A kind of head with enhanced boiling heat transfer network groove connected to the surface of the hole array

A technology of enhanced boiling and array holes, applied in sealing, nuclear power generation, climate sustainability, etc., can solve the problems of reliability, effectiveness, controllability, coating damage, etc., to delay critical crisis and increase heat transfer Area, the effect of enhancing the boiling heat transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

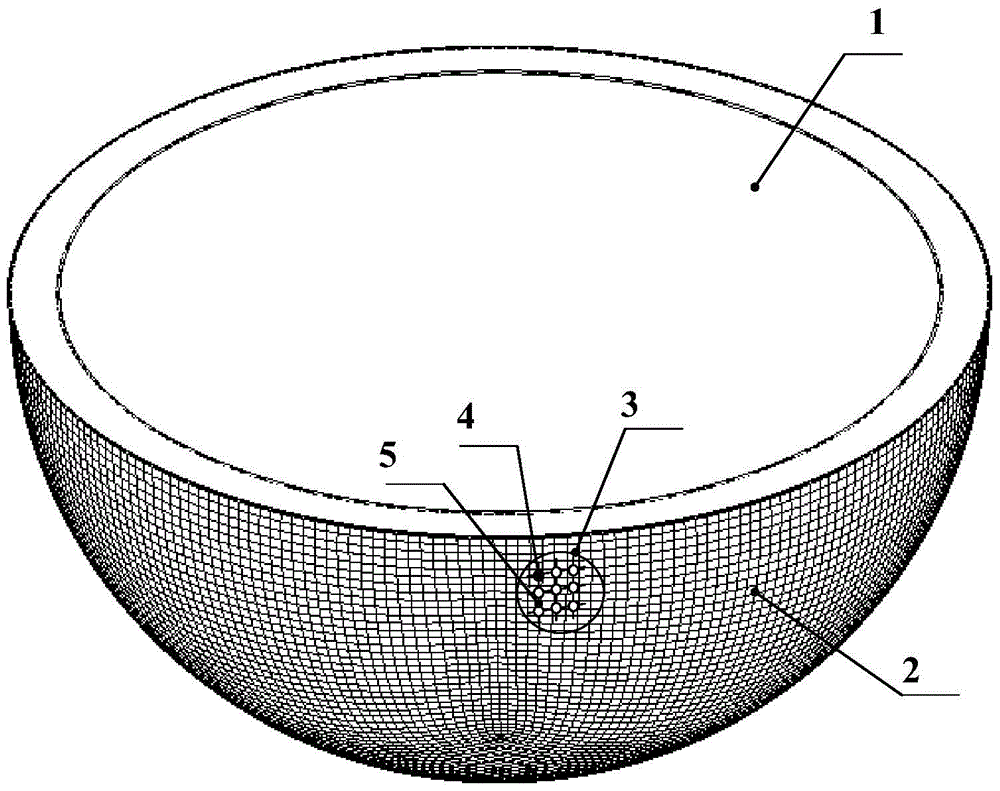

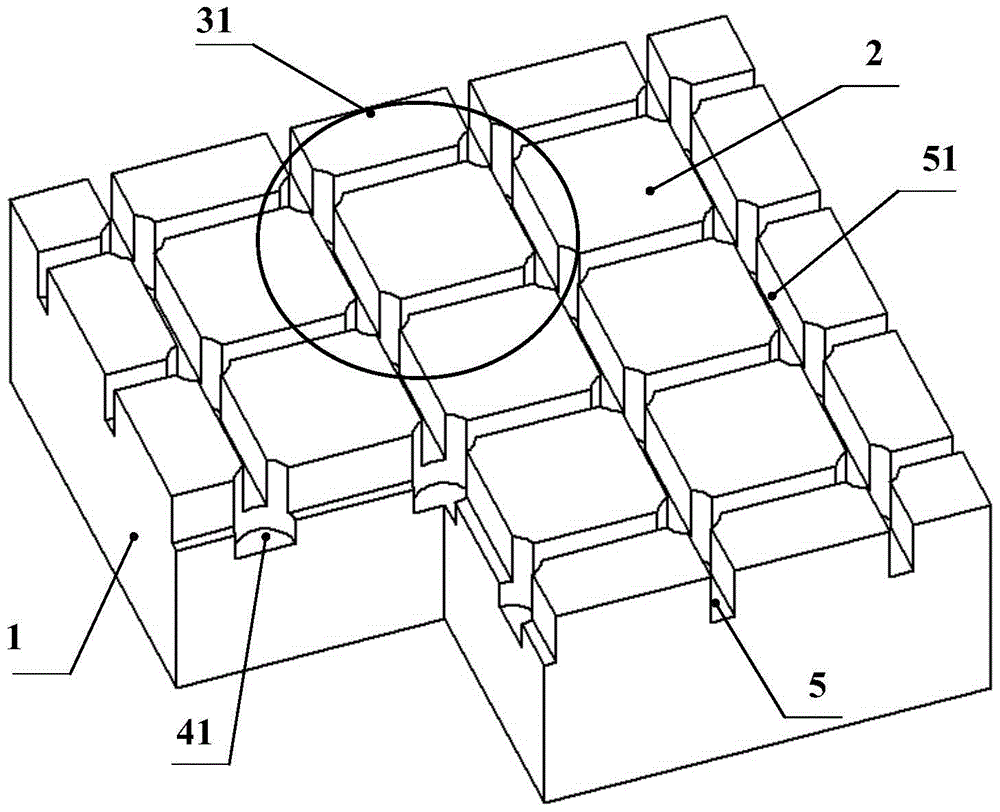

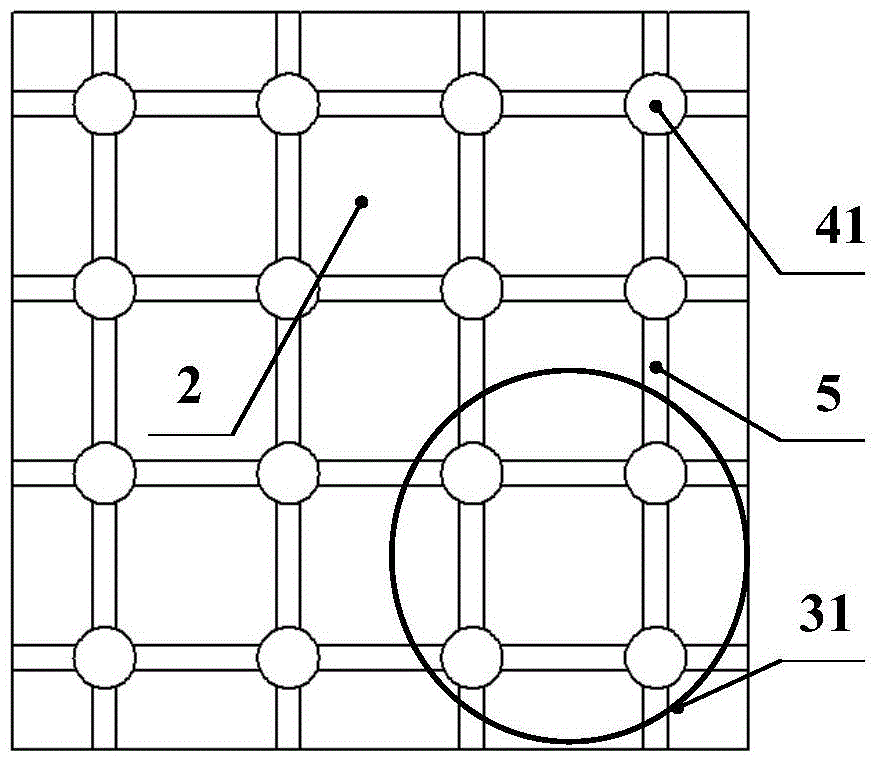

[0041] figure 1 It is a structural schematic diagram of a sealing head provided by the first embodiment of the present invention, which has network-like grooves communicating with the surface of array holes for enhanced boiling heat transfer. figure 2 It is a schematic diagram of a three-dimensional cross-sectional structure of an enhanced boiling heat exchange network groove interconnected array hole structure provided by the first embodiment of the present invention.

[0042] Such as figure 1 and figure 2As shown, a reticular groove 5 is arranged on the outer surface 2 of the lower head 1 of the reactor pressure vessel, and is arranged at the intersection of a plurality of groove units 51 that form the reticular cross-communication arrangement of the reticular groove 5 The communication hole unit 41, several groove units 51 communicate with the adjacent communication hole units 41, thereby forming a structure of array holes connected by network grooves on the head outer ...

Embodiment 2

