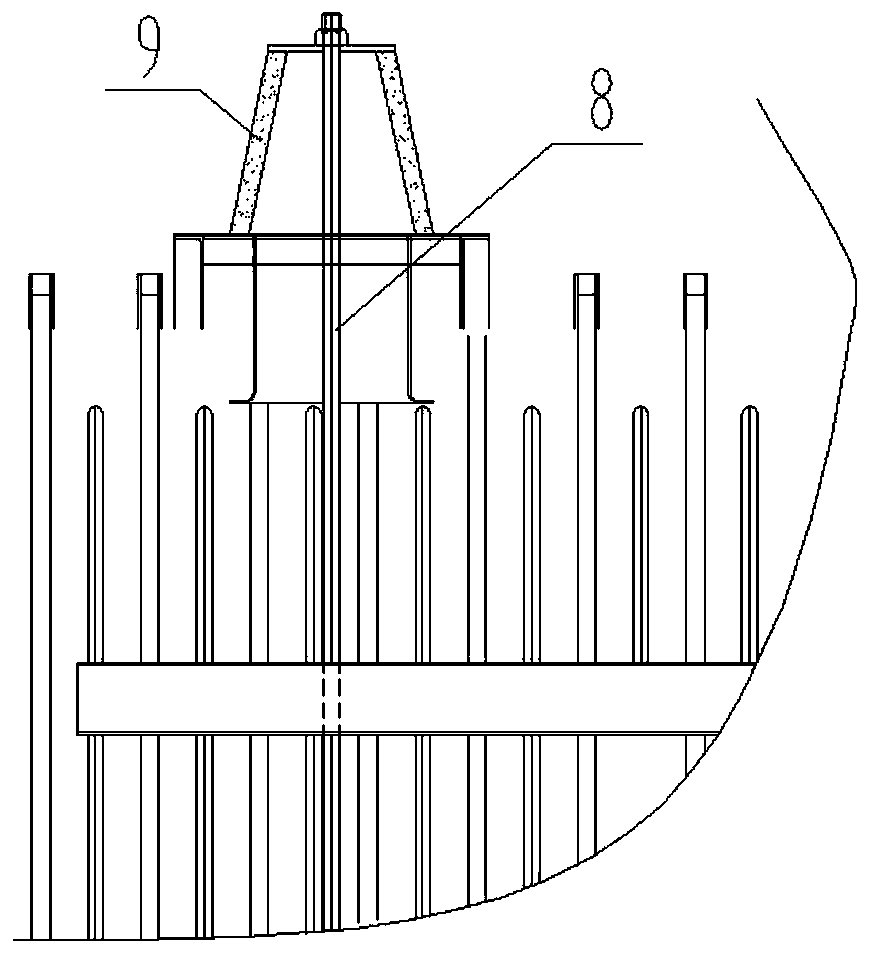

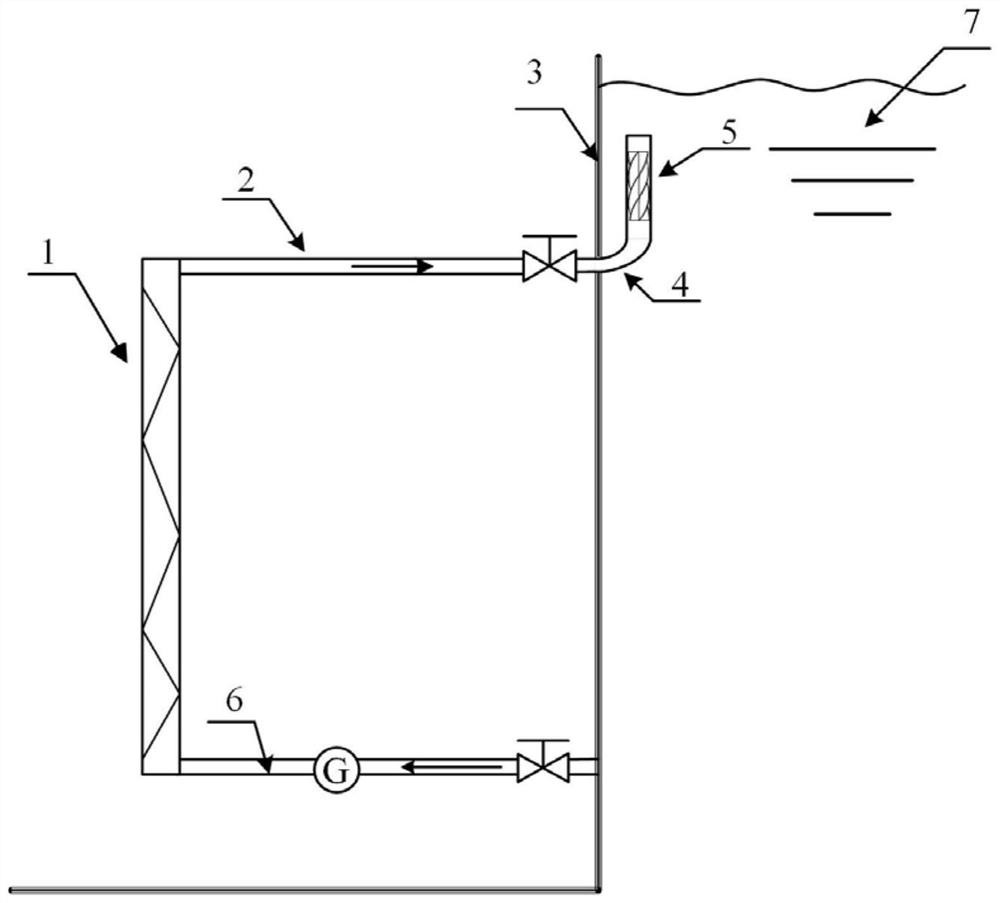

Passive safety system for inhibiting water hammer induced by steam condensation

ActiveCN112577333AEnhanced condensation heat transfer capacityInhibition formationSteam/vapor condensersSteam condensationWater hammer

The invention provides a passive safety system for inhibiting water hammer induced by steam condensation, which is used for inhibiting the steam condensation water hammer by installing a pore plate compartment at a pipe orifice of a heat pipe section. The pore plate compartment formed by splicing two pore plates is adopted, so that steam generated by a heat exchanger is condensed step by step in the pore plate compartment, and the phenomenon of the water hammer induced by the steam condensation in the heat pipe section due to violent condensation under low flow is fundamentally eliminated. Inaddition, the pore plate compartment avoids direct contact between steam and low-temperature seawater, the condensation heat exchange coefficient is reduced, and the water hammer of the steam on the seawater side is effectively restrained. The system has the advantages that the structure is simple, steam condensation induced water hammers on a pipeline and the seawater side can be restrained at the same time, and the application range is wide; and meanwhile, the improvement is convenient and easy, and engineering application is facilitated.

