A kind of gravity heat pipe device and preparation method

A gravity heat pipe and adiabatic section technology, applied in the field of heat pipes, can solve problems such as weakening condensation heat transfer performance, and achieve the effects of improving liquid film evaporation capacity, good infiltration effect, and heat transfer capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

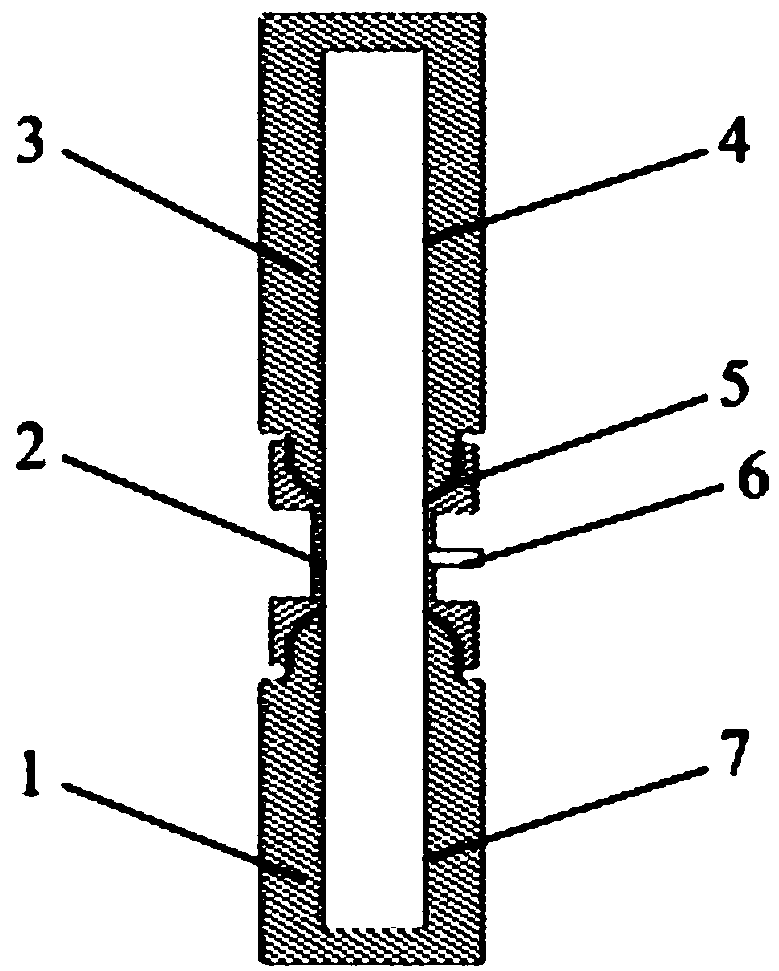

[0037] Such as figure 1 As shown, the gravity heat pipe device provided by the present invention with a super-hydrophilic evaporator and a SLIPS condenser includes: an evaporator 1 , an adiabatic section 2 , a condenser 3 and a working fluid filling port 6 . The evaporator 1 has a superhydrophilic surface 7 and the condenser 3 has a SLIPS surface 4 . The evaporator 1 and the heat insulation section 2 and the condenser 3 and the heat insulation section 2 are connected by a threaded tapered sealing surface 5 , and the working fluid filling port 6 is arranged on the side of the heat insulation section 2 . The inner diameters and lengths of the evaporator 1, the adiabatic section 2 and the condenser 3 are variable and can be adjusted according to actual conditions. The evaporator 1 and the condenser 3 only need to be able to reach super-hydrophilic and SLIPS surfaces respectively. Among them, the superhydrophilic surface is a surface with a contact angle of less than 5°, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com