[0056] Figure 15 Shown is a three-dimensional cross-sectional view of the second embodiment. In order to further increase the wettability of the array hole structure 3 connected by the mesh groove to further enhance the boiling heat transfer and increase the critical heat flux density, a mesh groove can be set on the outer surface 2 of the lower head of the reactor pressure vessel On the basis of the connected array hole structure, isolated hole units 42 are arranged on the smooth surface to further increase the heat exchange area, enhance the wettability of the wall surface, enhance boiling heat exchange and increase the critical heat flux density. The isolated hole unit 42 is a kind of hole unit not connected by the groove unit 51 , and the communicating hole unit 41 is a kind of hole unit connected by the groove unit 51 . The structural features of the isolated hole unit 42 and the connected hole unit 41 in this embodiment are the same or different. The hole unit 4 in th...

Embodiment 3

[0060] Figure 16 Shown is a three-dimensional cross-sectional view of a third embodiment. In order to further increase the wettability of the array hole structure 3 connected by the mesh groove to further enhance the boiling heat transfer and increase the critical heat flux density, a mesh groove can be set on the outer surface 2 of the lower head of the reactor pressure vessel On the basis of the connected array hole structure, set micro-surface structures such as micro-grooves, micro-protrusions and / or micro-holes, such as triangular micro-grooves, rectangular micro-grooves, columnar micro-protrusions, hemispherical micro-protrusions, micro-round holes , micro-irregular holes, sandblasting rough surface, rough surface processing, etc., can improve the wettability of the wall, and is more conducive to the liquid entering the heat transfer surface, so that the boiling heat transfer can be further enhanced and the critical heat flux density can be increased. The micro-surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com