Heat dissipation device and method for local high heat flow in limited space

A technology of limited space and heat dissipation device, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating renovation, etc. Unable to meet the local high heat flux density heat dissipation requirements and other problems, to achieve the effect of improving the overall heat exchange capacity, increasing the surface area, and reducing the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

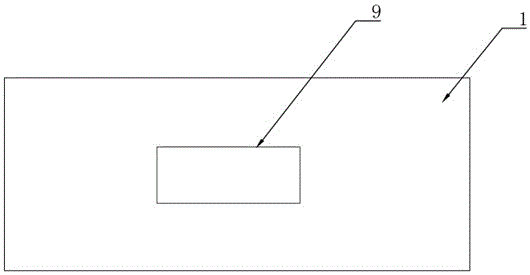

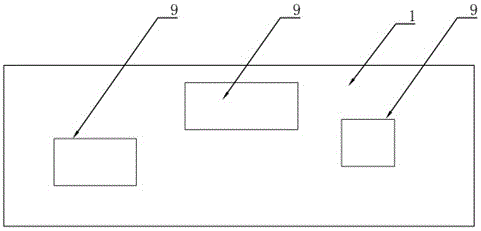

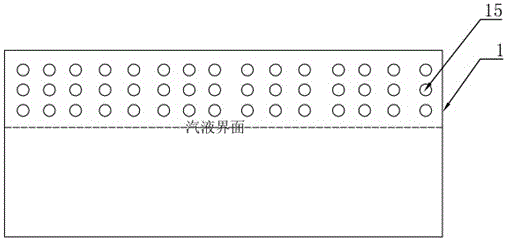

[0020] Such as Figure 1-5 As shown, the heat dissipation device with local high heat flow in a limited space includes a lower cover plate 1, a water inlet pipe 2, an inlet pipe connector 3, a vacuum pumping port 4, an upper cover plate 5, a support column 6, an accommodation space 7, a super-hydrophilic Micro-nano structure coating 8, evaporation area 9, micro-channel tube bundle 10, outlet pipe connector 11, water outlet pipe 12, local heating source 13, substrate 14, micro-channel hole 15; the lower cover plate 1 and the upper cover plate 5 are welded Connect to form a closed accommodation space 7; a support column 6 is provided between the lower cover 1 and the upper cover 5, and one end of the support column 6 is welded to the upper cover 5; the upper cover 5 is provided with a vacuum port 4; The inner surface of the lower cover plate 1 is coated with a super-hydrophilic micro-nano structure coating 8; the bottom surface of the lower cover plate 1 is mechanically pressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com