Patents

Literature

52results about How to "Enhanced boiling heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

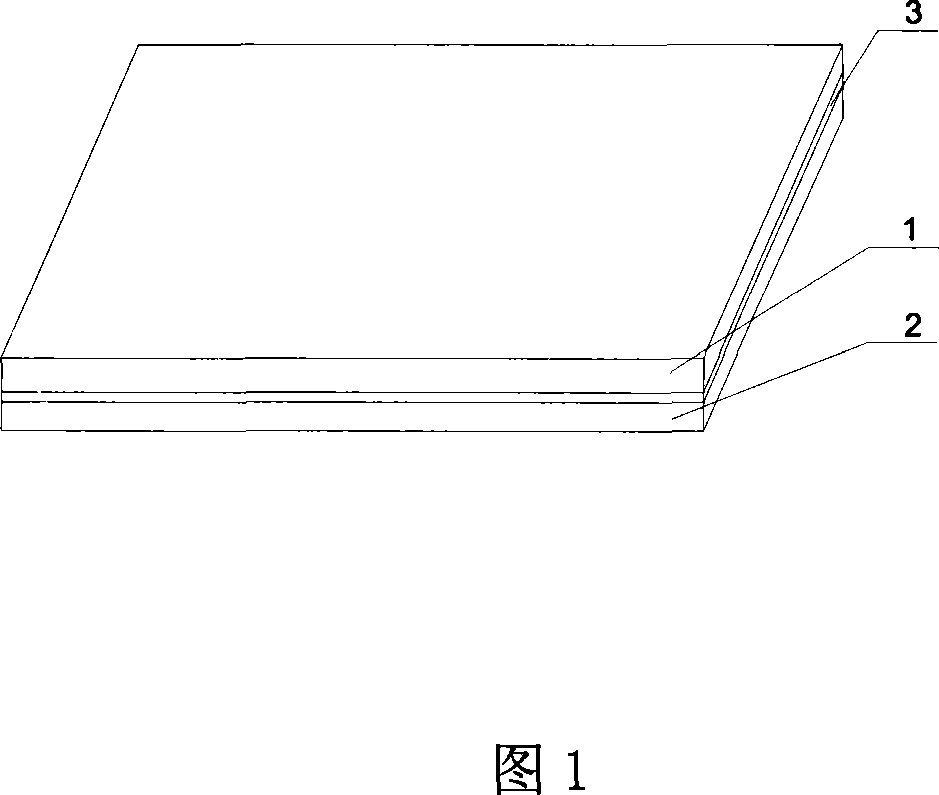

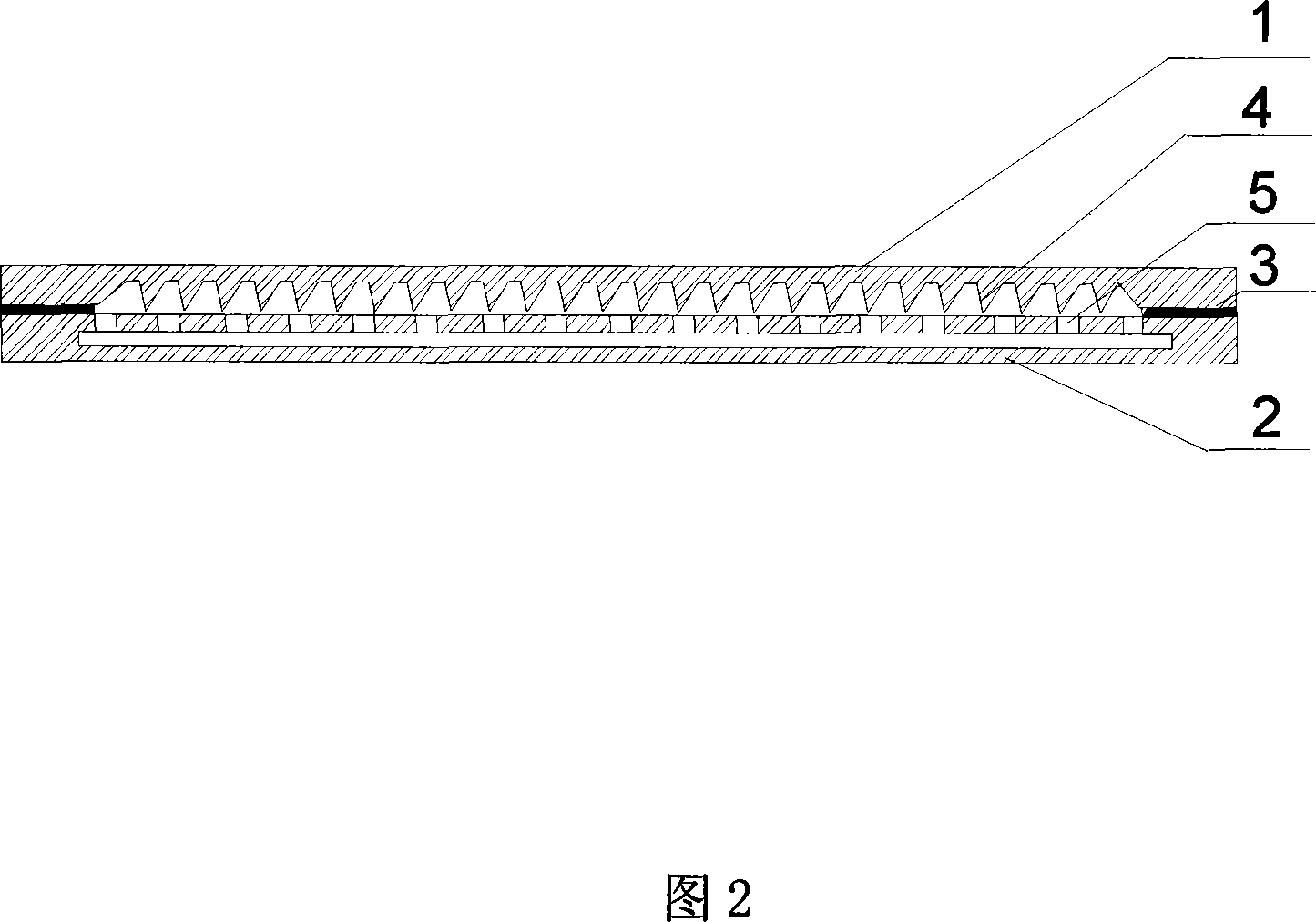

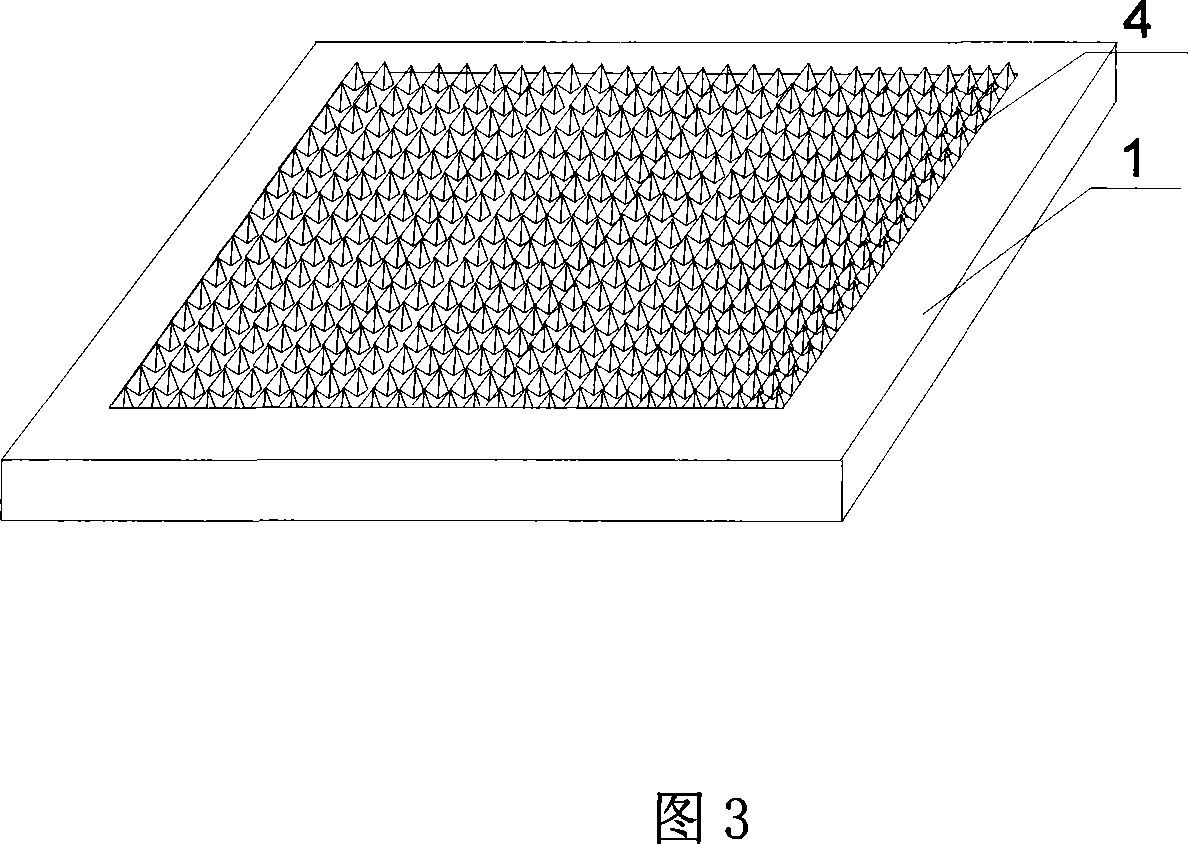

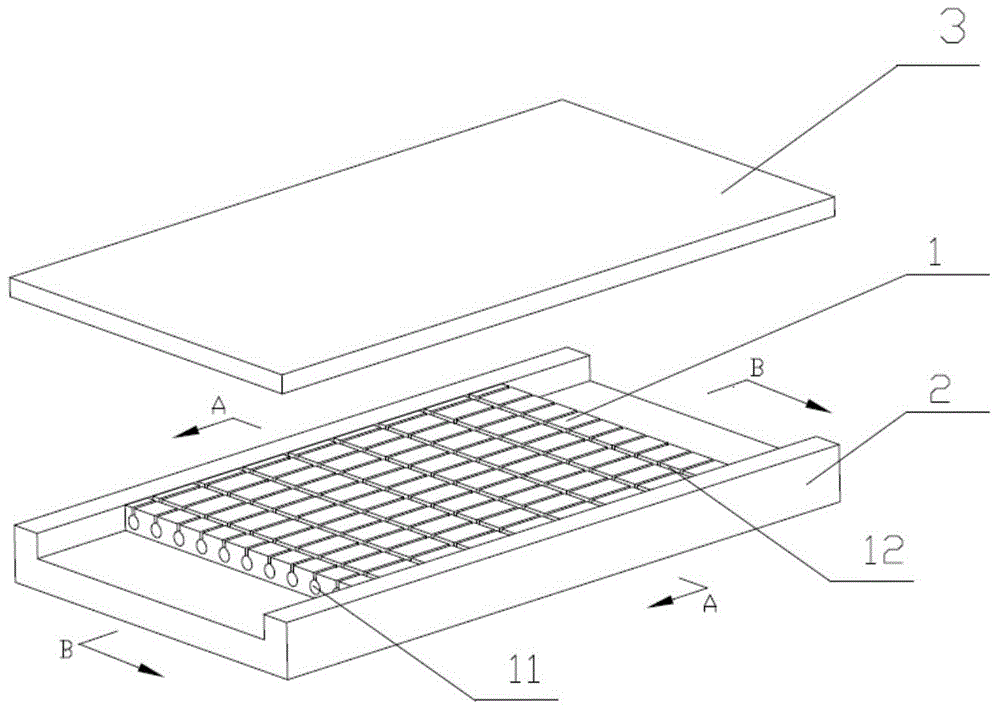

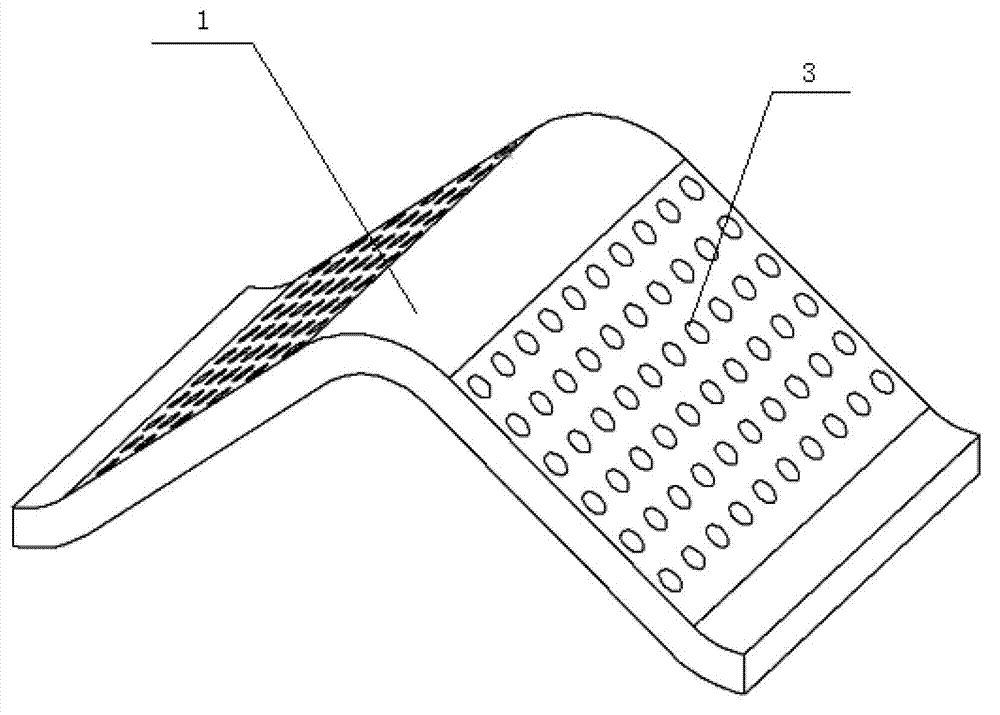

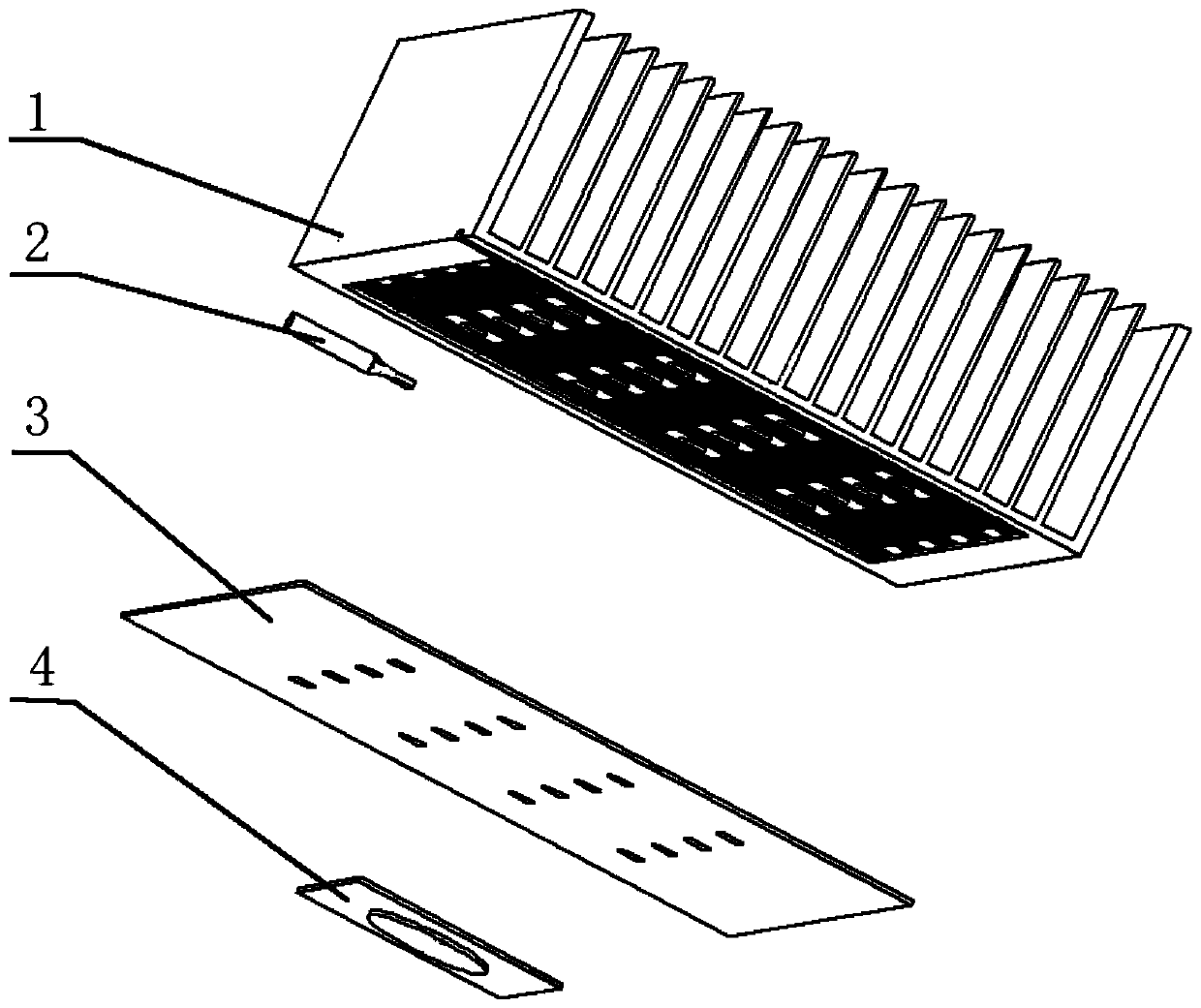

High efficiency heat radiation cool plate for electronic device

InactiveCN101052290ASolve the cooling problemCompact structureSemiconductor/solid-state device detailsSolid-state devicesCondensation processEvaporation

The invention comprises: a cold plate with 3D saw tooth-like fins and a surface evaporation plate with multi holes whose bottoms are connected each other with micro channels; the cold plate with 3D saw tooth-like fins is welded with the surface evaporation plate to form a sealed room filled out with working materials. The 3D saw tooth -like fins triggers the turbulent motion of gas and enhances the condensation process; the multi holes structure improves the heat conduction efficiency.

Owner:SOUTH CHINA UNIV OF TECH

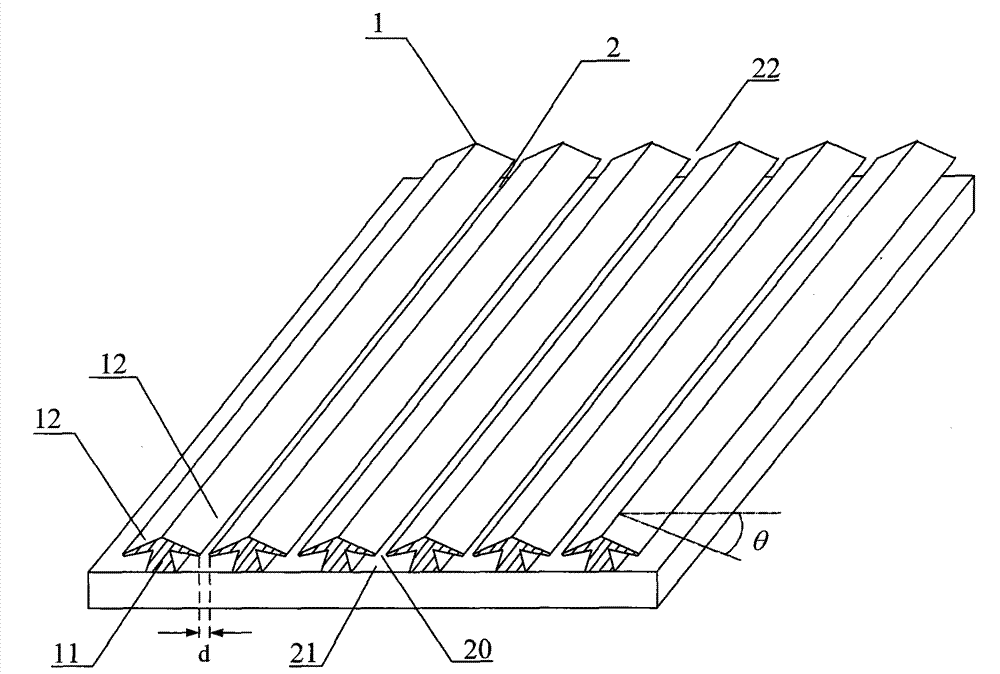

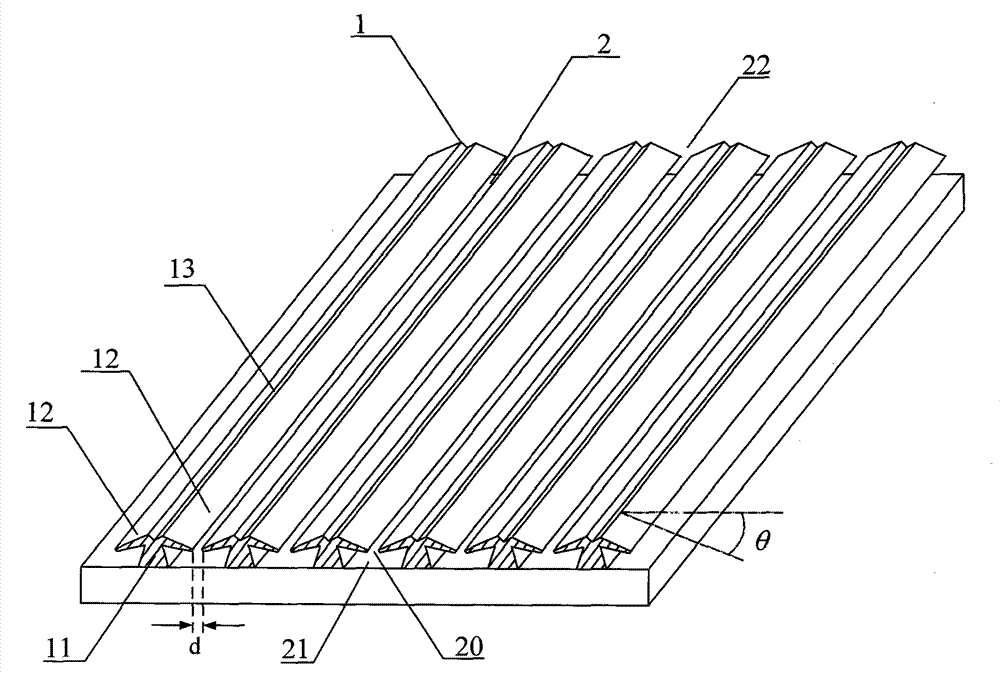

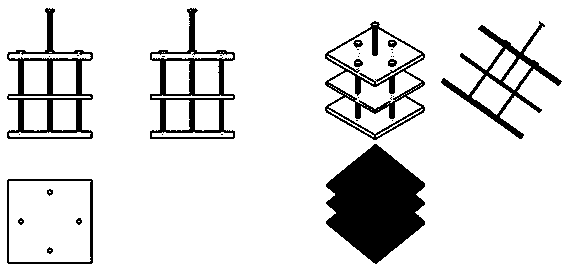

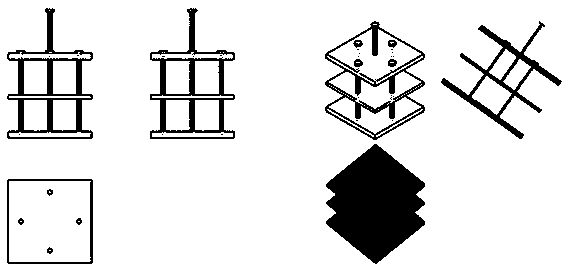

Micro-channel heat exchanger with staggered inner groove structure and manufacturing method of micro-channel heat exchanger

ActiveCN104154777AImprove distributionIncrease heat transfer areaStationary conduit assembliesHeat transfer modificationPlate heat exchangerEngineering

The invention discloses a micro-channel heat exchanger with a staggered inner groove structure and a manufacturing method of the micro-channel heat exchanger. The micro-channel heat exchanger with the staggered inner groove structure comprises a metal micro-channel substrate, wherein the metal micro-channel substrate comprises a plurality of longitudinal micro-channels and a plurality of transverse micro-channels; the longitudinal micro-channels are arrayed in parallel along a cooling liquid flowing direction; the transverse micro-channels are perpendicular to the longitudinal micro-channels; the longitudinal micro-channels and the transverse micro-channels are arranged at intervals; the micro-channels are in the shape of an inner groove; each micro-channel comprises an inlaid groove body and a slit; the inlaid groove bodies are positioned in the substrate; an opening position of the substrate is formed by the slits; and each inlaid groove body is connected with the corresponding slit. When the micro-channel heat exchanger is manufactured, the longitudinal inner groove micro-channels are machined along the liquid flowing direction in a linear cutting manner; after a workpiece rotates at an angle of 90 degrees, the transverse inner grooves are machined in a linear cutting manner, so that a crisscross micro-channel array is obtained; and the micro-channels are packaged by heat-resistant glass, and the staggered inner groove micro-channel heat exchanger is formed. The manufacturing process is simple and is low in cost; a thermal boundary layer is developed intermittently, and the heat transfer area is increased; and moreover, by the inner groove structure, boiling nucleation can be remarkably facilitated, and boiling heat transfer is strengthened, so that heat transfer is strengthened integrally.

