High-speed jet gas-liquid mixing-phase ejector

A technology of gas-liquid mixing and high-speed injection, which is applied in the direction of injection devices, liquid injection devices, etc., can solve the problems of low outlet velocity and insufficient penetration depth, and achieve the effect of high liquid flow velocity and weakened boundary layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

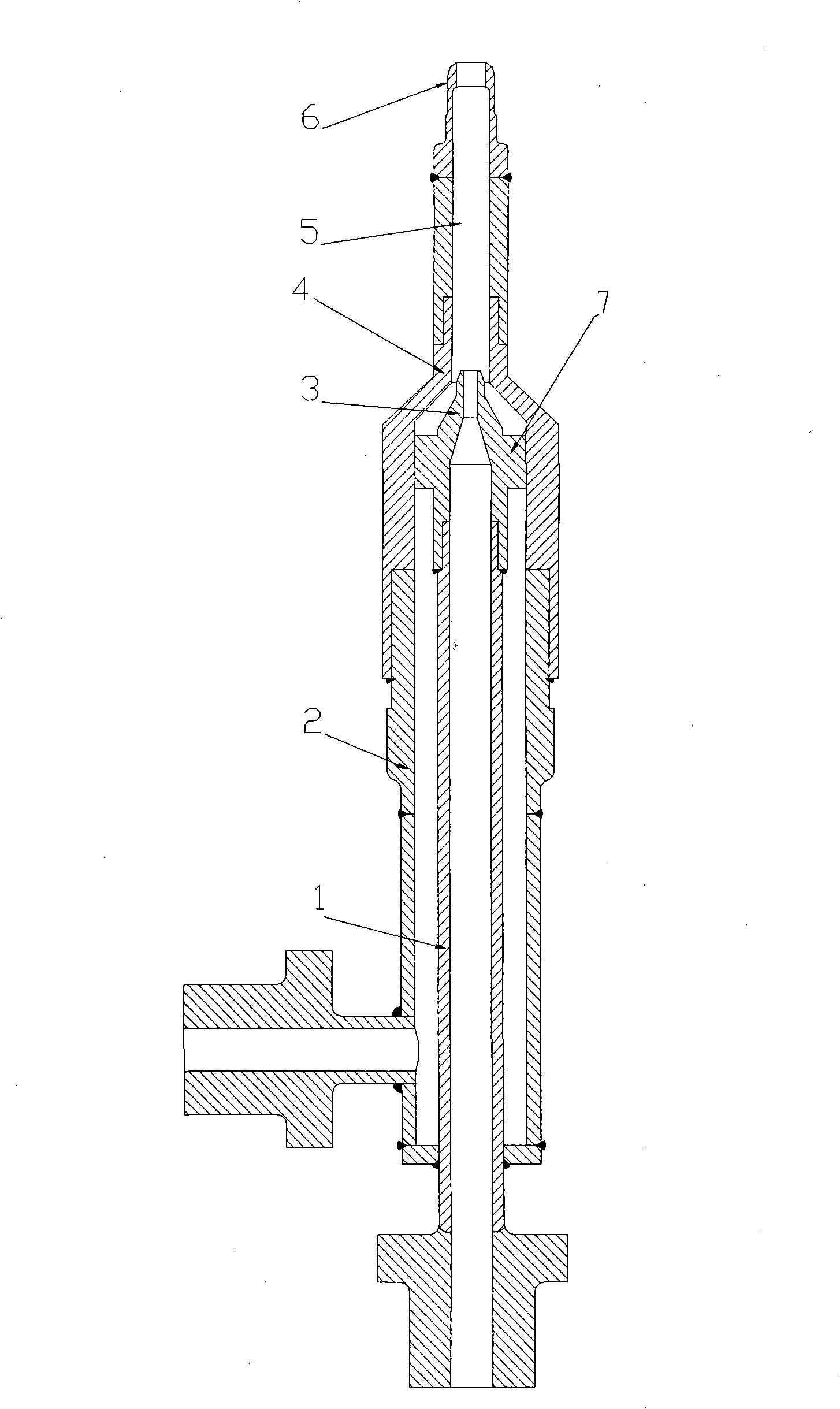

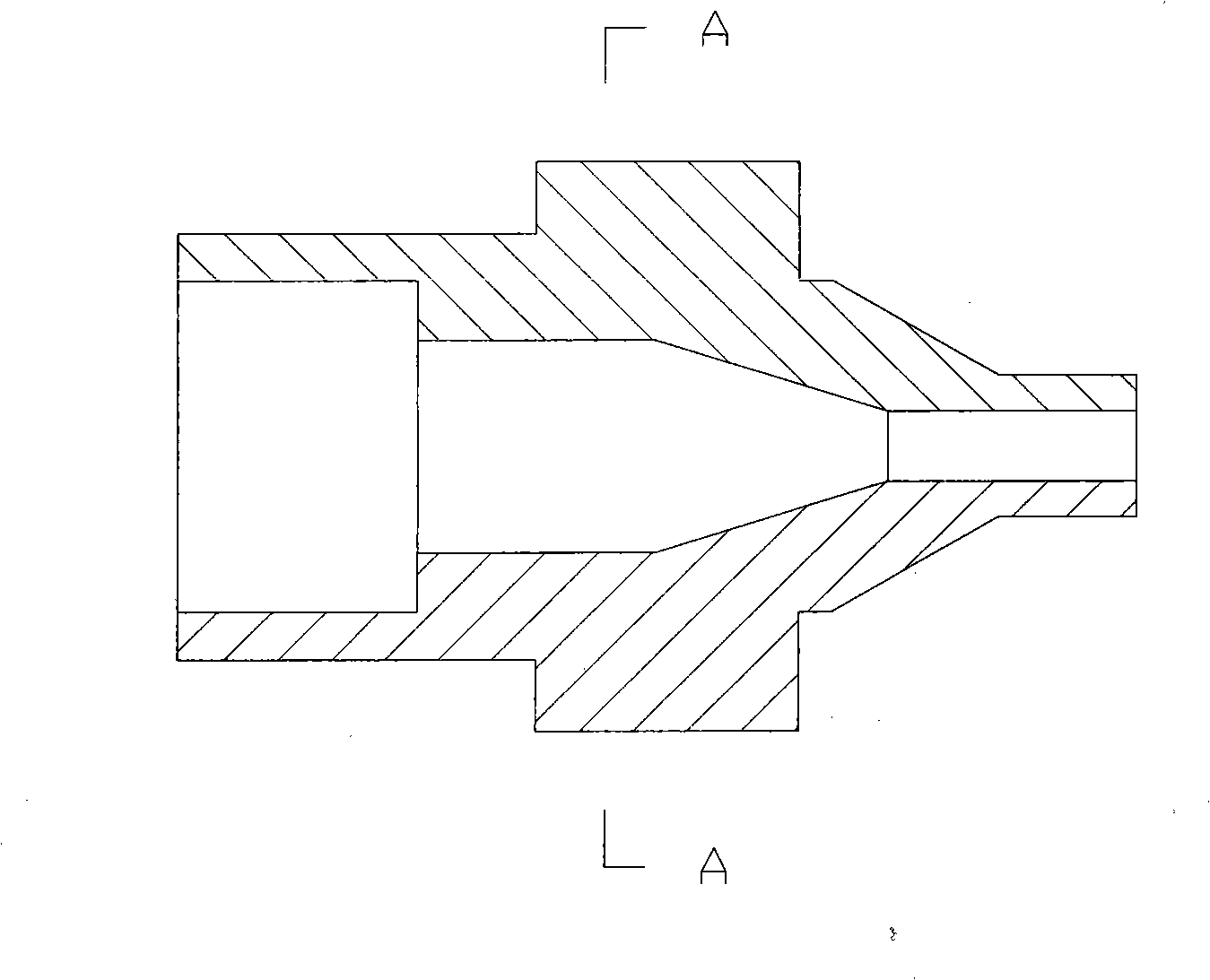

[0031] The gas-liquid mixed-phase injector for high-speed injection in this embodiment is made of 304 stainless steel, and includes a liquid phase inlet pipe 1 and a gas phase inlet pipe 2 with quick fittings respectively. The end of the liquid phase inlet pipe 1 is connected to the liquid phase Nozzle 3, the end of the gas phase inlet pipe 2 is connected to the gas phase nozzle 4; the gas phase inlet pipe 2 surrounds the outside of the liquid phase inlet pipe 1 and forms an annular gas phase flow channel, and the gas phase nozzle 4 surrounds the outside of the liquid phase nozzle 3 and connects the mixing The phase channel 5 and the end of the mixed phase channel 5 are connected to the outlet nozzle 6 .

