Integrated high power led high bay lamp based on phase change heat transfer technology

An LED industrial and mining lamp, an integrated technology, applied in semiconductor devices of light-emitting elements, office buildings, lighting and heating equipment, etc., to achieve the effect of compact structure, long service life and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below.

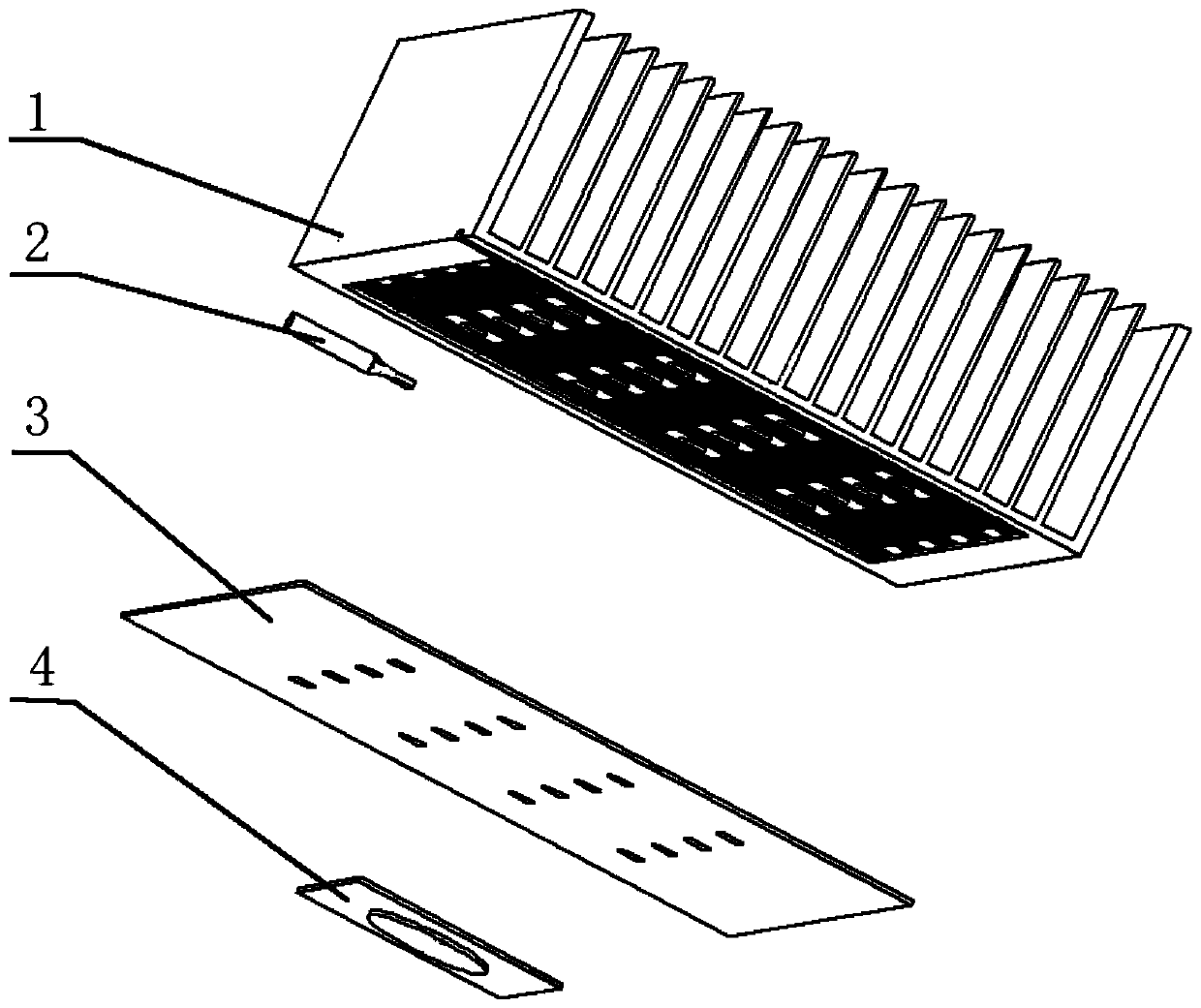

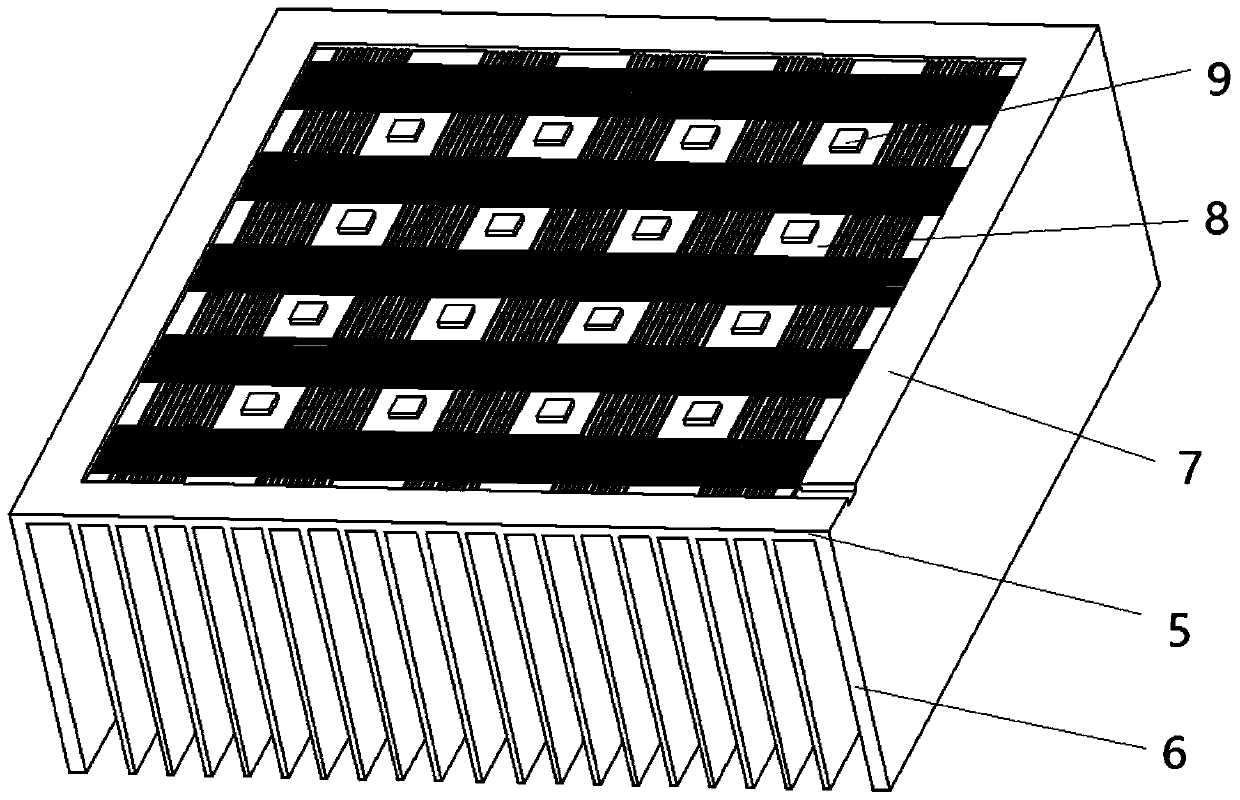

