Patents

Literature

250results about How to "Increase fluid velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

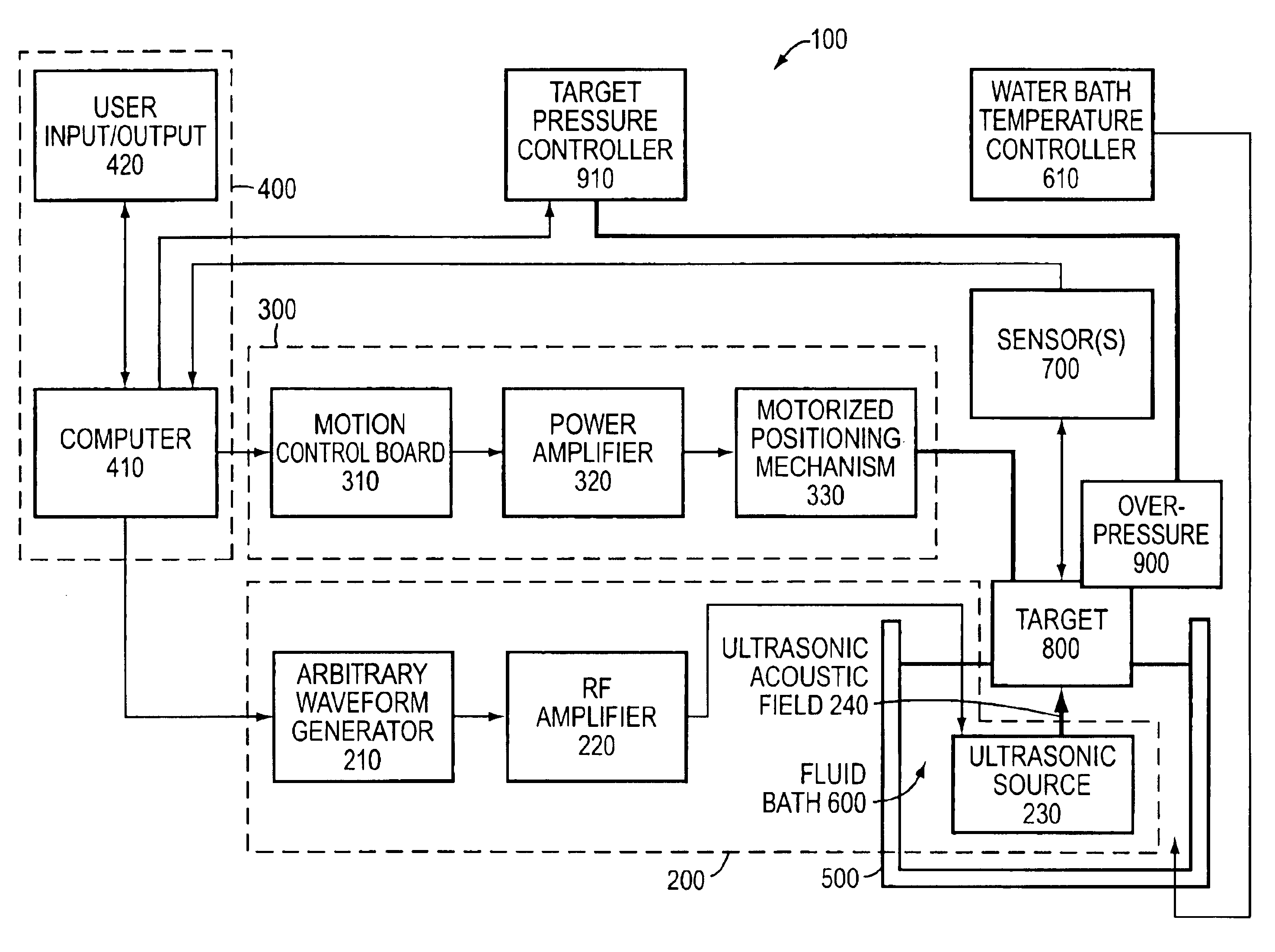

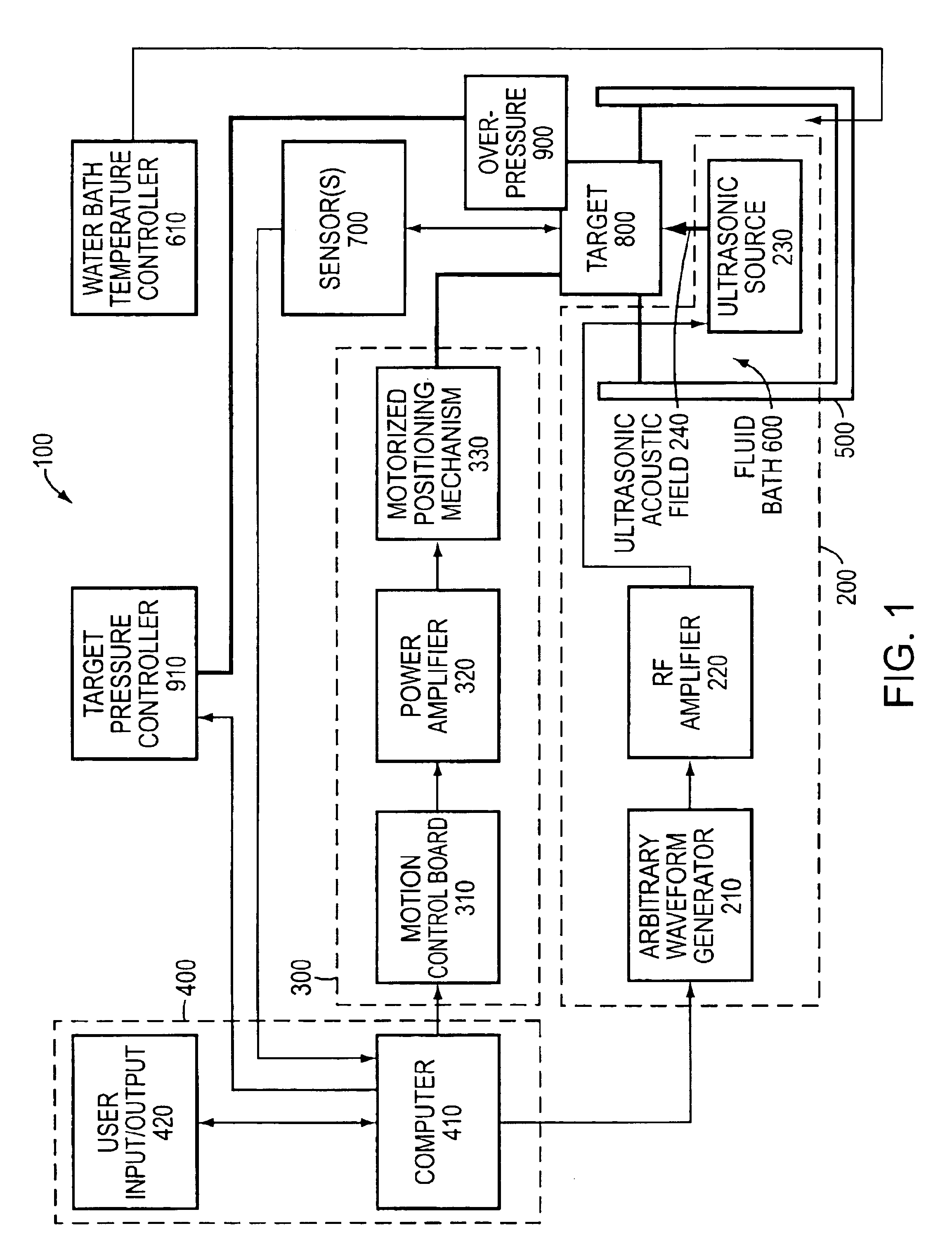

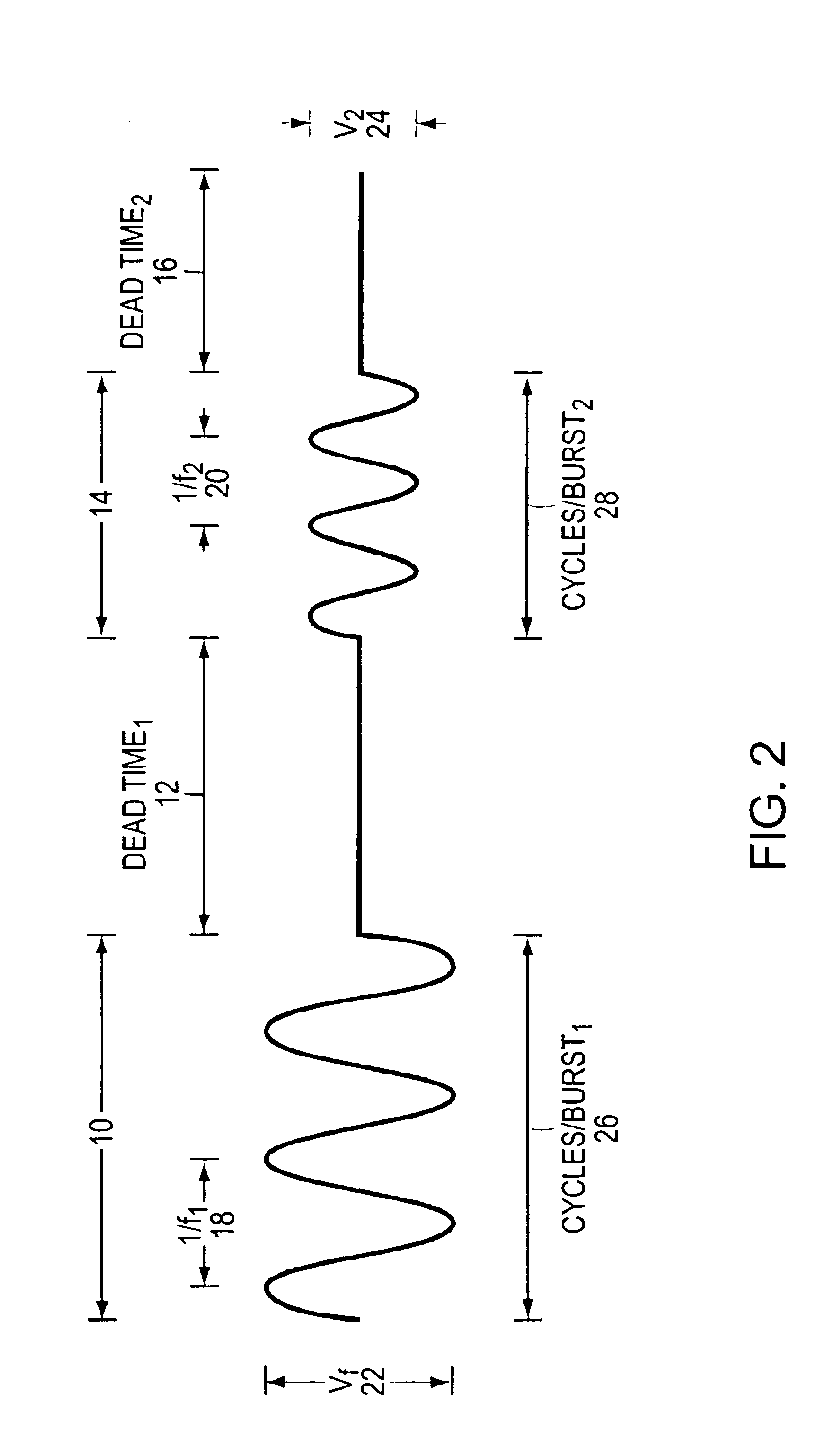

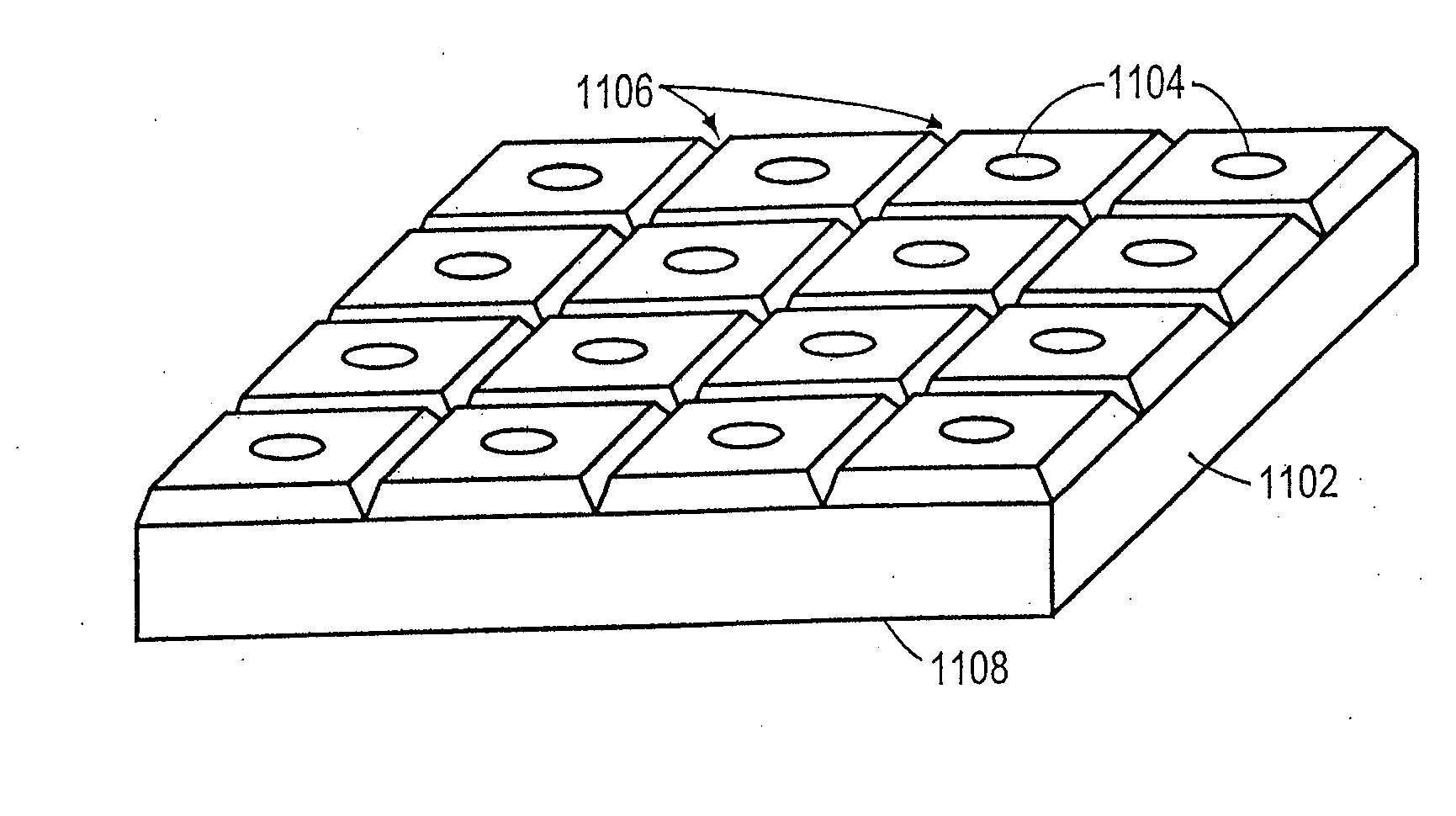

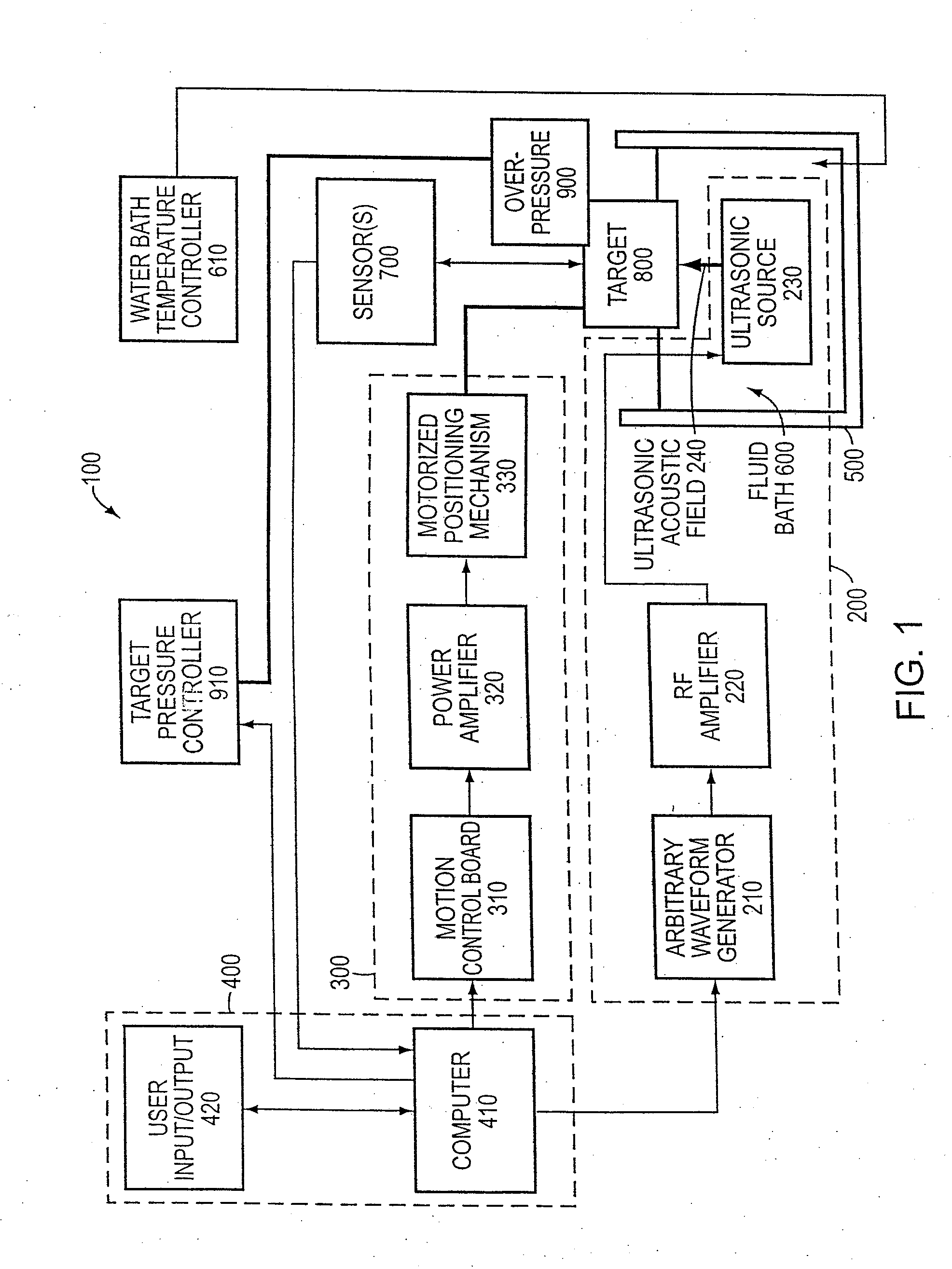

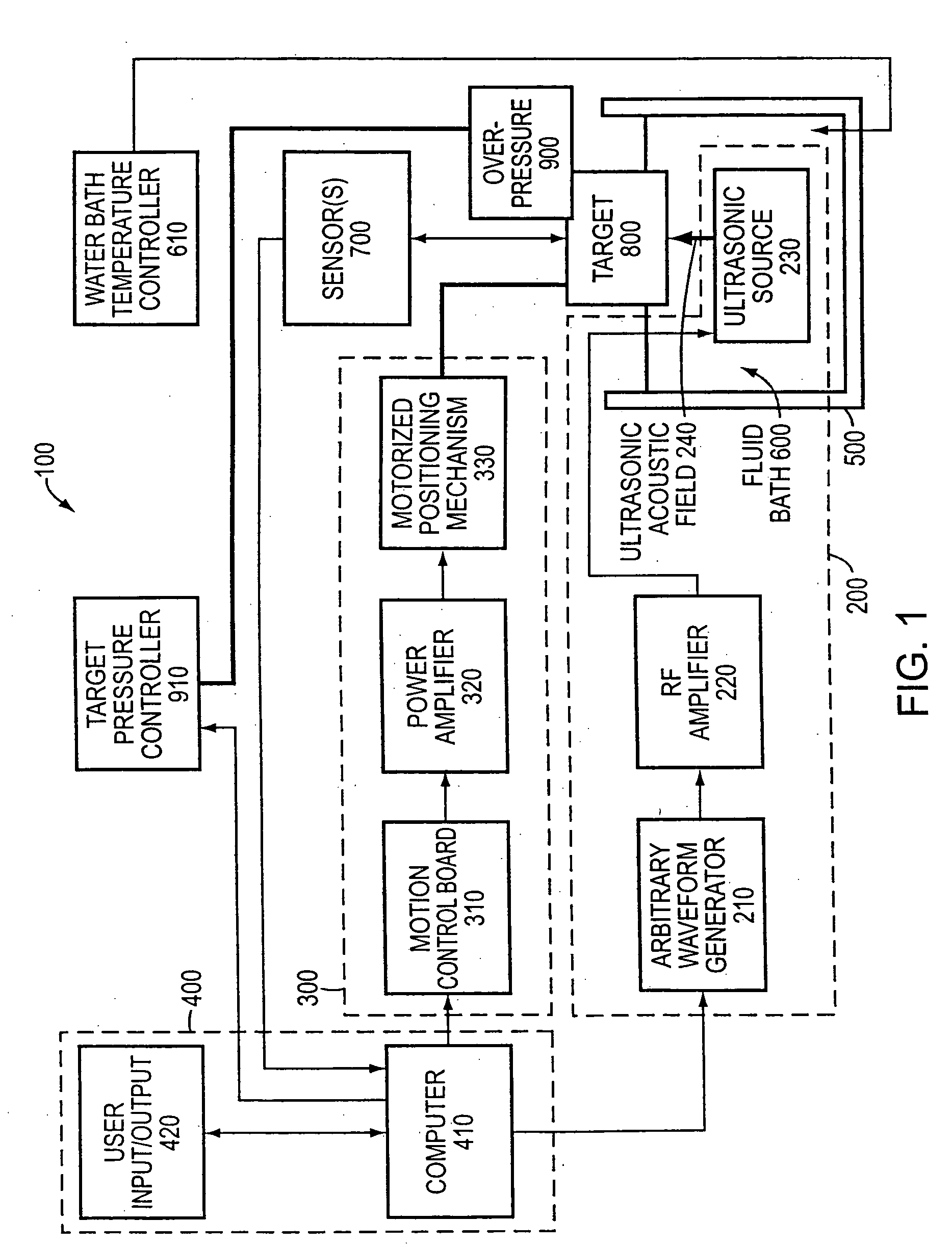

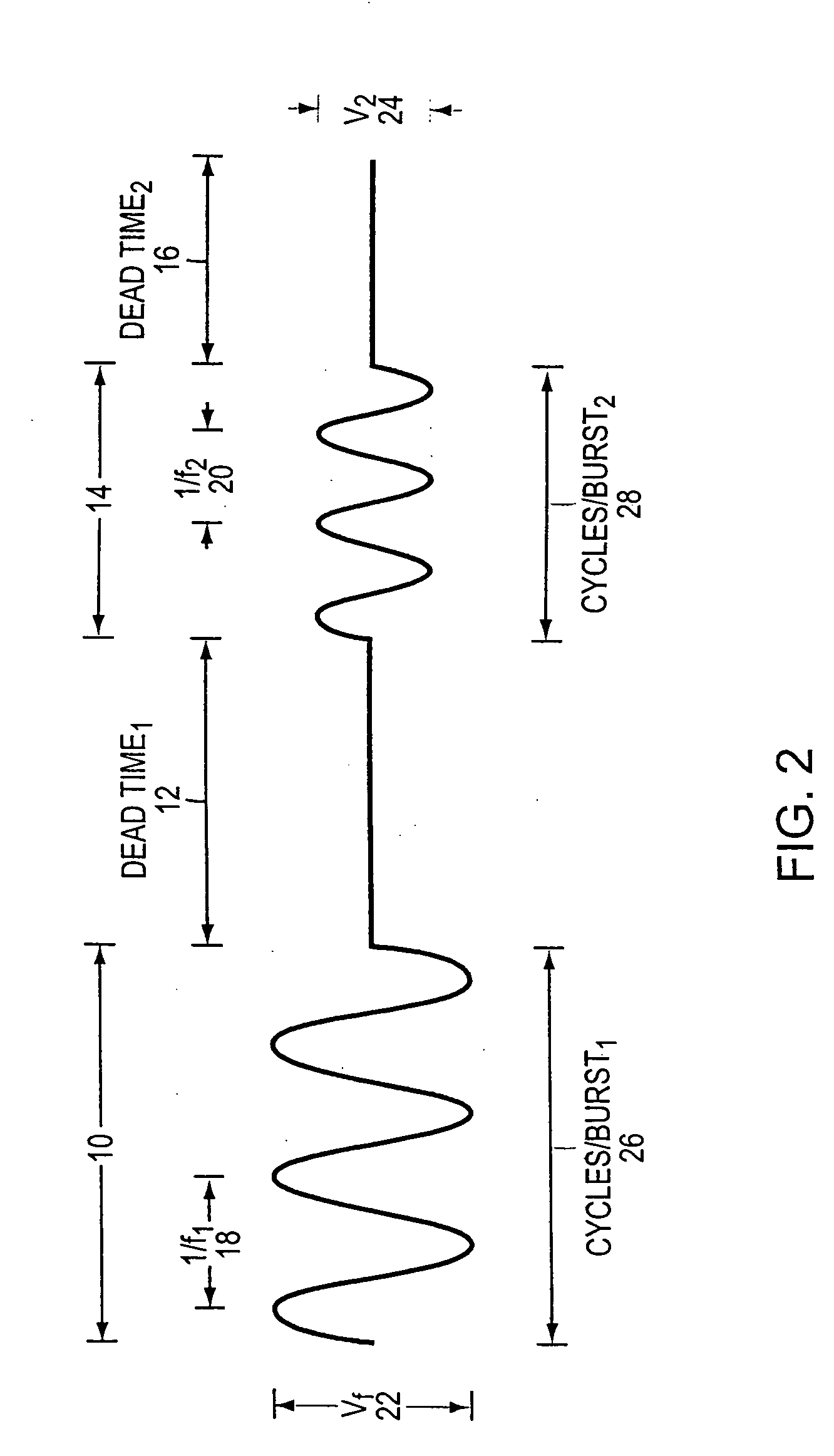

Method and apparatus for acoustically controlling liquid solutions in microfluidic devices

InactiveUS6948843B2Improve reaction speedAccelerating molecular interactionSequential/parallel process reactionsShaking/oscillating/vibrating mixersSound sourcesAcoustic energy

Acoustic energy is used to control motion in a fluid. According to one embodiment, the invention directs acoustic energy at selected naturally occurring nucleation features to control motion in the fluid. In another embodiment, the invention provides focussed or unfocussed acoustic energy to selectively placed nucleation features to control fluid motion. According to one embodiment, the invention includes an acoustic source, a controller for controlling operation of the acoustic source, and one or more nucleation features located proximate to or in the fluid to be controlled.

Owner:COVARIS INC

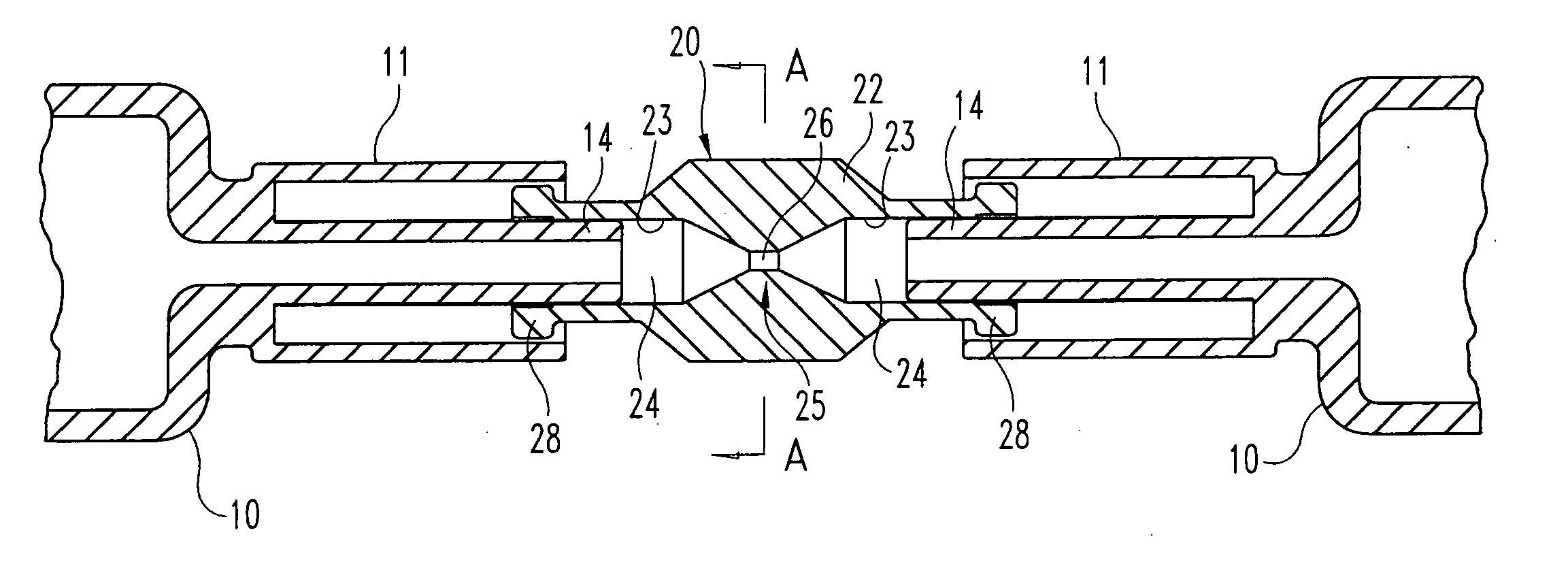

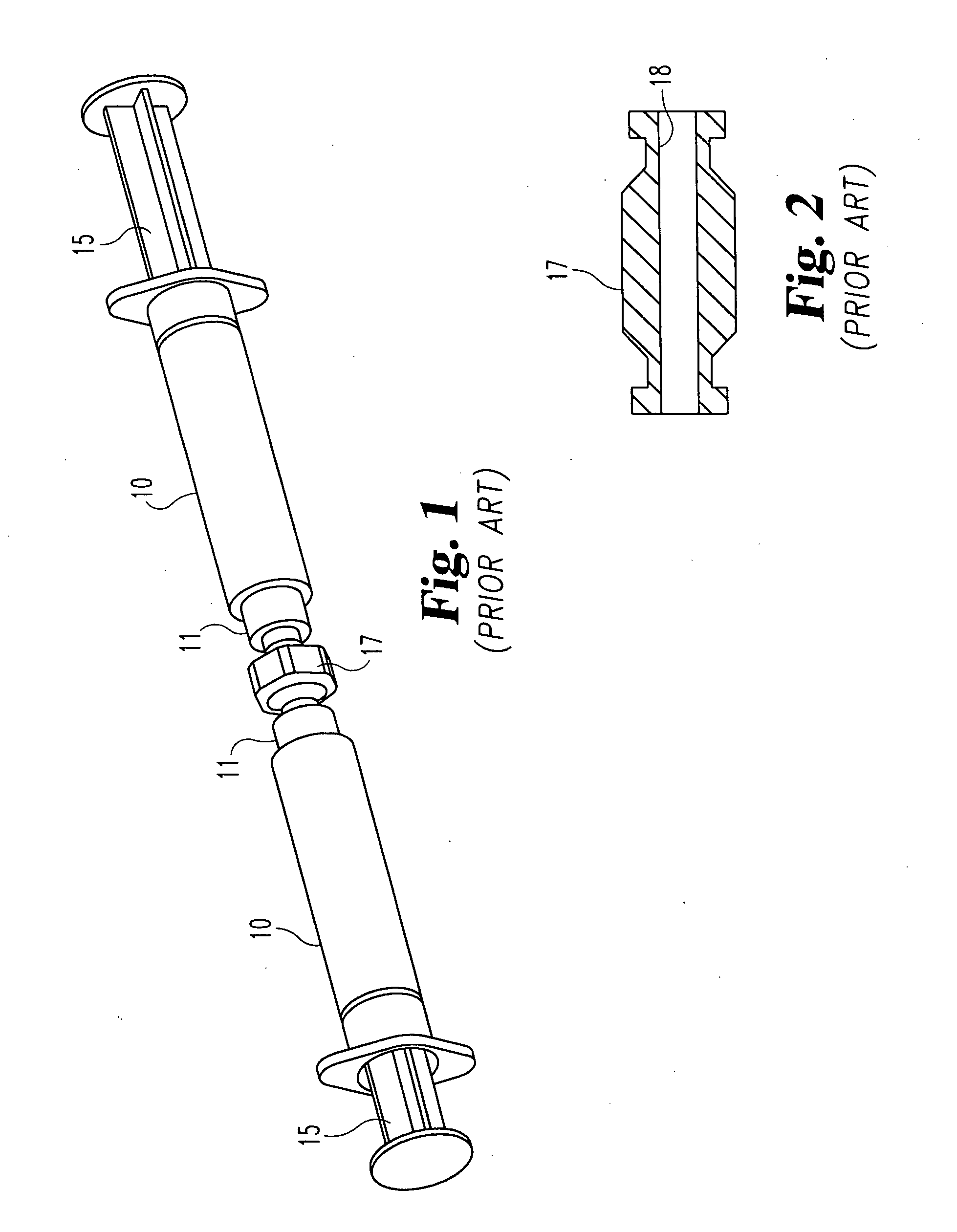

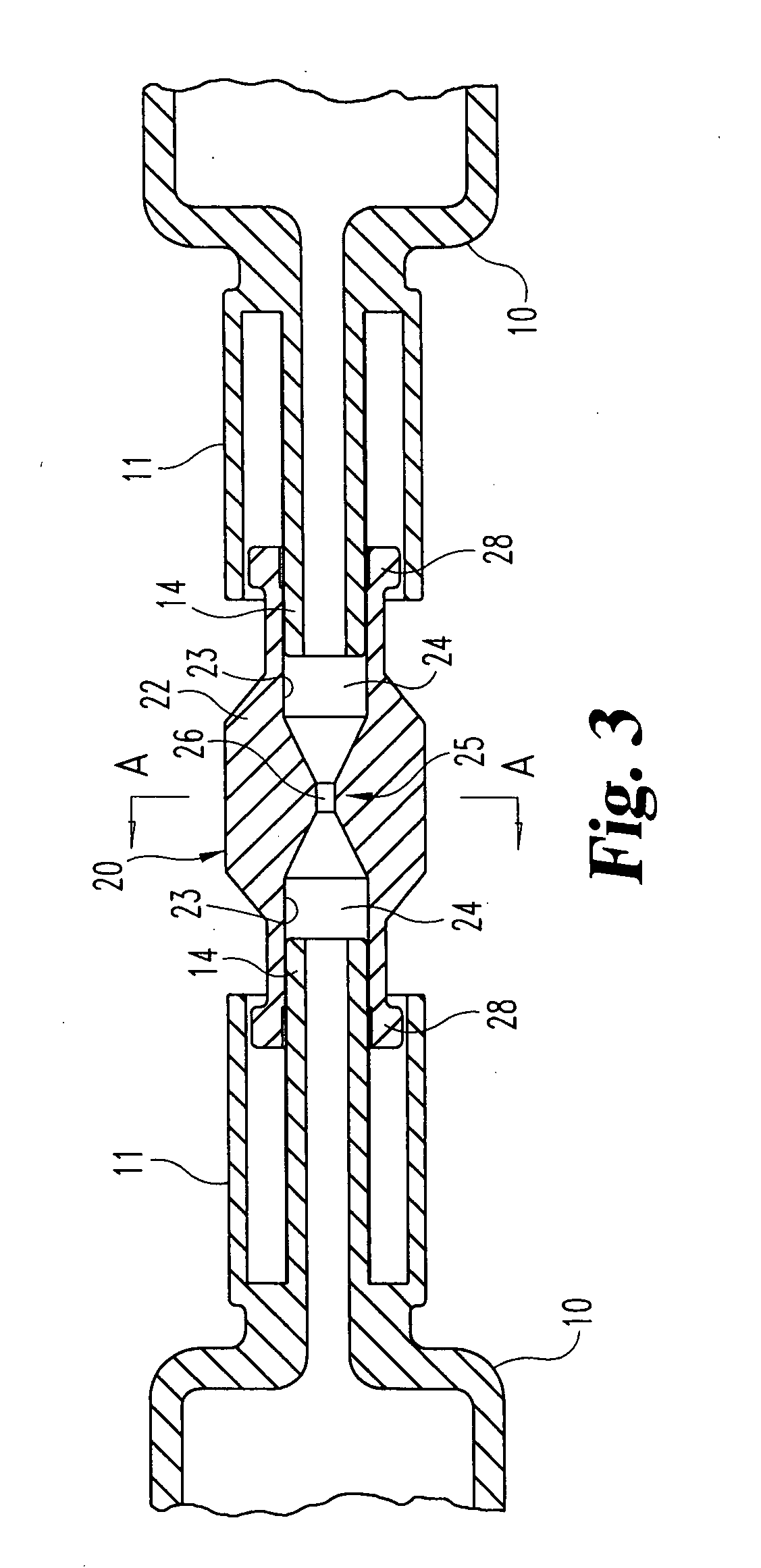

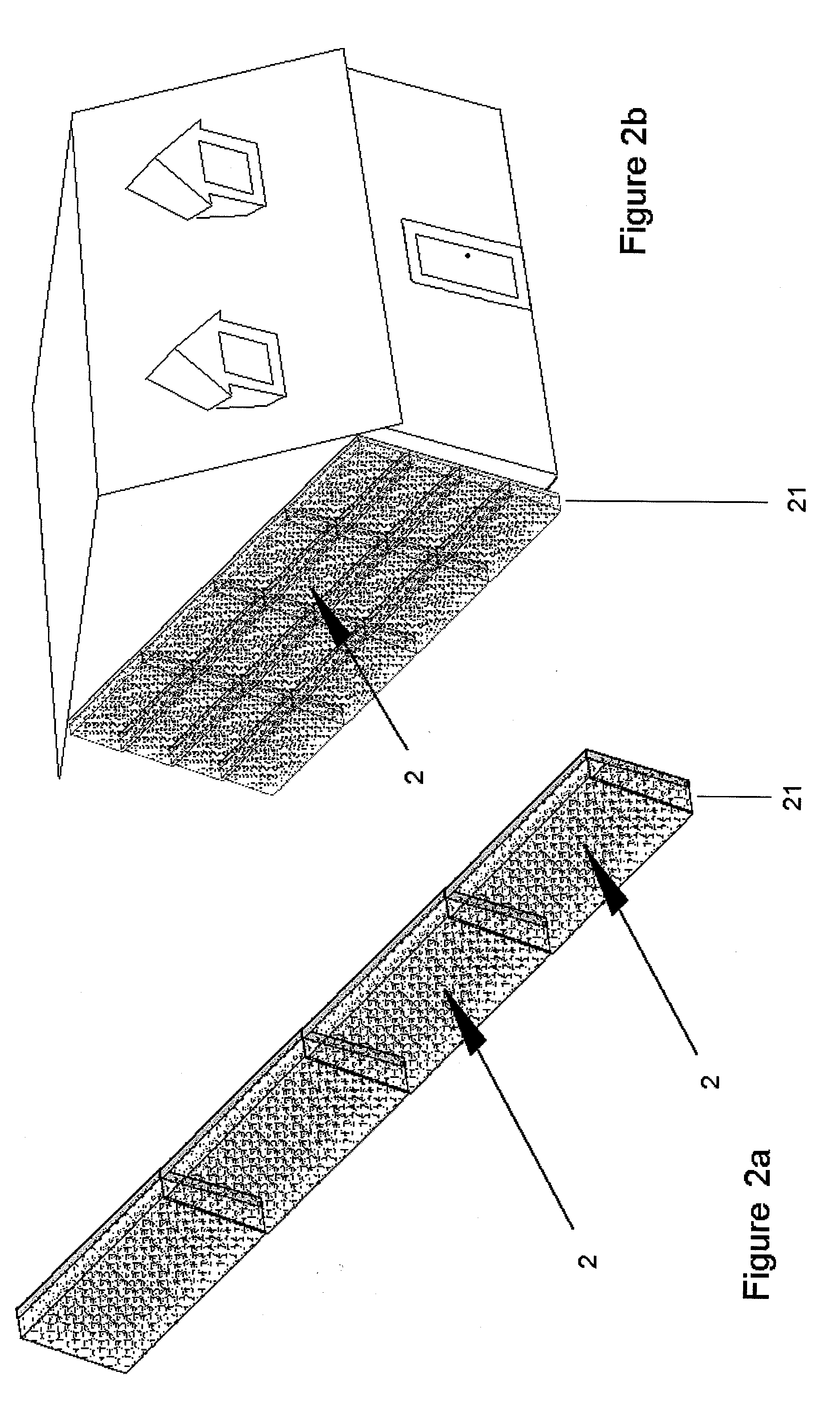

Systems and methods for mixing fluids

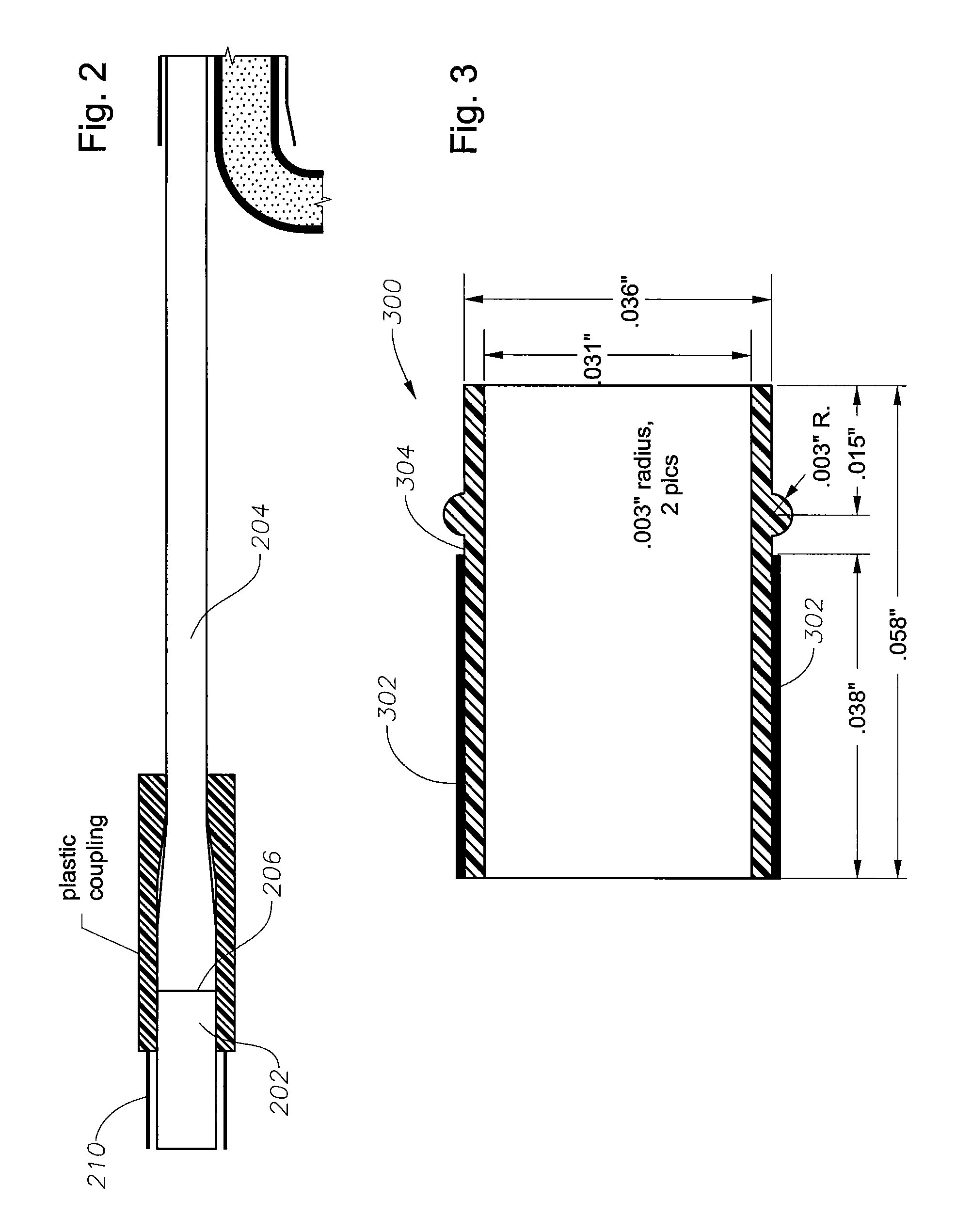

InactiveUS20050209555A1Minimal effortIncrease fluid velocityInfusion syringesPharmaceutical containersSyringeEngineering

Improvements are provided for a syringe-to-syringe mixing system to improve the mixing characteristics of the system. In one embodiment, a mixing apparatus includes opposite fittings for mounting to a pair of syringes. The mixing apparatus defines a fluid passageway therethrough and includes a flow modifying element disposed within the passageway. The flow modifying element is configured to increase the flow velocity, disrupt the fluid flow or introduce turbulence into the fluid flow between the two syringes. In another embodiment, a nozzle element is disposed within the tip of the syringe, the element configured to increase the fluid flow therethrough. The nozzle element can be a nozzle insert removably mounted within the tip, or an integrally formed nozzle within the tip.

