Patents

Literature

30results about How to "Improve boiling heat transfer capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

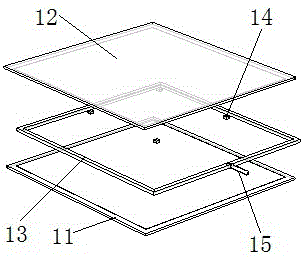

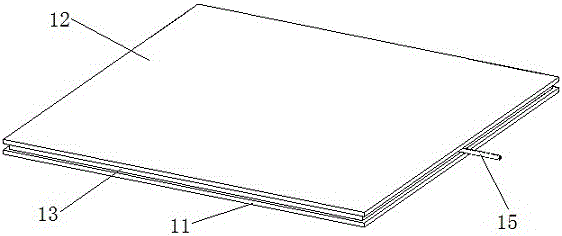

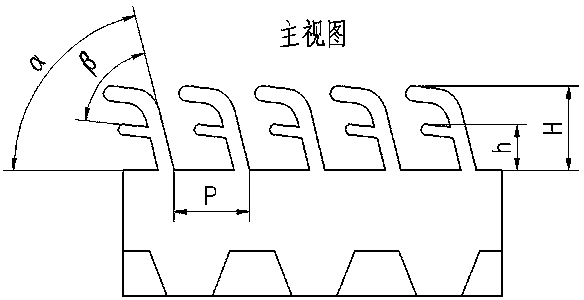

Flat-plate heat tube with nanometer structure

ActiveCN104634148AImprove temperature uniformityEnhanced boiling heat transfer capabilityIndirect heat exchangersHydrophobic surfacesEngineering

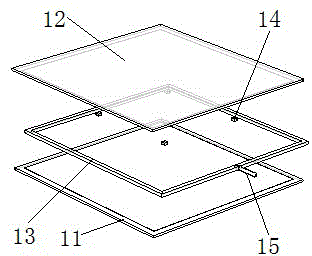

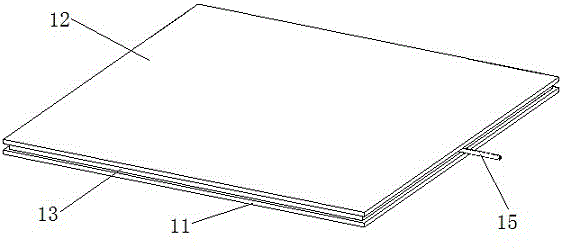

The invention discloses a flat-plate heat tube with a nanometer structure. The flat-plate heat tube with the nanometer structure comprises a bottom plate, a top plate and a supporting plate, wherein the supporting plate is positioned between the top plate and the bottom plate; the bottom plate, the top plate and the supporting plate are hermetically connected to one another to form a hollow closed cavity; a body of the bottom plate which serves as an evaporation surface of the flat-plate heat tube is a brass sheet; a copper oxide film which has a nanometer structure, has a super-hydrophilic property and is formed by electrochemical displacement covers the inner surface of the bottom plate; a body of the top plate which serves as a condensation surface of the flat-plate heat tube is a brass sheet; an electro-nickelling layer which has a nanometer structure and has a super-hydrophobic property covers the inner surface of the top plate; and small through holes are formed in a side surface of the supporting plate and are connected with capillary tubes. The evaporation surface and the condensation surface of the flat-plate heat tube are subjected to super-hydrophilic and super-hydrophobic surface modification, the evaporation speed and the condensation speed are increased, the heat exchange performance of an evaporation region and the heat exchange performance of a condensation region are improved, the thermal homogeneity is high, working medium is guided to return, and the working medium returning speed is increased, so that the whole heat exchange capability is improved.

Owner:GUANGDONG UNIV OF TECH

Gravity assisted heat pipe device and preparation method

InactiveCN105973044AEnhanced condensation heat transfer capacityReduce condensation thermal resistanceIndirect heat exchangersMicro structureNano structuring

The invention discloses a gravity assisted heat pipe device which comprises an evaporator, a heat insulation segment and a condenser. The evaporator and the condenser are in sealed connection with the heat insulation segment. The inner surface of the evaporator is a super-hydrophilic surface. The inner surface of the condenser is a smooth lubricant implanted porous surface (SLIPS). Lubricant on the SLIPS and a charged working medium cannot be mixed. A super-hydrophilic surface of a nano-micro structure is arranged on the inner wall of the evaporator, the working medium can completely moisten the wall face, a liquid film evaporates in the heating process, the evaporation intensity is improved, and the SLIPS of the condenser is formed by compounding the super-hydrophilic of a nano structure with implanted fluorine-containing lubricant or silicone oil or ionic liquid. Condensed liquid drops float on the SLIPS, are combined, fast fall off the SLIPS and sweep small liquid drops on the path of the condensed liquid drops, a condensation surface is provided for secondary condensation, and the condensation and heat exchange effect is remarkably improved. According to the gravity assisted heat pipe device, heat pipe heat resistance can be effectively reduced, the heat exchange performance of the device is improved, and wide application prospects are achieved.

Owner:SHANGHAI JIAO TONG UNIV

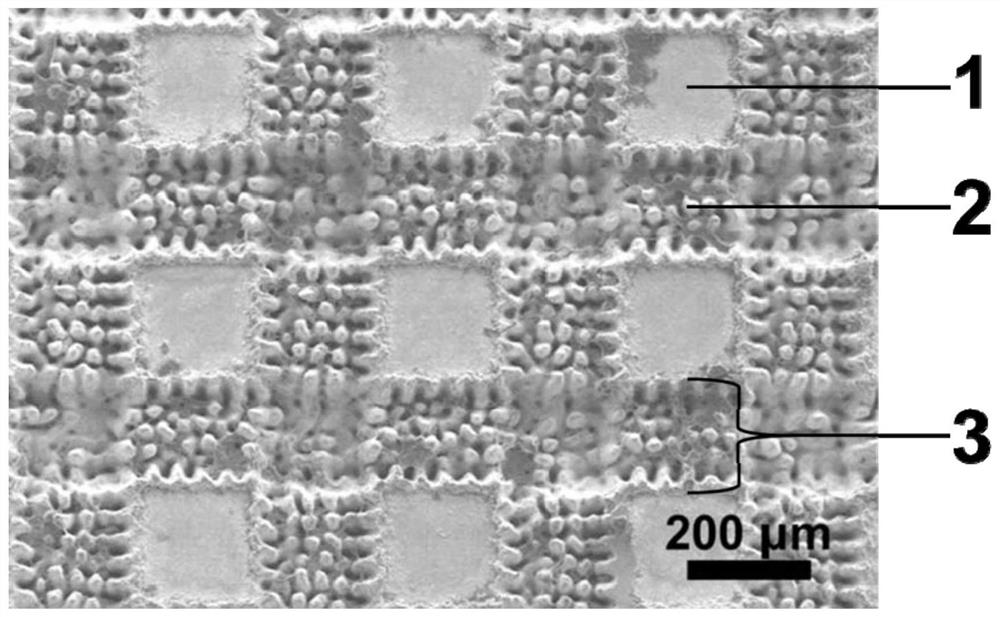

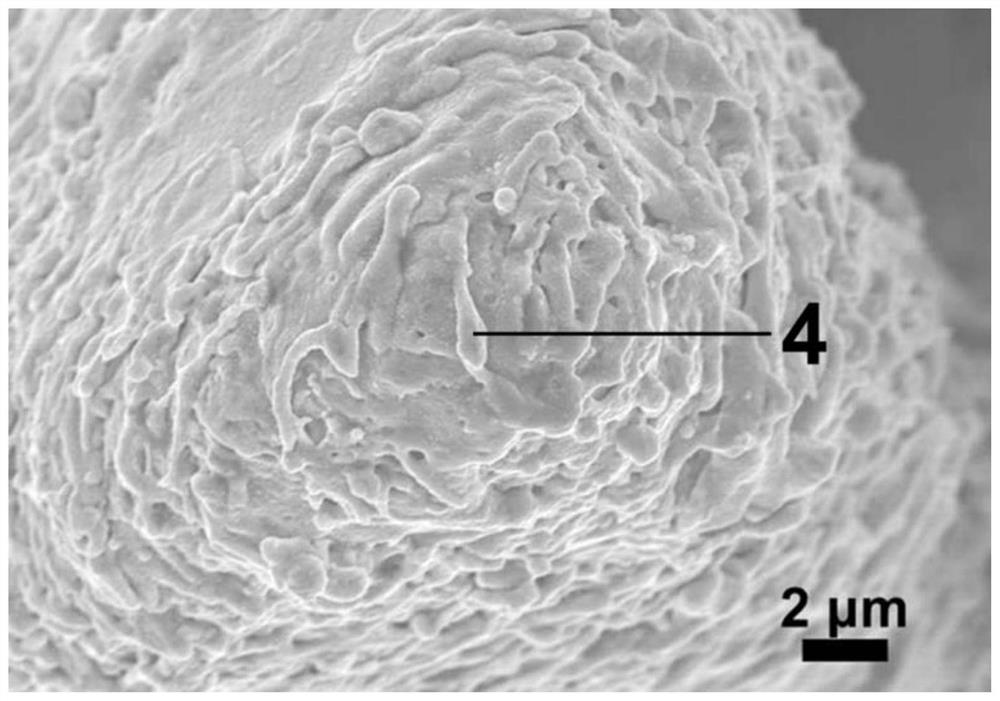

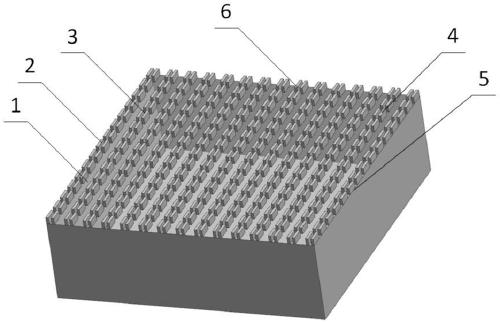

Material surface micro-nano composite strengthening boiling structure as well as preparation method and application thereof

ActiveCN109974512ALittle motor blockMultiple Vaporization CoresHeat transfer modificationLaser beam welding apparatusMicro nanoNanometre

The invention discloses a material surface micro-nano composite strengthening boiling structure as well as a preparation method and application of the material surface micro-nano composite strengthening boiling structure. The material surface micro-nano composite strengthening boiling structure comprises a base material and a micro-nano composite structure formed on the surface of the base material. The micro-nano composite structure comprises micro mastoids, communication-type grooves and nano-folds, wherein the micro mastoids are formed in the communication-type grooves, and the surfaces ofthe micro mastoids are provided with nano-fold shapes. The preparation method of the material surface micro-nano composite strengthening boiling structure comprises the following step of forming a micro-nano composite strengthening boiling structure on the base material through a laser integrated etching method. The material surface micro-nano composite strengthening boiling structure has multi-scale micron and nanometer characteristics in different levels.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

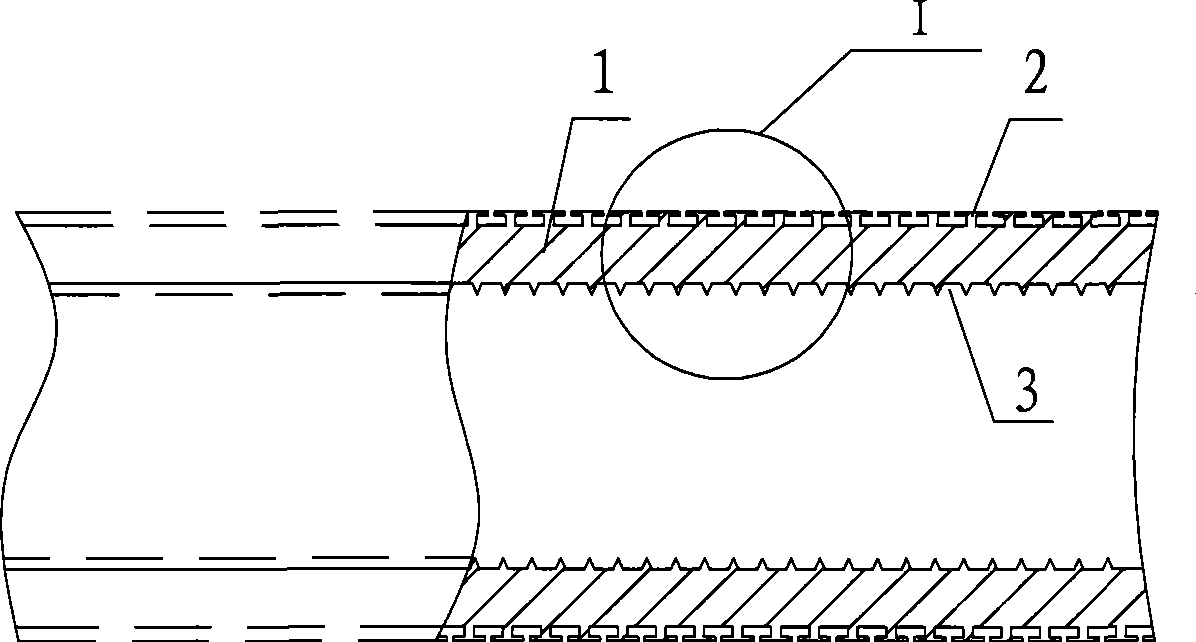

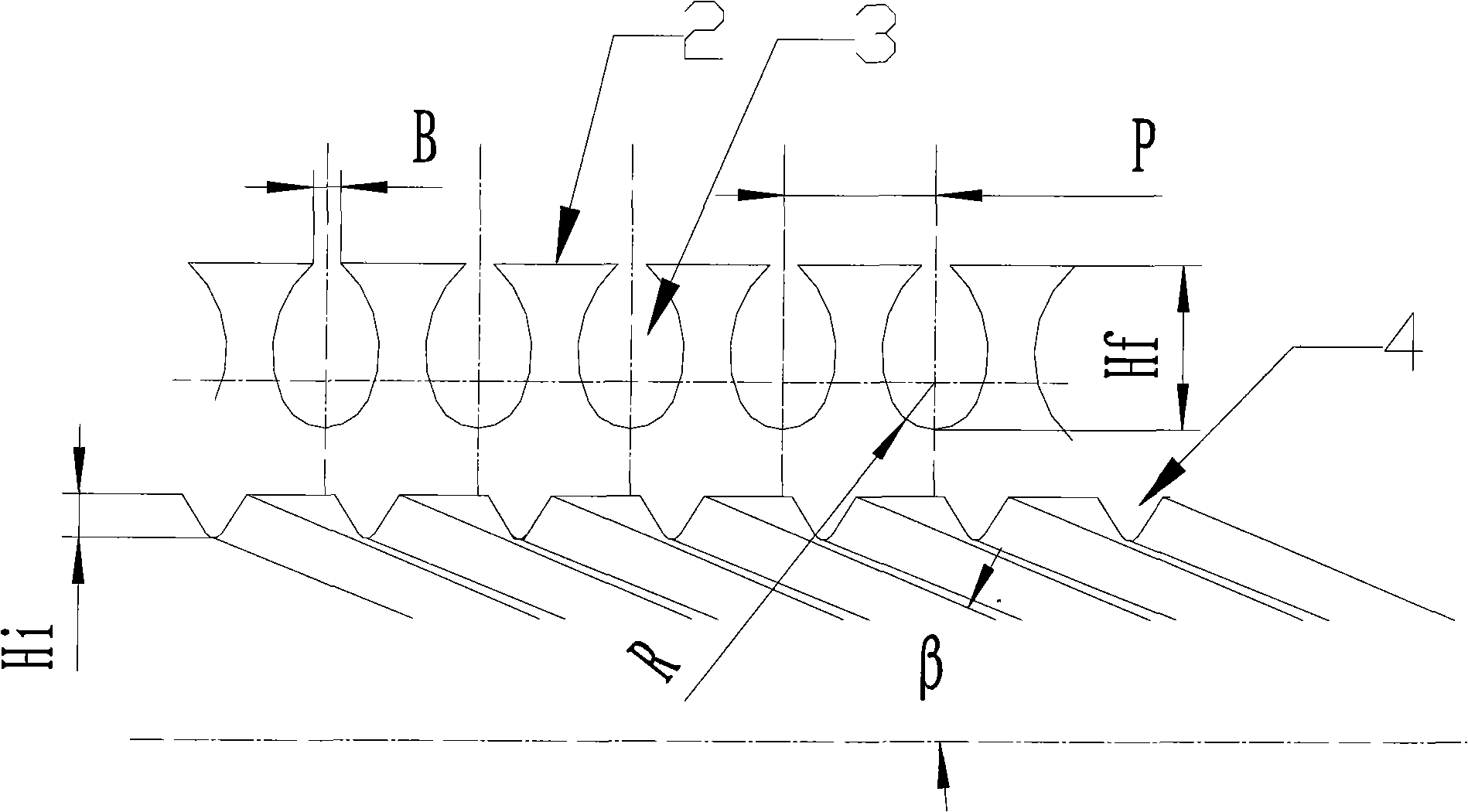

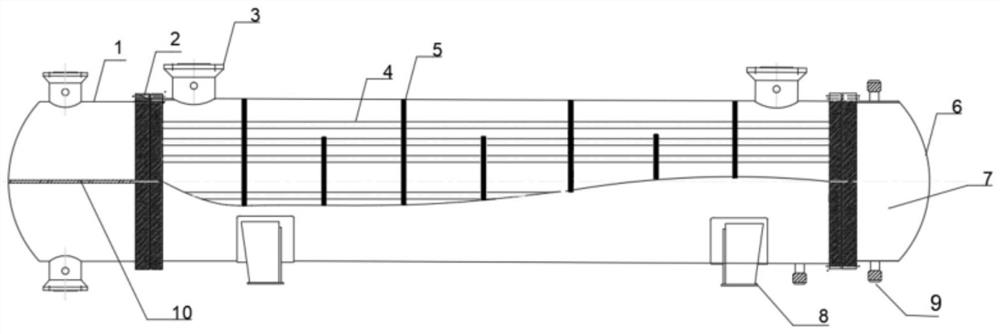

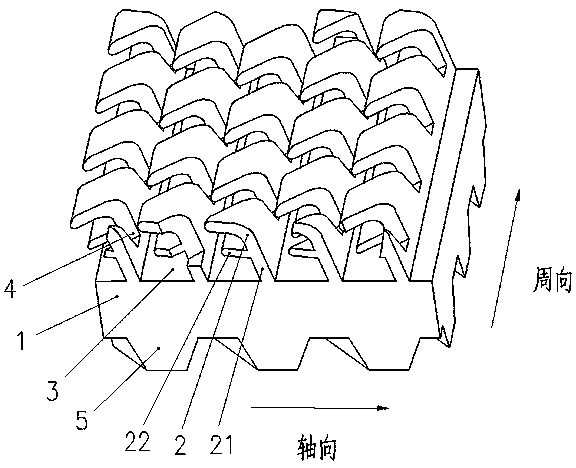

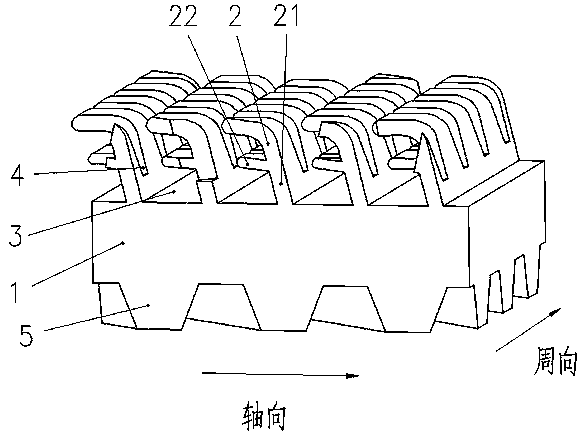

Heat transfer tube for evaporator and method of manufacturing same

The invention relates to a heat transfer pipe for an evaporator and a production method thereof. The heat transfer pipe is provided with a pipe body with an inner cavity, and fins arranged on the peripheral surface outside the pipe body and spirally distributed along the axial direction of the pipe body. Lateral walls of the fins incline from the bottoms of the fins towards the outside of the tops facing the fins. Empty cavities, the opening sections of which are less than the bottom areas, are formed between adjacent fins; and the bottom surface of each empty cavity is also provided with a first groove and a second groove crossed with the first groove, at least either the first groove or the second groove comprise a plurality of grooves, and the first groove and the second groove have a plurality of crossing nodes. The first grooves, the second grooves and the nodes of the first and the second grooves have worse moisturizing property than the bottoms of the empty cavities so that activation energy or superheat degree of foam generation and growth can be reduced, more gasification core points can be formed, and more foams can be formed so as to improve boiling heat exchange capability. The pipe-outside boiling heat exchange efficiency of the heat transfer pipe is higher than a conventional heat transfer pipe with smooth empty cavity bottom by 7-12 percent.

Owner:苏州新太铜高效管有限公司

Spray cooling device combining steam cavity and composite microstructure

ActiveCN110381701AImprove cooling effectImprove ductilityCooling/ventilation/heating modificationsVena contracta diameterEnhanced heat transfer

The invention discloses a spray cooling device combining a steam cavity and a composite microstructure. The device comprises a spray chamber, a spray chamber liquid inlet pipe, a spray chamber liquidoutlet pipe and a steam chamber, wherein the spray chamber and the steam chamber are integrally arranged; the spray chamber comprises a spray orifice plate, array nozzles and a composite microstructure which are positioned in the spray chamber; the spray orifice plate divides the spray chamber into a buffer chamber and a spray chamber; the spray chamber liquid inlet pipe is communicated with the buffer chamber; the spray chamber liquid outlet pipe is communicated with the spray chamber, the composite microstructure is arranged on the wall face, opposite to the array nozzle, in the spray chamber, the composite microstructure comprises a bottom layer liquid absorption core arranged on the wall face opposite to the array nozzle and a plurality of rib-shaped liquid absorption cores arranged onthe bottom layer liquid absorption core, and a phase change working medium is sealed in the steam chamber. The steam chamber expands heat generated by a heat source to the spraying wall face with a large area, the heat exchange performance of the wall face is improved through multi-nozzle array spraying, and the two-phase heat exchange capacity of spraying is improved through combination of the steam chamber and a composite microstructure enhanced heat transfer mode.