Owner:HARBIN ENG UNIV

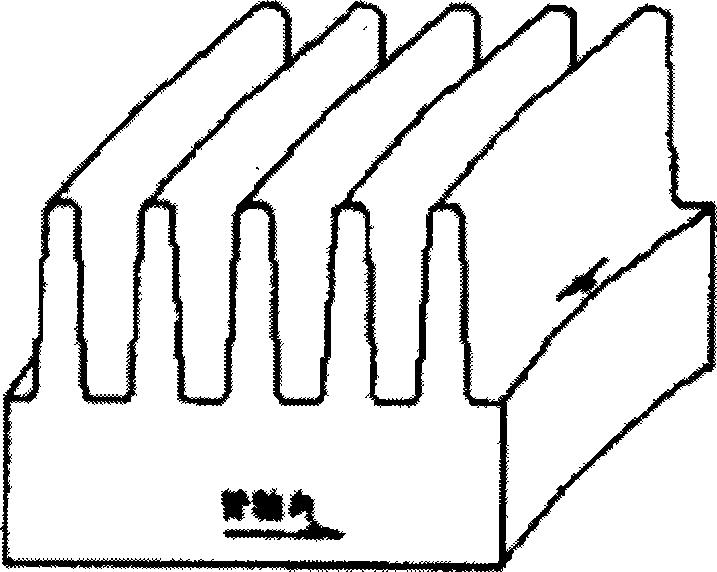

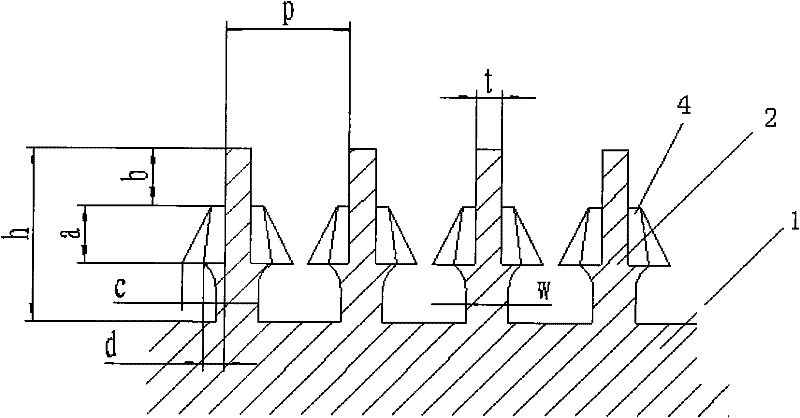

Enhanced condensation heat transfer tube

ActiveCN102679790BImprove heat transfer efficiencySpeed up drippingEvaporators/condensersHeat transfer modificationRegular patternCondensation heat transfer

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

Refrigerating condenser without refrigerant superheating section and refrigerating method thereof

InactiveCN104976832AImprove heat transfer effectLow costEvaporators/condensersRefrigeration safety arrangementProduct gasEngineering

The present invention discloses a refrigerating condenser without a refrigerant superheating section and a refrigerating method thereof. The refrigerating condenser comprises a horizontal lower end liquid tube and multi-group vertical heat exchange tubes vertically disposed on the horizontal lower end liquid tube; each group of vertical heat exchange tubes is formed by two vertical heat exchange tubes; upper and lowers of the two vertical heat exchange tubes of each group are respectively connected via an elbow so as to form an independent loop; and one end pipeline of the horizontal lower end liquid tube is provided with an air intake tube and a liquid outlet tube, a liquid seal device is disposed on a pipeline between the air intake tube and the liquid outlet tube, and the air intake tube and the liquid outlet tube are separated by the liquid seal device. Refrigerant enters into the air intake tube from an outlet of a compressor and then horizontally enters into the horizontal lower end liquid tube to be mixed with saturated liquid in the horizontal lower end liquid tube for mass and heat transfer, and the mixed saturated gas is distributed to each vertical heat exchange tube for condensation and heat exchange via communicating tubes; and no overheating steam exists in each vertical heat exchange tube, and compared with the prior art, condensation and heat exchange capabilities are largely improved.

