Patents

Literature

62results about How to "Increase critical heat flux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

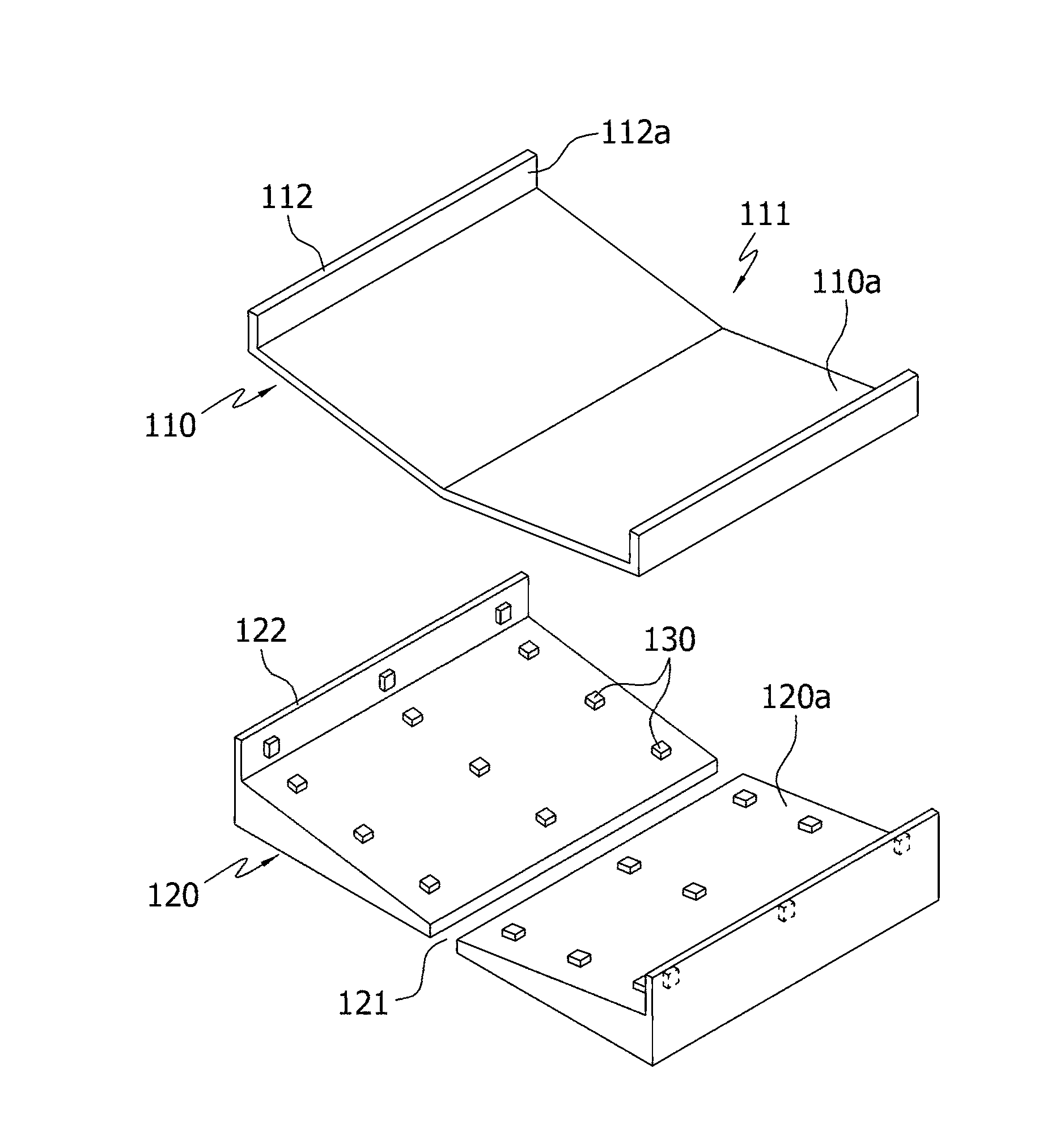

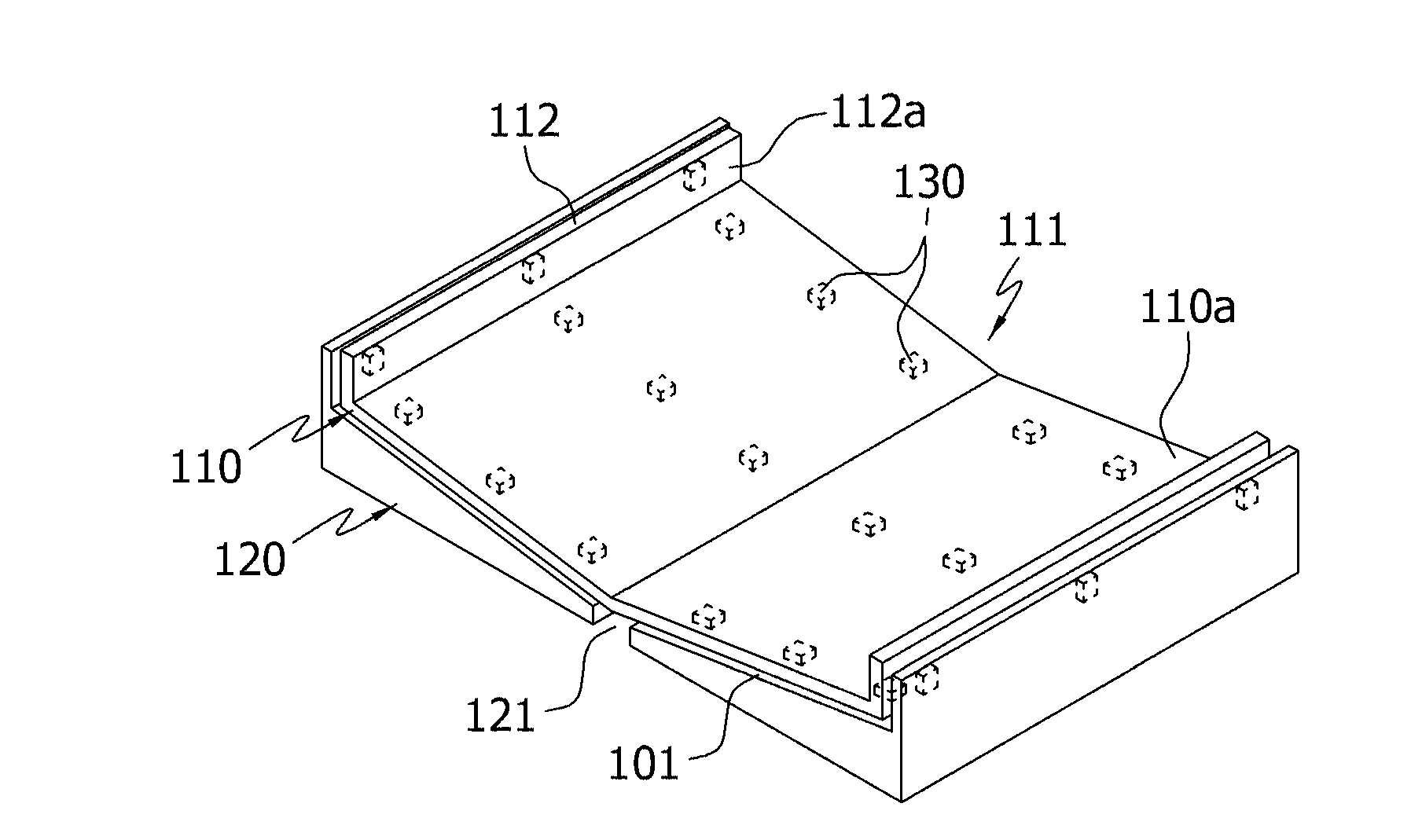

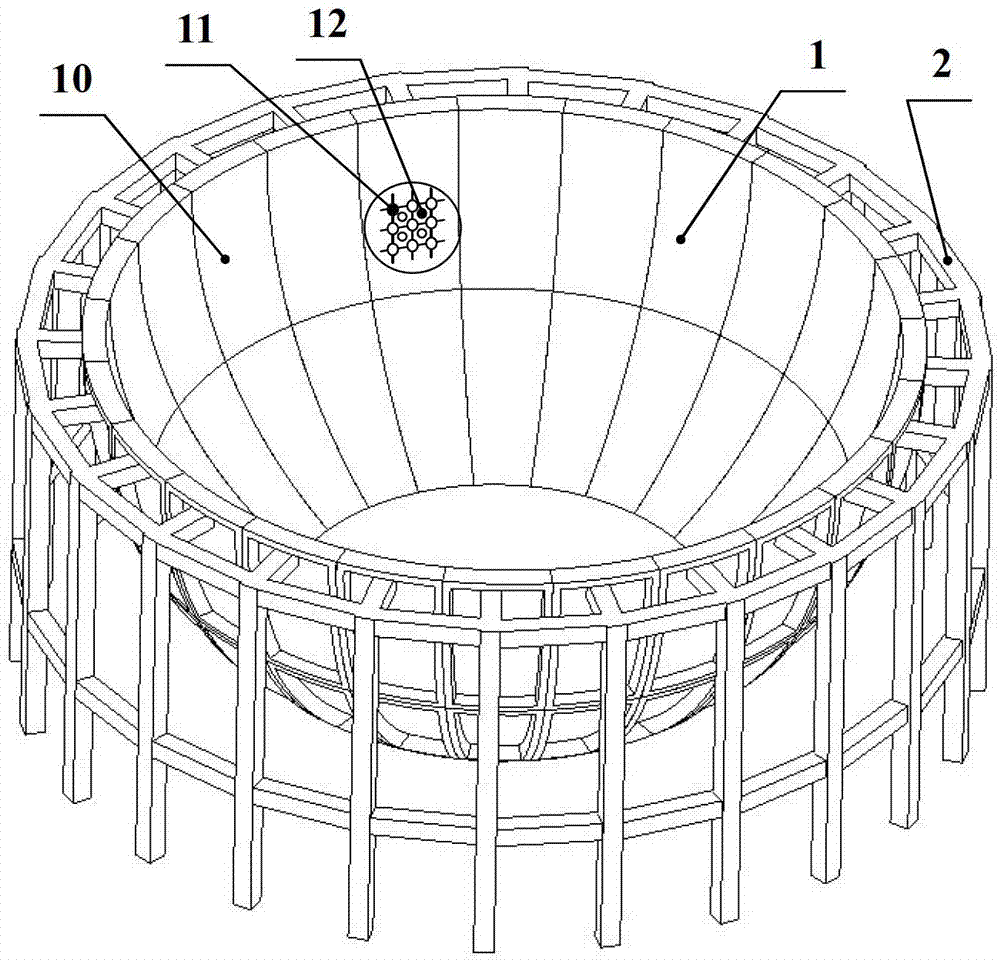

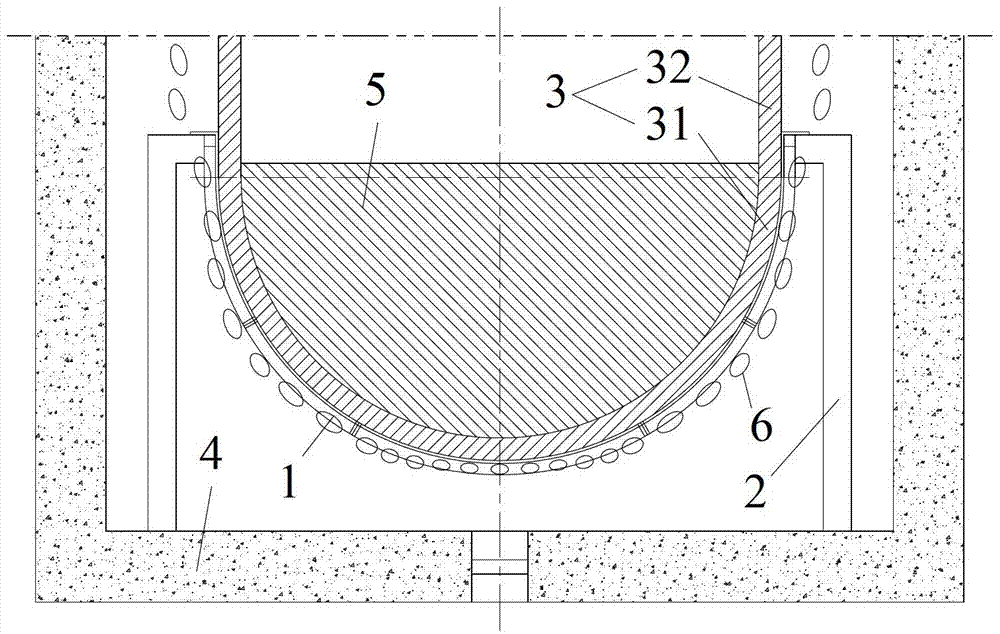