Owner:NANJING UNIV OF SCI & TECH

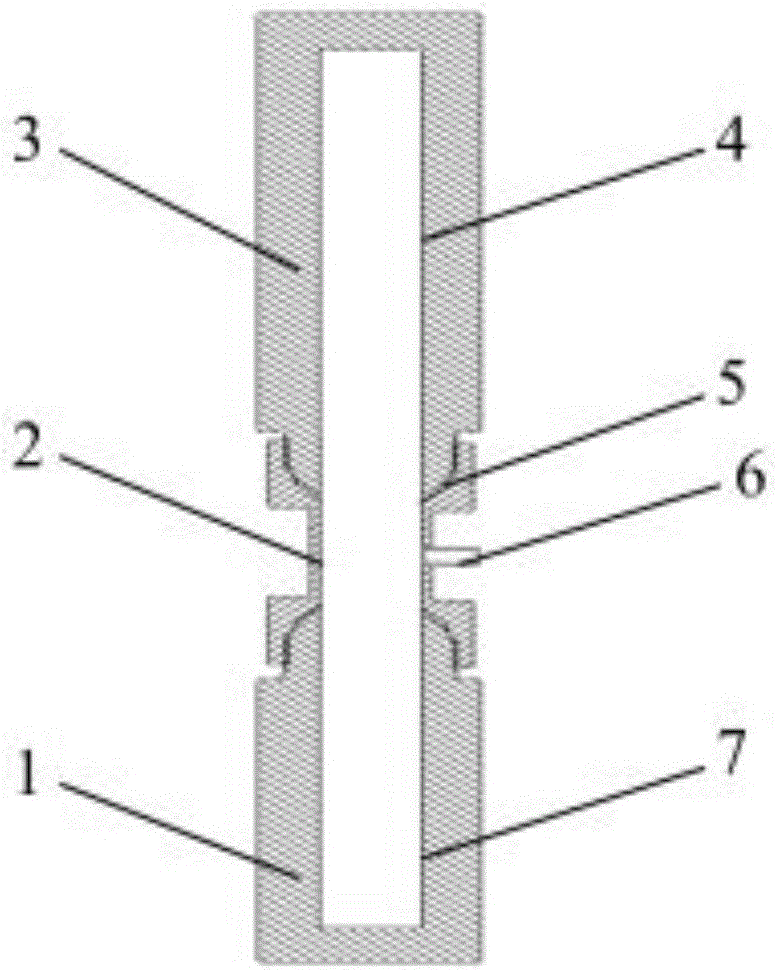

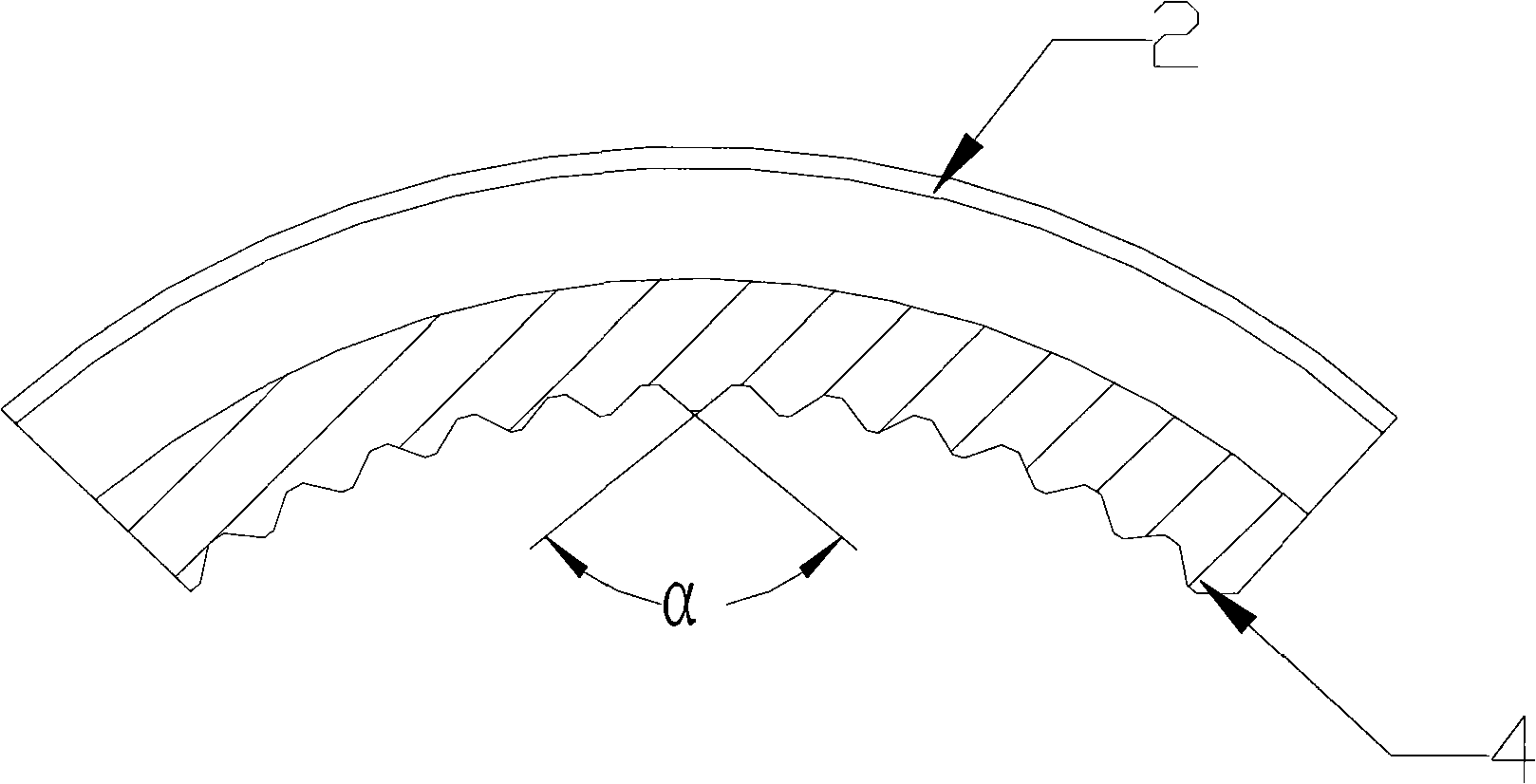

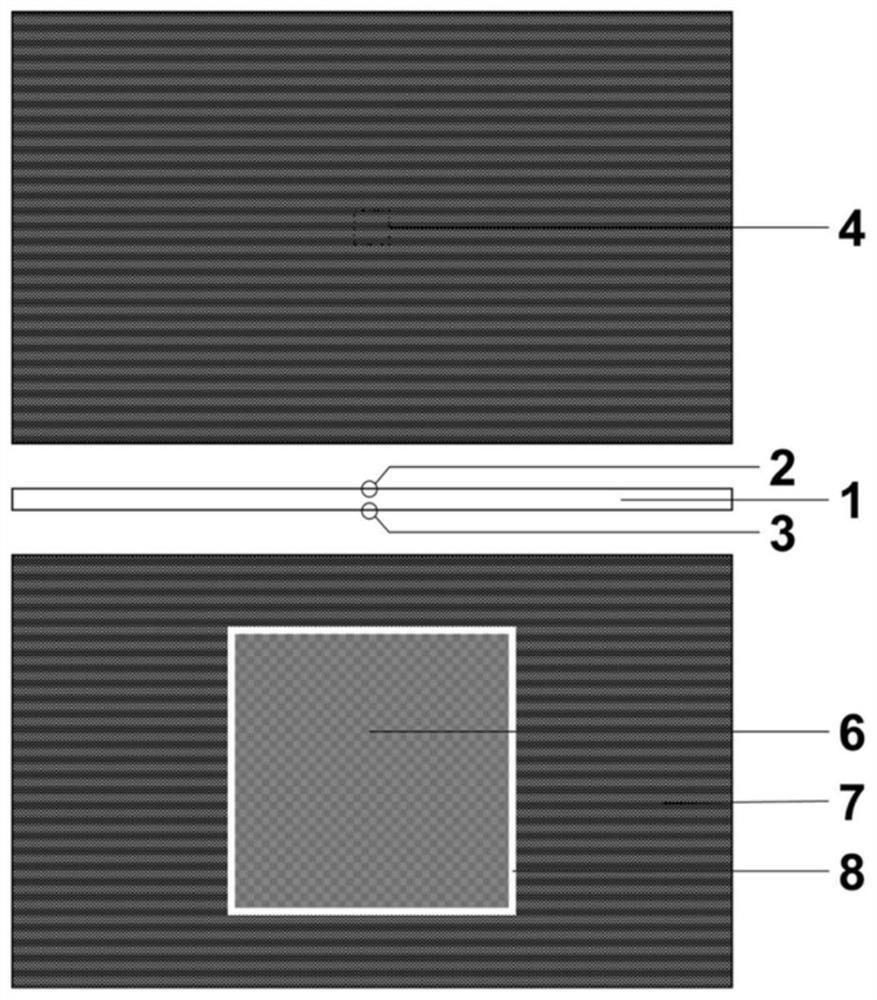

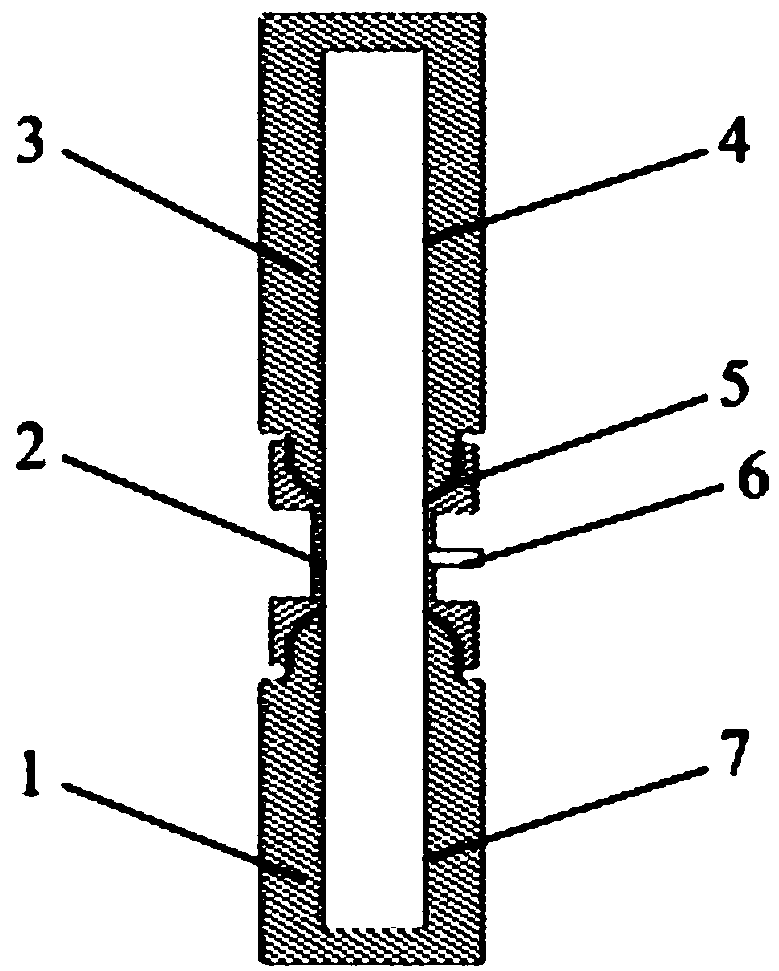

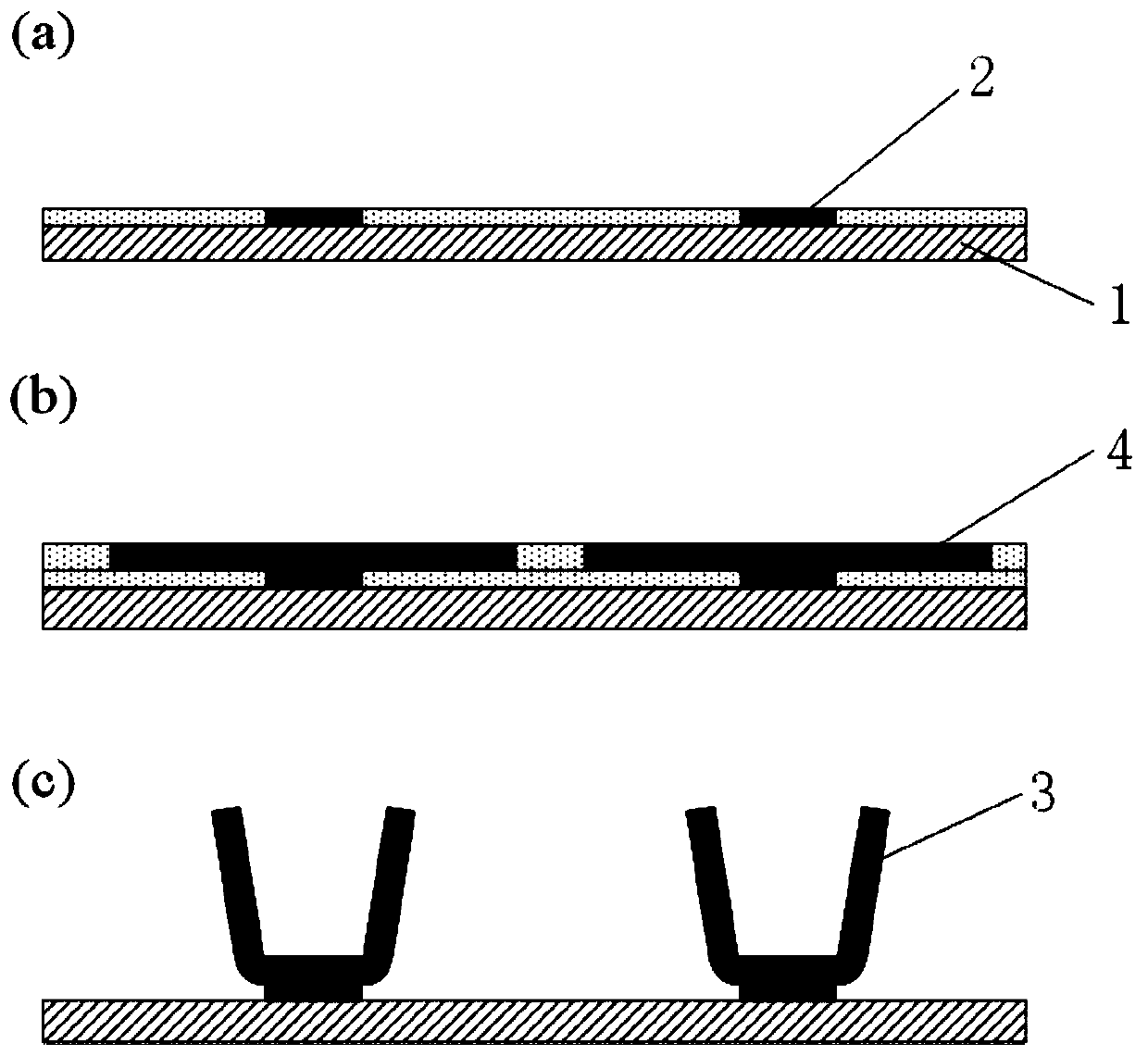

High-efficiency heat exchange tube for heat exchanger in ammonia/carbon dioxide cascade refrigeration system

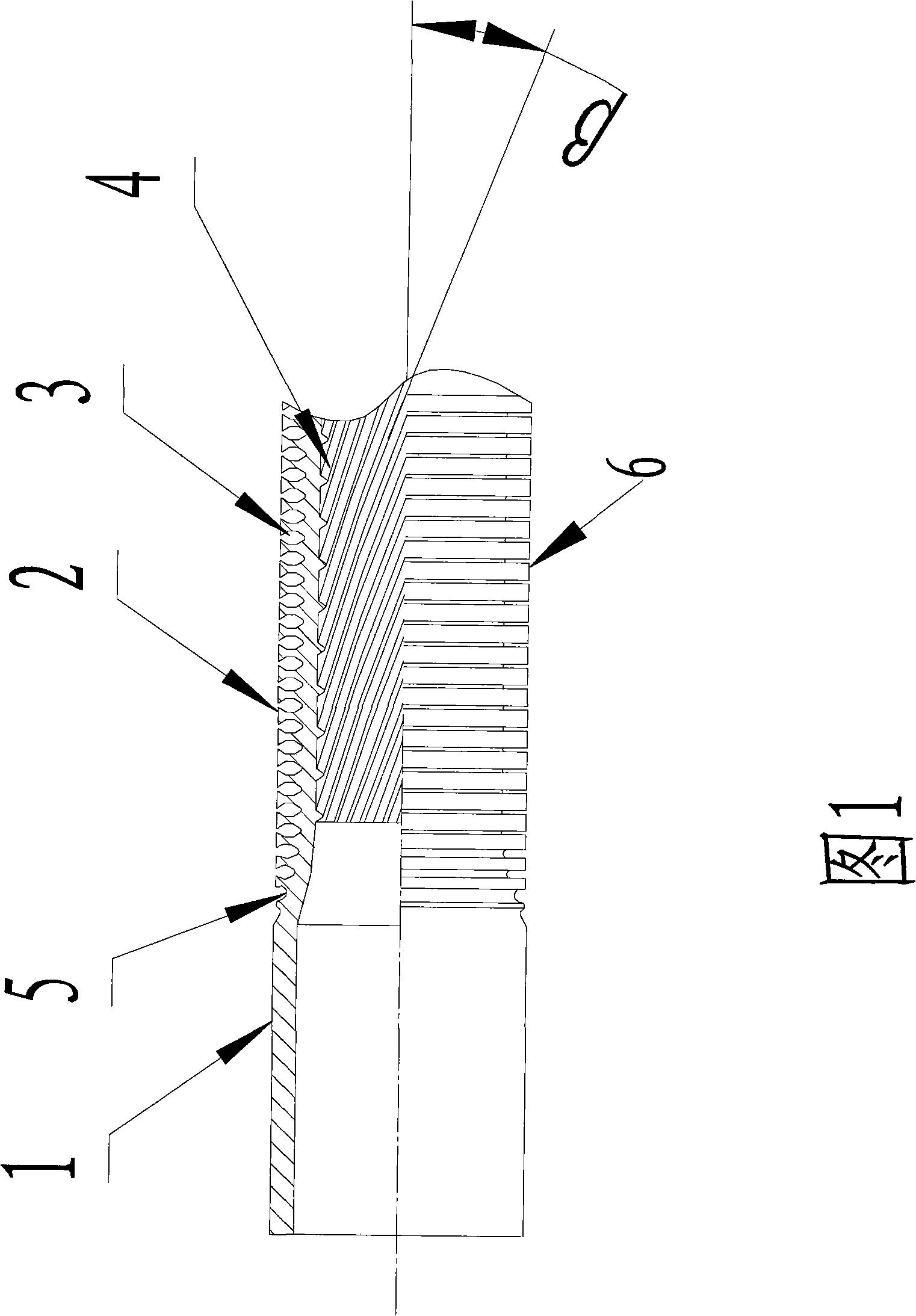

The invention relates to a heat exchanger used high-efficiency heat exchange tube in an ammonia / carbon dioxide overlapping refrigeration system. The heat exchange tube is a tube body with an inner cavity, and is characterized in that the tube body is composed of a plain tube part (1), a fin tube part (6) and a transition part (5) connecting the plain tube part (1) with the fin tube part (6); spiral fins (2) which are distributed along an axial direction of the tube body are disposed on the outer wall of the fin tube part (6); and a conduit (3) is formed between the adjacent fins (2), a space is left between the top parts of the adjacent fins (2), and spiral micro-serrations (4) are formed on the inner wall of the fin tube part (6). The heat exchange tube improves the heat transfer efficiency of the heat exchanger used heat exchange tube in the ammonia / carbon dioxide overlapping refrigeration system, reduces the system cost and allows the smaller volume of the system.