Owner:SOUTH CHINA UNIV OF TECH

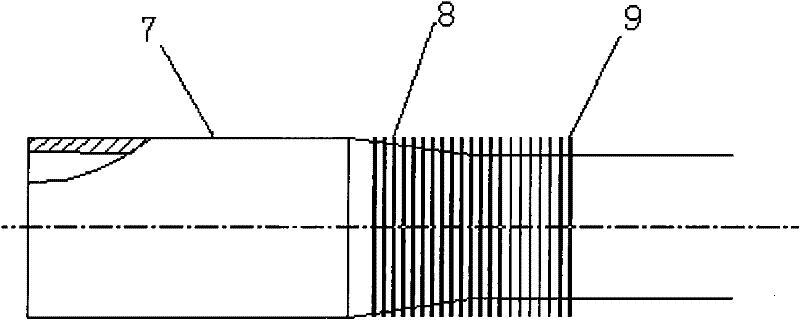

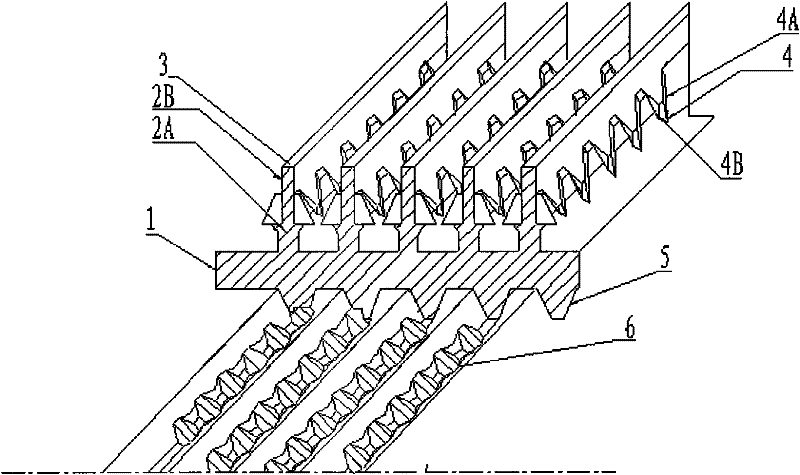

Novel high-efficiency heat exchange pipe for condenser of electric refrigeration unit

ActiveCN101949662BIncrease the areaIncrease discharge spaceTubular elementsCondenser (heat transfer)Engineering

The invention discloses a novel high-efficiency heat exchange pipe for the condenser of an electric refrigeration unit. The heat exchange pipe comprises a smooth pipe (7), a fin section (9) and a transition section (8) with a spiral fin. The heat exchange pipe is characterized in that the outside of the pipe body (1) of the fin section is provided with a spiral fin (2) which extends along the outer surface of the pipe body in a spiral manner; the outer diameter of the fin (2) is not more than that of the smooth pipe (7), the top (2B) of the spiral fin (2) is thinner than the root (2A), the upper ends of two side surfaces are smooth surfaces (3), the middle of the each side surface is provided with an inclined fin (4) which is 30-70 degrees to the pipe axis; the upper surface of each inclined fin (4) is a platform or an inclined plane, the side surfaces (4A, 4B) are trapezoidal, and one side surface (4A) is larger than the other opposite side surface (4B). The outside pipe condensation and heat exchange of the invention are reinforced; the discharge space of the condensate liquid is increased so that the condensate liquid can be fast discharged and the condensate liquid film can be expanded easily; and the turbulent flow and heat exchange in the pipe are reinforced so that the overall heat transfer efficiency can be obviously increased.