Owner:SPINEWAVE

Method and apparatus for acoustically controlling liquid solutions in microfluidic devices

InactiveUS20100124142A1Improve reaction speedAccelerating molecular interactionSequential/parallel process reactionsShaking/oscillating/vibrating mixersSound sourcesAcoustic energy

Acoustic energy is used to control motion in a fluid. According to one embodiment, the invention directs acoustic energy at selected naturally occurring nucleation features to control motion in the fluid. In another embodiment, the invention provides focussed or unfocussed acoustic energy to selectively placed nucleation features to control fluid motion. According to one embodiment, the invention includes an acoustic source, a controller for controlling operation of the acoustic source, and one or more nucleation features located proximate to or in the fluid to be controlled.

Owner:COVARIS INC

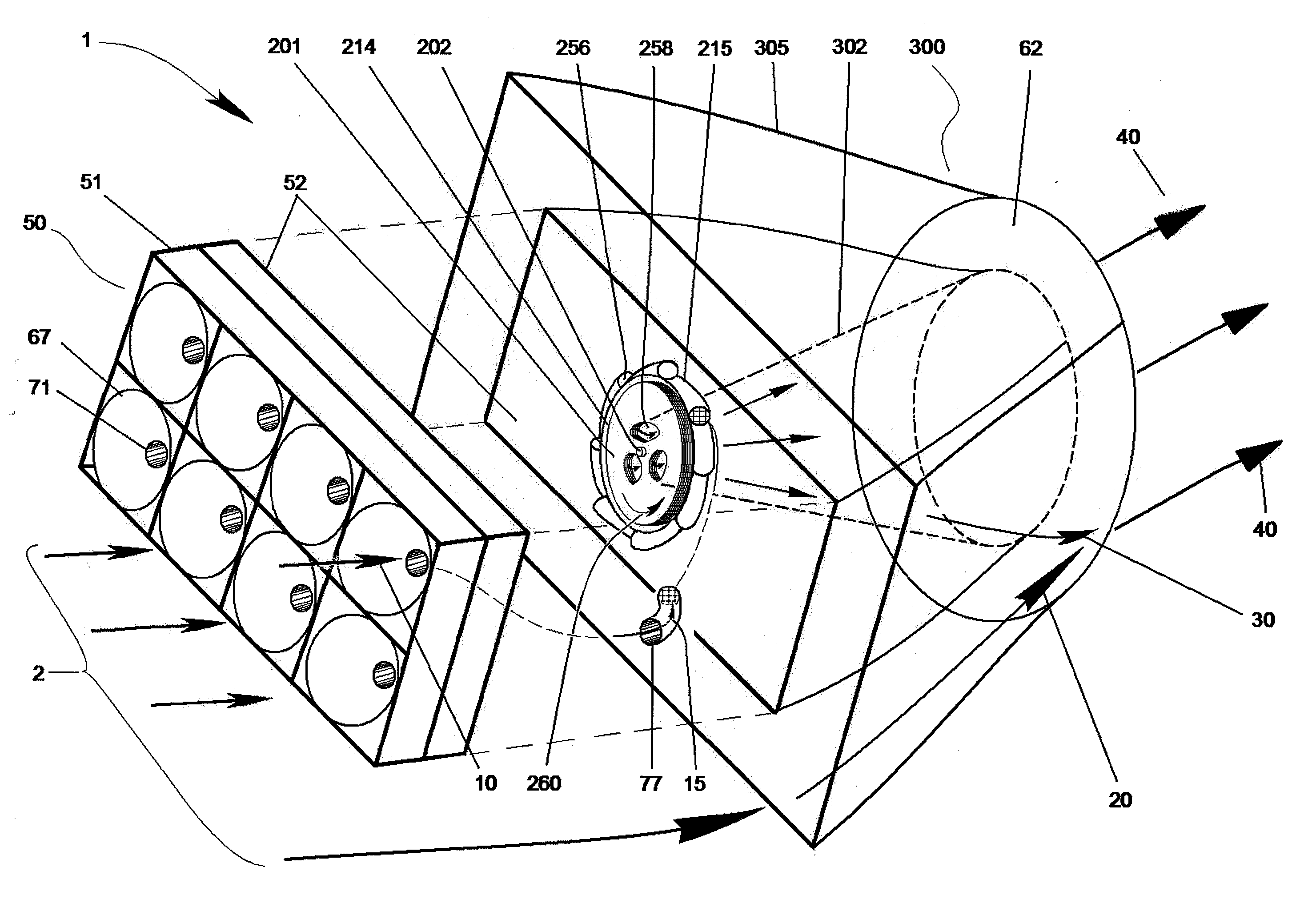

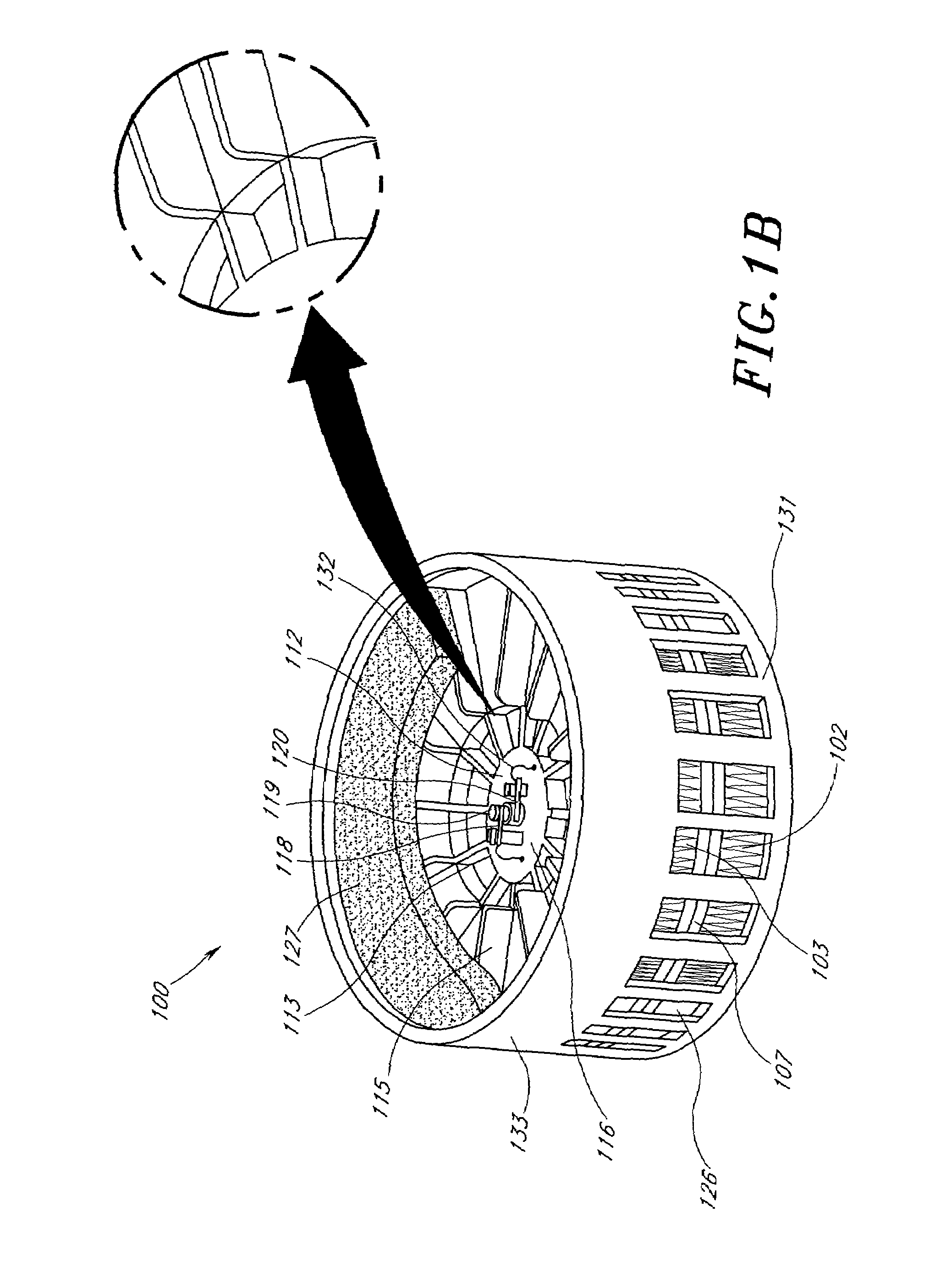

System and method for extracting power from fluid using a tesla-type bladeless turbine

InactiveUS20100129193A1Reduce lossesOptimal longitudinal spacingWind motor controlPump componentsSurface oceanViscous shear

Smooth, preferably variable-sweep fluid collection device surfaces disposed into opposition with wind, river, surf, ocean or tidal currents generate enhanced velocity fluid flows at length driven into onboard work-extracting disc turbines at advantageous angles of attack. Keyed to shafts turning freely through optionally extendable volutes, disc turbines comprising a dense population of smooth, axially fixed or adjustably spaced discs conducting preferably laminar flow between adjacent elements develop significant torque through boundary layer adhesion and viscous shear-stress between fluid layers. Exhaust of disc turbine throughput into divergent channels drafting into external currents of initially higher than ambient velocity and lower pressure may reduce turbine discharge backpressure, rapidly clear system throughput, and allow normally disadvantageous drag to be utilized to develop greater work generation. Gainfully turning with, instead of at odds to natural or anthropogenic currents provided, disc turbines utilized as disclosed may provide unprecedented renewable energy from fluids in motion.

Owner:SHERRER GORDON DAVID

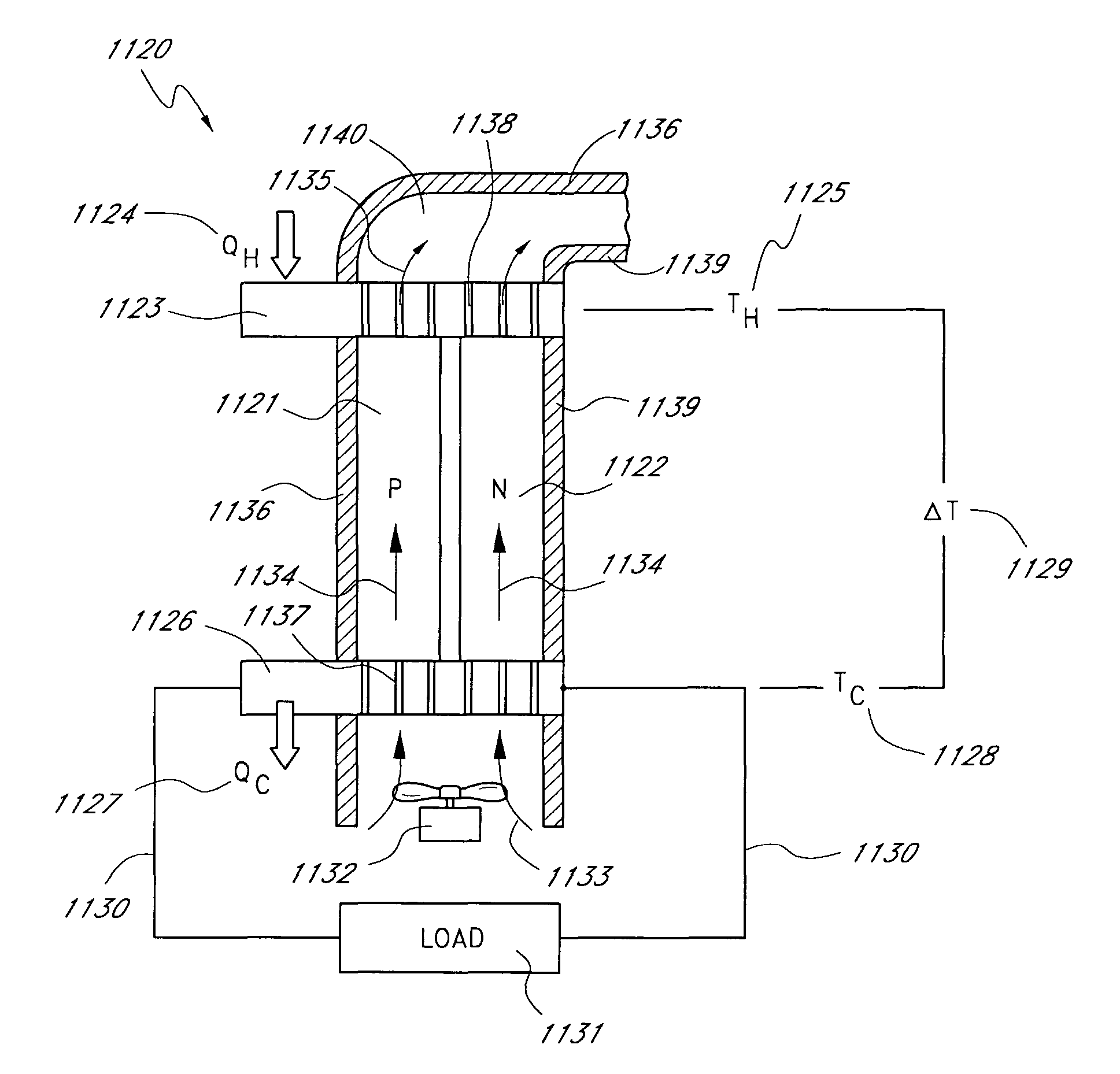

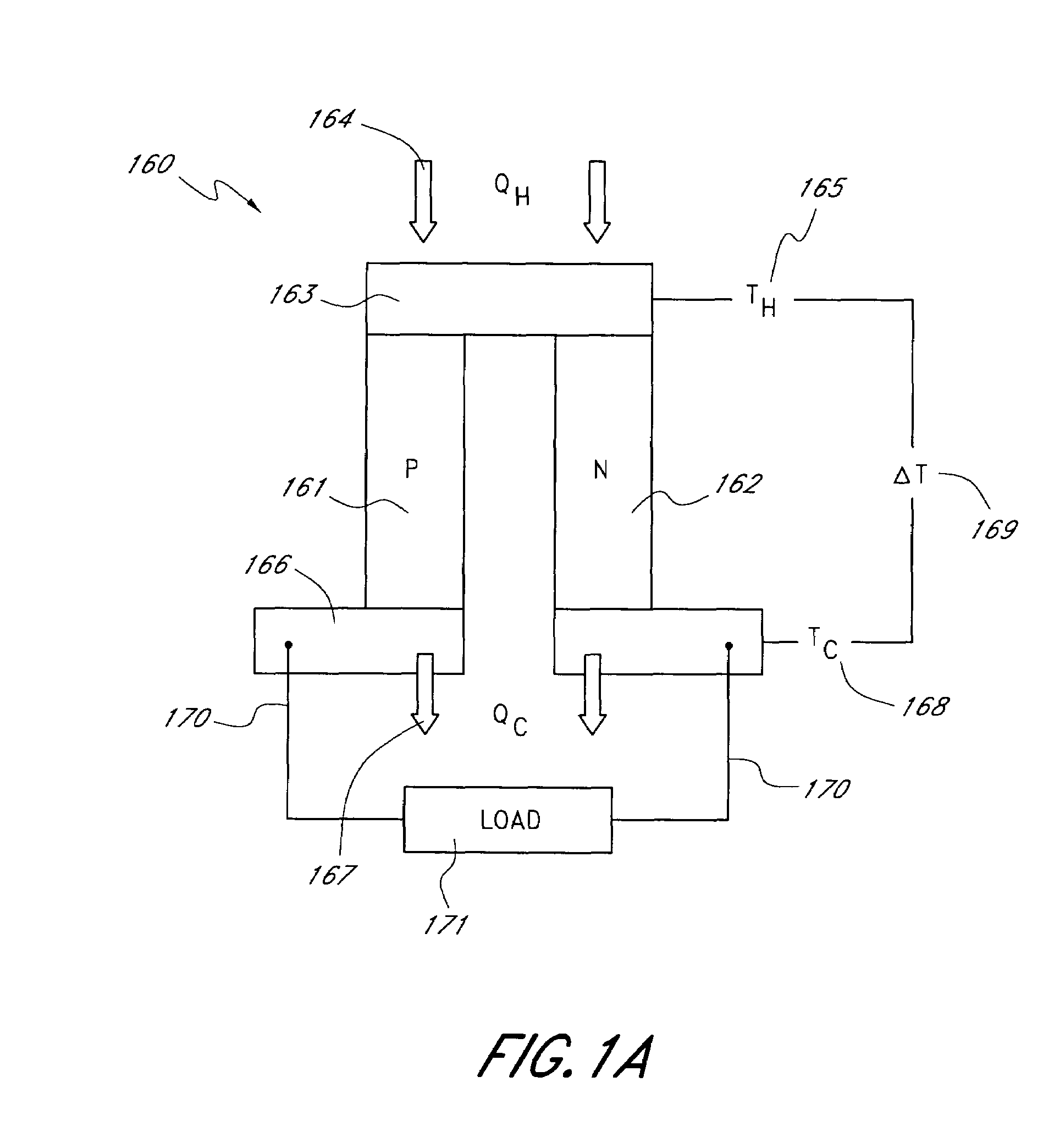

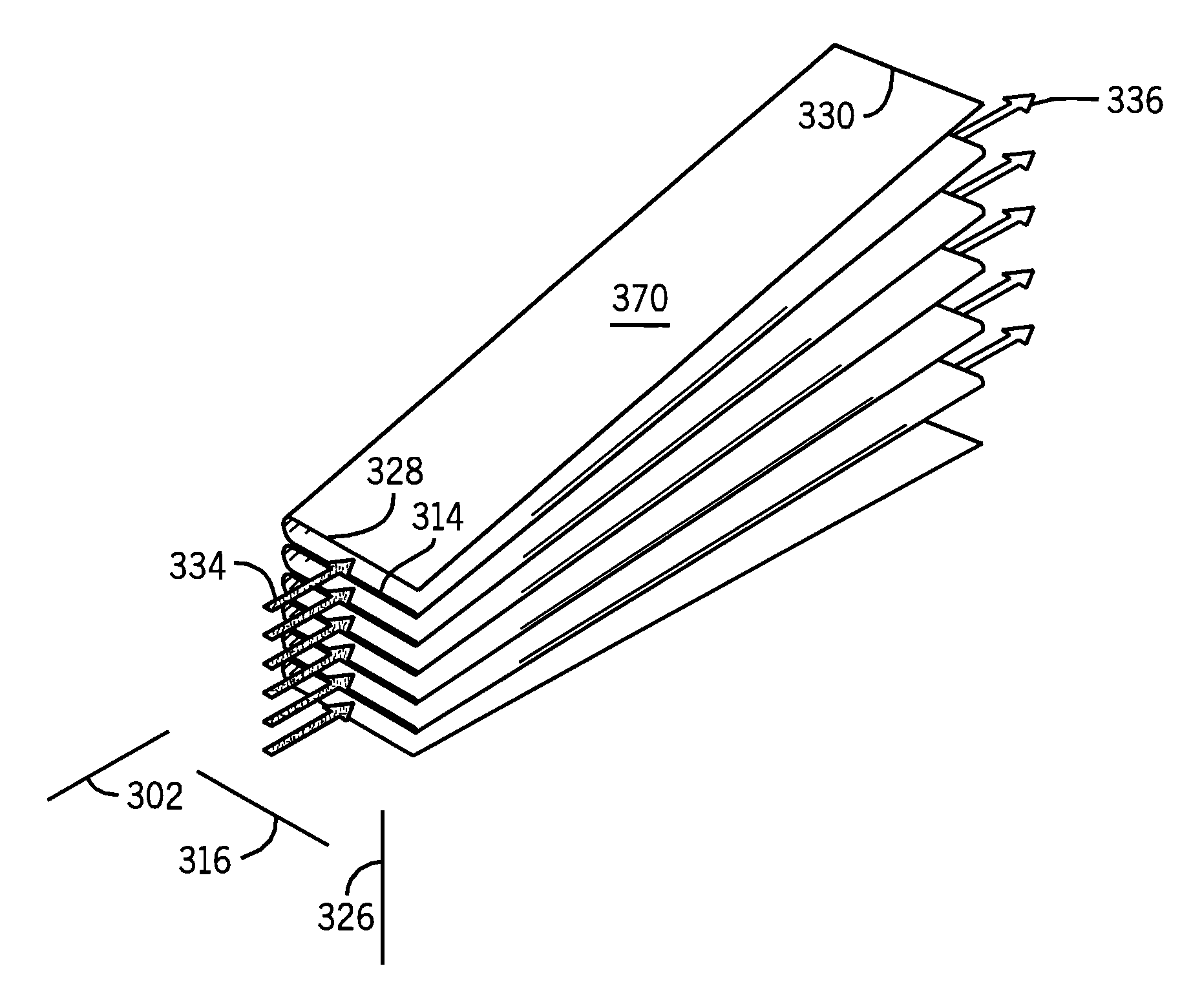

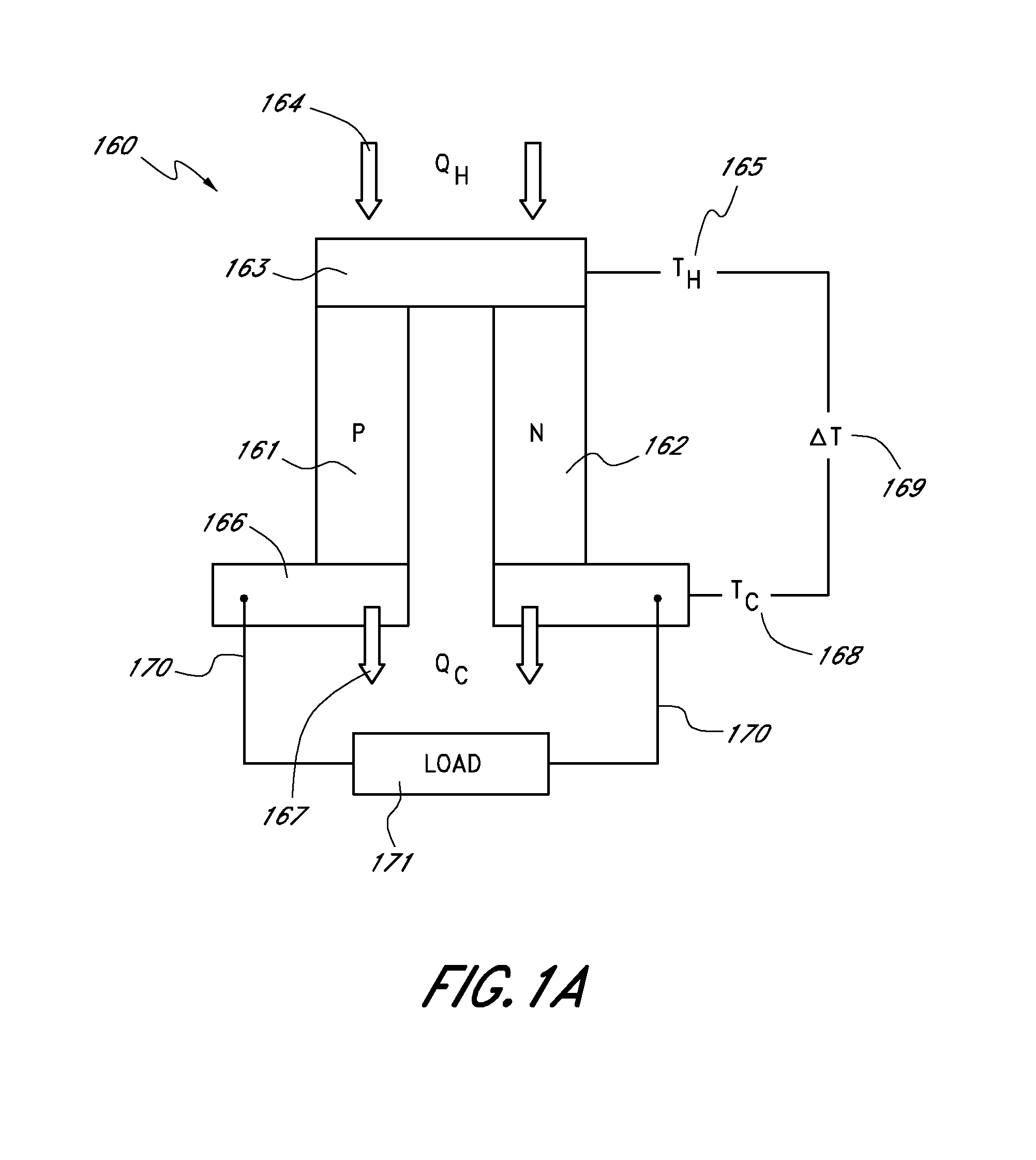

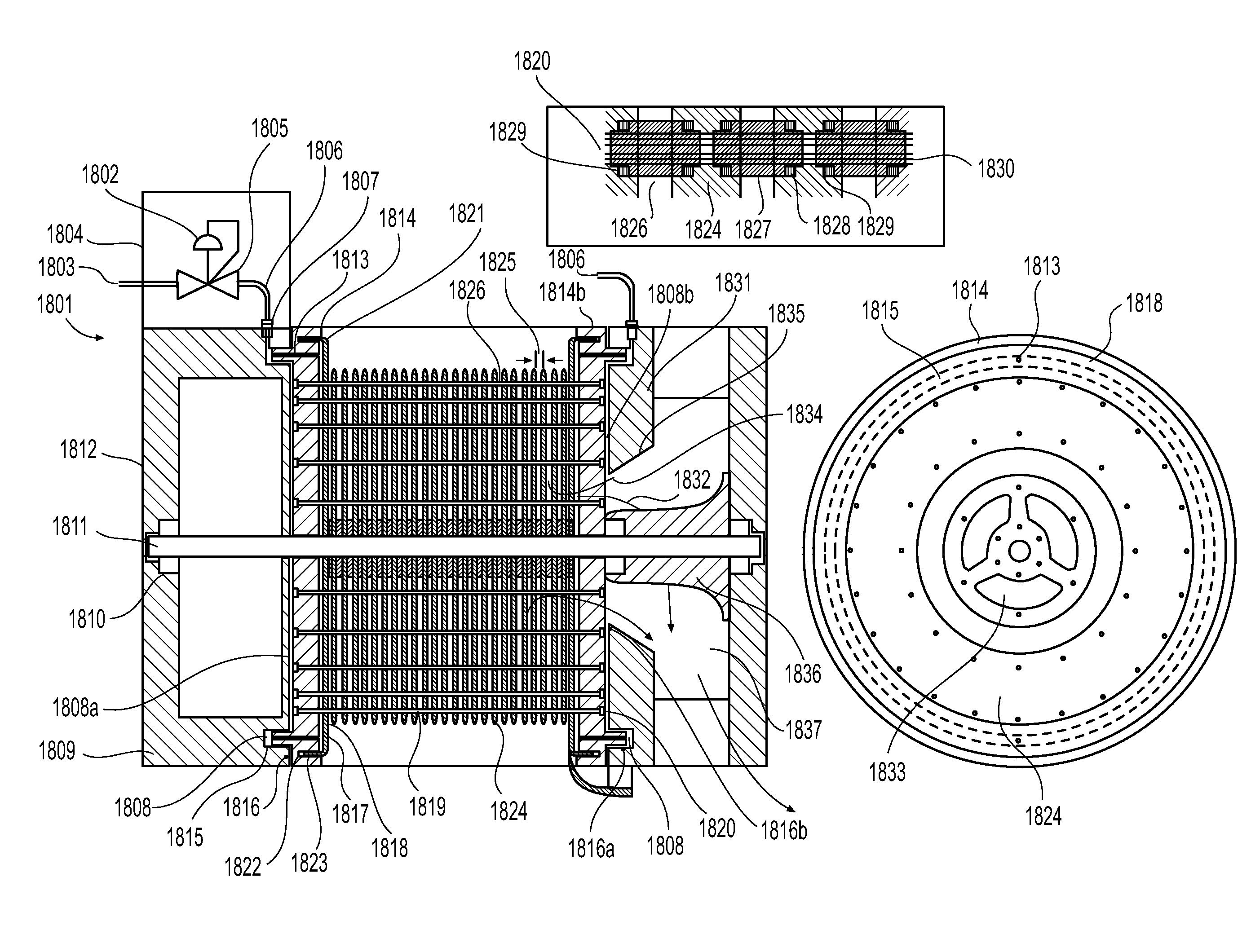

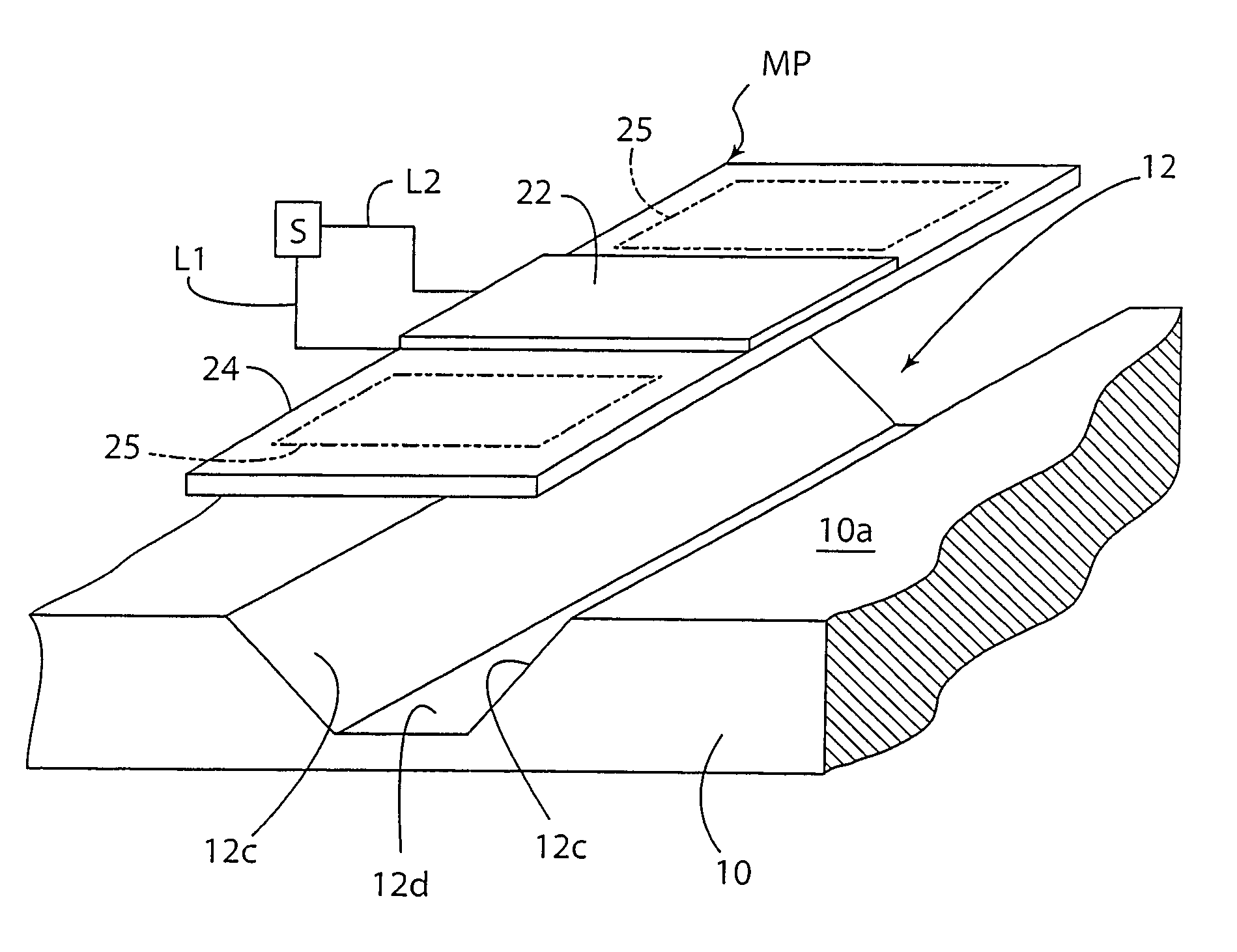

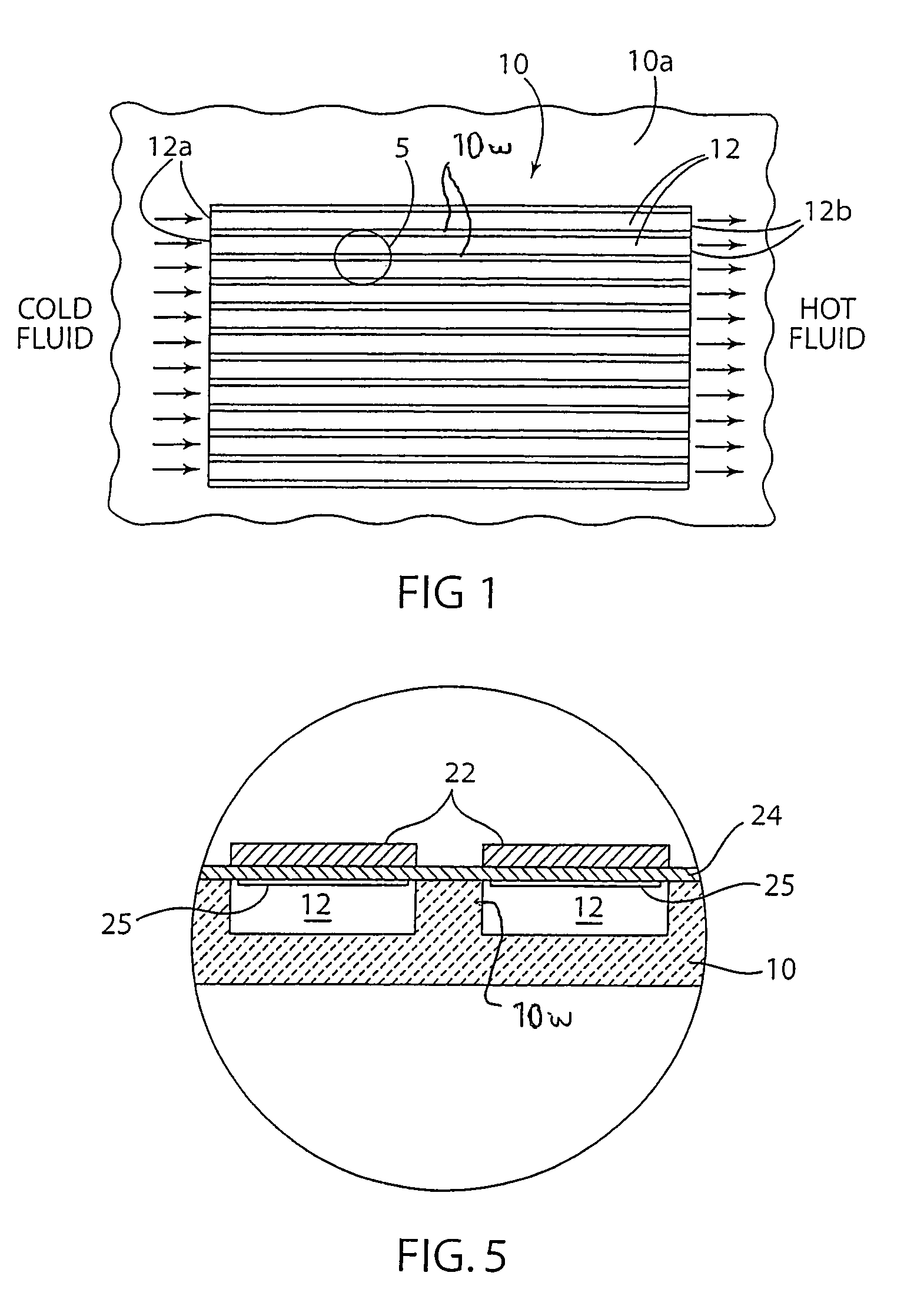

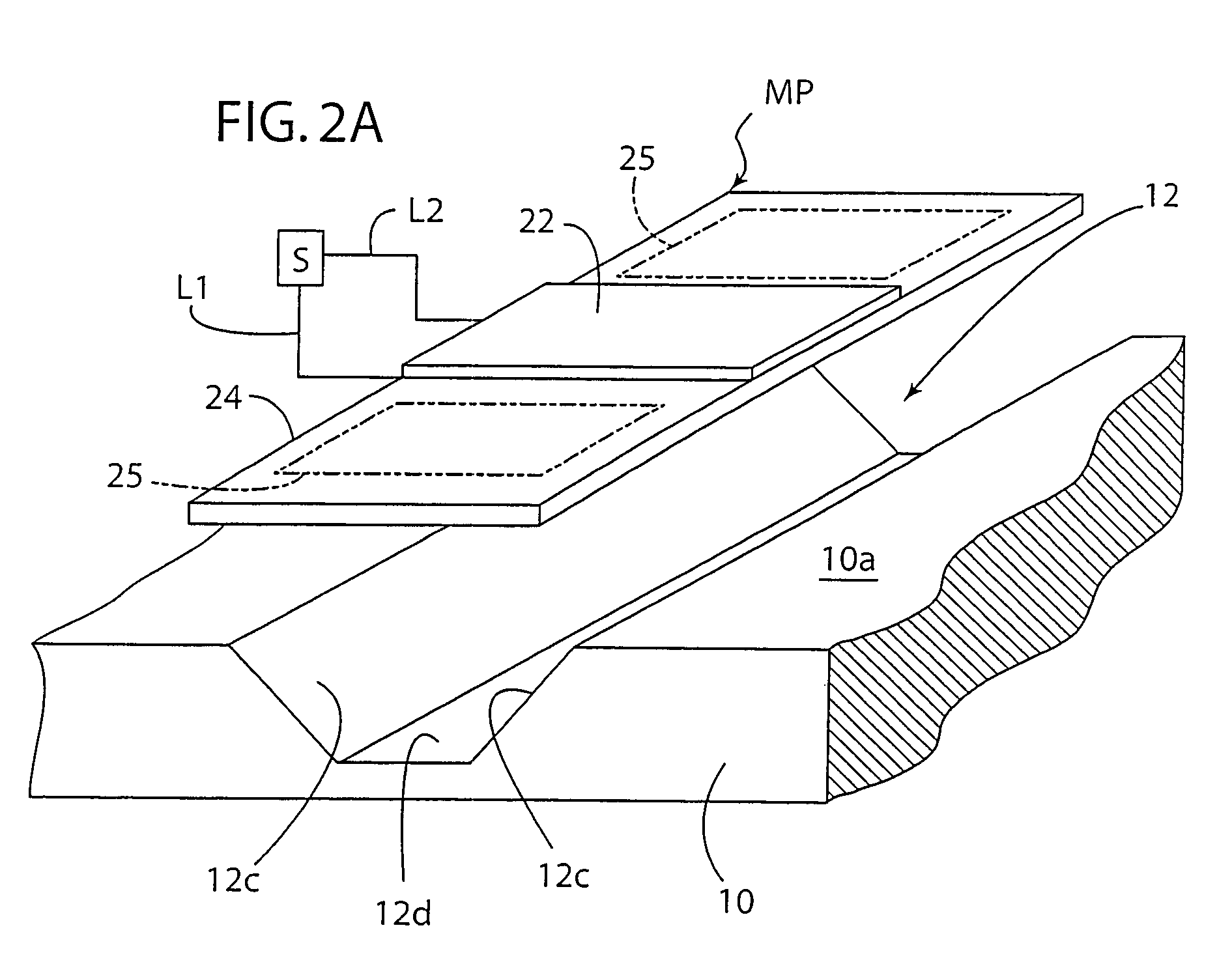

Thermoelectric power generation systems

InactiveUS7273981B2Renewed interestImprove power densityAir-treating devicesThermoelectric device with peltier/seeback effectEngineeringThermal efficiency

Representative configurations for improved thermoelectric power generation systems to improve and increase thermal efficiency are disclosed.