Owner:山东恒辉节能技术集团有限公司

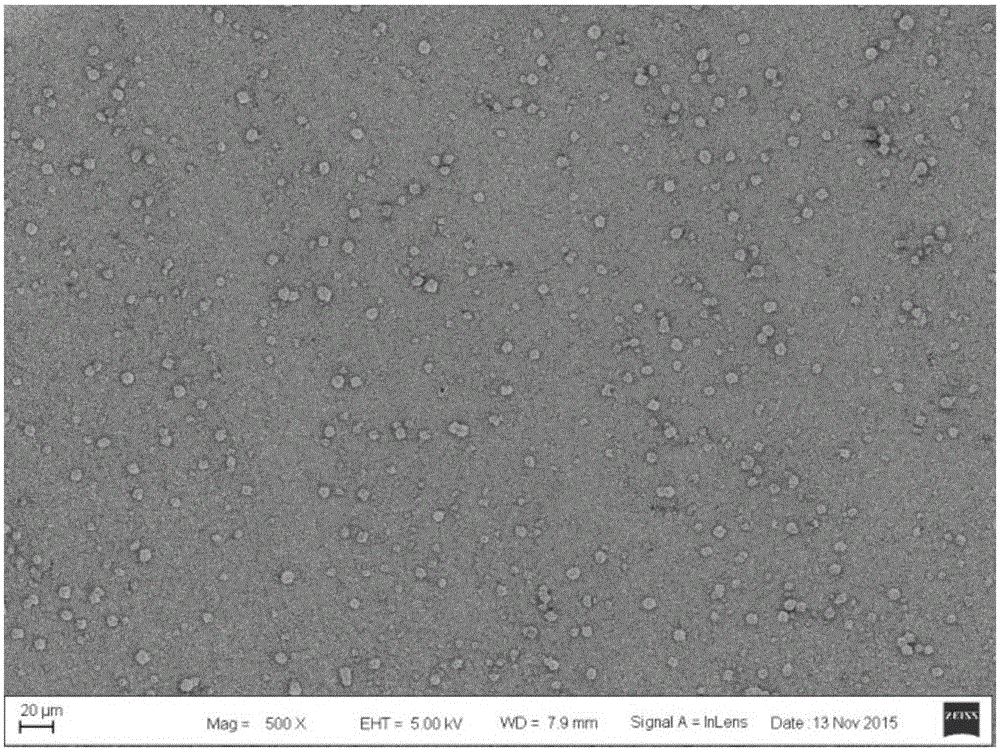

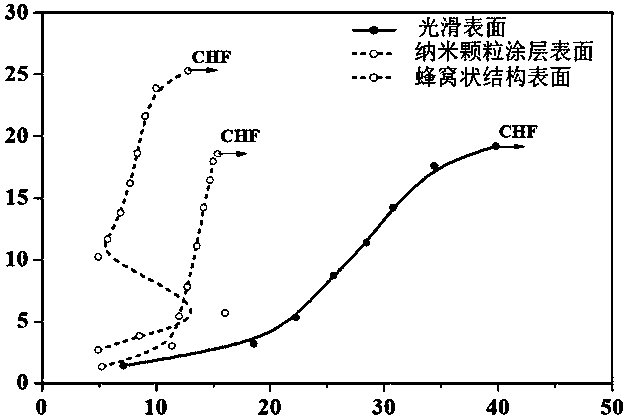

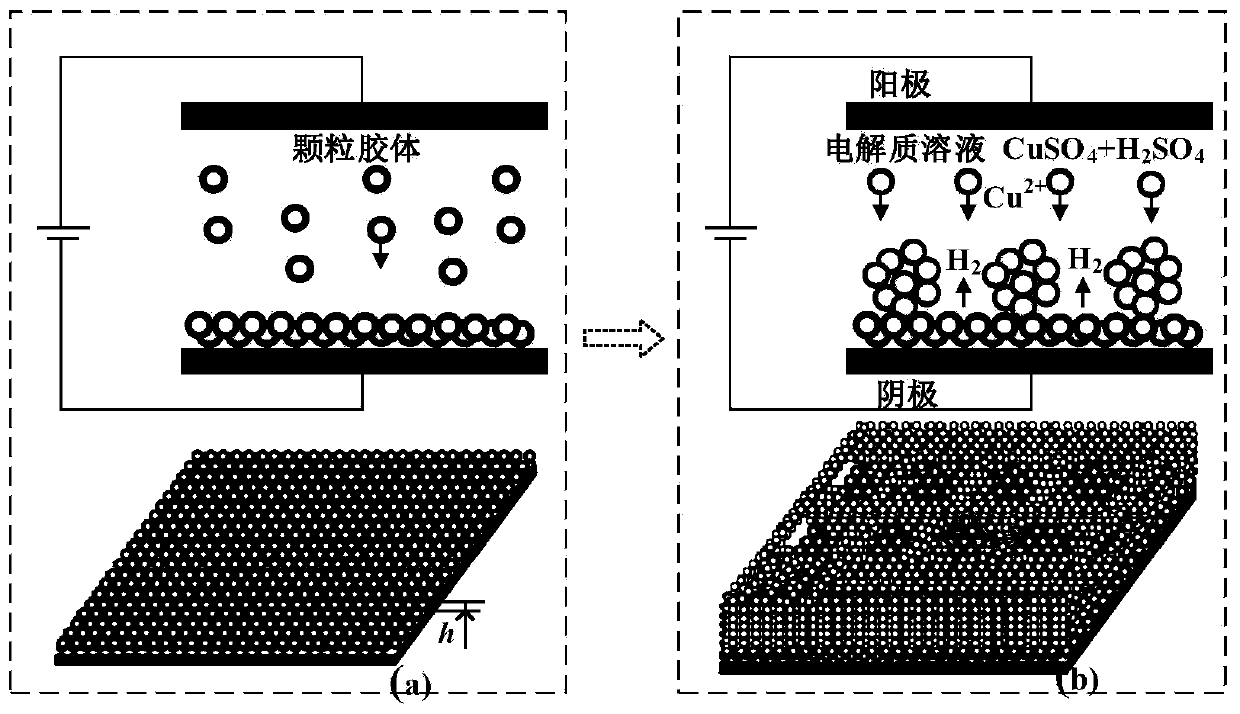

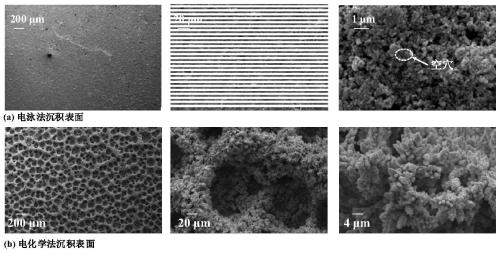

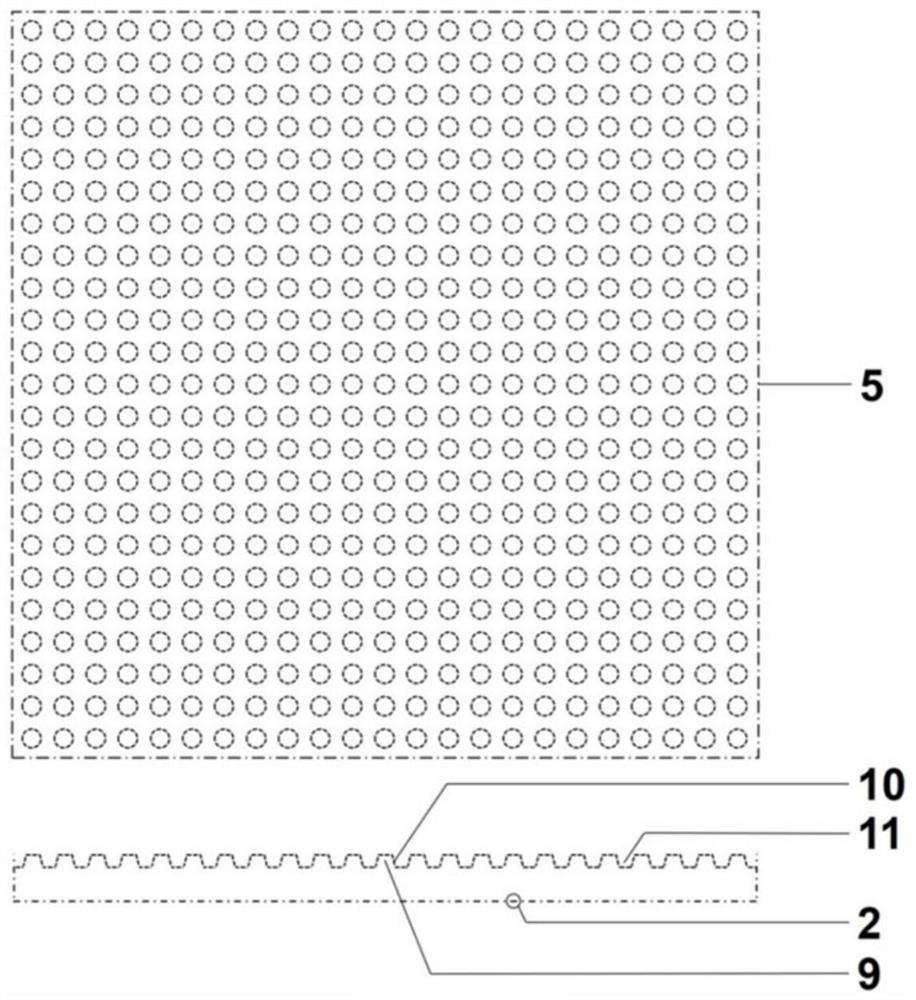

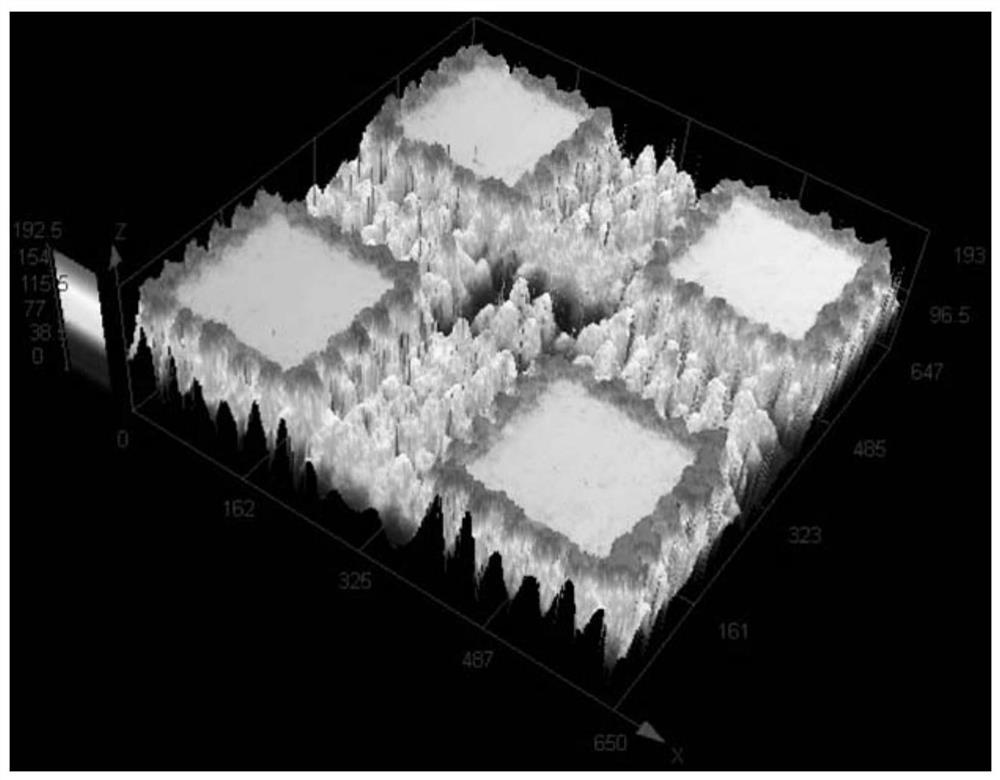

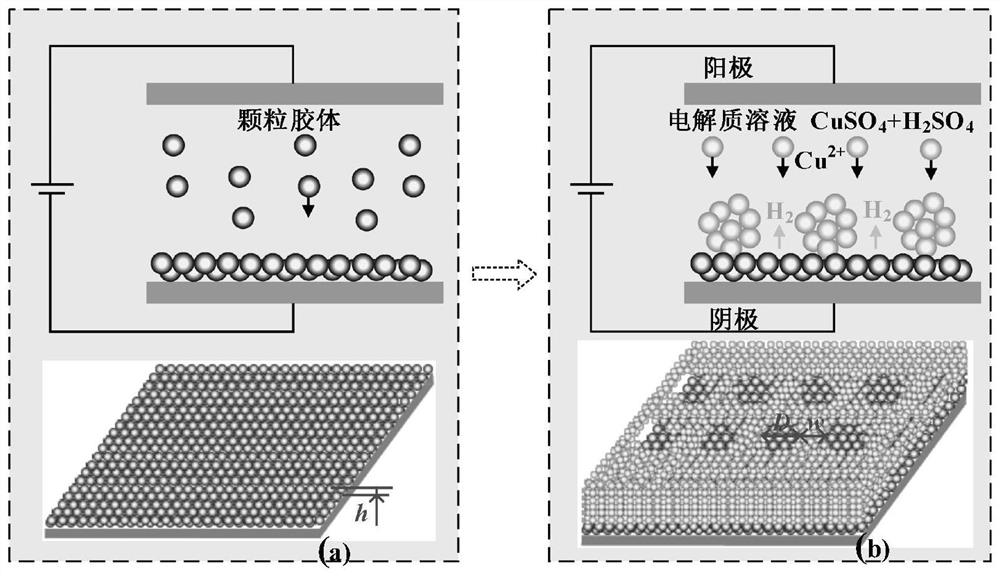

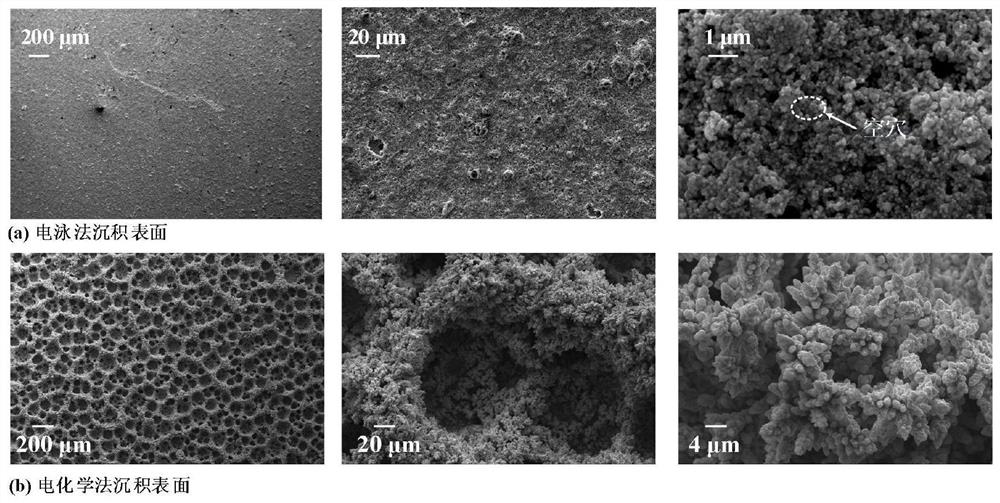

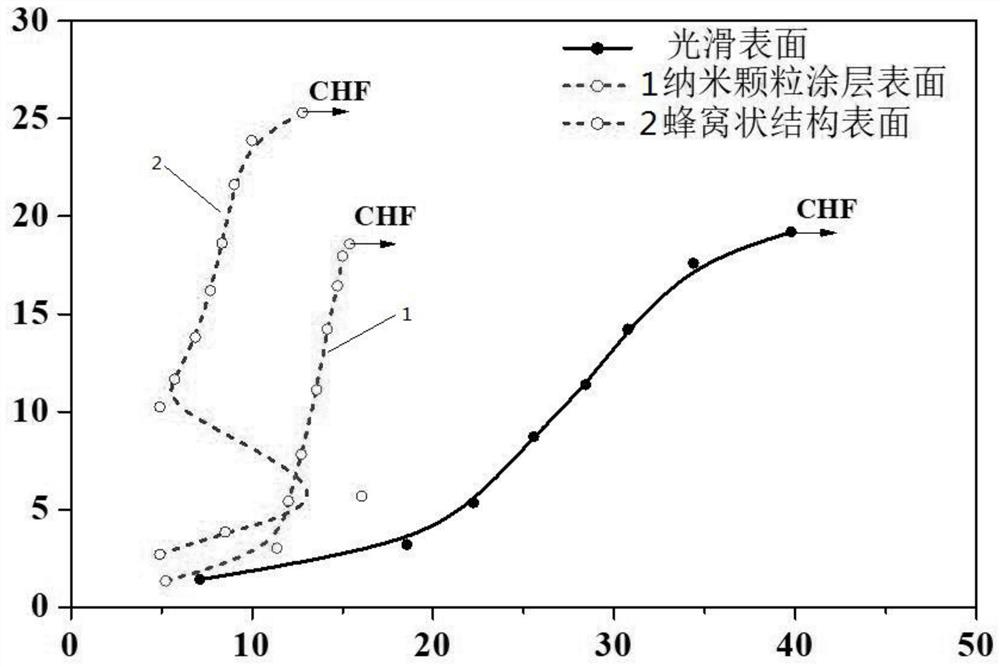

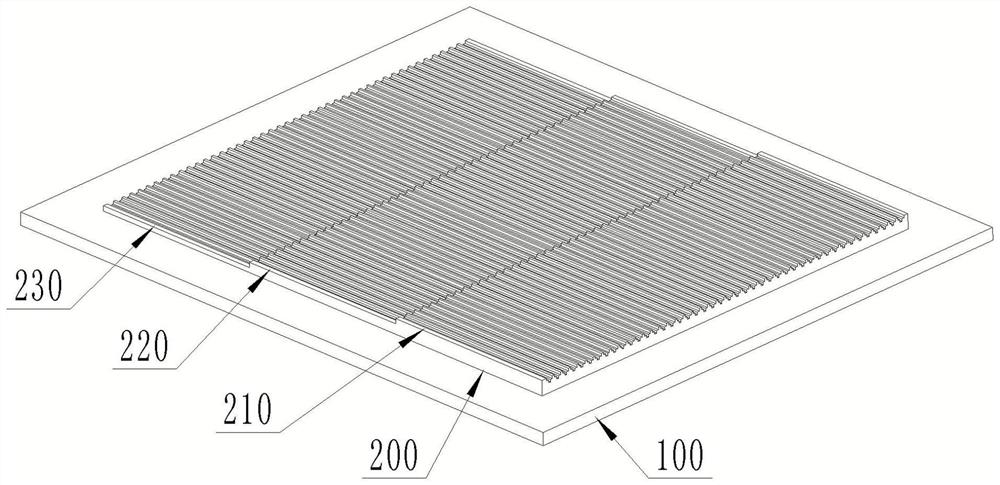

Multiscale surface with boiling enhancement function, and composite preparation method

ActiveCN110408977AIncrease the number ofImprove boiling heat transfer capacityElectrolytic coatingsHeat exchange apparatusMicro structureNanoparticle coating

The invention discloses a multiscale surface with a boiling enhancement function, and a composite preparation method. A nanoparticle coating layer is plated on the smooth surface of a metal or a metalalloy through an electrophoretic deposition method at first; and then a cellular micro-structure is generated on the surface of the nanoparticle coating layer by an electrochemical method, so that amultiscale composite structure surface is prepared. The composite structure surface integrates the advantages of two single preparation methods, on one hand, more effective nucleation sites can be provided; and on the other hand, the liquid supplementing capacity of the surface can be remarkably improved. Therefore, the composite structure surface is capable of enhancing boiling heat exchange performance which comprises a heat transfer coefficient and a critical heat flux density. The enhancement effect is also obvious for ultra-wetting fluids such as FC-72, HFE-7200 and NOVEC-649. Meanwhile,the preparation method is mature, simple and practicable, and low in cost, and provides possibility for large-scale and industrialized application for the preparation method.

Owner:UZHOU QIANXUN NEW ENERGY TECH CO LTD

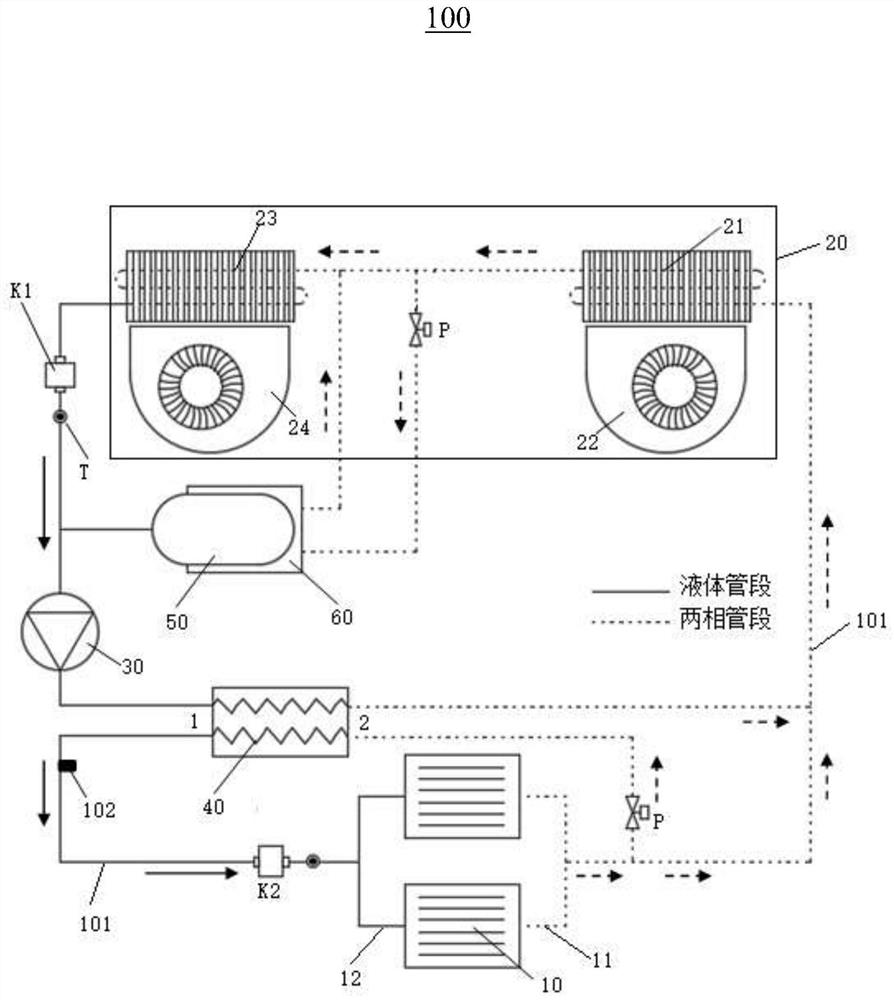

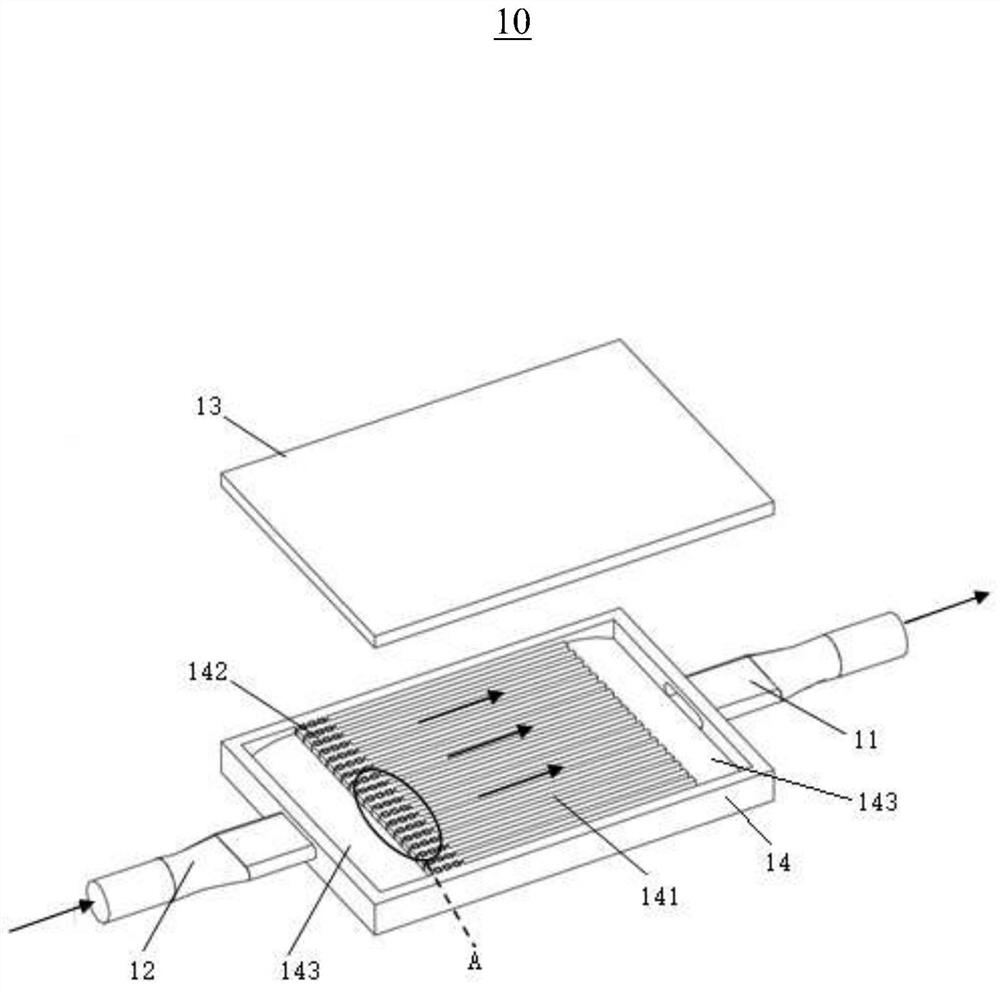

Heat dissipation device and electronic device

PendingCN113013120AStrong ability to resist external disturbanceReduce volumeSemiconductor/solid-state device detailsSolid-state devicesThermodynamicsHeat flow

The invention provides a heat dissipation device. The heat dissipation device comprises a micro-channel evaporator, a condenser, a micro pump, a heat regenerator and a pipeline. An outgoing pipe of the micro-channel evaporator is connected with the condenser through the pipeline, the condenser is connected with the micro pump through the pipeline, the micro pump is connected with the first end of the heat regenerator through the pipeline, and the second end of the heat regenerator is connected with the outgoing pipe of the micro-channel evaporator through the pipeline. The first end of the heat regenerator is further connected with an incoming pipe of the micro-channel evaporator through the pipeline. The invention further provides an electronic device. According to the heat dissipation device and the electronic device, the heat dissipation requirement of a high-heat-flux heat source in a narrow space can be met, and the heat dissipation efficiency is high.

Owner:SHANGHAI WINGTECH ELECTRONICS TECH

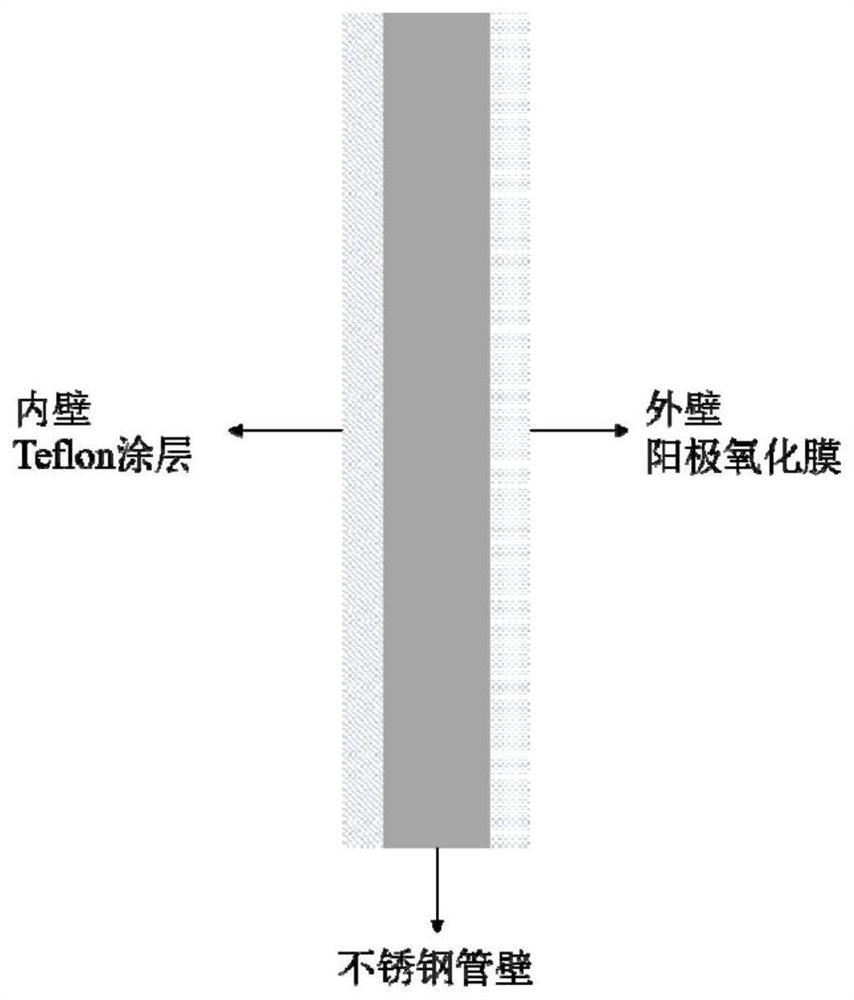

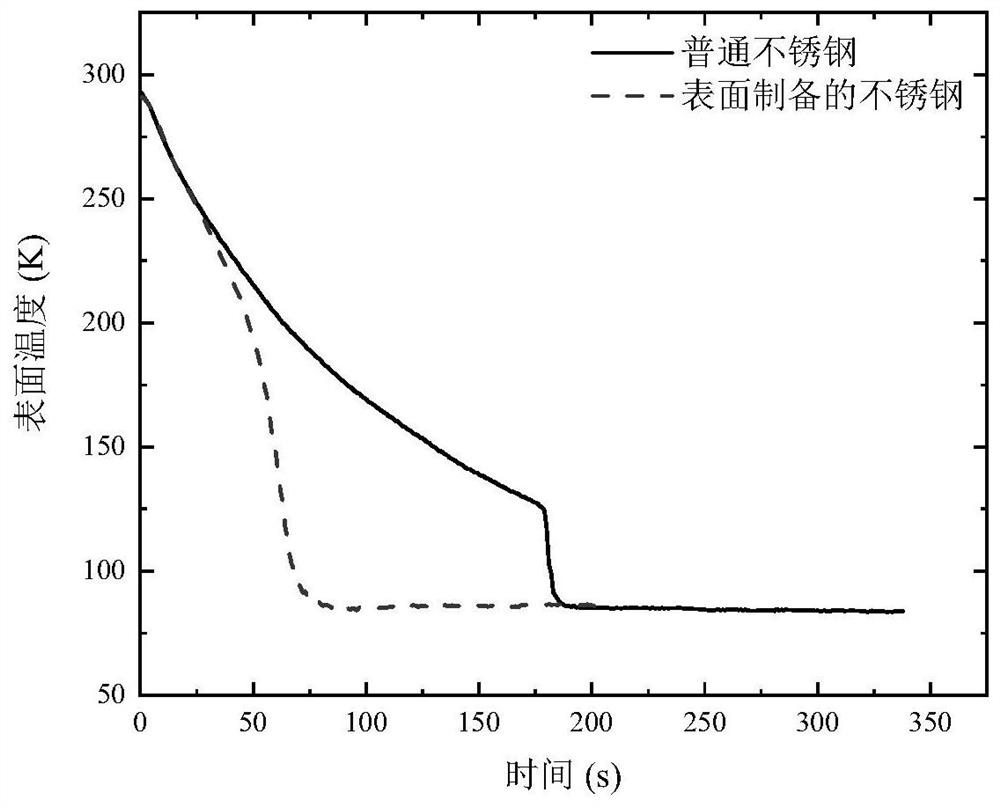

Heat exchange tube of efficient liquid nitrogen heat exchanger and heat exchanger

PendingCN111811315AImprove the effect of cooling and heat exchangeReduce frostingAnodisationHeat transfer modificationEngineeringHeat transfer efficiency

The invention relates to a heat exchange tube of an efficient liquid nitrogen heat exchanger and the heat exchanger. A hydrophobic layer is arranged on the outer surface of a heat exchange tube body,and a thin thermal resistance layer is arranged on the inner surface of the heat exchange tube body. The inner and outer surfaces of the heat exchange tube are specially machined, the heat exchange tube with the hydrophobic outer surface and the thin thermal resistance layer as the inner surface is provided, the hydrophobic outer surface can effectively slow down surface frosting, and the thin thermal resistance layer on the inner surface can significantly improve the internal boiling heat transfer efficiency. The heat exchange tube has the following advantages and effects: the heat exchange effect is good, rapid cooling can be realized, the use efficiency of liquid nitrogen is high, and a large amount of cold energy of cold nitrogen after the liquid nitrogen is vaporized can also be recycled.

Owner:SHANGHAI JIAO TONG UNIV

A nanostructure flat heat pipe

ActiveCN104634148BImprove distributionImprove temperature uniformityIndirect heat exchangersEvaporationCopper oxide

The invention discloses a flat-plate heat tube with a nanometer structure. The flat-plate heat tube with the nanometer structure comprises a bottom plate, a top plate and a supporting plate, wherein the supporting plate is positioned between the top plate and the bottom plate; the bottom plate, the top plate and the supporting plate are hermetically connected to one another to form a hollow closed cavity; a body of the bottom plate which serves as an evaporation surface of the flat-plate heat tube is a brass sheet; a copper oxide film which has a nanometer structure, has a super-hydrophilic property and is formed by electrochemical displacement covers the inner surface of the bottom plate; a body of the top plate which serves as a condensation surface of the flat-plate heat tube is a brass sheet; an electro-nickelling layer which has a nanometer structure and has a super-hydrophobic property covers the inner surface of the top plate; and small through holes are formed in a side surface of the supporting plate and are connected with capillary tubes. The evaporation surface and the condensation surface of the flat-plate heat tube are subjected to super-hydrophilic and super-hydrophobic surface modification, the evaporation speed and the condensation speed are increased, the heat exchange performance of an evaporation region and the heat exchange performance of a condensation region are improved, the thermal homogeneity is high, working medium is guided to return, and the working medium returning speed is increased, so that the whole heat exchange capability is improved.