Owner:XIAMEN UNIV

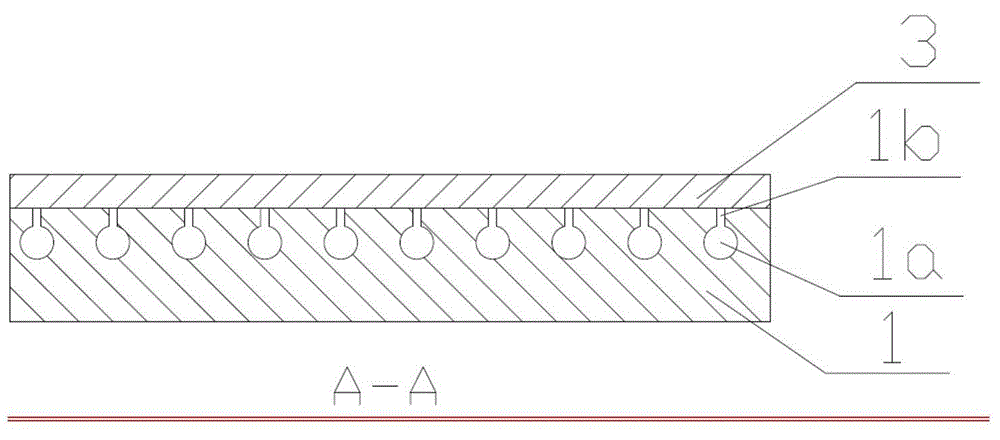

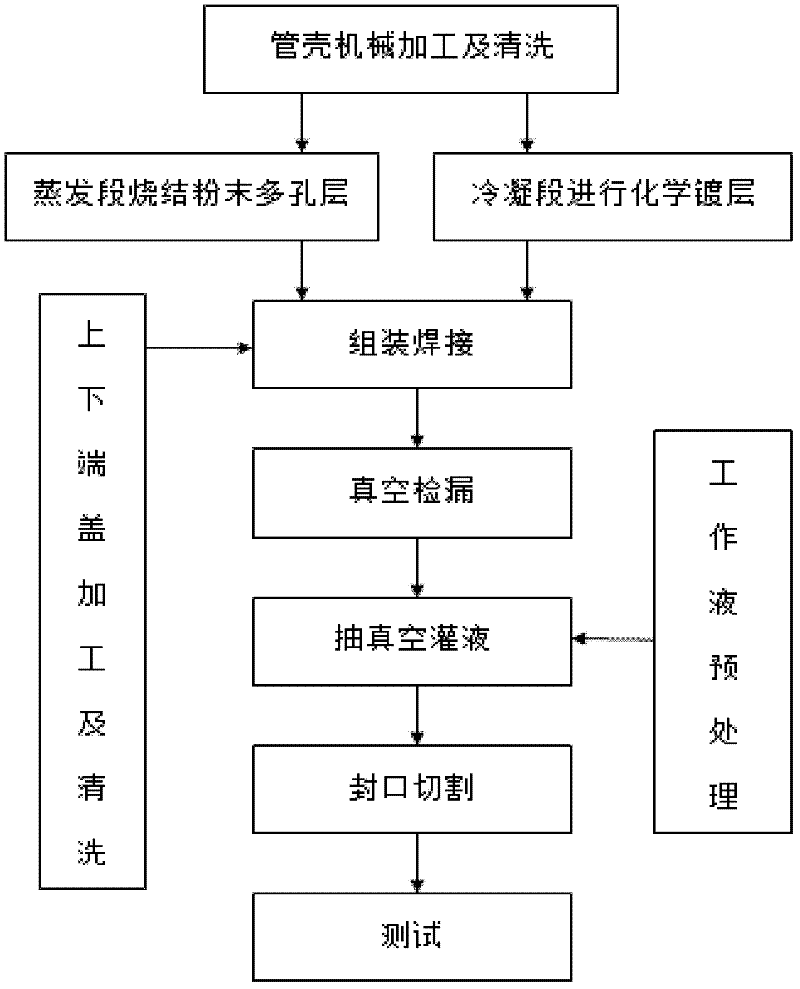

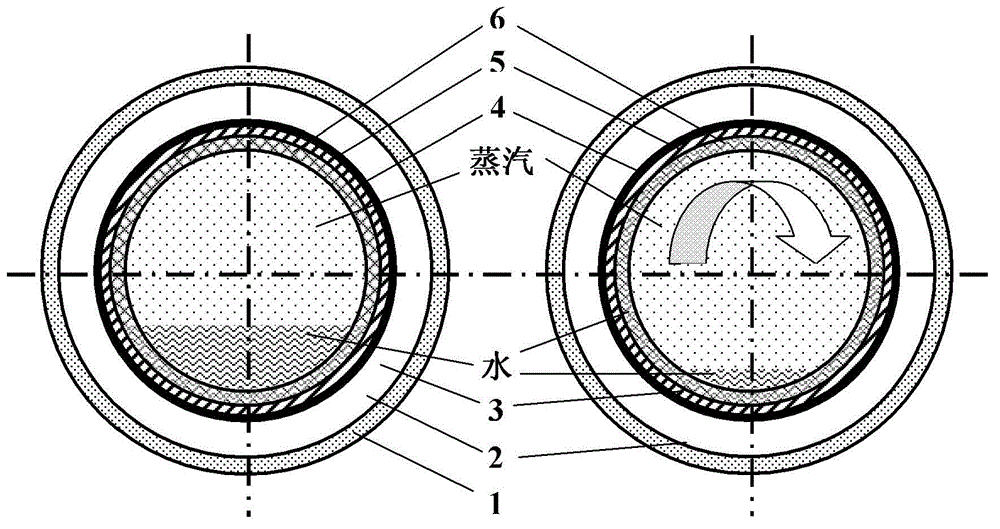

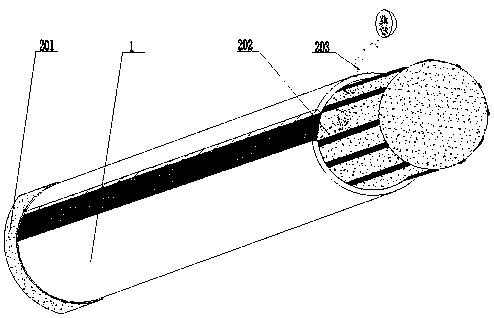

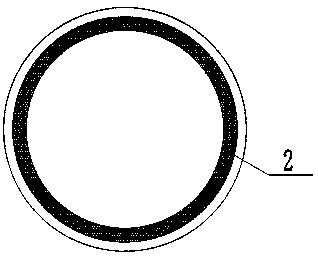

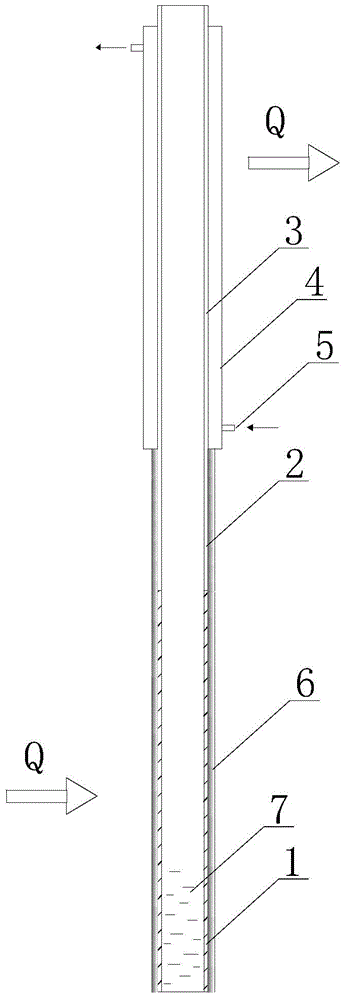

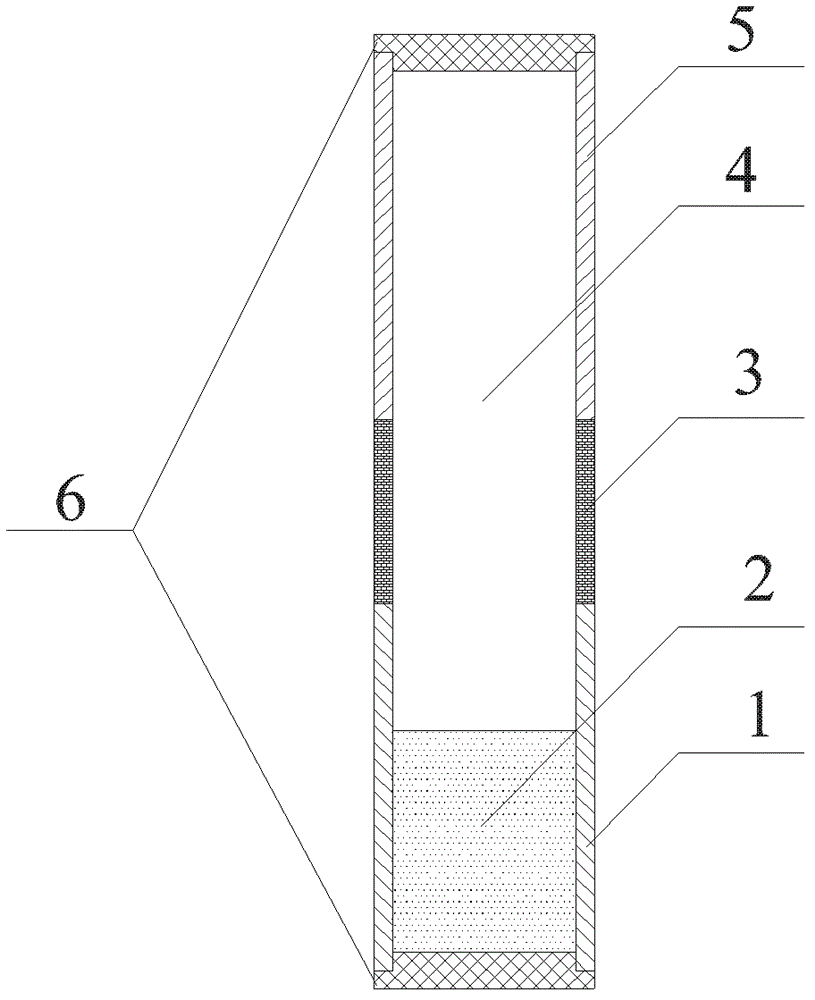

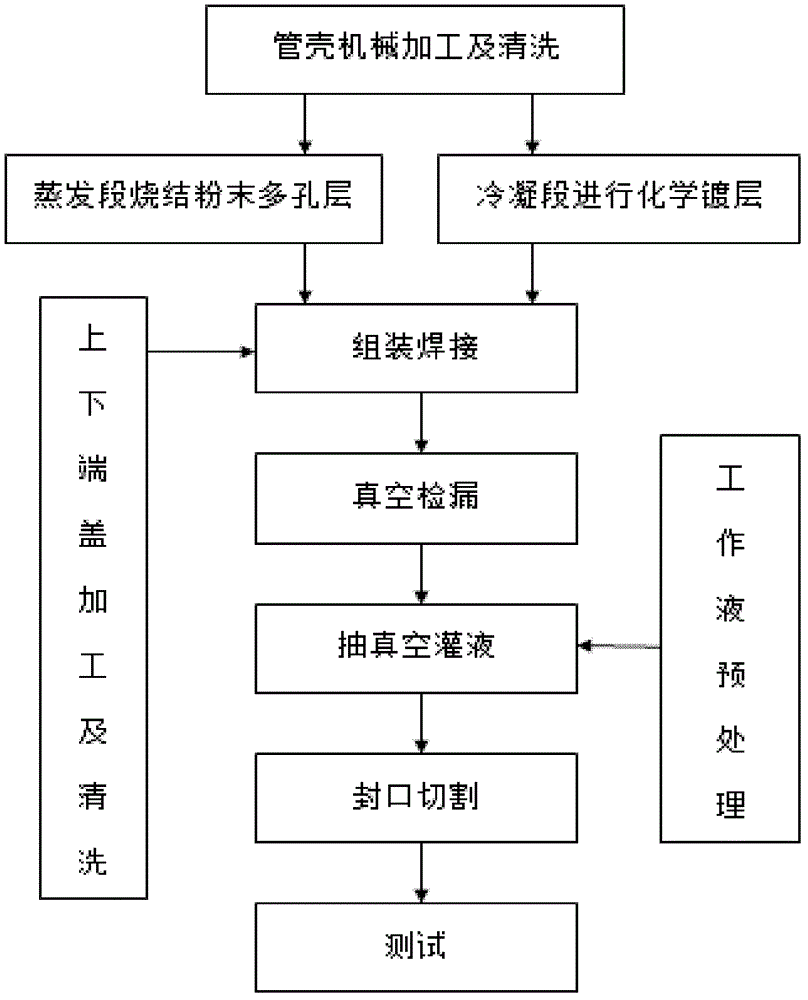

High-efficiency gravity heat pipe and manufacturing method thereof

ActiveCN102445097AContinuous boiling phenomenonEnhanced boiling heat transferIndirect heat exchangersLiquid/solution decomposition chemical coatingFree energiesPorous layer

The invention relates to a high-efficiency gravity heat pipe and a manufacturing method thereof. The high-efficiency gravity heat pipe comprises an evaporating section, a heat insulating section and a condensing section, and is characterized in that a metal powder porous layer is sintered on the inner surface of the heat tube evaporating section, and the condensing section is chemically coated. The heat tube manufactured by the process method in the invention can simultaneously reinforce boiling heat transfer and condensing heat transfer, so that a plurality of ideal vaporization cores are artificially increased, thus the boiling phenomenon of the liquid is continuously carried out to achieve a purpose of reinforcing the boiling heat transfer; on the other hand, the surface of a chemical coating of the heat tube condensing section is modified to acquire a low surface free energy value; simultaneously, the coating layer is a metal-based coating layer with good thermal conductivity, thus the condensing heat transfer can be reinforced; from the above, the high-efficiency gravity heat tube reinforce the boiling and condensing effects very remarkably, has the characteristics of good heat transfer reinforcing effect, high production efficiency, low cost and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

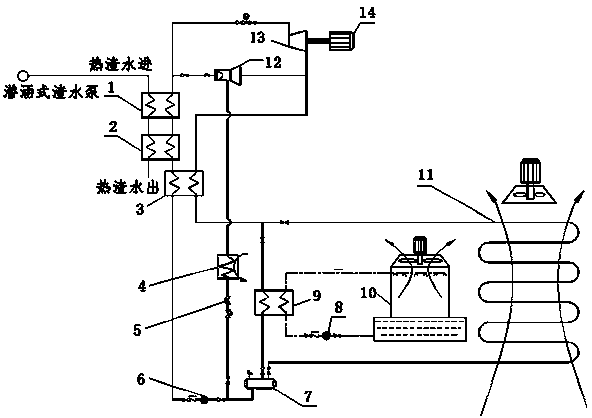

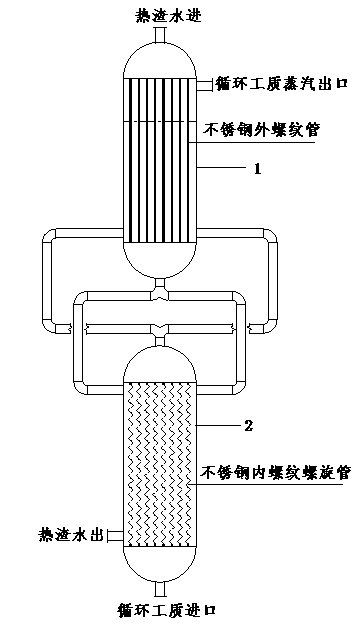

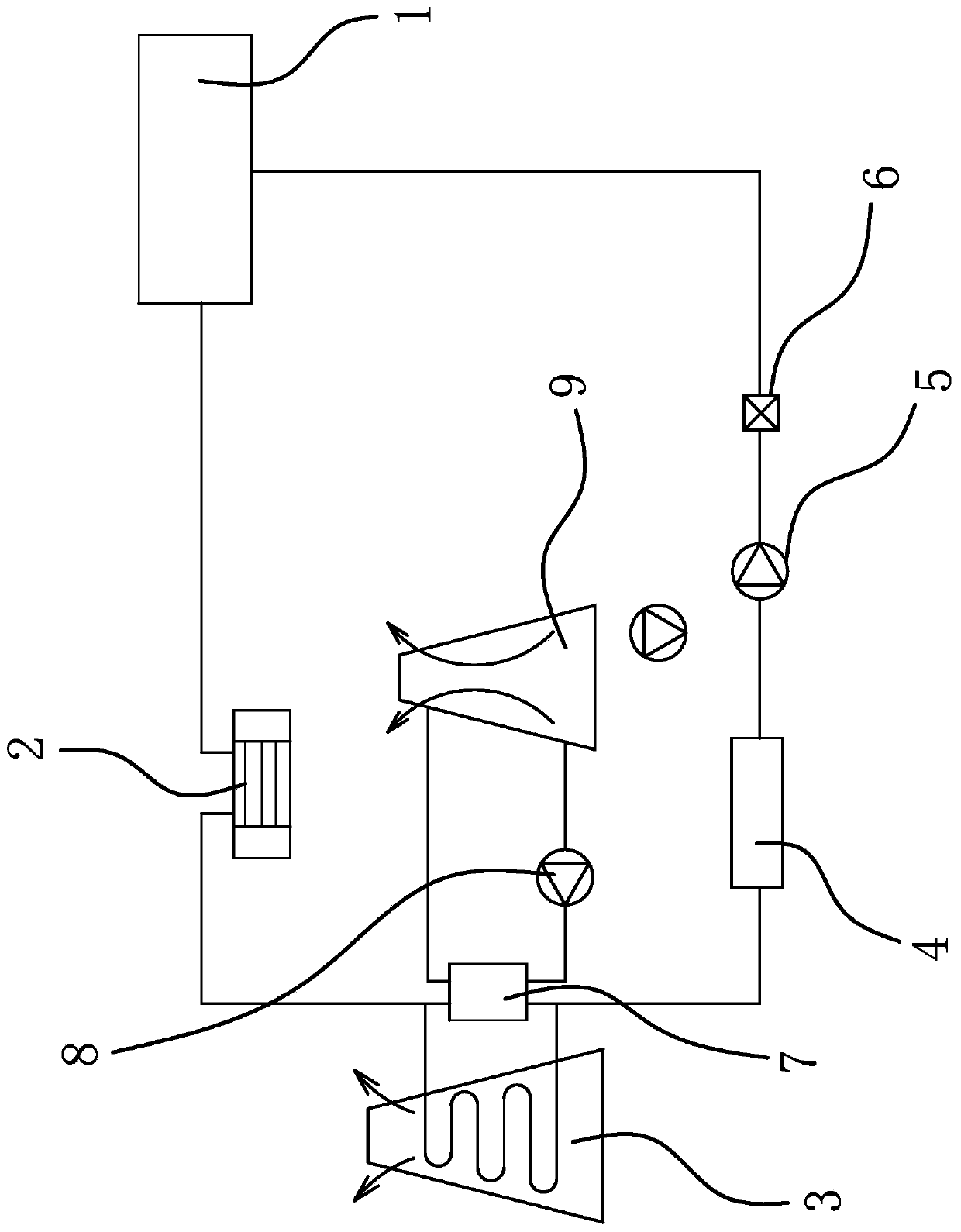

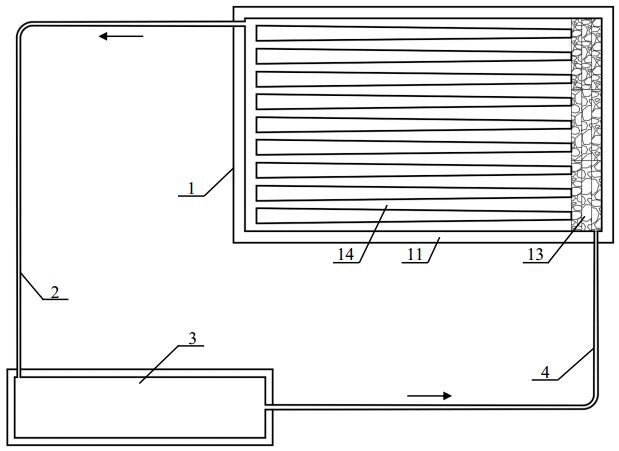

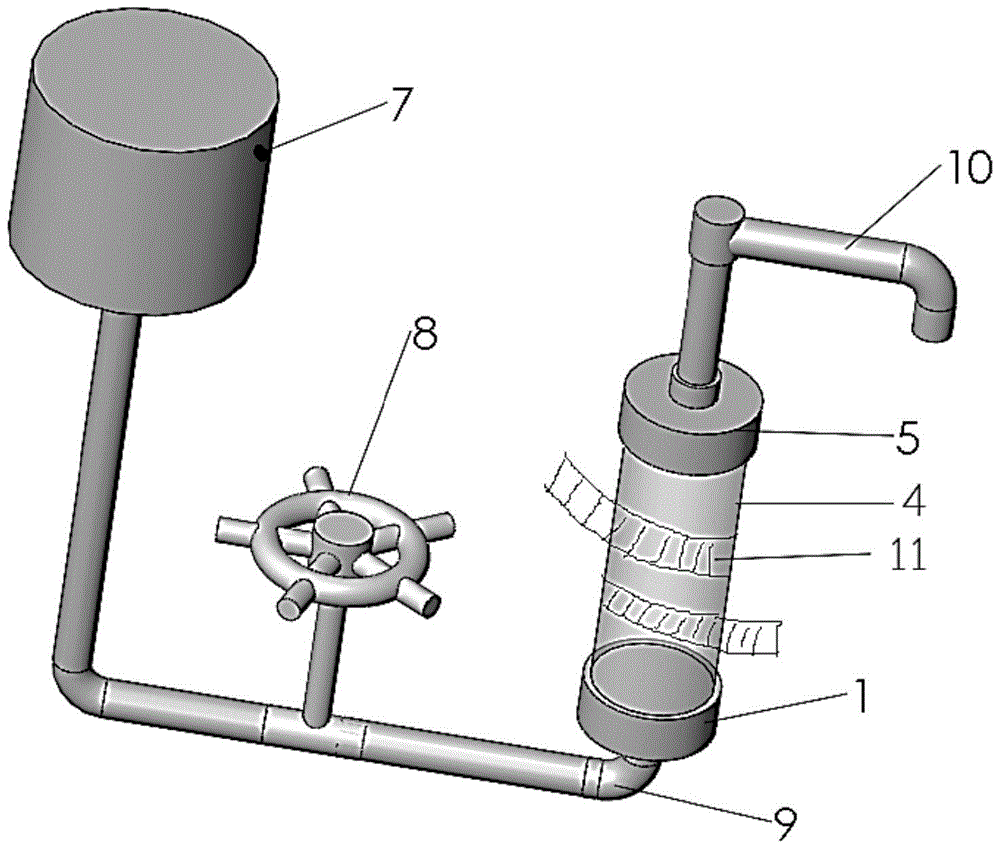

System capable of conducting power recovering and cooling by using waste heat of blast furnace slag flushing water

ActiveCN104196584AEnhanced boiling heat transferAvoid pollutionClimate change adaptationEnergy industryElectricityVapor–liquid separator

The invention relates to a system capable of conducting power recovering and cooling by using waste heat of blast furnace slag flushing water, and belongs to the technical field of energy and environment. The system comprises a slag flushing water heat recovery and heat exchange system, an organic Rankine cycle, a steam injection type cooling system and a cooling water circulation system. An internal-thread stainless steel spiral tube shell-and-tube heat exchanger is used as a pre-heater, an external-thread stainless steel tube shell-and-tube heat exchanger is used as a steam generator, and the steam generator is also used as a gas-liquid separator. The system has the advantages of being simple in structure, easy to machine and manufacture, low in manufacturing cost, capable of preventing blockage, capable of realizing countercurrent flow heat exchange, high in heat exchange efficiency, capable of effectively utilizing waste heat of the slag flushing water and the like; the system can be independently used for generating electricity or providing prime power, can also be independently used for cooling and can further provide electric power and chilled water required by a cooling air conditioner at the same time.

