Boiling enhanced heat transfer structure and liquid box for cooling high-power-density electrical equipment

A high power density, power equipment technology, applied in the cooling/ventilation of substations/switchgears, lighting and heating equipment, electrical components, etc., can solve the problems of heat conduction temperature difference reduction, etc., to reduce superheating temperature, enhance boiling heat transfer, Effect of improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

[0038] The present invention will be further described below in conjunction with embodiments with reference to the accompanying drawings.

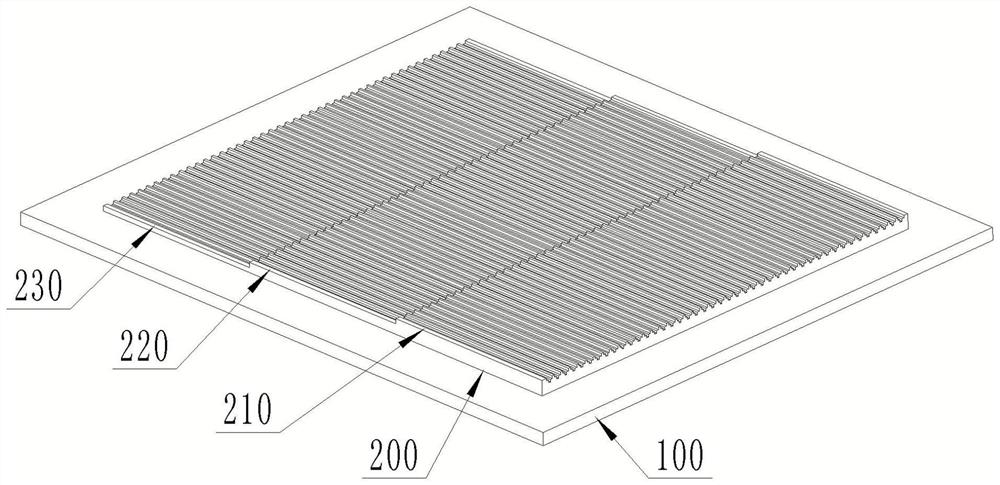