Owner:GUANGDONG UNIV OF TECH

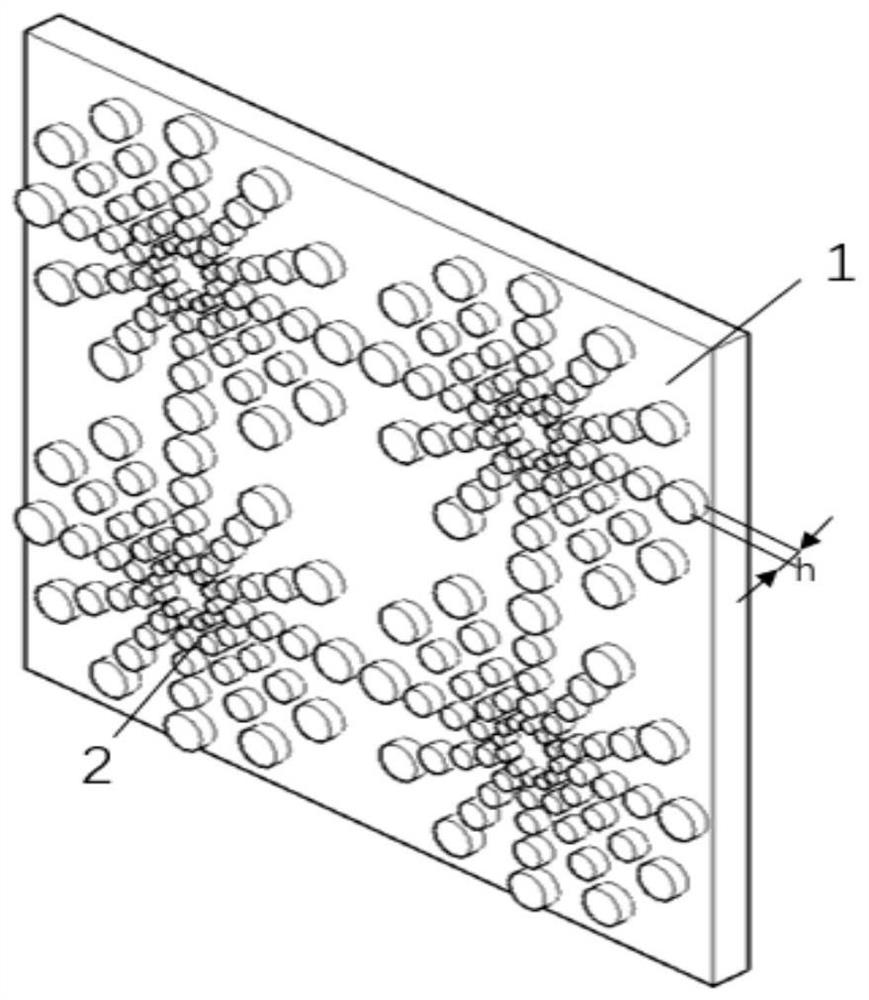

Self-sealing connection type super-aerophobic immersed phase-change liquid-cooling reinforced heat dissipation plate, preparation method and application thereof

PendingCN113677148AReduce thermal contact resistanceLarge specific surface areaModifications using liquid coolingModifications by conduction heat transferPower batteryThermodynamics

The invention discloses a self-sealing connection type super-aerophobic immersed phase-change liquid-cooling reinforced heat dissipation plate, which is characterized in that the surface of the reinforced heat dissipation plate comprises a first area and a second area, micron mastoid arrays are distributed on the surface of the reinforced heat dissipation plate in the first area, micron mastoid arrays are distributed on the surface of the reinforced heat dissipation plate in the second area, liquid-state metal is packaged in gaps of the micron mastoid arrays, the contact area of the reinforced heat dissipation plate and a heating device comprises the second area, the first area of the reinforcedheat dissipation plate comprises a large-area super-aerophobic reinforcedboiling structure so as to remarkably promoteliquid-gas phase change and improve the liquid cooling heat dissipation performance, and the second area has a gap self-filling type sealing connection function, so that the contact thermal resistance with the heating device can be greatly reduced, and the interface heat conduction efficiency is improved. According to the invention, the reinforced heat dissipation plate is low in cost, convenient to assemble and disassemble, stable in performance and simple in preparation process, and has a good application prospect in the fields of data center servers, aerospace thermal control equipment, advanced power batteries and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

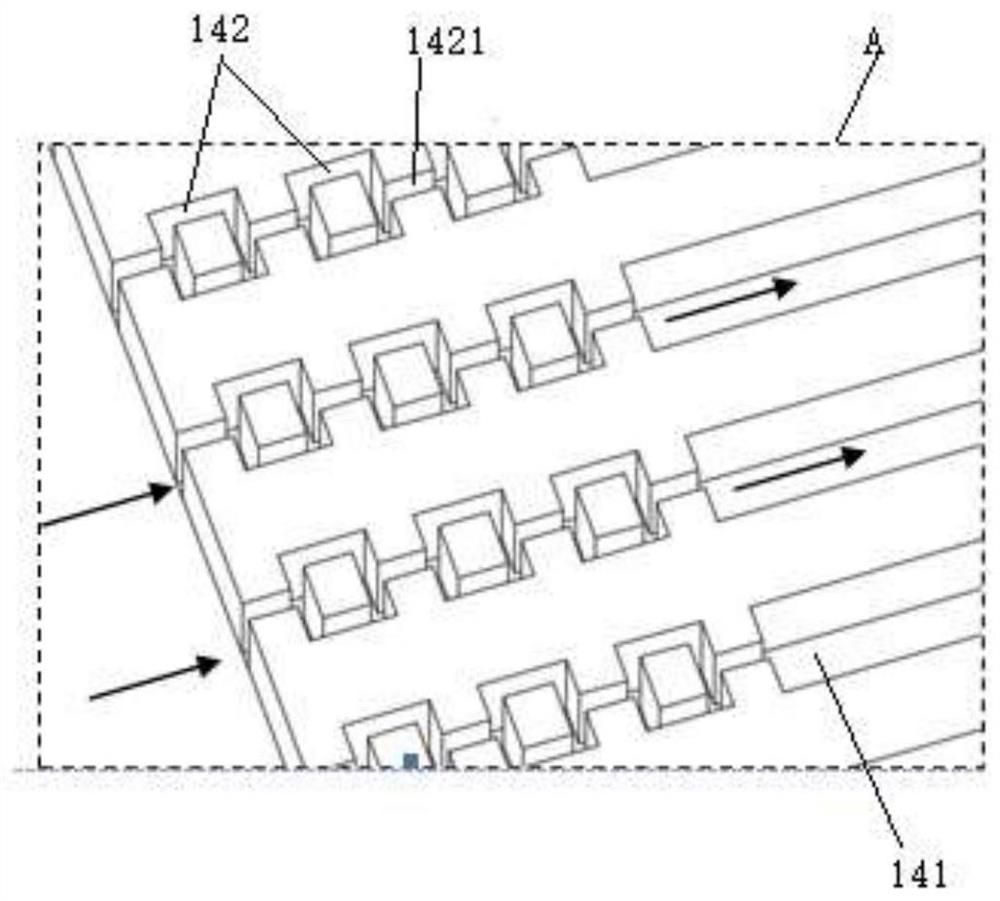

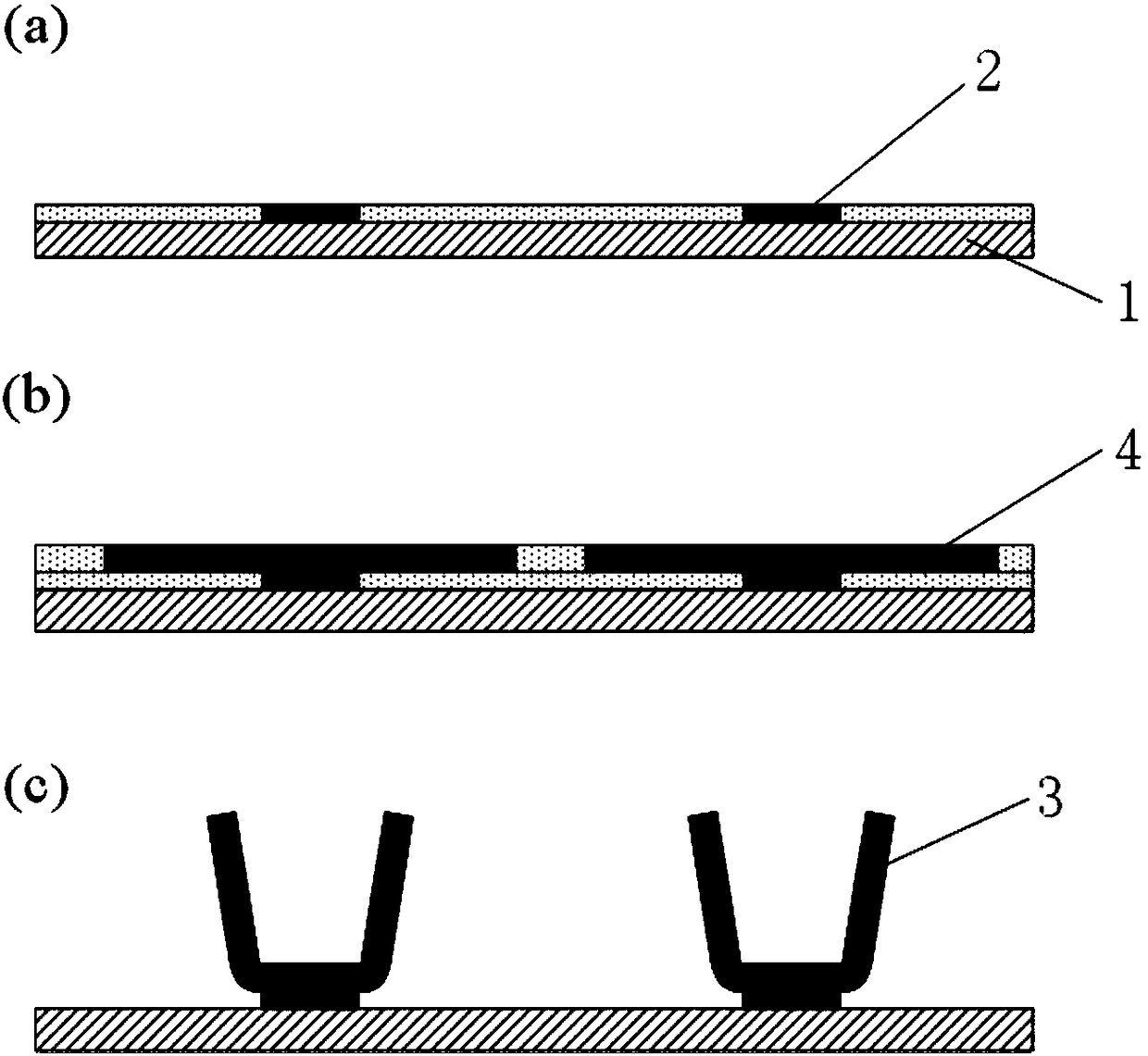

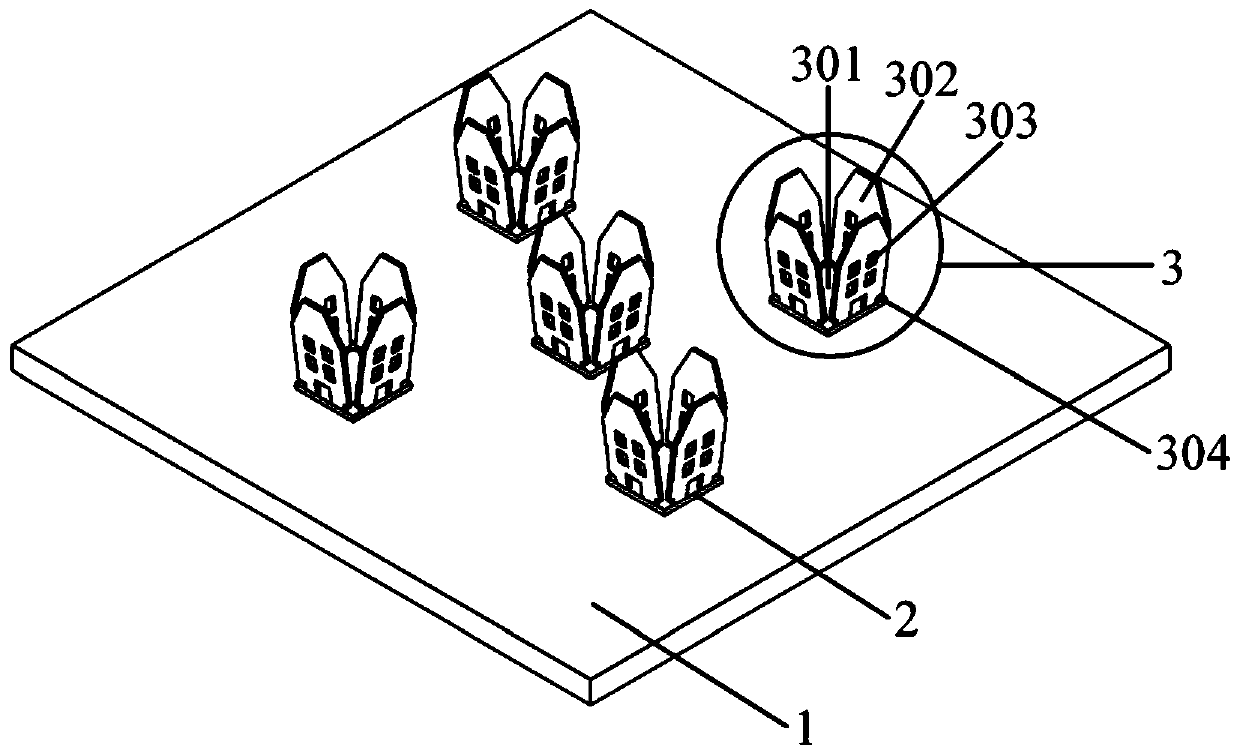

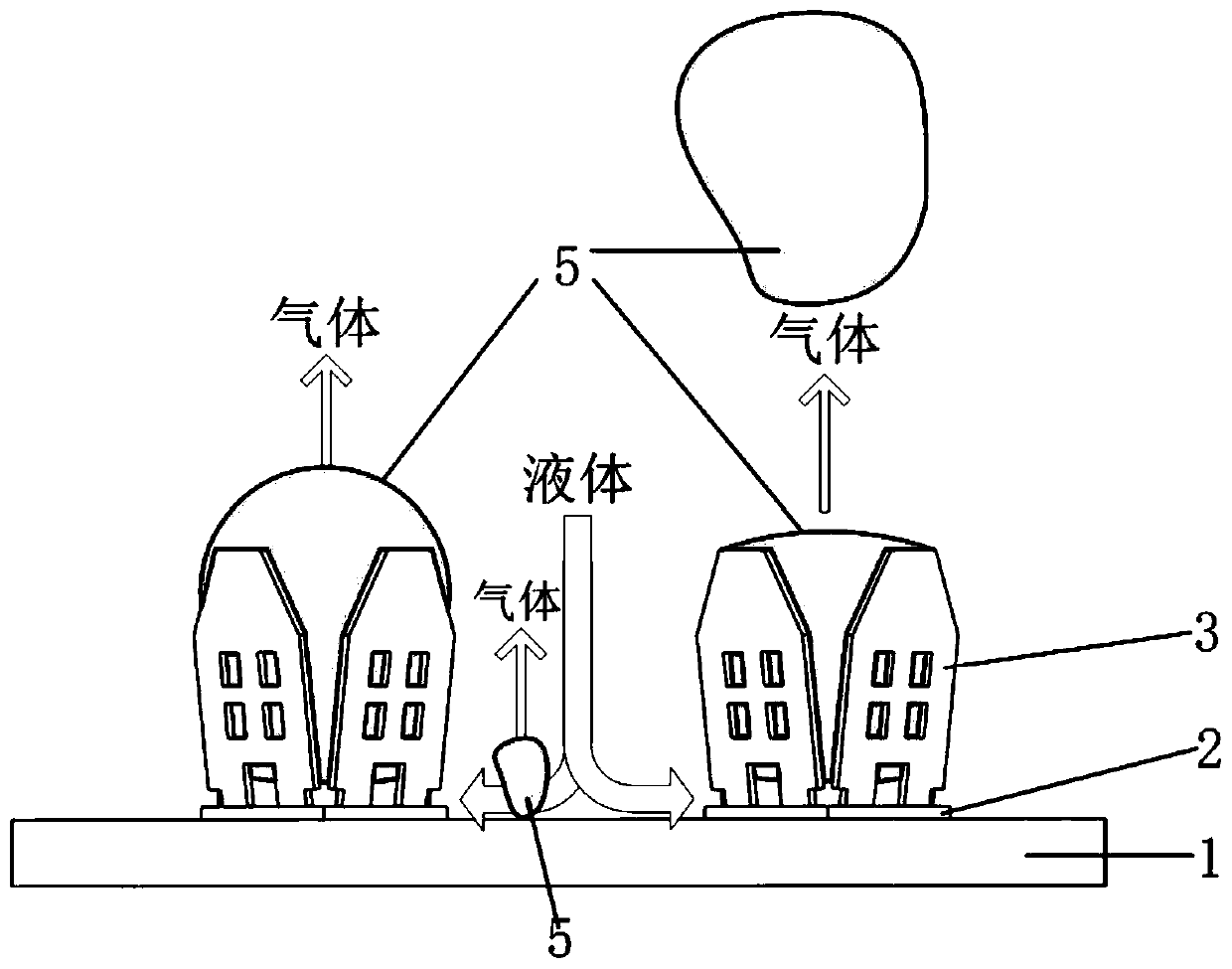

Chip integrated boiling enhancement heat exchange structure and preparation method thereof based on MEMS (Micro Electro Mechanical System) technology

ActiveCN108231712AEnhanced disengagement rateImprove detachment efficiencySemiconductor/solid-state device detailsSolid-state devicesHeat conductingEngineering

The invention provides a chip integrated boiling enhancement heat exchange structure and a preparation method thereof based on an MEMS (Micro Electro Mechanical System) technology. The chip integratedboiling enhancement heat exchange structure comprises a heat conducting substrate, wherein a supporting layer is arranged on the surface of the heat conducting substrate; a plurality of claw type structures are arranged on the supporting layer; the claw type structures are obtained by preparing suspended metal sheet structures by adopting a surface micro-machining method, and folding the suspended metal sheet structures along plane normal thereof. According to the chip integrated boiling enhancement heat exchange structure disclosed by the invention, a path of combining and growing a large amount of surface bubbles into an air film is blocked off by the array claw type structures, so that the dry burning risk is avoided; porous structures can be prepared in the side walls of the claw typestructures so as to ensure liquid supply below the bubbles in the cavity and intensify the separating efficiency of the bubbles; the effects of increasing the heat exchange area by the claw type structures and further intensifying heat exchange by using bubble turbulence and convection of the metal side wall can be realized. Besides, the designed substrate material and a processing mode are derived from a chip integration technology, and application of the structure in integrated heat dissipation of electronic devices is favorably realized.