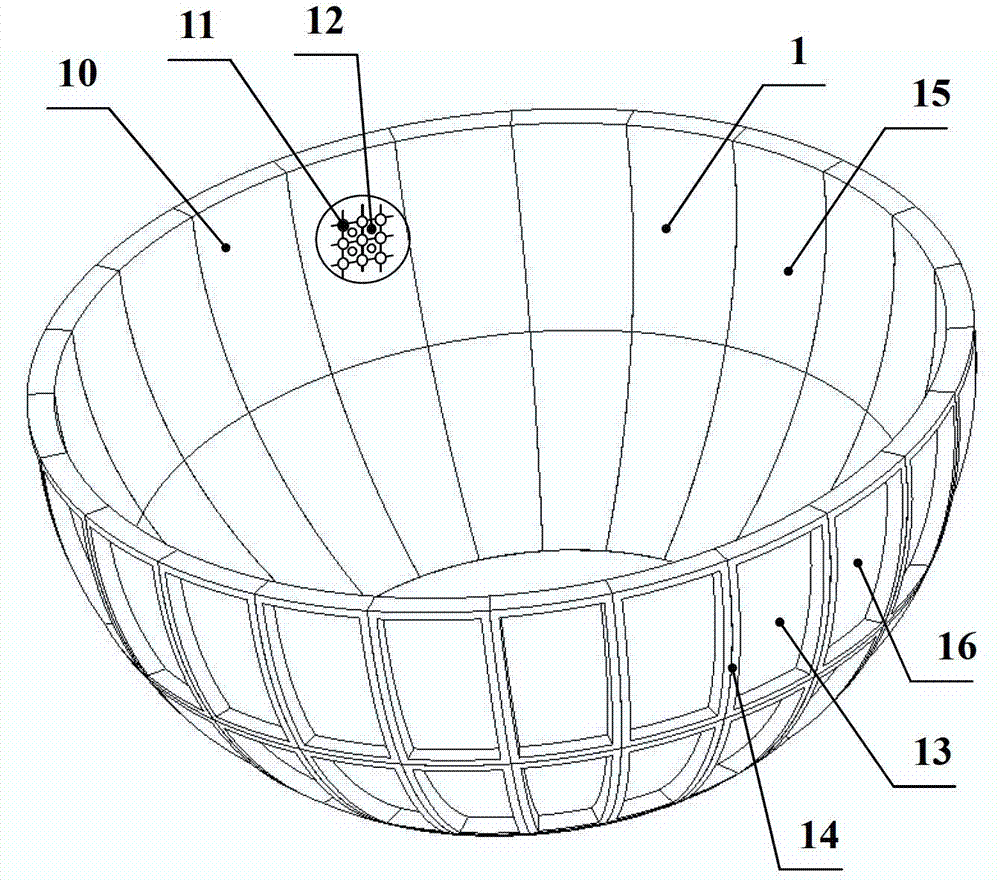

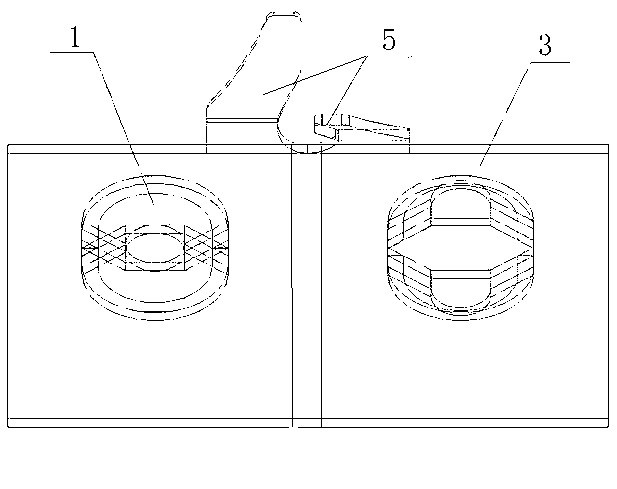

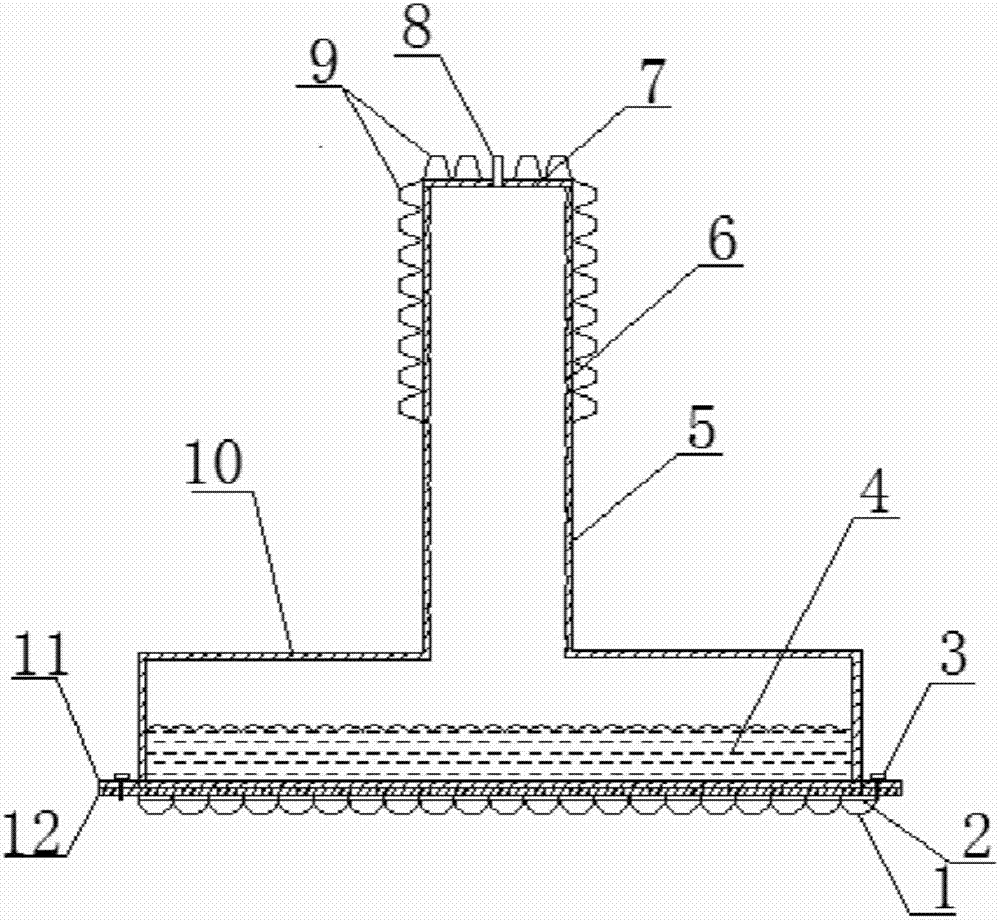

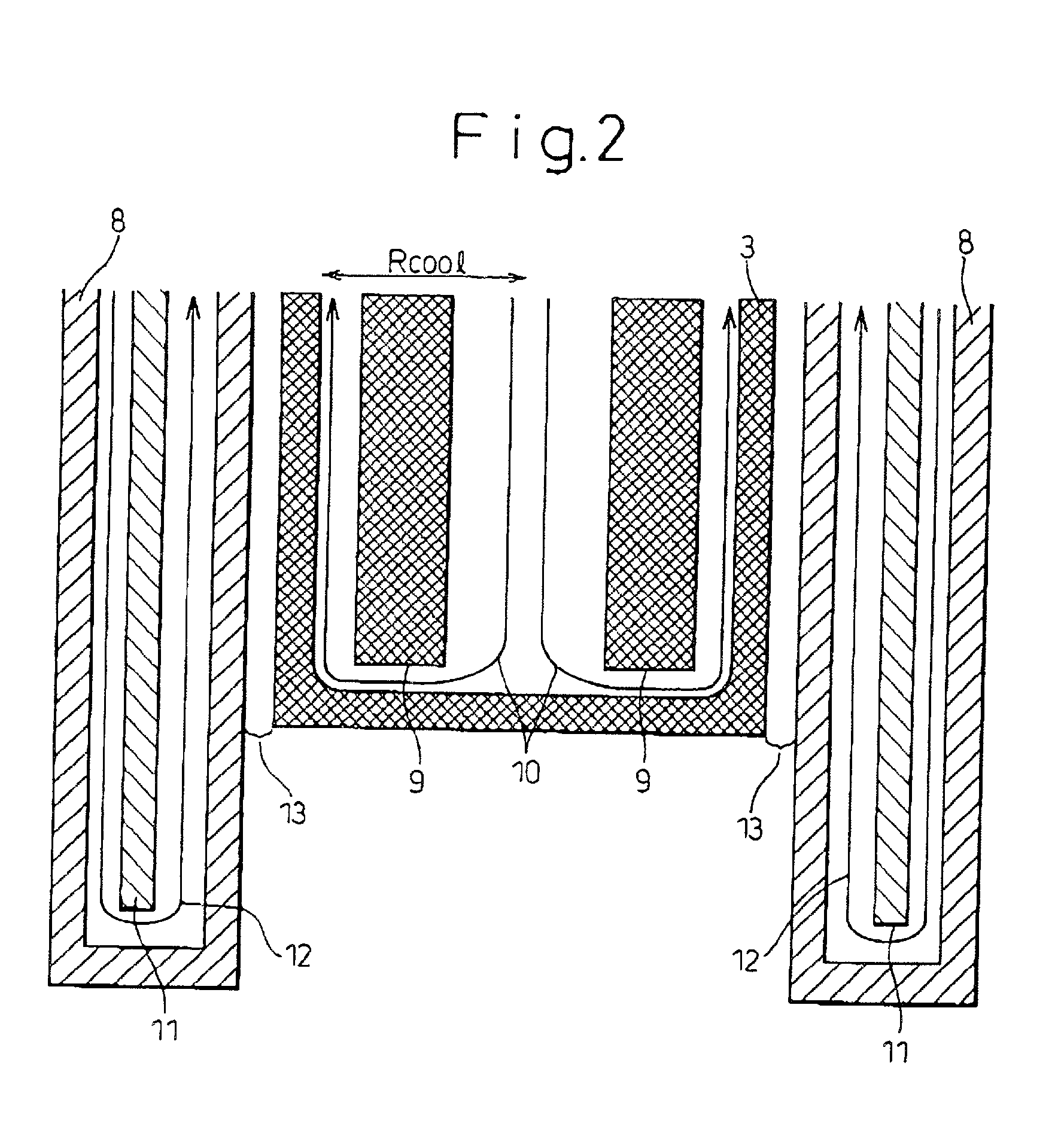

Core catcher having an integrated cooling path

ActiveCN103081023AIncrease heat transfer areaImprove cooling effectNuclear energy generationEmergency protection arrangementsCore catcherNuclear reactor

The object of the present invention is to provide a core catcher having an integrated cooling path, which comprises a structure able to effectively collect, retain and cool molten core material discharged through a damaged part of a nuclear reactor pressure container during a major incident in a nuclear power station. To this end, the present invention is a core catcher which is disposed underneath the nuclear reactor pressure container in order to retain and cool molten core material discharged through a damaged part of the nuclear reactor pressure container and prevent interaction between the molten core material and the pressure-holding structure of the reactor building during a major incident in the nuclear power station, and which comprises: a main container in the shape of an inverted roof which is provided underneath the nuclear reactor pressure container and collects the molten core material; and a lower structure which is disposed below and outside the main container with supports disposed at scattered points placed in between, thereby forming a cooling path having a predetermined spacing for eliminating the heat of the molten core material.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD +1