Owner:GENTHERM INC

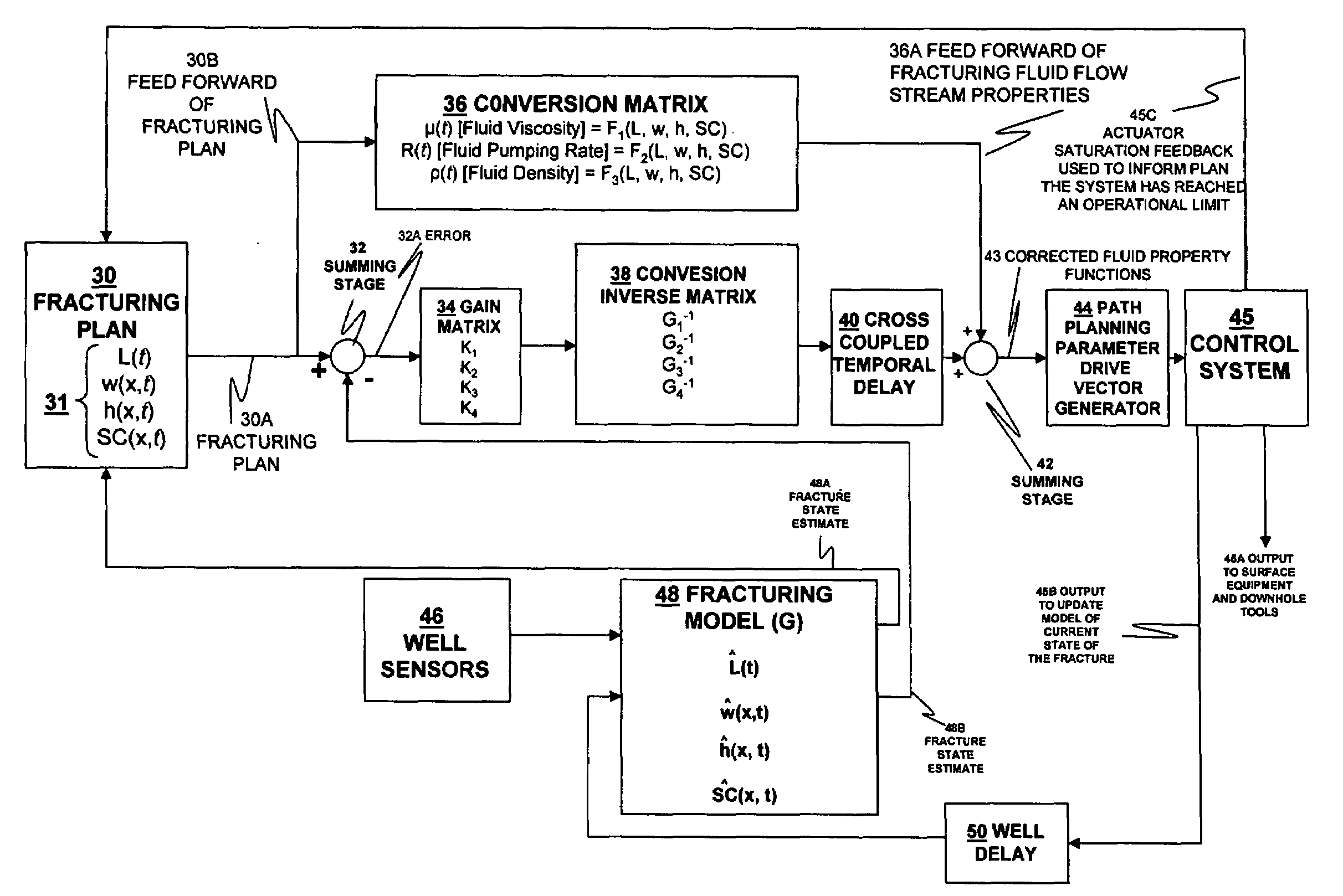

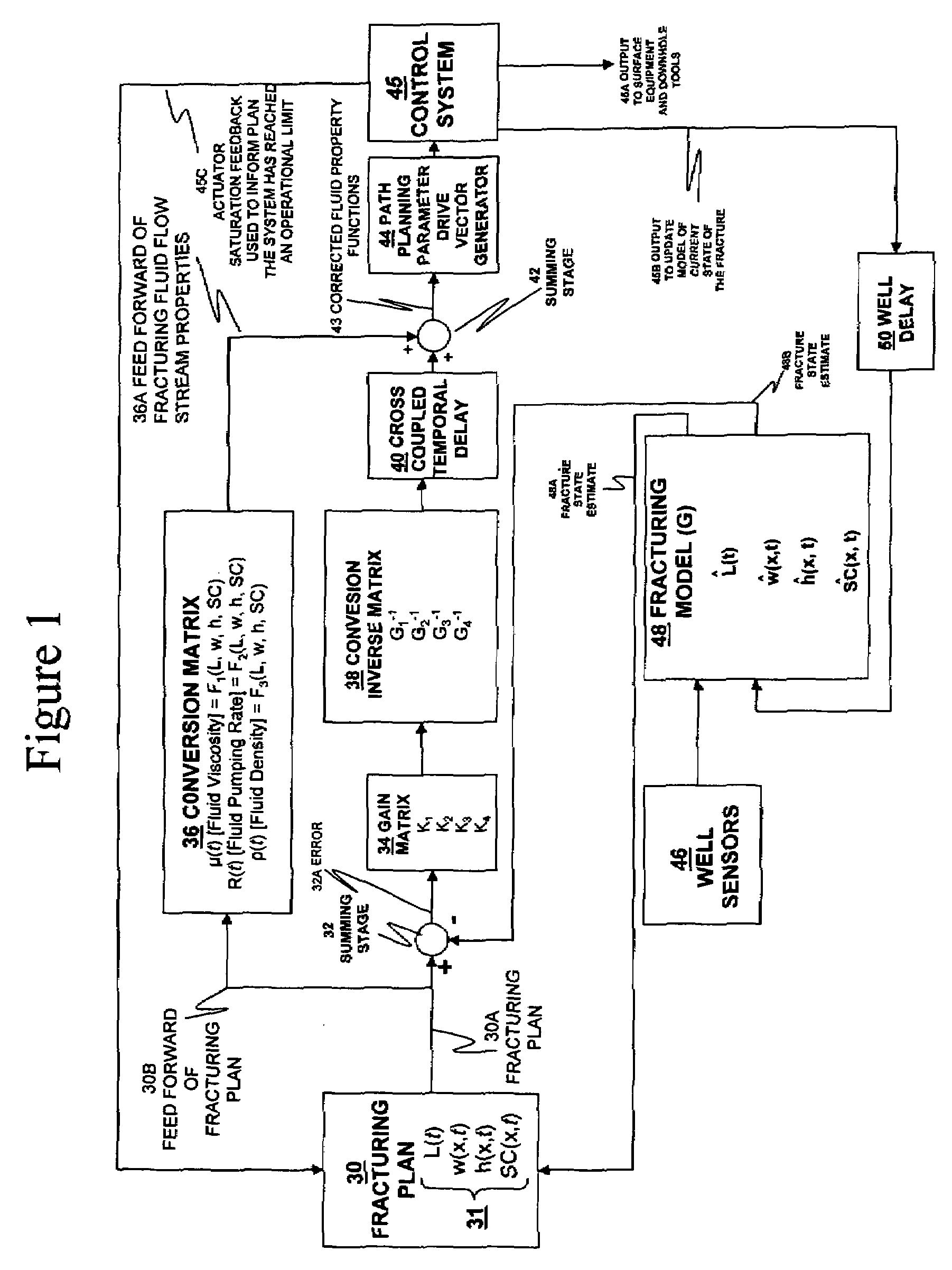

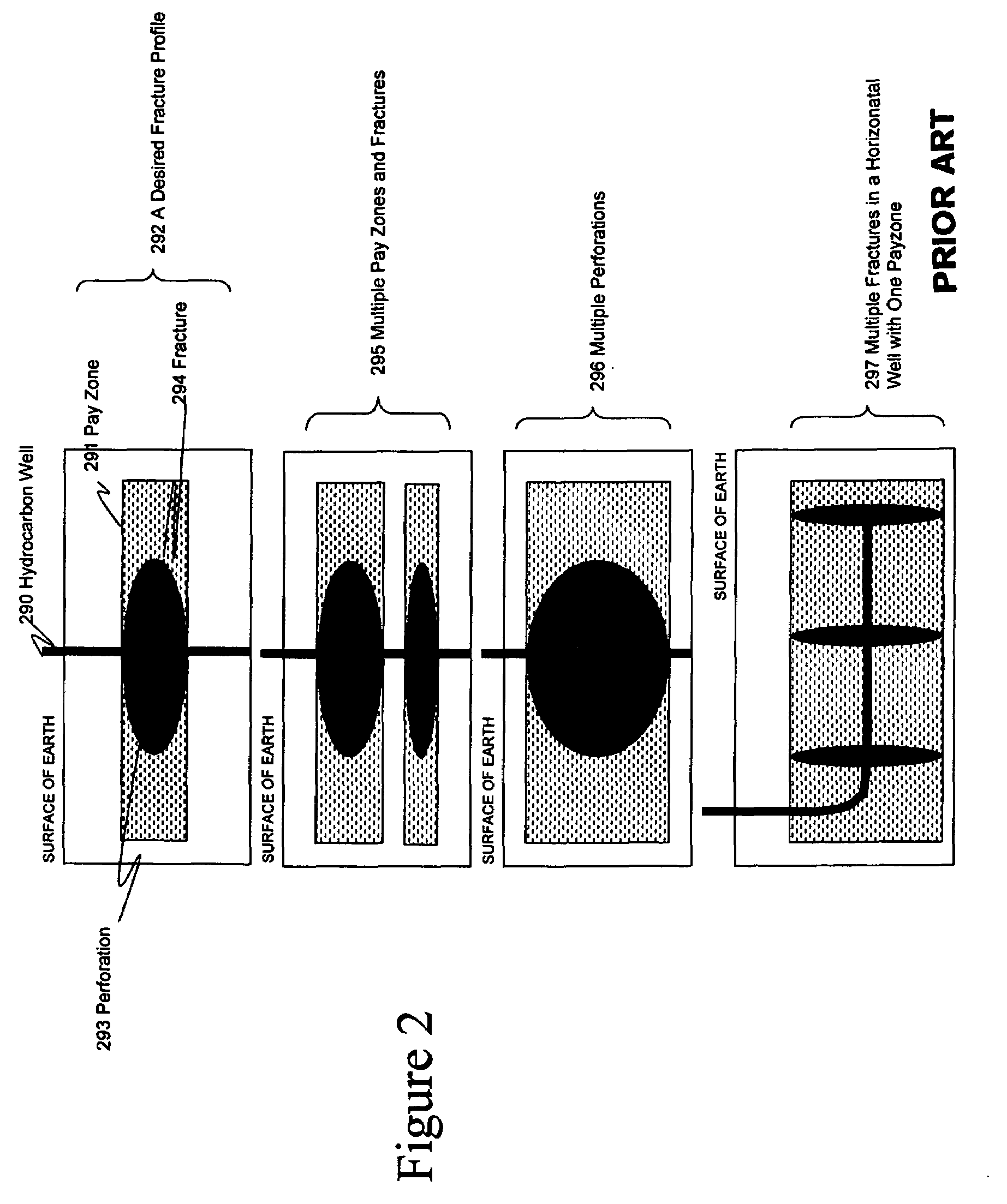

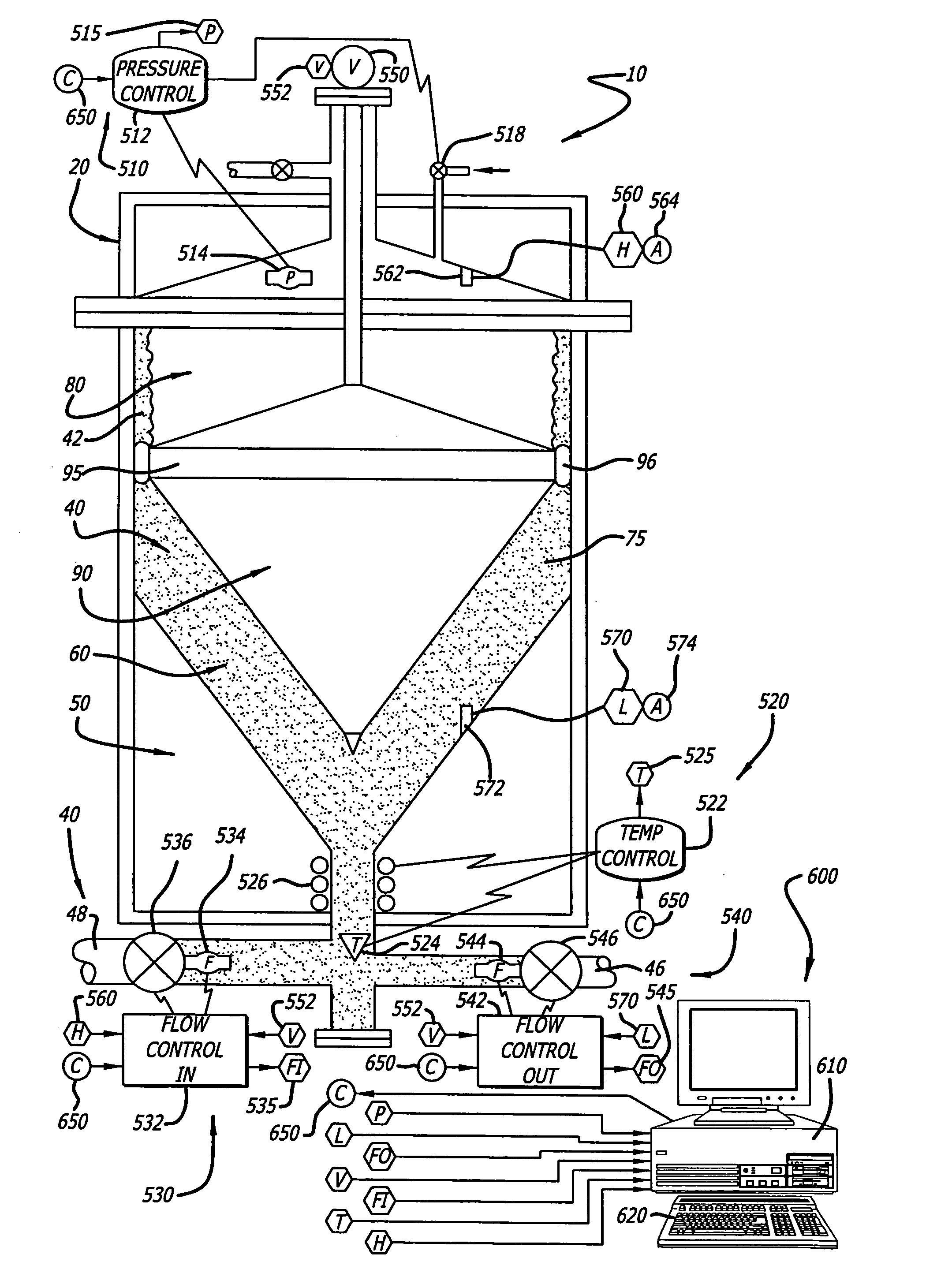

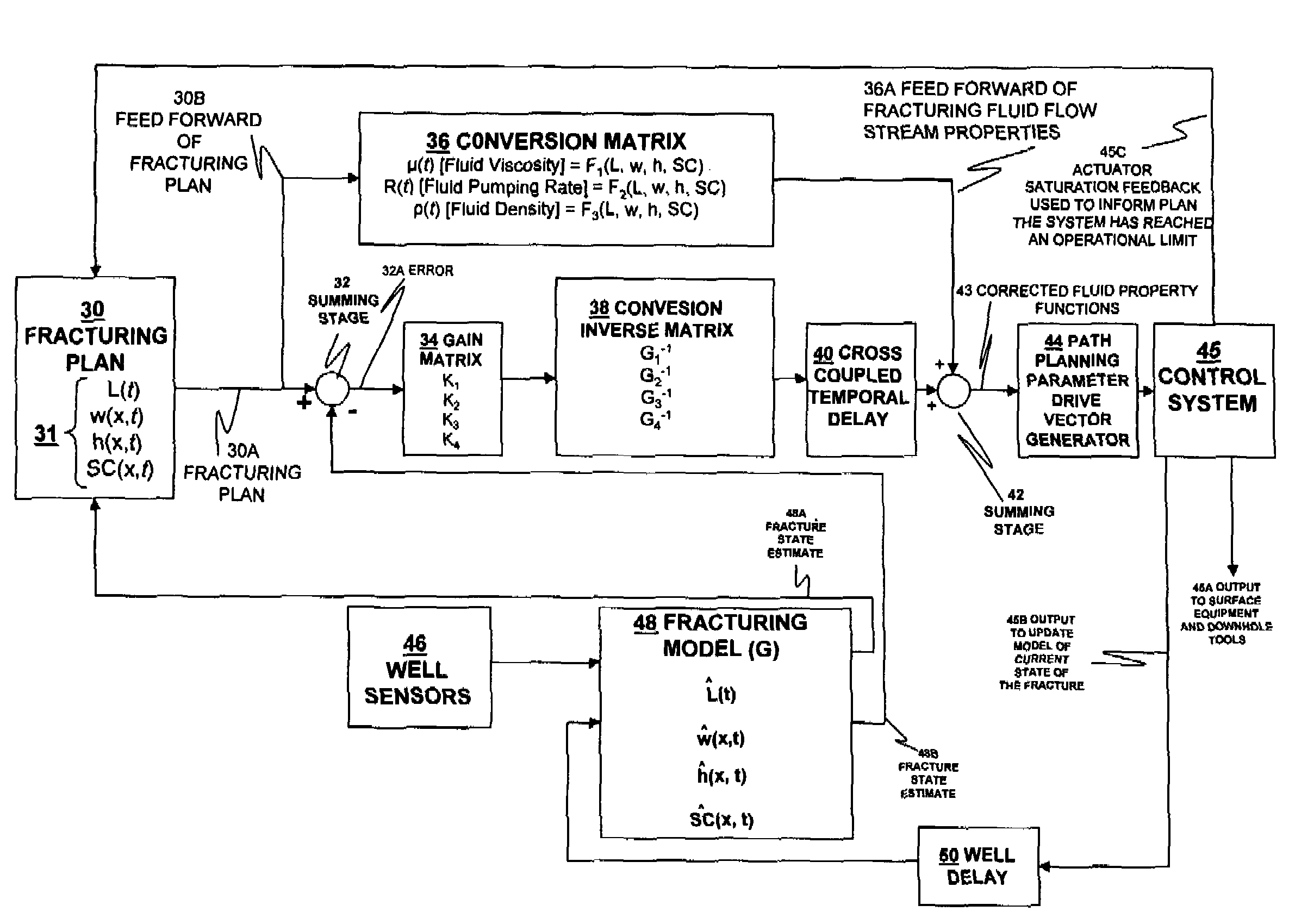

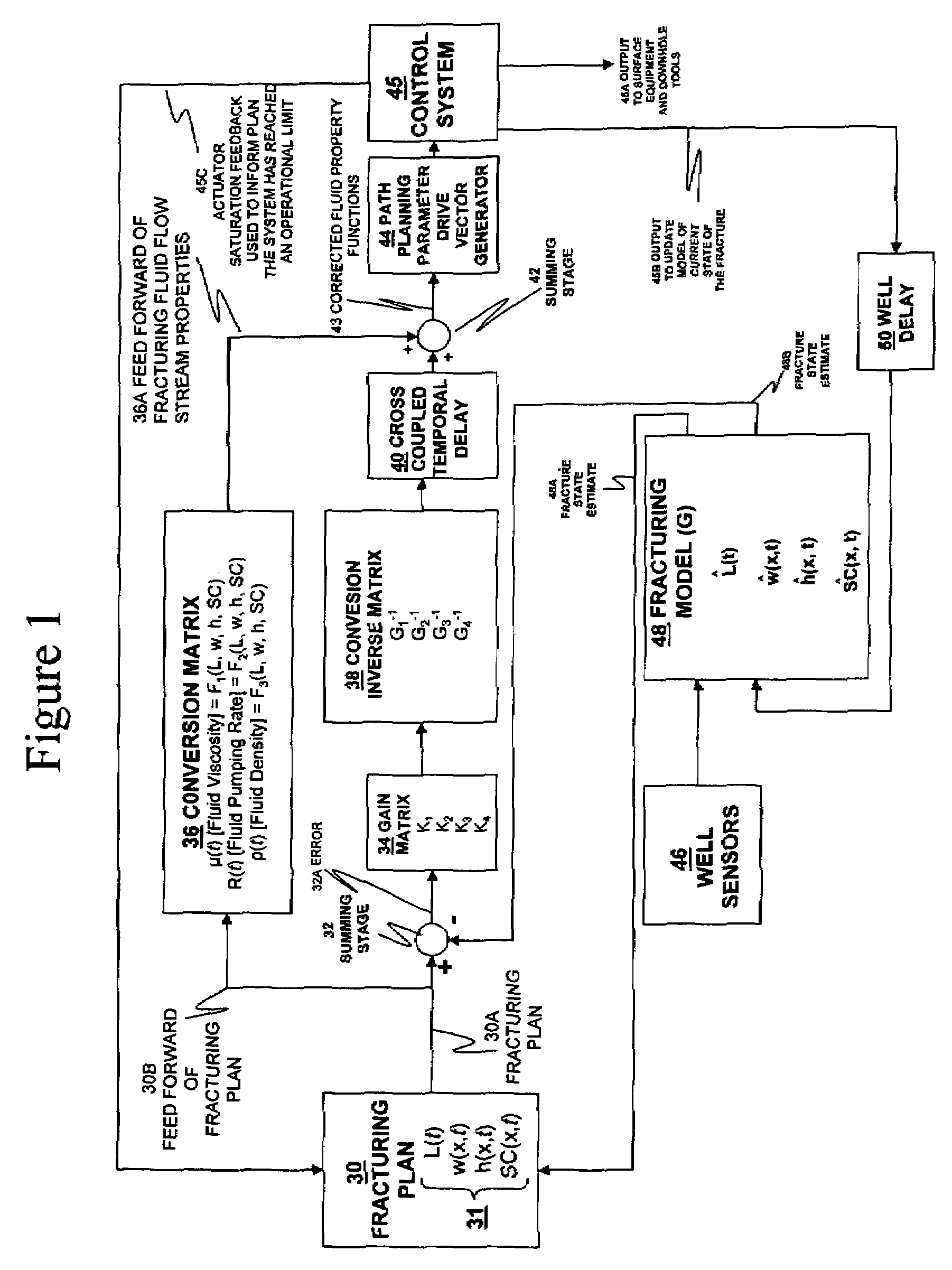

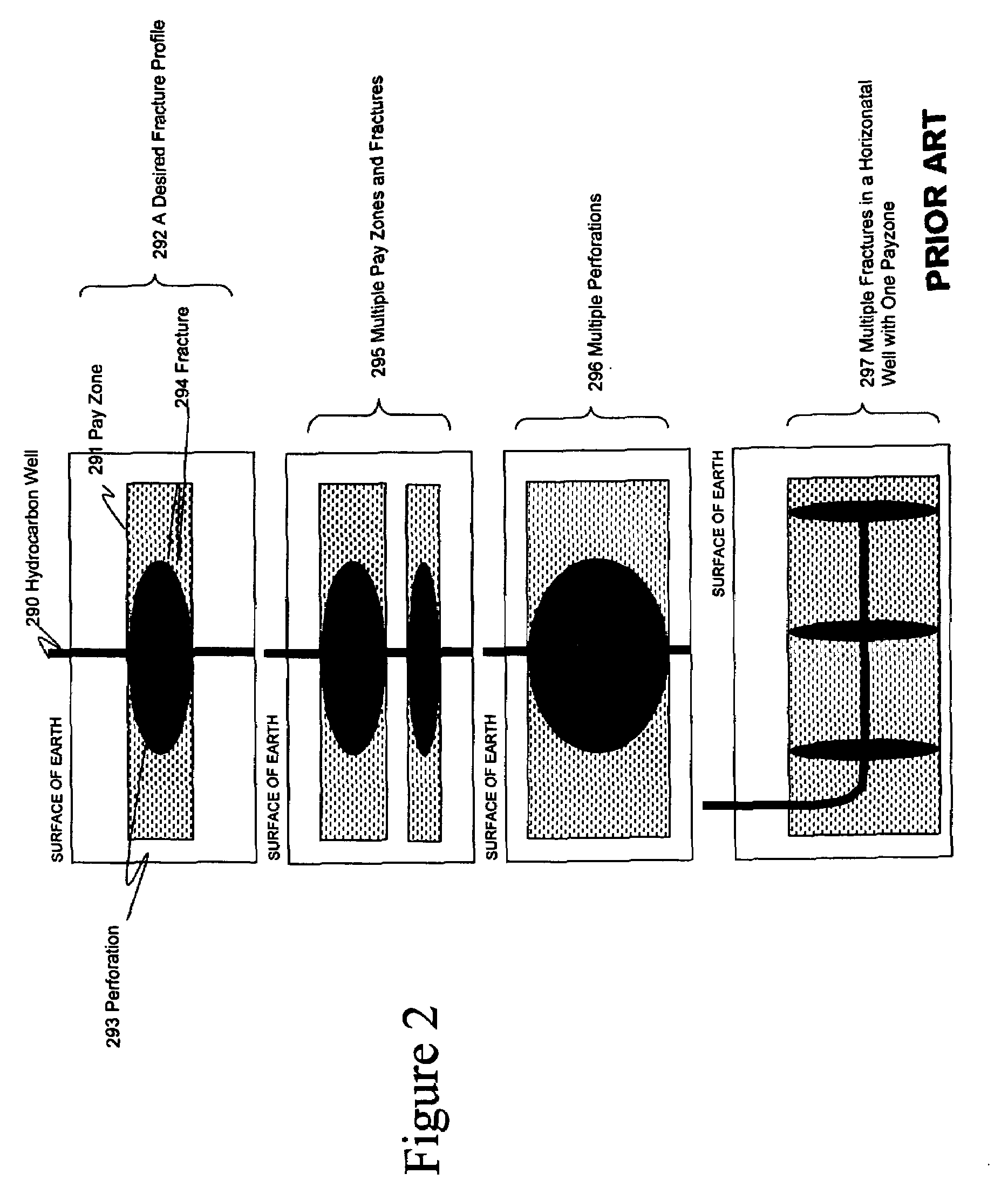

Methods and systems for fracturing subterranean wells

ActiveUS20080164021A1Reduce riskImprove permeabilitySurveyFluid removalControl flowAutomatic control

New methods and systems for subterranean fracturing for hydrocarbon wells. A plan of the fracture propagation and in-fracture proppant distribution is used with a real-time model of the status of the fracture dimensions and in-fracture proppant concentration to automatically control flow rates and properties of a fracturing fluid flow stream being used to induce and prop the fracture. Real-time measurements of the status of the fracture are made using surface and / or down-hole sensors. Real-time control over the flow rate and properties of a fracturing fluid flow stream are made by manipulating the fracturing fluid supply equipment. Real-time modifications of the fracturing model are made by comparing fracture sensor measurements of actual fracture dimensions to the predicted dimensions, and then adjusting the model for inaccuracies. Real-time updates to the fracturing plan are made by comparing actual fracture and propping results to desired results, and then adjusting to achieve optimal results.

Owner:HALLIBURTON ENERGY SERVICES INC

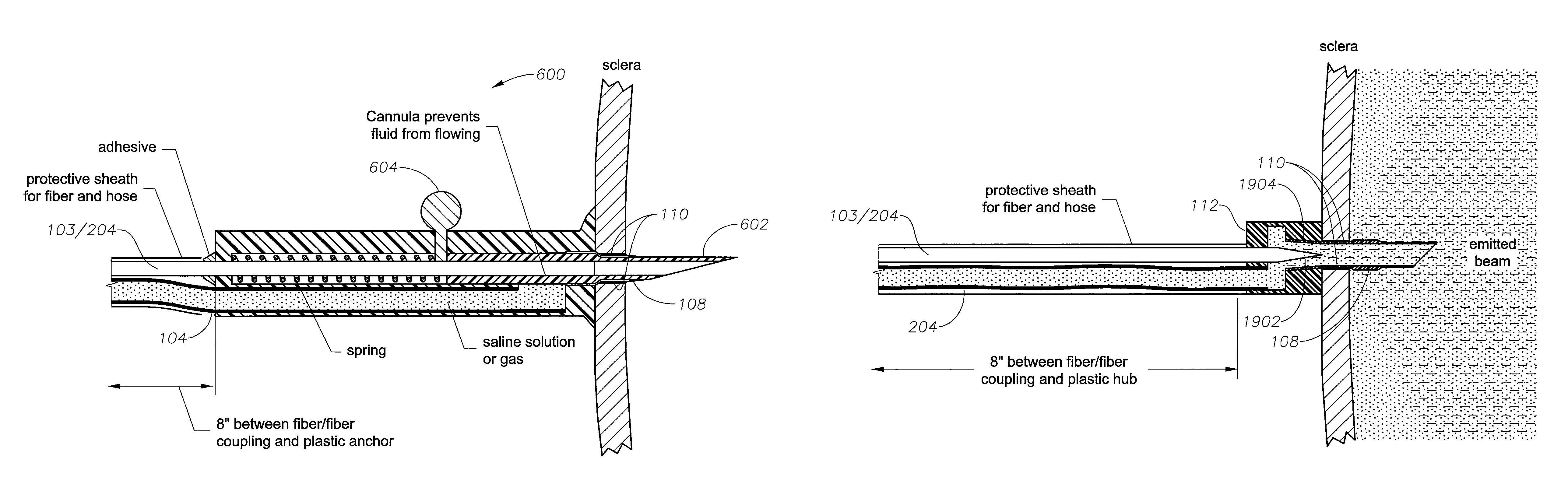

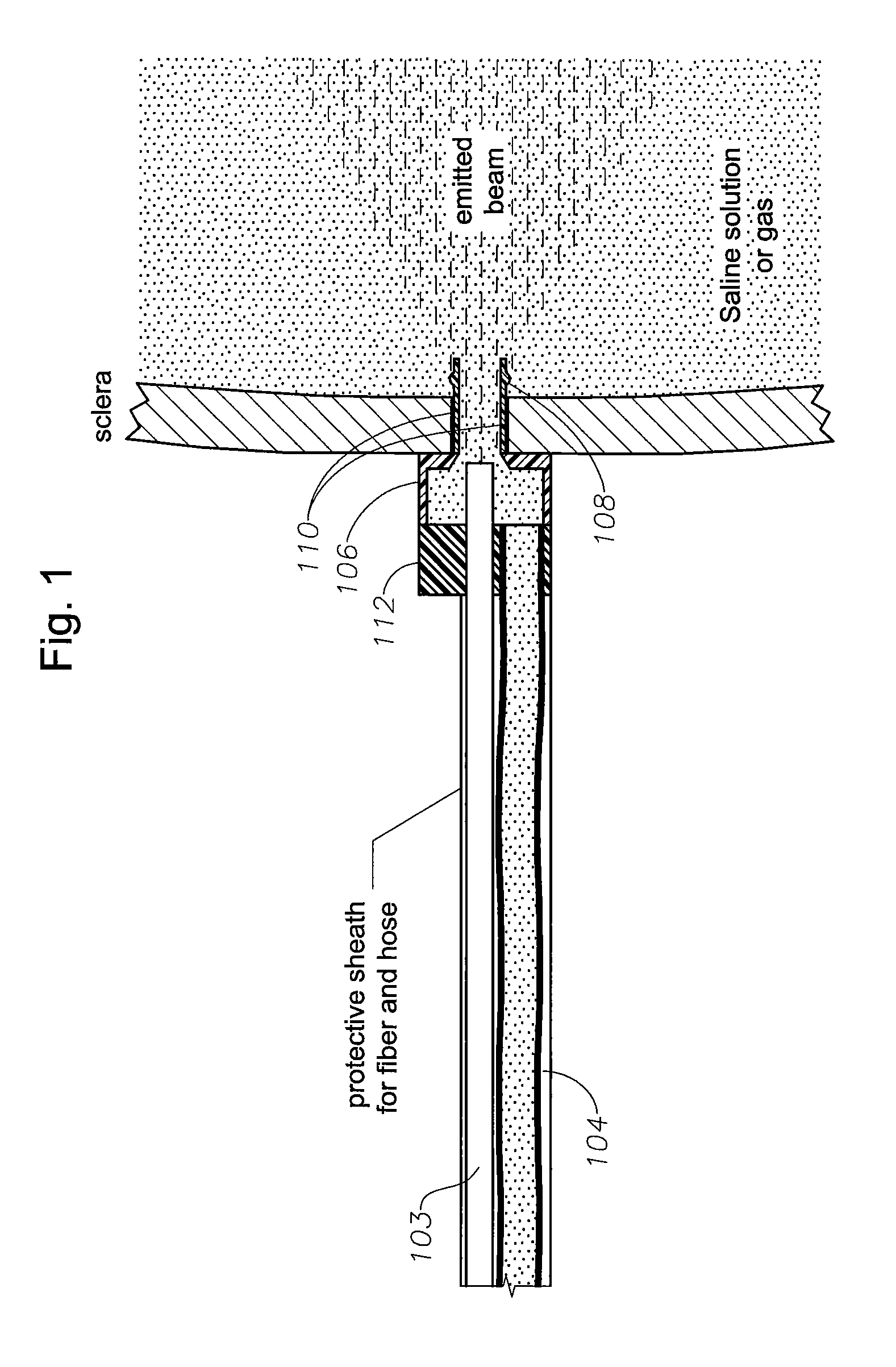

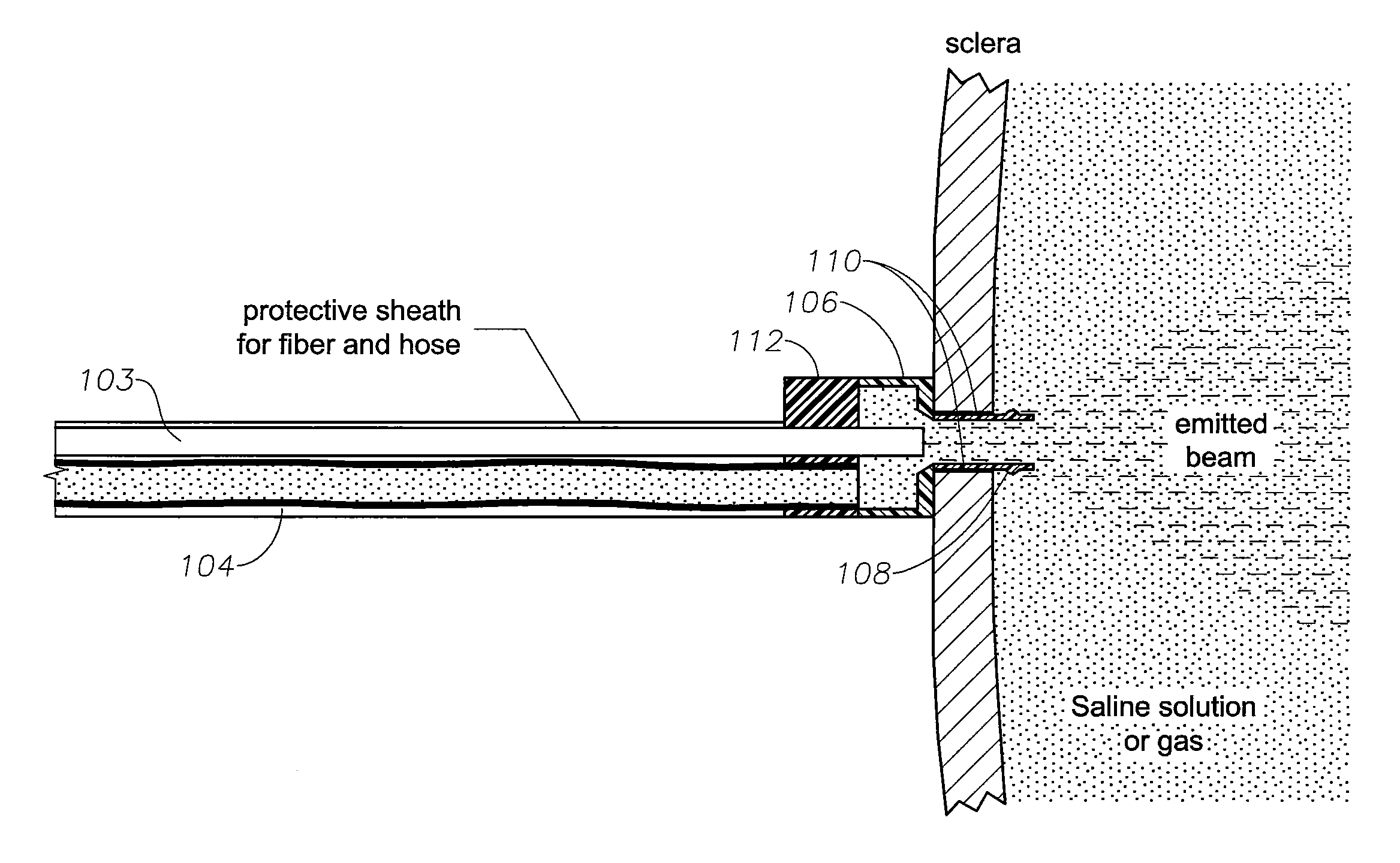

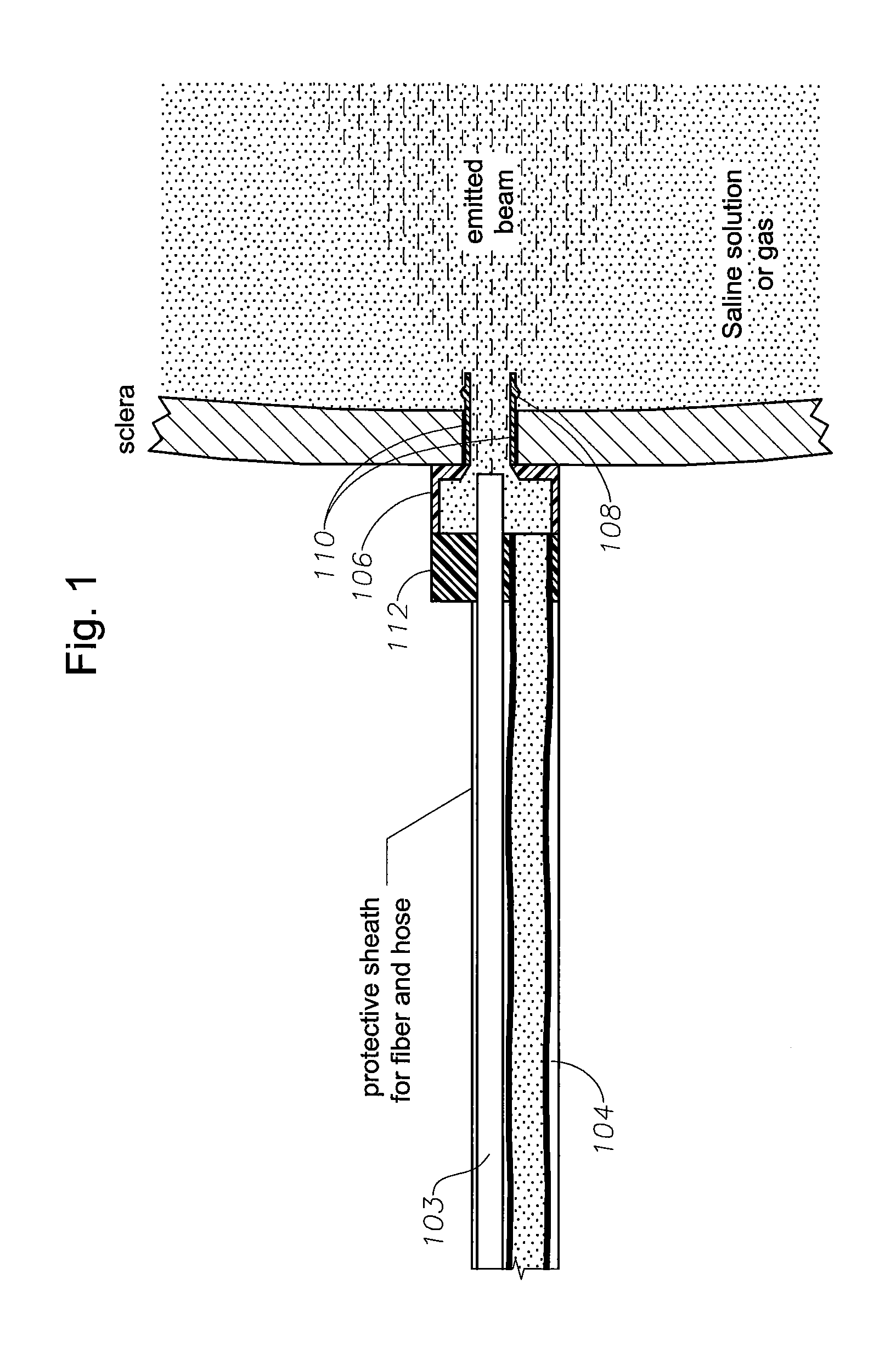

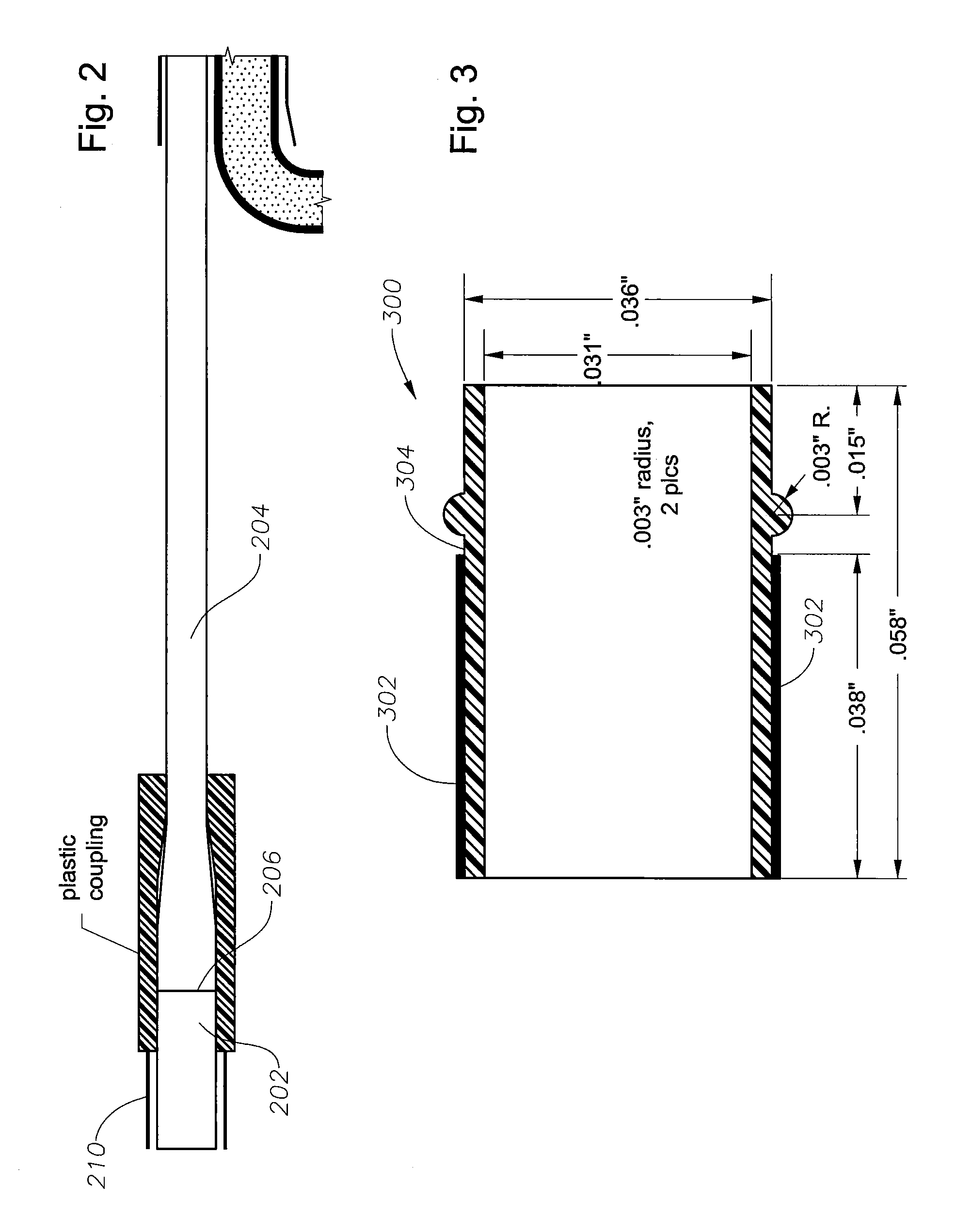

Illuminated infusion cannula

ActiveUS7783346B2Increase flow rateHigh light transmittanceElectrotherapyEye surgeryFiberTransmittance

A transparent illuminated infusion cannula is provided for illuminating an area during eye surgery. An optical fiber may be spaced a certain distance away from the cannula such that fluid flow around the distal end of the fiber and into the transparent cannula may occur with a much higher flow rate than what had previously been possible. The fiber cannula airspace may be optimized so that the cross-sectional area of the fluid conduit remains substantially constant in order to achieve a best compromise between high light transmittance and high fluid flow rate.