Owner:SHANGHAI JIAO TONG UNIV

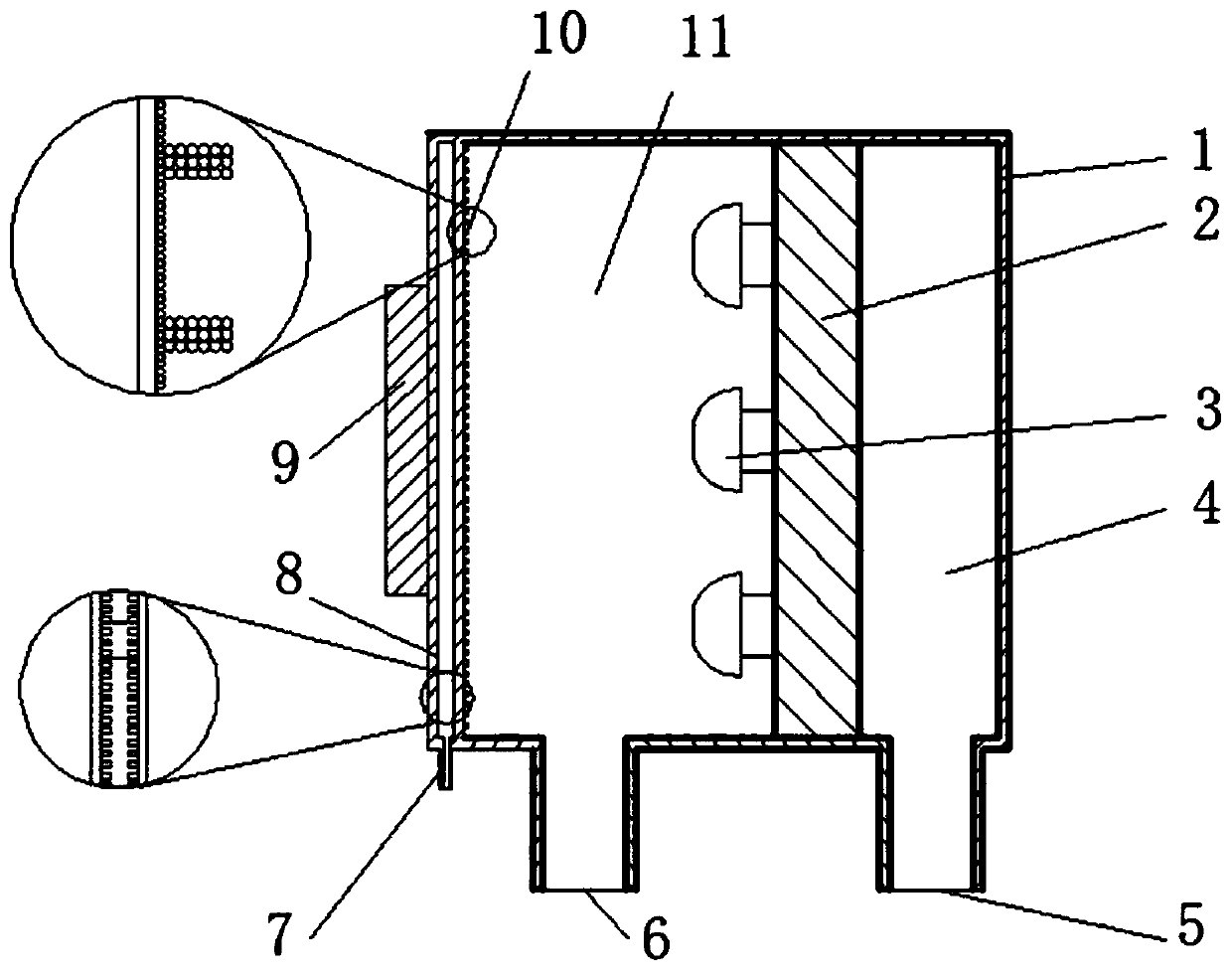

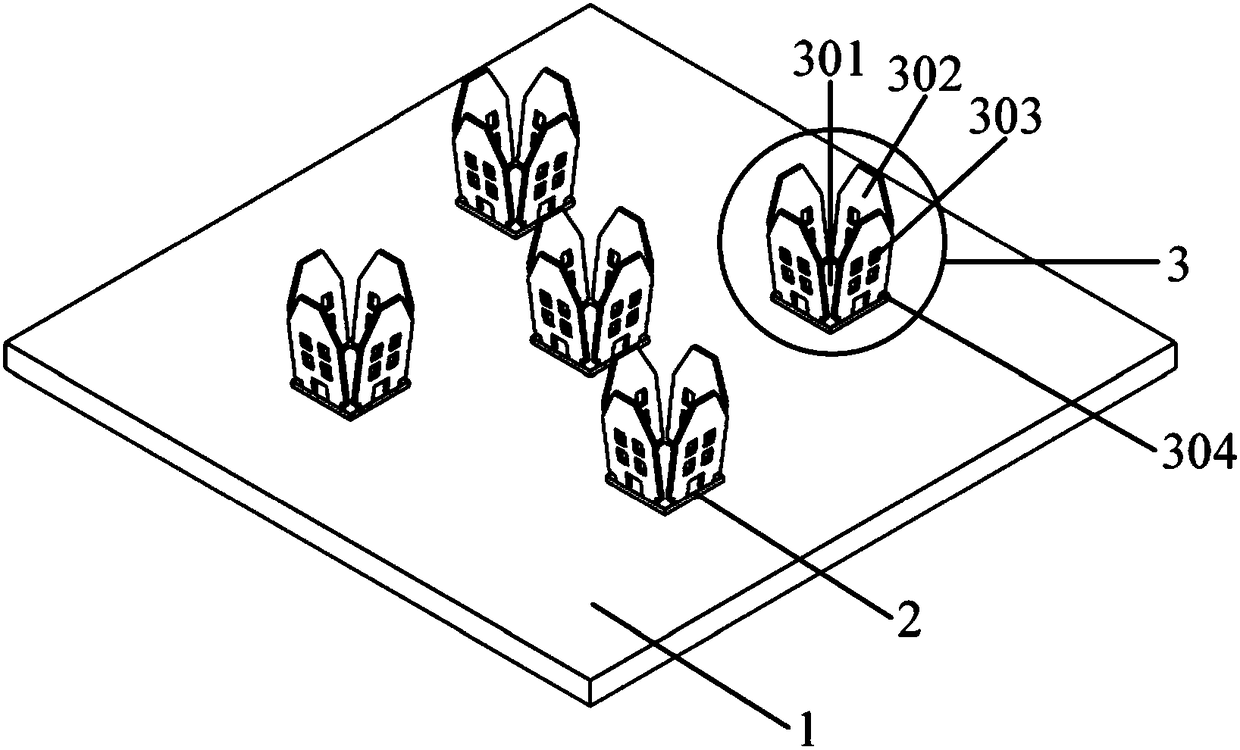

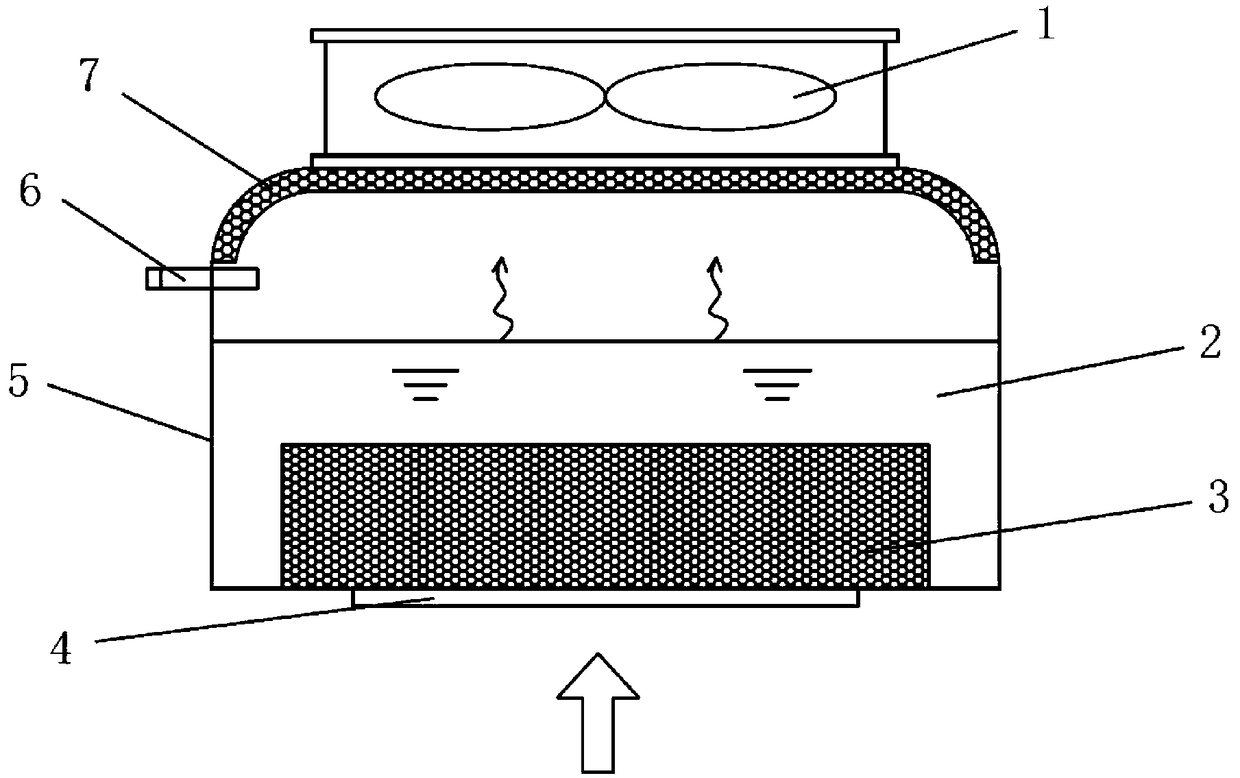

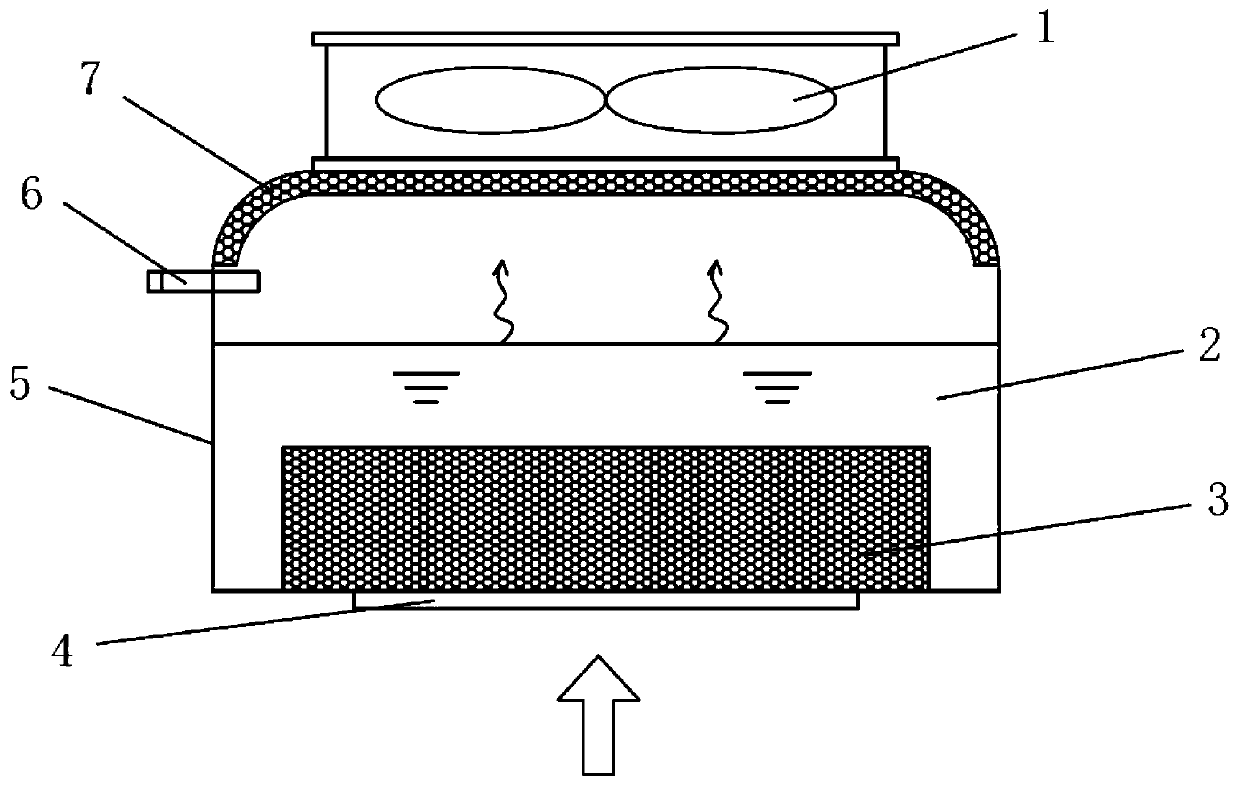

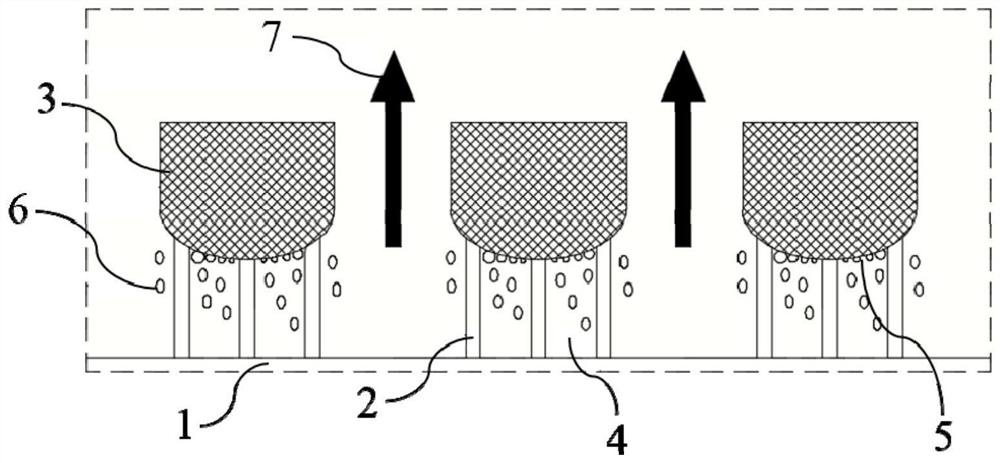

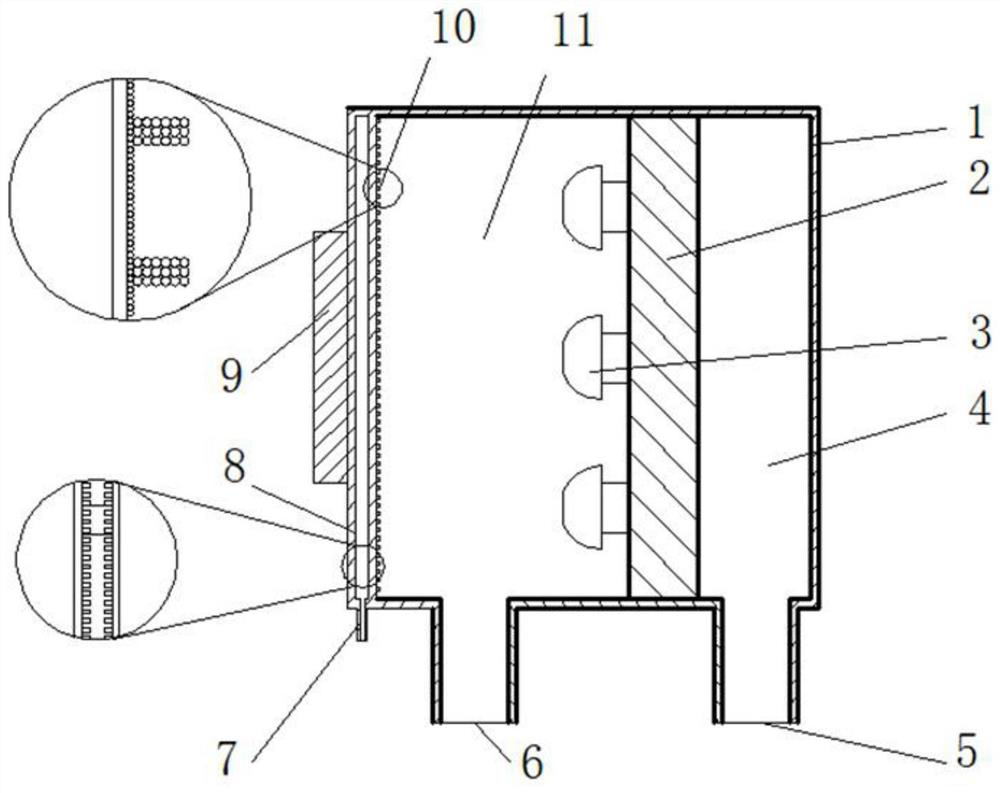

Intelligent foam metal reinforced boiling heat transfer cooling device

ActiveCN108666282ACompact structureImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesPorosityEvaporation

The invention provides an intelligent foam metal reinforced boiling heat transfer cooling device. The intelligent foam metal reinforced boiling heat transfer cooling device comprises a sealing cavity(5), wherein the sealing cavity (5) is filled with a refrigeration fluid (2); a bottom intelligent foam metal (3) is fixed on the inner surface of the bottom of the sealing cavity (5) and is immersedinside the refrigeration fluid (2); a top foam metal (7) is fixed on the inner surface of the top of the sealing cavity (5); a guide pipe (5) is arranged at the upper end of the side surface of the sealing cavity (5); a draught fan (1) is arranged on the outer surface of the top of the sealing cavity (5). The bottom intelligent foam metal (3) has a whole memory effect, and the porosities and poresizes of the foam metals change along with temperature. According to the cooling device provided by the invention, boiling heat transfer is reinforced by using the intelligent foam metals, the evaporation core and heat transfer areas are increased, the flow resistance is also reduced, and the escape speed of bubbles is increased effectively, so that the heat transfer quantity is obviously increased, and the cooling capacity is greatly strengthened.

Owner:SOUTHEAST UNIV

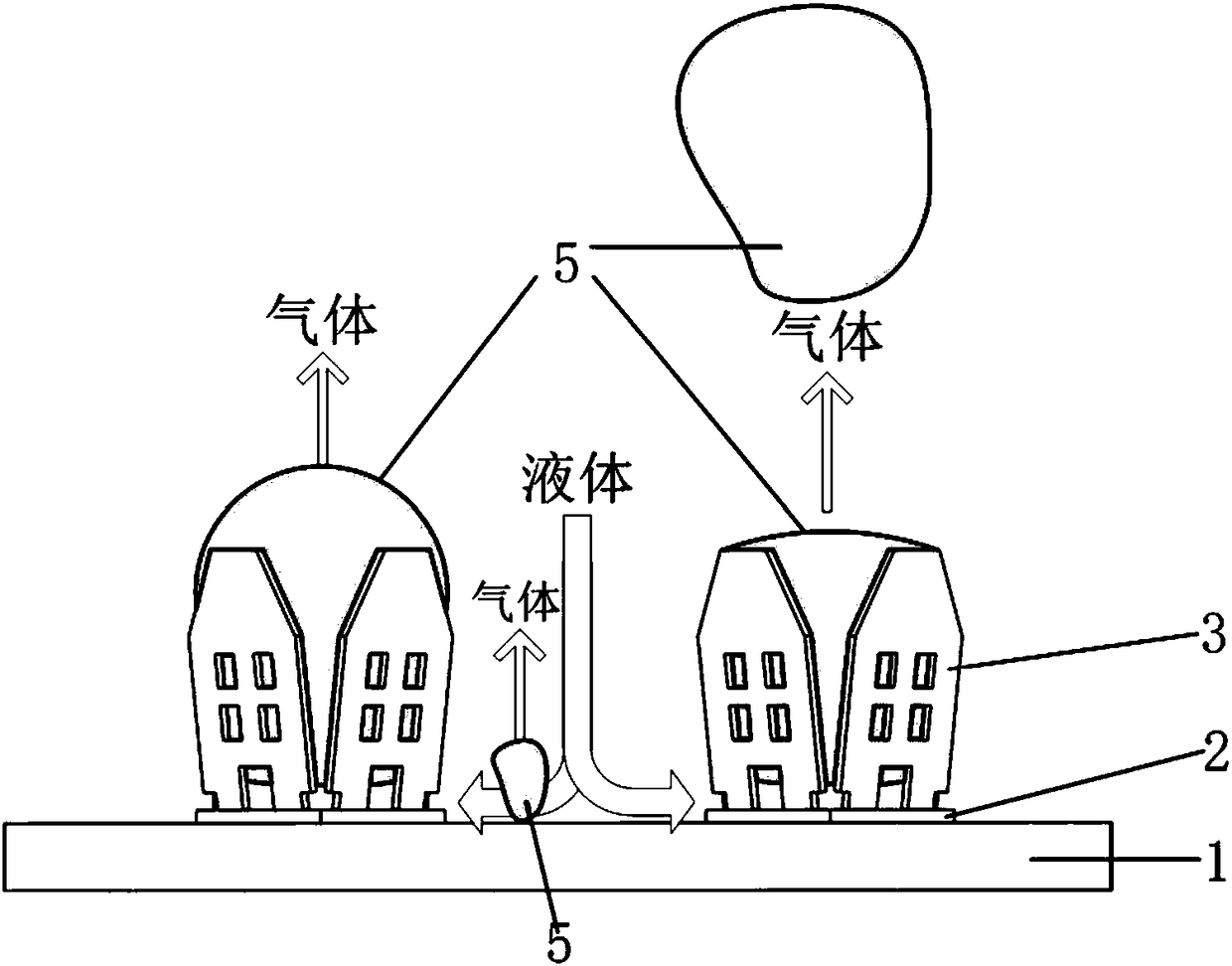

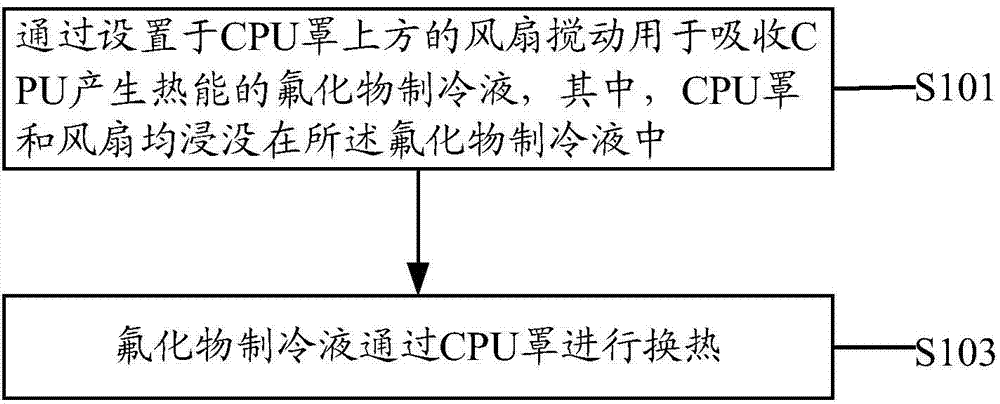

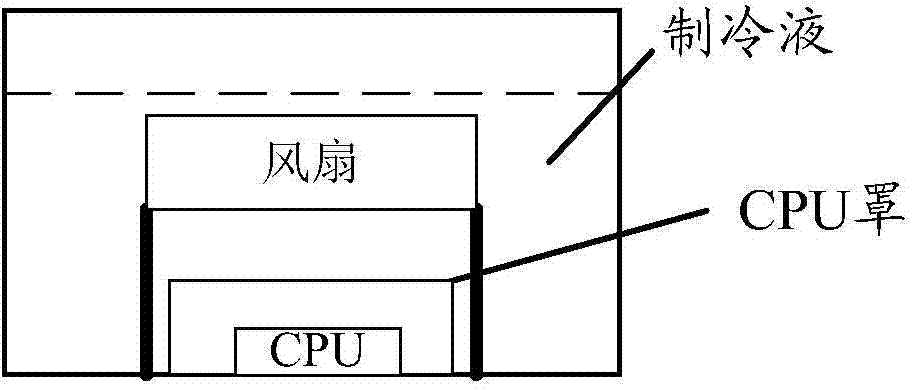

Heat dissipation method and equipment

InactiveCN104331138AImprove boiling heat transfer capacityImprove cooling effectDigital data processing detailsEngineeringFluoride

The invention discloses a heat dissipation method and equipment. The heat dissipation method comprises the following steps: stirring fluoride refrigerating fluid for absorbing heat energy produced by a CPU (Central Processing Unit) through a fan which is arranged on above a CPU housing, wherein the CPU housing and the fan are both immersed in the fluoride refrigerating fluid; performing heat exchange on the fluoride refrigerating fluid through the CPU housing. The surrounding refrigerating fluid is stirred through the fan to promote annihilation of bubbles on the surface of the CPU housing and production of new bubbles, so that the heat exchange performance of boiling is improved and the heat dissipation performance of the system is greatly improved.

Owner:DAWNING INFORMATION IND BEIJING

A kind of gravity heat pipe device and preparation method

InactiveCN105973044BEnhanced condensation heat transfer capacityReduce condensation thermal resistanceIndirect heat exchangersMicro structureNano structuring

The invention discloses a gravity assisted heat pipe device which comprises an evaporator, a heat insulation segment and a condenser. The evaporator and the condenser are in sealed connection with the heat insulation segment. The inner surface of the evaporator is a super-hydrophilic surface. The inner surface of the condenser is a smooth lubricant implanted porous surface (SLIPS). Lubricant on the SLIPS and a charged working medium cannot be mixed. A super-hydrophilic surface of a nano-micro structure is arranged on the inner wall of the evaporator, the working medium can completely moisten the wall face, a liquid film evaporates in the heating process, the evaporation intensity is improved, and the SLIPS of the condenser is formed by compounding the super-hydrophilic of a nano structure with implanted fluorine-containing lubricant or silicone oil or ionic liquid. Condensed liquid drops float on the SLIPS, are combined, fast fall off the SLIPS and sweep small liquid drops on the path of the condensed liquid drops, a condensation surface is provided for secondary condensation, and the condensation and heat exchange effect is remarkably improved. According to the gravity assisted heat pipe device, heat pipe heat resistance can be effectively reduced, the heat exchange performance of the device is improved, and wide application prospects are achieved.

Owner:SHANGHAI JIAO TONG UNIV

An intelligent foam metal enhanced boiling heat transfer cooling device

ActiveCN108666282BIncrease the number ofGuaranteed heat exchange effectSemiconductor/solid-state device detailsSolid-state devicesEvaporation heat transferEngineering

The invention provides an intelligent foam metal reinforced boiling heat transfer cooling device. The intelligent foam metal reinforced boiling heat transfer cooling device comprises a sealing cavity(5), wherein the sealing cavity (5) is filled with a refrigeration fluid (2); a bottom intelligent foam metal (3) is fixed on the inner surface of the bottom of the sealing cavity (5) and is immersedinside the refrigeration fluid (2); a top foam metal (7) is fixed on the inner surface of the top of the sealing cavity (5); a guide pipe (5) is arranged at the upper end of the side surface of the sealing cavity (5); a draught fan (1) is arranged on the outer surface of the top of the sealing cavity (5). The bottom intelligent foam metal (3) has a whole memory effect, and the porosities and poresizes of the foam metals change along with temperature. According to the cooling device provided by the invention, boiling heat transfer is reinforced by using the intelligent foam metals, the evaporation core and heat transfer areas are increased, the flow resistance is also reduced, and the escape speed of bubbles is increased effectively, so that the heat transfer quantity is obviously increased, and the cooling capacity is greatly strengthened.

Owner:SOUTHEAST UNIV

A kind of material surface micro-nano composite enhanced boiling structure and preparation method and application thereof

ActiveCN109974512BLittle motor blockMultiple Vaporization CoresHeat transfer modificationLaser beam welding apparatusMicro nanoComposite structure

The invention discloses a material surface micro-nano composite strengthening boiling structure as well as a preparation method and application of the material surface micro-nano composite strengthening boiling structure. The material surface micro-nano composite strengthening boiling structure comprises a base material and a micro-nano composite structure formed on the surface of the base material. The micro-nano composite structure comprises micro mastoids, communication-type grooves and nano-folds, wherein the micro mastoids are formed in the communication-type grooves, and the surfaces ofthe micro mastoids are provided with nano-fold shapes. The preparation method of the material surface micro-nano composite strengthening boiling structure comprises the following step of forming a micro-nano composite strengthening boiling structure on the base material through a laser integrated etching method. The material surface micro-nano composite strengthening boiling structure has multi-scale micron and nanometer characteristics in different levels.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Chip-integrated boiling enhanced heat transfer structure based on mems technology and its preparation method

ActiveCN108231712BEnhanced disengagement rateImprove detachment efficiencySemiconductor/solid-state device detailsSolid-state devicesHeat conductingEngineering

The invention provides a chip integrated boiling enhancement heat exchange structure and a preparation method thereof based on an MEMS (Micro Electro Mechanical System) technology. The chip integratedboiling enhancement heat exchange structure comprises a heat conducting substrate, wherein a supporting layer is arranged on the surface of the heat conducting substrate; a plurality of claw type structures are arranged on the supporting layer; the claw type structures are obtained by preparing suspended metal sheet structures by adopting a surface micro-machining method, and folding the suspended metal sheet structures along plane normal thereof. According to the chip integrated boiling enhancement heat exchange structure disclosed by the invention, a path of combining and growing a large amount of surface bubbles into an air film is blocked off by the array claw type structures, so that the dry burning risk is avoided; porous structures can be prepared in the side walls of the claw typestructures so as to ensure liquid supply below the bubbles in the cavity and intensify the separating efficiency of the bubbles; the effects of increasing the heat exchange area by the claw type structures and further intensifying heat exchange by using bubble turbulence and convection of the metal side wall can be realized. Besides, the designed substrate material and a processing mode are derived from a chip integration technology, and application of the structure in integrated heat dissipation of electronic devices is favorably realized.