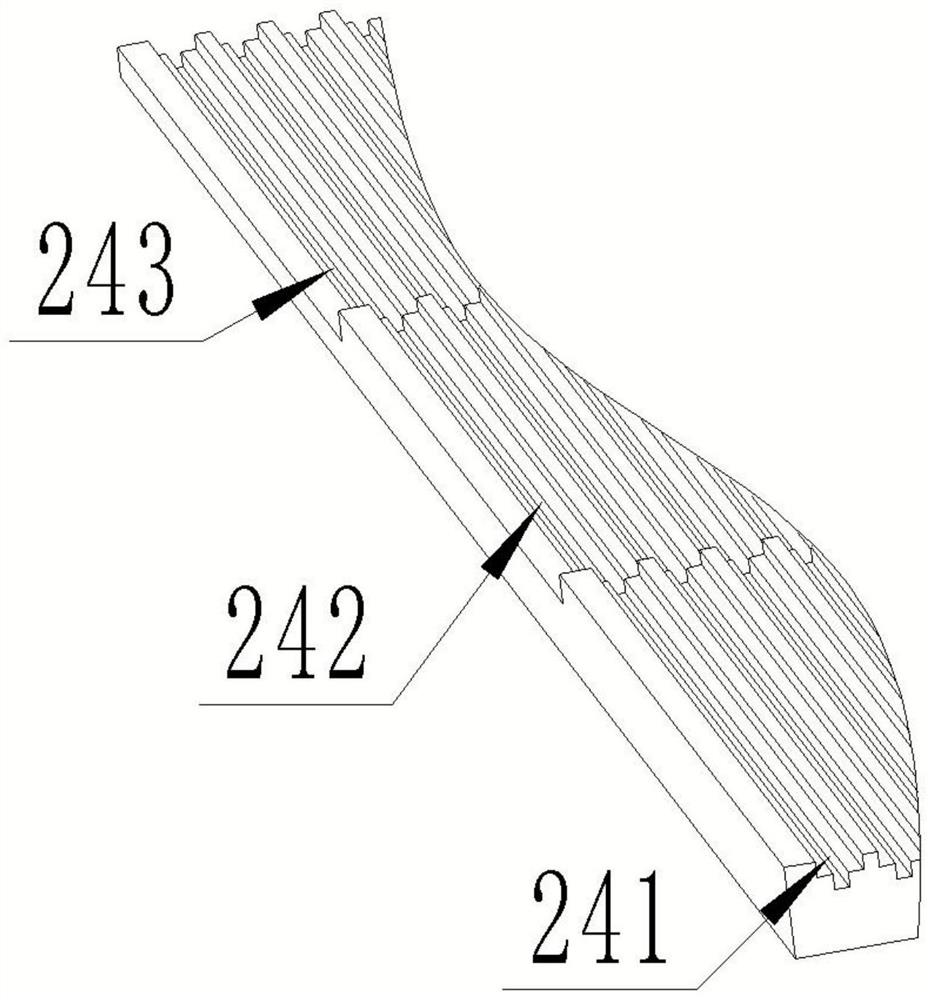

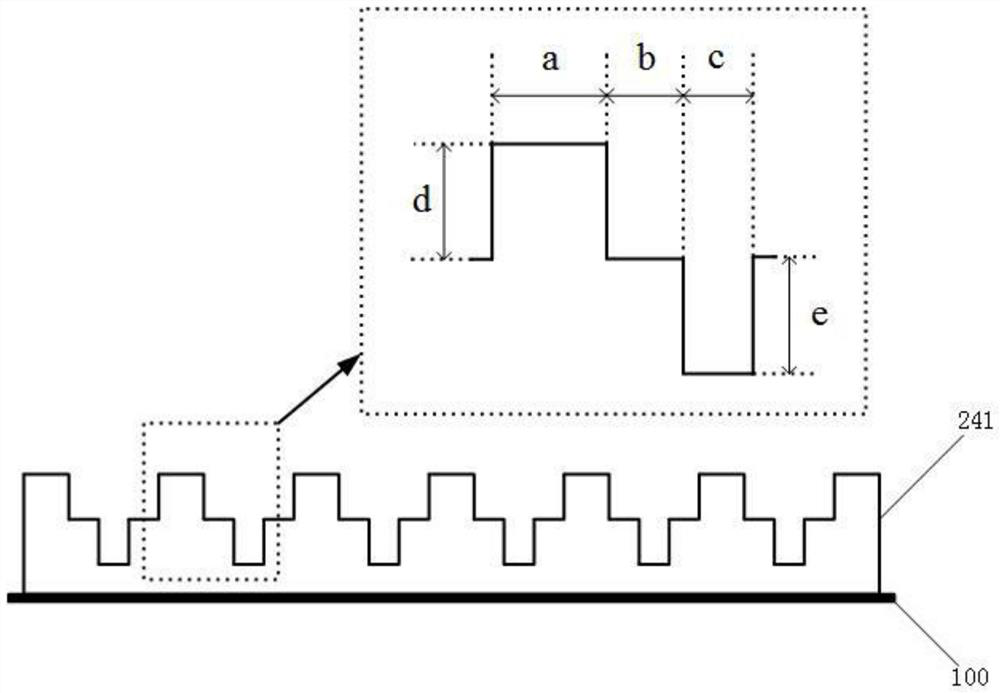

[0039] Refer to attached figure 1 to attach image 3 , the first aspect of the present invention provides a boiling enhanced heat transfer structure for cooling high power density electrical equipment, including a plate-shaped body 200, a first structural segment 210, a second structural segment 220 and a third structural segment 230, The first structural section, the second structural section, and the third structural section are sequentially laid along the longitudinal direction of the plate-shaped bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com