Owner:ALCON INC

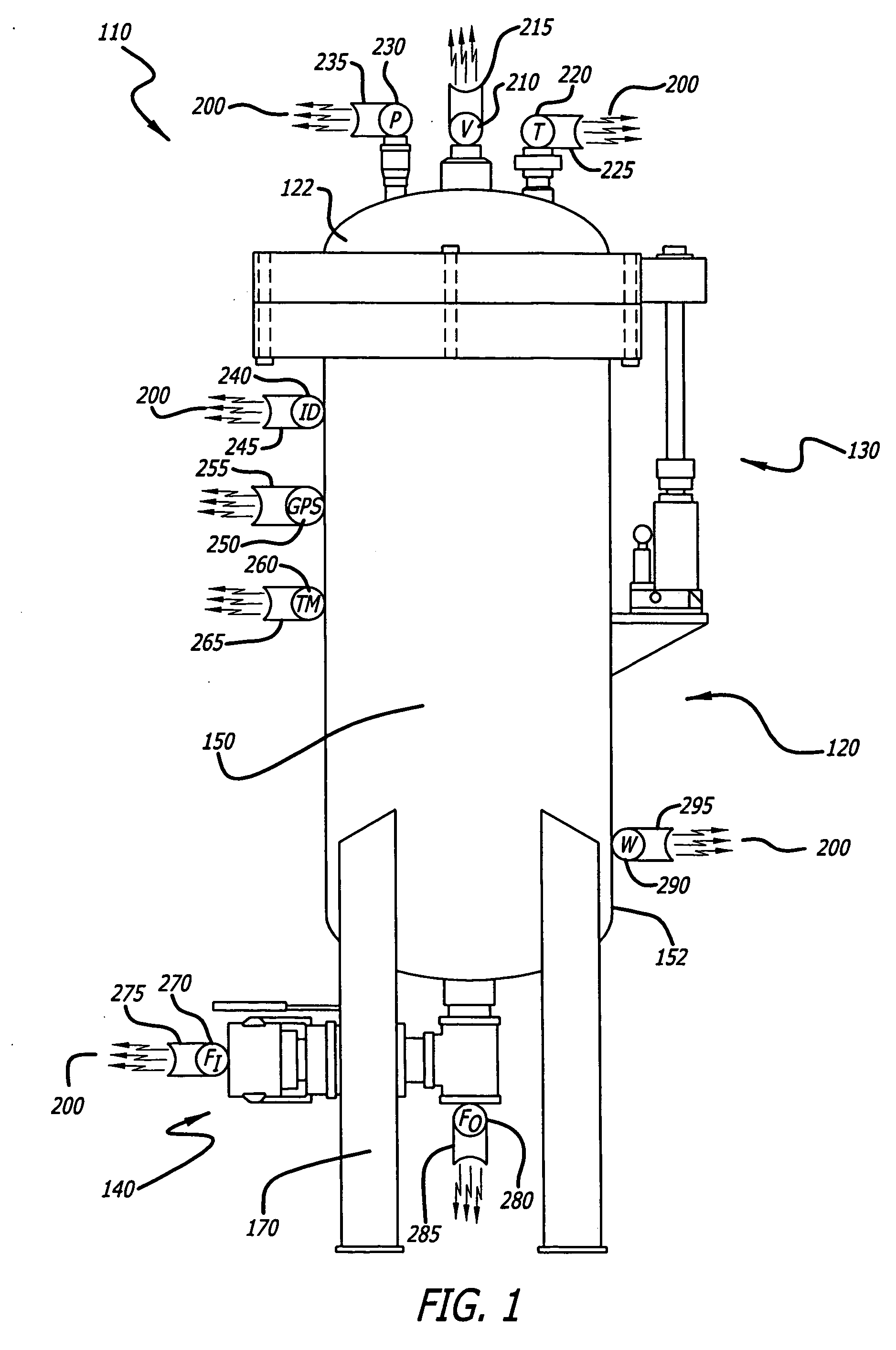

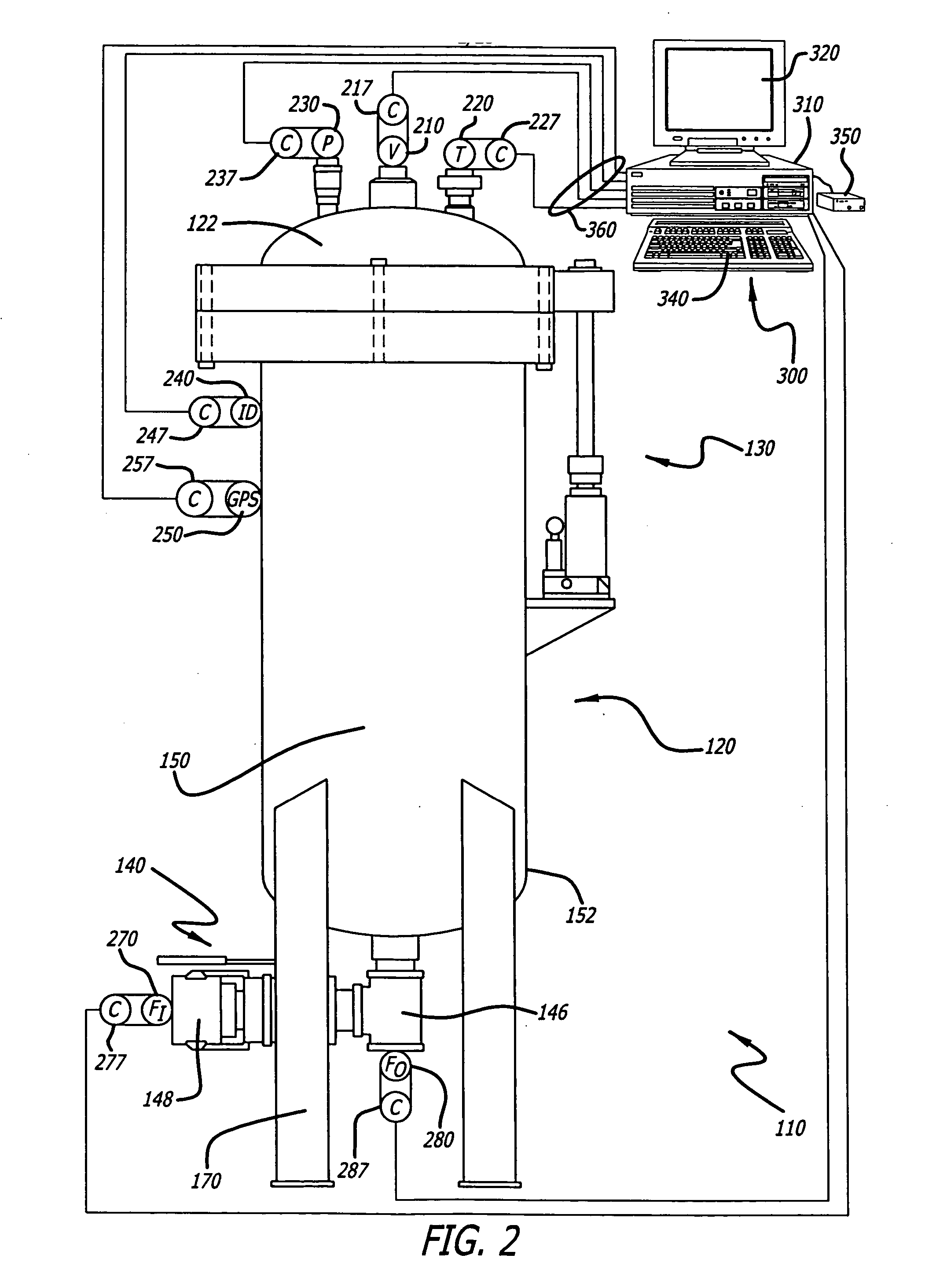

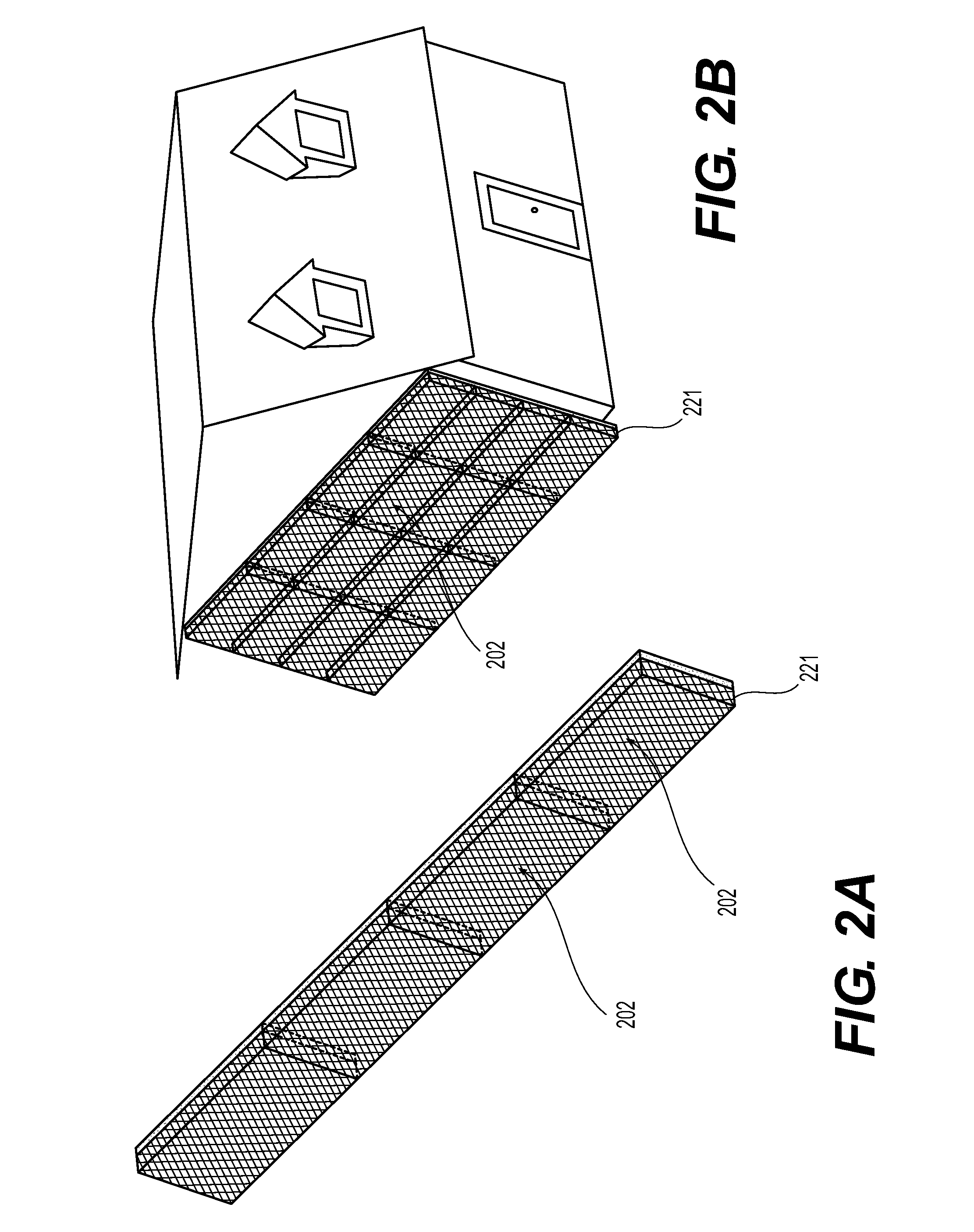

Integrated material transfer and dispensing system

ActiveUS20070090132A1Increase fluid velocityWide operating temperature rangeLiquid flow controllersLiquid transferring devicesStream flowMaterial transfer

An integrated material transfer and dispensing system for storing, transferring and dispensing materials, such as fluids, and liquids, for example, liquid applied sound deadener (LASD). The system includes at least one vessel having a force transfer device. Each vessel may be removably enclosed in cabinet to form an automated station. Each vessel may be configured with a data logger, cleanout port, a sample valve at least one sight window and an access port for introducing a compound such as a biocide. Each vessel may be configured with instruments including sensors for measuring process variables, such as material volume, level, temperature, pressure and flow. The system may further include a metering device system and a robotic material dispenser system without a pump interface. The robotic system may further include a computer control system connected to flow and pressure sensors. The system may directly feed an applicator without an intervening pump.

Owner:CH & I TECH INC

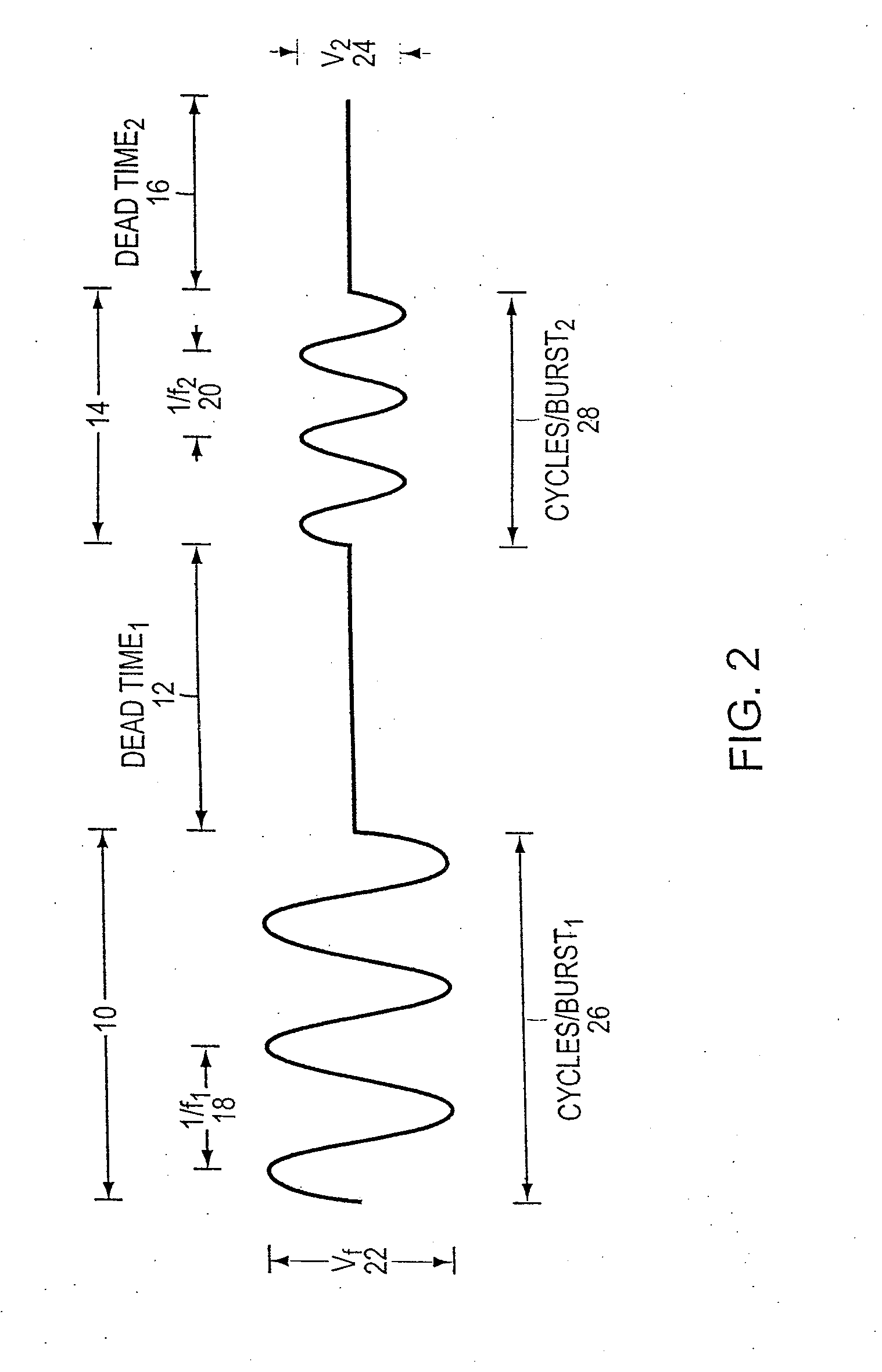

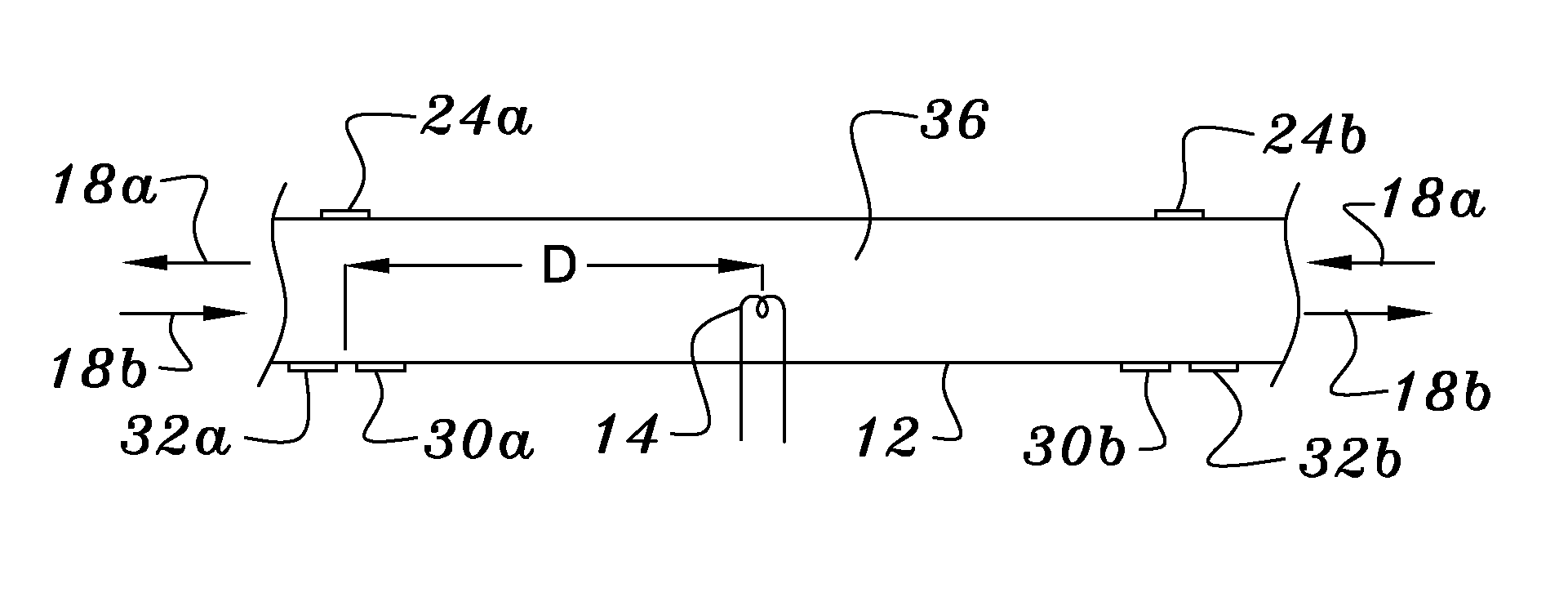

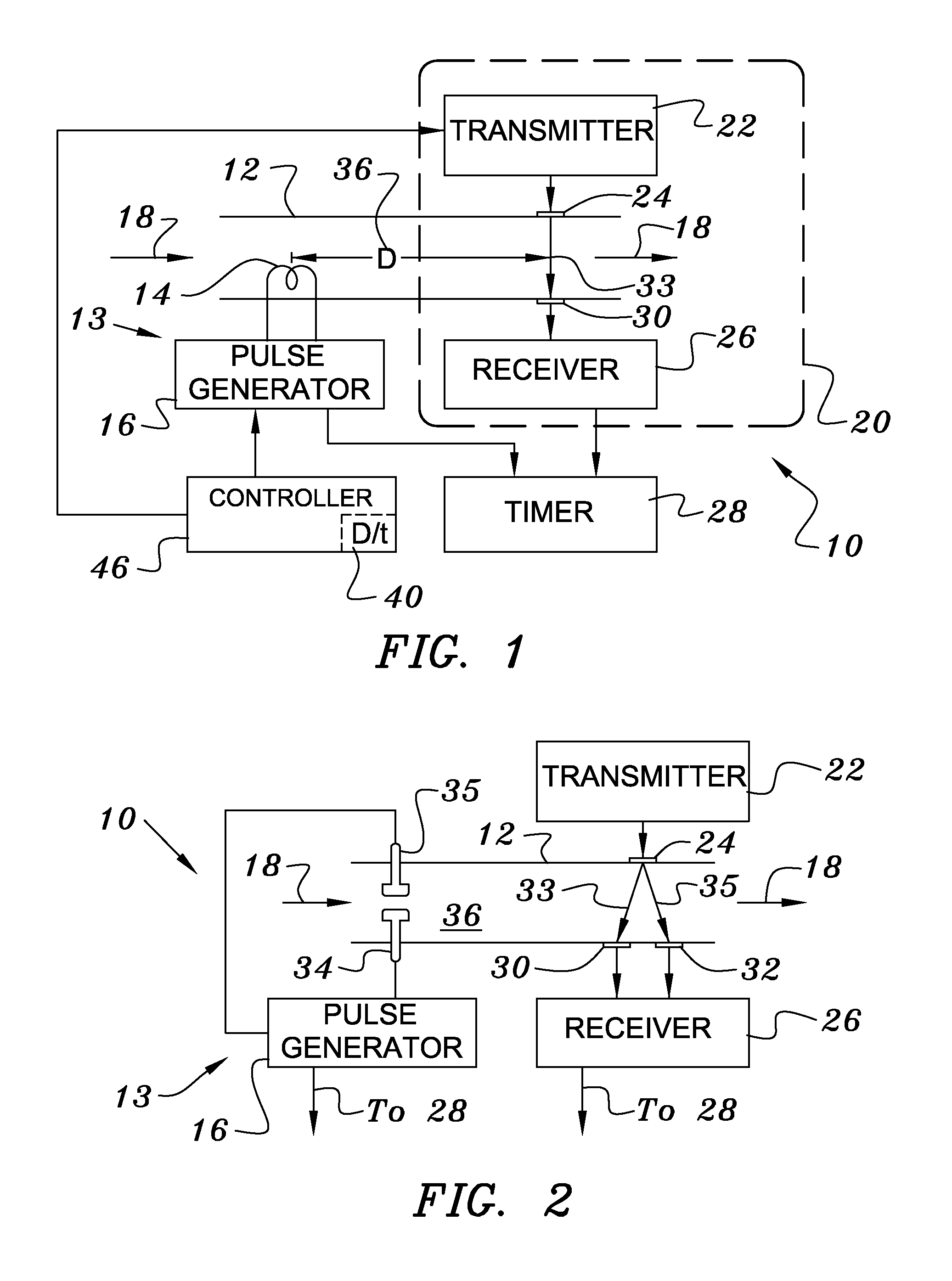

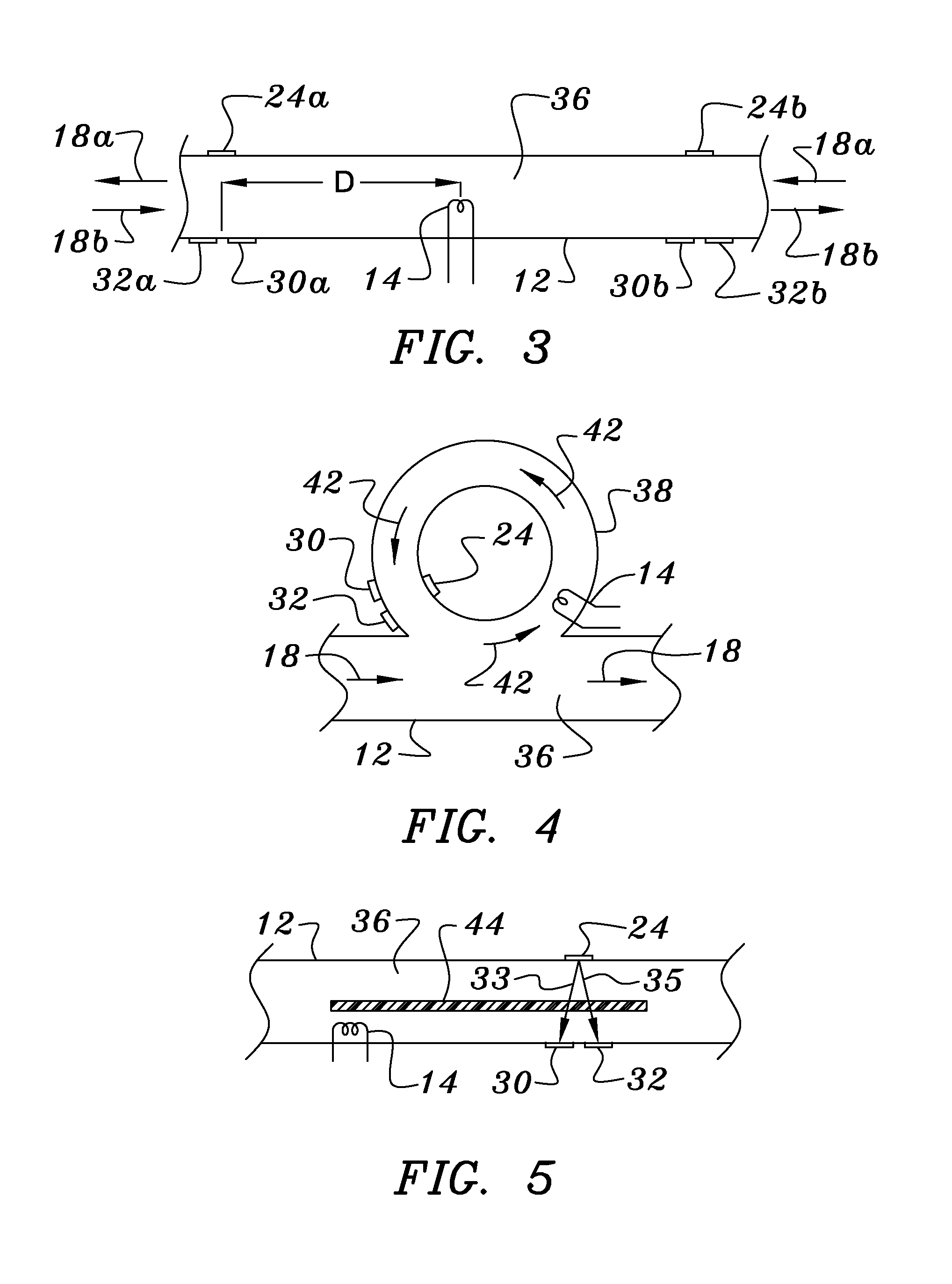

Thermal pulsed ultrasonic flow sensor

InactiveUS7270015B1Practical size limitationSmall sizeVolume/mass flow measurementDiagnostic recording/measuringAcoustic transmissionTransducer

In thermal pulse flow measurements a relatively small bolus of flowing fluid is heated or cooled and the time required for the bolus to move downstream a known distance is measured. In many fluids, changing the temperature changes the acoustic transmission properties of the bolus from those of the rest of the fluid, so the bolus can be detected when it intersects an acoustic beam. The use of an acoustic beam or beams, which are usually defined between acoustic transmitting receiving transducers, typically provides a high frequency carrier which is modulated by the change in acoustic properties of the bolus when it passes between the two transducers. When compared to conventional thermal measurements, this acoustic approach provides faster response times and can thus be used for measuring higher flow rates.

Owner:ONICON INC

Method and apparatus for acoustically controlling liquid solutions in microfluidic devices

InactiveUS20060029525A1Increase fluid velocityAchieved mixedSequential/parallel process reactionsShaking/oscillating/vibrating mixersSound sourcesAcoustic energy

Acoustic energy is used to control motion in a fluid. According to one embodiment, the invention directs acoustic energy at selected naturally occurring nucleation features to control motion in the fluid. In another embodiment, the invention provides focussed or unfocussed acoustic energy to selectively placed nucleation features to control fluid motion. According to one embodiment, the invention includes an acoustic source, a controller for controlling operation of the acoustic source, and one or more nucleation features located proximate to or in the fluid to be controlled.

Owner:COVARIS INC

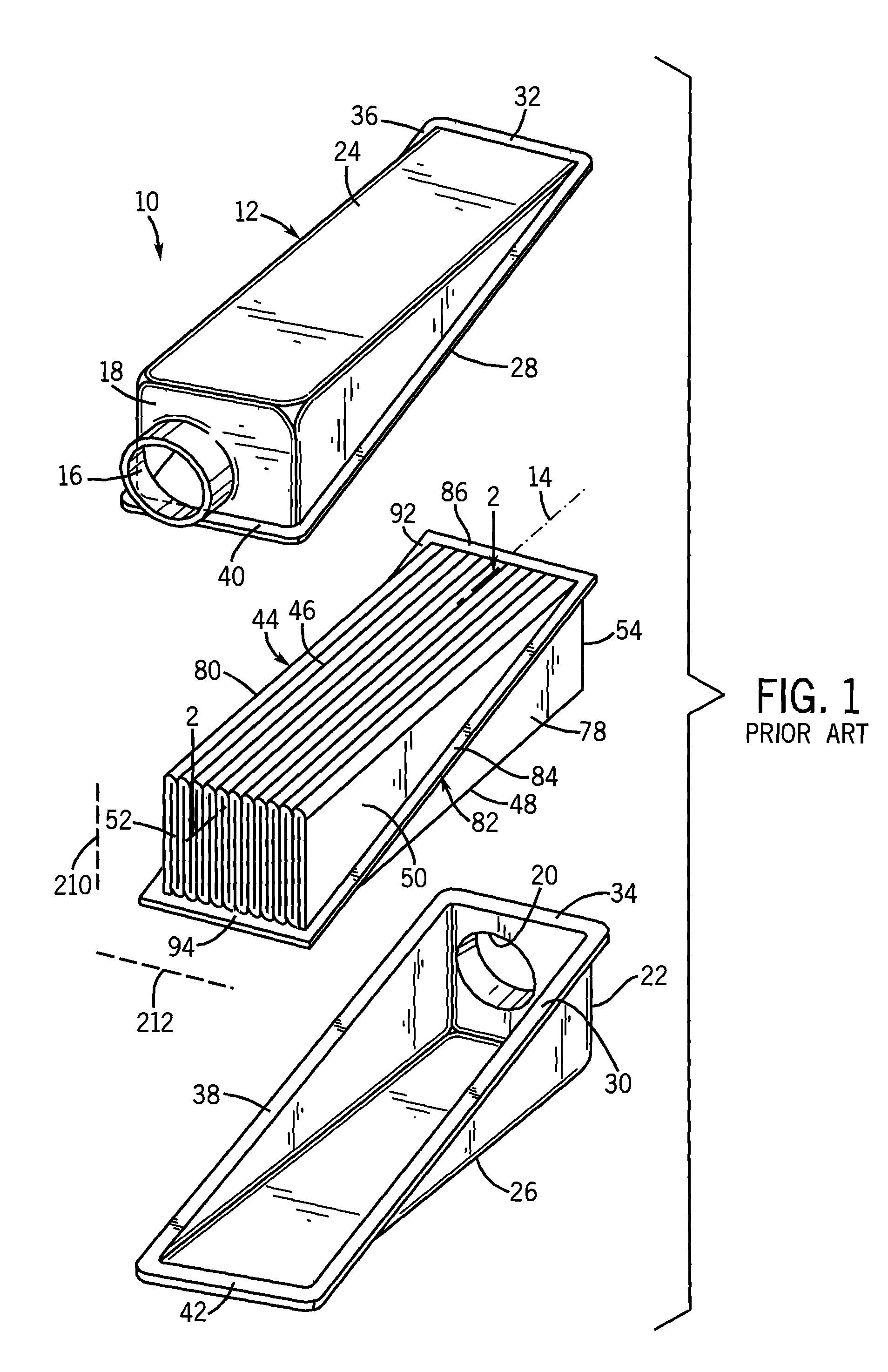

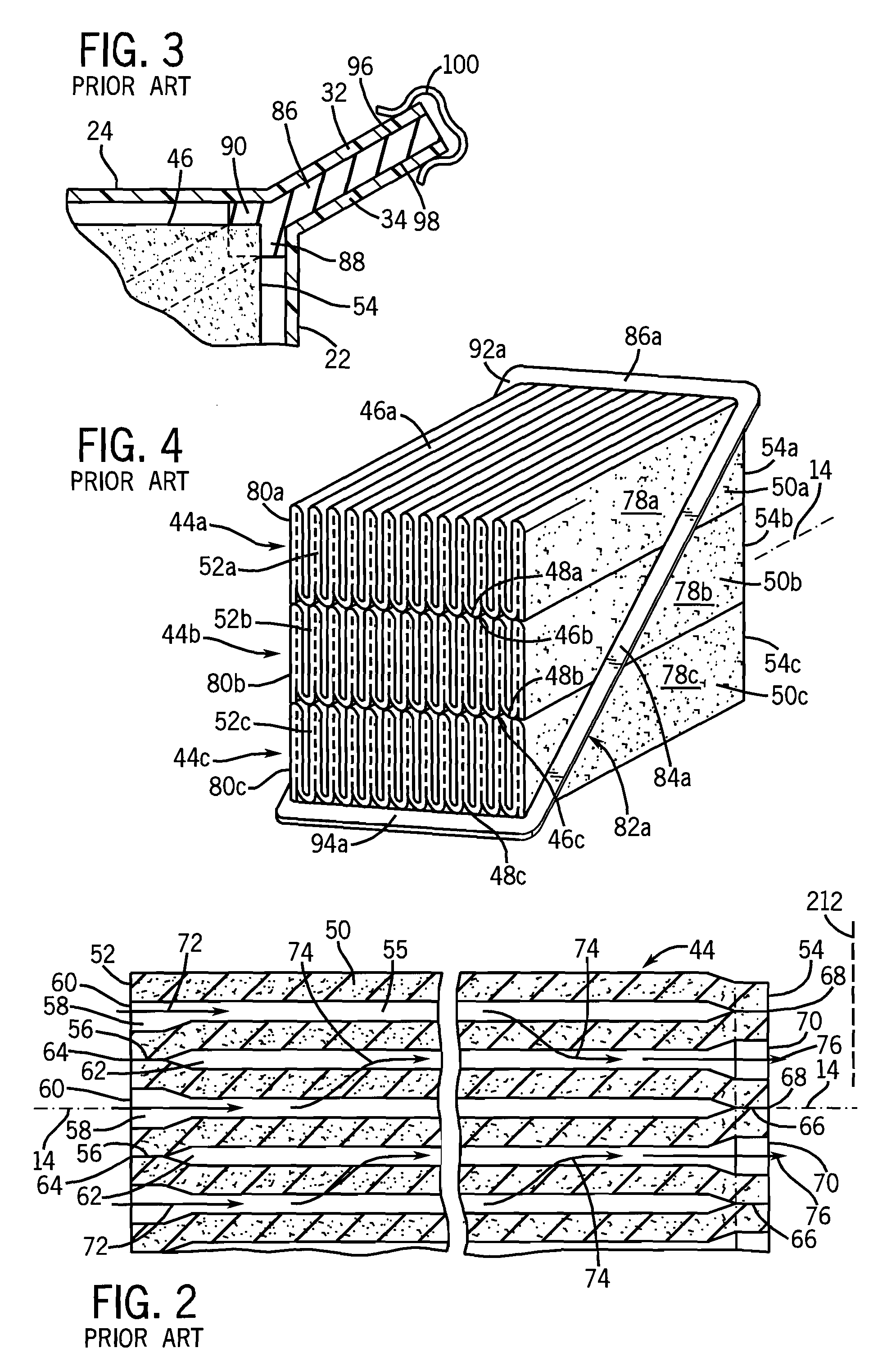

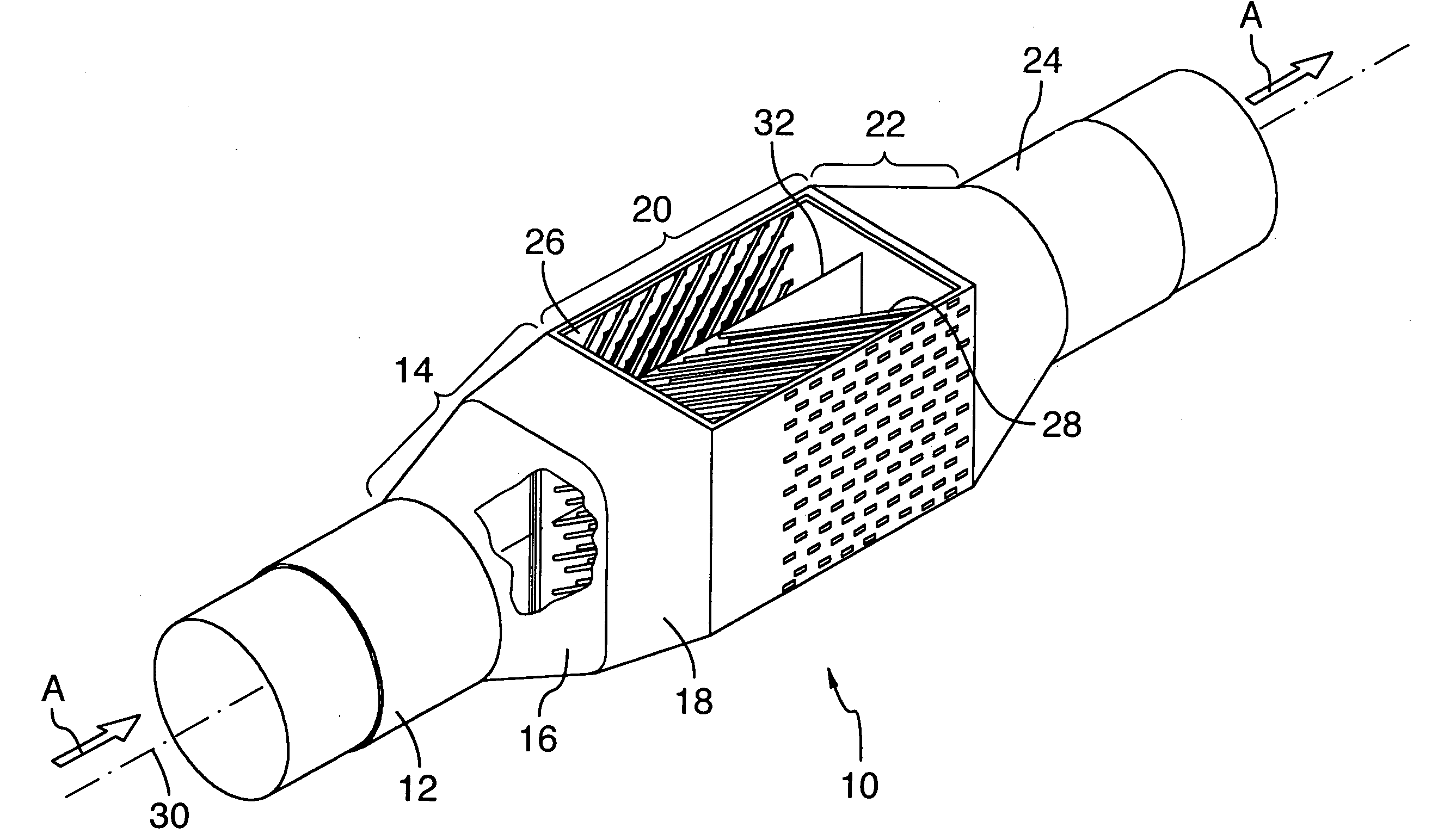

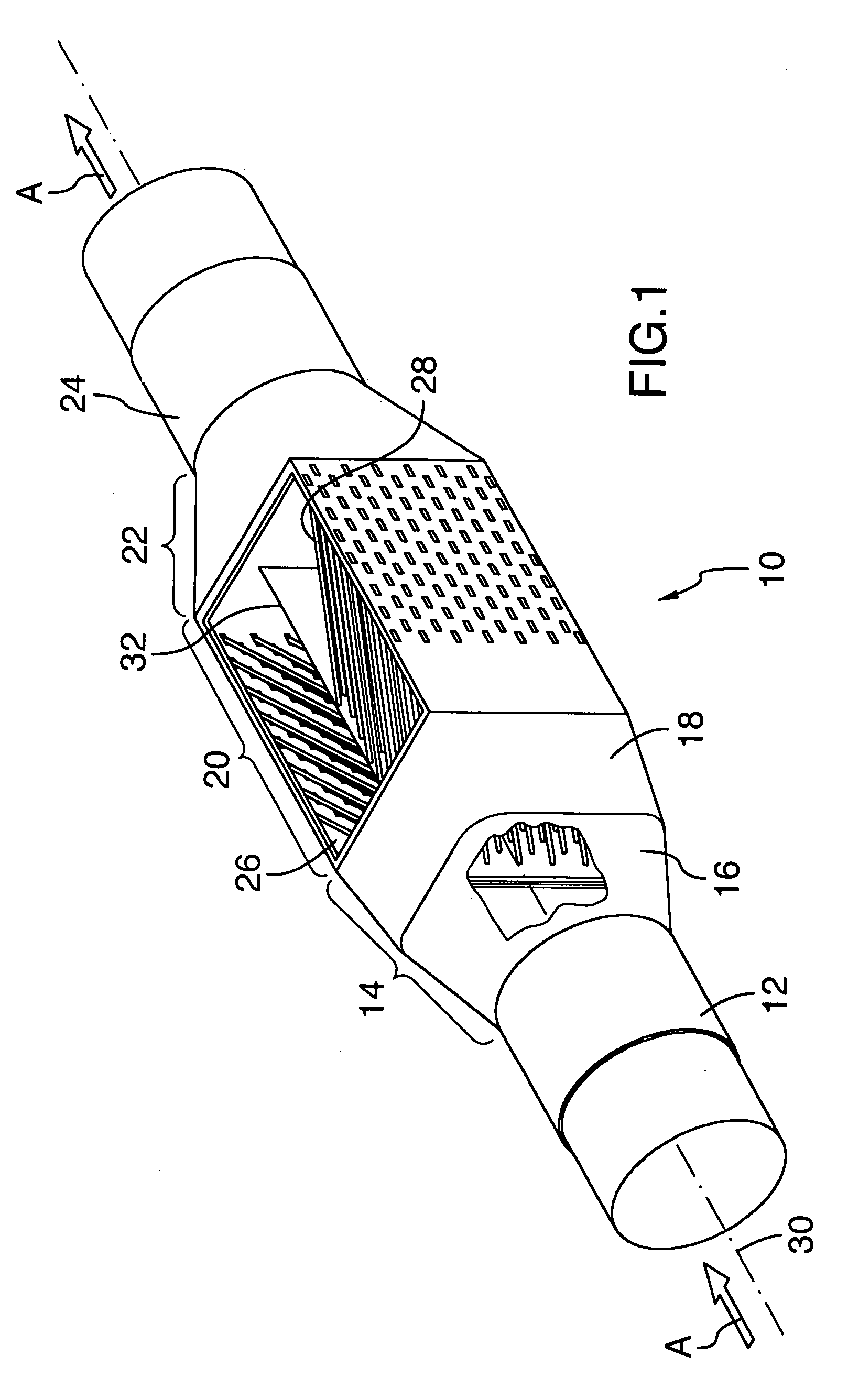

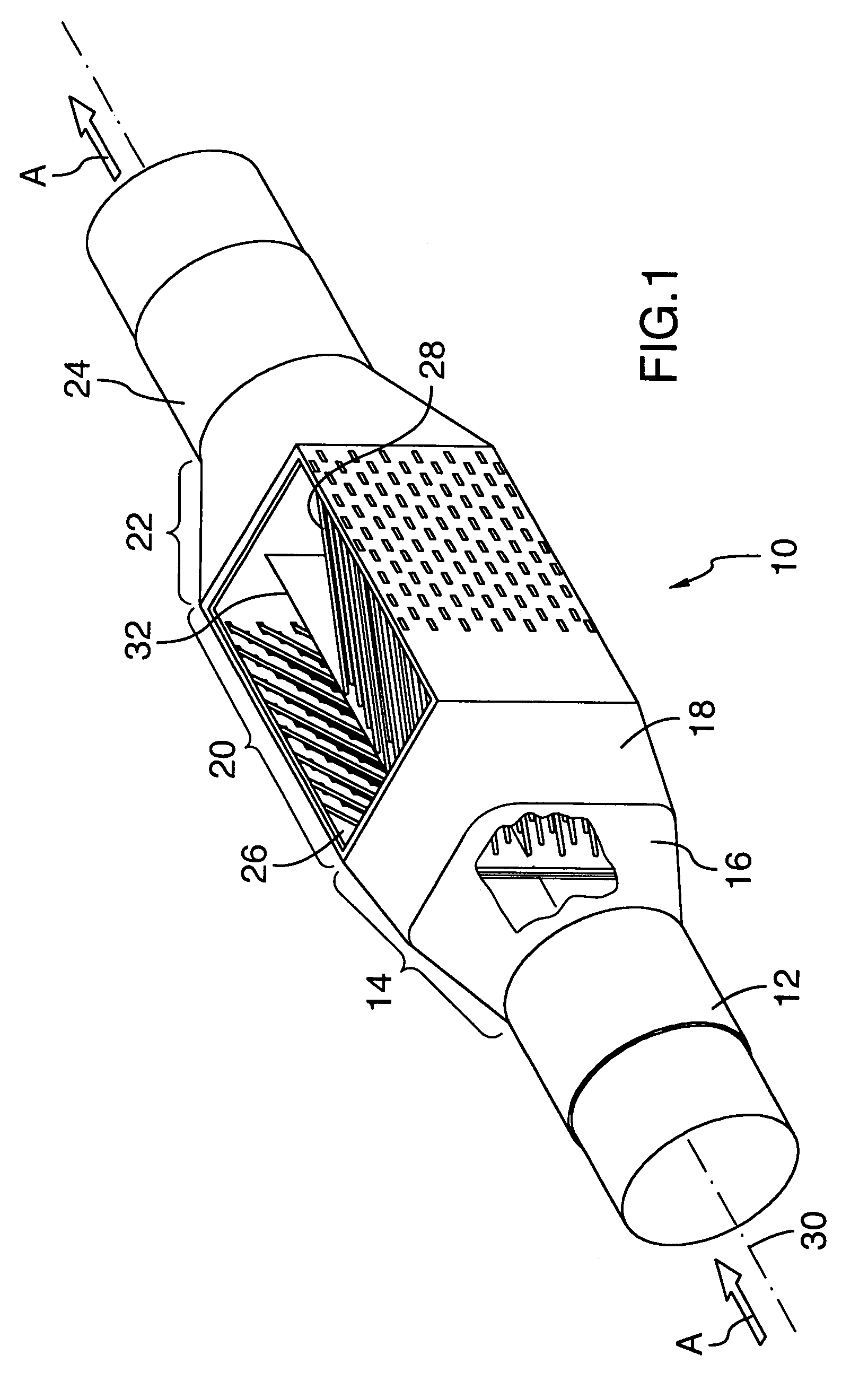

Pleated panel fluid filter

InactiveUS7314558B1Maximize useReduce filter sizeCombination devicesDispersed particle filtrationEngineeringChannel width

A pleated panel fluid filter filters fluid flowing along an axial flow direction and includes angled panels and / or progressively increasing flow channel width and / or skewed panel projections and / or flattened pleat tip bend lines.