Owner:SHANGHAI JIAOTONG UNIV

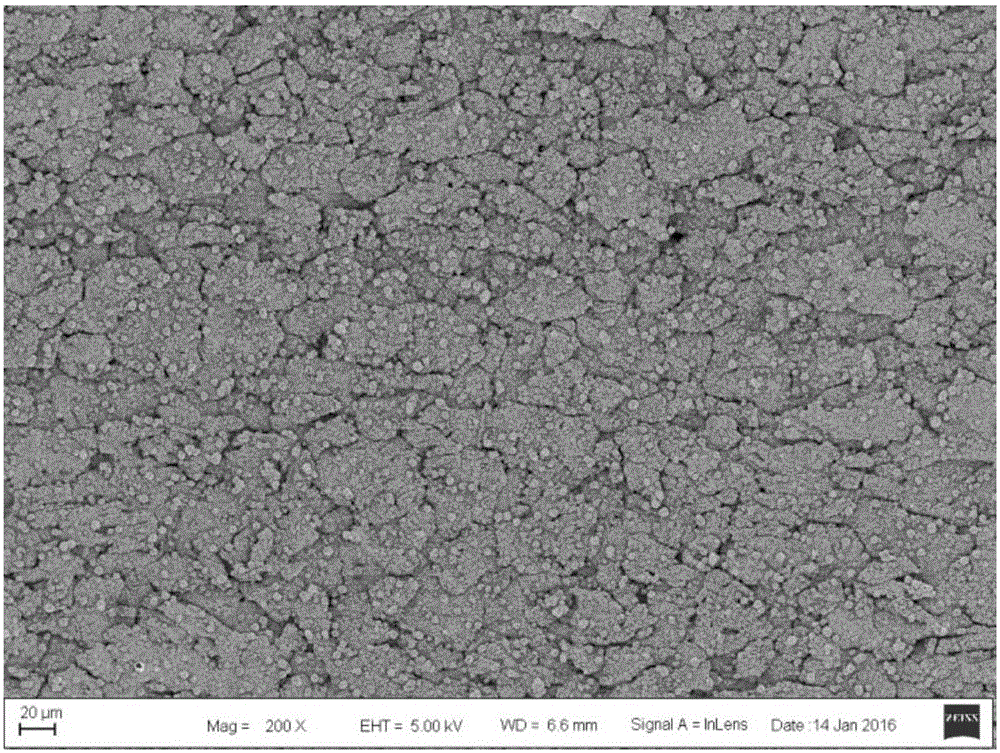

A multi-scale enhanced boiling functional surface and composite preparation method

ActiveCN110408977BIncrease the number ofImprove boiling heat transfer capacityElectrolytic coatingsHeat exchange apparatusElectrochemistryBoiling heat transfer

The invention discloses a multi-scale enhanced boiling surface and a composite preparation method thereof. Firstly, the nanoparticle coating is plated on the smooth surface of the metal or metal alloy by electrophoretic deposition. Subsequently, a honeycomb microstructure was generated on the surface of the nanoparticle coating by an electrochemical method. Thus, a multi-scale composite structure surface is prepared. The composite structure surface combines the advantages of two single preparation methods. On the one hand, it can provide more effective vaporization cores, and on the other hand, it can significantly improve the surface rehydration ability. Therefore, the composite structure surface can enhance the boiling heat transfer performance, including heat transfer coefficient and critical heat flux. For super-wetting fluids, such as FC‑72, HFE‑7200, NOVEC‑649, etc., the strengthening effect is also obvious. At the same time, the preparation method is mature, simple, and low-cost, which provides the possibility of its large-scale and industrial application.

Owner:UZHOU QIANXUN NEW ENERGY TECH CO LTD

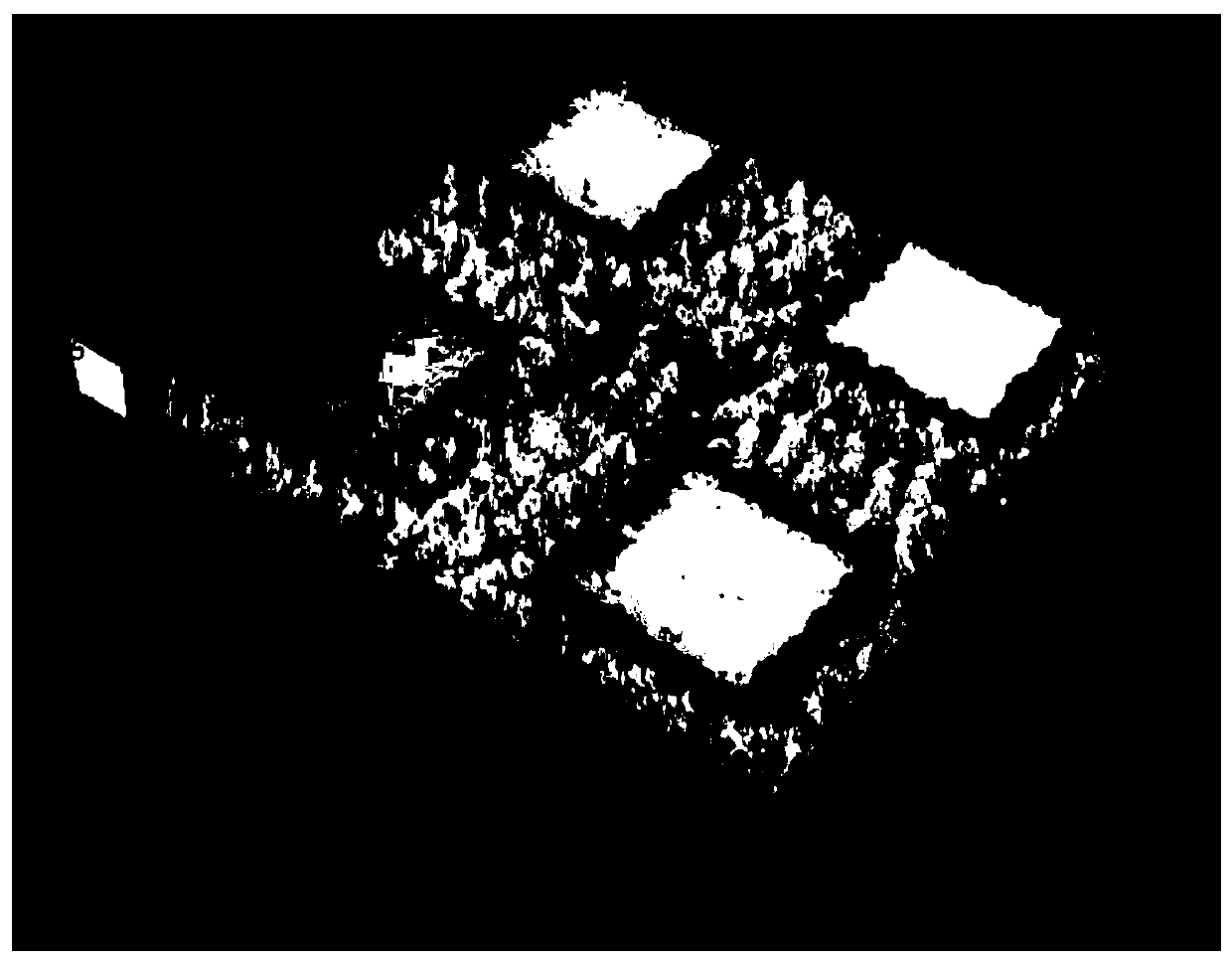

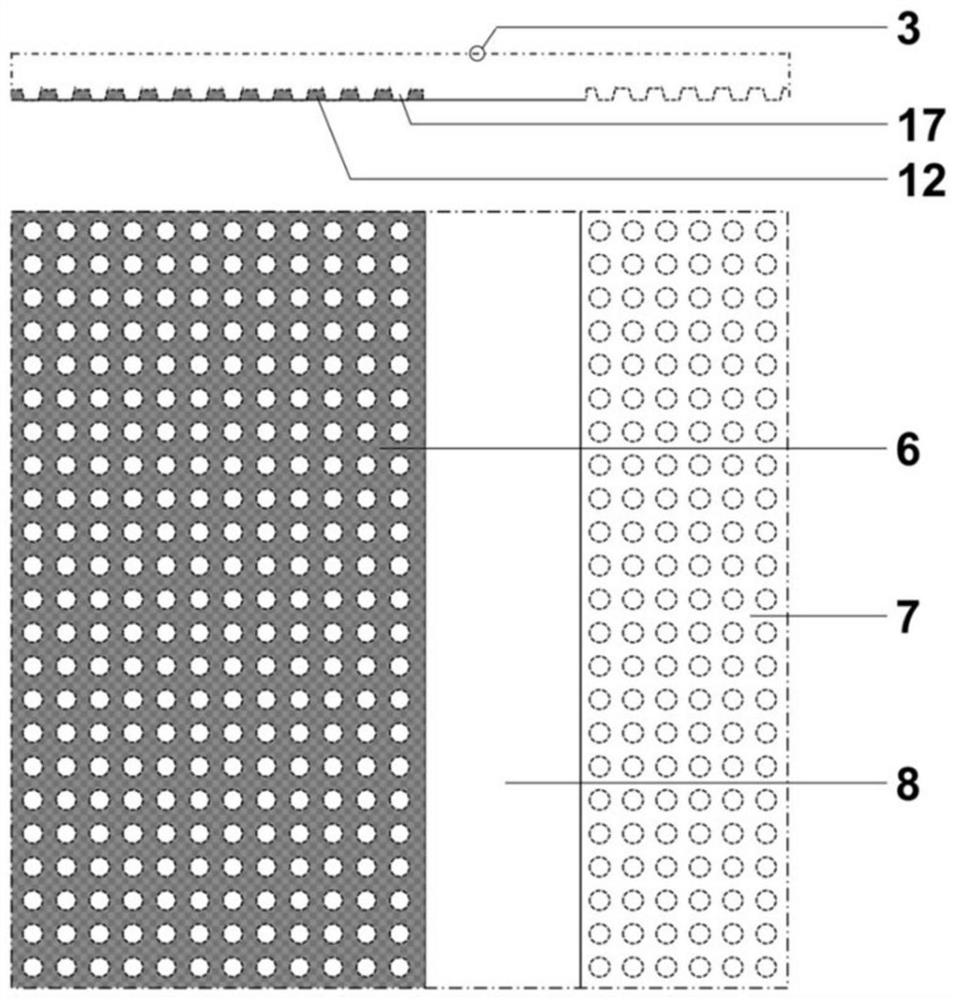

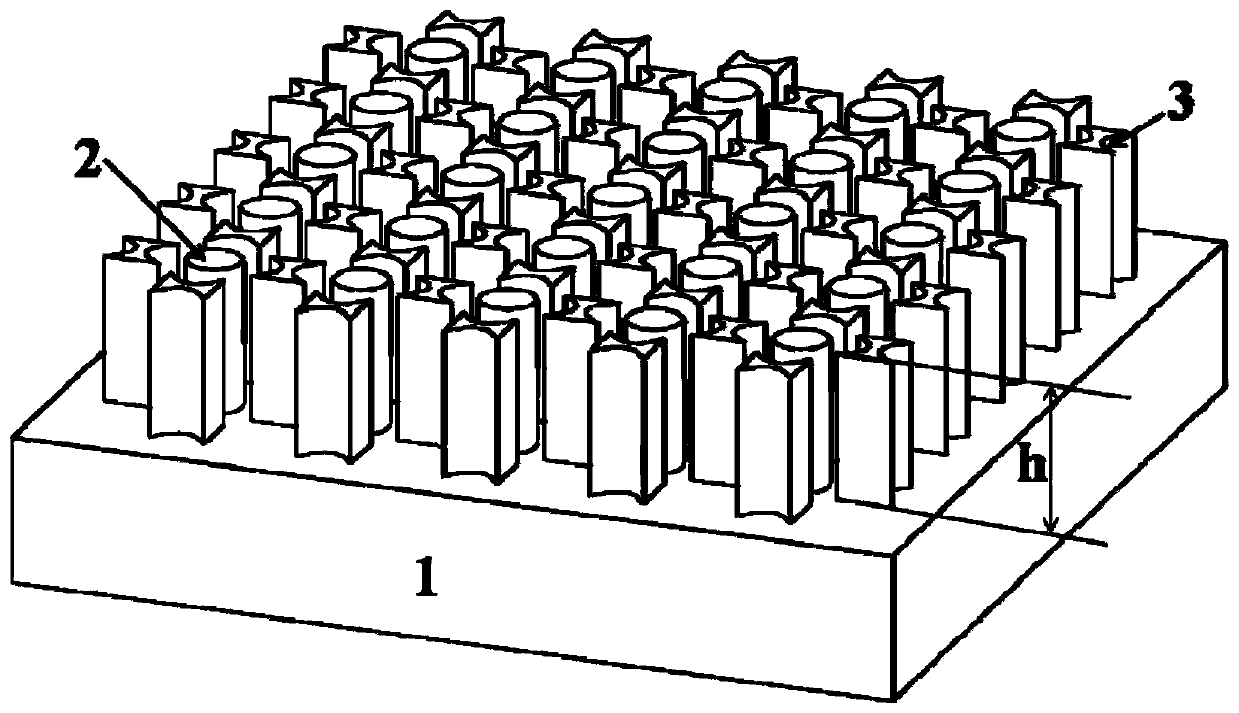

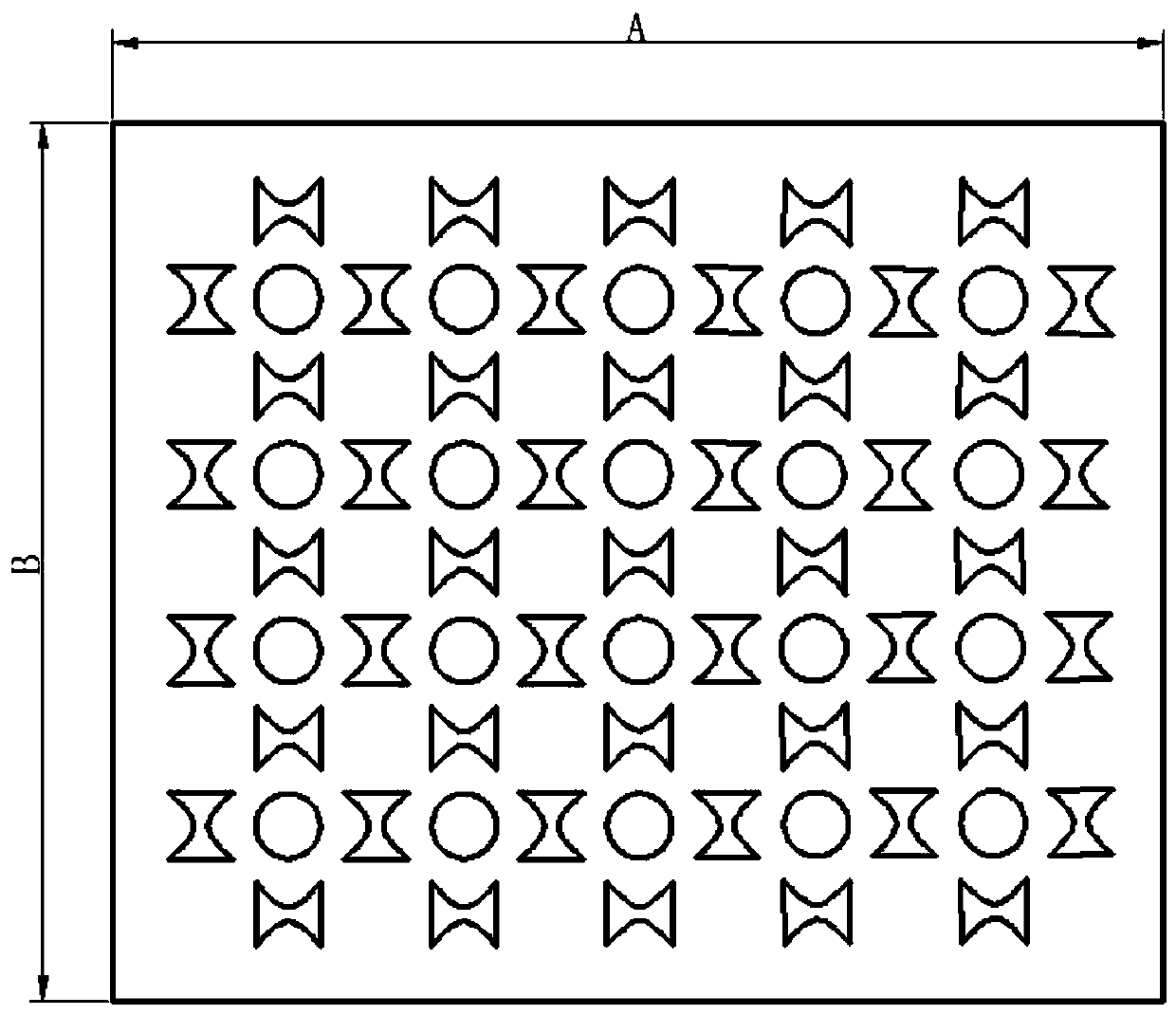

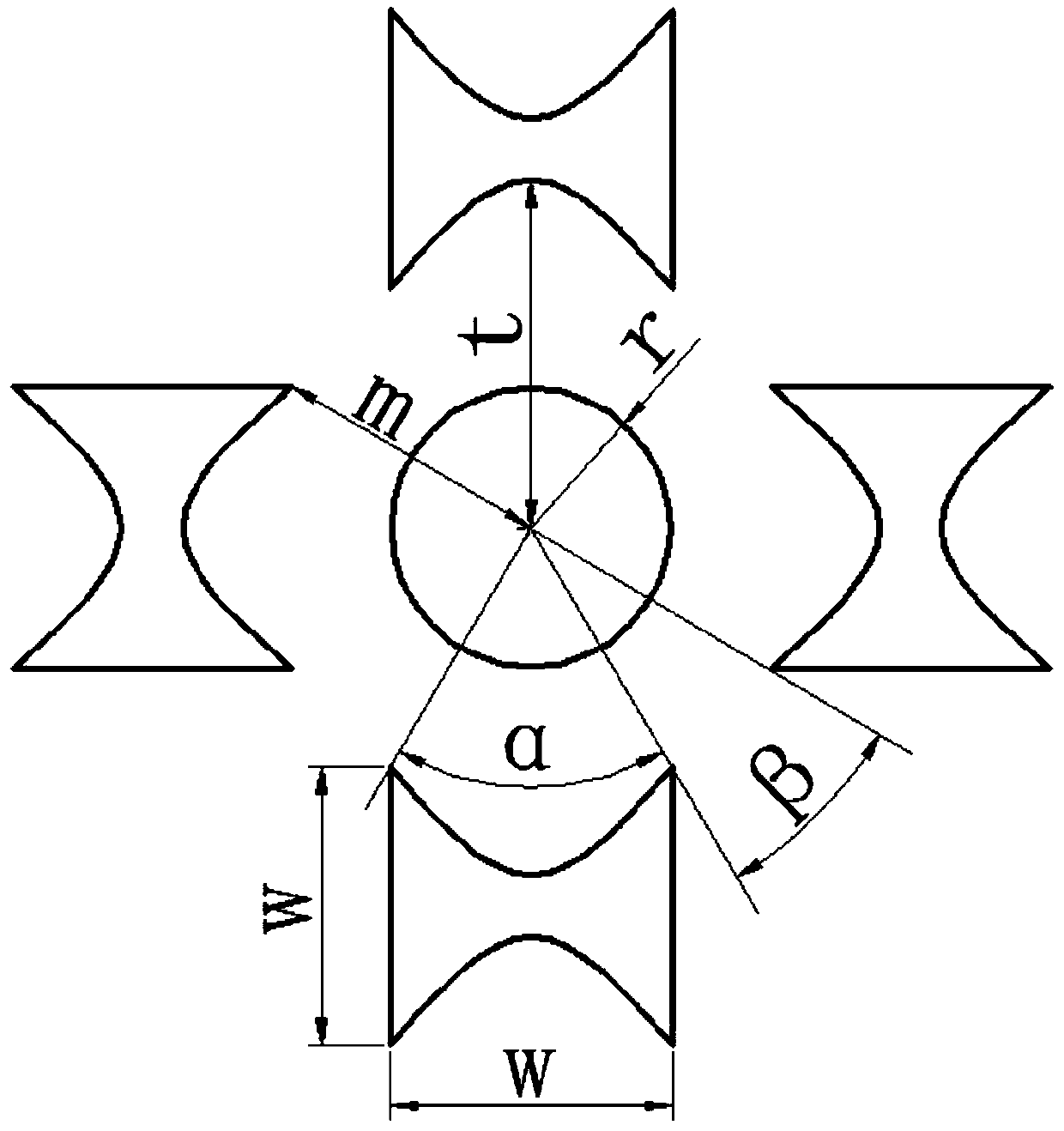

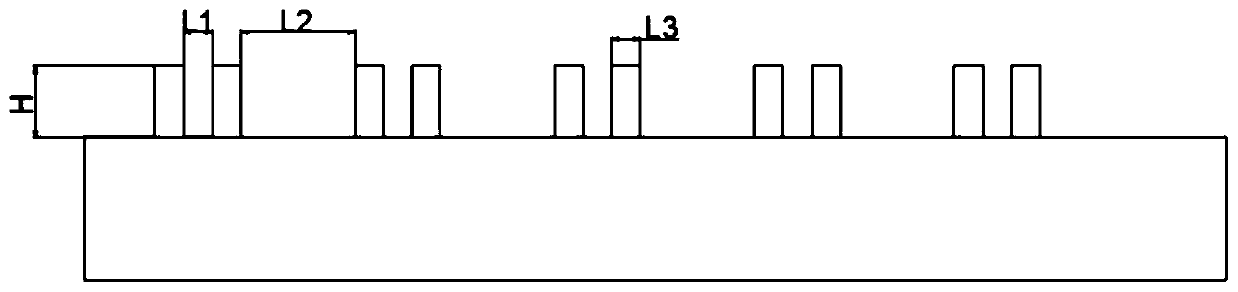

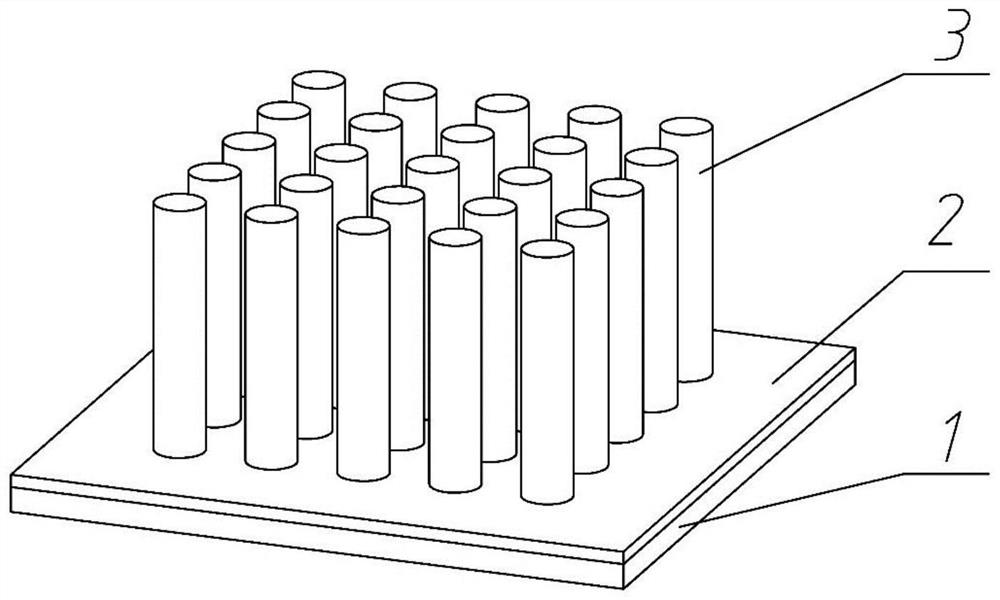

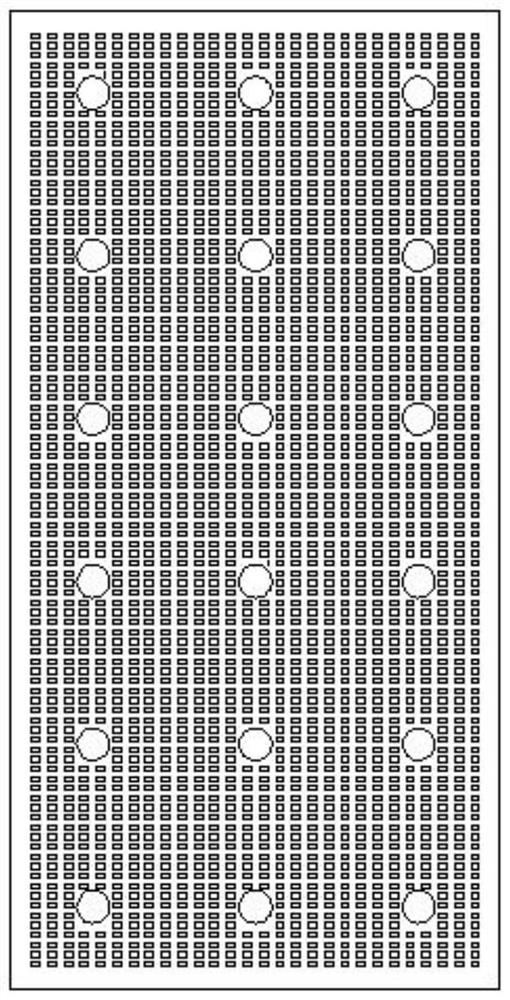

A combined columnar chip enhanced boiling heat transfer microstructure and its manufacturing method

ActiveCN108321135BIncrease the number ofImprove performanceSemiconductor/solid-state device detailsSolid-state devicesMicro columnEvaporation

The invention discloses a combined cylindrical chip reinforced boiling heat transfer microstructure and a manufacturing method thereof. The microstructure comprises a heat-dissipation plate arranged on the surface of a chip. The heat-dissipation plate is provided with a plurality of combination units. Each combination unit is formed by five microcolumns. The center of each combination unit is a cylindrical micro-column, and the rest four H-shaped micro-columns are arranged around the cylindrical micro-column symmetrically. The two surfaces of each H-shaped micro-column facing to the cylindrical micro-column and opposite to the cylindrical micro-column are the same parabolic surfaces, and the rest two sides surfaces and the top surface are planes; and every two adjacent combination units share one H-shaped micro-column. The microstructure can greatly increase the number of bubble evaporation cores, and greatly improve nucleate boiling heat transfer performance and critical heat flux density.

