Composite microcolumn-porous surface structure for enhancing boiling heat transfer

A technology to enhance boiling and surface structure, applied in electrical components, electric solid devices, circuits, etc., can solve problems such as deteriorating heat transfer, affecting boiling heat transfer effect, reducing heat transfer area, etc., to increase heat transfer area, enhance The effect of boiling heat transfer and the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

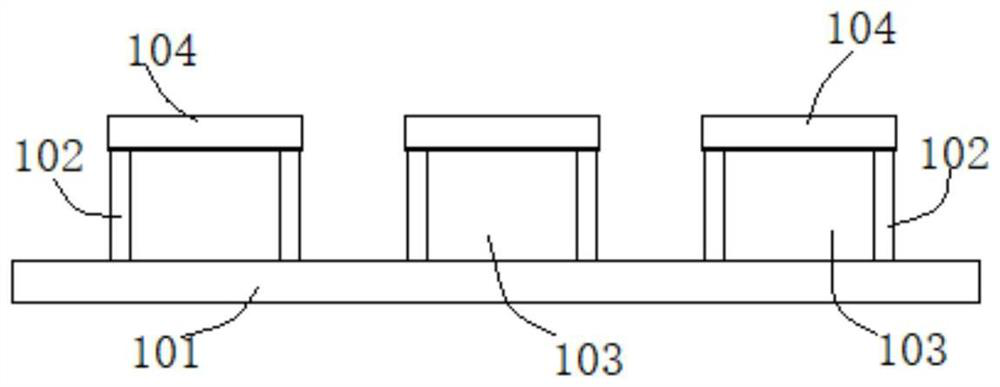

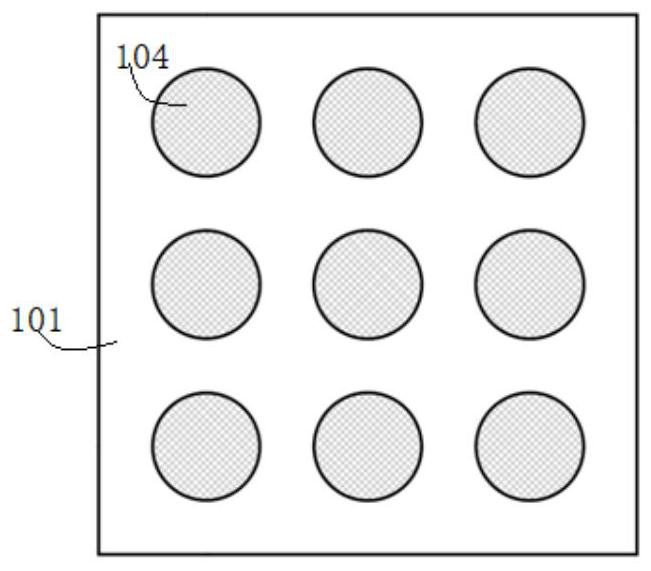

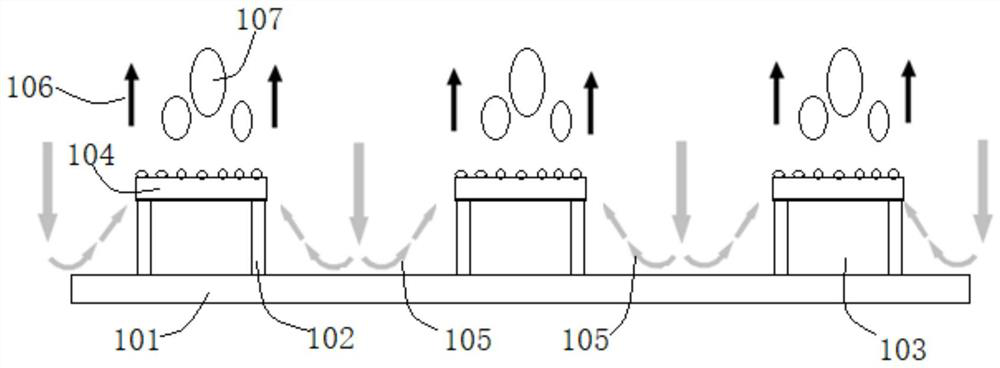

[0032] Such as Figure 1-Figure 4 As shown, a composite microcolumn-porous surface structure for enhancing boiling heat transfer in this embodiment includes a heating substrate 101 and several microcolumn structures arranged on the surface of the heating substrate 101. The microcolumn structure consists of an internal high It consists of a thermally conductive inner core 103, a high thermal resistance wall 102 surrounding the outside, and a porous capillary core 104 at the top, and channels are formed between several microcolumn structures. Specifically, the high thermal conductivity inner core 103 is made of a high thermal conductivity material whose thermal conductivity is not lower than 2000W / m·K. The high thermal resistance wall surface 102 is made of high thermal resistance material, and its thermal conductivity is below 0.05W / m·K.

[0033] In this embodiment, the micro-column structure can adopt various structural forms, such as cylindrical, conical, etc., or a columnar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com