Owner:KUNMING UNIV OF SCI & TECH

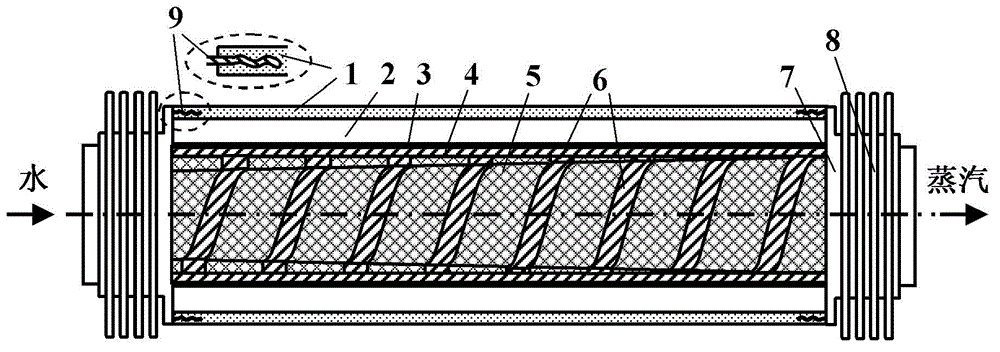

Groove type solar direct steam heat collecting pipe

ActiveCN103335427AEnhanced boiling heat transferImprove reliabilitySolar heating energySolar heat devicesEngineeringHeat stress

The invention discloses a groove type solar direct stream heat collecting pipe which is used for a solar thermal power generation system. The heat collecting pipe can directly receive solar focusing radiation to heat working medium water in the pipe so as to generate steam and comprises an absorption pipe, a glass casing pipe and connection devices at the two ends of the heat collecting pipe. A heat absorption pipe is composed of a stainless steel pipe, a selective absorption coating on the surface of the outer wall of the heat absorption pipe and a filling structure in the heat absorption pipe. The filling structure is an annular metal foam layer with an axial spiral groove, and the thickness of the layer gradually reduces in the flowing direction of a work medium. A vacuum layer is arranged between the absorption pipe and the glass casing pipe. The connection devices at the two ends of the heat collecting pipe are made of flanges and corrugate pipes. A glass-metal sealing connecting opening is processed in a crumpling mode. According to the groove type solar direct stream heat collecting pipe, on one hand, radial gas-liquid two-phase flow type reconstruction with gas inside and liquid outside in the absorption pipe is achieved, the fact that circumferential heat stress distribution of the absorption pipe is uneven is changed, and the problem of induction invalidation of heat stress is solved; on the other hand, local residual stress in the heat sealed technology can be reduced, and the problem of invalidation of end portion sealing connecting of the glass casing pipe is solved. The groove type solar direct stream heat collecting pipe can obviously improve the reliability and stability of the solar direct stream heat collecting pipe.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

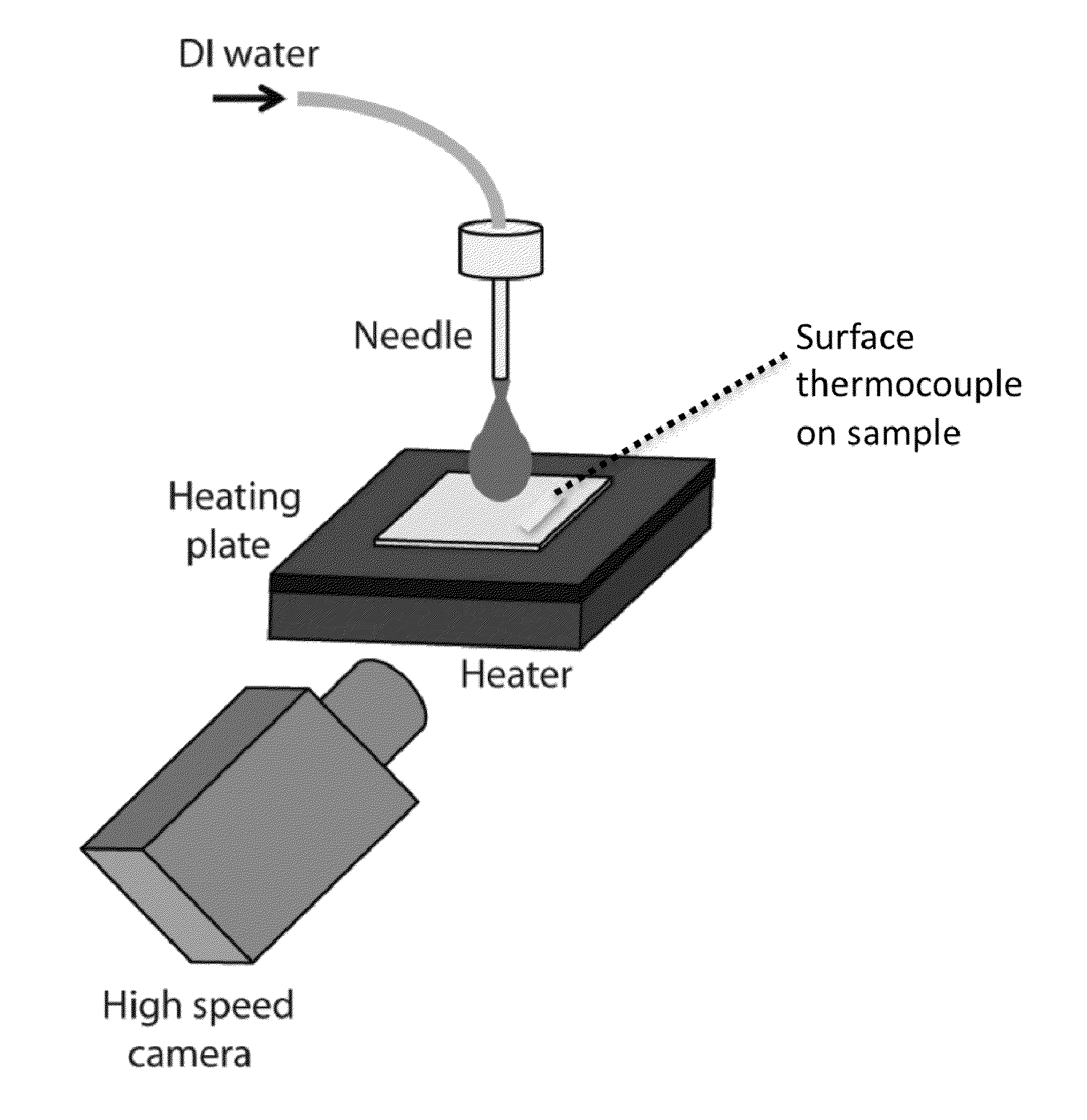

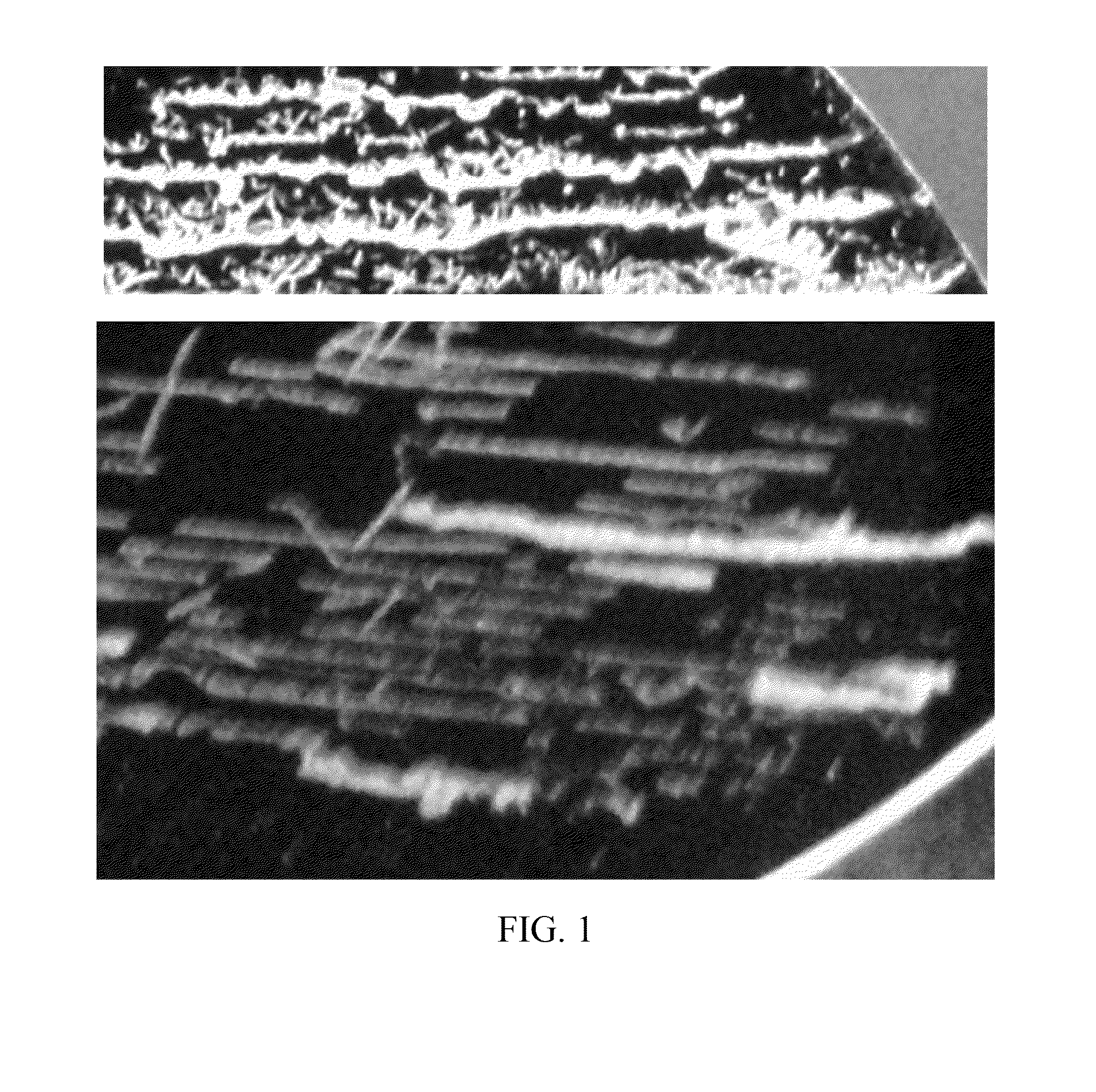

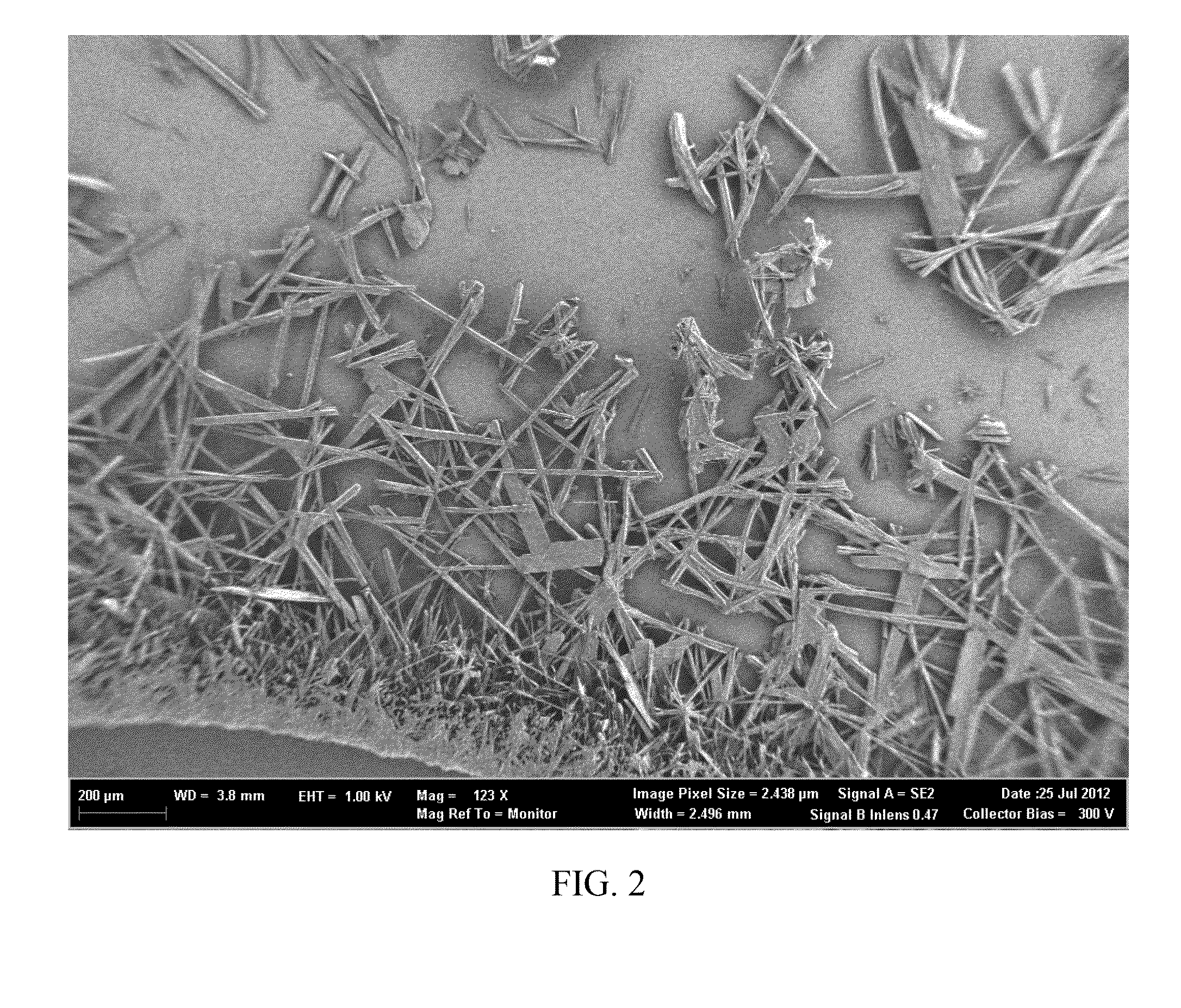

Articles and methods for enhanced boiling heat transfer

ActiveUS20140314947A1Improve heat transfer performanceEnhanced boiling heat transferBoiler water tubesVolume/mass flow measurementBoiling heat transferMaterials science

The present disclosure provides, among other things, scale-coated surfaces, vessels with controlled deposits of scale, and associated methods for enhanced boiling heat transfer. It is presently found that creating and / or maintaining a scale deposit at a controlled thickness actually enhances a type of boiling called nucleate boiling, which improves heat transfer.