[0032] The liquid-phase inlet pipe 1 and the gas-phase inlet pipe 2 are respectively connected to a source of ammonia solution with a concentration of about 10% and a source of compressed air through a threaded quick-fit joint. The liquid phase inlet pipe 1 is welded to the ...

specific Embodiment example 2

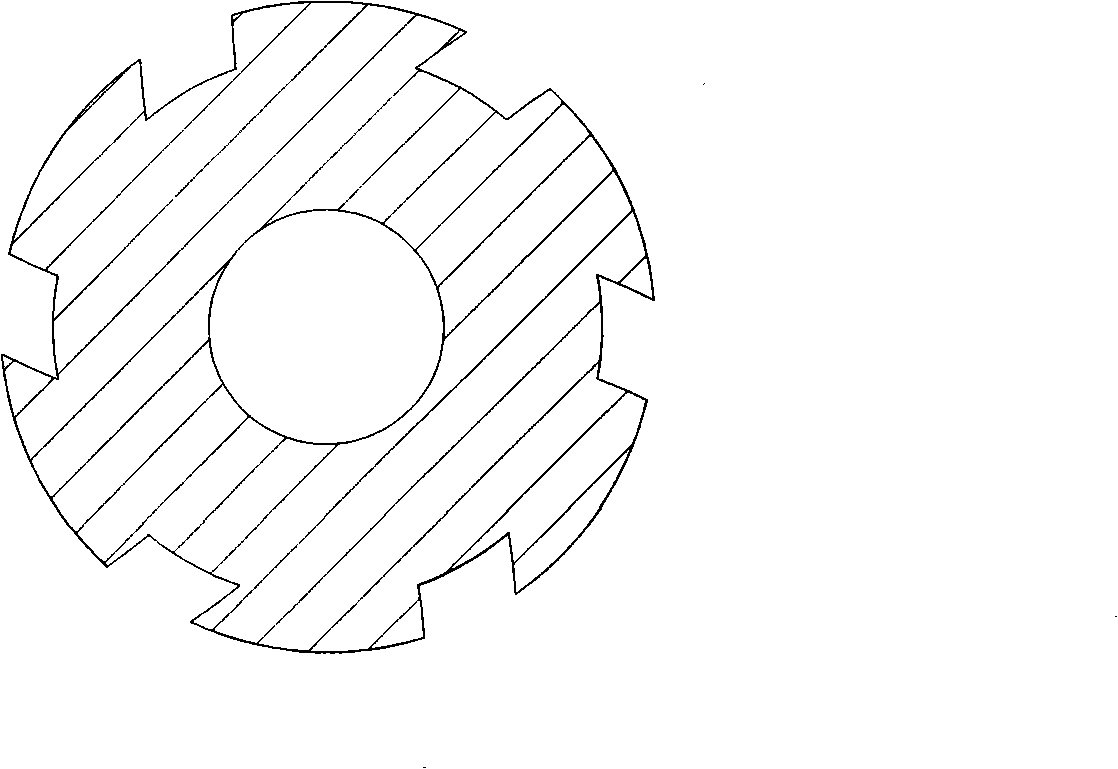

[0035] Different from Embodiment 1, the outlet nozzle 6 of the gas-liquid mixed-phase injector for high-speed injection in this embodiment is provided with 3 outlet holes of equal size, the included angle of the axes is 30°, and the gas-phase swirl sheet is arranged outside the liquid-phase nozzle 3 7. The swirl blade angle is 30°.

[0036] The liquid phase inlet pipe 1 and the gas phase inlet pipe 2 are respectively connected to a urea solution source with a concentration of about 10% and a superheated steam source through a threaded quick-fit joint. The liquid phase inlet pipe 1 is welded to the liquid phase nozzle 3, the gas phase inlet pipe 2 is welded to the gas phase nozzle 4, the gas phase nozzle 4 is welded to the mixed phase flow channel 5, and the outlet nozzle 6 is connected to the mixed phase flow channel 5 with sealing threads.

[0037] The working process of the injector of the present invention is as follows: the urea solution source with a concentration of abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com