Owner:CUMMINS FILTRATION INC

Illuminated infusion cannula

ActiveUS20070179430A1Increase flow rateHigh light transmittanceElectrotherapyEye surgeryFiberTransmittance

A transparent illuminated infusion cannula is provided for illuminating an area during eye surgery. An optical fiber may be spaced a certain distance away from the cannula such that fluid flow around the distal end of the fiber and into the transparent cannula may occur with a much higher flow rate than what had previously been possible. The fiber cannula airspace may be optimized so that the cross-sectional area of the fluid conduit remains substantially constant in order to achieve a best compromise between high light transmittance and high fluid flow rate.

Owner:ALCON INC

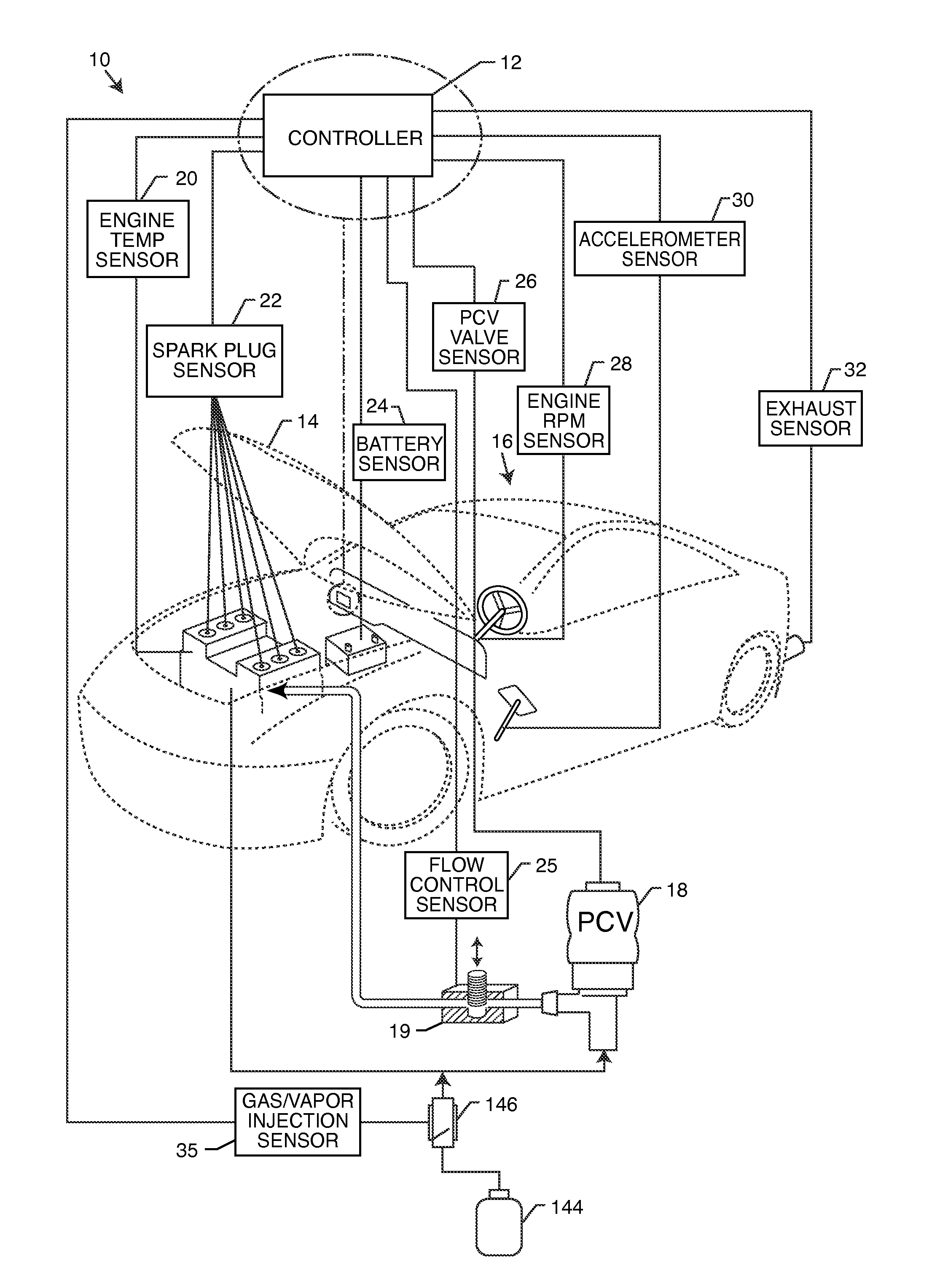

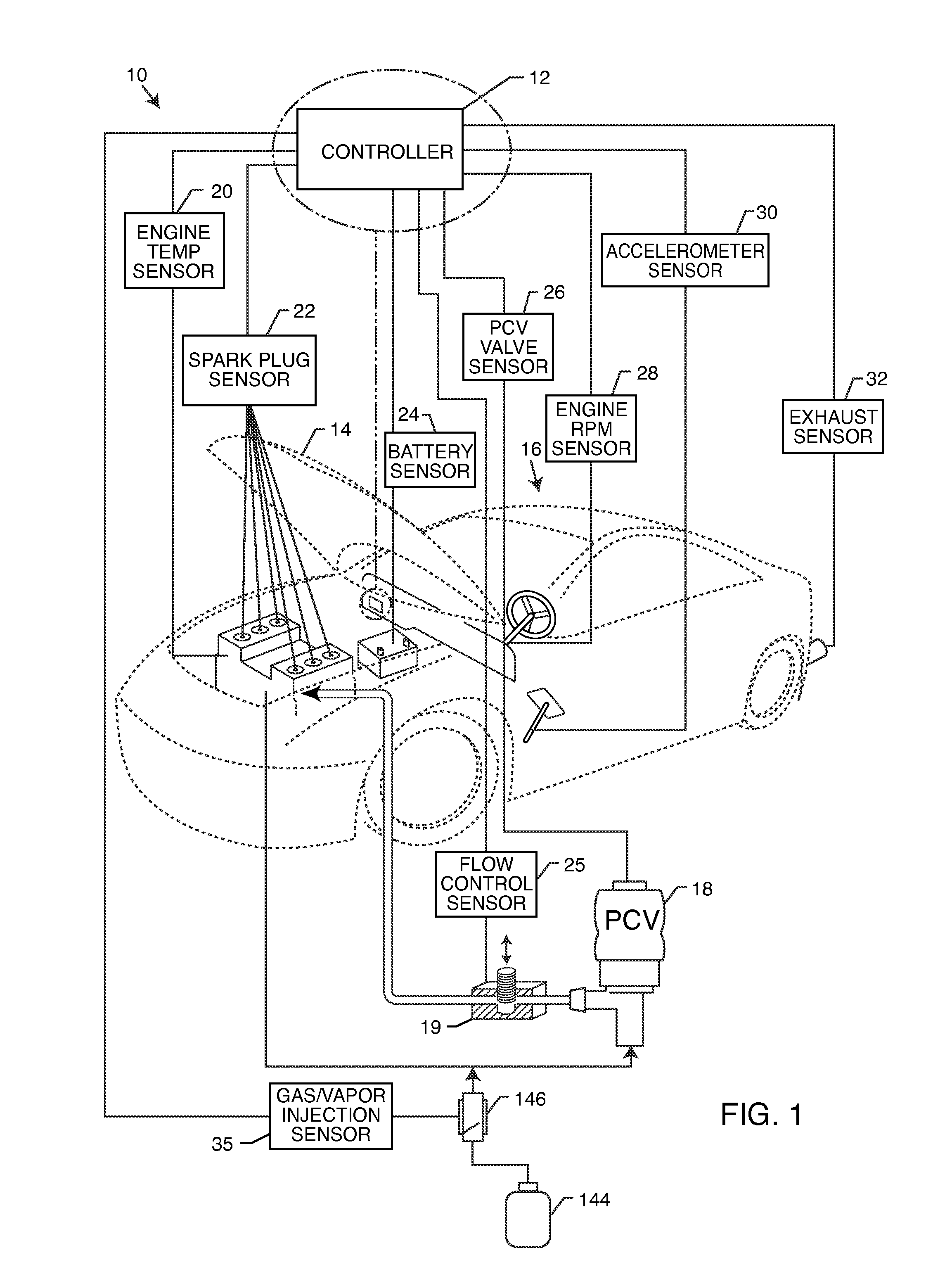

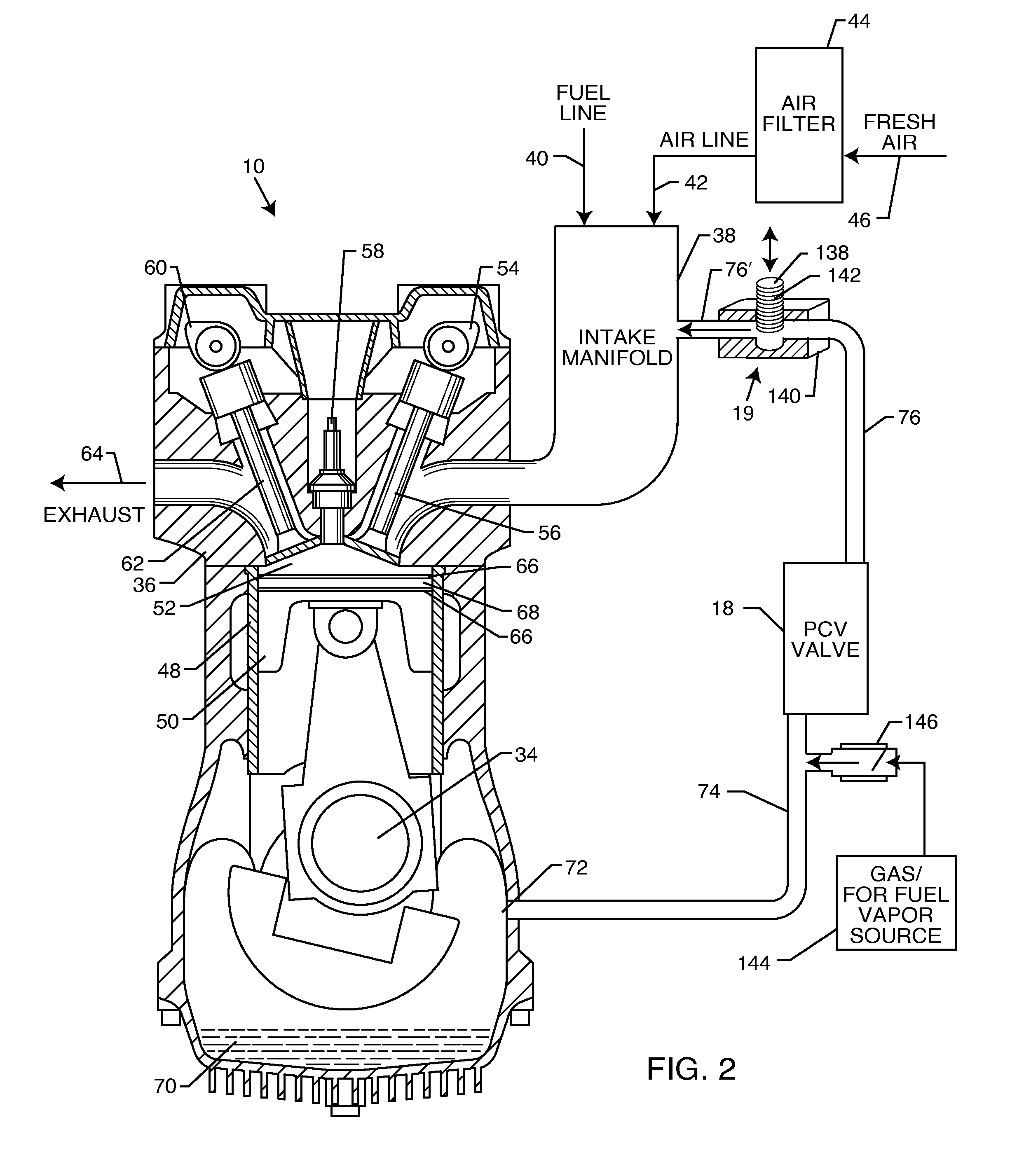

Pollution control system

ActiveUS20100076664A1Reduce fluid flow rateIncrease fluid velocityAnalogue computers for vehiclesInternal combustion piston enginesVacuum pressureCombustion

The pollution control system includes a controller coupled to a sensor monitoring an operational characteristic of a combustion engine, such as engine RPM. A PCV valve having an inlet and an outlet is adapted to vent blow-by gas out from the combustion engine. A fluid regulator associated with the PCV valve and responsive to the controller selectively modulates engine vacuum pressure to adjustably increase or decrease a fluid flow rate of blow-by gas venting from the combustion engine. The controller selectively adjustably positions the fluid regulator to vary the degree of vacuum pressure to optimize the recycling of blow-by gases.

Owner:SVMTECH

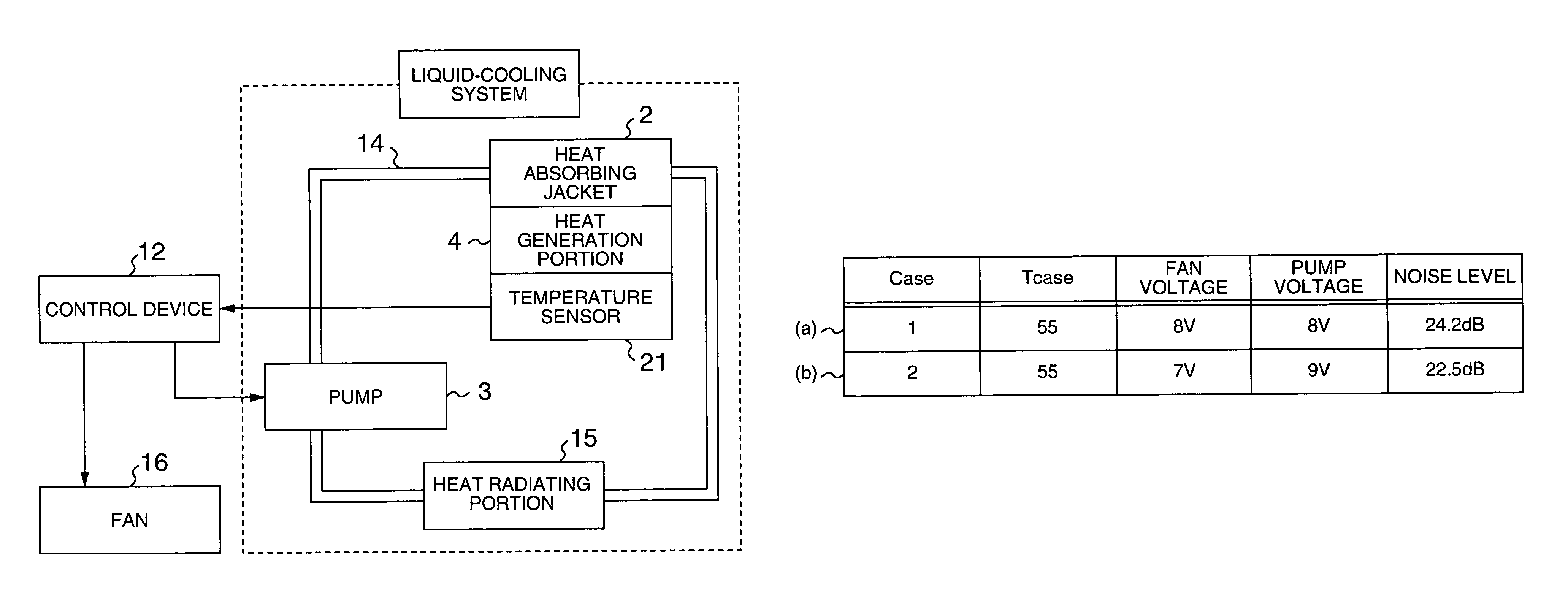

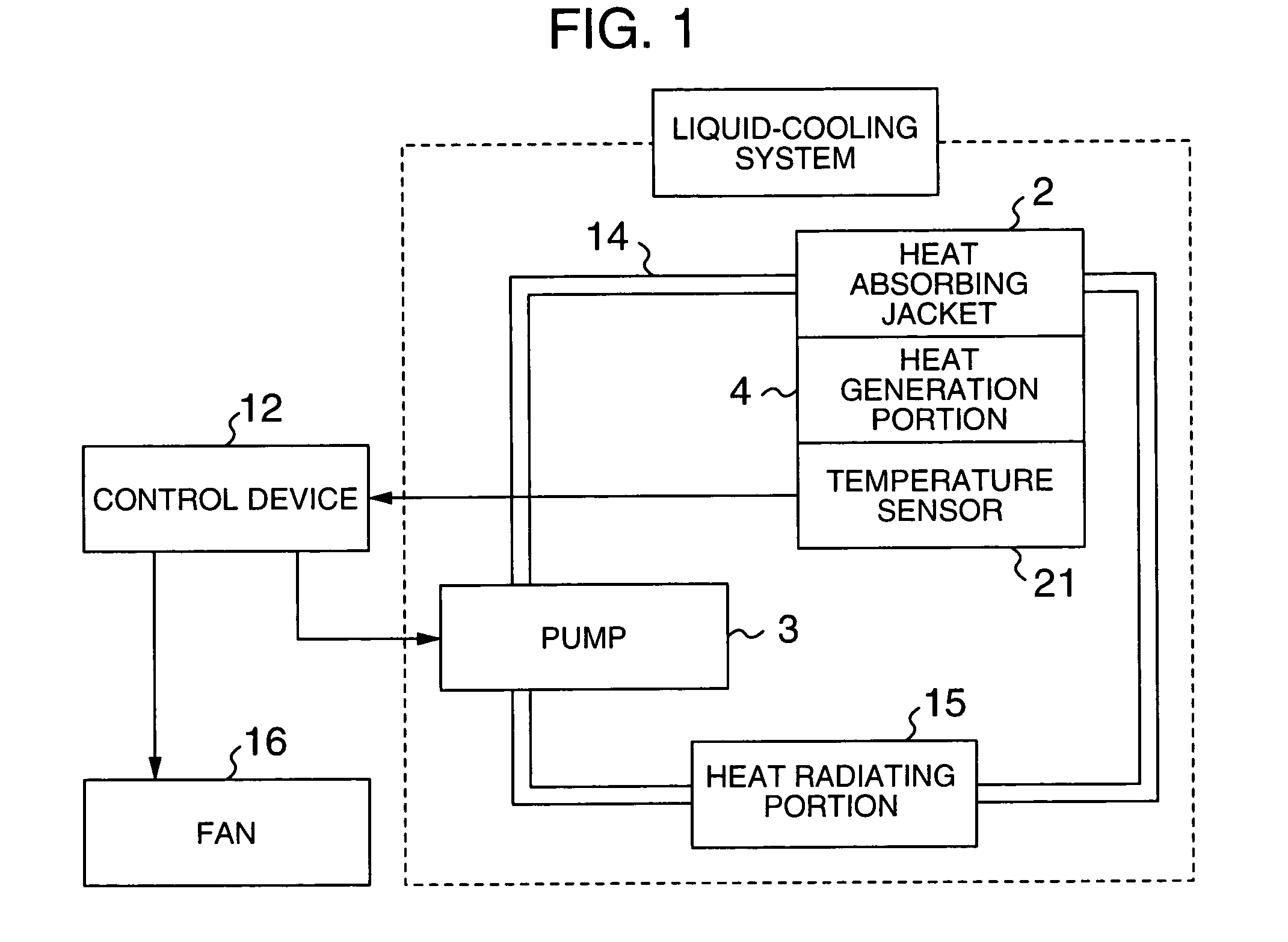

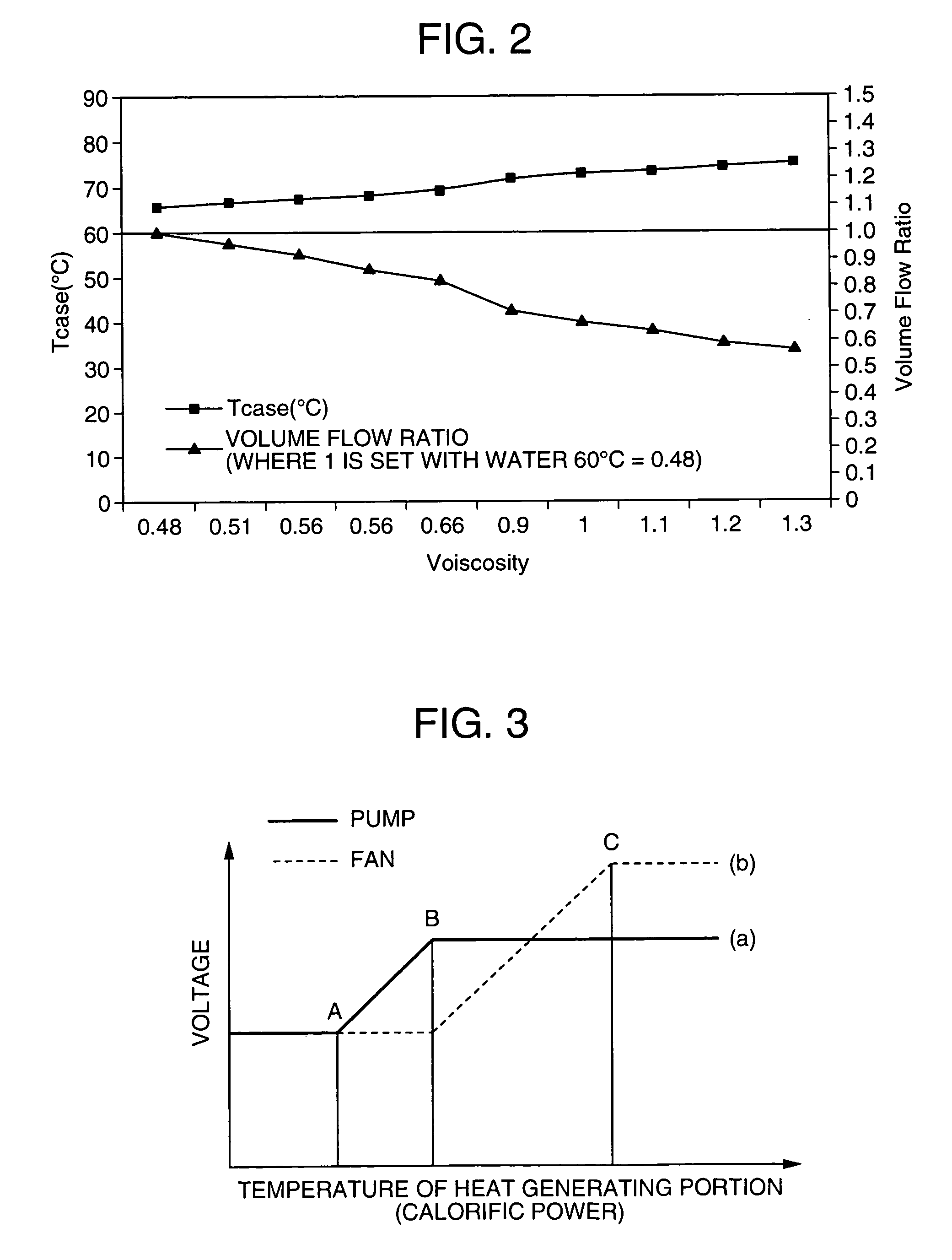

Electronic equipment provided with cooling system

ActiveUS7455103B2Large heat transmitting capacityReduce noiseTemperatue controlHeat storage plantsLiquid cooling systemEngineering

An electronic equipment is provided, which comprises a liquid-cooling system and a cooling fan as a cooling system, efficiently cools the liquid-cooling system, and reduces fan noise. The electronic equipment is provided with a liquid-cooling system, in which heat generated in a heat generating portion is transmitted to a heat radiating portion with a liquid as a medium to achieve cooling, and an air-cooling system, in which heat transmitted to the heat radiating portion is forcedly cooled, and comprises a pump that circulates the liquid between the heat generating portion and the heat radiating portion, a fan that forcedly discharges heat of the heat radiating portion to an outside, a temperature sensor that detects temperature of the heat generating portion, and storage information that beforehand prescribes the relationship between temperature of the heat generating portion and voltages of the pump and the fan, the electronic equipment being constructed such that a pump voltage is raised without changing a fan voltage when the detected temperature exceeds a first temperature, and a fan voltage is raised when temperature detected by the temperature sensor exceeds a second temperature higher than the first temperature, thus further increasing a cooling capacity.

Owner:MAXELL HLDG LTD

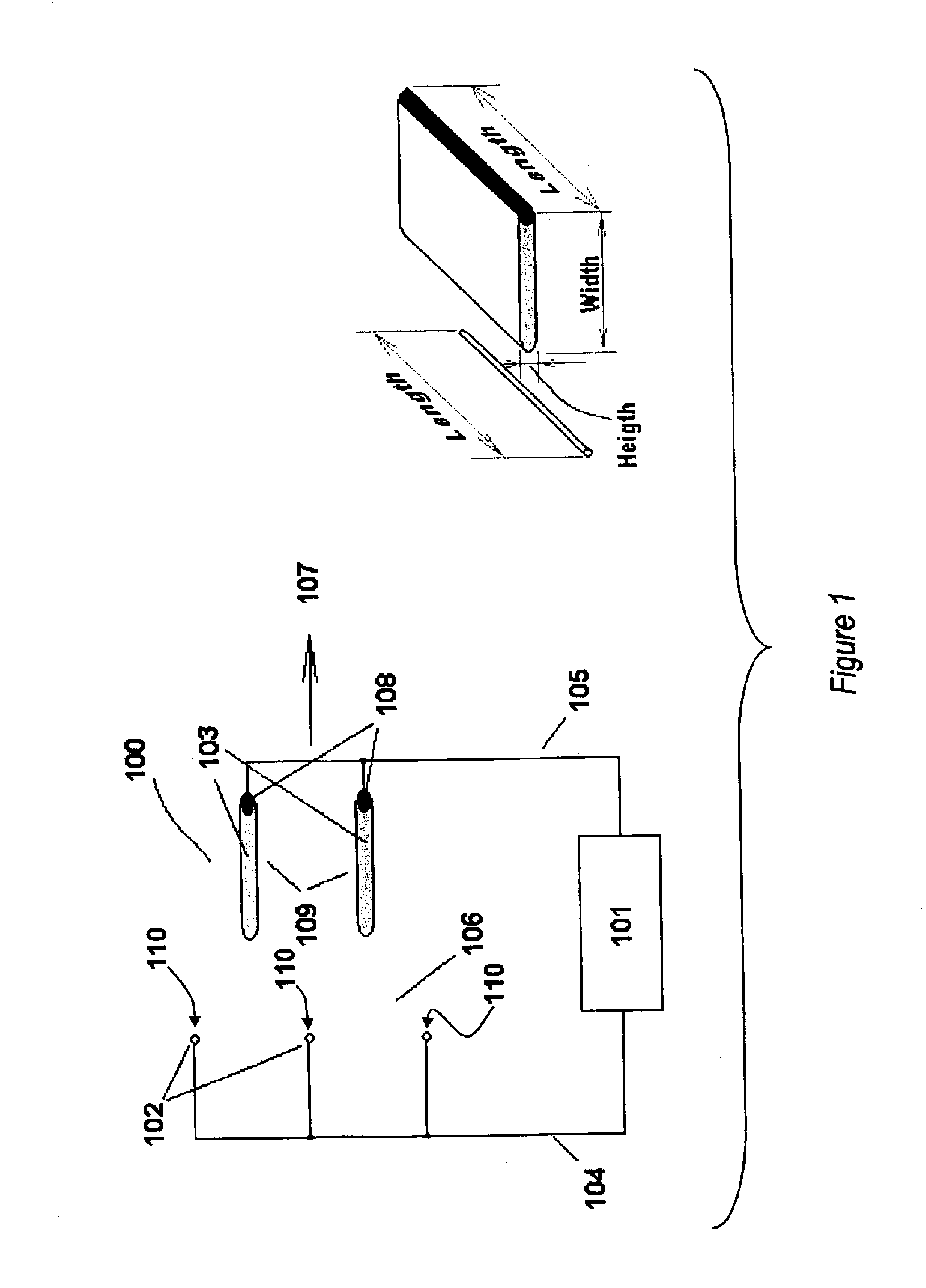

Electrostatic fluid accelerator for and method of controlling a fluid flow

InactiveUS6919698B2Increase electrode densityReduce fluid resistanceTransit-time tubesOzone preparationHigh intensityElectric field

An electrostatic fluid accelerator includes a first number of corona electrodes and a second number of accelerating electrodes spaced apart from and parallel to adjacent ones of the corona electrodes. An electrical power source is connected to supply the corona and accelerating electrodes with an operating voltage to produce a high intensity electric field in an inter-electrode space between the corona electrodes and the accelerating electrodes. The accelerating electrodes may be made of a high electrical resistivity material, each of the electrodes having mutually perpendicular length and height dimension oriented transverse to a desired fluid flow direction and a width dimension oriented parallel to the desired fluid flow direction. A length of the electrodes in a direction transverse to a desired fluid flow direction is greater than a width of the electrodes parallel to the fluid flow direction, and the width of the electrodes is at least ten times a height of the electrodes in a direction transverse to both the desired fluid flow direction and to the length.

Owner:TESSERA INC

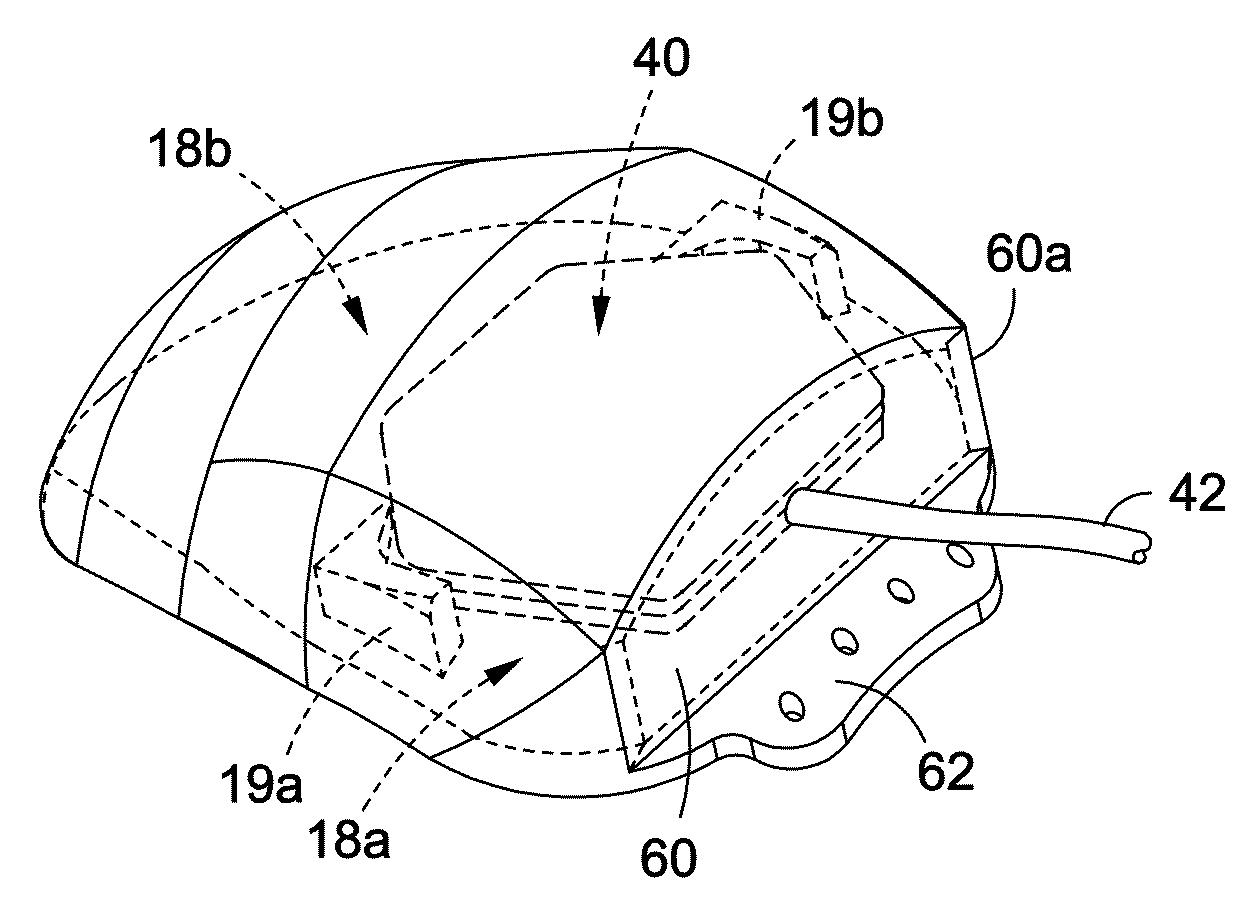

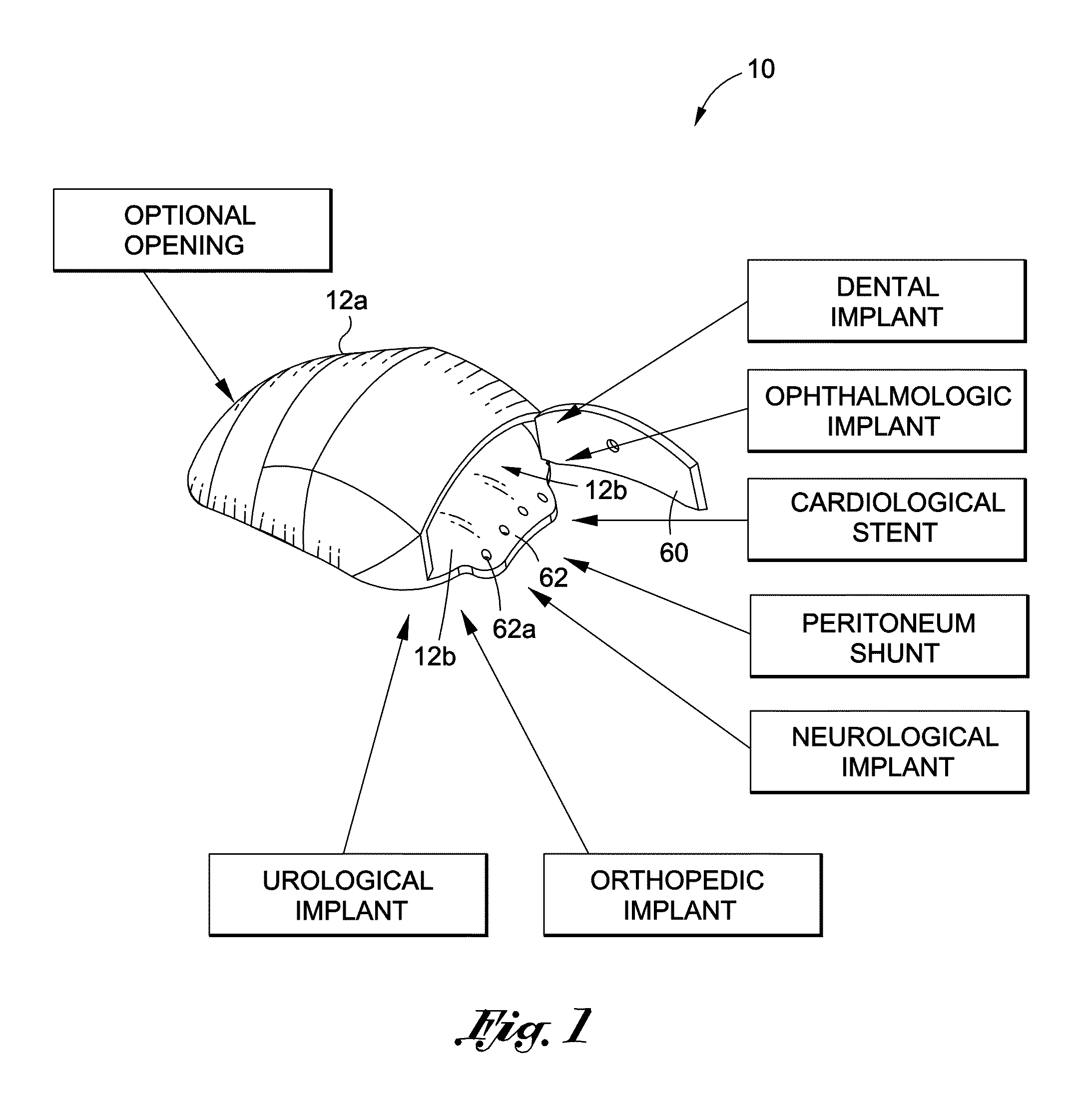

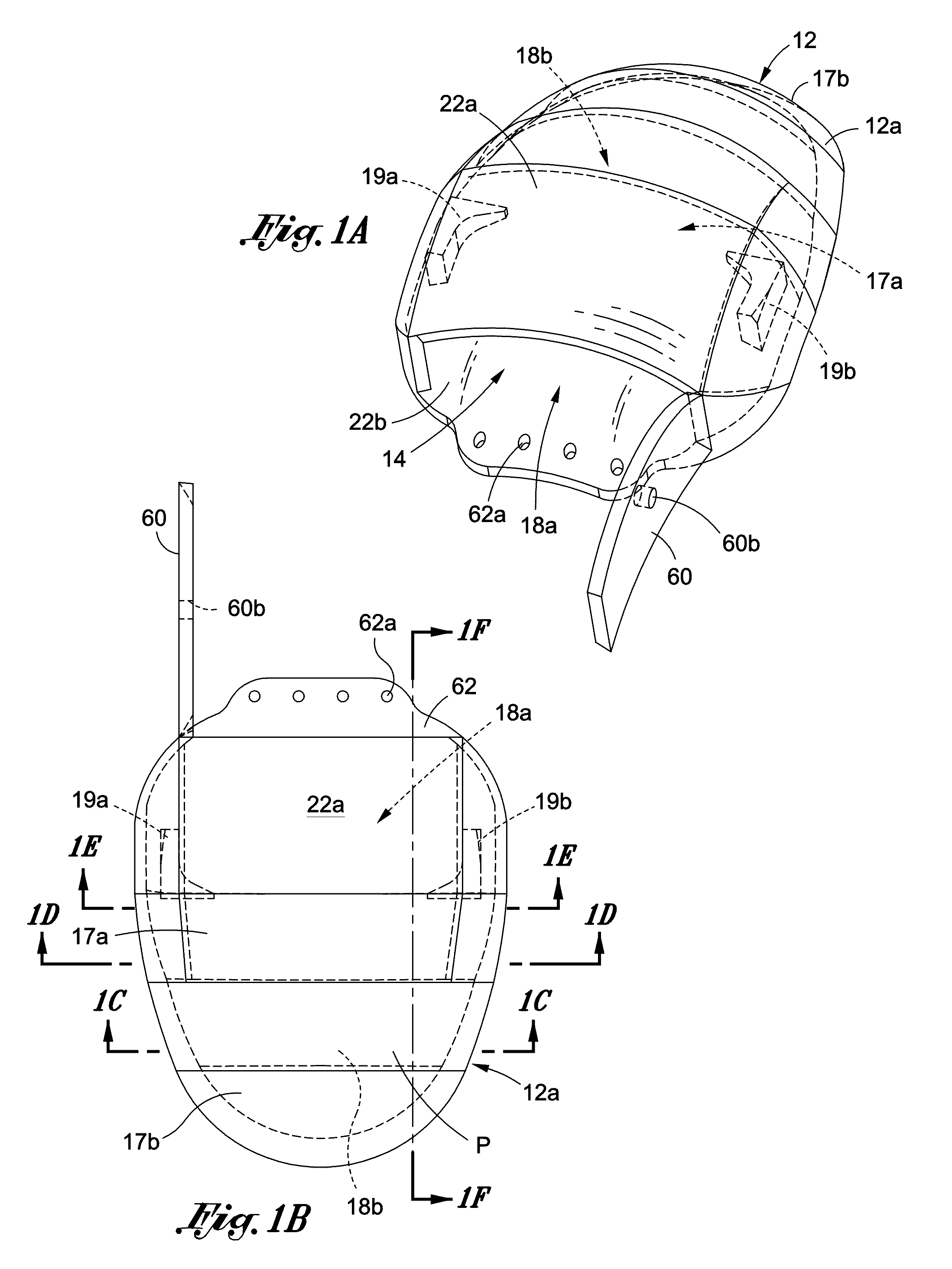

Implantable medical assembly and methods

ActiveUS8632489B1High speedReduce resistanceAdditive manufacturing apparatusEye surgeryBody fluidMedical device

An implantable medical assembly includes a cover having a porous chamber. Enclosed within the chamber is a medical device through which aqueous body fluid flows from an outlet of the device into the chamber. The chamber is formed at least in part from a porous material that promotes vascularization and inhibits fibrotic encapsulation upon implantation and that allows aqueous body fluid in the chamber to flow through the porous material into body tissue in which the assembly is implanted. The chamber has a pair of walls that are spaced apart at a first portion of the chamber at or near the outlet and converge at a second portion of the chamber downstream of the outlet.