Owner:山东恒辉节能技术集团有限公司

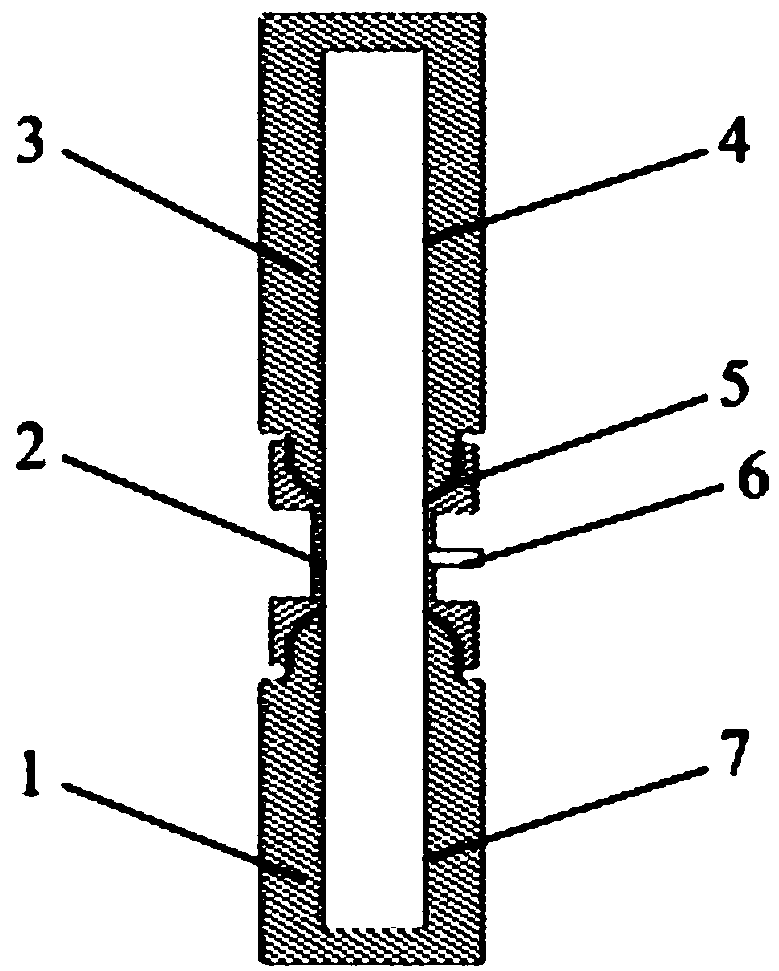

Vacuum interlayer fractionation column and fractionation device

The invention relates to a vacuum interlayer fractionation column. The vacuum interlayer fractionation column comprises a gas outlet, a gas inlet, an outer pipe, an inner column, a plurality of thorn-shaped clamping grooves and a plurality of spherical glass plugs, wherein the bottom end of the inner column extends outward to be provided with the gas inlet; the top end of the inner column extendsoutward to be provided with a connection pipe; the gas outlet is arranged at one side of the connection pipe; the outer pipe is located on an outer layer of the inner column; the outer pipe is used for surrounding and coating the inner column and sealing openings are fused at the bottom end and top end of the inner column, so that a gap is left between an inner wall of the outer pipe and an outerwall of the inner column and is used as a vacuum interlayer; the plurality of thorn-shaped clamping grooves are formed in an inner wall of the inner column; the inner column is inward sunken at the lower side of each thorn-shaped clamping groove to form a hoop; the spherical glass plugs are inserted into the hoops and are movably connected with the hoops. By adopting a vacuum interlayer structureof the vacuum interlayer fractionation column, after boiled steam of a mixed solution enters, the contact time of descending condensed liquid and ascending steam can be prolonged through the additional spherical glass plugs, and the descending condensed liquid and the ascending steam can be subjected to sufficient heat exchange; the condensation and heat exchange effects can be remarkably improved.

Owner:马钢奥瑟亚化工有限公司

Discharge condensation water collection system for collaborative removal of pollutants

ActiveCN108636047BEnhanced condensation heat transfer capacityImprove water collection efficiencyCombination devicesGas treatmentThermodynamicsSteam condensation

The invention relates to a system for removing pollutants while discharging, condensing and collecting water. The system comprises a shell, wherein a pre-charged subsystem, a condensing heat exchangesubsystem and a multifunctional subsystem which are communicated with one another are arranged in sequence in the shell in a flue gas charging direction; the pre-charged subsystem comprises a first-level tank; a first discharge electrode wire is arranged in the first-level tank; the condensing heat exchange subsystem comprises a second-level tank; a first heat exchange tube bundle is arranged in the second-level tank; the multifunctional subsystem comprises a third-level tank; a second discharge electrode wire and a second heat exchange tube bundle are arranged in the third-level tank. By adopting the system, a pre-charged technology, a discharging, condensing, heat exchange, coupling, strengthen steam condensation efficient water collection technology and a pollutant synergetic removal technology are adopted, so that the condensing heat exchange effect of flue gas is enhanced, the water collection efficiency is increased, and fine particles, residual liquid drops, condensable particles and soluble salts in the flue gas can be captured in order to realize effecient and synergistic removal of pollutant components in the flue gas.

