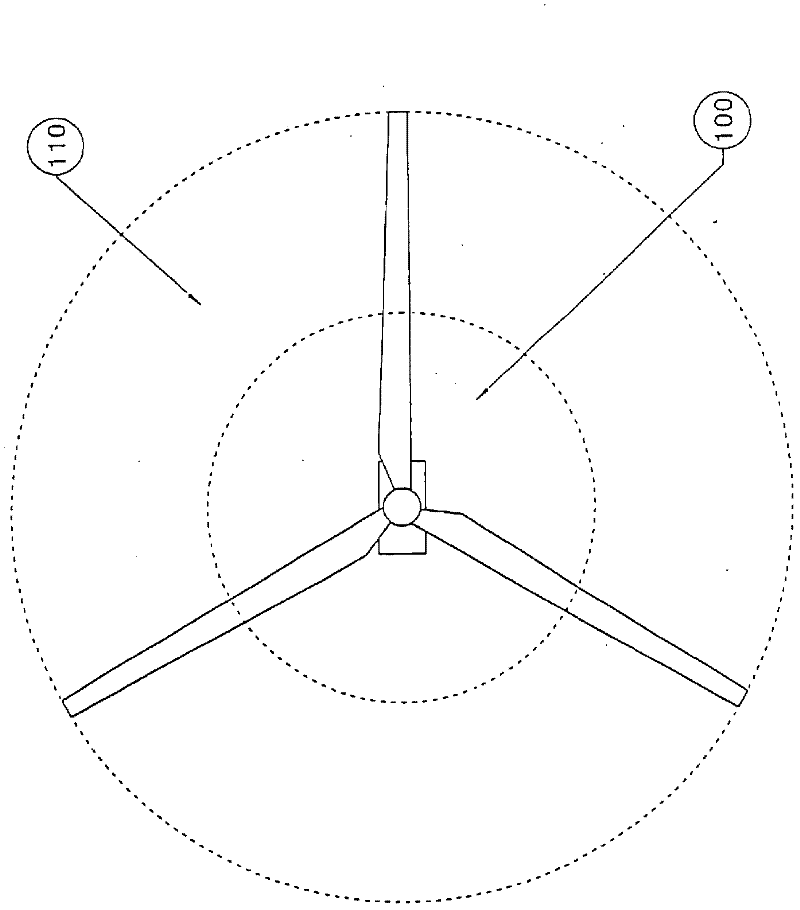

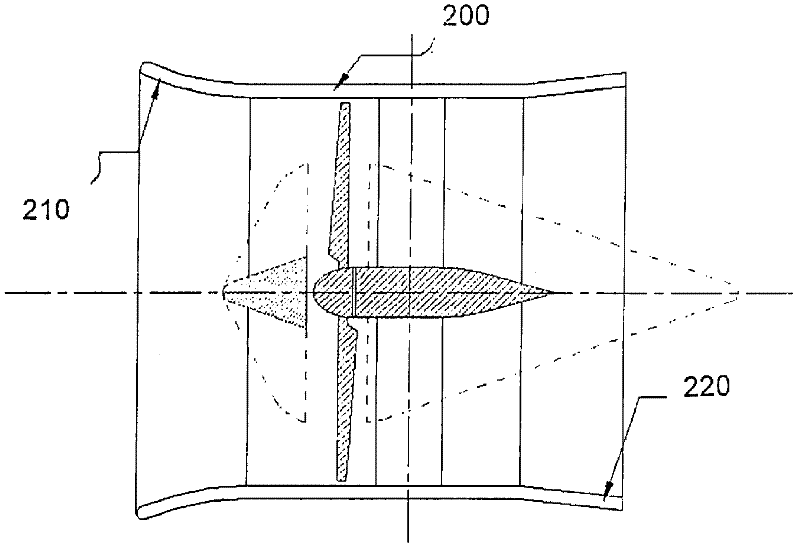

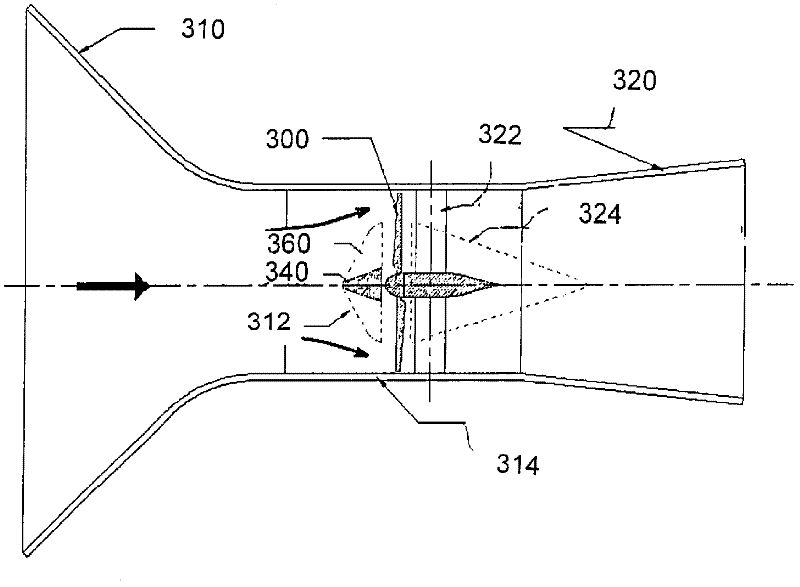

Fluid guidance systems for turbines

A guidance system and turbine technology, applied in the application of control systems, control of reaction engines, wind turbines, etc., can solve the problems of power voltage fluctuation, slow adjustment of hydraulic drive spacing, thick blades, etc., and achieve the effect of stabilizing the rotor speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0138] Example 1: 4.0m / s HAWT segmented rotor

[0139] At 4.0m / s, the segment ratio varies between 1.0 and 0.25. The power generated increases from 10kW to 55kW, or a 5.5-fold increase.

example 2

[0140] Example 2: 7.0m / s HAWT segmented rotor

[0141] At 7.0m / s, the segment ratio varies between 1.0 and 0.25. The power generated increases from 30kW to 300kW, or a 10-fold increase.

example 3

[0142] Example 3: HAWT Segmented Rotor at 12.0m / s

[0143] At 12.0m / s, the segment ratio varies between 1.0 and 0.25. Electricity generated increases from 190kW to 1500kW, or a 7.7-fold increase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com