Energy-saving explosion-proof water and electricity separated electric heating tube

A technology of electric heating tube and heating film, which is applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve hidden dangers and other problems, and achieve the goals of improving safety, reducing heat transfer inhomogeneity, and enhancing boiling heat transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

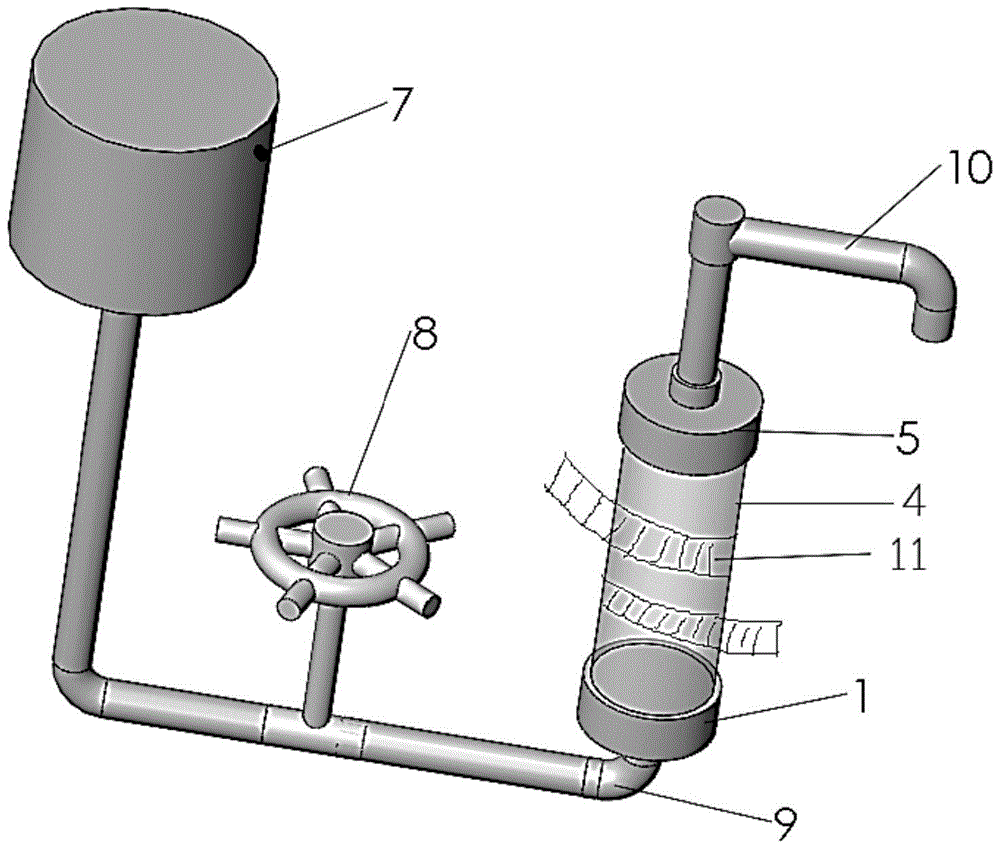

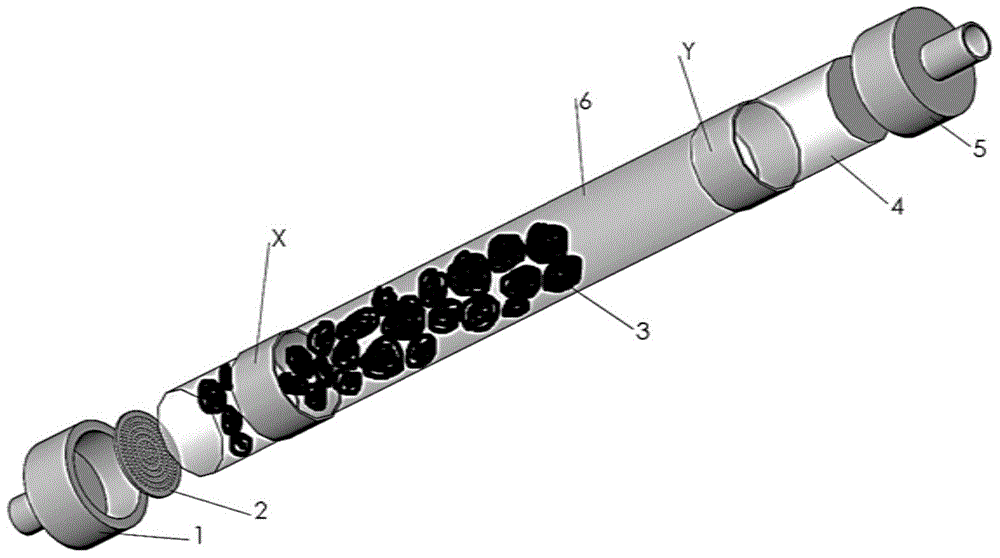

[0021] Such as figure 1 As shown, this embodiment includes: a base quartz glass tube 4, a metal heating film 6 coated on the outer surface of the quartz glass tube, and a high temperature resistant heat insulating material 11 wrapped on the outer surface of the metal heating film.

[0022] The fluid area in the matrix quartz glass tube 4 is filled with various explosion-proof purification particles 3, and the contact point between the particles and the quartz glass tube can form a boiling vaporization core well and destroy the thermal boundary layer to enhance boiling heat transfer; at the same time Reduce the cross-sectional flow area of the flow channel, increase the fluid flow rate, and have the characteristics of a fluidized bed, thereby reducing the heat transfer inhomogeneity on the flow cross-section of the quartz tube, enhancing heat transfer and reducing the flow instability of the boiling two-phase flow, thus effectively Maximize the heat transfer heat flux density...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com