Owner:ZHEJIANG UNIV

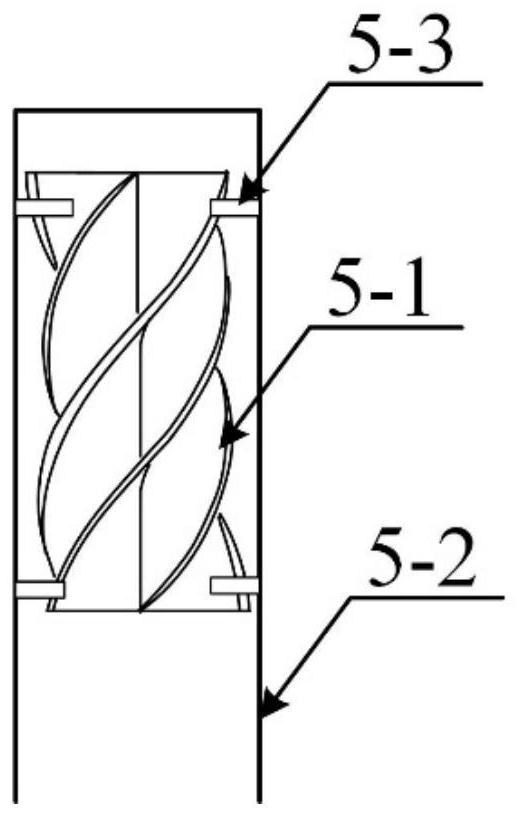

Passive safety system for eliminating water hammer induced by steam condensation

PendingCN112595135ADegassing water hammerWater hammer suppressionSteam/vapor condensersSeawaterSafe system

The invention provides a passive safety system for eliminating a water hammer induced by steam condensation. The passive safety system is used for eliminating the water hammer induced by steam condensation by installing an elbow and a steam eliminating device on a seawater side. According to the passive safety system, a twisted belt is installed in a hole pipe through a clamping ring, so that a steam-water mixture generated by a heat exchanger spirally flows upwards in a flow channel formed by the twisted belt and the hole pipe and directly makes contact with seawater through the flow holes inthe side face and the top face of the hole pipe to be condensed, he steam is gradually condensed under the stirring effect of the twisted belt, so that the effect of eliminating the water hammer induced by steam condensation is achieved. The passive safety system has the advantages that the passive safety system is simple in structure and wide in application range, water hammers induced by pipeline and seawater side steam condensation can be eliminated at the same time, the natural circulation capacity of the passive safety system is improved, meanwhile, the improvement is convenient and easy, and engineering application is facilitated.

Owner:HARBIN ENG UNIV

Refrigeration condenser without refrigerant superheating section and refrigeration method thereof

InactiveCN104976832BEnhanced condensation heat transfer capacityReduce liquid storageEvaporators/condensersRefrigeration safety arrangementEngineeringRefrigerant

The present invention discloses a refrigerating condenser without a refrigerant superheating section and a refrigerating method thereof. The refrigerating condenser comprises a horizontal lower end liquid tube and multi-group vertical heat exchange tubes vertically disposed on the horizontal lower end liquid tube; each group of vertical heat exchange tubes is formed by two vertical heat exchange tubes; upper and lowers of the two vertical heat exchange tubes of each group are respectively connected via an elbow so as to form an independent loop; and one end pipeline of the horizontal lower end liquid tube is provided with an air intake tube and a liquid outlet tube, a liquid seal device is disposed on a pipeline between the air intake tube and the liquid outlet tube, and the air intake tube and the liquid outlet tube are separated by the liquid seal device. Refrigerant enters into the air intake tube from an outlet of a compressor and then horizontally enters into the horizontal lower end liquid tube to be mixed with saturated liquid in the horizontal lower end liquid tube for mass and heat transfer, and the mixed saturated gas is distributed to each vertical heat exchange tube for condensation and heat exchange via communicating tubes; and no overheating steam exists in each vertical heat exchange tube, and compared with the prior art, condensation and heat exchange capabilities are largely improved.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com