Owner:MASSACHUSETTS INST OF TECH

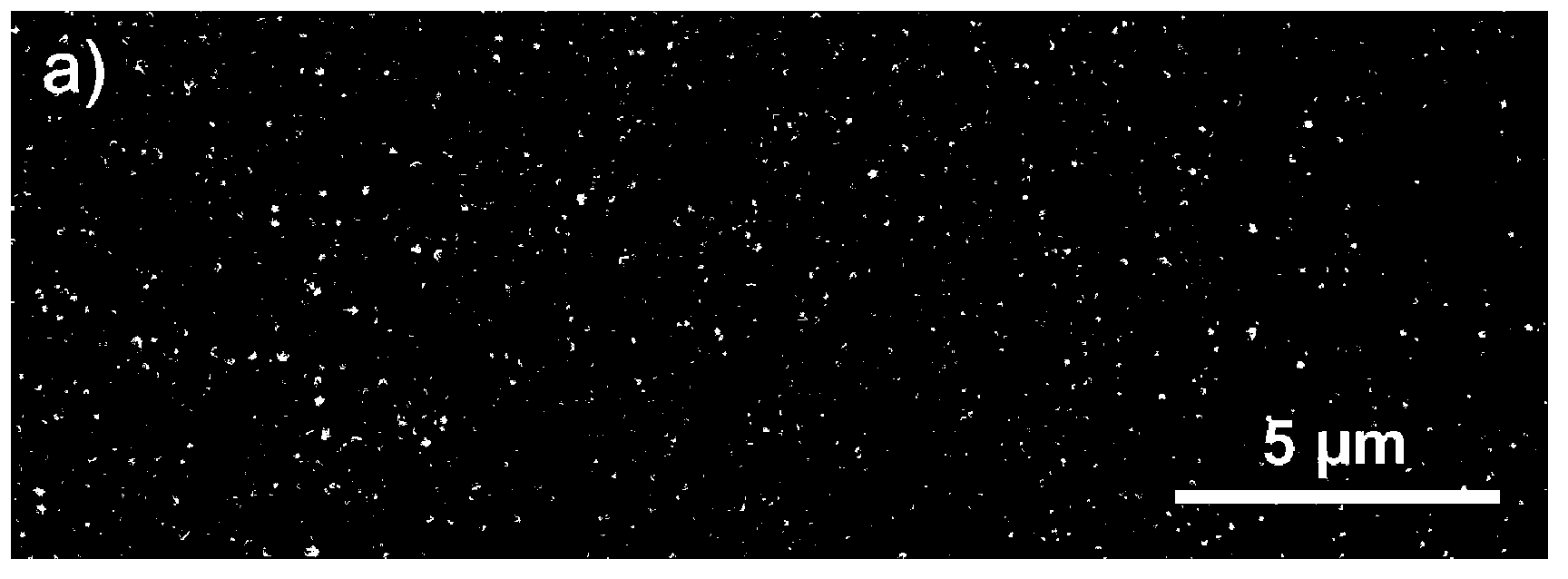

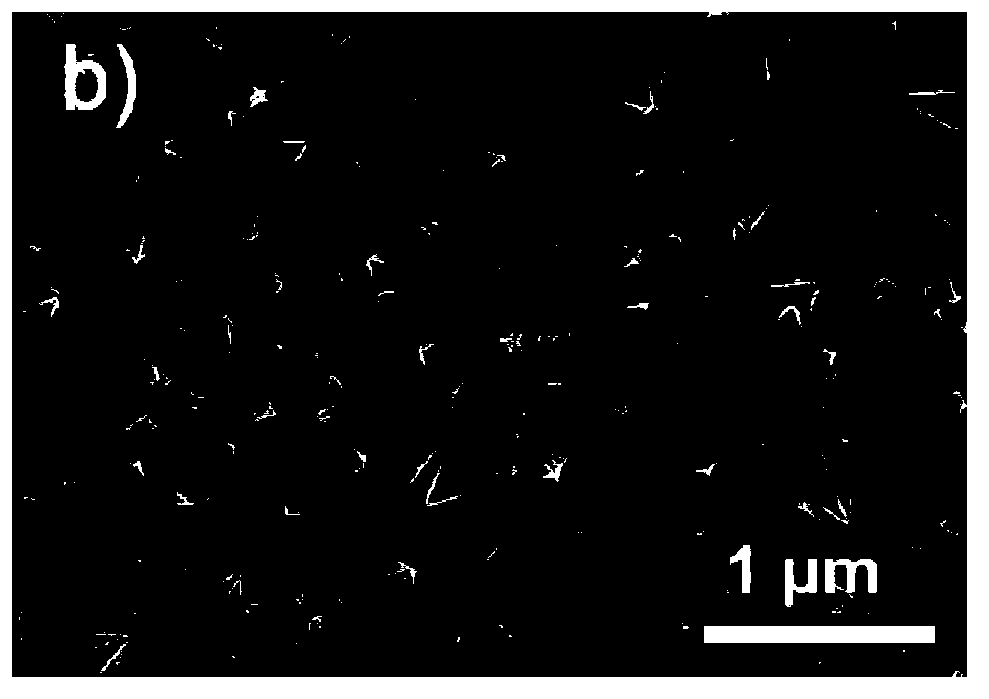

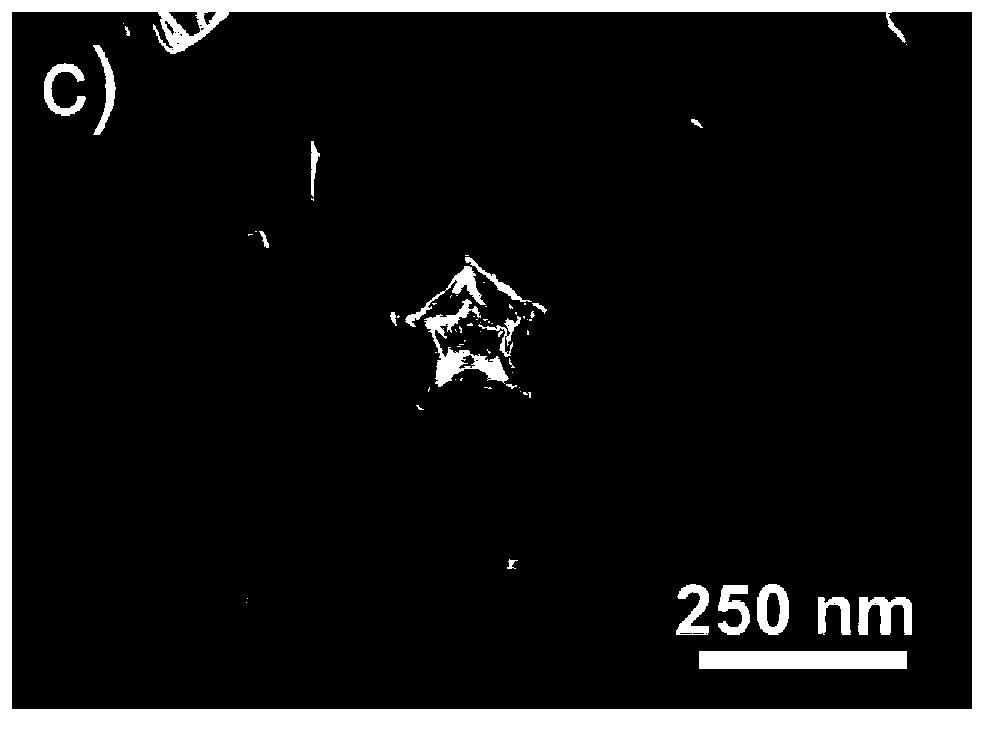

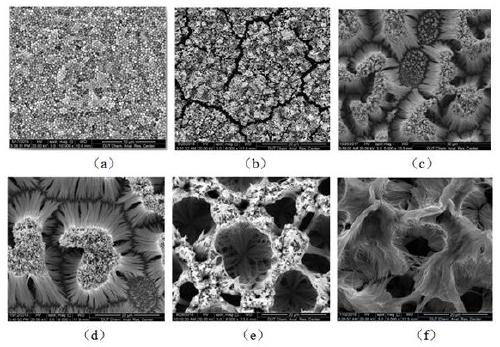

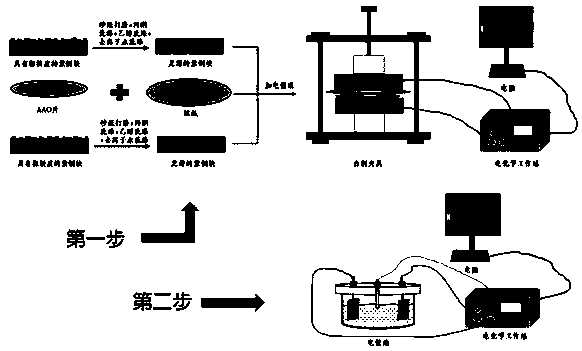

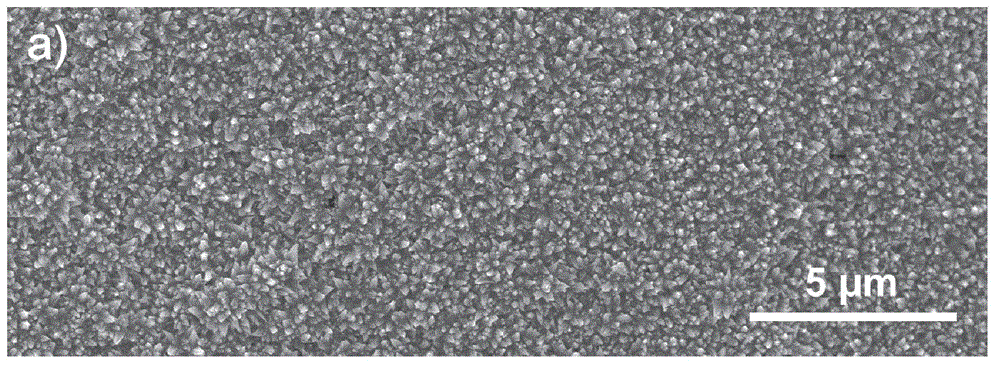

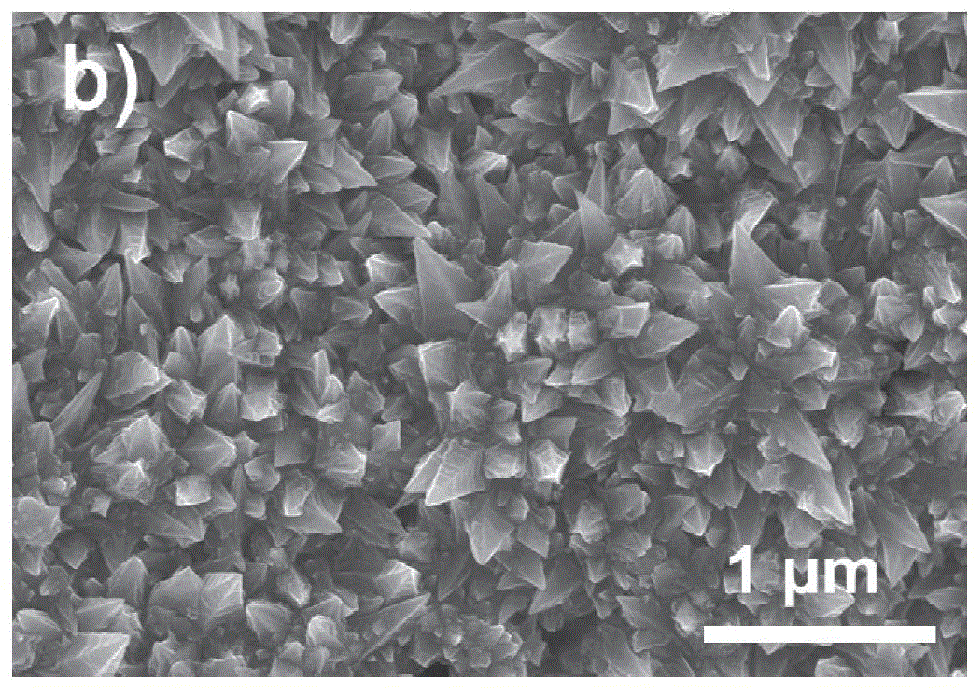

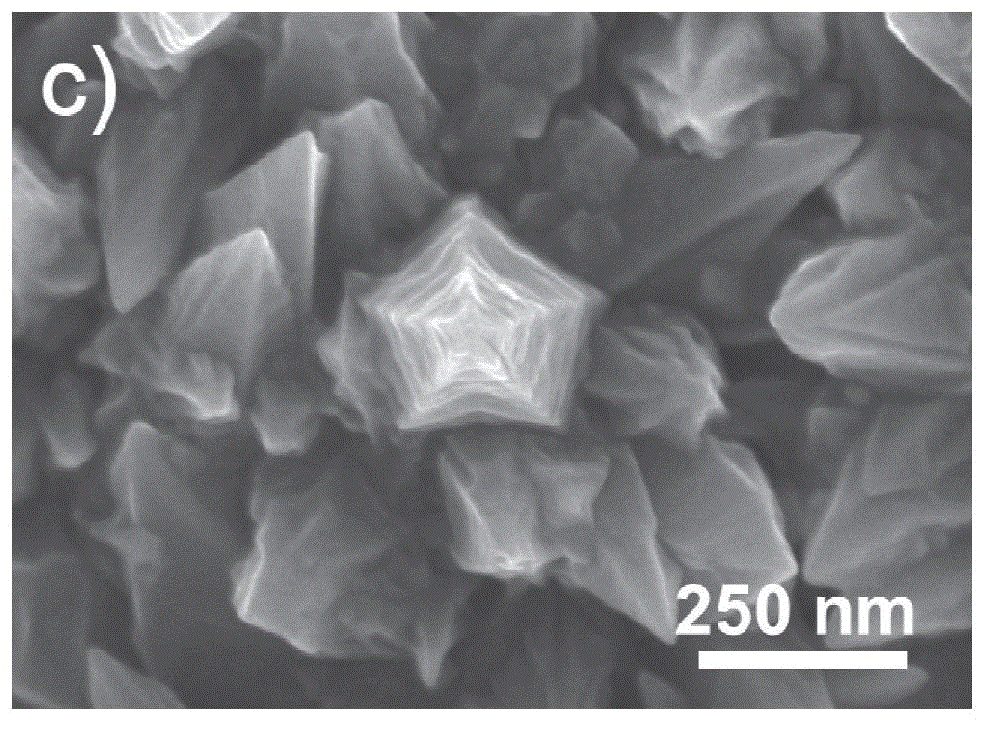

Nanometer copper material capable of transferring heat with high efficiency, and preparation method thereof

The invention discloses a nanometer copper material capable of transferring heat with high efficiency, and a preparation method thereof. The surface of the nanometer copper material is coated with an ultra-thin nano or micro-nano composite porous nickel film with super wetting ability; the ultra-thin nano composite porous nickel film comprises a porous structure which is mainly made of nickel nano flowers; and the ultra-thin micro-nano composite porous nickel film comprises a porous structure which is mainly formed by accumulation of micron or nanometer nickel triangular sheets. The preparation method comprises following steps: a substrate is taken as working electrode; the working electrode, a counter electrode and a reference electrode are placed in a weak acid nickel salt electrolyte so as to form a reduction system; reduction current is provided between the working electrode and the counter electrode so as to realized nickel electro-deposition on the surface of the substrate; and then the ultra-thin nano or micro-nano composite porous nickel film is formed on the surface of the substrate. The ultra-thin nano or micro-nano composite porous nickel film is capable of increasing utilization stability of the nanometer copper material, and improving filmwise condensation heat transfer performance, boiling heat transfer performance and spray cooling heat dissipation performance of the nanometer copper material greatly. The formula of the electrode needed in the preparation method is simple; raw material are cheap and easily available; optional range of electroplating mode is wide; and the preparation method is suitable for industrialized large-scaled application.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

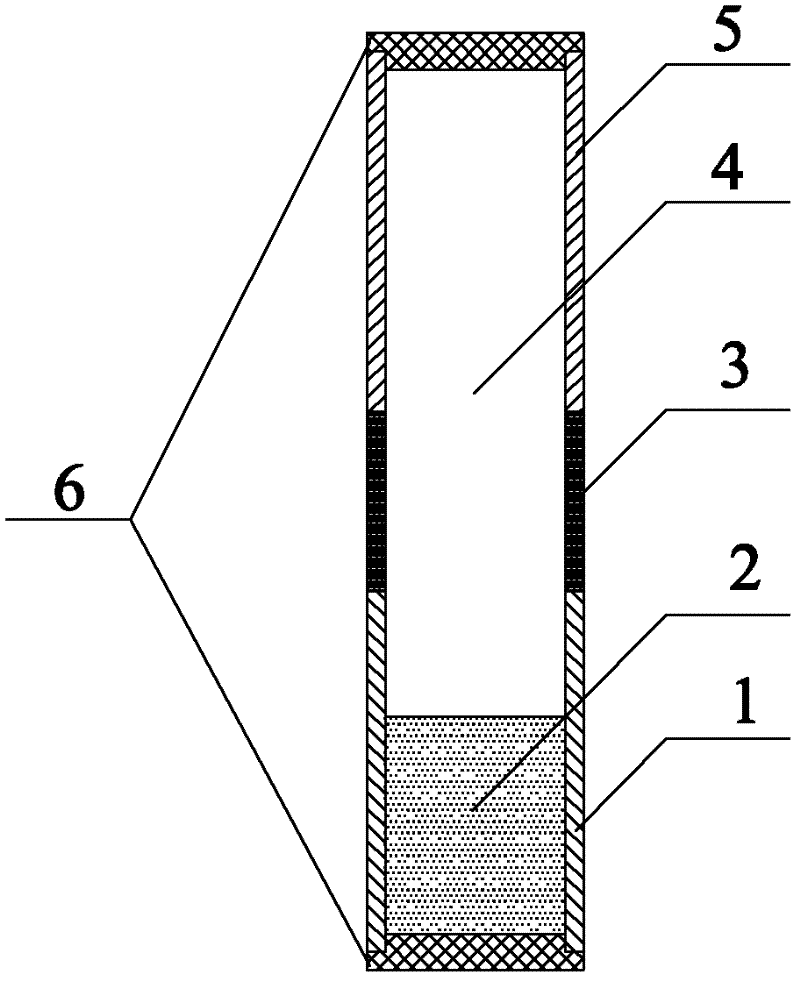

Efficient boiling enhanced heat exchange tube and manufacturing method thereof

ActiveCN111207619AIncrease supplementImprove wettabilityHeat transfer modificationEvaporation heat transferProcess engineering

The invention discloses an efficient boiling enhanced heat exchange tube and a manufacturing method thereof, and belongs to the technical field of heat exchangers. The efficient boiling enhanced heatexchange tube is structurally composed of an external base tube and a tube inner wall sintered layer, wherein the tube inner wall sintered layer is a heterogeneous super-hydrophilic copper powder particle layer, and is distributed along the cross section of the base tube in a space mode that particles on the upper wall surface are thin and dense, particles on the lower wall surface are thick and sparse, and the side wall surface is uniformly changed, so that the anti-gravity migration of liquid at the bottom of the tube can be effectively realized, and the flow pattern in the tube is improved.The tube inner wall sintered layer can provide a large number of stable vaporization cores, meanwhile, tiny holes in the tube can provide large capillary force to promote liquid supplement, the dynamic behavior of steam bubbles is changed, the steam bubble separation period is shortened, the distribution in the base tube is regulated and controlled, and boiling heat exchange is effectively enhanced. The efficient boiling enhanced heat exchange tube can be applied to a medium-low temperature waste heat power generation system, an air conditioner evaporator, a groove type solar heat collectingtube and a boiler water wall, and has wide application value and social value.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Evaporation heat transfer pipe

ActiveCN101776412BIncrease the number of vapor coresIncreased turbulenceHeat transfer modificationLaminated elementsEvaporation heat transferEvaporation

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

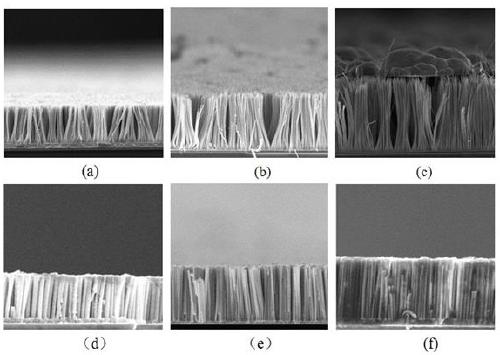

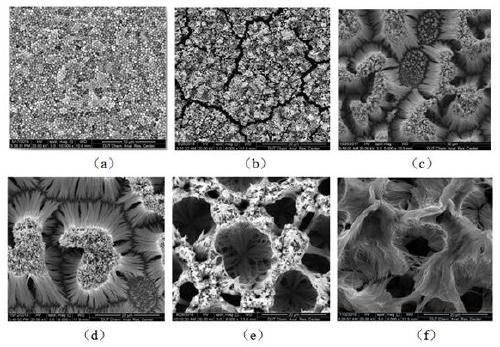

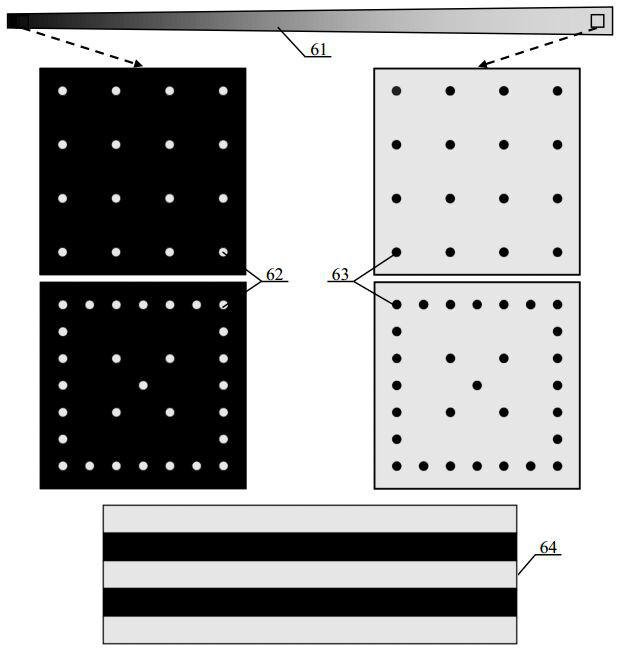

Surface preparation method capable of preparing various nanowire structures

ActiveCN111218702AGreat potentialControllable surface topographyMaterial nanotechnologyNanowirePhase change heat transfer

The invention relates to a surface preparation method capable of preparing various nanowire structures, and belongs to the technical field of surface treatment. According to the method, a template-assisted electroplating method is utilized, and multiple structural shapes such as upright type, agglomeration type and round pit type can be formed by changing hole spacing, hole diameter and electroplating duration of the template, and the structure height and an included angle of the upright type and the agglomeration type can be changed. The height of nanowires is 4 microns-50 microns, the centerdistance of the nanowires is 60nm-500nm, and the diameter of the nanowires is 5nm-400nm. The surface shapes prepared by the preparation method are controllable, structural form is diversified, and cross-scale effect can be achieved, the upright type and the agglomeration type can be used for condensation and the round pit type can be used in the field of phase change heat transfer such as boiling.

Owner:DALIAN UNIV OF TECH

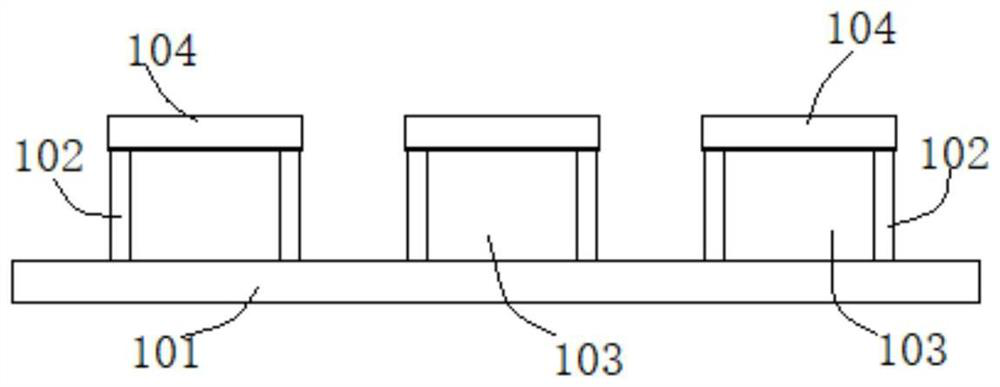

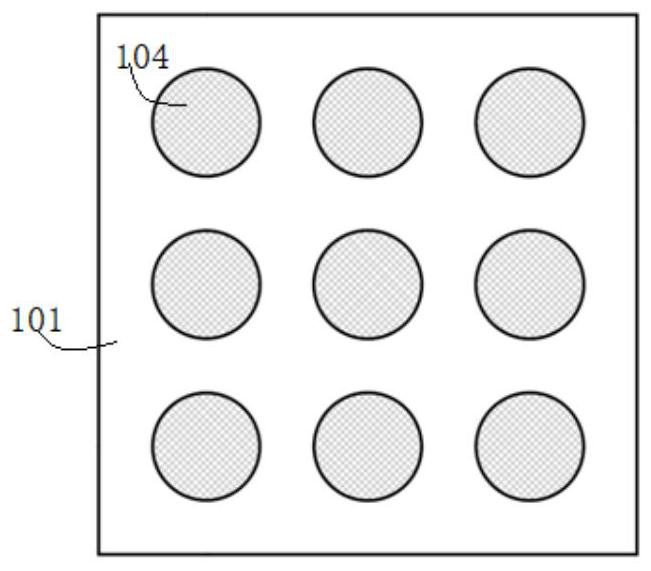

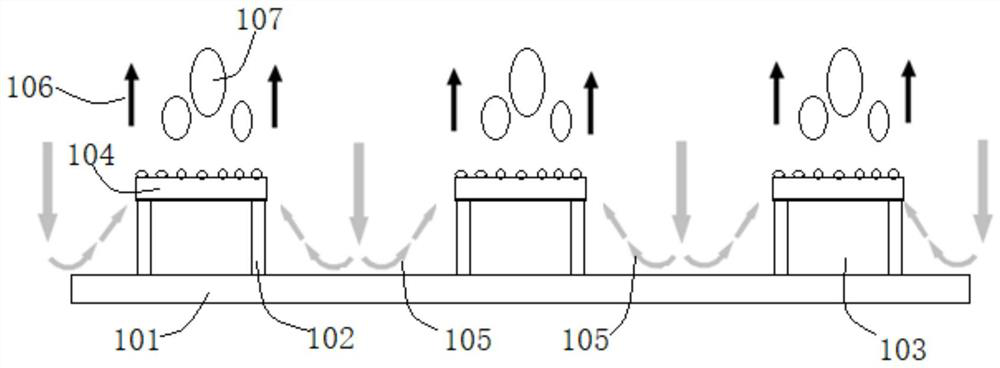

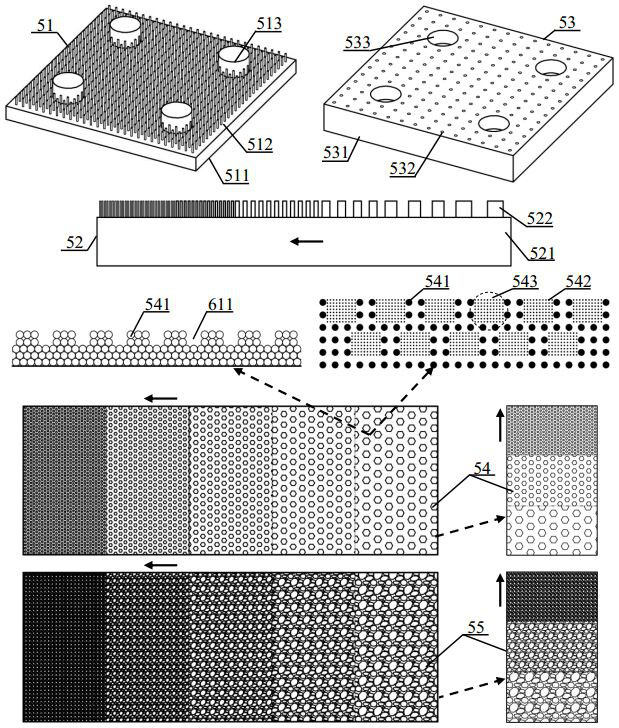

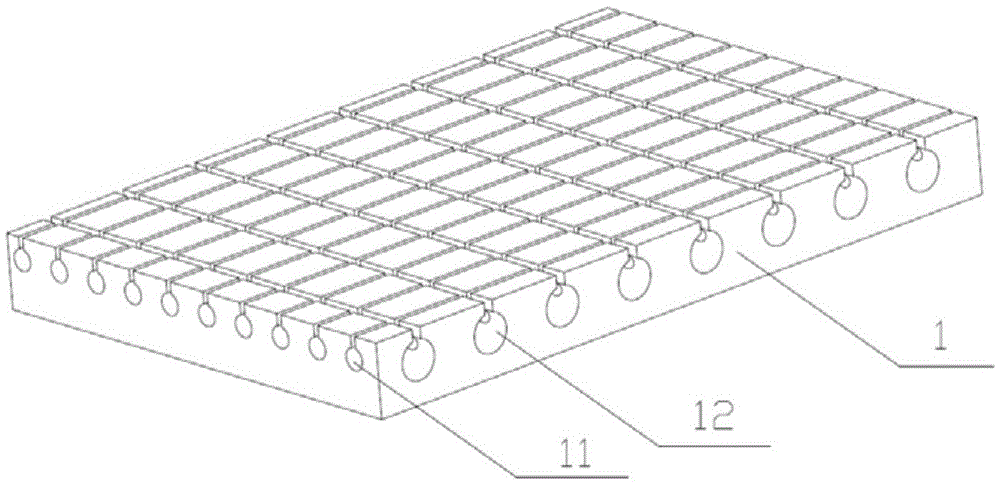

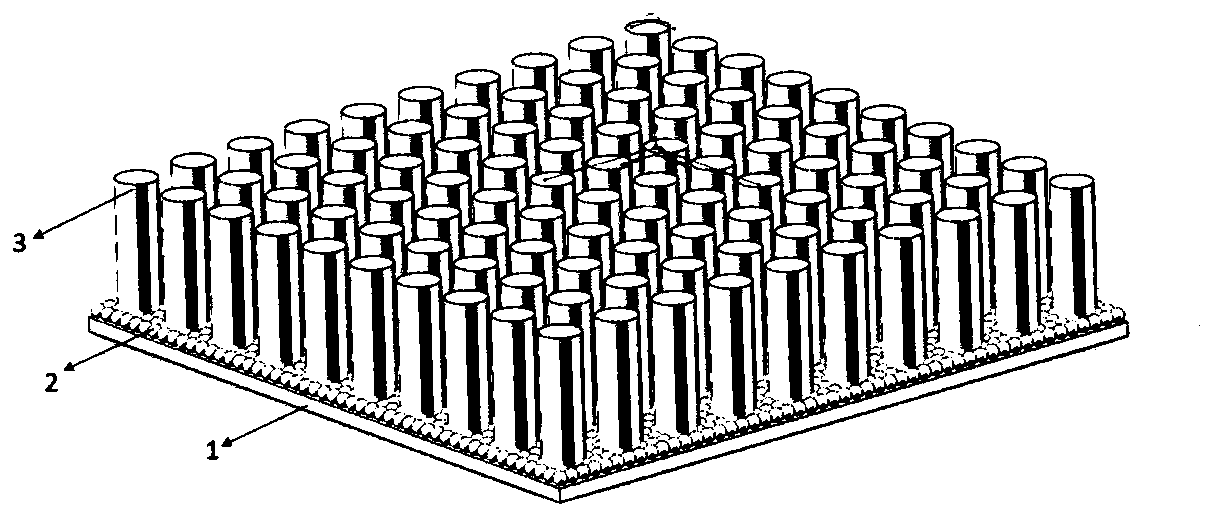

Composite microcolumn-porous surface structure for enhancing boiling heat transfer

InactiveCN114023710AReduce lossHypernucleated pointSemiconductor/solid-state device detailsSolid-state devicesBoiling heat transferMaterials science

The invention discloses a composite microcolumn-porous surface structure for enhancing boiling heat transfer, and belongs to the field of boiling heat transfer enhancing. The structure comprises a heating substrate and a plurality of micro-column-shaped composite porous surface micro-structures on the substrate. The tops of the micro-column structures are capillary cores made of a porous material, the bottoms of the micro-column structures are made of a composite material, the interiors of the structures are made of a high-thermal-conductivity material, the exteriors of the structures are wrapped with a layer of high-thermal-resistance materials, and channels are formed among the micro-structures. According to the surface structure, heat is introduced into fluid through the high-heat-conductivity micro-columns, the porous material is used for increasing the gasification core, reducing the boiling starting point and sucking the supplied liquid, the temperature superheat degree of the boiling wall surface is reduced, and the bubble separation rate is increased; and a fluid working medium is timely ejected into the porous core to form a stable gas-liquid flowing path, a gas film formed by direct boiling on a heating surface is avoided, and boiling heat transfer is enhanced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

