PEMFC (proton exchange membrane fuel cell) metal bipolar plate conducive to improving fluid distribution

A technology of proton exchange membrane and metal bipolar plate, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of difficult to realize the precise positioning of the stack, unfavorable water and gas tail gas removal, and the distribution head is limited to the gas flow field, etc. , to achieve the effect of simplifying internal water management, avoiding distortion and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The bipolar plate forming process steps of embodiment 1 are:

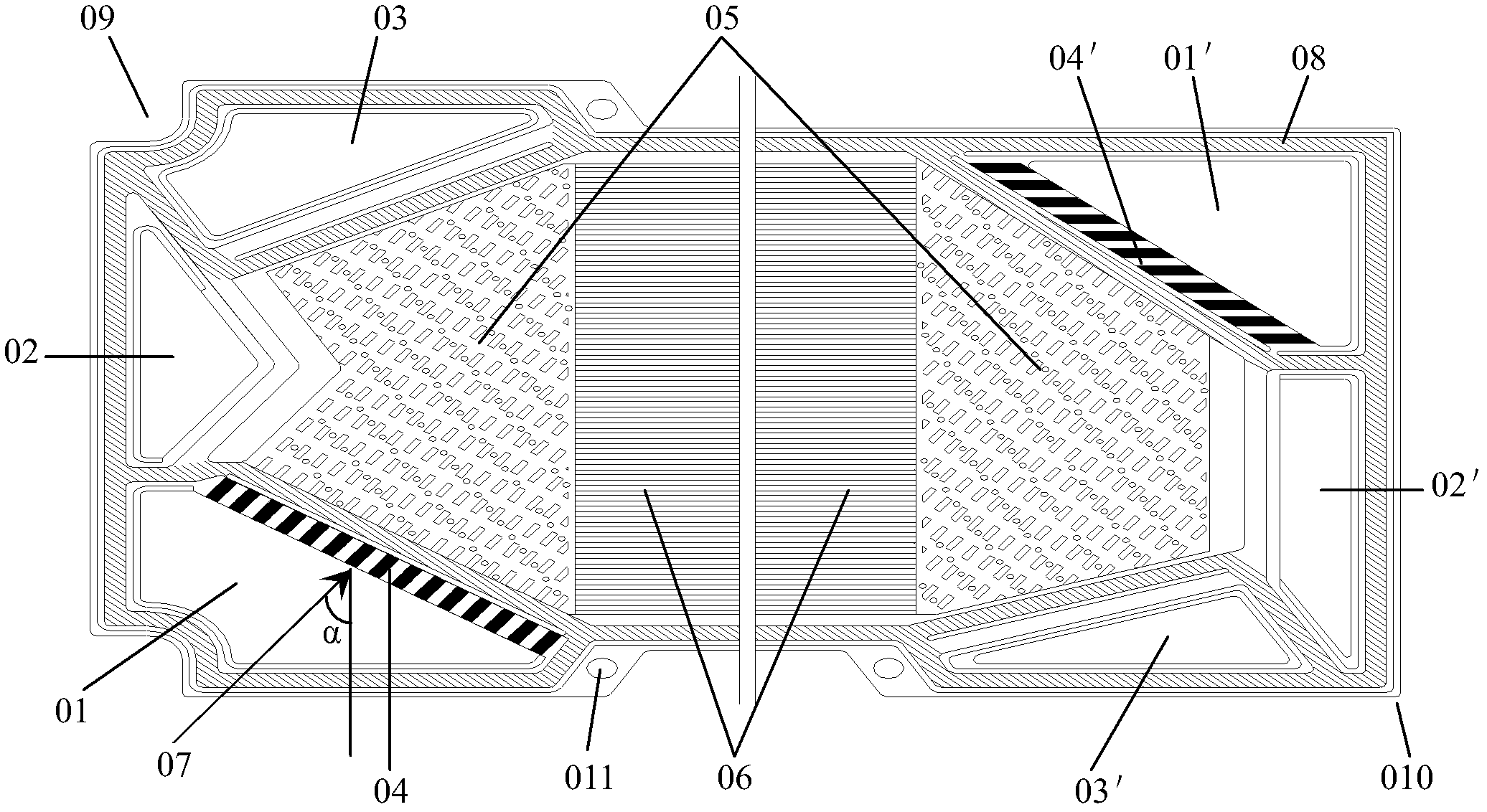

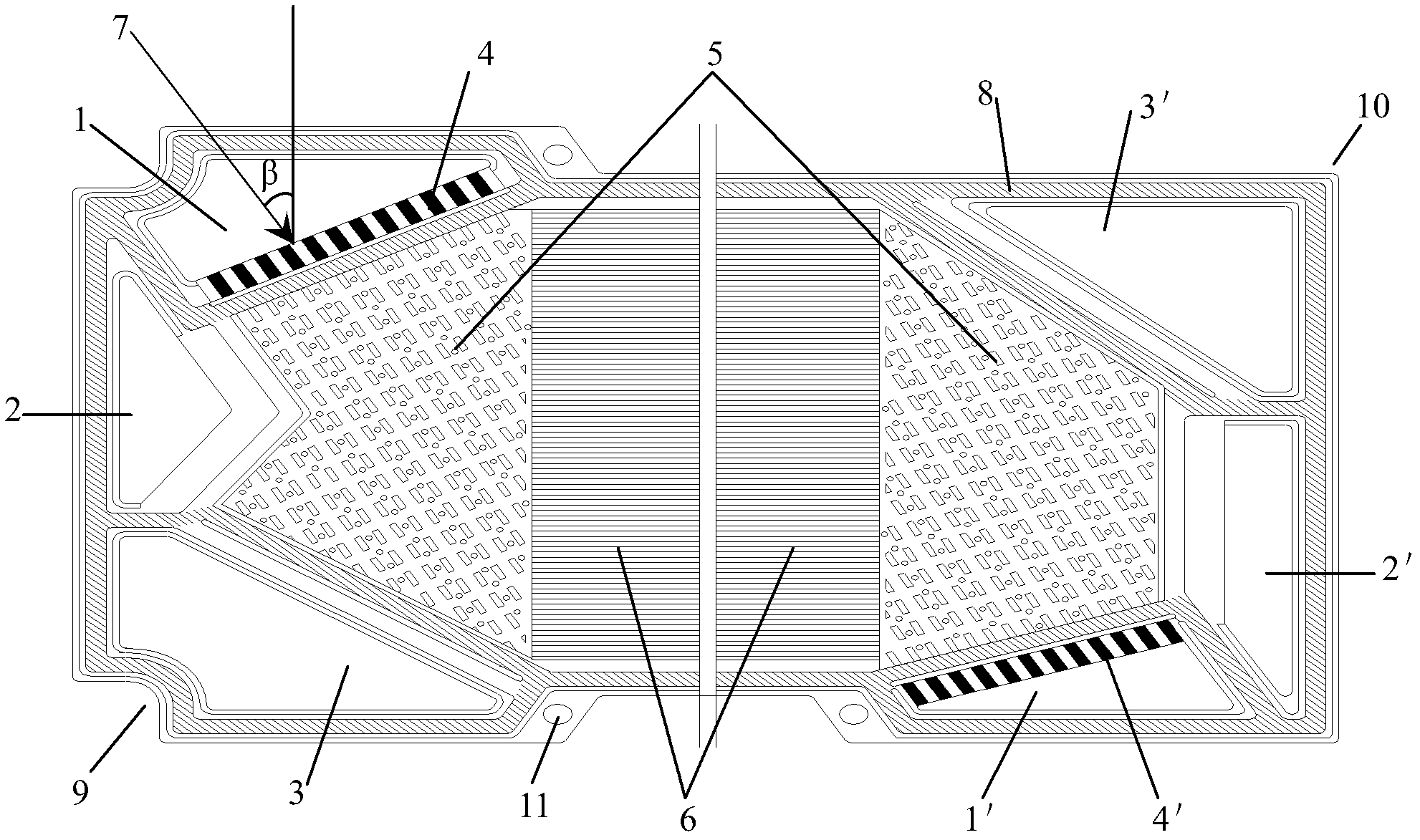

[0033] 1) Select a SUS316L stainless steel sheet with a thickness of 0.1mm, and cold-press the cathode and anode unipolar plates on a four-column hydraulic press, such as figure 1 , figure 2 shown. On both sides of the cathode and anode unipolar plates, there are air chamber common pipes 01, 01', 1, 1', hydrogen chamber common pipes 03, 03', 3, 3' and cooling chamber common pipes 02, 02', 2, 2' , there are DC field flow channels 06 and 6 formed by parallel protrusions and grooves in the middle, and the two ends of the DC field flow channel are rectangular guide islands 13 protruding to the front of the cathode and anode unipolar plates and protruding to the back. The air and hydrogen distribution flow channels 05, 5 formed by the supporting points 14 of the support points and the air and hydrogen gas inlet and outlet flow channels 04, 04', 4, 4' connected with the distribution flow channels, and the dive...