Owner:AHMED A MATEEN

Methods and systems for fracturing subterranean wells

ActiveUS7516793B2Improve permeabilityIncrease fluid velocitySurveyFluid removalControl flowAutomatic control

Owner:HALLIBURTON ENERGY SERVICES INC

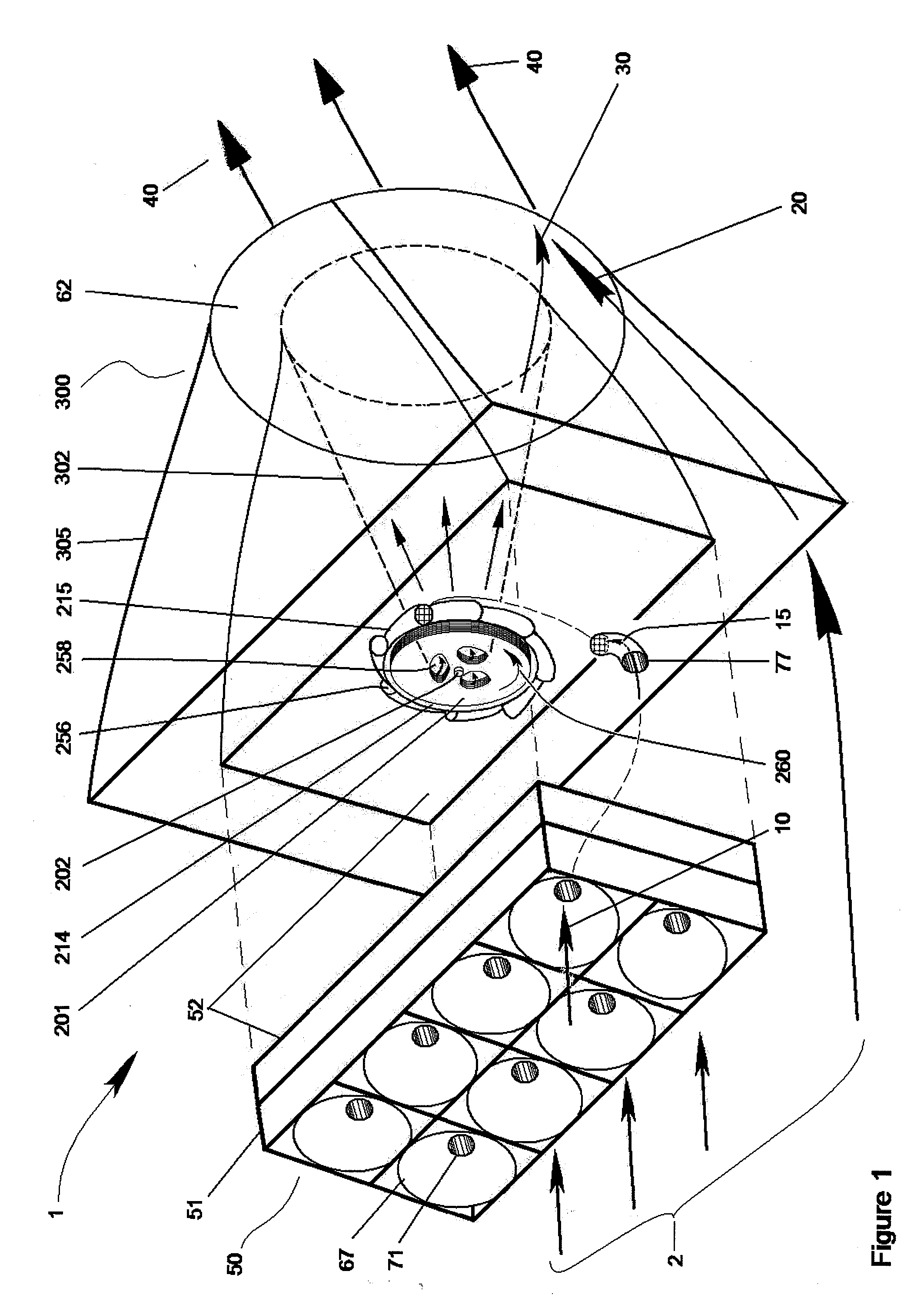

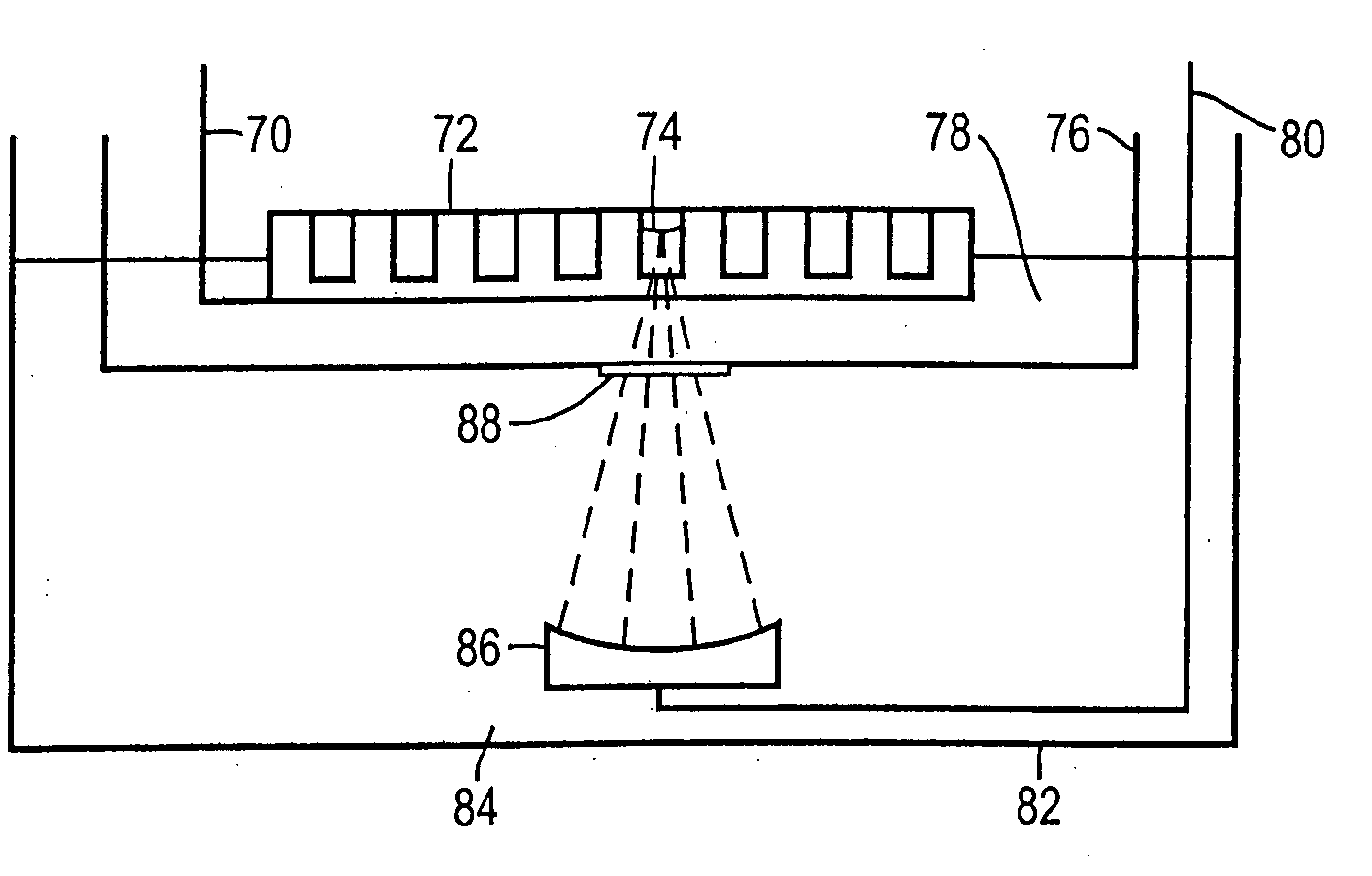

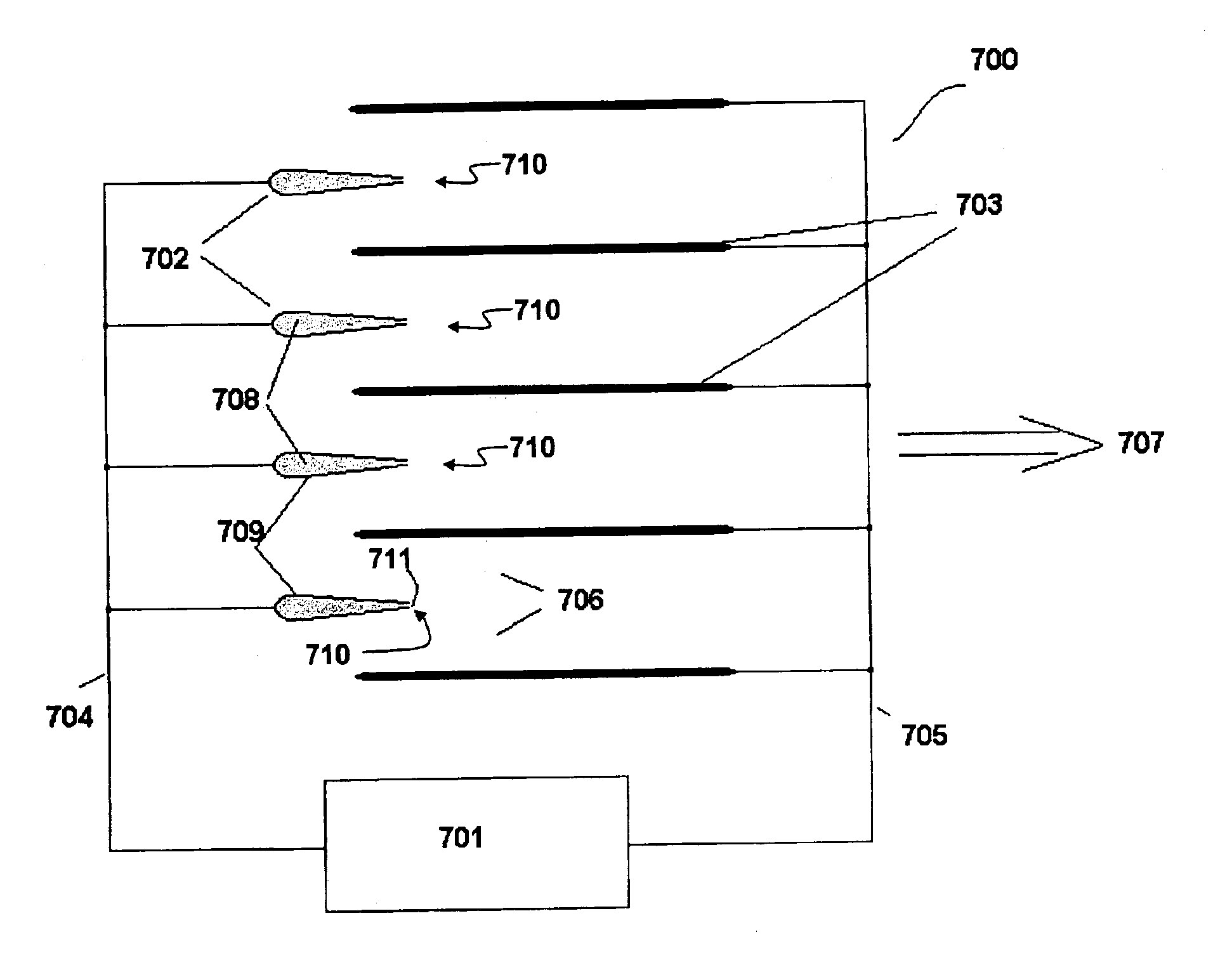

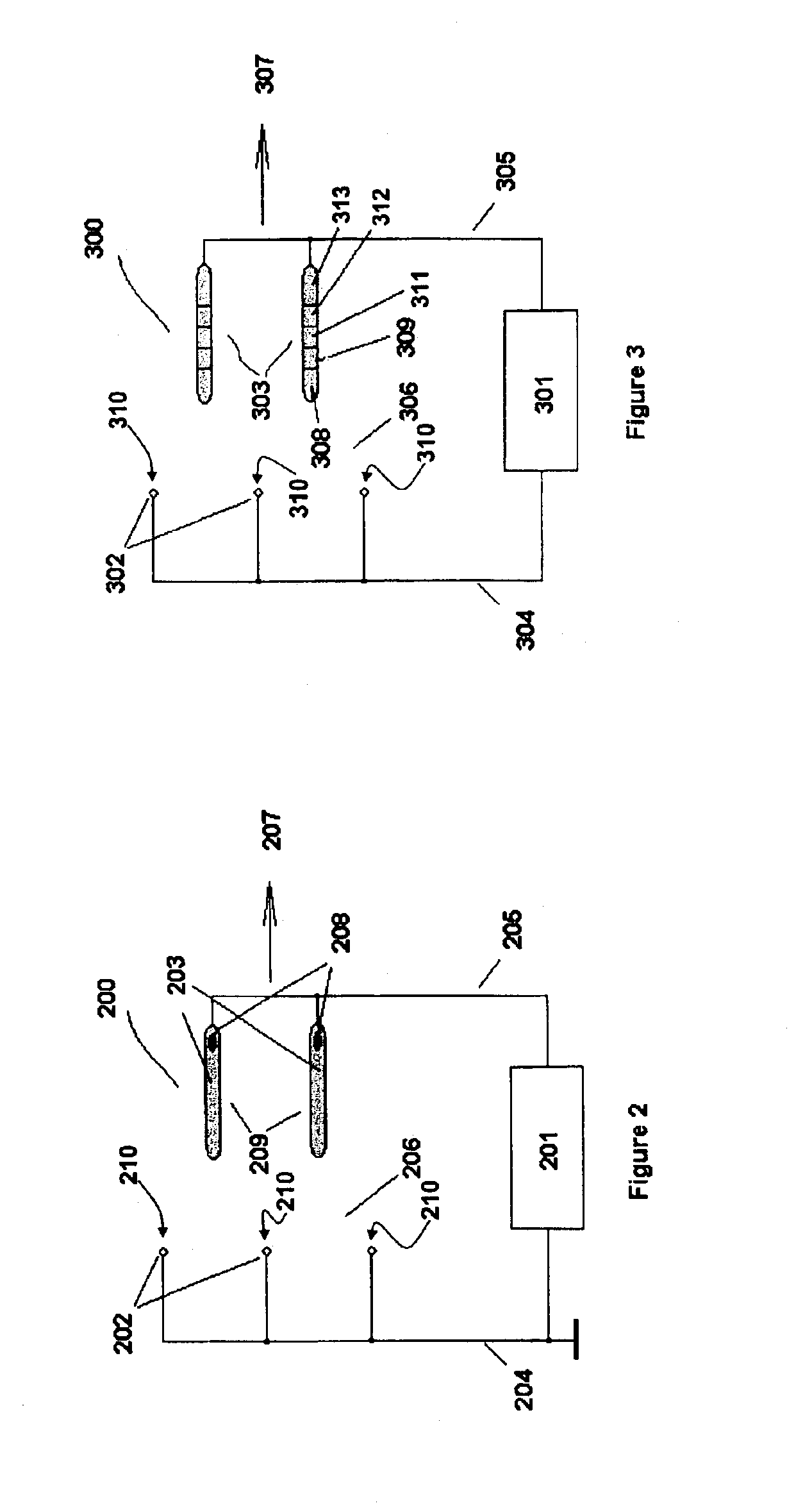

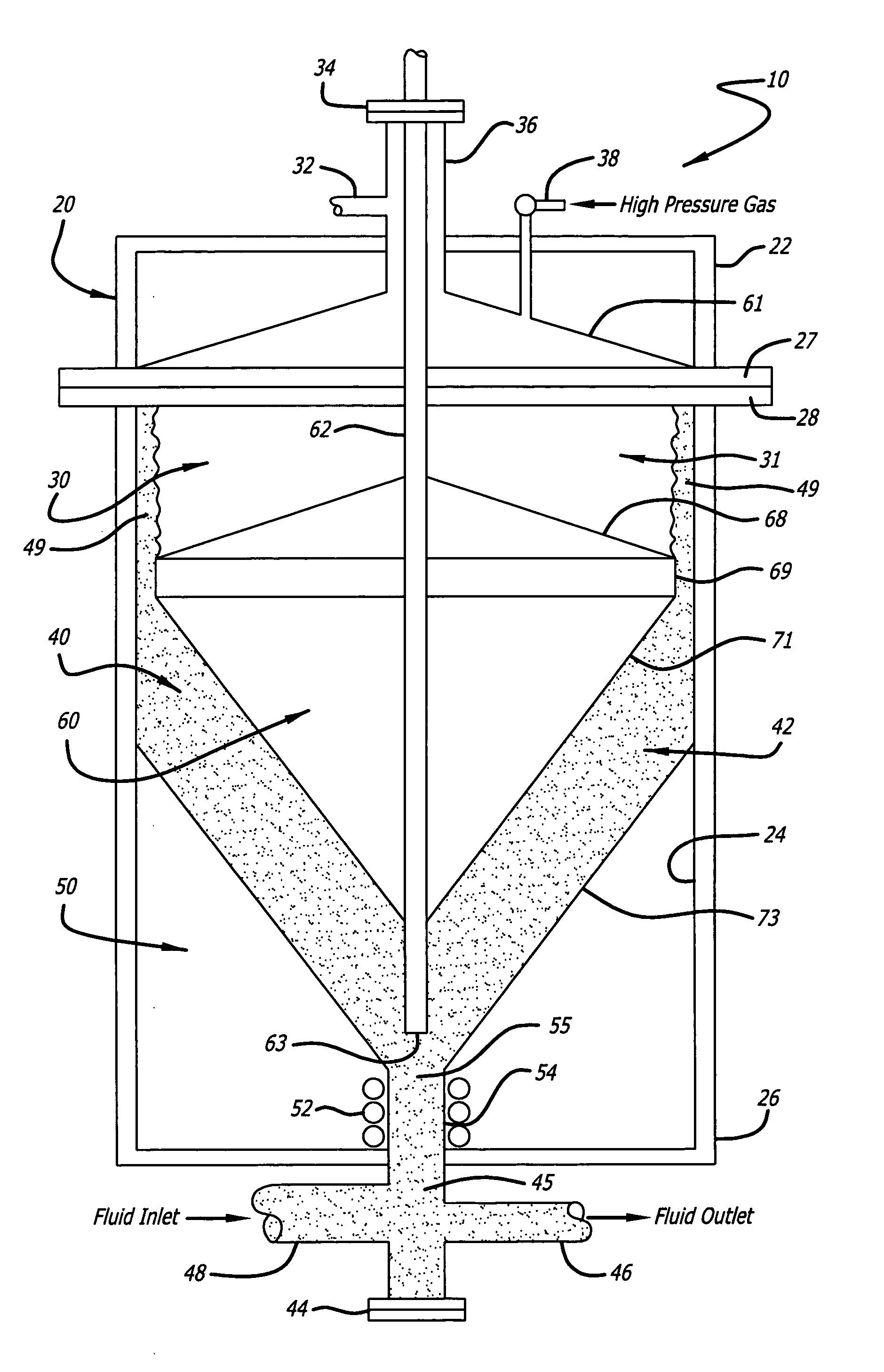

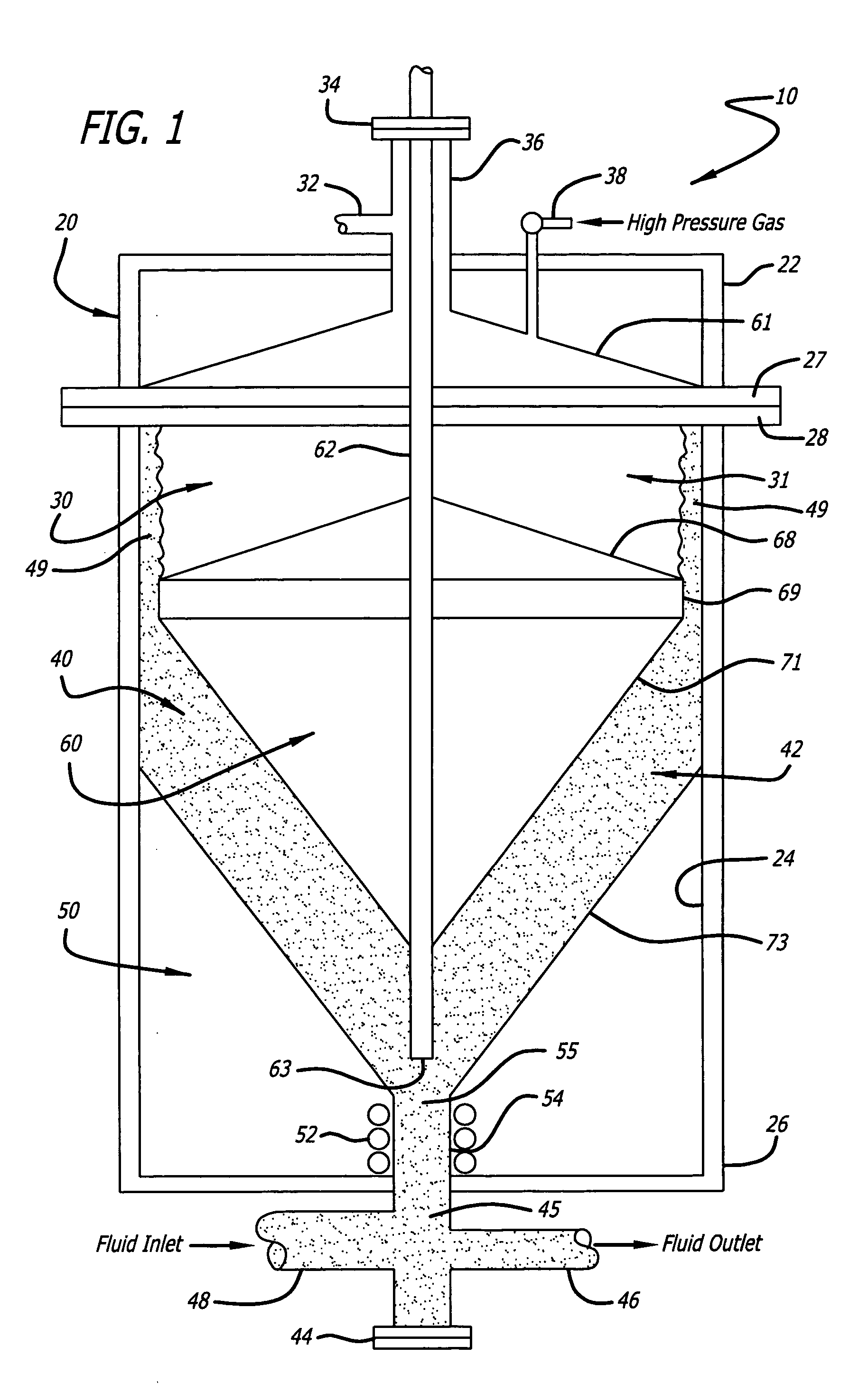

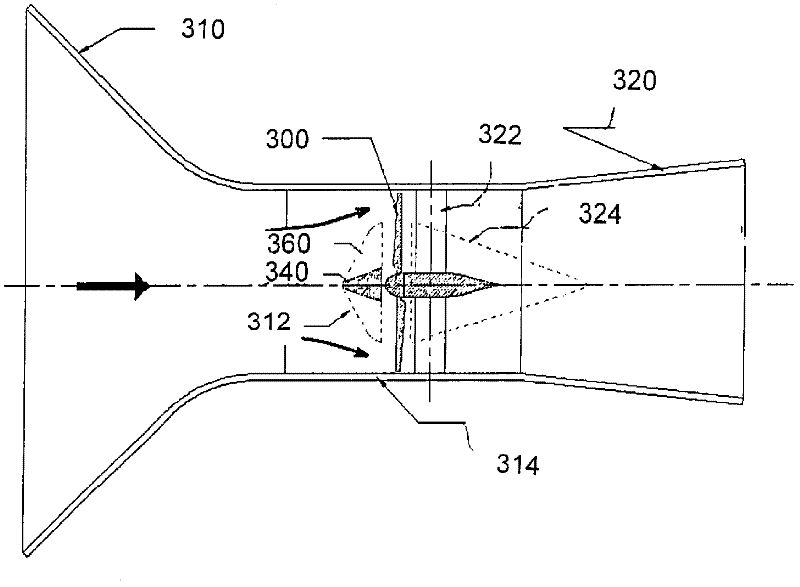

Fluid treatment system

ActiveUS20050263716A1Reducing velocity of fluid flowingIncrease fluid velocityLiquid separation by electricityWater/sewage treatment by irradiationWastewaterForced oscillation

The present invention relates to a fluid treatment system comprising: an inlet; an outlet; and a fluid treatment zone disposed between the inlet and the outlet. The fluid treatment zone has disposed therein: (i) an elongate first radiation source assembly having a first longitudinal axis, and (ii) an elongate second radiation source assembly having a second longitudinal axis. The first longitudinal axis and the second longitudinal axis are non-parallel to each other and to a direction of fluid flow through the fluid treatment zone. The present fluid treatment system has a number of advantages including: it can treat large volumes of fluid (e.g., wastewater, drinking water or the like); it requires a relatively small “footprint”; it results in a relatively lower coefficient of drag resulting in an improved hydraulic pressure loss / gradient over the length of the fluid treatment system; and it results in relatively lower (or no) forced oscillation of the radiation sources thereby obviating or mitigating of breakage of the radiation source and / or protective sleeve (if present). Other advantages are discussed in the specification.

Owner:TROJAN TECH

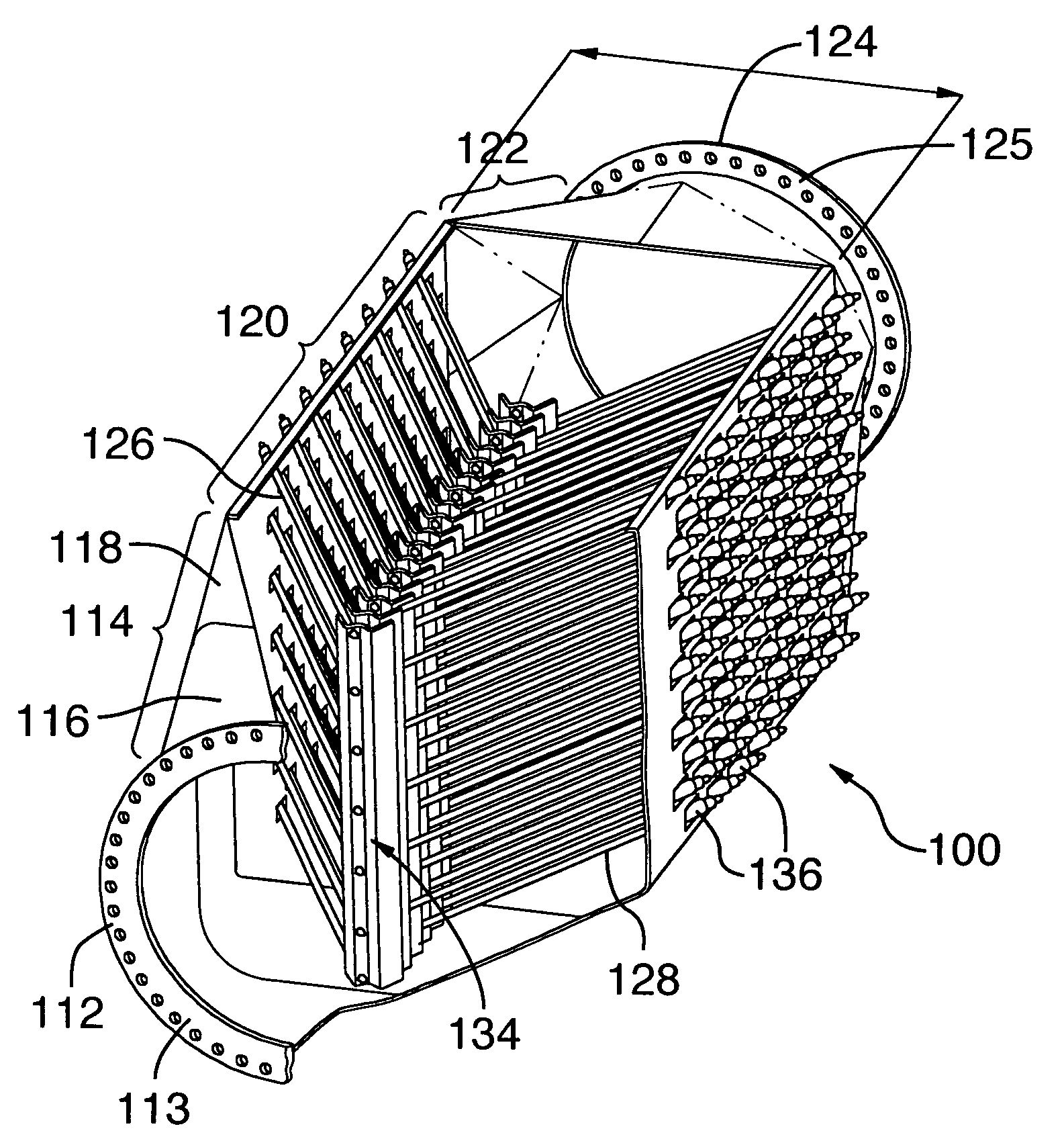

Thermoelectric power generation systems

InactiveUS20080035195A1Renewed interestImprove power densityAir-treating devicesThermoelectric device with peltier/seeback effectEngineeringThermal efficiency

Representative configurations for improved thermoelectric power generation systems to improve and increase thermal efficiency are disclosed.

Owner:GENTHERM INC

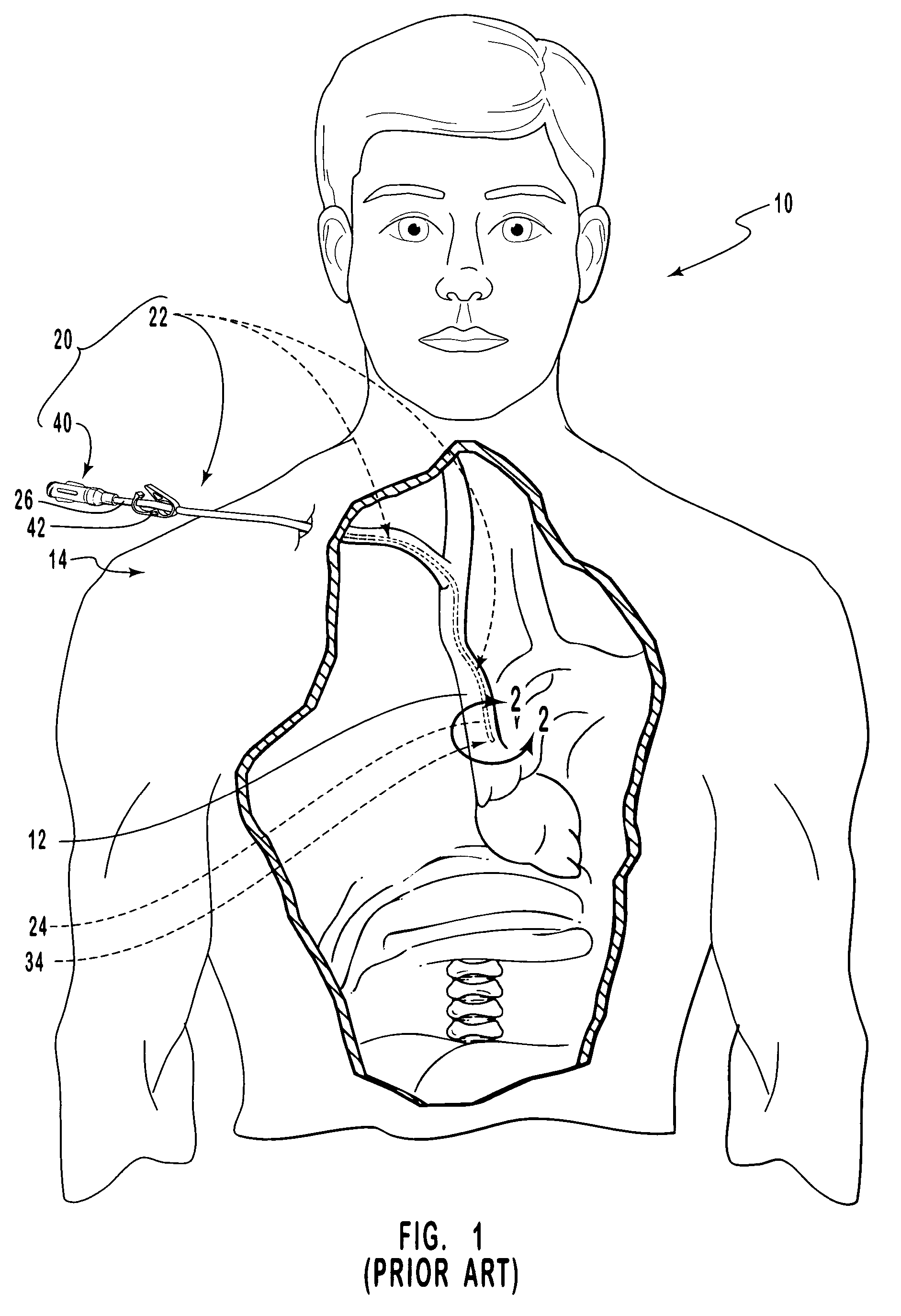

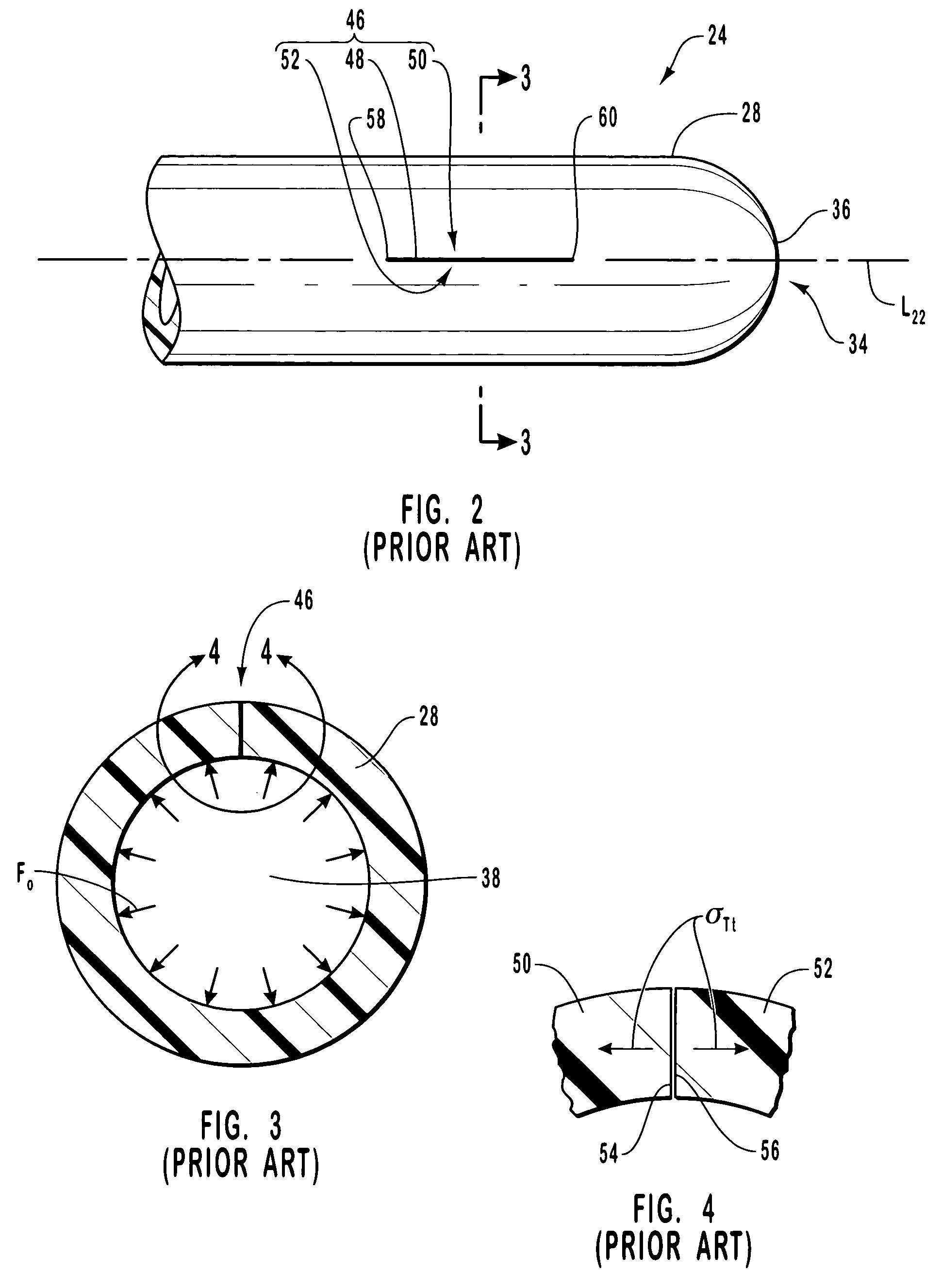

Cardiovascular access catheter with slit valve

ActiveUS7491192B2Minimize injuryIncreased durabilityCatheterIntravenous devicesPressure differenceBiomedical engineering

Two-way, three-position and one-way, two-position slit valves in cardiovascular access catheters with closed distal ends have slit geometries configured to overcome adhesion between opposed abutting slit faces, when pressure differentials are applied between the interior and the exterior of the catheter. Portions of the slit are oriented at a non-zero angle relative to the longitudinal axis of the catheter causing shear forces to be generated in abutting slit faces. Shear forces arise from tangential, radial, or longitudinal stresses generated in the catheter body. Slit geometries are planar or curved or include multiple end-to-end connected slit subsections. If a slit partially circumscribes a portion of the adjacent outer wall of the catheter body, restraint to outward and inward movement on that portion is reduced. Slit valves are configured to open inwardly to aspirate fluids, to open outwardly to infuse fluids, or both.