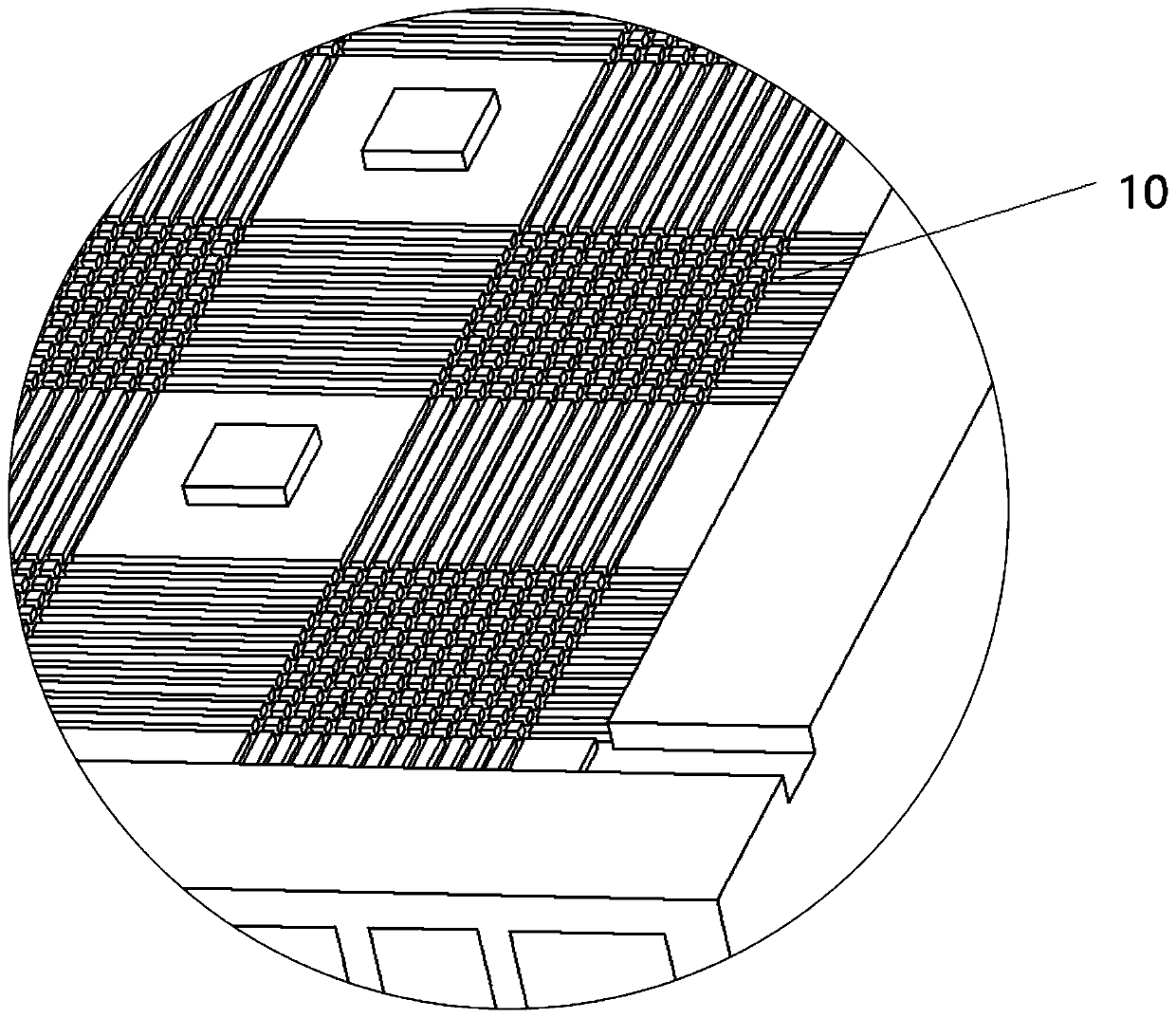

[0033] An integrated high-power LED industrial and mining lamp based on phase change heat transfer technology, including a COB light source, an evaporating plate, and a radiator connected sequentially from bottom to top, and also includes a cavity connected between the evaporating plate and the radiator. Liquid column. The radiator, liquid filling column and evaporating plate are welded to form a whole, and the cavity formed by the base of the radiator and the evaporating plate is evacuated and filled with working fluid through the liquid filling column, and then sealed; then the COB light source is pasted on the The lower surface of the evaporation plate.

[0034] The radiator is extruded first, and there are many vertical fins on it. The fins are rectangular and evenly distributed on the base of the radiator. The fins are parallel to each other with a certain gap. The thickness of the base is 2mm.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com