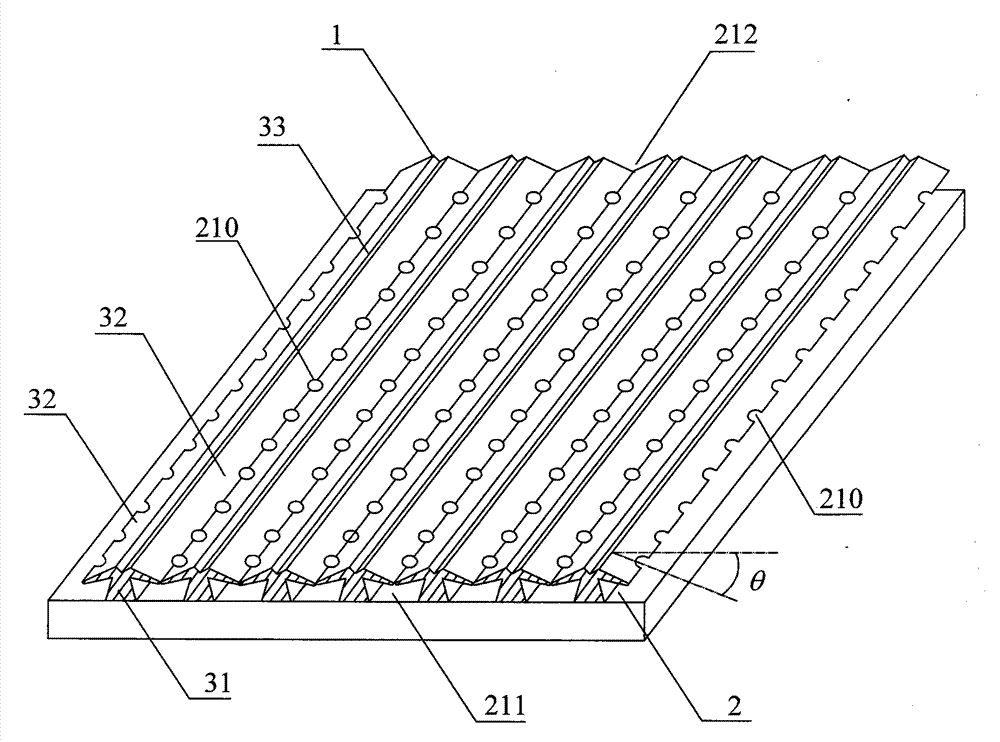

Heat exchange plate for plate-type evaporator

InactiveCN103175432AIncrease the number ofReduce superheatLaminated elementsRough surfaceHeat transmission

The invention belongs to the technical field of heat transmission, and relates to a heat exchange plate, in particular to a heat exchange plate for a plate-type evaporator. On the basis of a heat exchange plate substrate, the upper end face of the heat exchange plate substrate is provided with micro ribs and micro grooves, and alternatively, the surface of the heat exchange plate substrate is provided with rough structures. The heat exchange plate has the advantages that multiple rough surfaces can increase vaporization core number, reduce the degree of superheat of the wall surface, strengthen boiling heat transfer, and further improve the total heat transfer coefficient of the evaporator.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

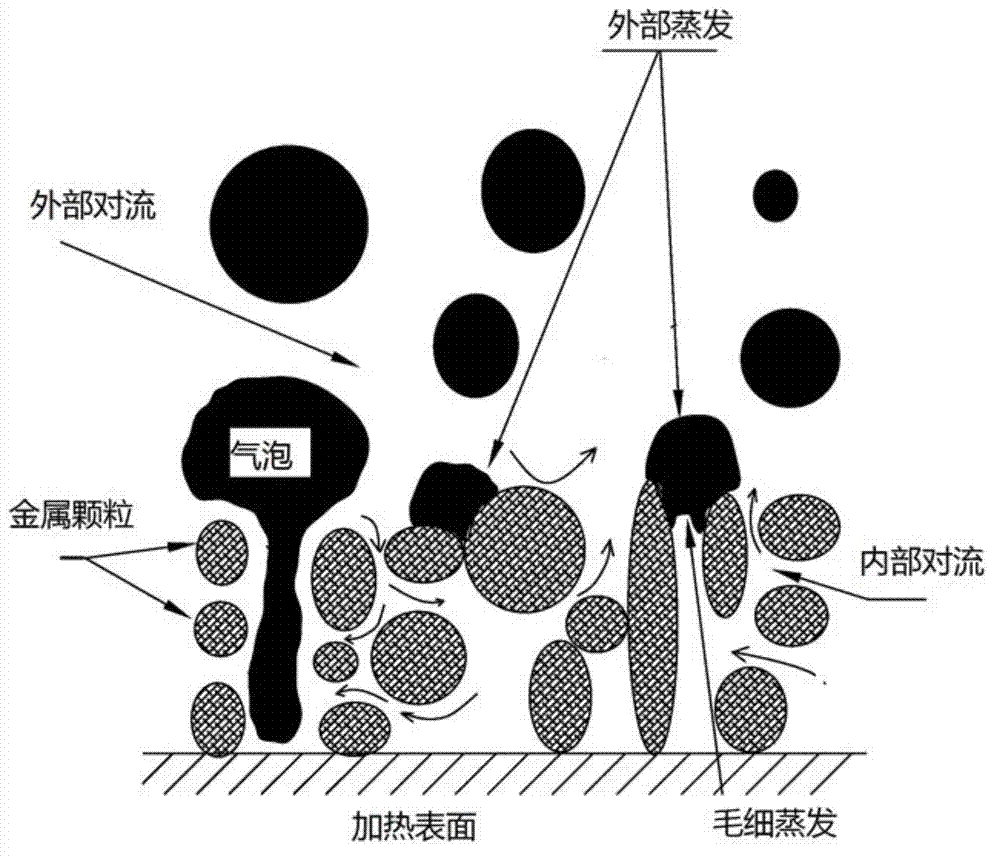

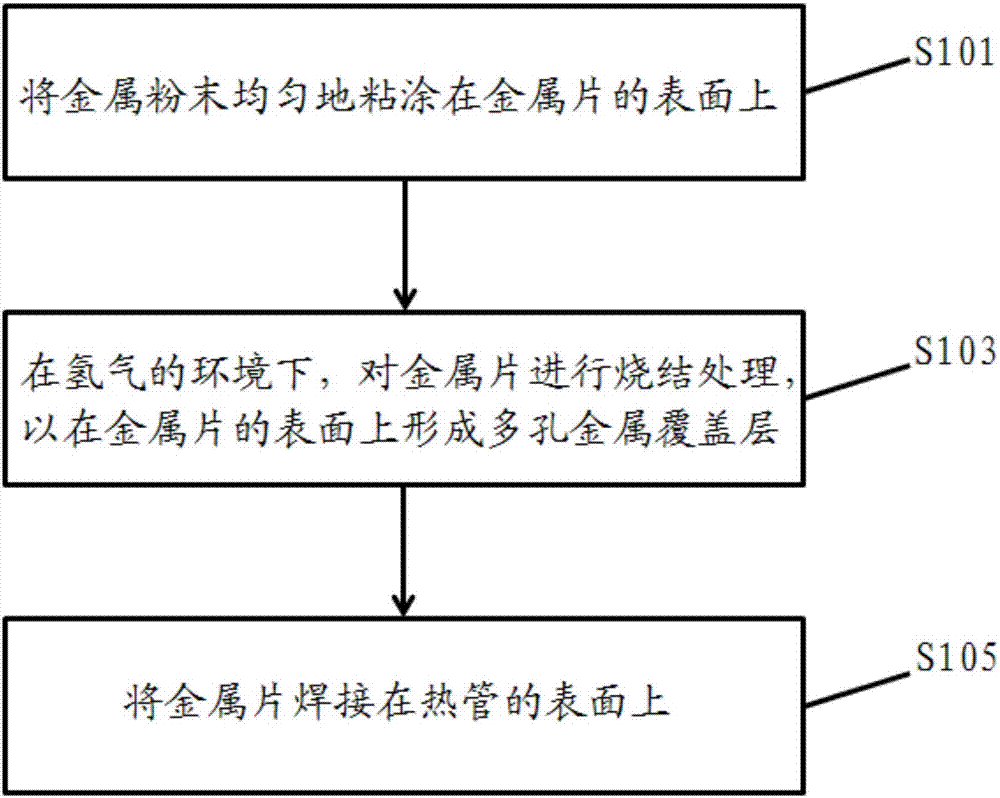

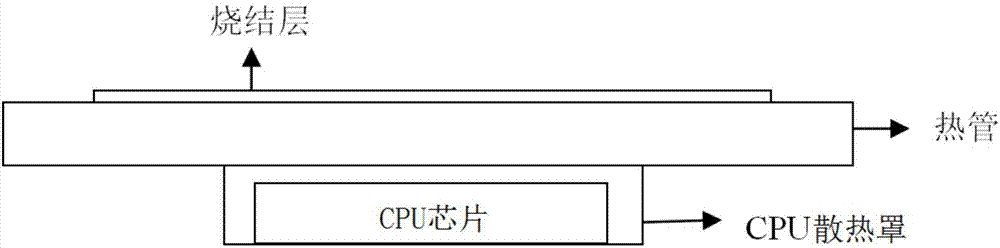

CPU cooling method and apparatus

InactiveCN107168493AUniform temperature fieldLower core temperatureDigital data processing detailsModifications by conduction heat transferHydrogenEvaporation

The invention discloses a CPU cooling method and apparatus. The CPU cooling method comprises the steps of uniformly adhering metal powder to the surface of a metal sheet; in a hydrogen environment, performing sintering processing on the metal sheet to form a porous metal coverage layer on the surface of the metal sheet; and welding the metal sheet on the surface of a heat pipe. According to the method and the apparatus, the metal powder is uniformly adhered to the surface of the metal sheet, then in the hydrogen environment, the metal sheet is subjected to the sintering processing to form the porous metal coverage layer on the surface of the metal sheet, and the metal sheet is welded on the surface of the heat pipe; the heat pipe is mounted on the surface of a CPU chip, and the surface of heat pipe is subjected to sintering and enhanced boiling processing, so that a temperature field of the boiling surface is uniform, and the boiling area and the evaporation core are enlarged; and enhanced boiling heat transfer is performed, so that the core temperature of the chip is reduced.

Owner:SUGON DATAENERGYBEIJING CO LTD

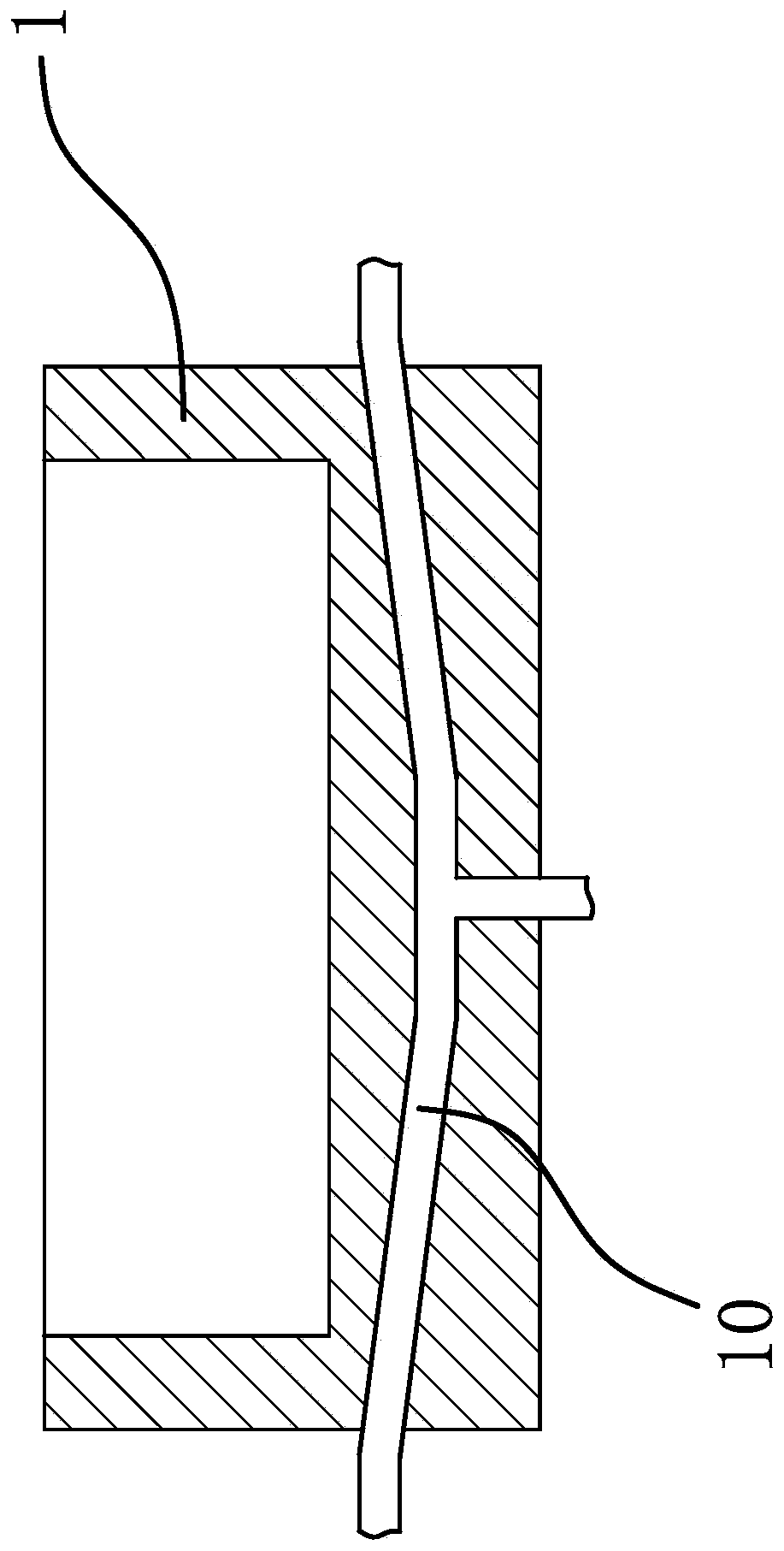

Automobile hub die cooling system

InactiveCN109926547ASimple structureEasy to processFoundry mouldsFoundry coresCooling towerAir cooling system

The invention provides an automobile hub die cooling system, and belongs to the technical field of mechanisms. The automobile hub die cooling system solves the problem of low stability in the prior art. The cooling system comprises a working medium circulating system and a cooling water circulating system and direct air cooling system, wherein the working medium circulating system comprises a hubdie, a compressor, a liquid storing tank, a working medium circulating pump, an expansion valve, an evaporating flowing channel, a water cooling condenser or an air cooling condenser and a pipeline; and the cooling water circulating system comprises a water cooling condenser, a cooling tower and a circulating water pump. According to the system, pure organic working mediums such as HFCs, HCs, HEFs, PFCs, CF3I and HFO1234y or water is used as a circulating working medium the working medium circulating system; a water cooling or direct air cooling manner can be carried out on the cold end; and the two cooling manners can be independently set or combined. The system is high in stability.

Owner:JIAXING UNIV

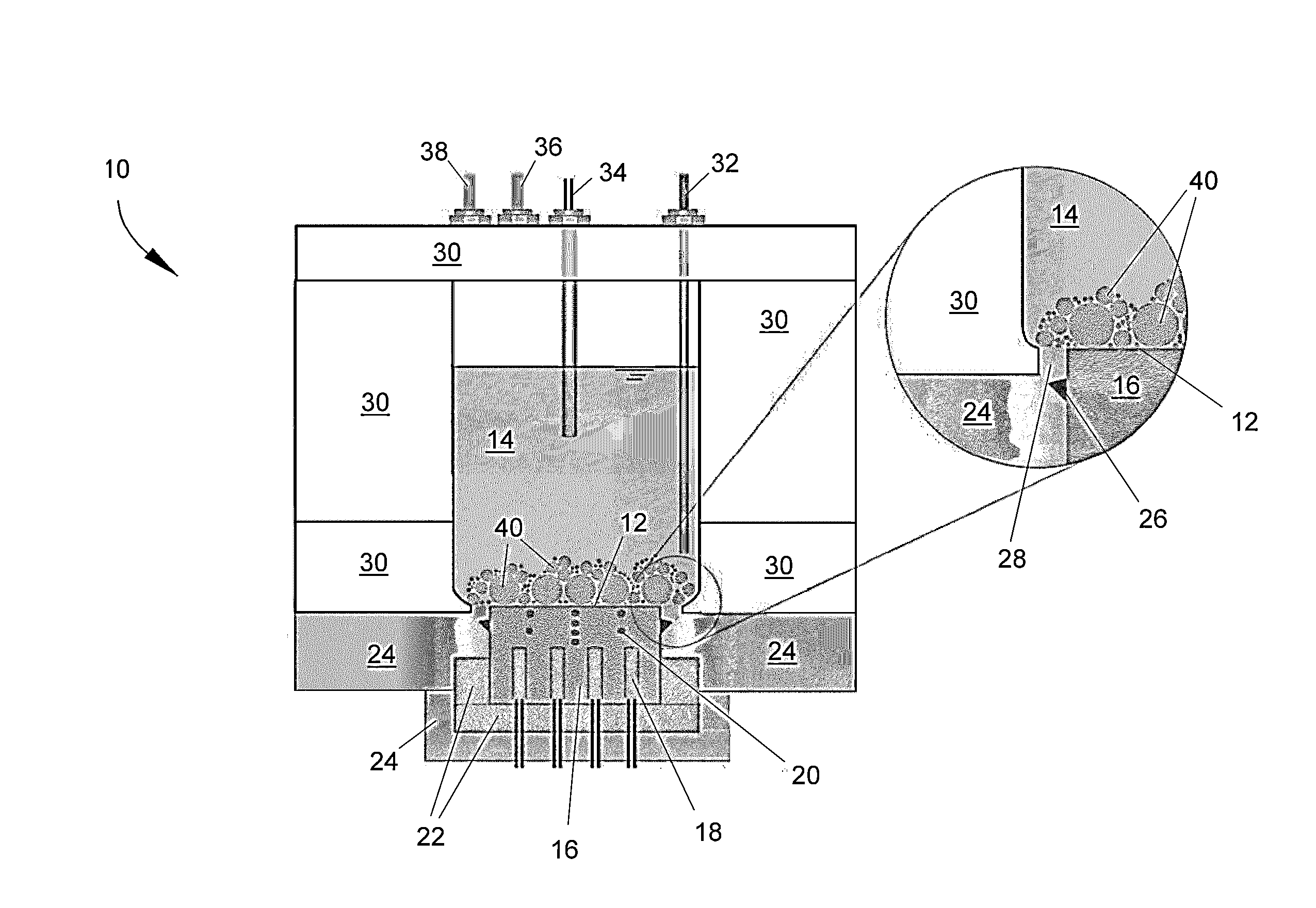

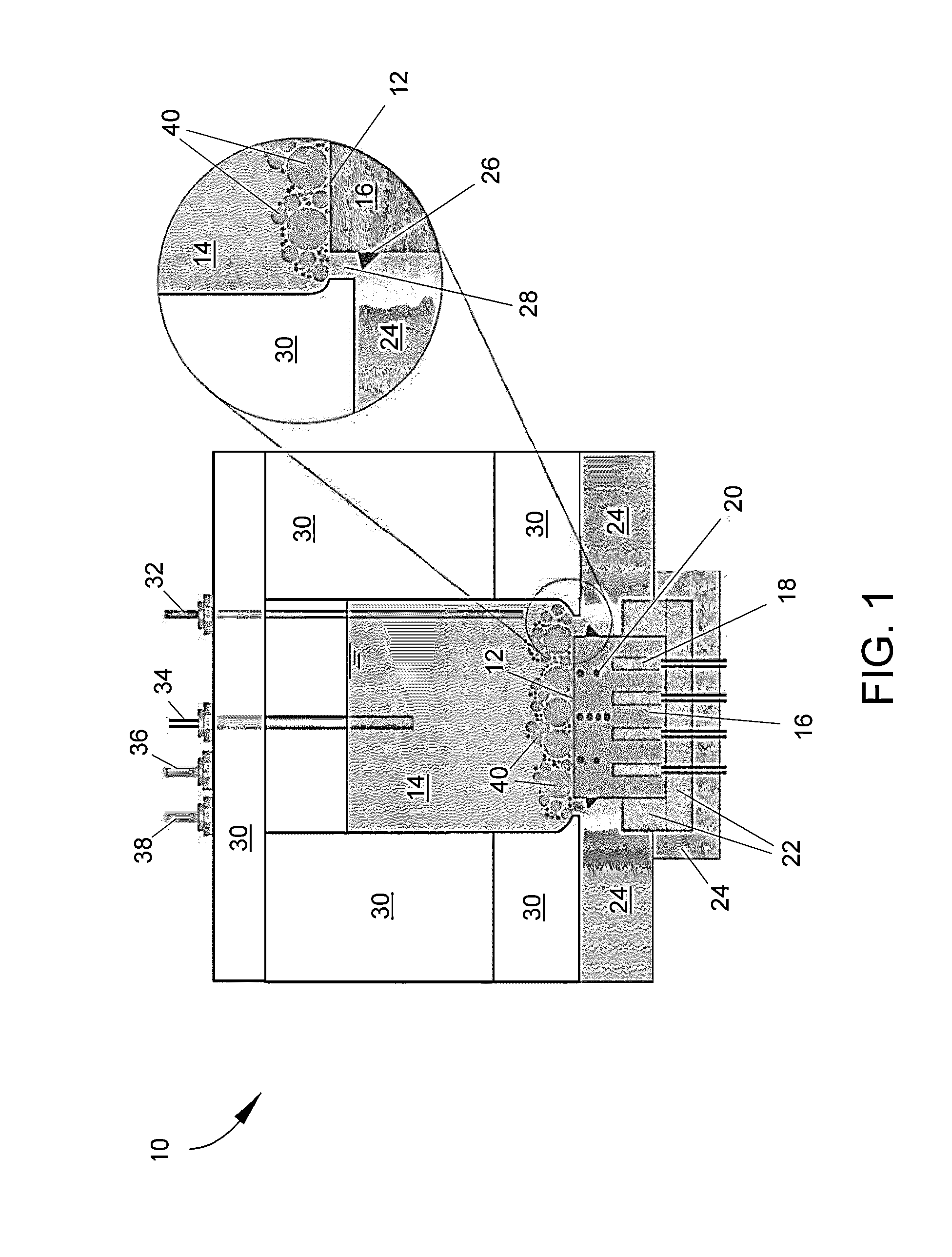

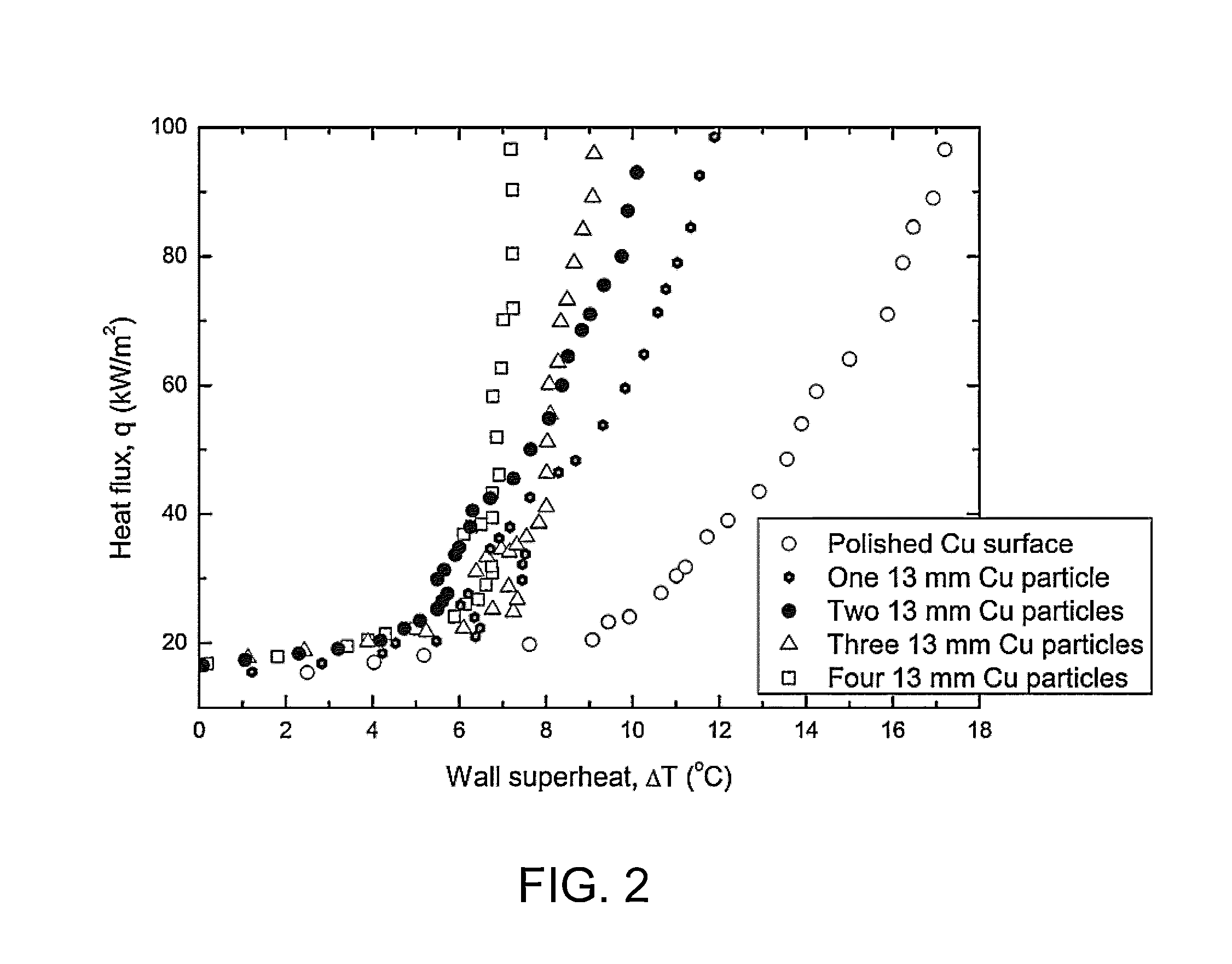

Apparatus and method for increasing boiling heat transfer therein

ActiveUS20150068712A1Enhanced boiling heat transferImprove heat transfer performanceCorrosion preventionCoatingsWorking fluidBoiling heat transfer

An apparatus and a method of enhancing boiling heat transfer therein capable of increasing both the critical heat flux and nucleate boiling heat transfer of a working fluid. The method includes placing free particles on a surface so as to define narrow corner gaps and cavities at interfaces between the particles and the surface and heating the surface while the surface is contacted by the working fluid to bring the working fluid to a boil, with the result that bubble nucleation is facilitated and nucleate boiling heat transfer from the surface is increased.