Owner:CR BARD INC

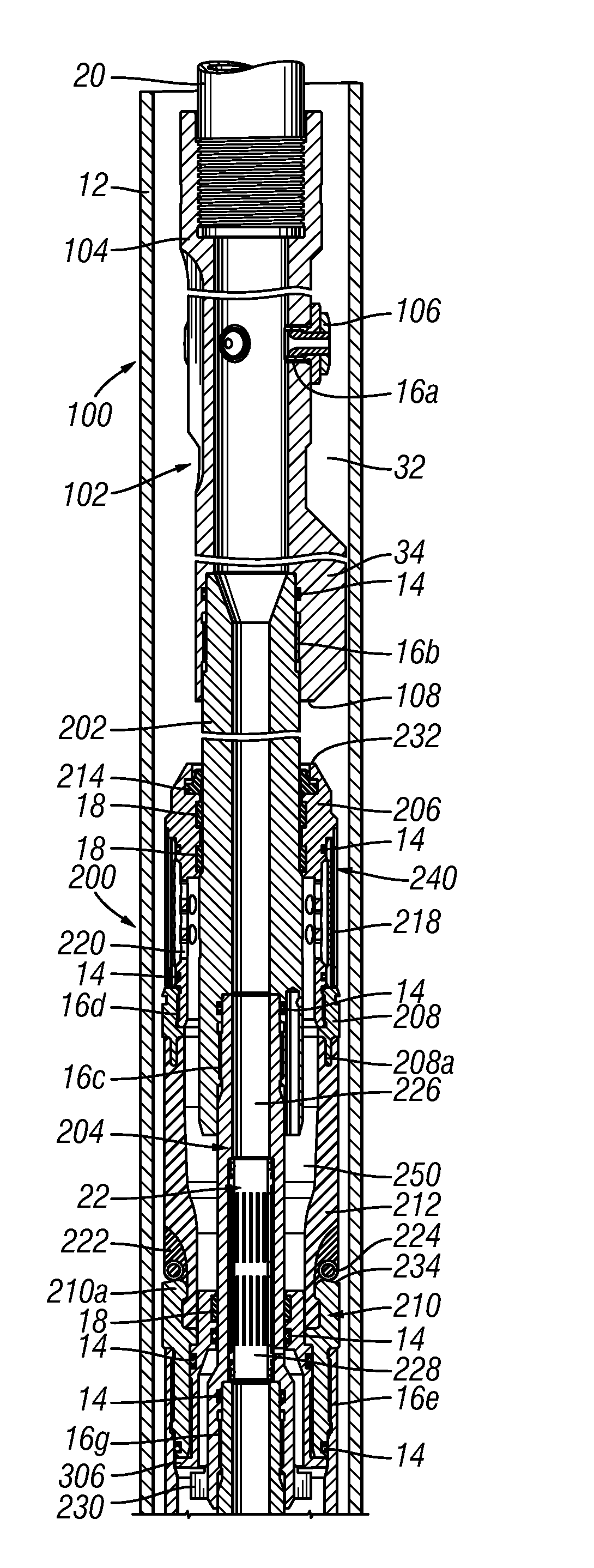

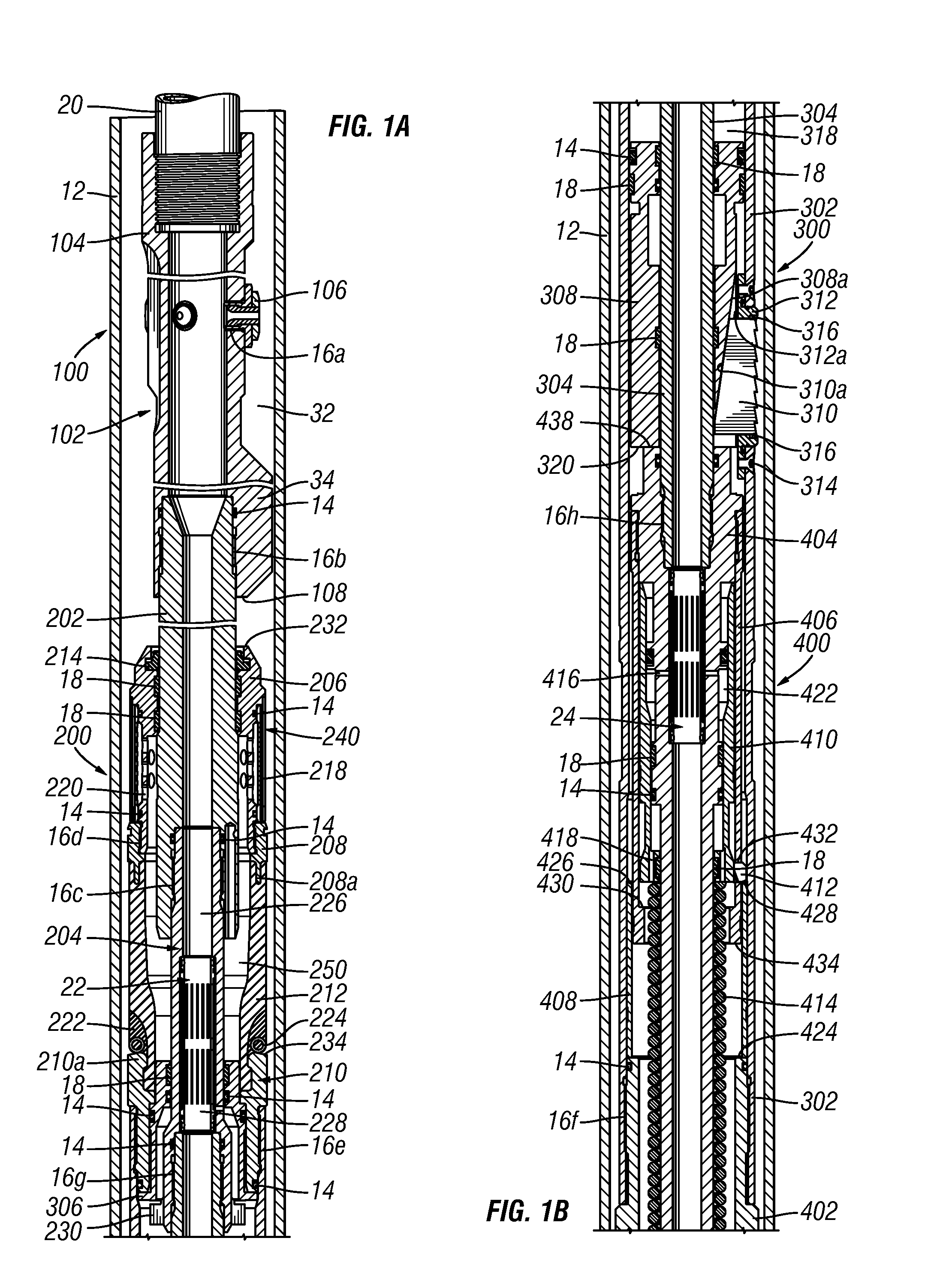

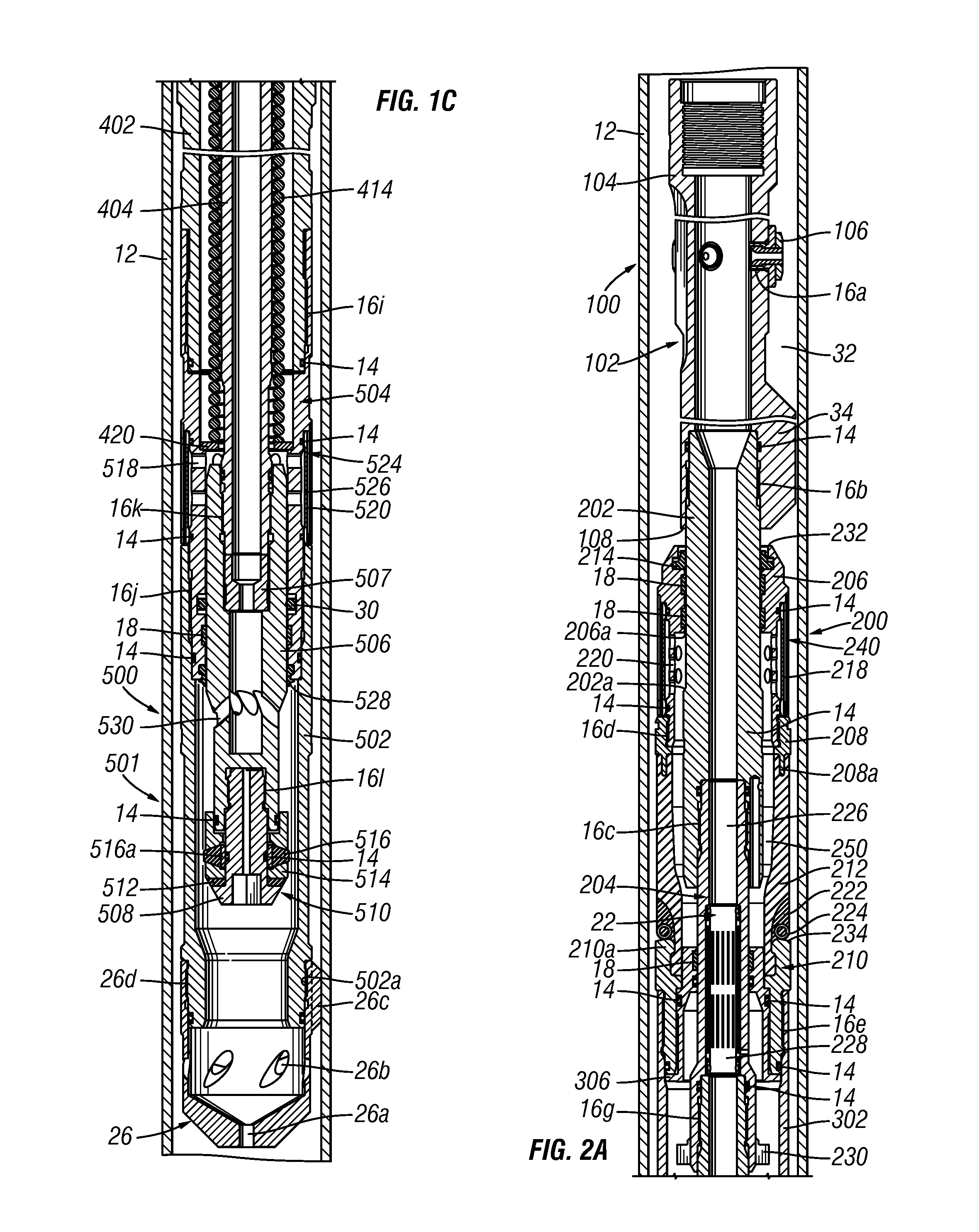

Coiled tubing bottom hole assembly with packer and anchor assembly

ActiveUS20100126725A1Protection from damageDifficult to measureDrilling rodsFluid removalDifferential pressureCoiled tubing

A bottom hole assembly (BHA), adapted to be positioned in a casing and to isolate a portion of a wellbore, which includes a packer assembly with a first sealing element extending between first and second portions of the packer assembly. A method of setting a BHA in a casing which includes increasing a BHA pressure to activate an anchor assembly, applying a mechanical force to mechanically deform a first sealing element to thereby establish an initial seal between the first sealing element and an interior surface of the casing, and increasing a pressure in a space between the BHA and the casing and in a cavity within the BHA to increase a differential pressure across the first sealing element and thereby establish a pressure-energized seal between the first sealing element and the interior surface of the casing.

Owner:BAKER HUGHES INC

Fluid treatment system

ActiveUS7408174B2Reduce the average velocityIncrease fluid velocityLiquid separation by electricityWater/sewage treatment by irradiationWastewaterForced oscillation

The present invention relates to a fluid treatment system comprising: an inlet; an outlet; and a fluid treatment zone disposed between the inlet and the outlet. The fluid treatment zone has disposed therein: (i) an elongate first radiation source assembly having a first longitudinal axis, and (ii) an elongate second radiation source assembly having a second longitudinal axis. The first longitudinal axis and the second longitudinal axis are non-parallel to each other and to a direction of fluid flow through the fluid treatment zone. The present fluid treatment system has a number of advantages including: it can treat large volumes of fluid (e.g., wastewater, drinking water or the like); it requires a relatively small “footprint”; it results in a relatively lower coefficient of drag resulting in an improved hydraulic pressure loss / gradient over the length of the fluid treatment system; and it results in relatively lower (or no) forced oscillation of the radiation sources thereby obviating or mitigating of breakage of the radiation source and / or protective sleeve (if present). Other advantages are discussed in the specification.

Owner:TROJAN TECH

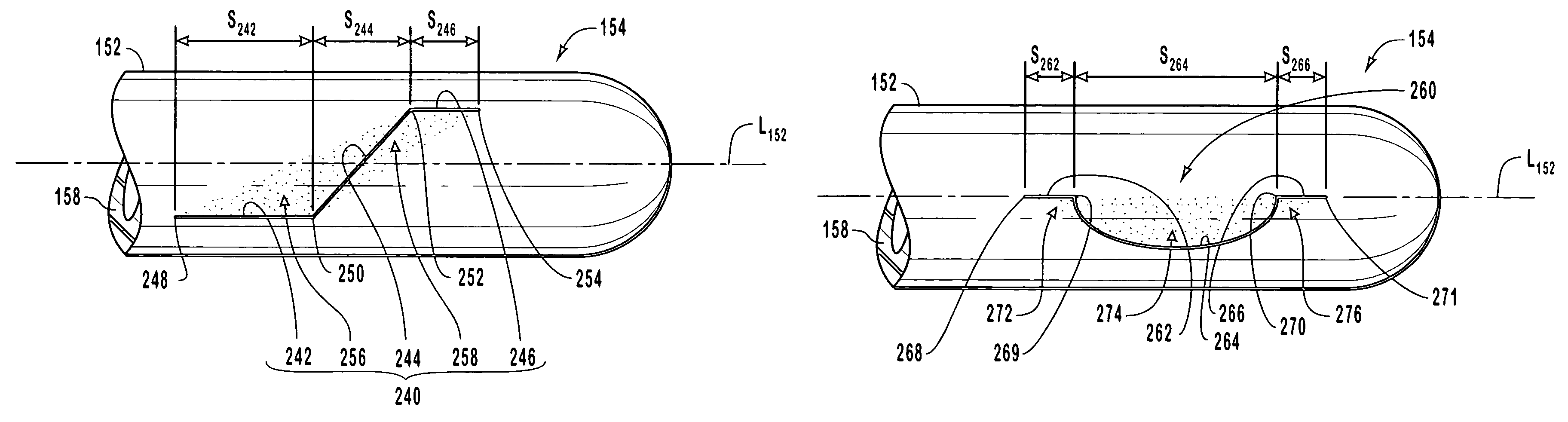

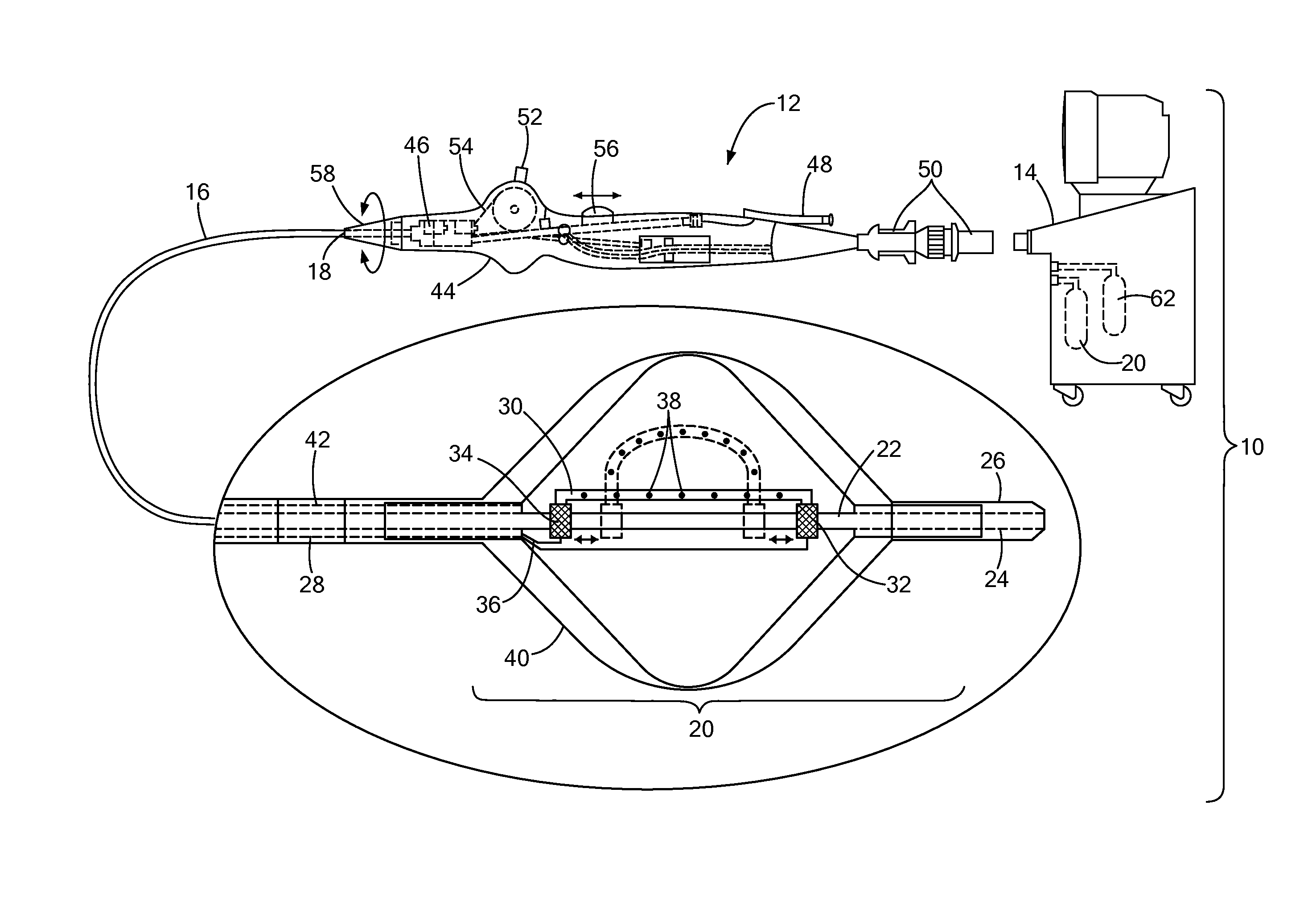

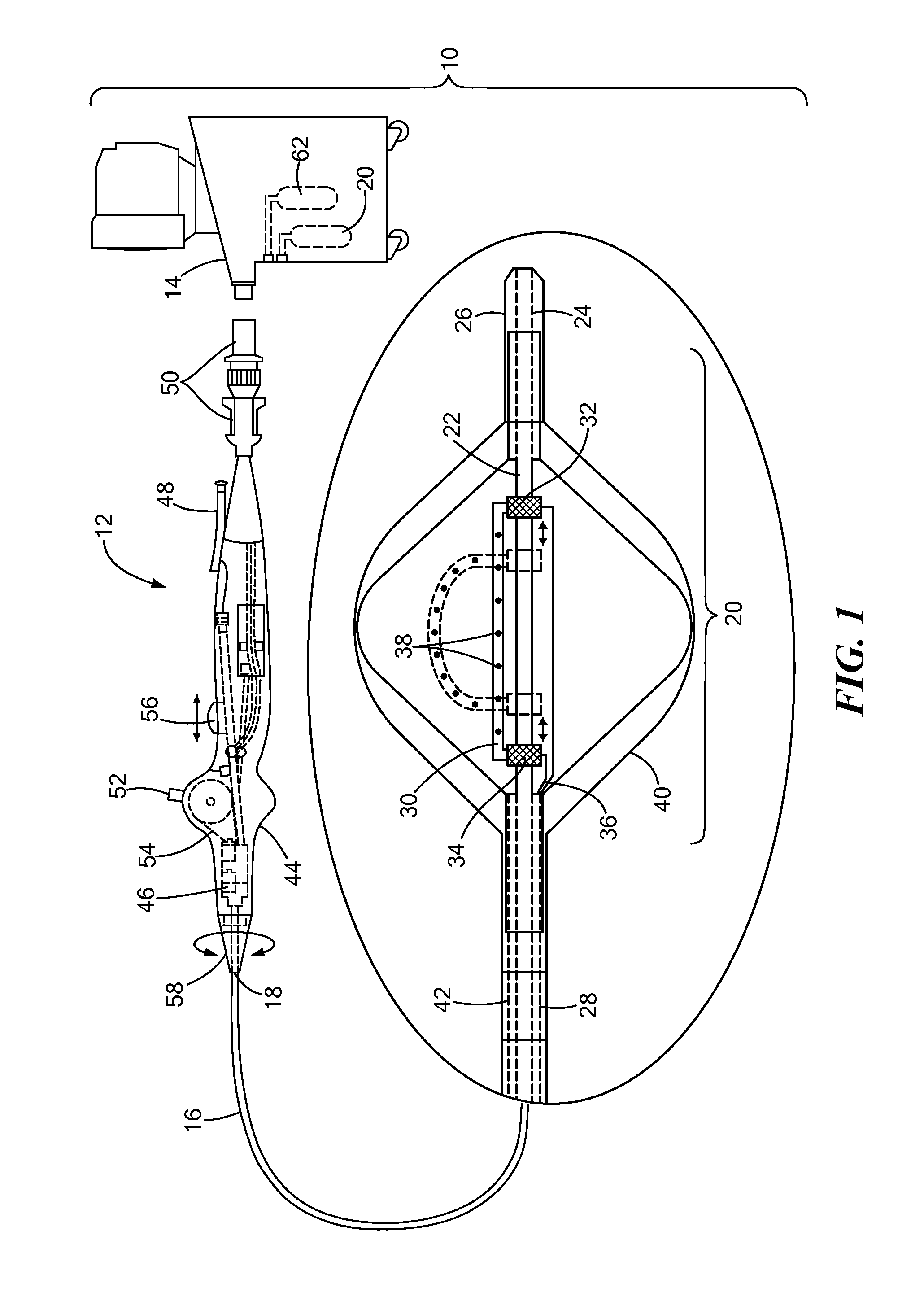

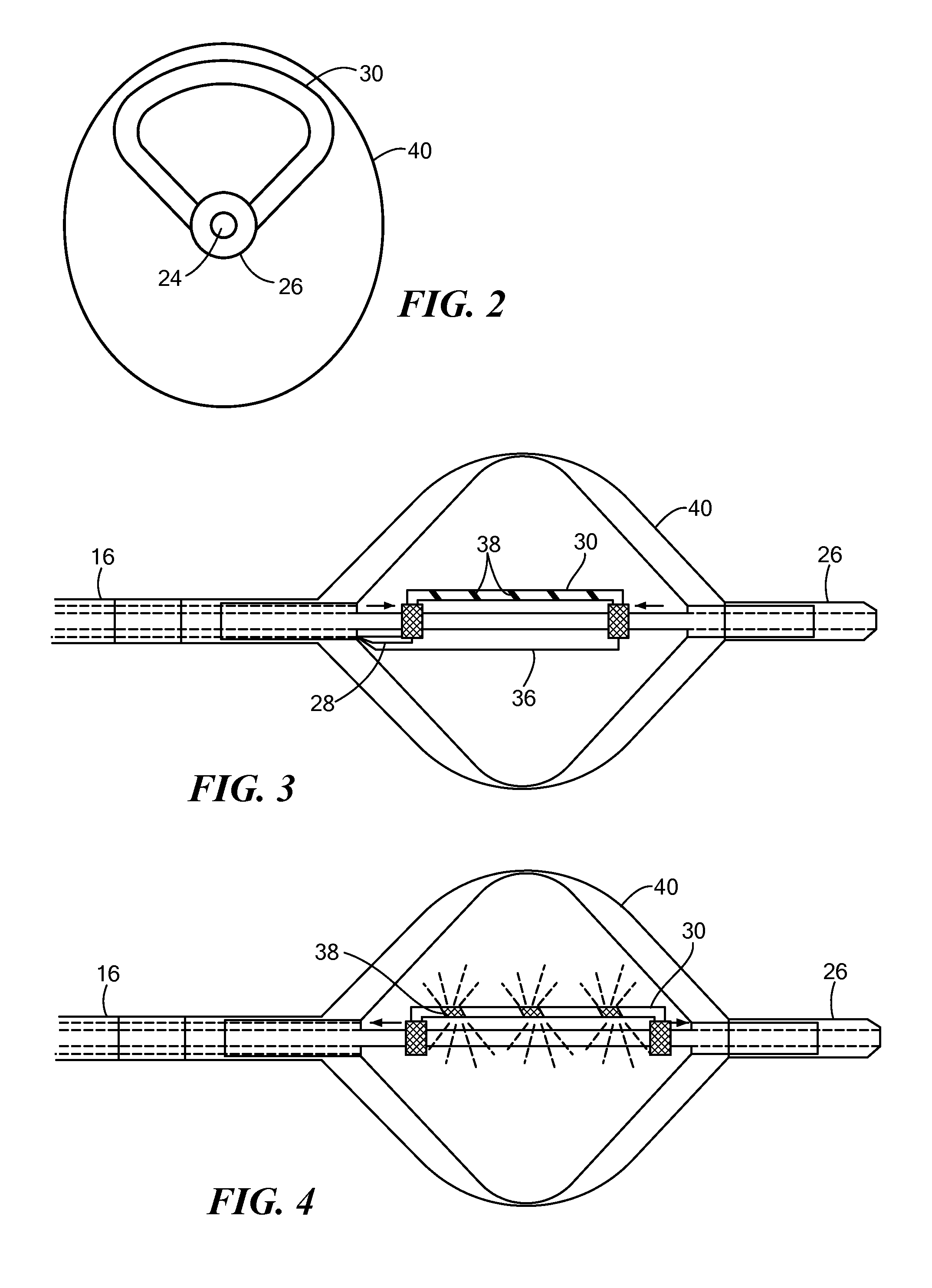

Balloon catheter with deformable fluid delivery conduit

InactiveUS8911434B2Increase fluid velocityReduce fluid flow rateStentsCatheterDistal portionLinear configuration

A medical device, including an elongate body having a proximal portion and a distal portion; a shaft at least partially disposed within the elongate body; an expandable element at the distal portion of the elongate body; and a fluid delivery conduit defining a deflectable segment movably coupled to the shaft, the deflectable segment being transitionable from a substantially linear configuration to a substantially curvilinear configuration.

Owner:MEDTRONIC CRYOCATH LP

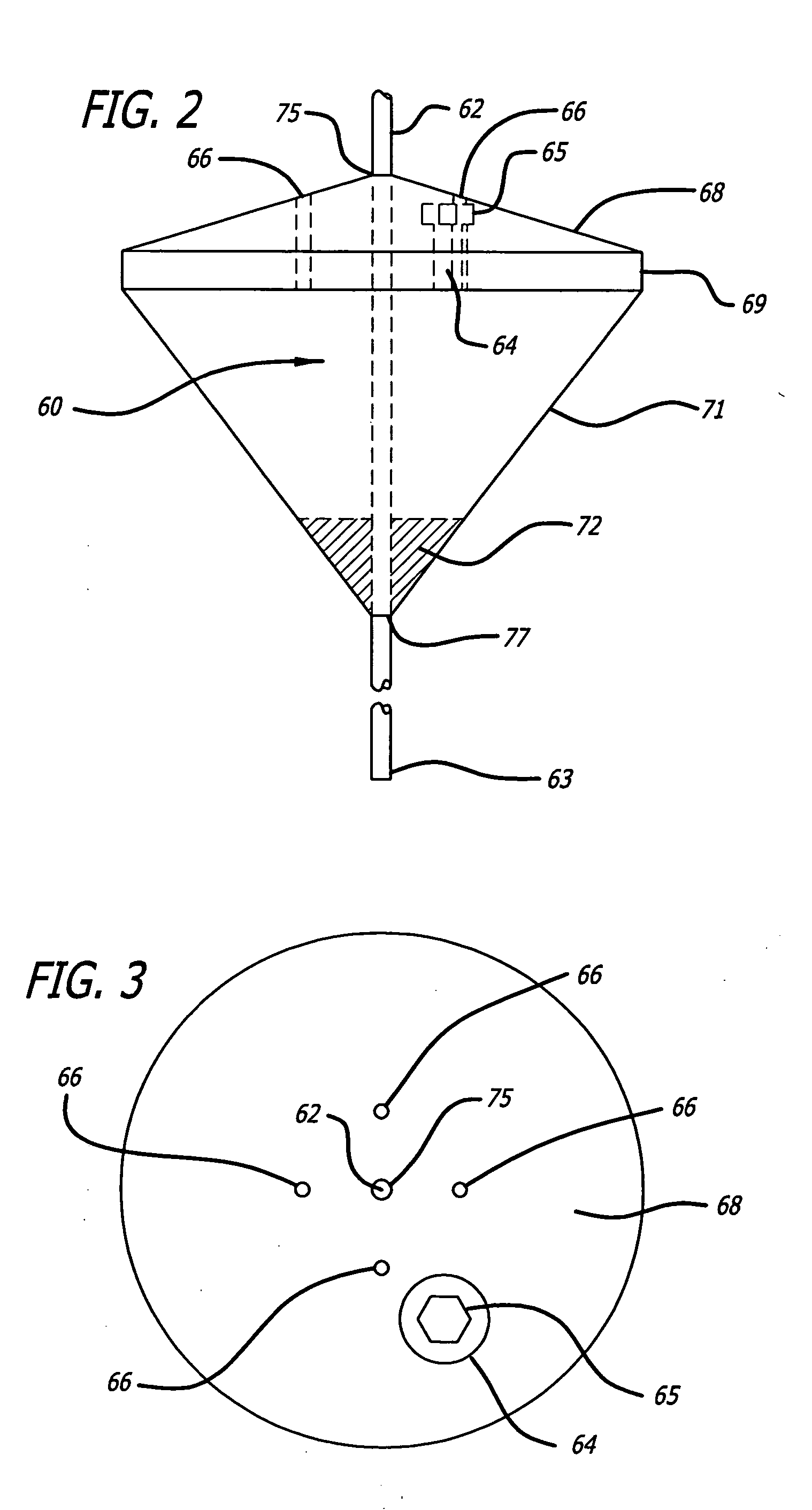

Refillable material transfer system

InactiveUS20050232072A1Increase fluid velocityWide operating temperature rangeMixer accessoriesLiquid transferring devicesAdhesiveTransducer

A material transfer system for storing, transferring and dispensing viscous material, such as fluids and liquids, includes a material containment vessel with an upper region incorporating a motive force and a bottom region with a material ingress and egress opening. A diconical or other shaped force transfer device is located in the material containment area. The force transfer device is an energy transducer when the material containment is filled with highly viscous materials, such as adhesives, sealants, mastics or lubricating greases. The force transfer device serves as an integral part of a level indicator for both viscous fluids and lower viscosity liquids. The viscous material itself forms a seal between the interface region of the force transfer device and the inside wall of the fluid vessel. Vertical stabilizing elements may extend outward from the force transfer device.

Owner:CH & I TECH INC

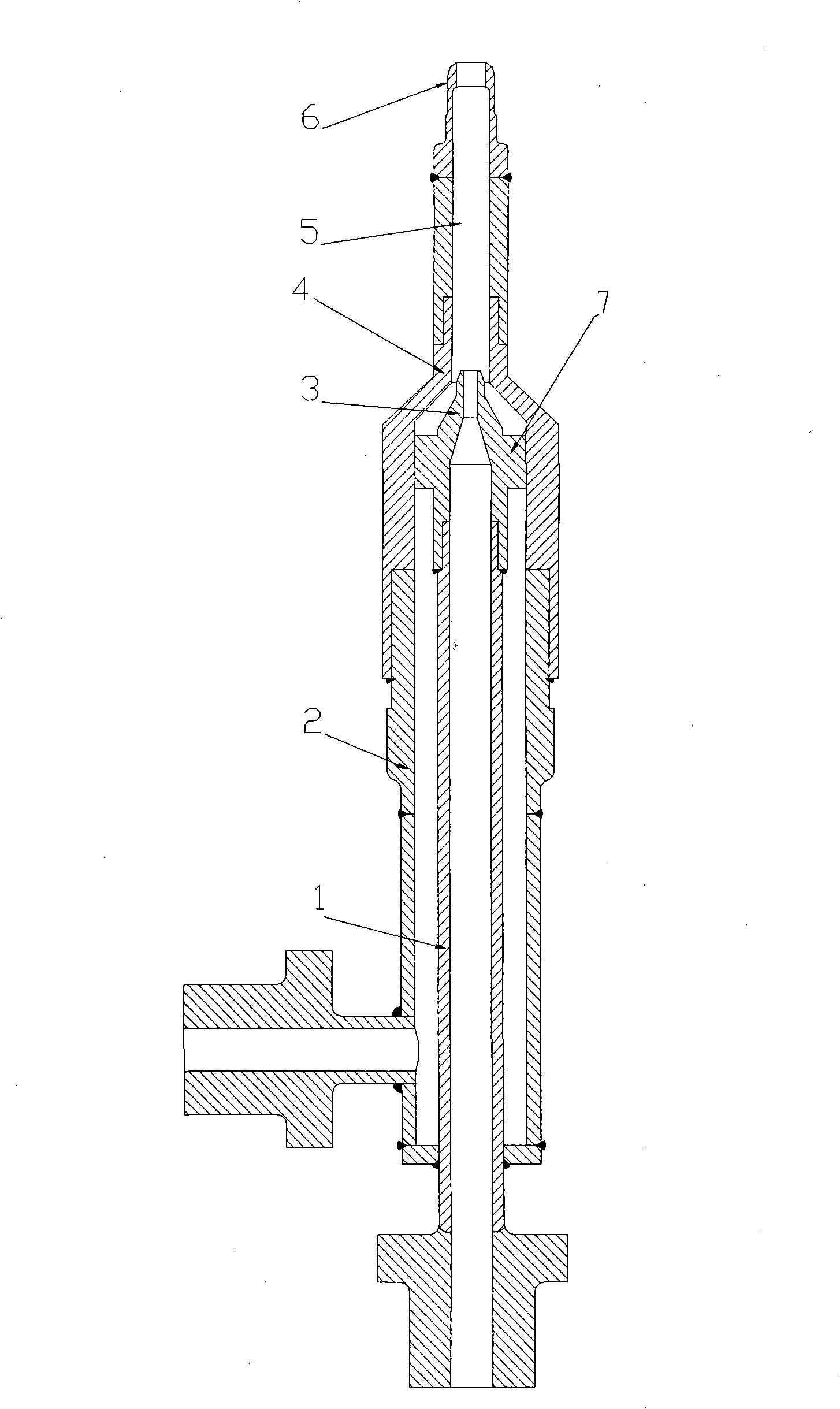

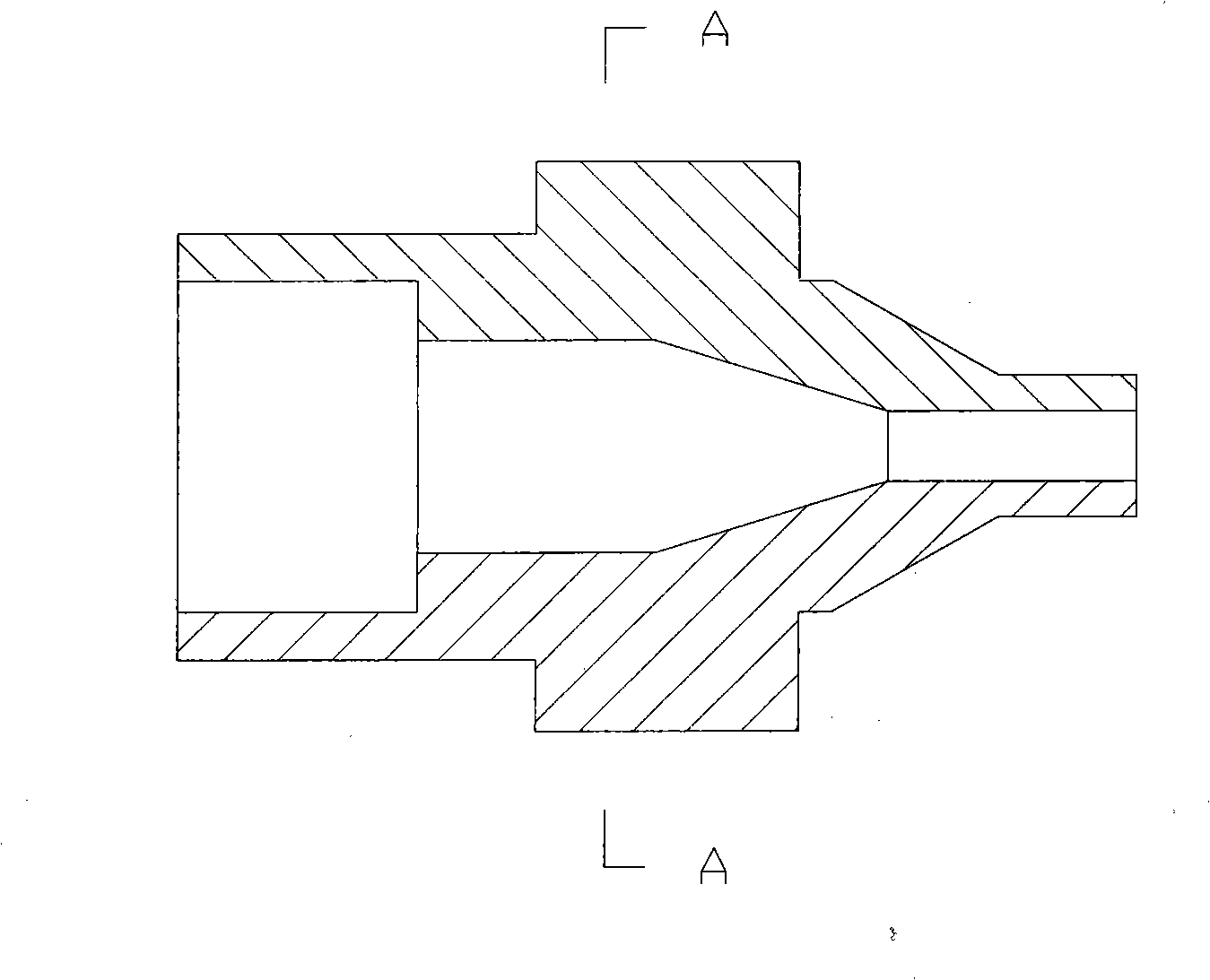

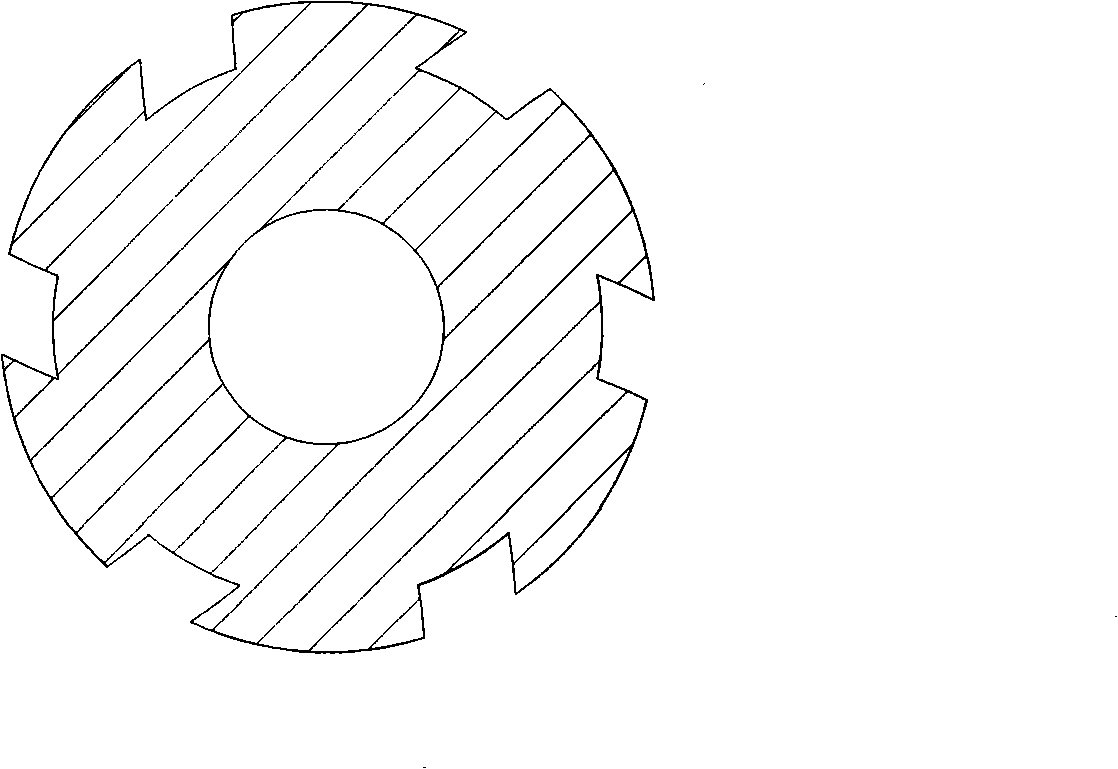

High-speed jet gas-liquid mixing-phase ejector

InactiveCN101491794AGuaranteed high-speed jetStrong penetrating powerLiquid spraying apparatusJet flowGas phase

The invention relates to a fluid ejector, and aims to provide a gas-liquid mixed phase ejector for ejecting at a high speed. The ejector comprises a liquid phase inlet pipe and a gas phase inlet pipe which are provided with a quick coupler respectively; the tail end of the liquid phase inlet pipe is connected with a liquid phase nozzle; the tail end of the gas phase inlet pipe is connected with a gas phase nozzle; the liquid phase nozzle is a single-hole nozzle; a flow passage from the liquid phase inlet pipe to the liquid phase nozzle has smooth transition; the gas phase inlet pipe encloses the outside of the liquid phase inlet pipe to form an annular gas phase flow passage; the gas phase nozzle encloses the outside of the liquid phase nozzle and is connected with a mixed phase flow passage; the tail end of the mixed phase flow passage is connected with an outlet nozzle; and an outlet circulation sectional area of the outlet nozzle is smaller than that of a circulation sectional area of the mixed phase flow passage. The liquid phase nozzle has high-speed outlet liquid flow, and the high-speed outlet liquid flow is interacted with high-speed gas phase flow in the mixed phase flow passage to realize atomization and once more acceleration, thereby the ejector greatly weakens boundary layer effect on the outlet, avoids that liquid drops separating from main jet flow are convergent to drop on the outlet, and can flexibly adjust and control atomization fineness and distribution.