Owner:XI AN JIAOTONG UNIV

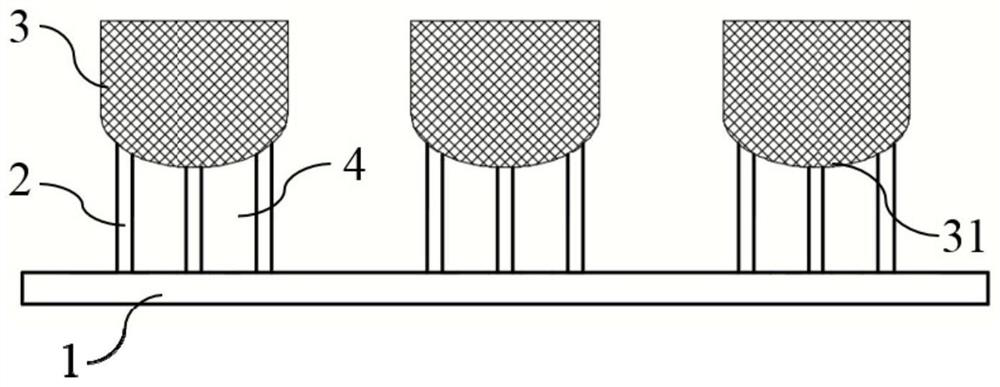

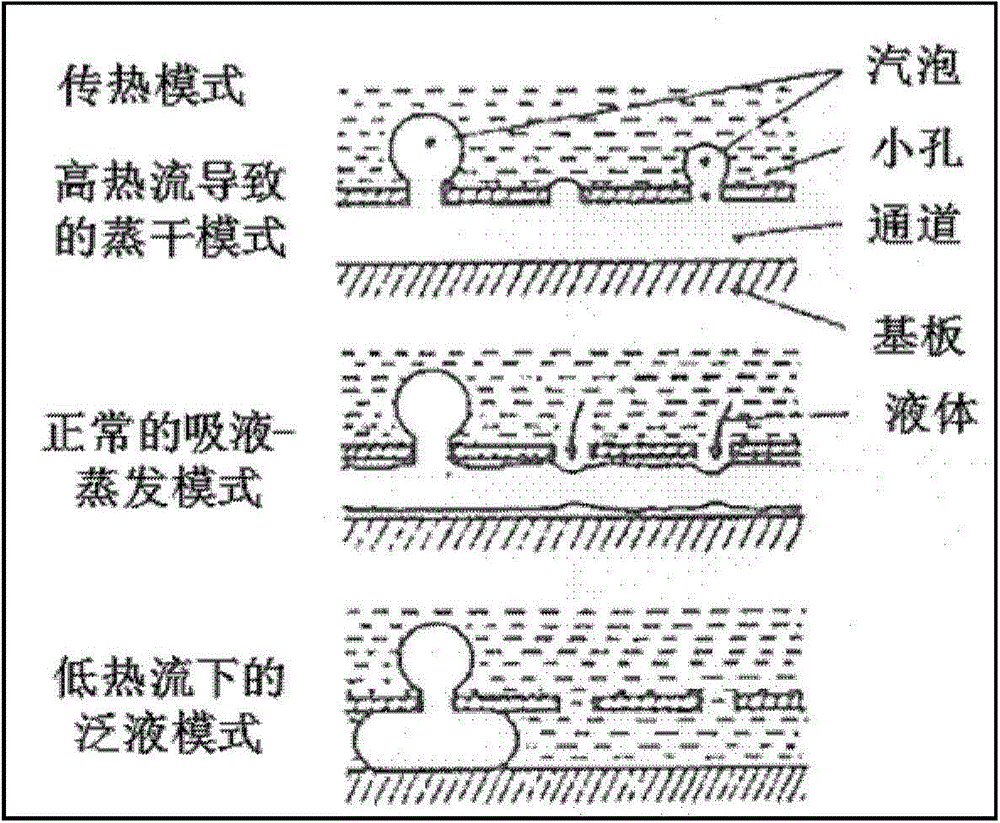

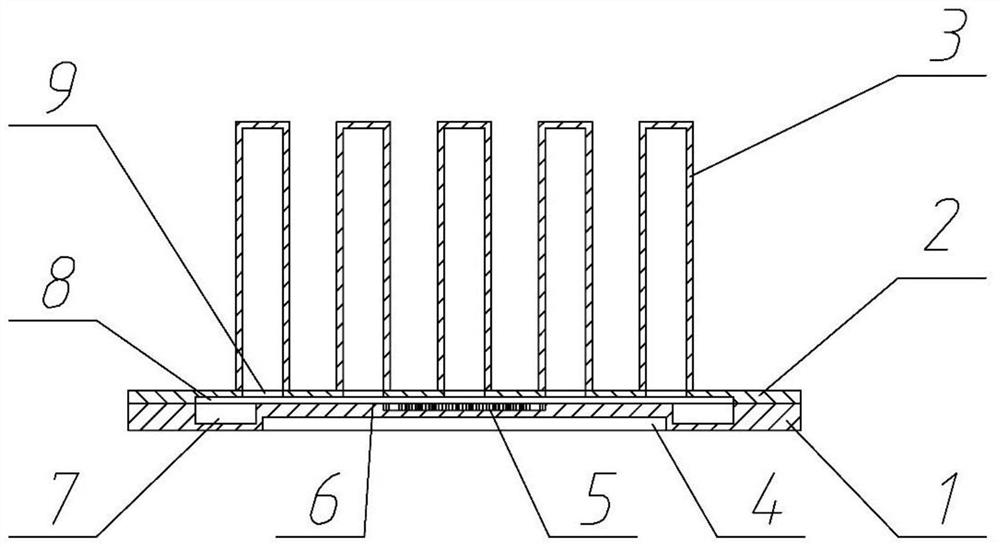

Evaporation-boiling longitudinal coexistence composite structure for enhancing boiling heat transfer

PendingCN114543571AIncrease disturbanceEnhanced boiling heat transfer effectSemiconductor/solid-state device detailsSolid-state devicesPhysicsComposite structure

The invention discloses an evaporation-boiling longitudinal coexistence composite structure for strengthening boiling heat transfer, and relates to the technical field of strengthening boiling heat transfer. The evaporation-boiling longitudinal coexistence composite structure for strengthening boiling heat transfer comprises a heating substrate and a plurality of heat conduction micro-columns arranged on the substrate, the upper ends of the heat conduction micro-columns are combined with a porous capillary core to form a composite structure, and small bubbles discharged by evaporation of the porous capillary core are utilized to increase a gasification core of a boiling area at the bottom of the porous capillary core. The boiling starting point is lowered, flow field disturbance is enhanced, boiling heat transfer of a bottom liquid area is enhanced, and in addition, the heat transfer area is increased in the longitudinal direction. Protrusions are arranged on the lower surface of the porous capillary core, so that small bubbles are easier to separate and enter a superheated fluid working medium area at the bottom, stable separation of the bubbles is accelerated, occurrence of an air film formed by direct boiling in an area between a heating surface and the lower surface of the porous capillary core is delayed, and porous evaporation-boiling synergistic reinforcement phase change heat transfer is achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

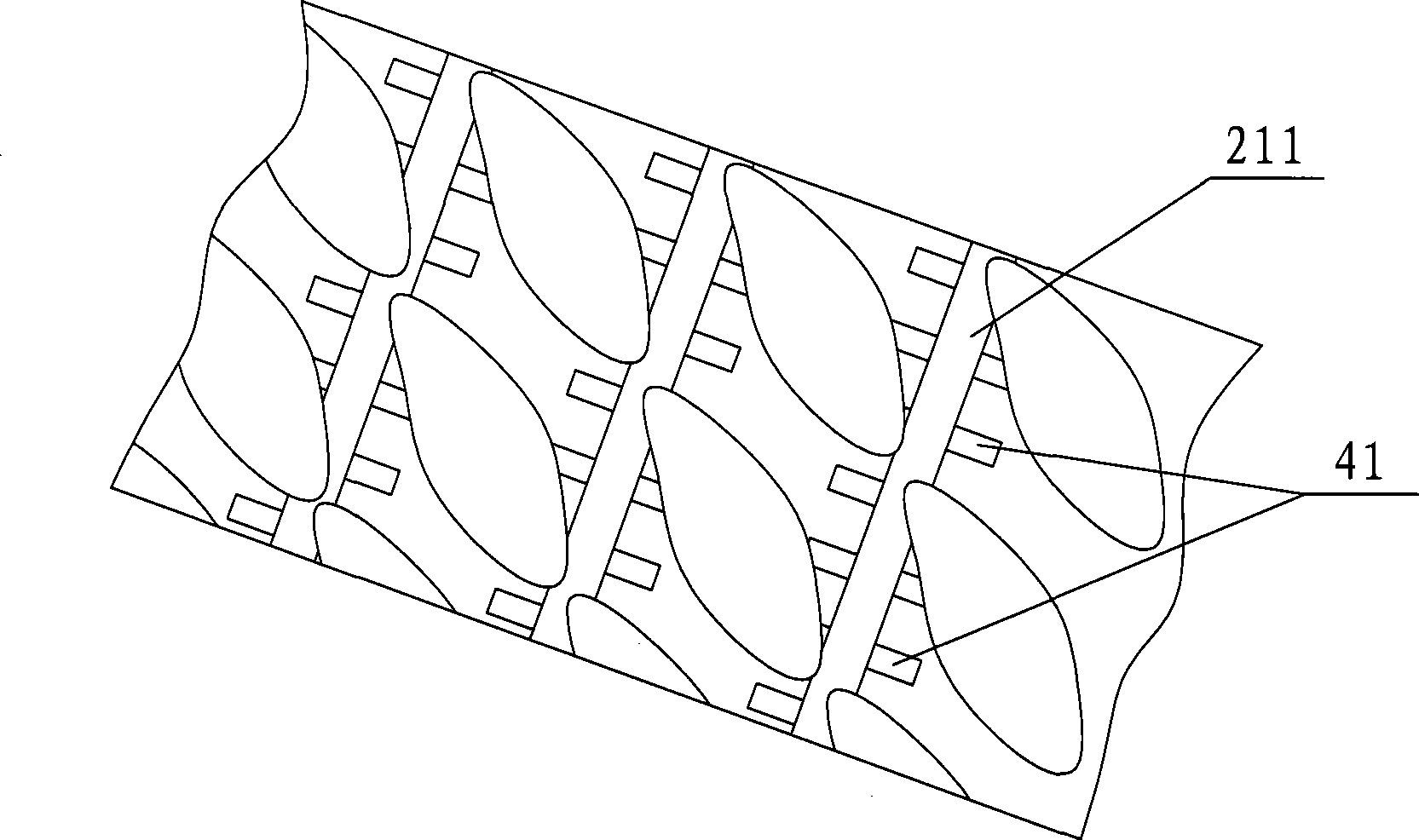

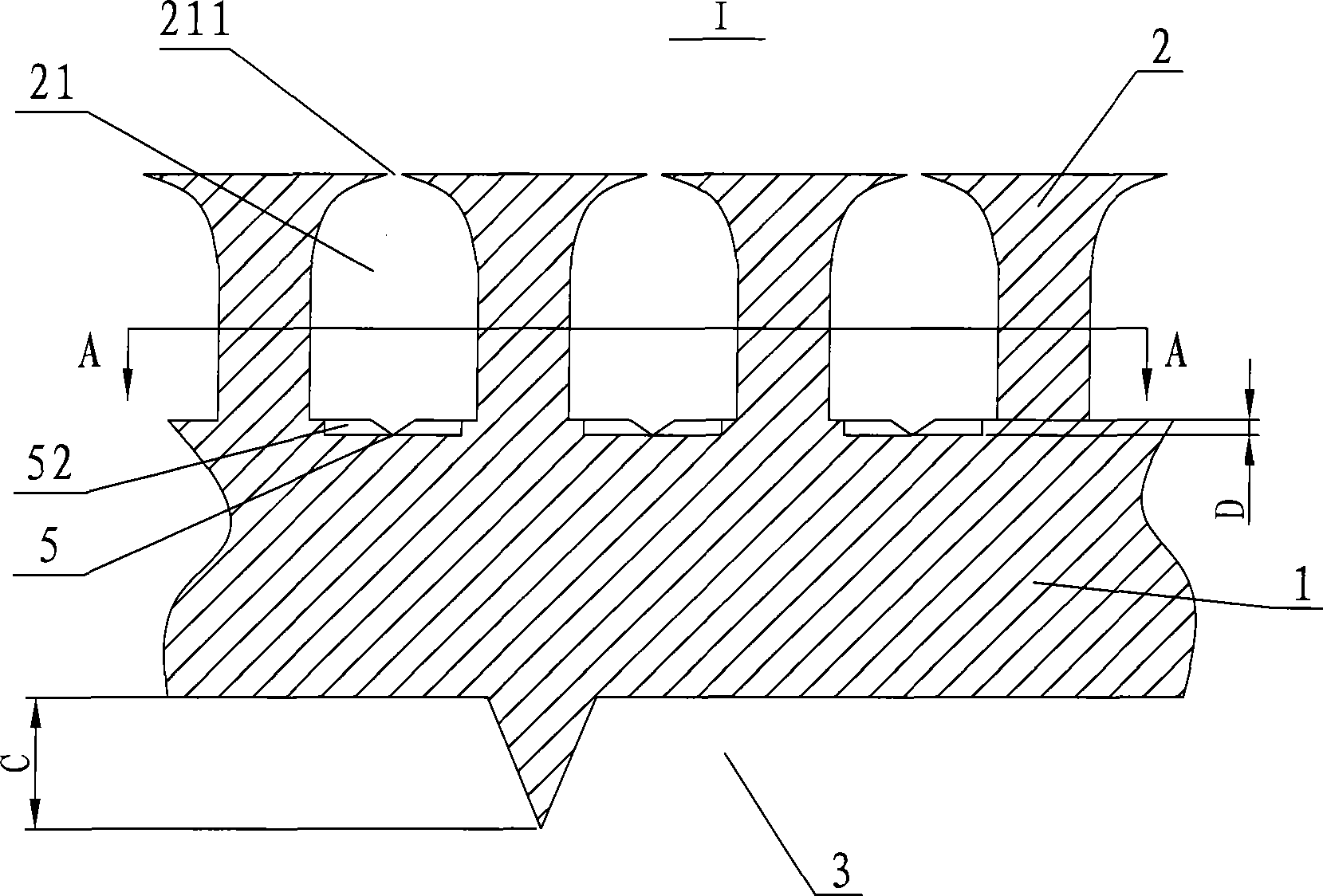

Composite hole evaporation heat exchange tube

PendingCN110425774AAvoid bending deformationPromote growthEvaporators/condensersBoiling processEvaporation

The invention provides a composite hole evaporation heat exchange tube. The composite hole evaporation heat exchange tube comprises a tube body and spiral outer fins which are in an integral structurewith the tube body, secondary side fins are arranged on one sides of the outer fins, the top of the outer fins is processed to form an inclined shape, the inclination direction of the outer fins is consistent with the extending direction of the secondary side fins to form a composite spiral channel communicating with gaps between the F-shaped outer fins and the outer fins, the F-shaped outer finsare further processed with fin grooves which are staggered and communicate with the spiral channel, the spiral channel is divided into a plurality of composite hole structures, and inner threaded ribs are arranged on the inner surface of the tube body in a protruding mode. The composite hole evaporation heat exchange tube has the advantages that the composite annular channel formed by the gap ofthe F-shaped outer fins provides a large amount of vaporization cores and is beneficial to rapid growth and rapid overflow of bubbles; and meanwhile, the composite hole structures are beneficial to evaporation of refrigerants in the holes during the evaporation heat exchange process, so that the timely filling of the refrigerants and the effective discharge of steam are ensured, the boiling process is continuous, and the effect of strengthening the boiling heat exchange is achieved.

Owner:JIANGSU CUILONG PRECISION COPPER TUBE CORP

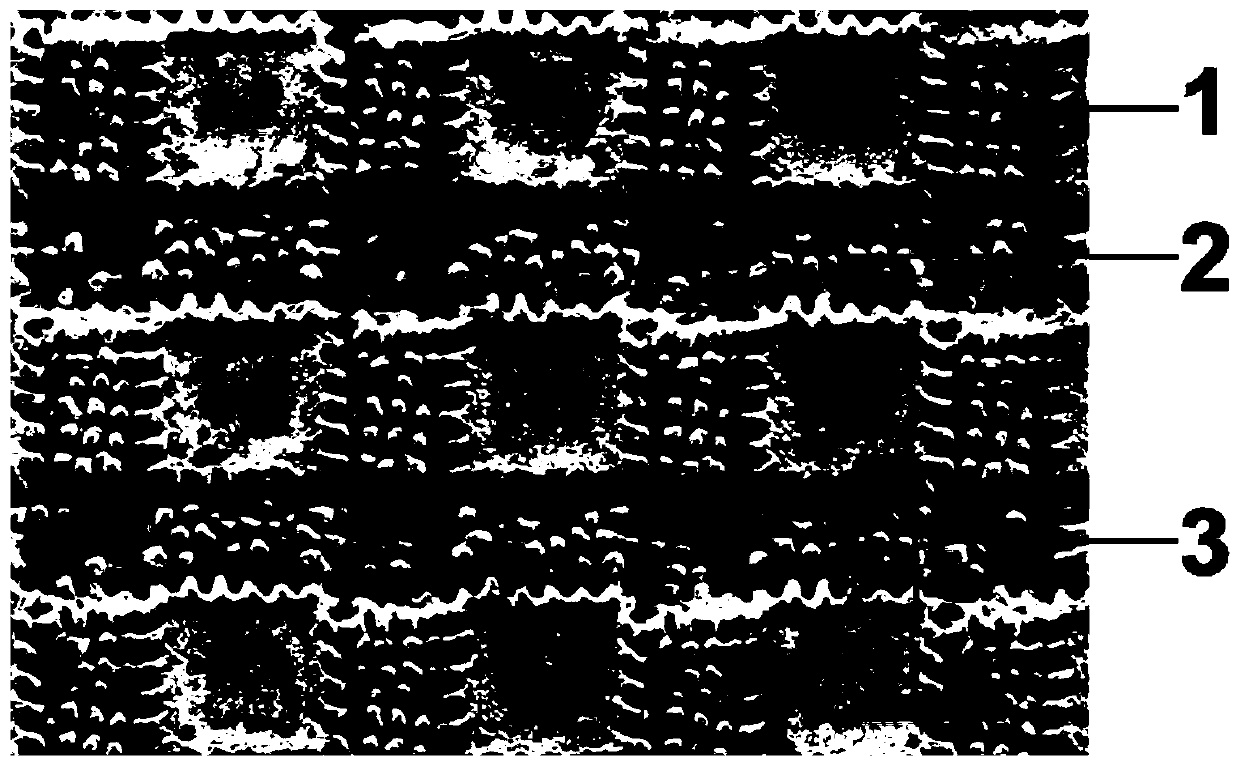

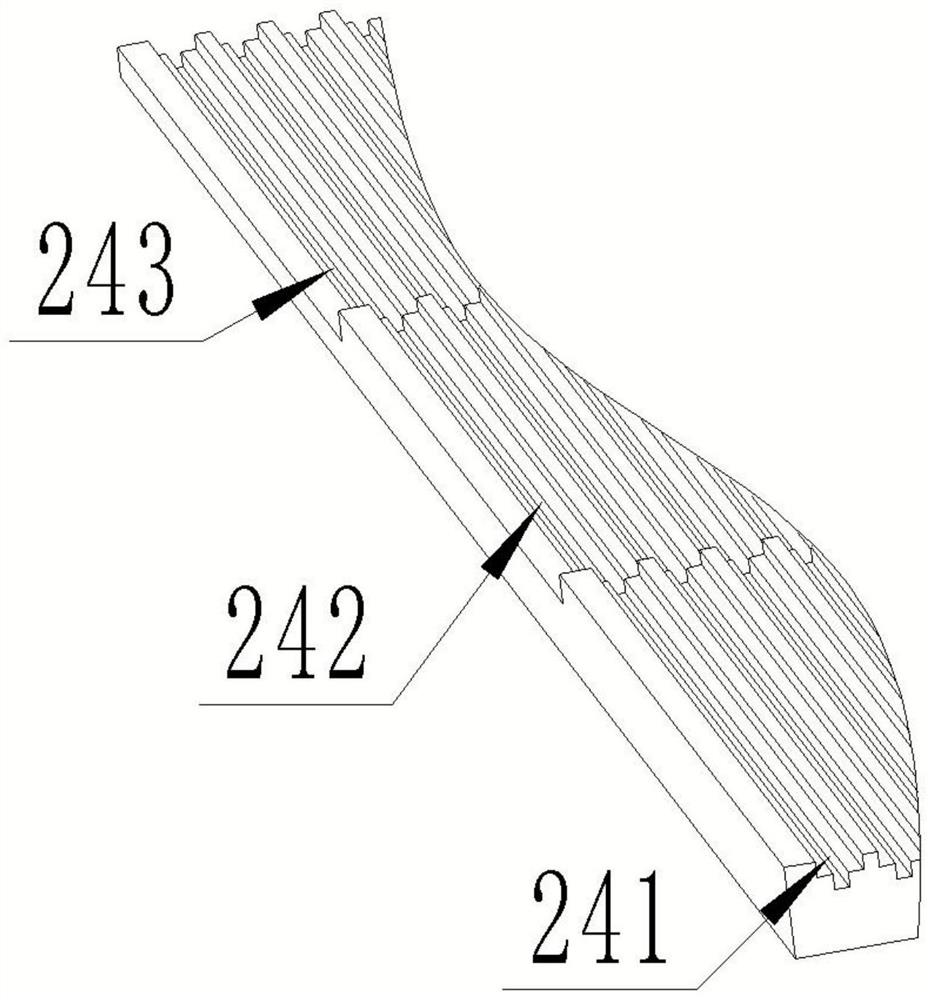

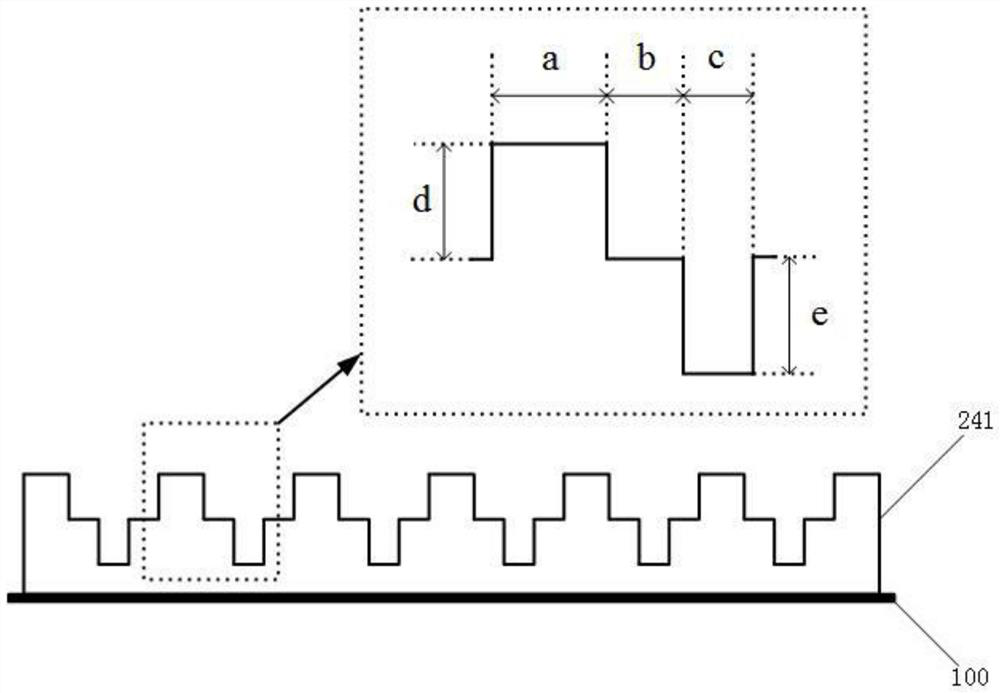

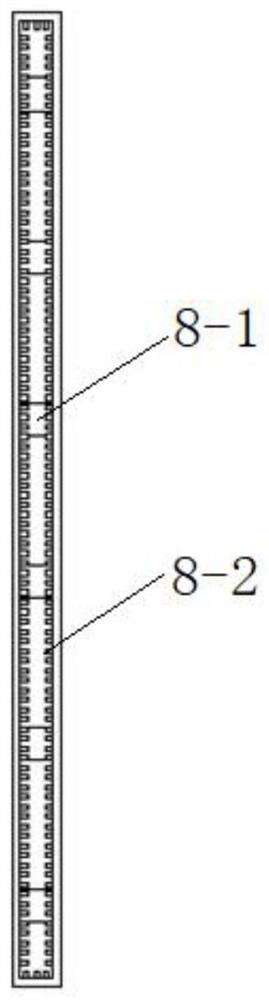

Boiling enhanced heat transfer structure and liquid box for cooling high-power-density electrical equipment

PendingCN114498393AImprove cooling effectEnhanced boiling heat transferSubstation/switching arrangement cooling/ventilationIndirect heat exchangersEnhanced heat transferElectric power equipment

The invention belongs to the technical field of equipment cooling, particularly relates to a boiling enhanced heat transfer structure and a liquid box for cooling high-power-density power equipment, and aims to solve the heat dissipation problem of the high-power-density power electronic equipment. The boiling enhanced heat transfer structure comprises a plate-shaped body, a first structural section, a second structural section and a third structural section, and the first structural section, the second structural section and the third structural section are sequentially arranged in a covering mode in the longitudinal direction of the plate-shaped body. The second structural section and the first structural section form a lower step structure, and the third structural section and the second structural section form a lower step structure; the first structural section covers the cooling working medium inflow area, and the third structural section covers the cooling working medium outflow area; a first zigzag groove is formed in the outer surface of the first structural section; a second zigzag groove is formed in the outer surface of the second structural section; a third zigzag groove is formed in the outer surface of the third structural section; boiling heat transfer can be effectively enhanced, and the heat dissipation capacity of the liquid box is greatly improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

A microscale cooperative surface structure for enhanced boiling heat transfer

InactiveCN109974513BAccelerated disengagementReduced escape diameterHeat transfer modificationLaser burnSuperhydrophobe

The invention belongs to the technical field of enhanced heat transfer, and provides a micro-scale collaborative surface structure for enhancing boiling heat transfer. The structure comprises a largegroove, a small groove, a connecting groove, a micro rib, a base surface and a super-hydrophobic coating; the base surface of the structure for enhancing boiling heat transfer is subjected to mechanical cutting, structure electroplating or laser burning to form a synergistic scale surface; the surface of the base surface is divided into the large groove, the small groove and the connecting groovethrough ribs. According to the structure, the micro-scale collaborative surface structure can achieve the capillary force effect, so that a liquid can reach a vaporization core point faster, the requirement of the boiling heat transfer vaporization process on the scale can be further met under the condition of different superheat degrees, the connecting groove between the large groove and the small groove enables liquid between the grooves to interact, so that steam is easier to discharge, and then the boiling heat transfer is enhanced.