Owner:PURDUE RES FOUND INC

Surface preparation method capable of preparing various nanowire structures

InactiveCN110387565AGreat potentialControllable surface topographyMaterial nanotechnologyNanowireElectroplating

The invention discloses a surface preparation method capable of preparing various nanowire structures, and belongs to the technical field of surface treatment. According to the method, by means of a template-assisted electroplating method, various structural appearances such as an upright type, an agglomeration type and a round pit type can be formed by changing the interval and aperture of template holes and the electroplating time, and the structure height and included angle of the upright type and the agglomeration type can be changed. Nanowires are 4-50 microns high, the center distance ofthe nanowires is 60-500 nm, and the diameter of the nanowires is 5-400 nm. The surface appearances prepared through the preparation method are controllable, the structural form is diversified and cross-scale, the upright type and the agglomeration type can be used for condensation, and the round pit type can be applied to the field of phase-change heat transfer such as boiling.

Owner:DALIAN UNIV OF TECH

Loop heat pipe with multi-scale structure synergistic mixed wettability inner surface

PendingCN113048824AEnhanced boiling heat transferSatisfy nuclearizationIndirect heat exchangersLiquid lineEngineering

The invention discloses a loop heat pipe with a multi-scale structure synergistic mixed wettability inner surface. All parts are sequentially connected in series to form a cycle, the interior of the loop heat pipe is provided with the multi-scale structure synergistic mixed wettability inner surface, and the loop heat pipe comprises an evaporator, a condenser, a steam line and a liquid line, and the evaporator is provided with a multi-scale capillary core with gradient hydrophilicity and hydrophobicity. The size is gradually reduced in the circulation direction, the surface is transited from hydrophobicity to hydrophilicity, hydrophobic points are arranged in a hydrophilic area, and hydrophilic points are arranged in a hydrophobic area. The condenser is provided with a multi-scale micro-column inner surface with gradient hydrophobicity, the surface of a nanoneedle transits from super hydrophobicity to hydrophobicity in the circulation direction, and the top end of the embedded micro-column is hydrophilic and forms a hydrophilic point. The steam line and the liquid line are reducing pipes, the pipe diameter and the size of the porous structure on the inner surface are gradually reduced in the circulation direction, and gradient wettability is achieved. By means of the reasonably-designed cooperation mode of the surface multi-scale structure and the mixed wettability, the requirements of different areas and stages of the loop heat pipe for the structure scale and wettability can be met, and the heat exchange performance of the loop heat pipe is improved through all-around cooperation.

Owner:CHINA UNIV OF MINING & TECH

High-efficiency heat transfer nano-copper material and preparation method thereof

The invention discloses a nanometer copper material capable of transferring heat with high efficiency, and a preparation method thereof. The surface of the nanometer copper material is coated with an ultra-thin nano or micro-nano composite porous nickel film with super wetting ability; the ultra-thin nano composite porous nickel film comprises a porous structure which is mainly made of nickel nano flowers; and the ultra-thin micro-nano composite porous nickel film comprises a porous structure which is mainly formed by accumulation of micron or nanometer nickel triangular sheets. The preparation method comprises following steps: a substrate is taken as working electrode; the working electrode, a counter electrode and a reference electrode are placed in a weak acid nickel salt electrolyte so as to form a reduction system; reduction current is provided between the working electrode and the counter electrode so as to realized nickel electro-deposition on the surface of the substrate; and then the ultra-thin nano or micro-nano composite porous nickel film is formed on the surface of the substrate. The ultra-thin nano or micro-nano composite porous nickel film is capable of increasing utilization stability of the nanometer copper material, and improving filmwise condensation heat transfer performance, boiling heat transfer performance and spray cooling heat dissipation performance of the nanometer copper material greatly. The formula of the electrode needed in the preparation method is simple; raw material are cheap and easily available; optional range of electroplating mode is wide; and the preparation method is suitable for industrialized large-scaled application.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

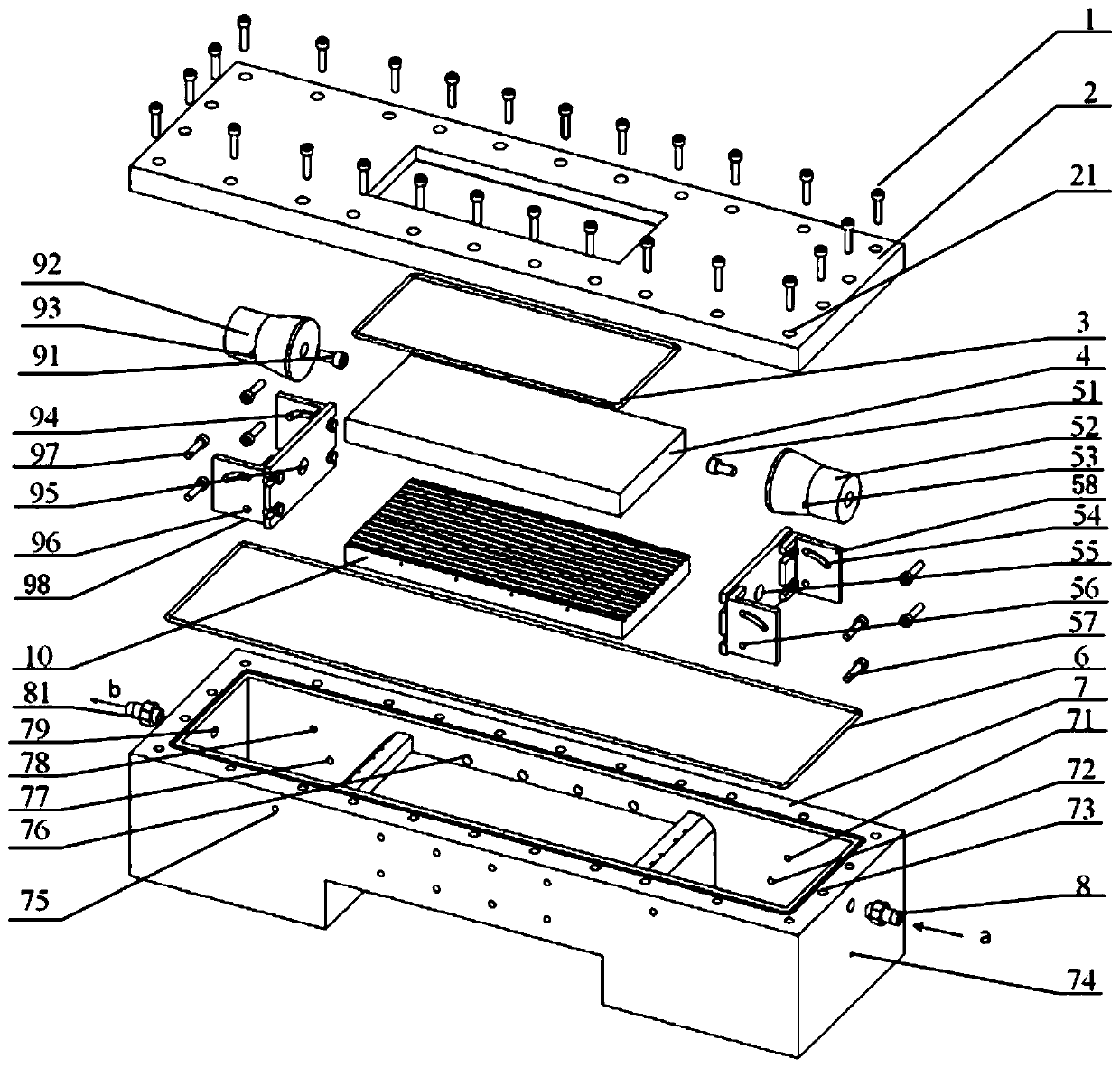

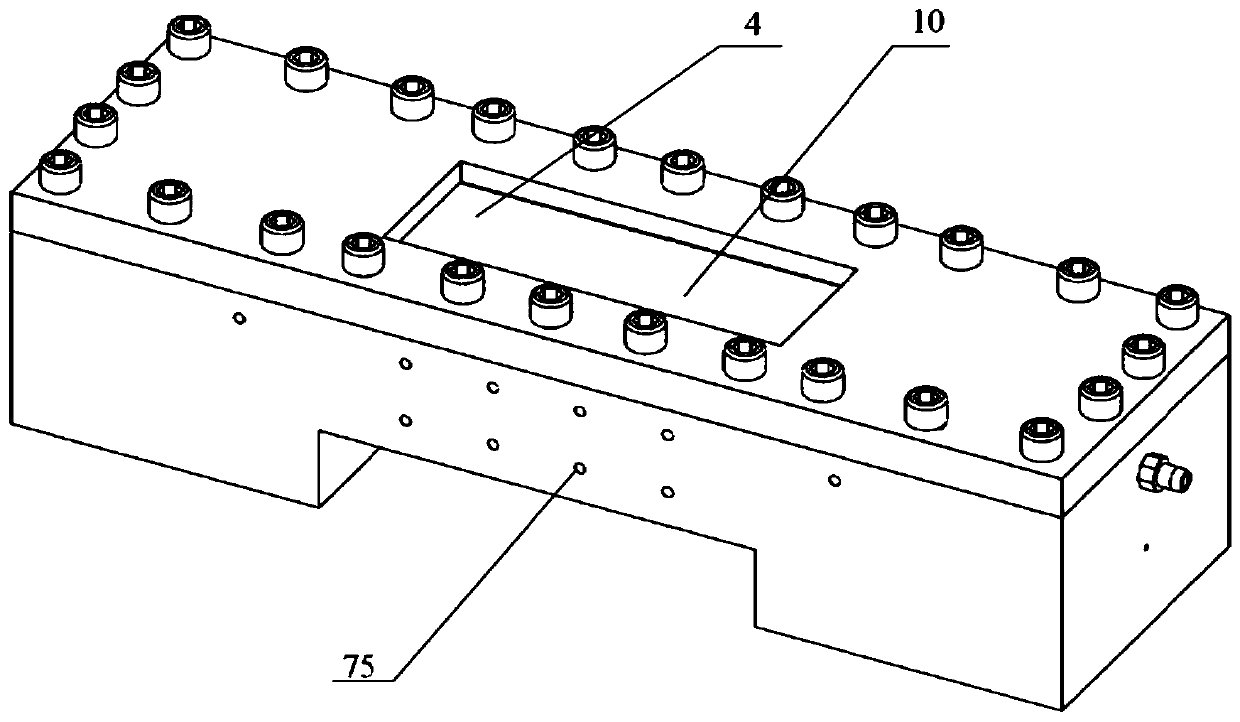

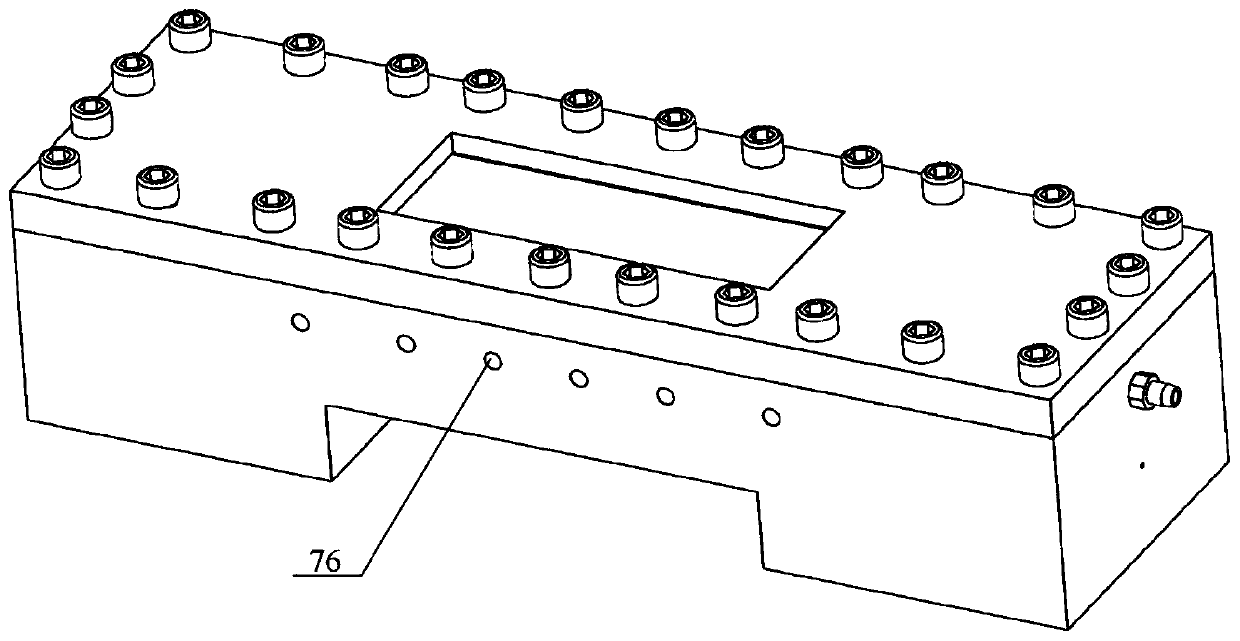

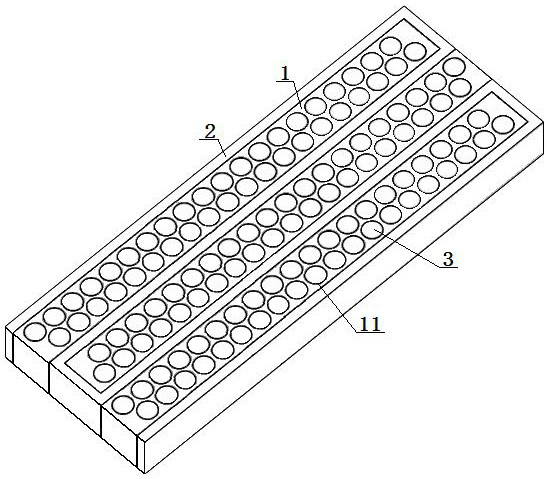

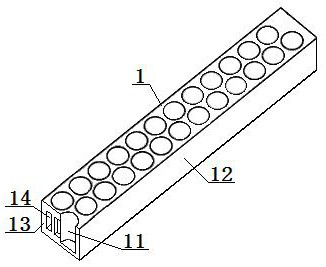

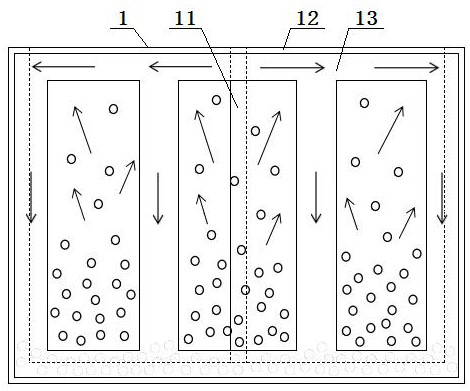

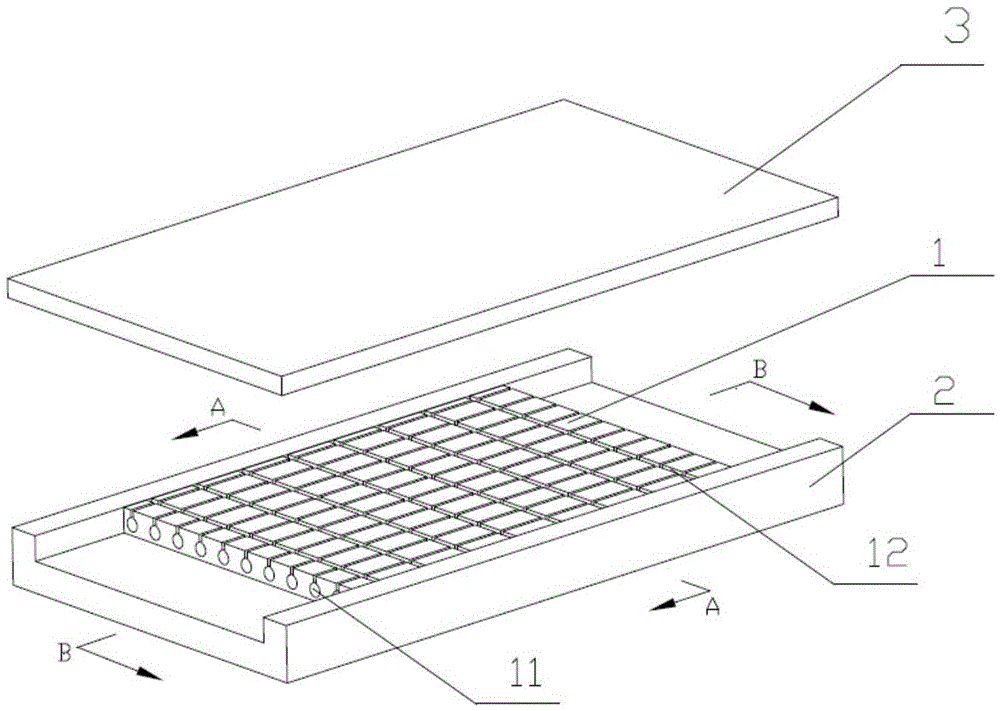

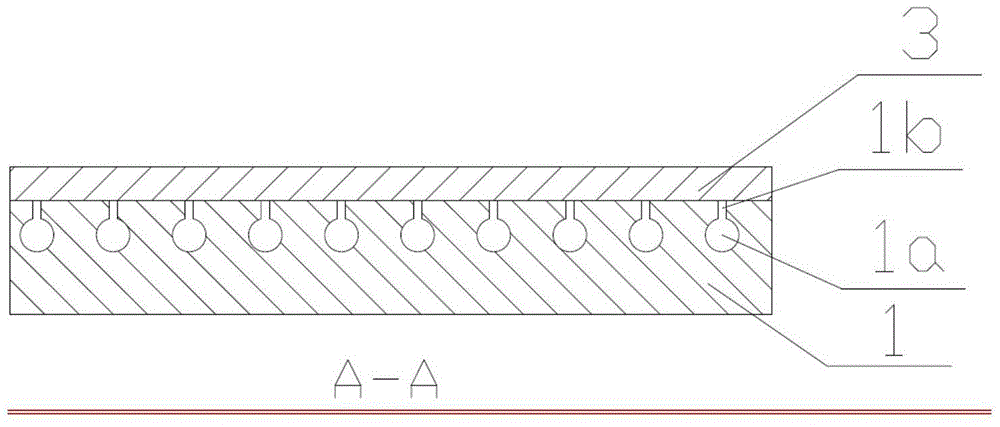

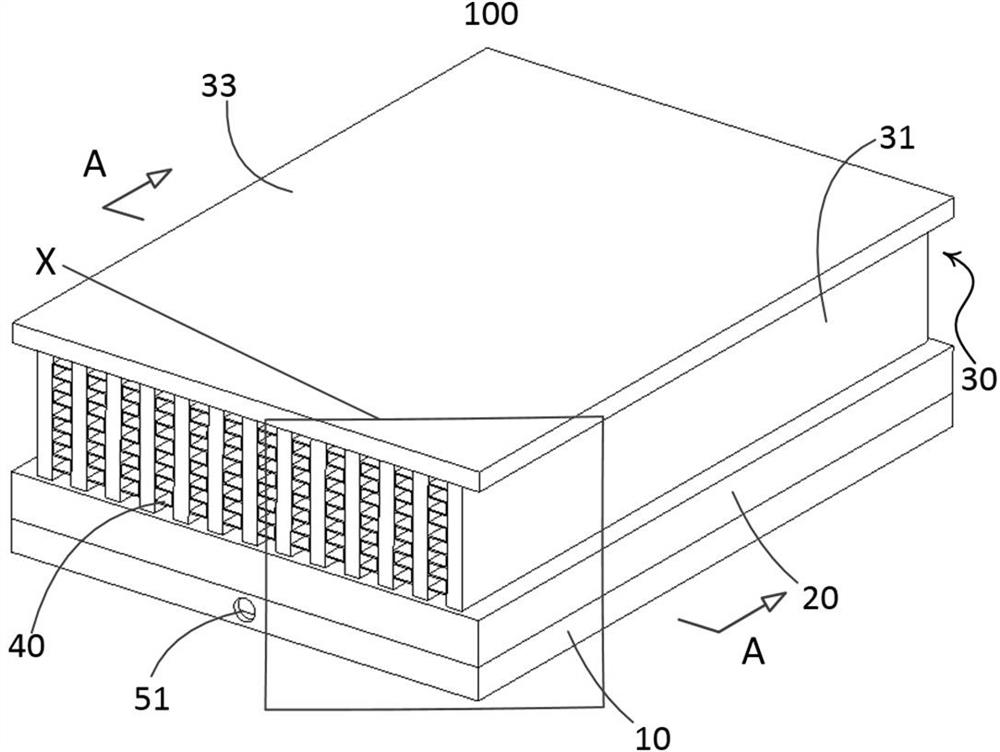

Sound field enhanced nanofluid phase change heat transfer micro-channel heat exchanger

PendingCN110557934APromotes an increase in the number of bubblesBubble movement speed increasedModifications using liquid coolingNanofluidNanometre

The invention discloses a sound field enhanced nanofluid phase change heat transfer micro-channel heat exchanger. The micro-channel heat exchanger comprises a heat exchanger substrate internally provided with a rectangular groove, a micro-channel base plate arranged in the rectangular groove of the heat exchanger substrate, and a cover plate covering an opening of the rectangular groove of the heat exchanger substrate in a sealed mode through several bolts. Two ends of the heat exchanger substrate are provided with an inlet joint and an outlet joint of inflow and outflow nanofluids. The heat exchanger also comprises at least one ultrasonic transducer component whose pitching angle is adjustably and fixedly arranged in the rectangular groove of the heat exchanger substrate. In the invention, an application of ultrasonic enhanced heat transfer technology to the micro-channel heat exchanger is achieved, an ultrasonic transducer is arranged in heat exchanger and can directly act on a heatexchange working medium, growth and separation of boiling bubbles are promoted, and heat transfer performance of the micro-channel heat exchanger is increased by above 20% in combination with a nanofluid enhanced heat transfer technology compared with that of a common micro-channel heat exchanger.