Owner:ZHEJIANG UNIV +1

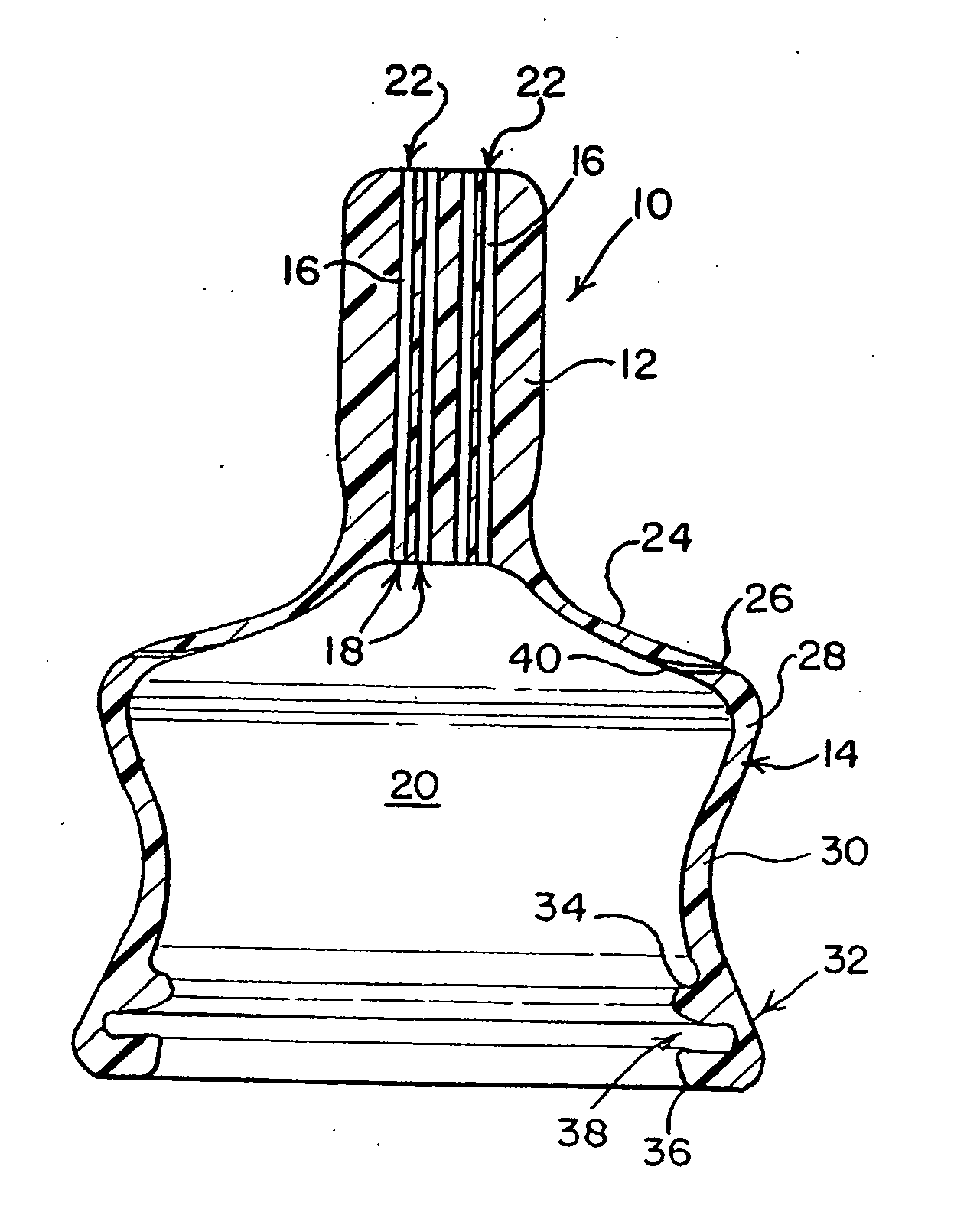

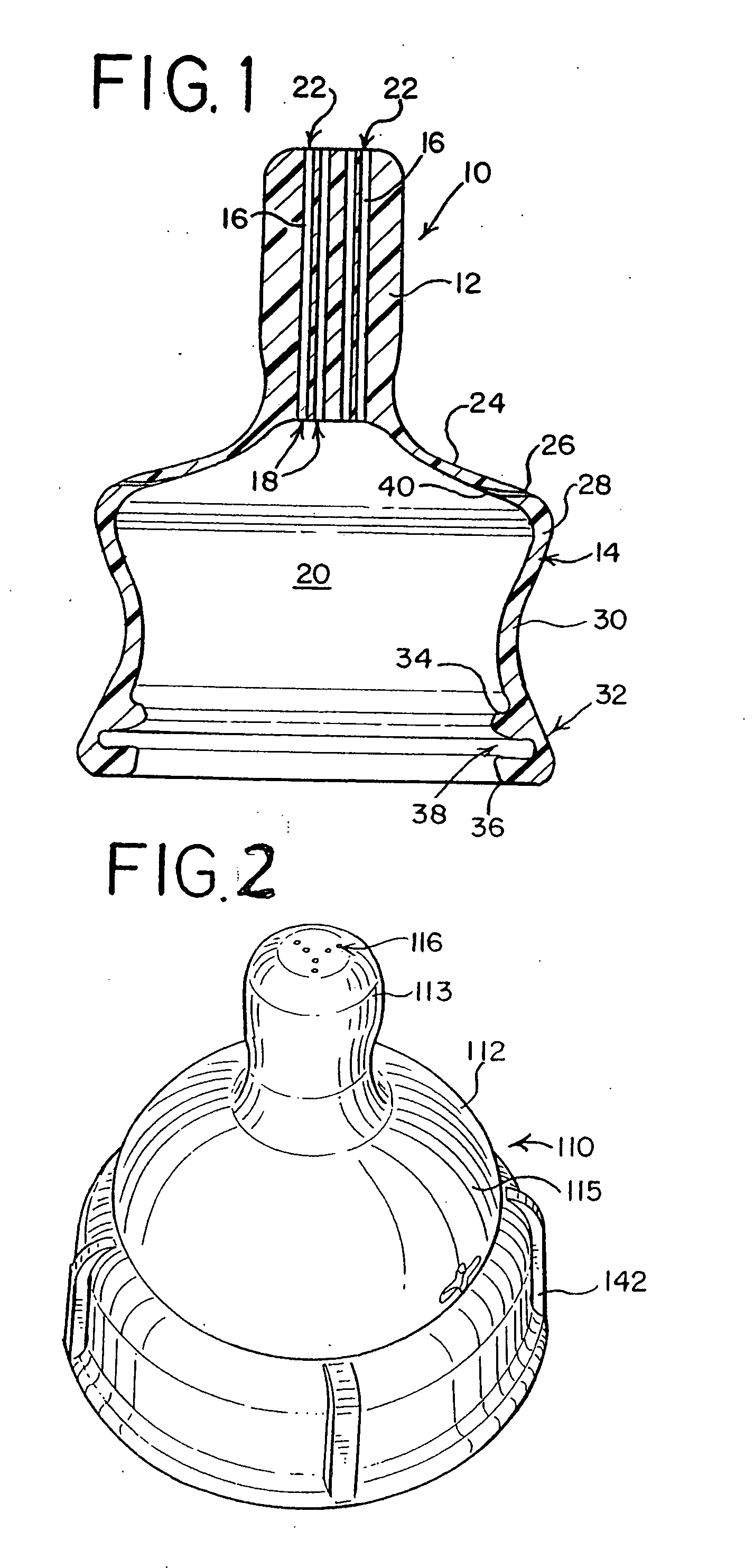

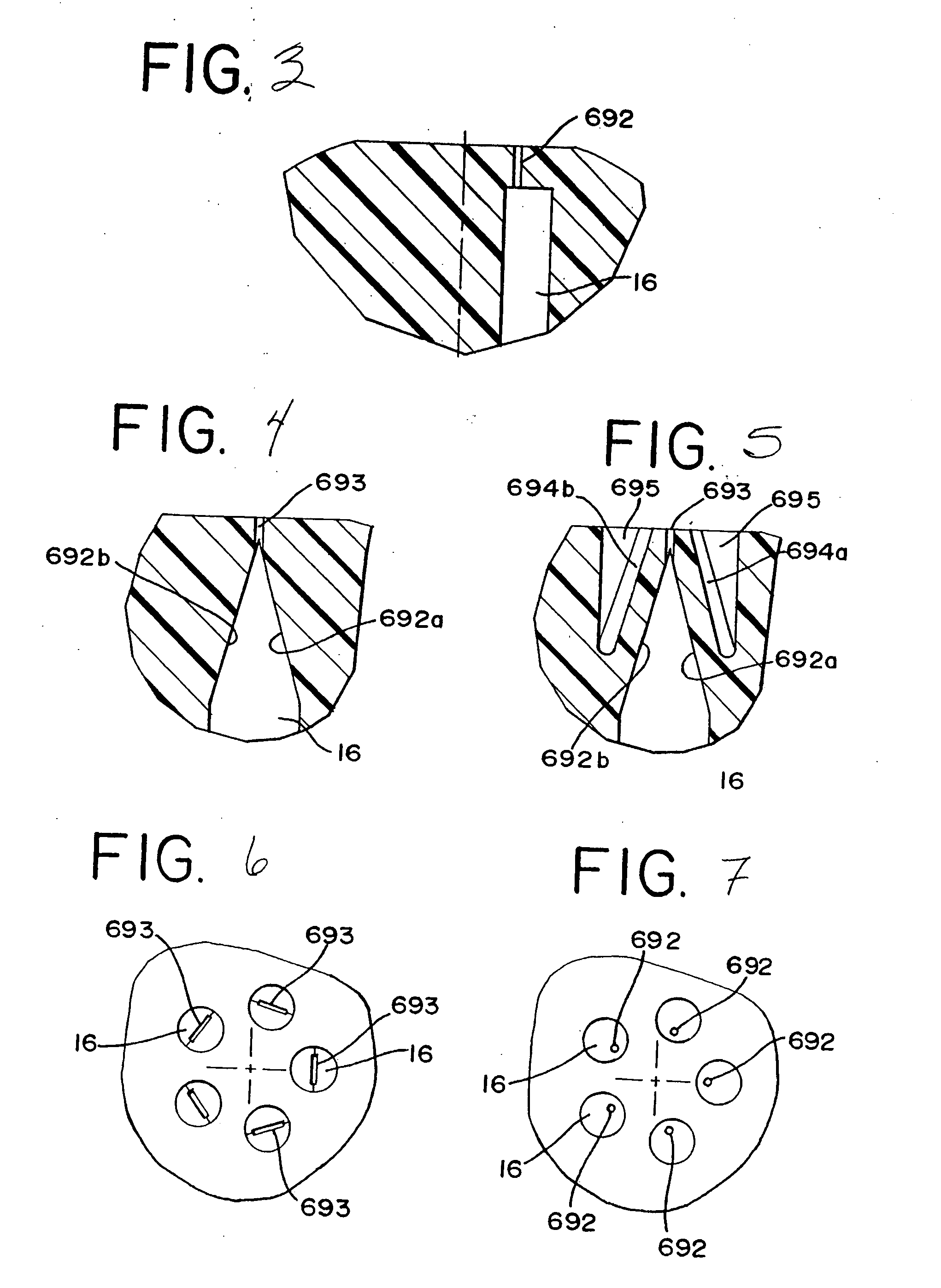

Artificial feeding nipple tip

InactiveUS20050258123A1Increase fluid velocityIncrease flow rateFeeding-bottlesTeatsEngineeringMechanical engineering

Owner:MEDELA HLDG AG

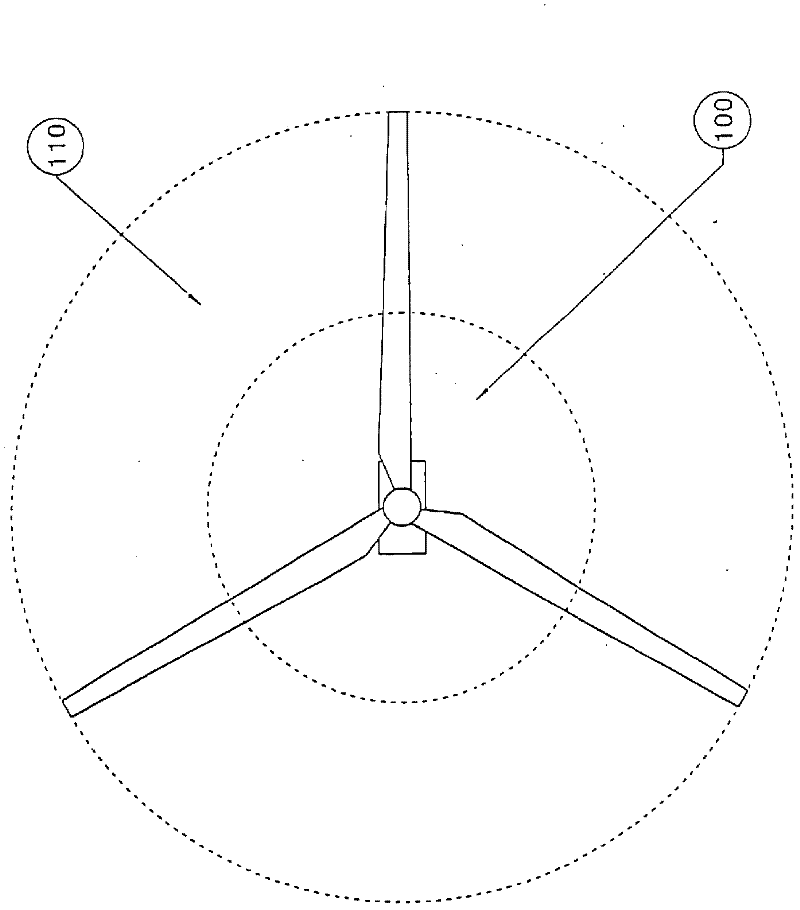

System and method for extracting power from fluid using a Tesla-type bladeless turbine

InactiveUS8801359B2Speed up the extraction processIncrease fluid velocityPump componentsWind motor controlSurface oceanTurbine

Smooth, preferably variable-sweep fluid collection device surfaces disposed into opposition with wind, river, surf, ocean or tidal currents generate enhanced velocity fluid flows at length driven into onboard work-extracting disc turbines at advantageous angles of attack. Keyed to shafts turning freely through optionally extendable volutes, disc turbines comprising a dense population of smooth, axially fixed or adjustably spaced discs conducting preferably laminar flow between adjacent elements develop significant torque through boundary layer adhesion and viscous shear-stress between fluid layers. Exhaust of disc turbine throughput into divergent channels drafting into external currents of initially higher than ambient velocity and lower pressure may reduce turbine discharge backpressure, rapidly clear system throughput, and allow normally disadvantageous drag to be utilized to develop greater work generation. Gainfully turning with, instead of at odds to natural or anthropogenic currents provided, disc turbines utilized as disclosed may provide unprecedented renewable energy from fluids in motion.

Owner:SHERRER GORDON DAVID

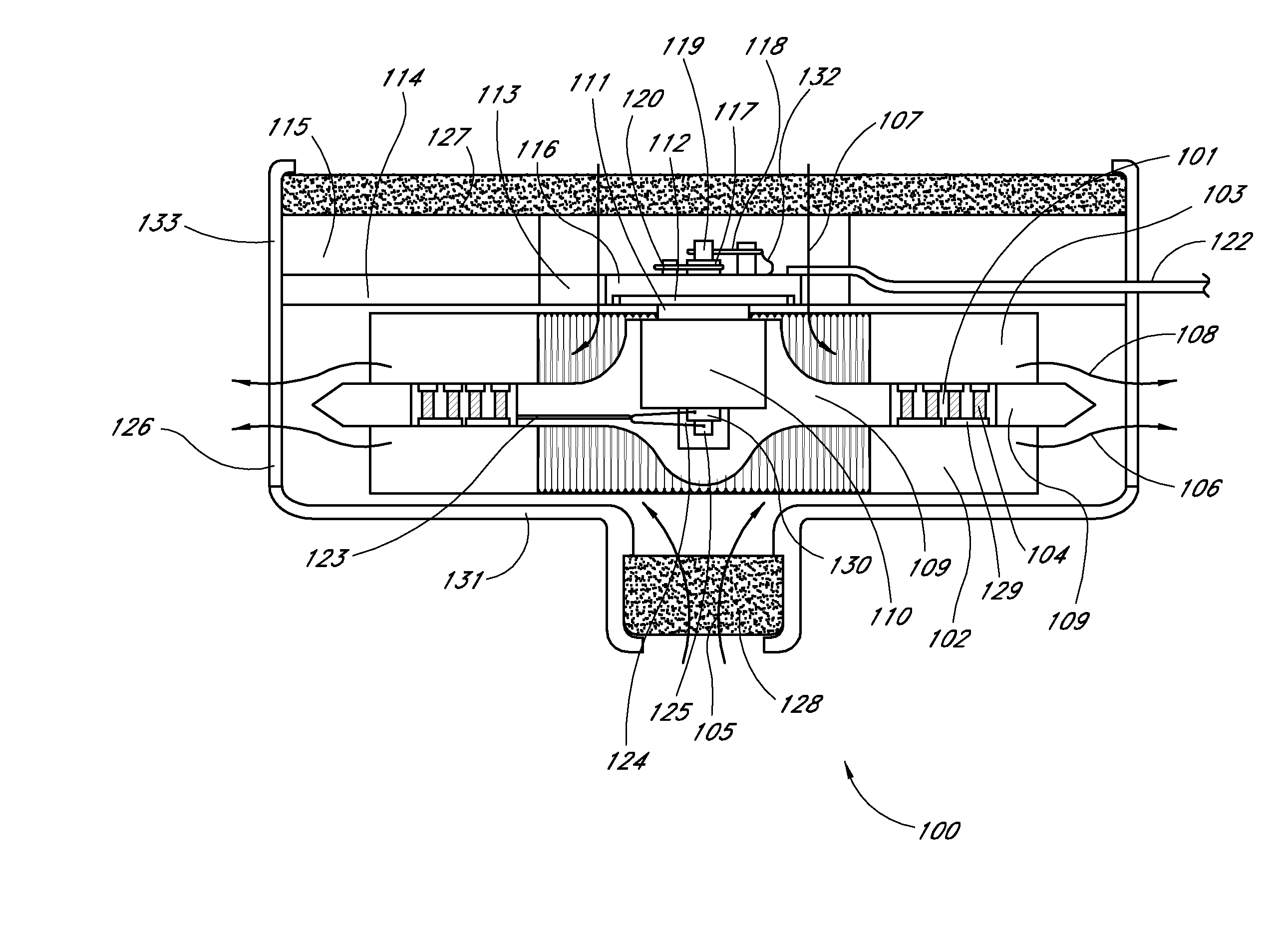

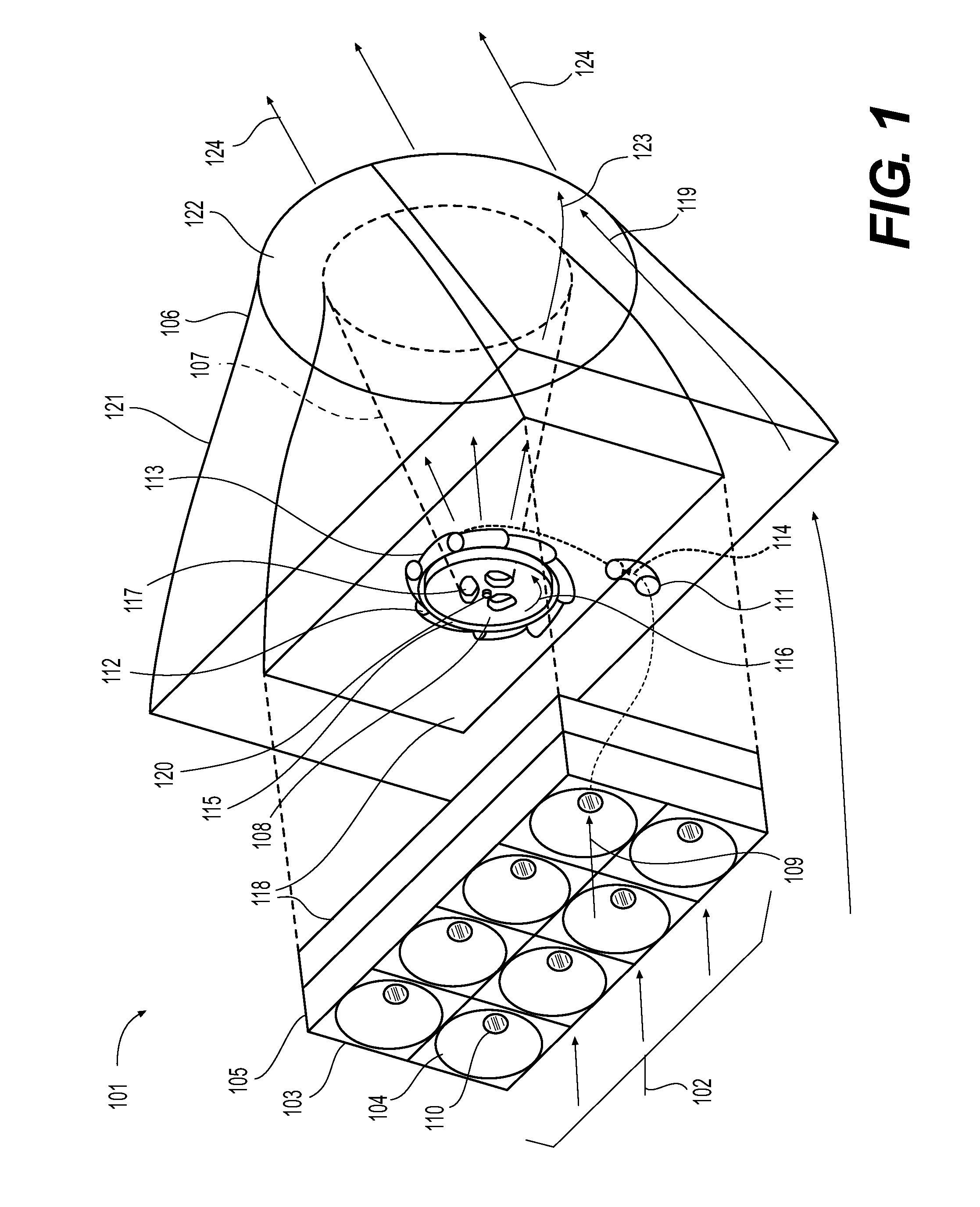

Micropump for electronics cooling

InactiveUS7802970B2Improve fluid flowIncrease fluid velocityPositive displacement pump componentsFlexible member pumpsWorking fluidElectronics cooling

A micropump including one or more microchannels for receiving a fluid and a plurality of electrodes arranged on a diaphragm and energized in a manner to provide an enhanced electrohydrodynamic flow of fluid through the one or more microchannels. The micropump may be used for pumping a working fluid for removing heat from a heat-generating electronic component or for delivery of a drug, medicine, or other treatment agent as or in a fluid to a patient.

Owner:PURDUE RES FOUND INC

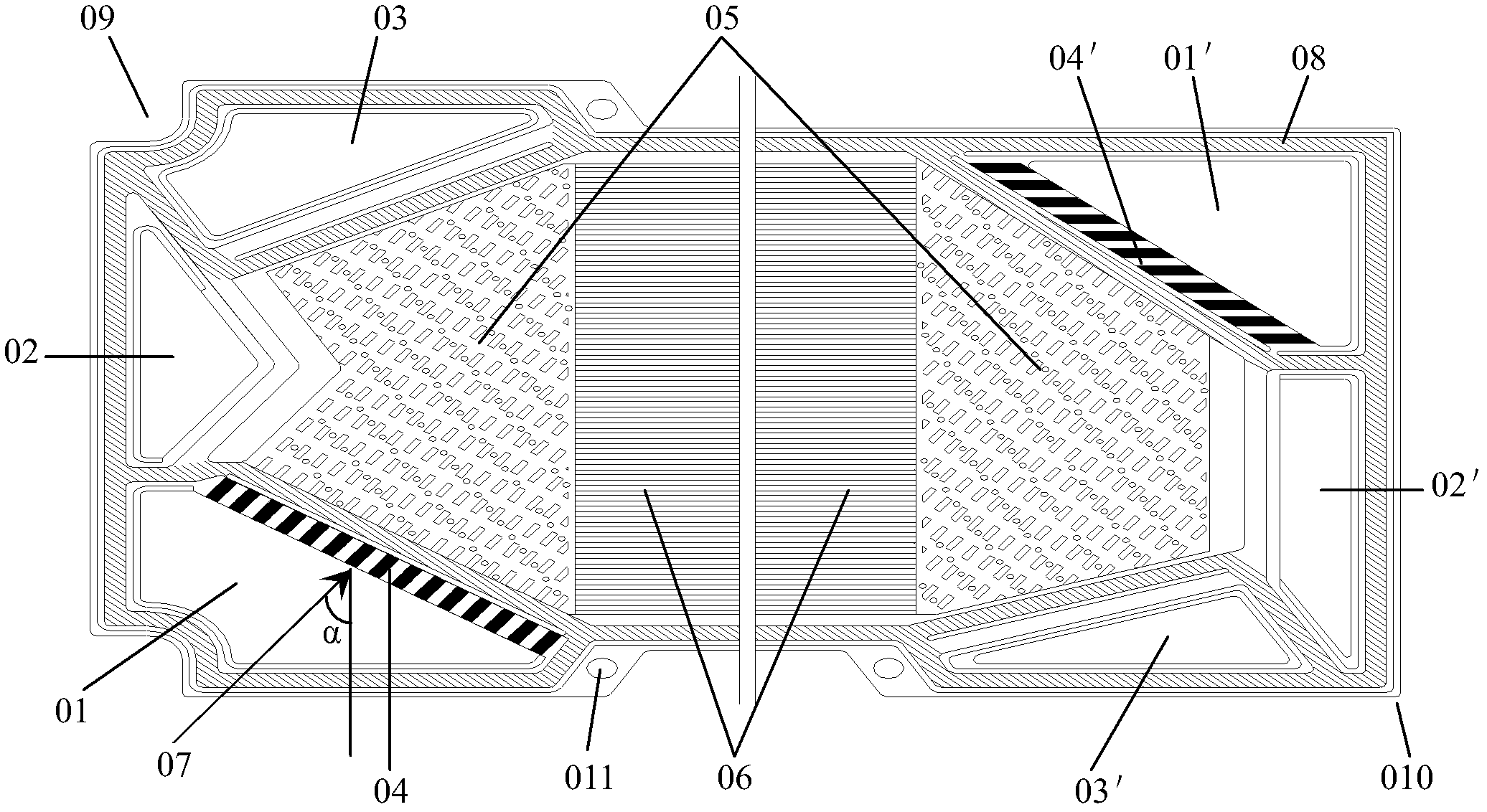

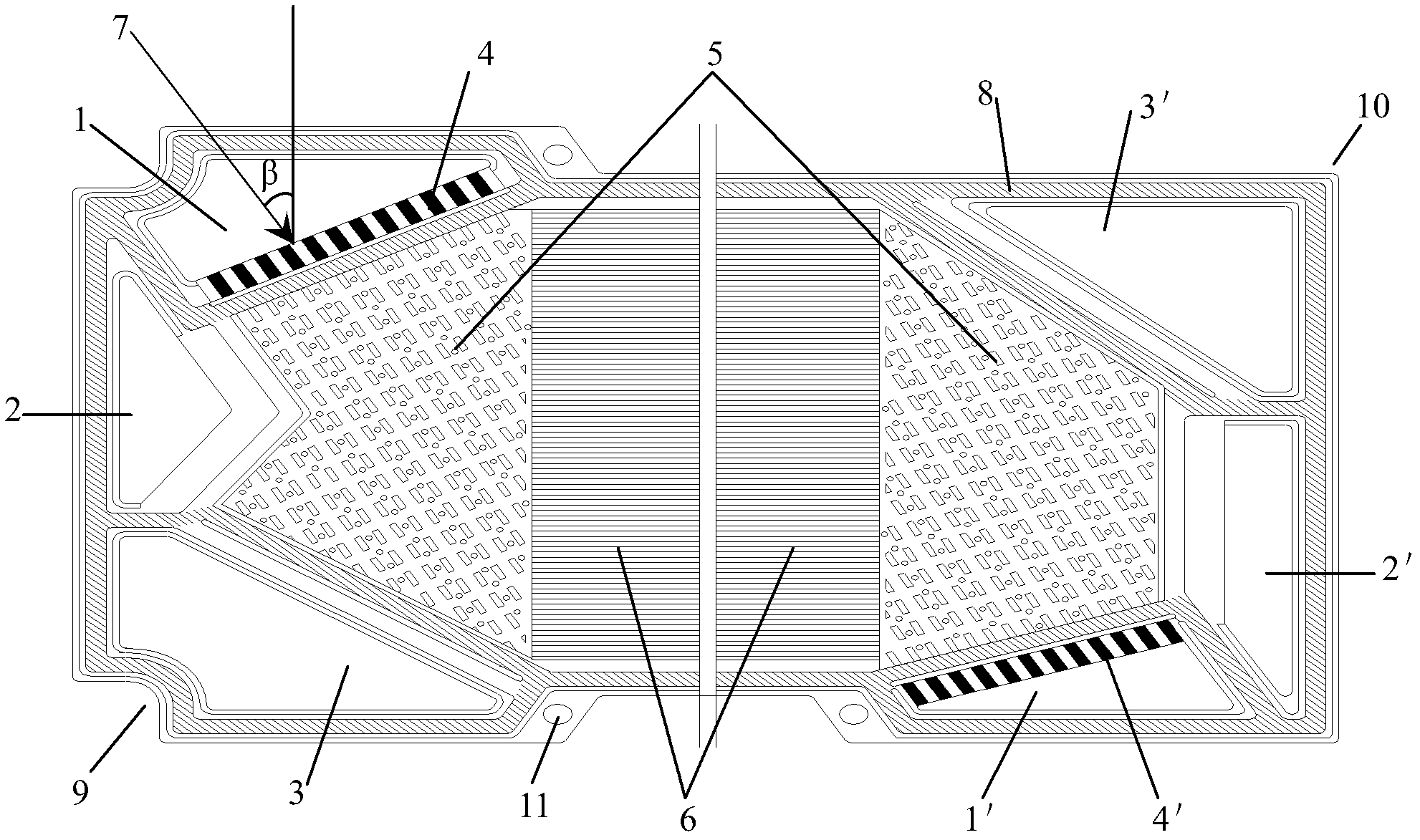

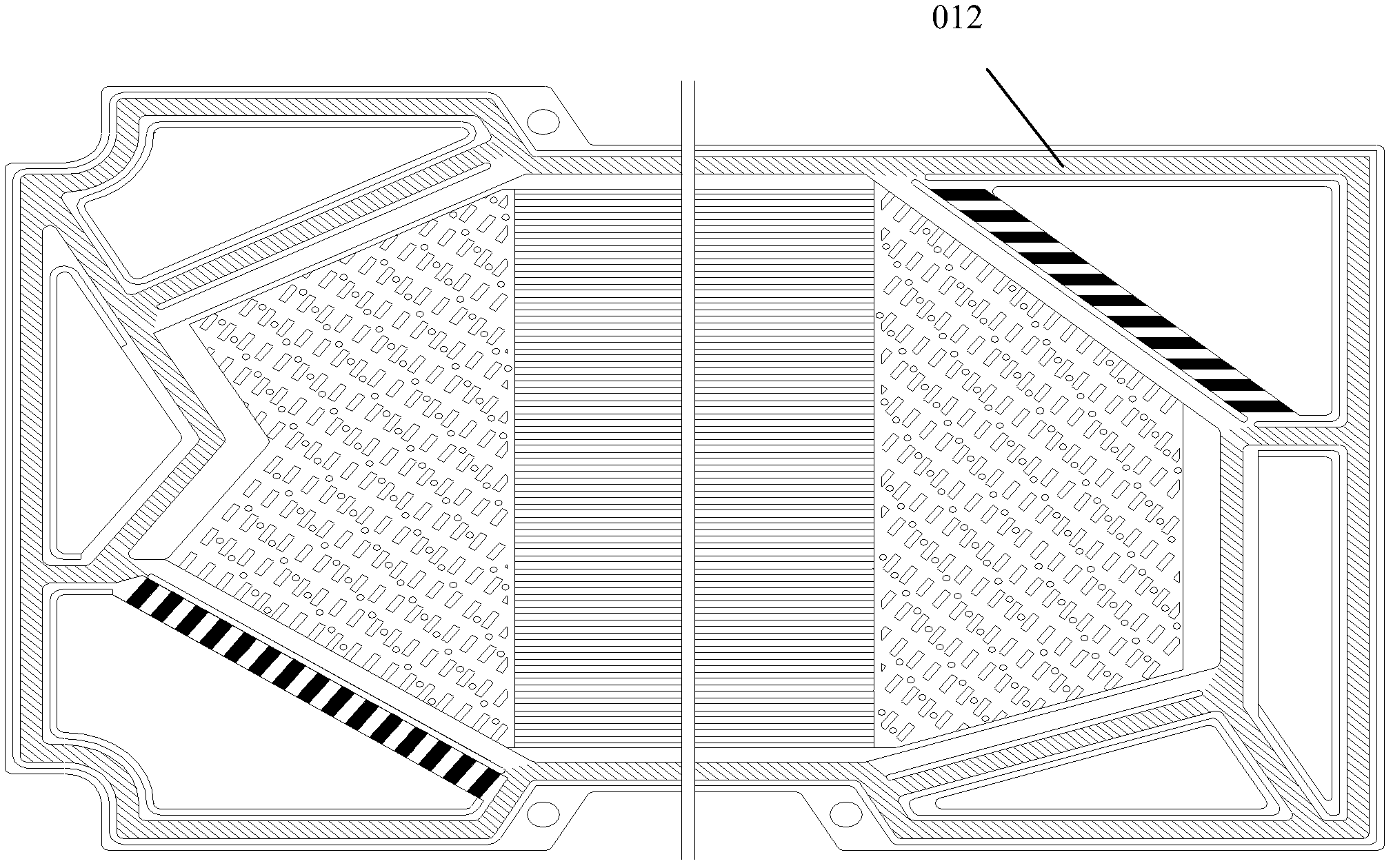

PEMFC (proton exchange membrane fuel cell) metal bipolar plate conducive to improving fluid distribution

ActiveCN102306805AIncrease the differential pressureReduce resistanceCell electrodesProton exchange membrane fuel cellSupport point

The invention provides a PEMFC (proton exchange membrane fuel cell) metal bipolar plate conducive to improving fluid distribution. The PEMFC metal bipolar plate comprises a cathode monopolar plate and an anode monopolar plate in corresponding connection, wherein three-cavity public pipelines are arranged on the two sides of the cathode and anode monopolar plates, and a direct current field flow channel, a distribution flow channel and an inlet / outlet flow channel are arranged in the middle;; the direct current field flow channel is formed by bulges and grooves in parallel; the distribution flow channel is formed by channelization islands distributed regularly and reversely-convex support points; the inlet side and outlet side of the cathode and anode monopolar plates are asymmetrical; andthe inlet area of an air cavity public pipeline is 0.1-0.5 time greater than the outlet area. The metal bipolar plate has the advantages that: the distribution flow channel improves the distribution conditions of reaction gas and cryogen, and thus can improve the galvanic pile performance and optimize the galvanic pile water management capacity; the inlets and outlets of three cavities are asymmetrical, thereby saving space to the greatest degree; an assembled galvanic pile is suitable for the operations of horizontally, laterally and vertically placing the galvanic pile; and the outer positioning in battery pile assembly can avoid torsion and deformation of the battery pile, thereby improving the flatness of the battery pile.

Owner:SUNRISE POWER CO LTD +1

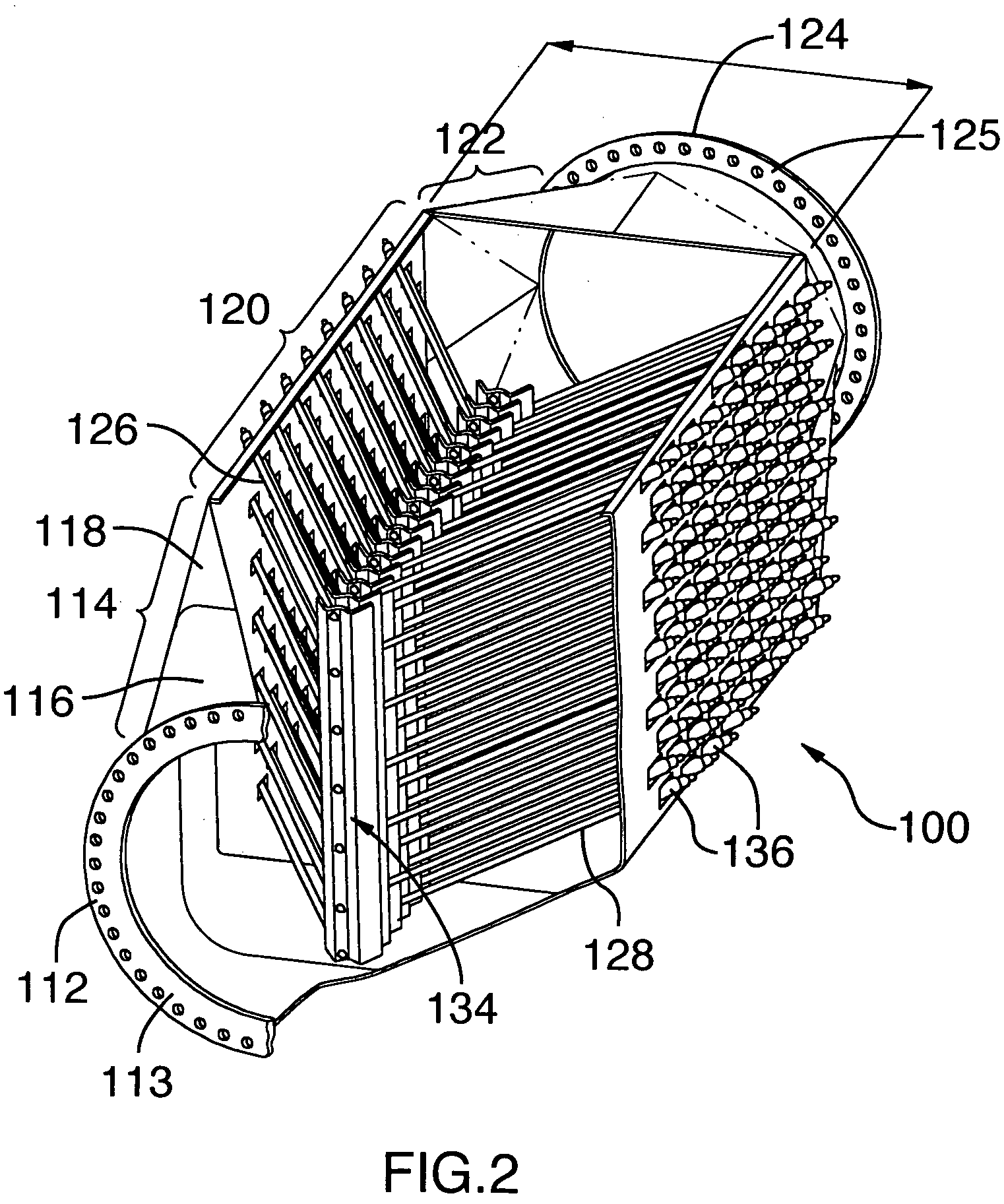

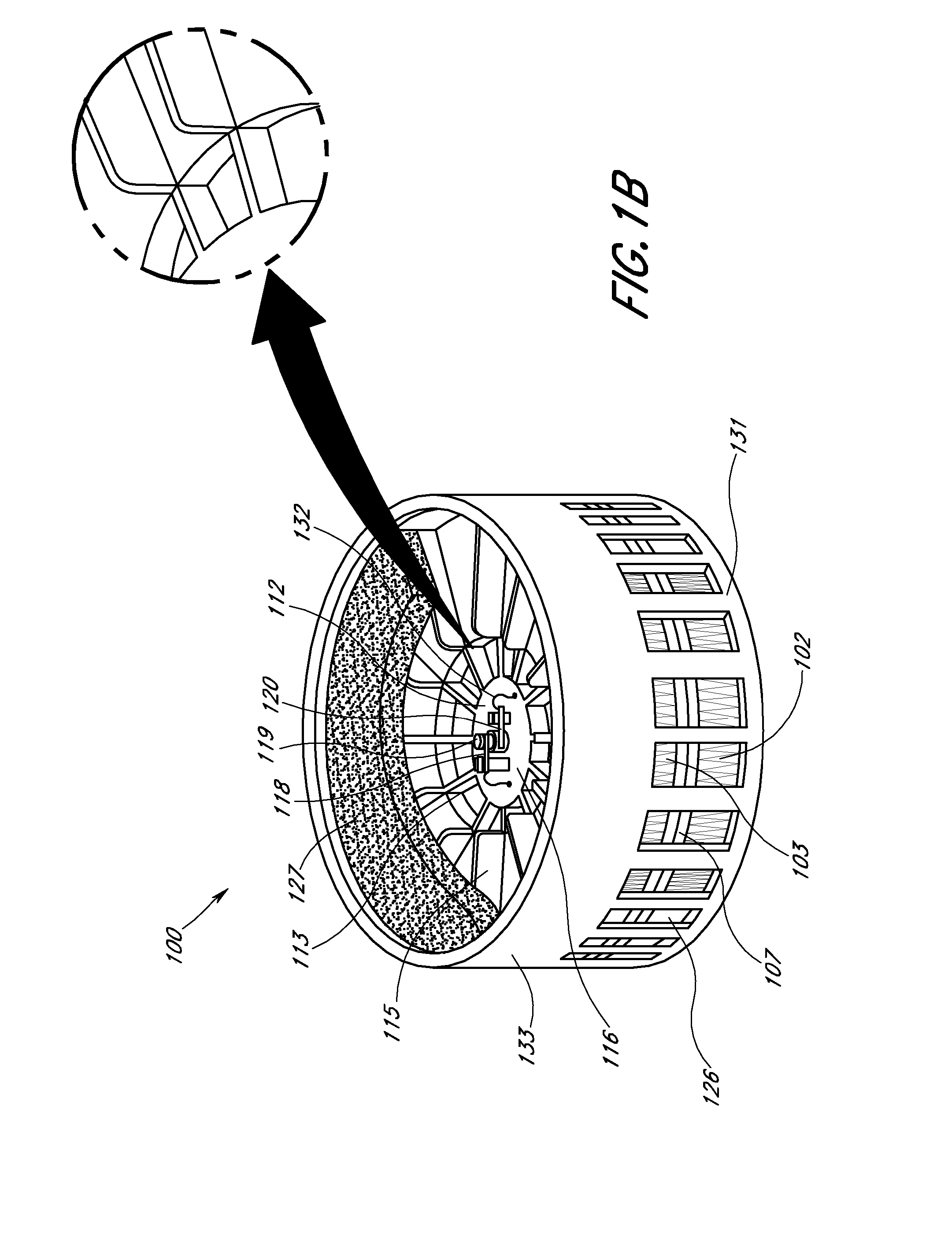

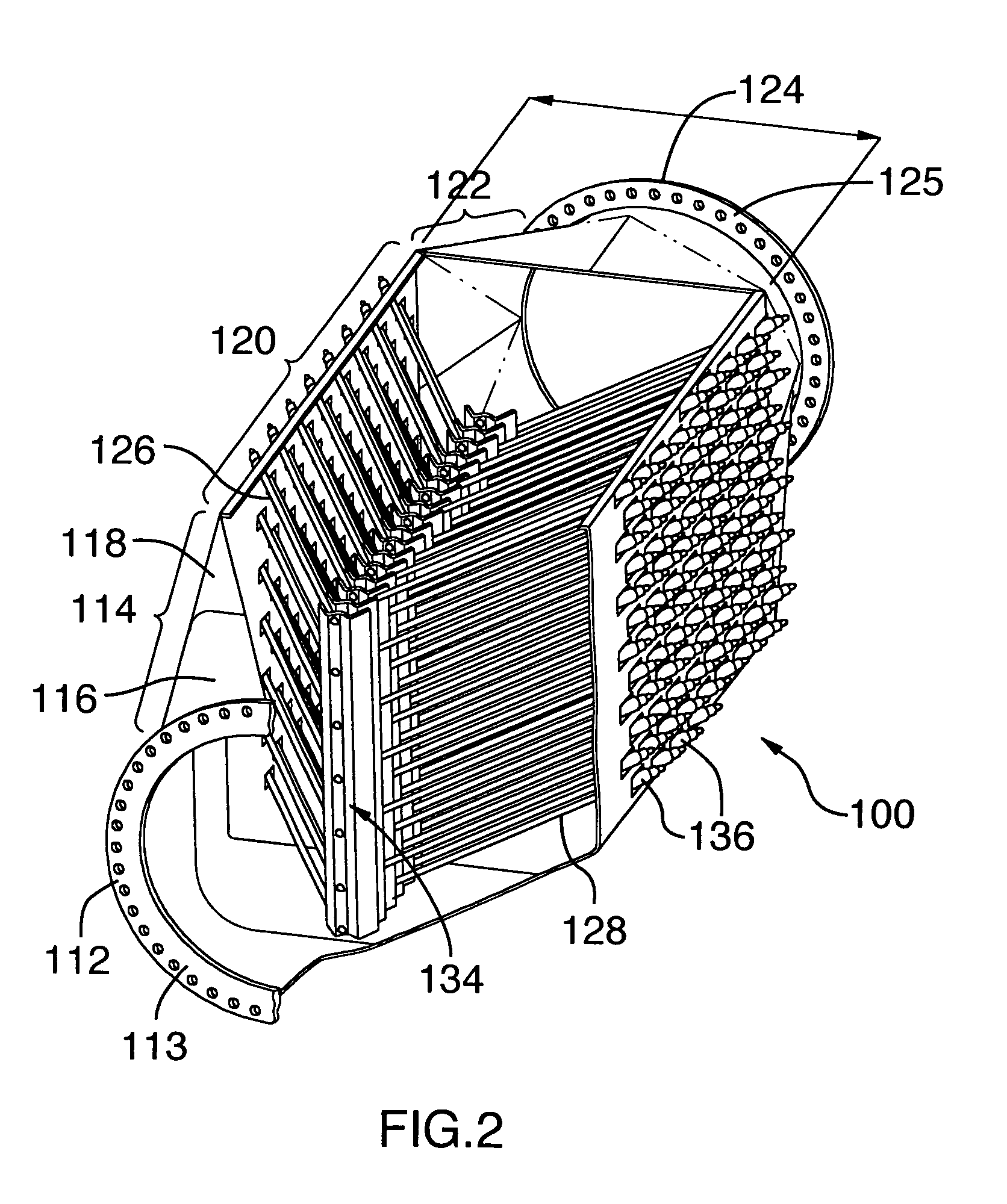

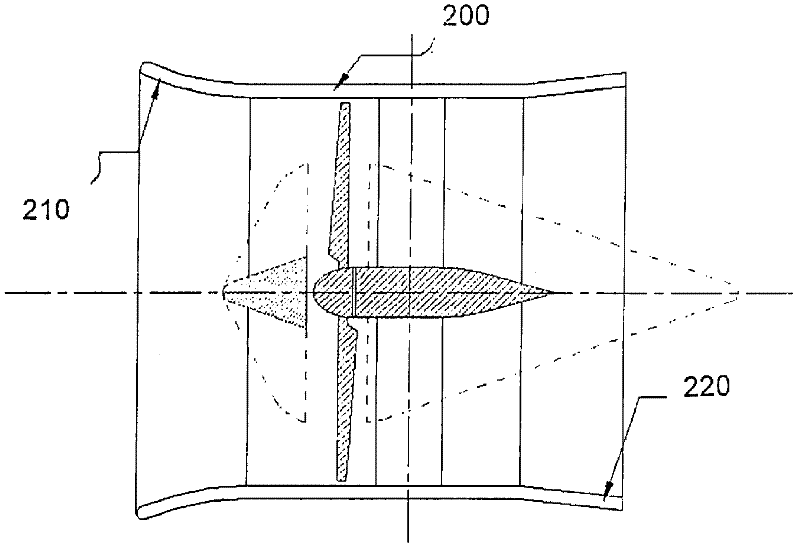

Fluid guidance systems for turbines

InactiveCN102272444AIncrease fluid velocityIncrease fluid pressureRotational speed controlWind motor controlTurbine bladeCross-flow turbine

A directing system for directing fluid entering an axial flow turbine along an inlet flow direction. The turbine includes a plurality of turbine blades. The directing system includes a base structure, a plurality of directing segments attached to the base structure, downstream of the base structure, and a directing segment adjustment system for adjustably positioning the directing segments between a retracted configuration and a deployed configuration. The directing segments, in the deployed configuration, extend beyond the base structure in a direction transversal to the inlet flow direction and deflect the fluid towards an outer circumference of the plurality of turbine blades corresponding to a higher torque area of the blades. A directing system for directing fluid entering a cross-flow turbine is also disclosed. In the cross-flow turbine, the fluid is directed towards a centerline of the rotor of the turbine, which is a high torque area of the turbine blades.

Owner:ORGANOWORLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com