Owner:DALIAN UNIV OF TECH

Heat dissipation device and method for local high heat flow in limited space

ActiveCN103940273BSave spaceImprove heat transfer effectIndirect heat exchangersCooling/ventilation/heating modificationsVacuum pumpingMicro nano

Owner:ZHEJIANG UNIV

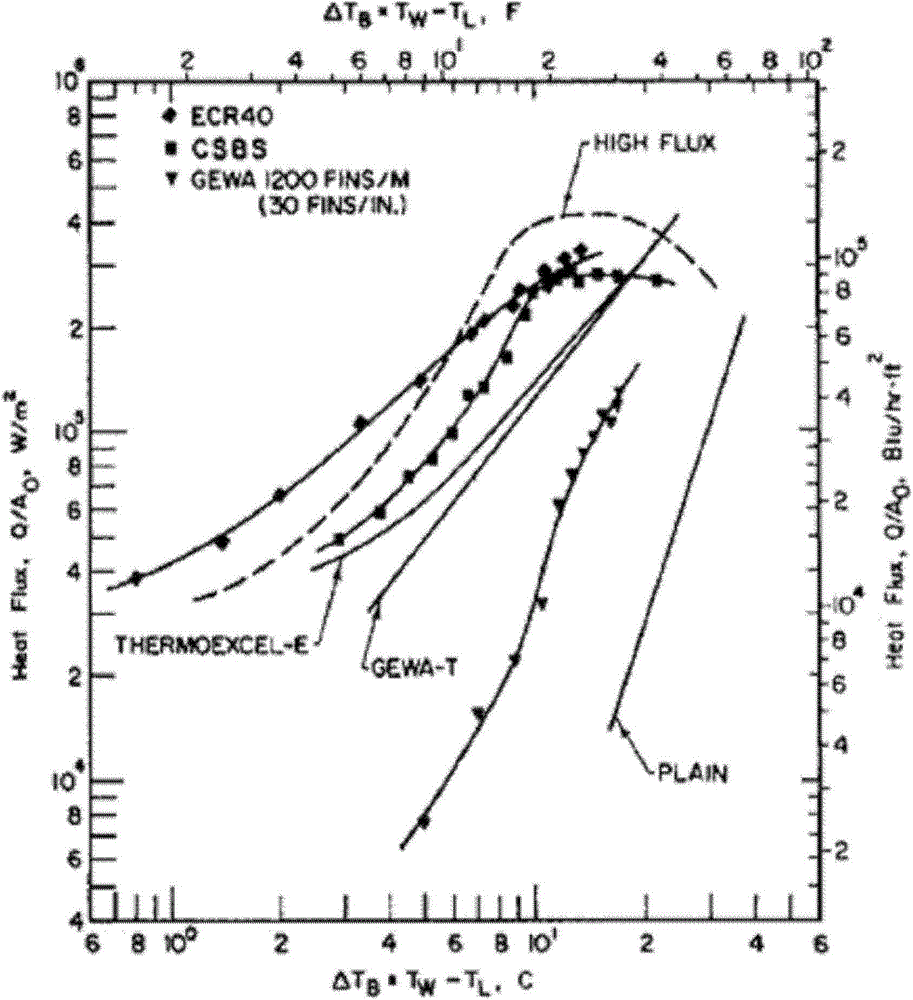

Porous surface boiling heat transfer enhancement device and preparation method thereof

ActiveCN103822519BImprove boiling heat transfer capacityIncrease heatIndirect heat exchangersTemperature controlShape-memory alloy

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

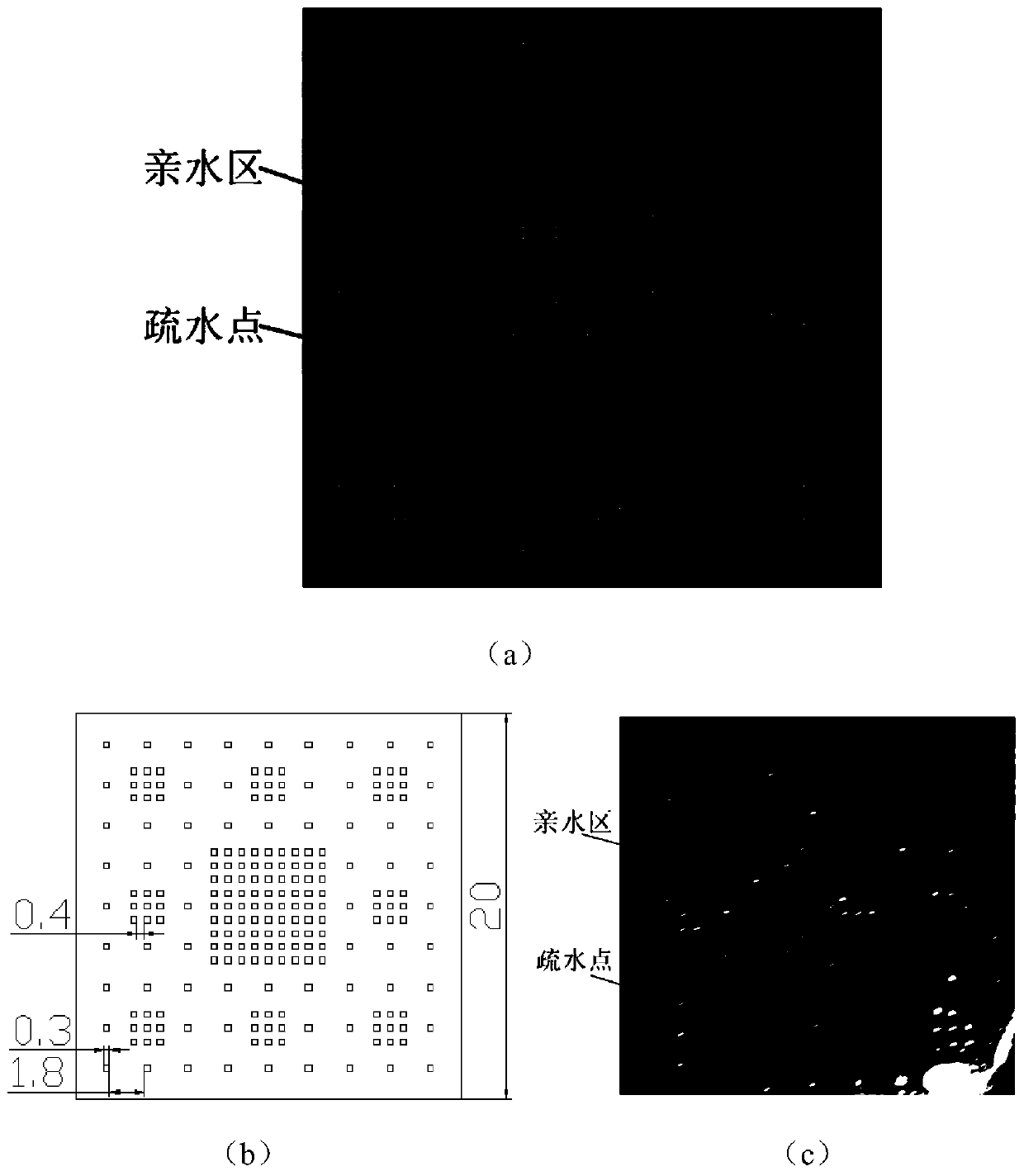

A non-uniform wetting surface with fractal properties and its preparation method

ActiveCN109295431BProduce quicklyImprove wetting abilityVacuum evaporation coatingSputtering coatingEvaporation heat transferHeat flow

Owner:XI AN JIAOTONG UNIV

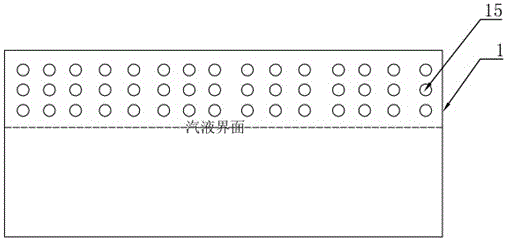

A liquid cavity heat dissipation device based on pool boiling heat dissipation

ActiveCN112492853BPrevent dryingIncrease effective spaceModifications using liquid coolingEvaporation heat transferEngineering

A liquid chamber heat dissipation device based on pool boiling heat dissipation includes a liquid chamber and an external heat dissipation device. The liquid chamber is composed of a bottom plate of the liquid chamber, a top plate of the liquid chamber and a heat dissipation pipe, and is filled with a phase change working fluid. The liquid phase-change working fluid absorbs the heat at the bottom of the boiling zone and undergoes boiling heat exchange to generate steam. The steam rises to the heat dissipation pipe through the through hole on the top plate of the liquid chamber, and is condensed into liquid by means of an air-cooled or water-cooled external heat sink and flows back into the liquid chamber. The compensation chamber and the liquid delivery area can effectively supply the phase change working medium to the boiling area. The invention adopts the heat exchange method of pool boiling and has strong heat dissipation capability. Compared with existing radiators designed based on steam chambers such as vapor chambers, it does not require a capillary core structure, is easy to process, and can effectively prevent internal evaporation while having a thinner thickness. It is suitable for heat dissipation of high-power heating equipment.

Owner:XI AN JIAOTONG UNIV

A spray cooling device combining steam chamber and composite microstructure

ActiveCN110381701BImprove cooling effectImprove permeabilityCooling/ventilation/heating modificationsEnhanced heat transferSpray cooling

Owner:NANJING UNIV OF SCI & TECH

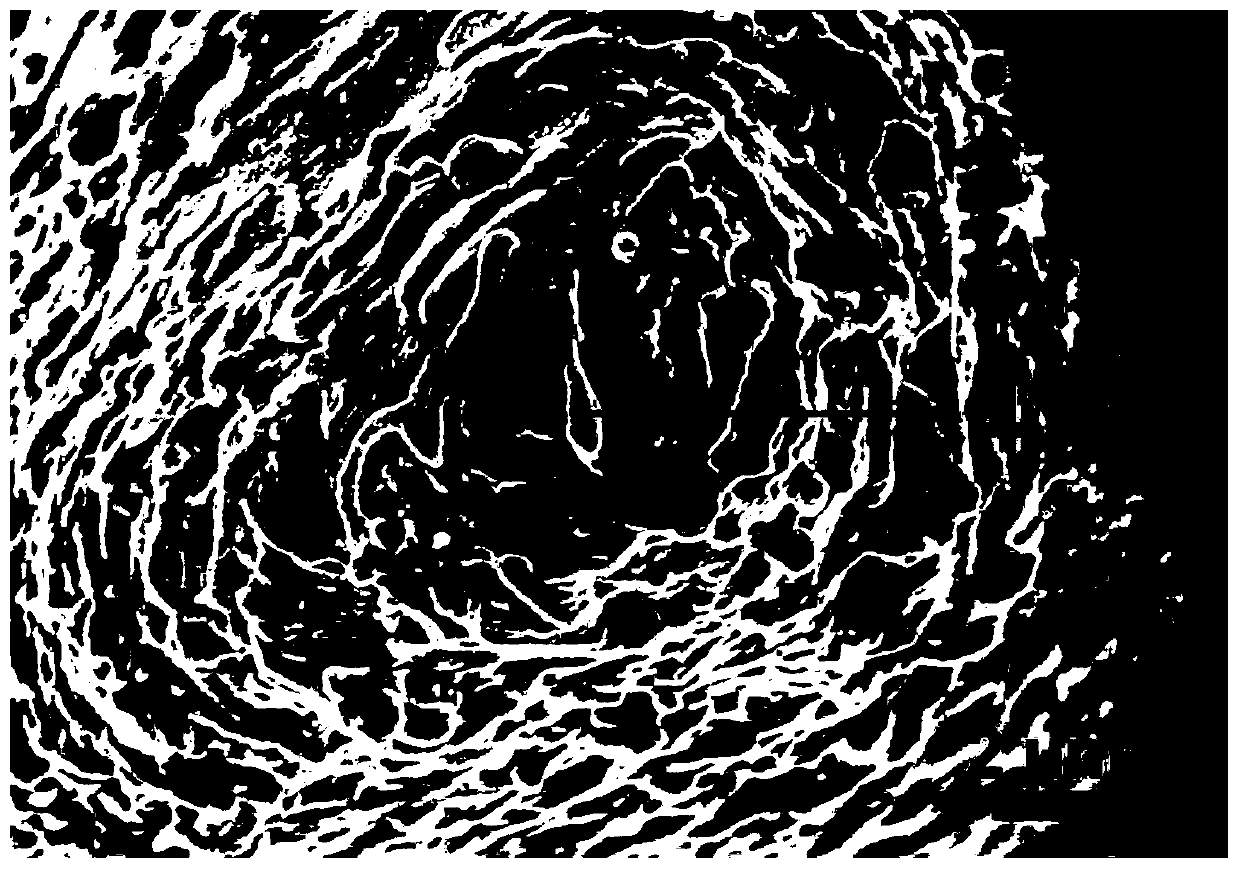

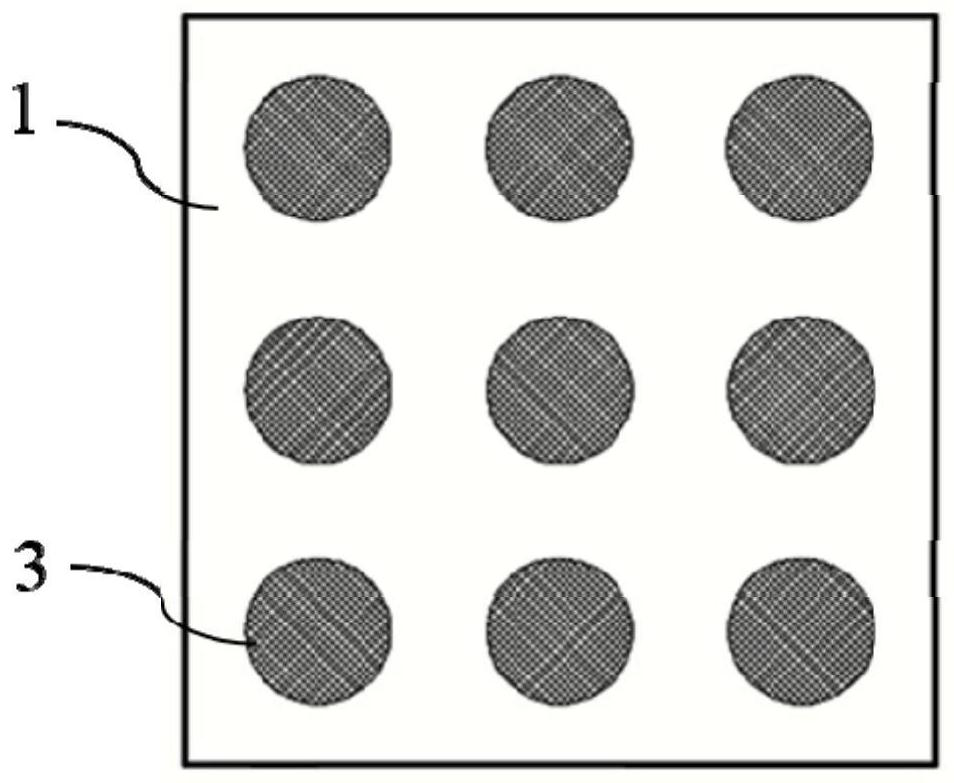

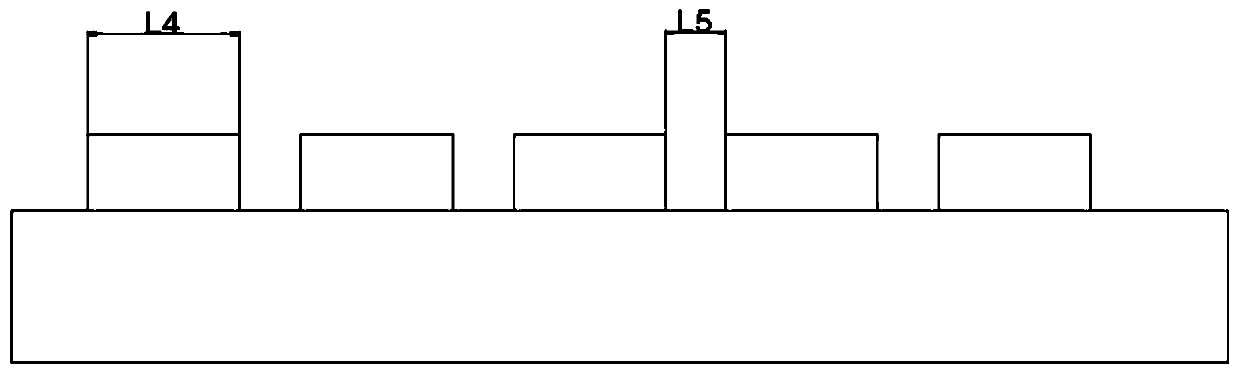

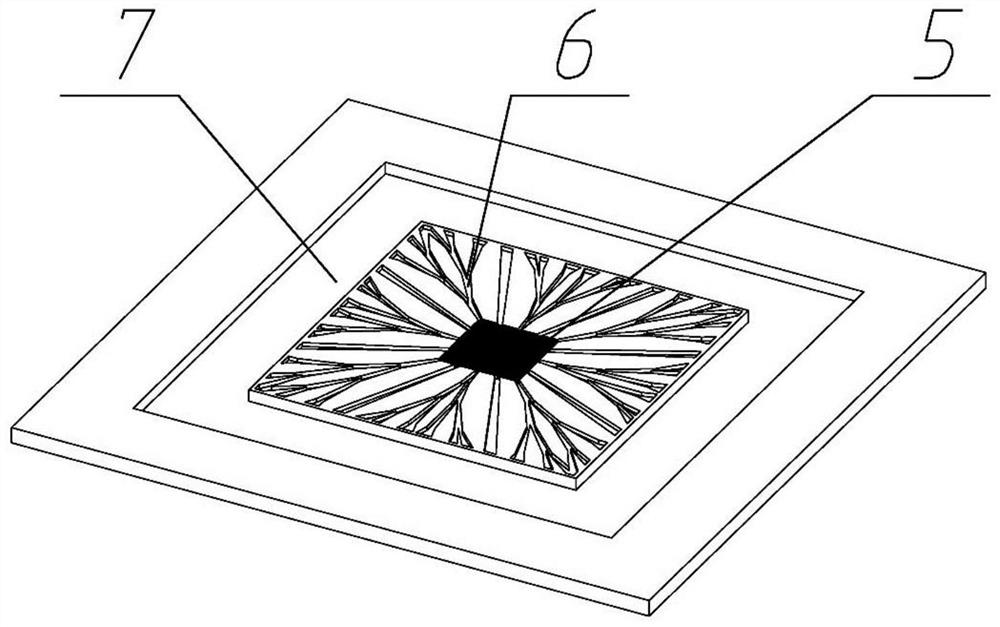

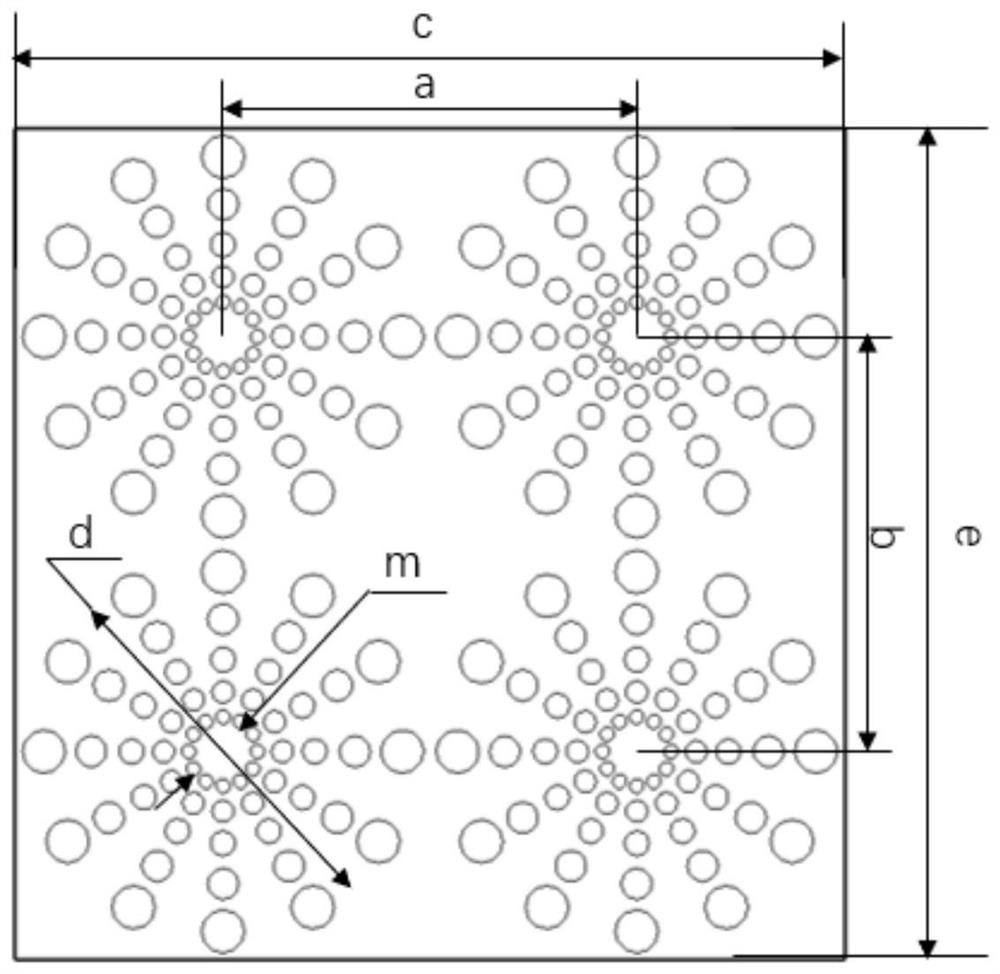

A block-type enhanced boiling heat transfer microstructure and its manufacturing method

ActiveCN110595241BImprove boiling heat transfer capacityIncrease the heat exchange areaSemiconductor/solid-state device detailsSolid-state devicesThermodynamicsEvaporation heat transfer

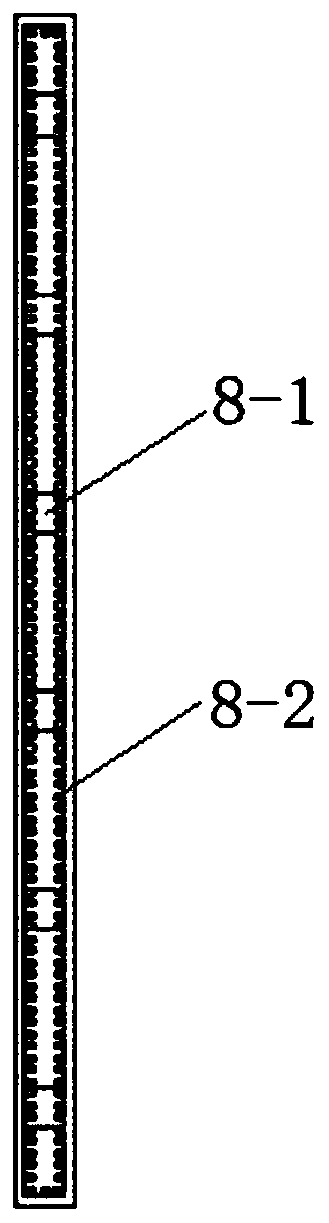

The invention discloses a partitioned block type strengthened boiling heat exchange microstructure and a manufacturing method thereof. The heat exchange microstructure comprises a radiating plate, wherein a plurality of circular block units are arranged on the radiating plate, each block unit is composed of a plurality of circles of microcolumns, and the block units are distributed on the radiating plate in an array mode. On the one hand, space distances between gas columns and the radius of the gas columns when heat flux is high can be limited, the merging among the gas columns is prevented,the boiling heat exchange performance of a high heat flux area is remarkably enhanced, and critical heat flux of chip boiling heat exchange is greatly improved; and on the other hand, each block unitis formed by the circular microcolumns which are arranged in a concentric circle, and microcolumn space distances from inner rings to outer rings are sequentially increased, so that flow resistance that fluid is directionally conveyed to a microstructure area from a smooth area is reduced, fresh liquid is timely supplied to the bottom of the of a bubble center under the condition of the high heatflux, the bubble evaporation is maintained, and the critical heat flux is further improved.

Owner:西安交通大学深圳研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com