Embodiment 2

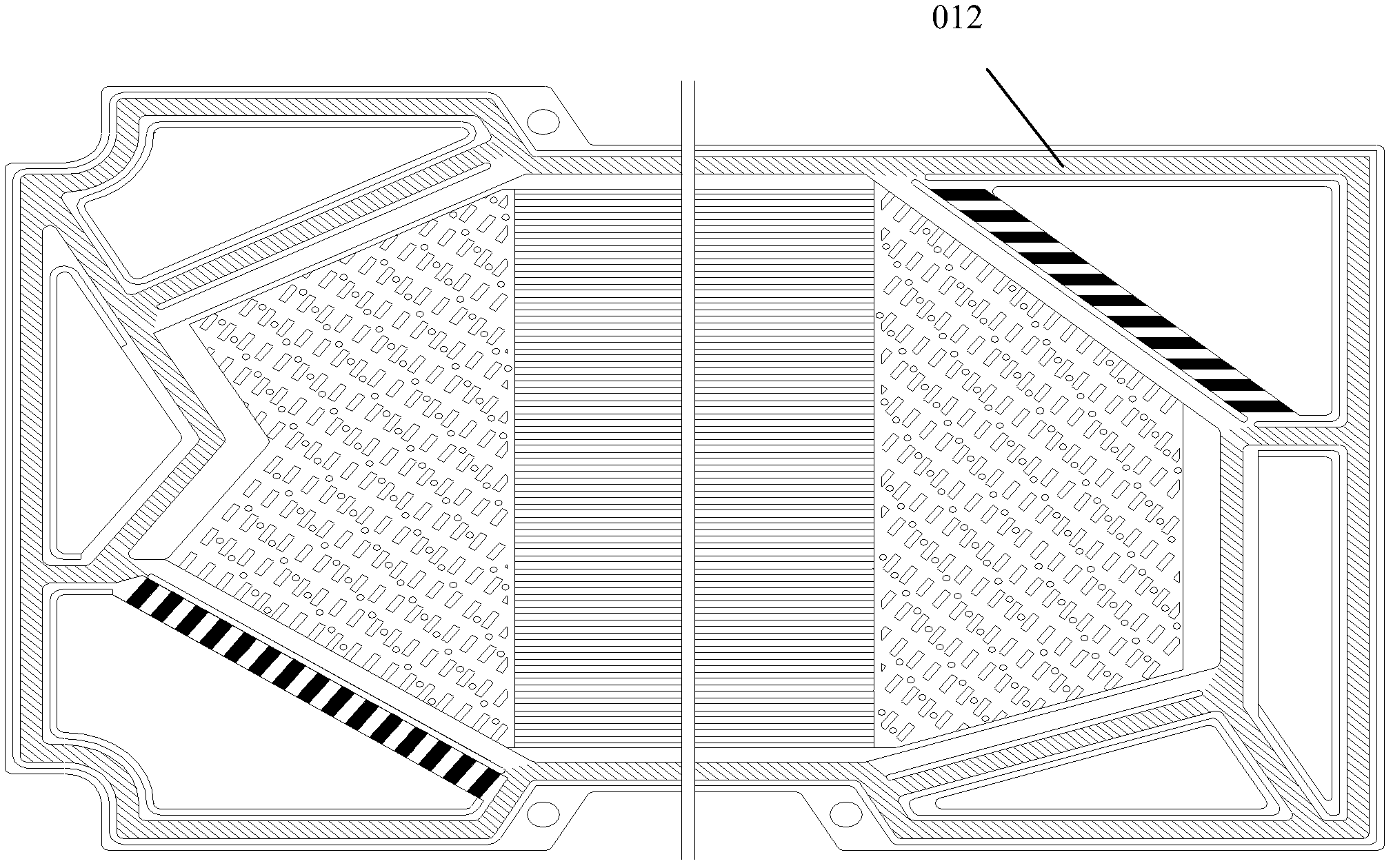

[0041] Expand the effective area of the flow field in Example 1 to the distribution flow channels 05 and 5 of the cathode and anode plates to activate the distribution flow channels 05 and 5, and keep other processes unchanged to obtain bipolar plates with the same flow field design. At this time, the effective area of the flow field can be expanded to 316cm 2 .

Embodiment 3

[0043] Change the height and shape of the diversion island 13 and the support point 14 in the airflow field distribution channel 05 and 5 in Embodiment 1, wherein the diversion island 13 is rhombus in shape, the height becomes 0.2mm, and the length of the long diagonal of the rhombus is 3mm, The length of the short diagonal is 1 mm, the shape of the supporting point 14 is an equilateral triangle, the side length of the triangle is 1 mm, the height becomes 0.4 mm, and other processes remain unchanged, another bipolar plate can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com