Truss beam of tower appts.

A technology for supporting beams and truss beams, applied in the field of truss supporting beams, can solve the problems of large space occupation, large beam weight, affecting the gas-liquid two-phase flow state and mass transfer effect in the tower, and achieves weight reduction and enhancement. Strength, the effect of improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

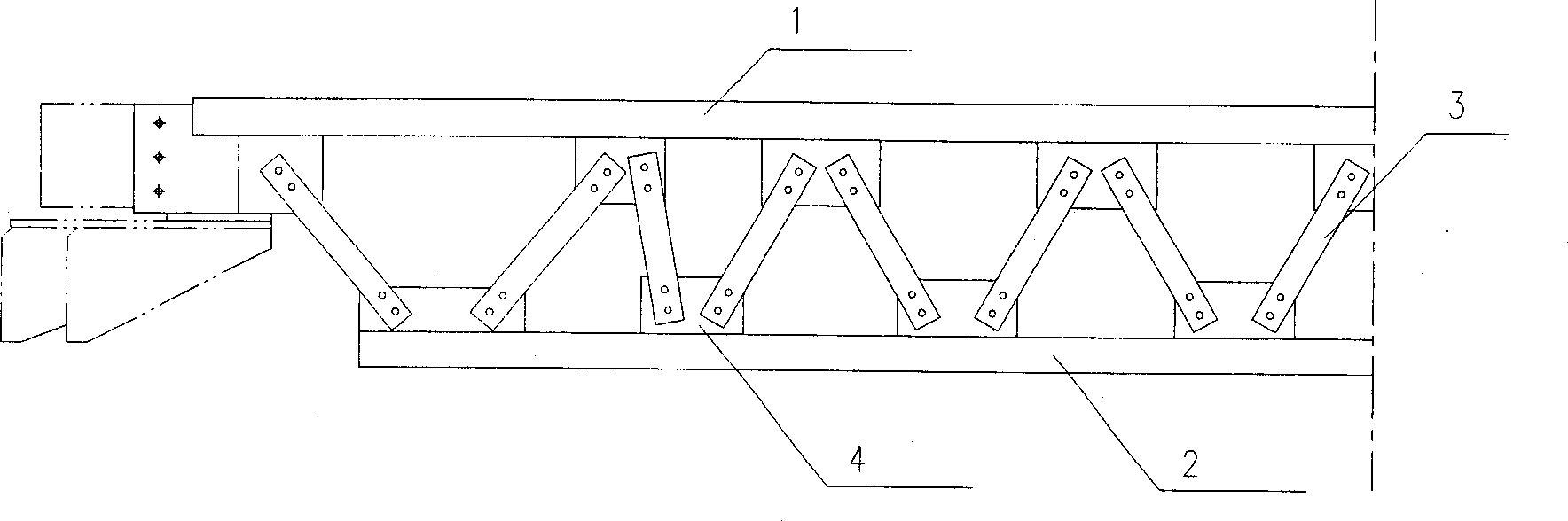

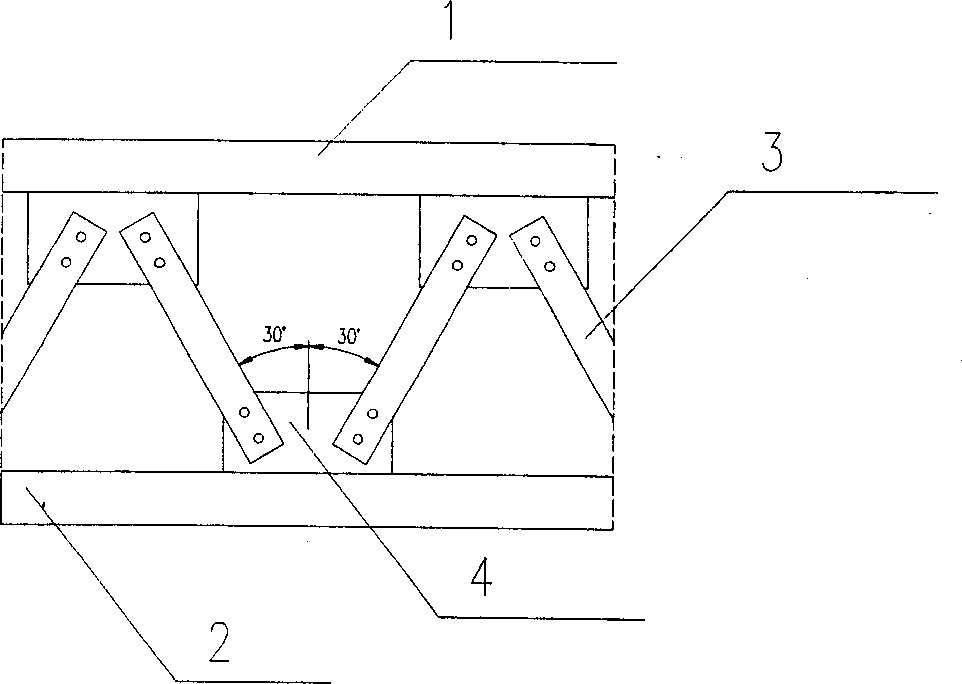

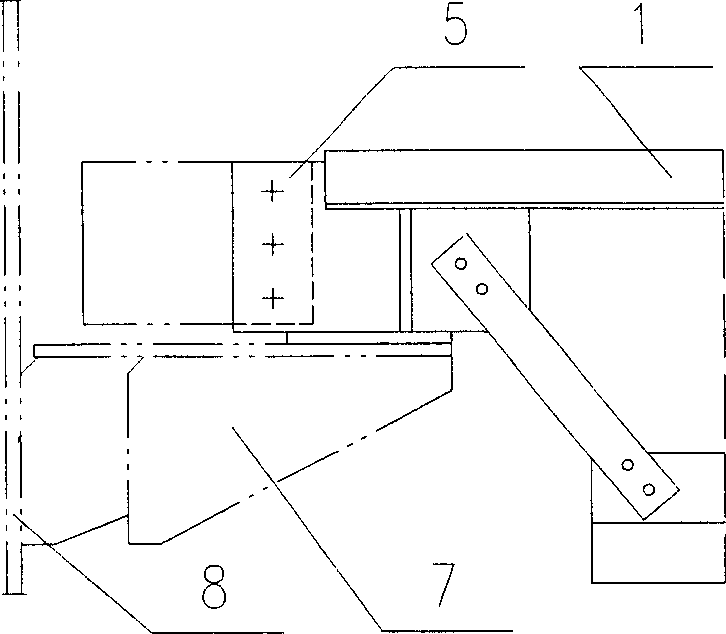

[0021] Such as figure 1 and figure 2 As shown, the main truss beam 1 of the tower truss support beam is connected with the auxiliary truss beam 2 through the connecting plate 4 and the support member 3, and the main truss beam 1 can be the upper end beam of the support beam or the lower end beam of the support beam , the two ends of the auxiliary truss beam 2 are suspended in the air, and the two ends of the main truss beam 1 are connected on the support 7, and are connected with the tower wall 8 through the reinforcing rib 5 at the same time.

[0022] The connecting plates 4 are respectively welded on the main truss girder 1 and the auxiliary truss girder 2, and the connecting plates 4 connect the main truss girder 1, the auxiliary truss girder 2 and the support member 3 through welding or bolt connection, and the two ends of the support member 3 are respectively connected On the connecting plate 4 on the main truss girder 1 and the auxiliary truss girder 2, the angle betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com