Owner:SOUTH CHINA UNIV OF TECH

Automobile battery liquid cooling heat dissipation device based on steam cavity heat dissipation technology

An automobile battery liquid cooling heat dissipation device based on a steam cavity heat dissipation technology comprises a heat conduction steam cavity, a liquid cooling channel and a plurality of power batteries, the liquid cooling channel is of a return bending structure, the heat conduction steam cavity tightly attached to the liquid cooling channel is arranged between bending areas of the liquid cooling channel, a plurality of battery mounting grooves are formed in the heat conduction steam cavity, and a power battery is fixed in each battery mounting groove. According to the design, the steam cavity structure is adopted for heat transfer, the steam cavity structure is good in heat dissipation performance, flexible, simple and convenient, local heat generated by the battery pack module can be rapidly taken away, high effective heat dissipation of an electric vehicle battery under the high heat flux density is achieved, meanwhile, uniform temperature distribution is kept in the running process, and the service life and the cruising ability of the automobile battery are prolonged.

Owner:WUHAN UNIV OF TECH

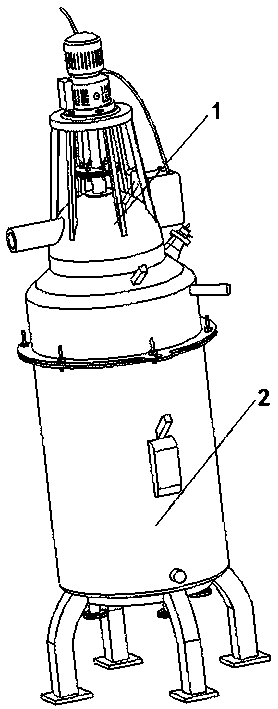

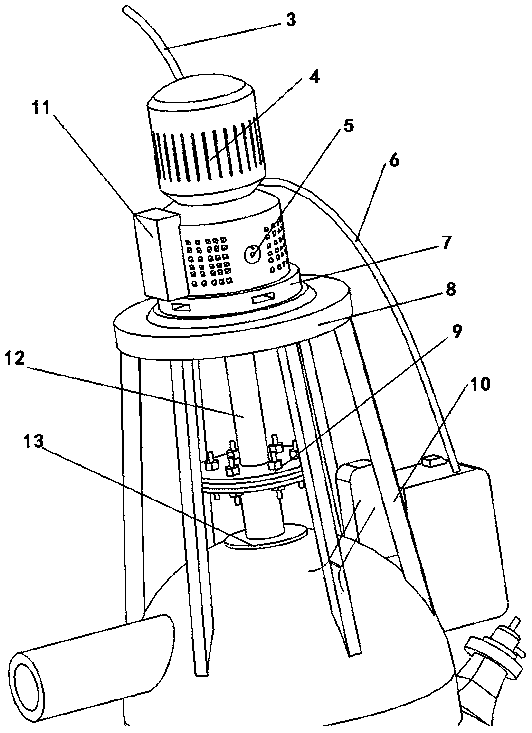

Waste-heat-utilization-type methanol evaporator

ActiveCN108355364ATake advantage ofSave electricityChemical industryHydroxy compound separation/purificationChemical reactionHeater Rod

The invention relates to a waste-heat-utilization-type methanol evaporator, and belongs to the technical field of methanol preparation equipment. The waste-heat-utilization-type methanol evaporator comprises a three-layer reaction chamber system, a mechanical transmission stirring system and a control device, and the inner part of the three-layer reaction chamber system is inserted into the mechanical transmission stirring system. The invention provides the waste-heat-utilization-type methanol evaporator. The methanol evaporator is a gas generating device which can be used to carry out heatingevaporation and chemical reactions in a mode with high automatic degree, high efficiency, energy conservation, safety and stabilization. The methanol evaporator can use waste heat in a multi-functional manner, high-temperature gas of a reactor or a heating plate can pass through a spiral coiled pipe, gas heat is fully utilized for pre-heating a methanol liquid, and then electric heating rods areutilized for auxiliary heating. Electric energy is saved and waste heat is fully utilized.

Owner:KUNMING UNIV OF SCI & TECH

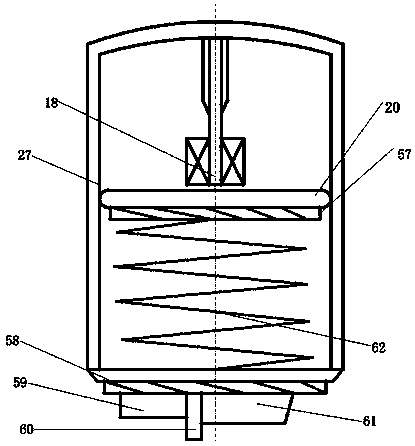

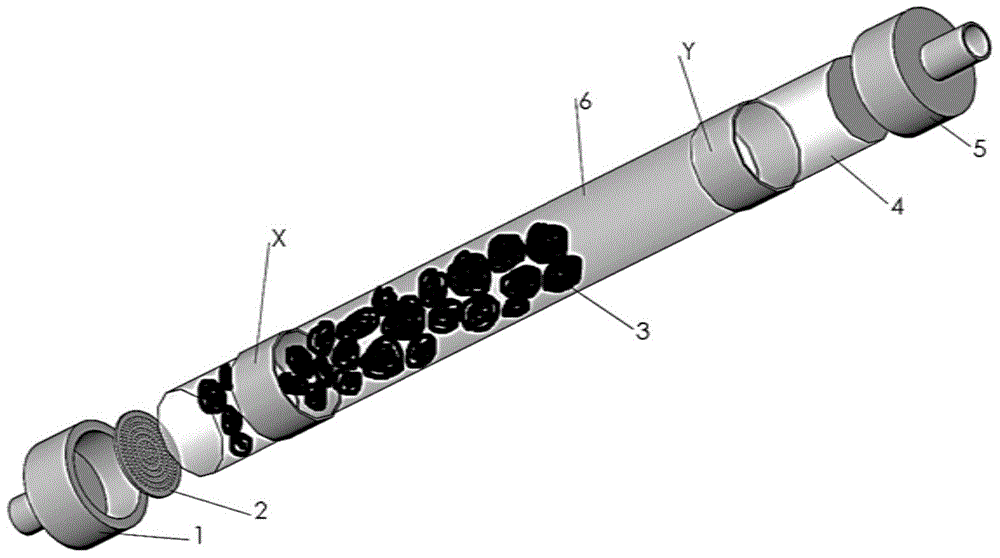

Heat conduction PA6/water three-phase flow closed type gravity-assisted heat pipe

ActiveCN105066755AImprove heat transfer effectImprove heat transfer performanceIndirect heat exchangersMomentumEvaporation

The invention relates to the technical field of gravity-assisted heat pipes, and discloses a heat conduction PA6 / water three-phase flow closed type gravity-assisted heat pipe. The heat conduction PA6 / water three-phase flow closed type gravity-assisted heat pipe comprises an evaporation section, a heat insulation section and a condensation section; a mixing working medium composed of heat conduction PA6 particles and water is arranged in the evaporation section, the liquid filling rate is 30%-55% of the volume of the evaporation section, and the best liquid filling rate is 30%; the volume containing rate of the heat conduction PA6 particles in the mixing working medium is 20%-35%, the heat conduction PA6 particles are cylindrical preferably, and the equivalent diameter ranges from 1 mm to 1.5 mm; and the density is 1.9 kg / m<3>, and the heat conductivity coefficient is 10W.m<-1>.DEG C<-1>. The heat conduction PA6 / water is adopted as the working medium, the heat transfer coefficient of the evaporation section of the heat pipe is improved, the wall temperature of the evaporation section is decreased, and the entire thermal resistance of the heat pipe is reduced; and collision momentum between the heat conduction particles and the wall face is large in the heat conduction particle motion process, and the heat transferring effect and the scale preventing and removing effects are obvious.

Owner:TIANJIN UNIV

High-efficiency gravity heat pipe and manufacturing method thereof

ActiveCN102445097BContinuous boiling phenomenonEnhanced boiling heat transferIndirect heat exchangersLiquid/solution decomposition chemical coatingFree energiesPorous layer

The invention relates to a high-efficiency gravity heat pipe and a manufacturing method thereof. The high-efficiency gravity heat pipe comprises an evaporating section, a heat insulating section and a condensing section, and is characterized in that a metal powder porous layer is sintered on the inner surface of the heat tube evaporating section, and the condensing section is chemically coated. The heat tube manufactured by the process method in the invention can simultaneously reinforce boiling heat transfer and condensing heat transfer, so that a plurality of ideal vaporization cores are artificially increased, thus the boiling phenomenon of the liquid is continuously carried out to achieve a purpose of reinforcing the boiling heat transfer; on the other hand, the surface of a chemical coating of the heat tube condensing section is modified to acquire a low surface free energy value; simultaneously, the coating layer is a metal-based coating layer with good thermal conductivity, thus the condensing heat transfer can be reinforced; from the above, the high-efficiency gravity heat tube reinforce the boiling and condensing effects very remarkably, has the characteristics of good heat transfer reinforcing effect, high production efficiency, low cost and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Energy-saving explosion-proof water and electricity separated electric heating tube

ActiveCN104482646BOvercoming the disadvantages of low heat fluxReduced flow areaWater heatersBoiling processWater quality

The invention relates to an energy-saving explosion-proof water and electricity separating type electric heating tube. The energy-saving explosion-proof water and electricity separating type electric heating tube comprises a quartz glass tube as a matrix, a metal heating film plated on the external surface of the quartz glass tube, explosion-proof purification particles filled in the quart glass tube and a high temperature resistant insulating material covering the outer surface of the metal heating film. According to the energy-saving explosion-proof water and electricity separating type electric heating tube disclosed by the invention, the explosion-proof purification particles are added to the quartz glass tube, on the one hand, a special runner structure is provided for a fluid area in the tube to further realize enhancement of heat transfer and prevent local overheating of the quartz glass tube and the flow instability in the boiling process from happening, and thus the quartz tube is well prevented from cracking; on the other hand, water is purified and the water quality is regulated according to characteristics of water qualities in different areas. In the meantime, the high temperature resistant insulating material covers the outer surface of the metal heating film, so that the heat loss of the electric heating tube is reduced and the energy-saving characteristic is achieved.

Owner:SHANGHAI JIAO TONG UNIV

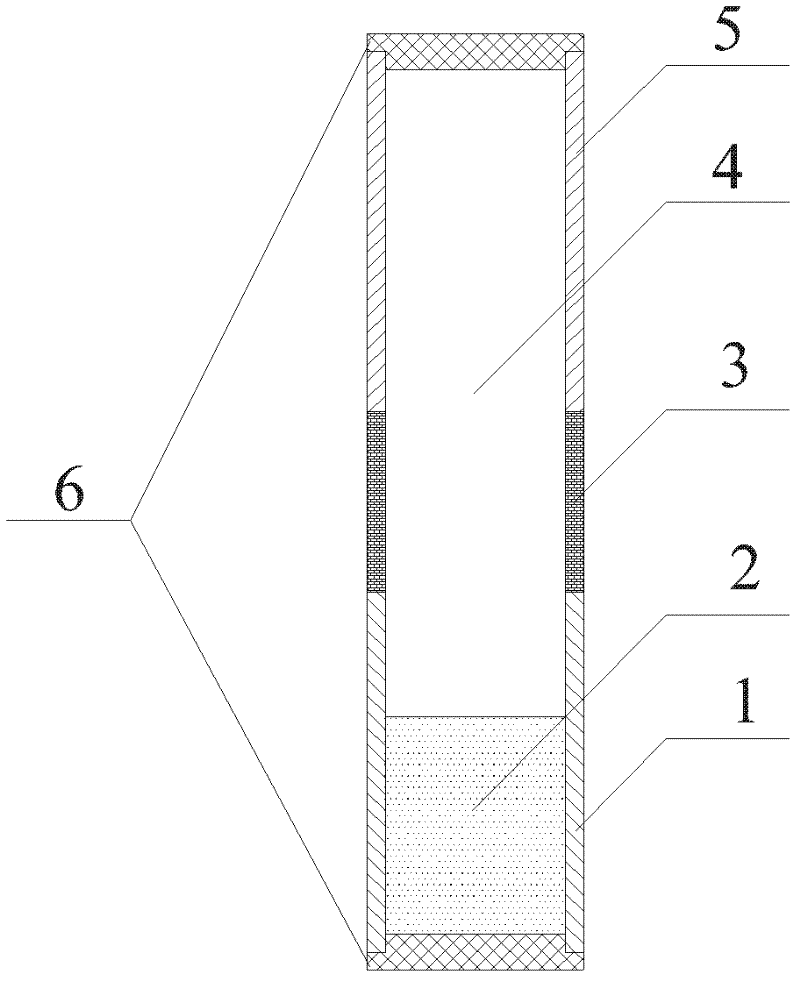

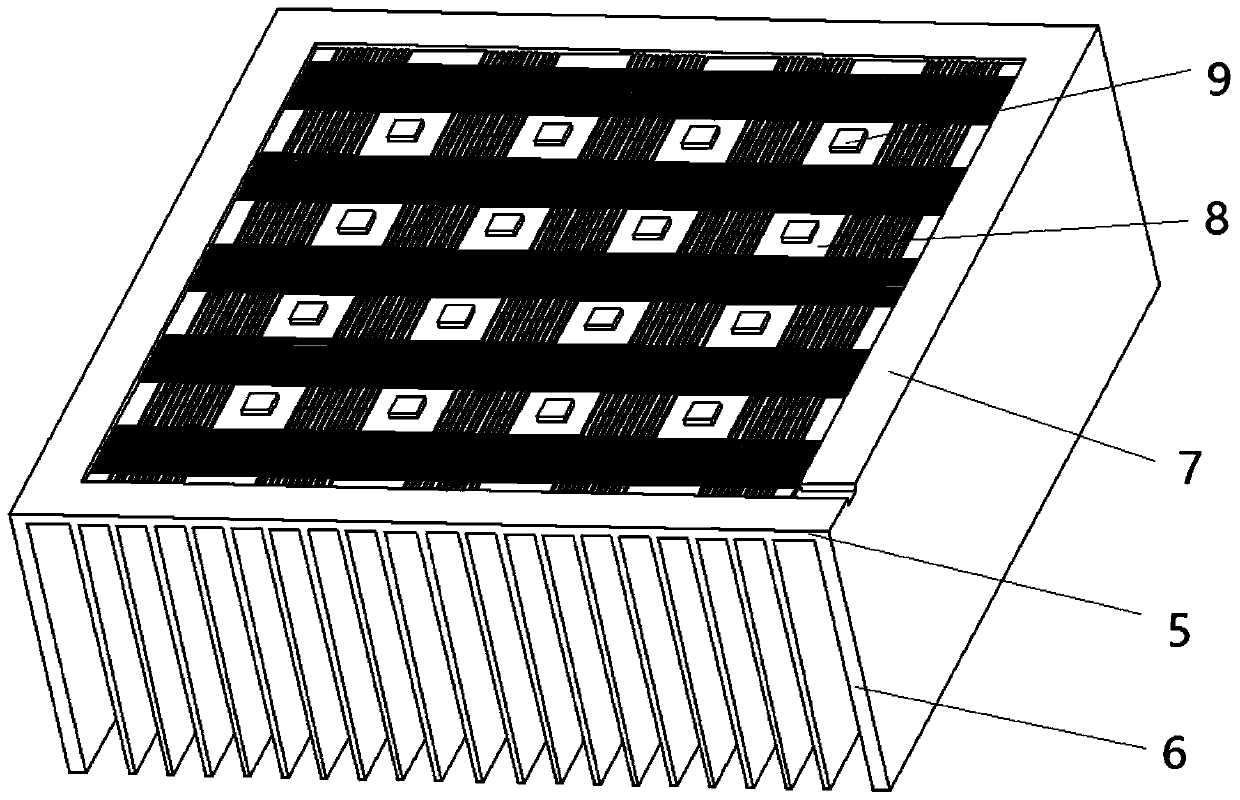

Integrated high power led high bay lamp based on phase change heat transfer technology

ActiveCN107143777BCompact structureReduce volumeLighting applicationsMechanical apparatusEngineeringLED lamp

The invention relates to an integrated type high-power LED lamp for industrial use based on a phase-change heat transfer technology. The integrated type high-power LED lamp for the industrial use comprises a COB light source, an evaporation plate and a radiator which are sequentially connected from bottom to top; the upper end of the evaporation plate and the lower end of the radiator define a vacuumized containing cavity, and the containing cavity is internally filled with a liquid working medium; and liquid absorption cores with one micro-groove-shaped surfaces are arranged at the upper end and the lower end of the interior of the containing cavity separately. The integrated type high-power LED lamp for the industrial use is compact in structure, small in size, light in weight, capable of meeting high-power illumination and fast in radiating, and relates to the technical field of LED lamp radiating.

Owner:SOUTH CHINA UNIV OF TECH

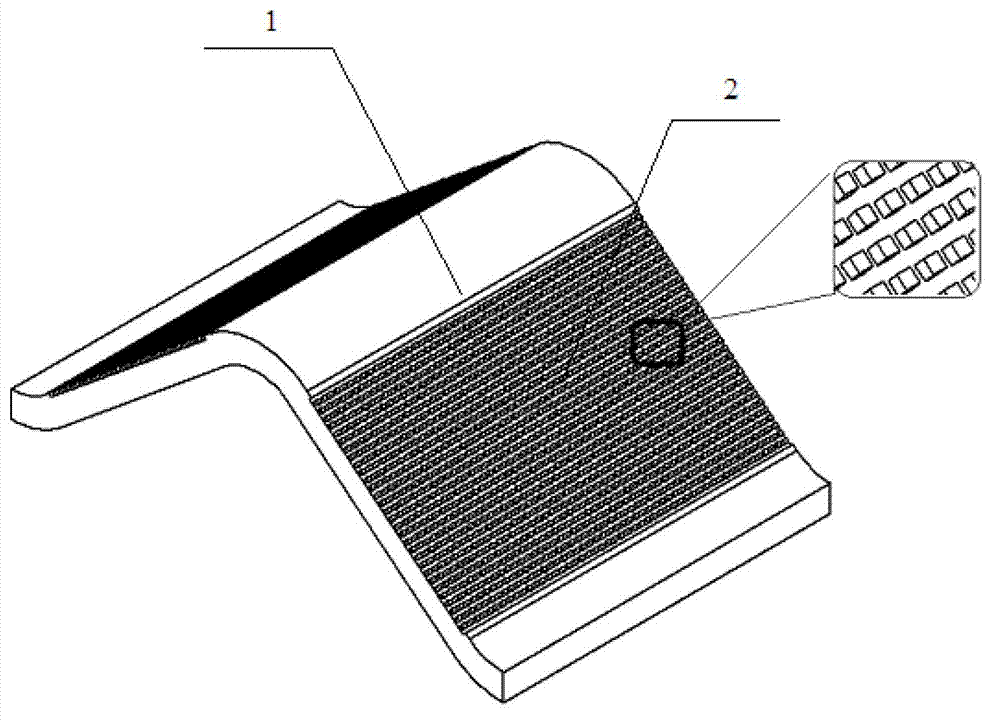

A microchannel heat exchanger with staggered inner groove structure and its manufacturing method

ActiveCN104154777BImprove distributionIncrease heat transfer areaStationary conduit assembliesHeat transfer modificationEngineeringNucleation

The invention discloses a micro-channel heat exchanger with a staggered inner groove structure and a manufacturing method of the micro-channel heat exchanger. The micro-channel heat exchanger with the staggered inner groove structure comprises a metal micro-channel substrate, wherein the metal micro-channel substrate comprises a plurality of longitudinal micro-channels and a plurality of transverse micro-channels; the longitudinal micro-channels are arrayed in parallel along a cooling liquid flowing direction; the transverse micro-channels are perpendicular to the longitudinal micro-channels; the longitudinal micro-channels and the transverse micro-channels are arranged at intervals; the micro-channels are in the shape of an inner groove; each micro-channel comprises an inlaid groove body and a slit; the inlaid groove bodies are positioned in the substrate; an opening position of the substrate is formed by the slits; and each inlaid groove body is connected with the corresponding slit. When the micro-channel heat exchanger is manufactured, the longitudinal inner groove micro-channels are machined along the liquid flowing direction in a linear cutting manner; after a workpiece rotates at an angle of 90 degrees, the transverse inner grooves are machined in a linear cutting manner, so that a crisscross micro-channel array is obtained; and the micro-channels are packaged by heat-resistant glass, and the staggered inner groove micro-channel heat exchanger is formed. The manufacturing process is simple and is low in cost; a thermal boundary layer is developed intermittently, and the heat transfer area is increased; and moreover, by the inner groove structure, boiling nucleation can be remarkably facilitated, and boiling heat transfer is strengthened, so that heat transfer is strengthened integrally.

Owner:XIAMEN UNIV

Ultra-thin flat heat pipe liquid-absorbing core and manufacturing method thereof

ActiveCN110769645BImprove thermal conductivityReduce thermal resistanceCooling/ventilation/heating modificationsEngineeringElectroless deposition

The invention discloses an ultra-thin flat heat pipe type liquid-absorbing core and a manufacturing method thereof. Based on a colloid crystal template method, a physical vapor deposition technology and an electrochemical deposition method, the liquid-absorbing core with micro-nano spherical holes and cylindrical holes is designed. The liquid-absorbing core has the following advantages that 1) theliquid-absorbing core is integrated with the heating surface of a heat pipe, thereby avoiding the contact thermal resistance; 2) the micro-nano holes cooperate, so that the gasification core number and capillary force of the boiling surface are taken into consideration; (3) gas and liquid channels are separated, so that the gas and liquid flow resistance is reduced; (4) the liquid-absorbing corehas the bearing capacity, so that the flat heat pipe does not need additional support; (5) the hole size can be arbitrarily adjusted and the capillary force is provided according to actual requirements, so that the heat pipe runs under the reverse gravity; and the manufacturing method is simple, few in consumables and low in cost. Low-temperature-difference and high-heat-flux-density heat dissipation and cooling in the fields of machinery, electronics, aerospace and the like can be realized in a narrow and small space.

Owner:DALIAN UNIV OF TECH

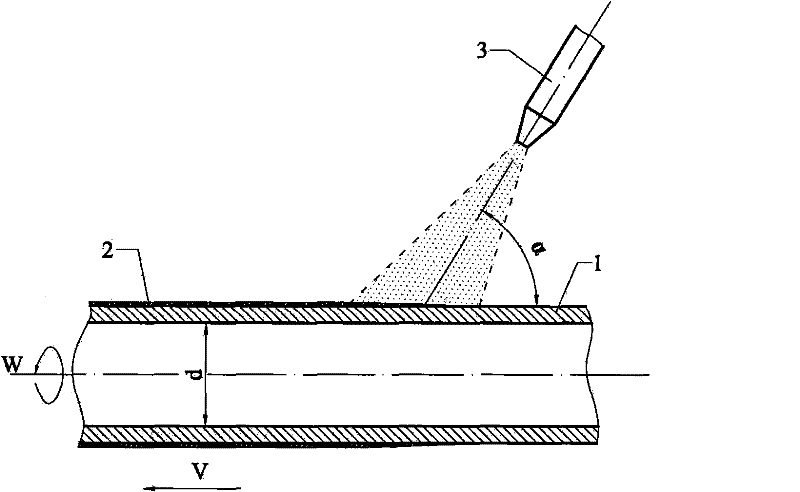

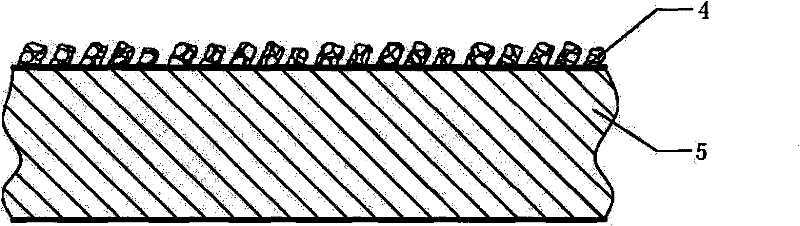

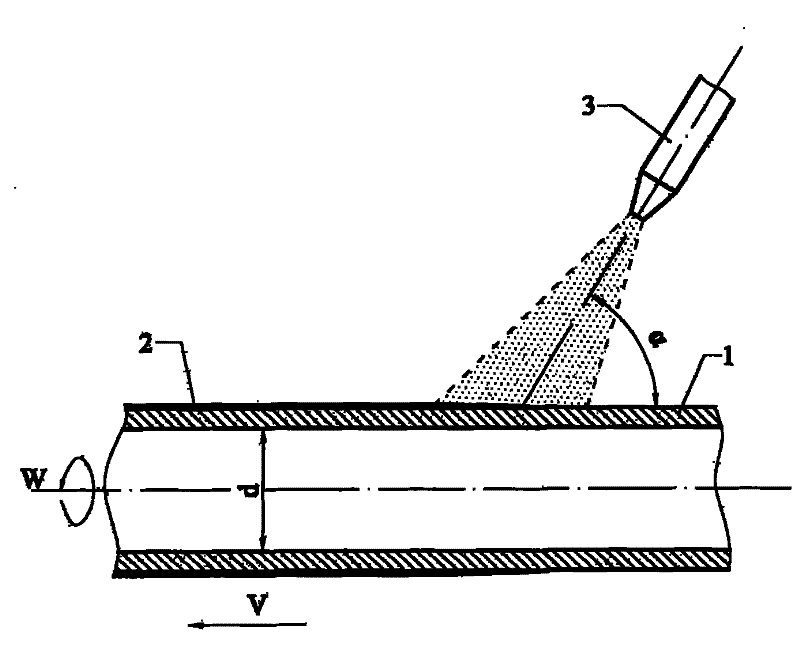

Method for preparing thermally-sprayed iron-based powder porous surface heat exchange tube

ActiveCN101705464BReduce the temperatureSmall size deformationMolten spray coatingPorous layerOxygen

The invention relates to a method for preparing a thermally-sprayed iron-based powder porous surface heat exchange tube. The heat exchange tube consists of a tube matrix and a surface porous layer, wherein the surface porous layer uses iron or iron alloy finely-grained powder as a main ingredient, contains a certain proportion of nickel-coated aluminum powder and spray accessories and is formed by thermal spray; the surface porous layer is positioned on the outer surface of a tube; and the inner surface of the tube is smooth or has a longitudinal groove structure with reinforcing and condensing functions. The preparation method comprises: mixing the iron-based alloy powder, the nickel-coated aluminum powder and the spray accessories in a certain proportion to prepare mechanical alloyed powder; and spraying the mechanical alloyed powder by using oxygen-ethyne flame onto the surface of a preprocessed metal tube at a certain angle to form the iron-based alloy powder metal porous layer. The method has the advantages of no addition of a pore-forming material, simple process, high processing efficiency, low cost and capacity of meeting requirements for industrial application.

Owner:WUXI CHEM EQUIP CO LTD

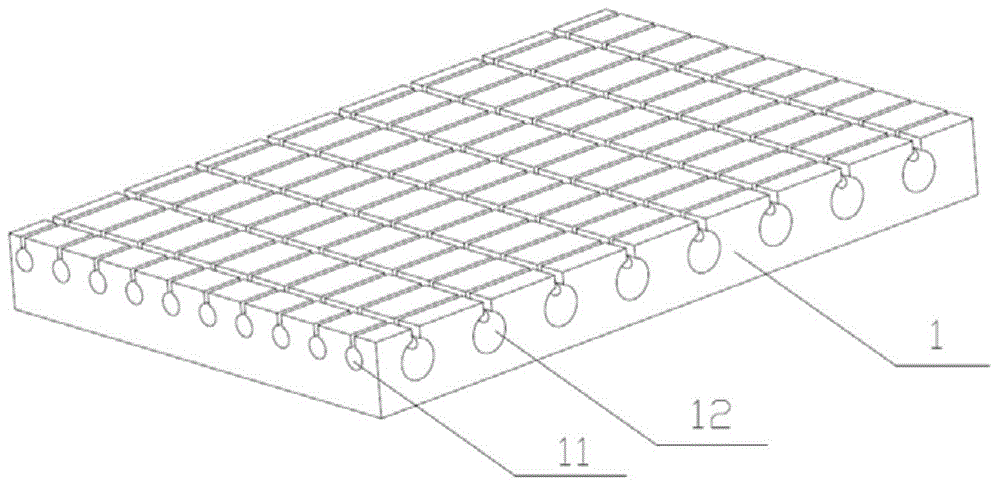

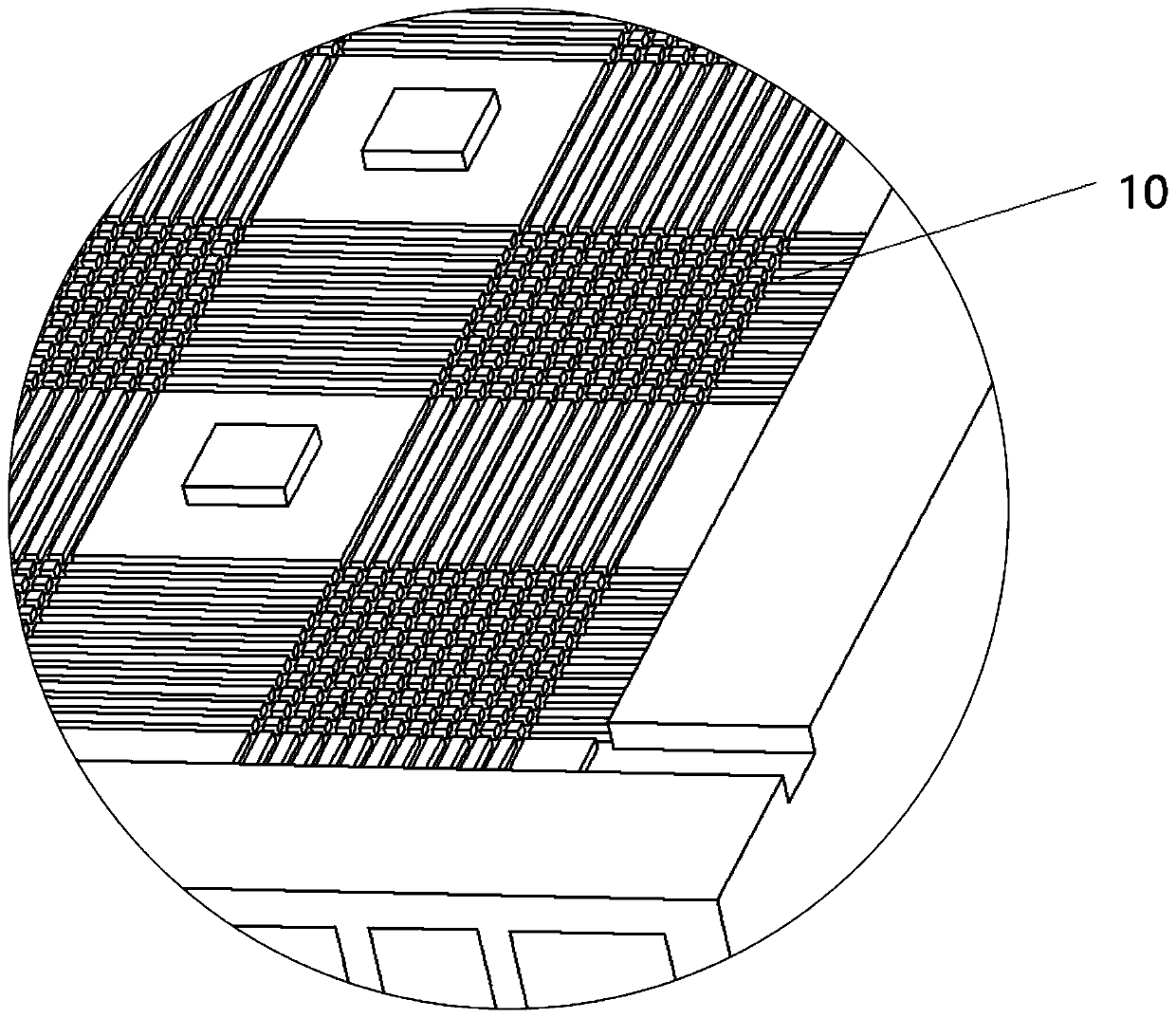

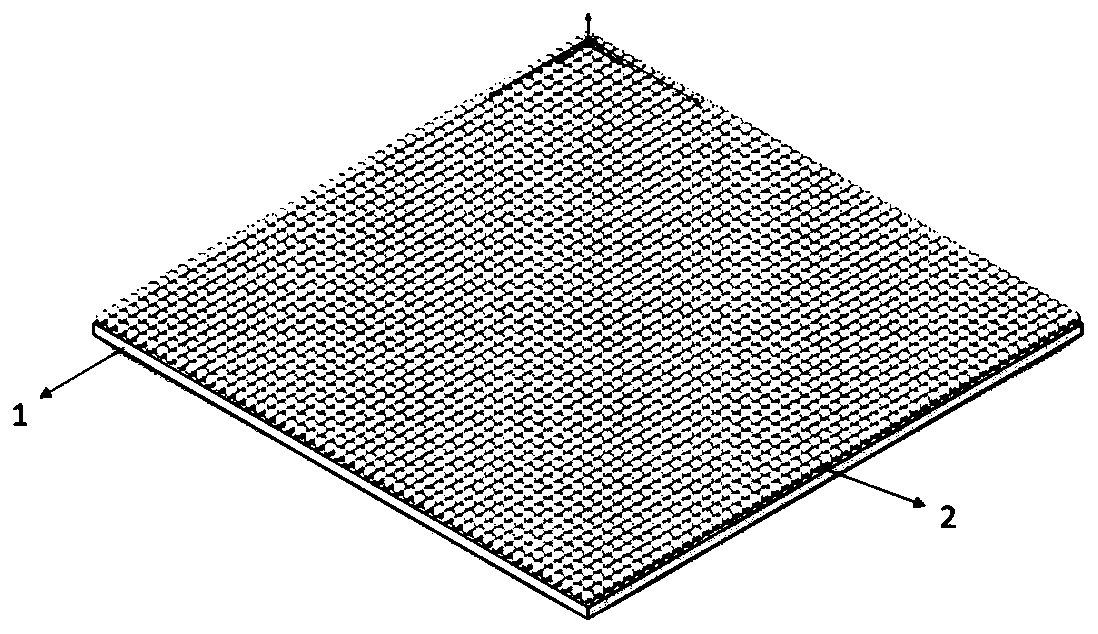

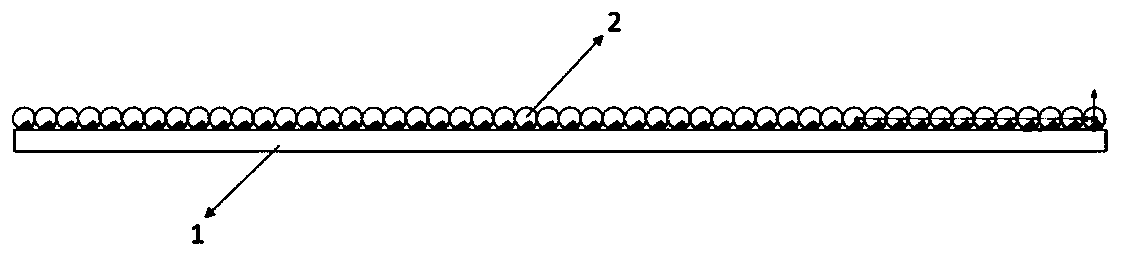

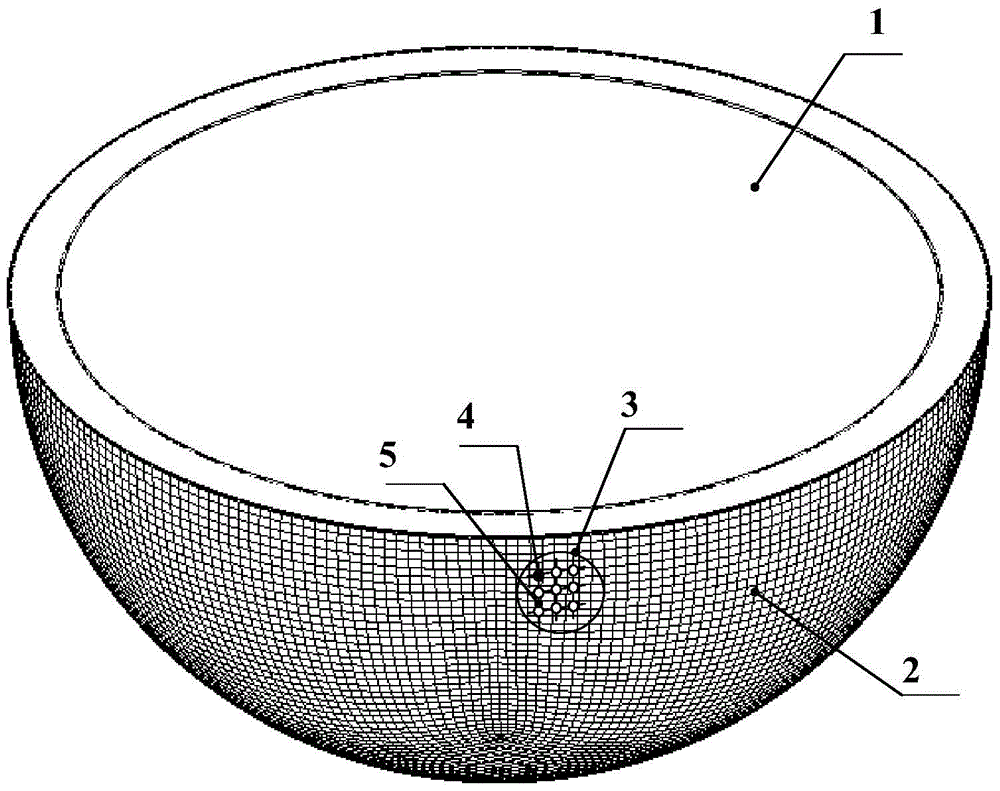

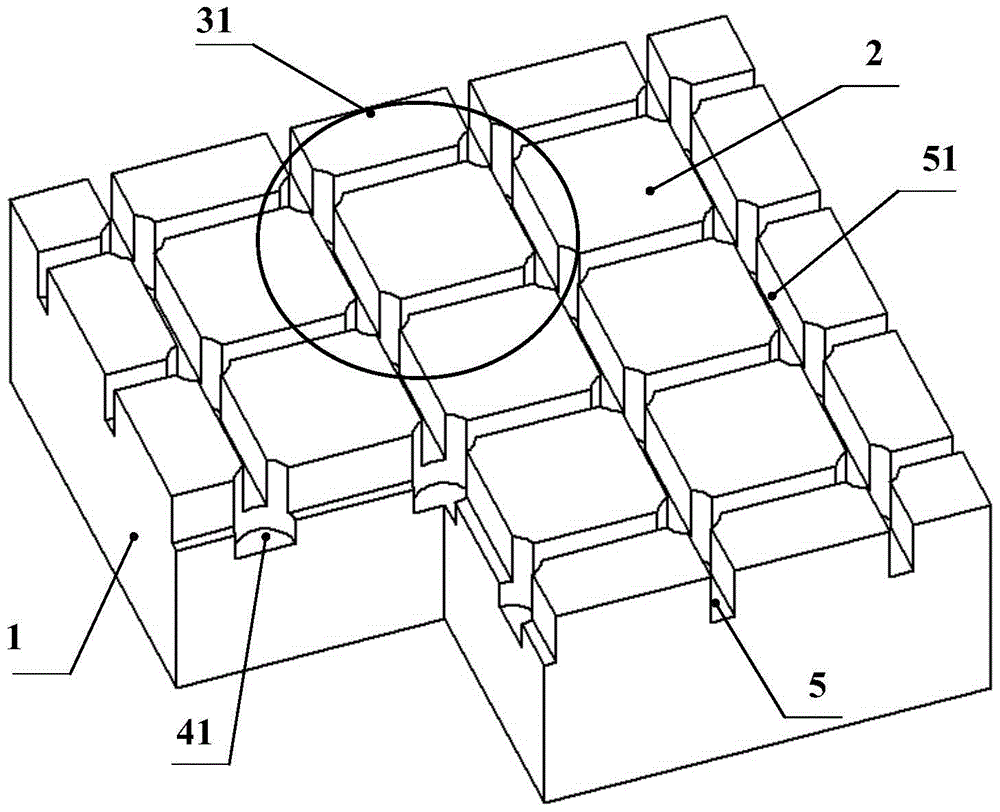

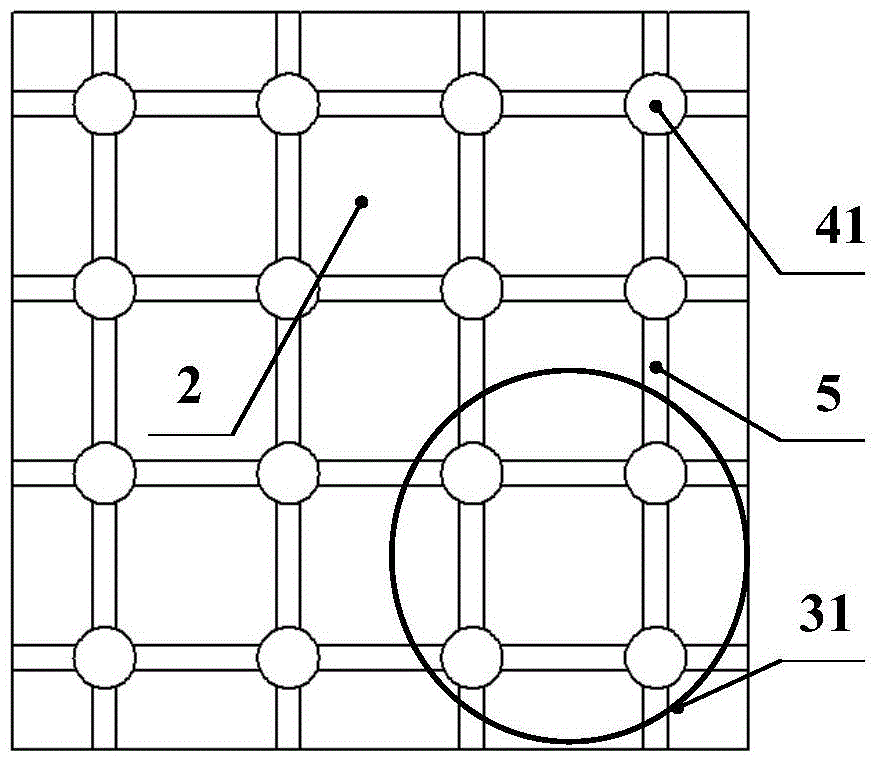

A kind of head with enhanced boiling heat transfer network groove connected to the surface of the hole array

InactiveCN103903658BHigh densityIncrease the heat exchange areaNuclear energy generationCooling arrangementHeat flowNuclear reactor

The invention relates to the technical field of enhanced heat exchange and particularly relates to a sealing head with an enhanced boiling heat exchange array hole surface with a communicated net-shaped groove. The sealing head is characterized in that the net-shaped groove is arranged on the outer surface of a lower sealing head of a reactor pressure container and consists of a plurality of groove units which are intersected in a net shape and are distributed in a communicating manner; the intersecting positions of the groove units are respectively provided with a communicating hole unit, so that an array hole structure with the communicated net-shaped groove is formed on the outer surface of the sealing head. When the nuclear reactor starts an external cooling measure of the pressure container, cooling water can form a stable vaporization core by the array hole structure and generate steam jet continuously, the communicated net-shaped groove can absorb the cooling water under the action of capillary force to wet the heat exchange surface, and cooling water needed for boiling heat exchange at the array hole structure is continuously supplemented. The sealing head has the advantages that the boiling heat exchange process can be obviously enhanced, and the critical heat-flow density can be obviously increased, so that the safety of the nuclear reactor is obviously improved.

Owner:TSINGHUA UNIV

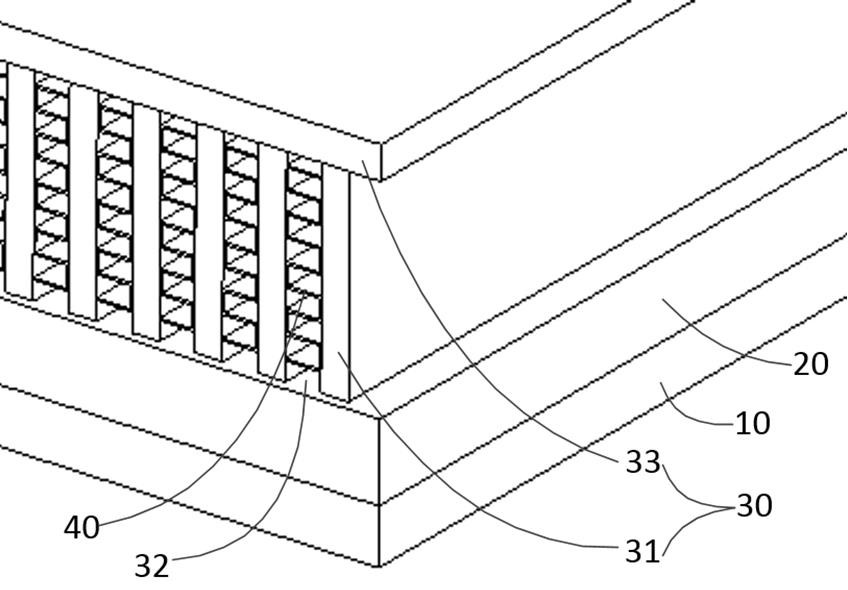

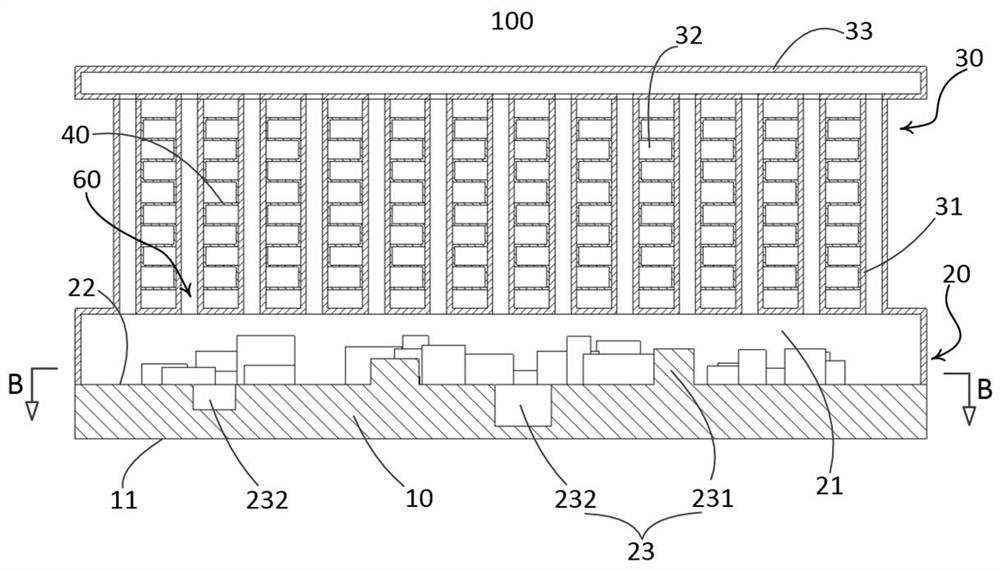

Liquid cooling heat dissipation device and heat dissipation circulation system

ActiveCN114786451ASpeed up the flowReduce resistanceCooling/ventilation/heating modificationsThermodynamicsEngineering

The invention provides a liquid cooling heat dissipation device and a heat dissipation circulation system, and the device comprises a heated part which comprises a heated area used for receiving heat generated by a to-be-cooled part; the medium flow channel allows a heat dissipation medium to flow therein, can be communicated with an external heat removal space and is provided with a flowing surface which is in heat conduction connection with the heated area; the liquid cooling heat dissipation device is further provided with an internal heat dissipation space communicated with the medium flow channel, and the flow surface is provided with a fluctuating structure used for disturbing and dividing the heat dissipation medium into a plurality of flow branches, so that the flow branches can flow to the external heat dissipation space and the internal heat dissipation space respectively.

Owner:ZHEJIANG DAHUA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com