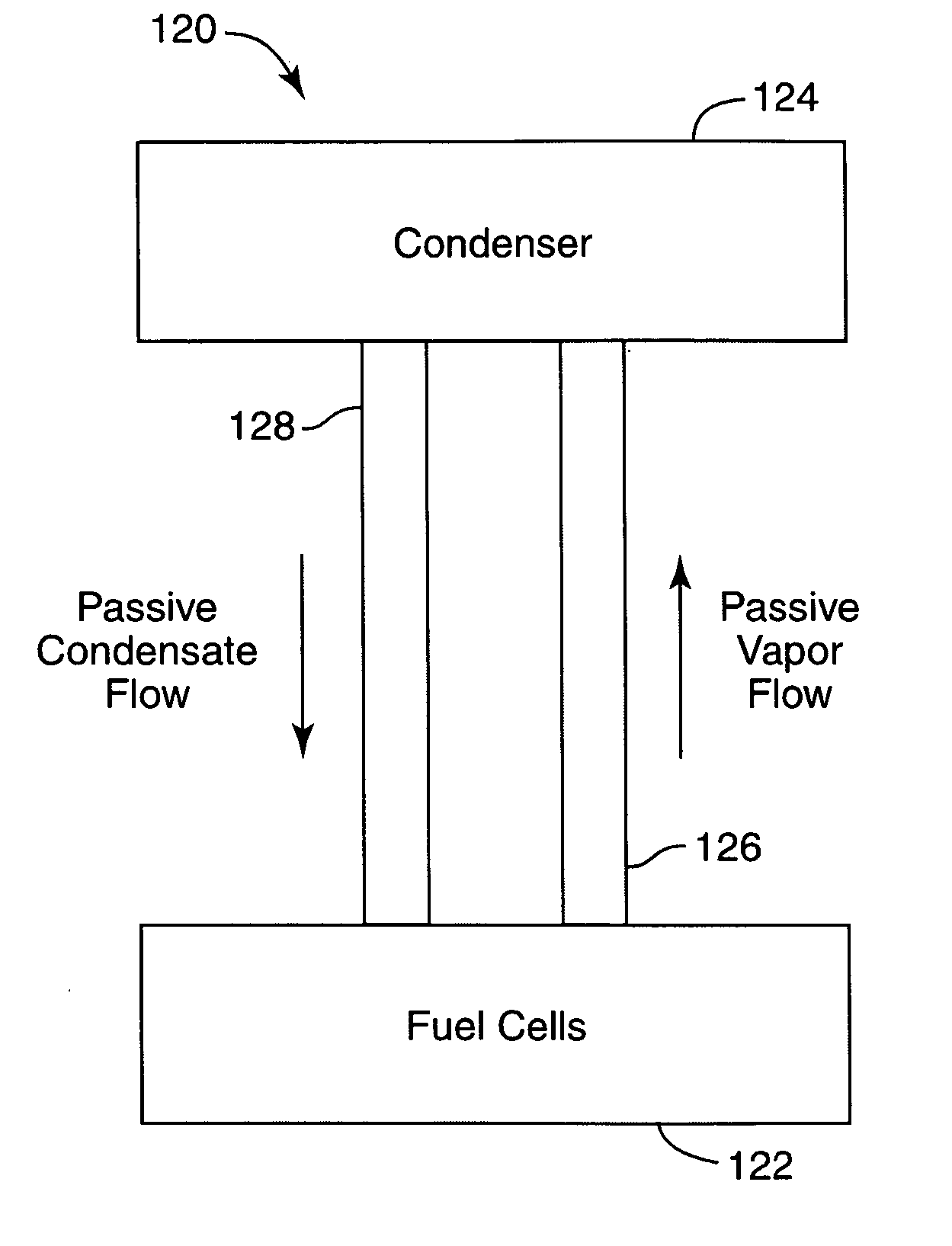

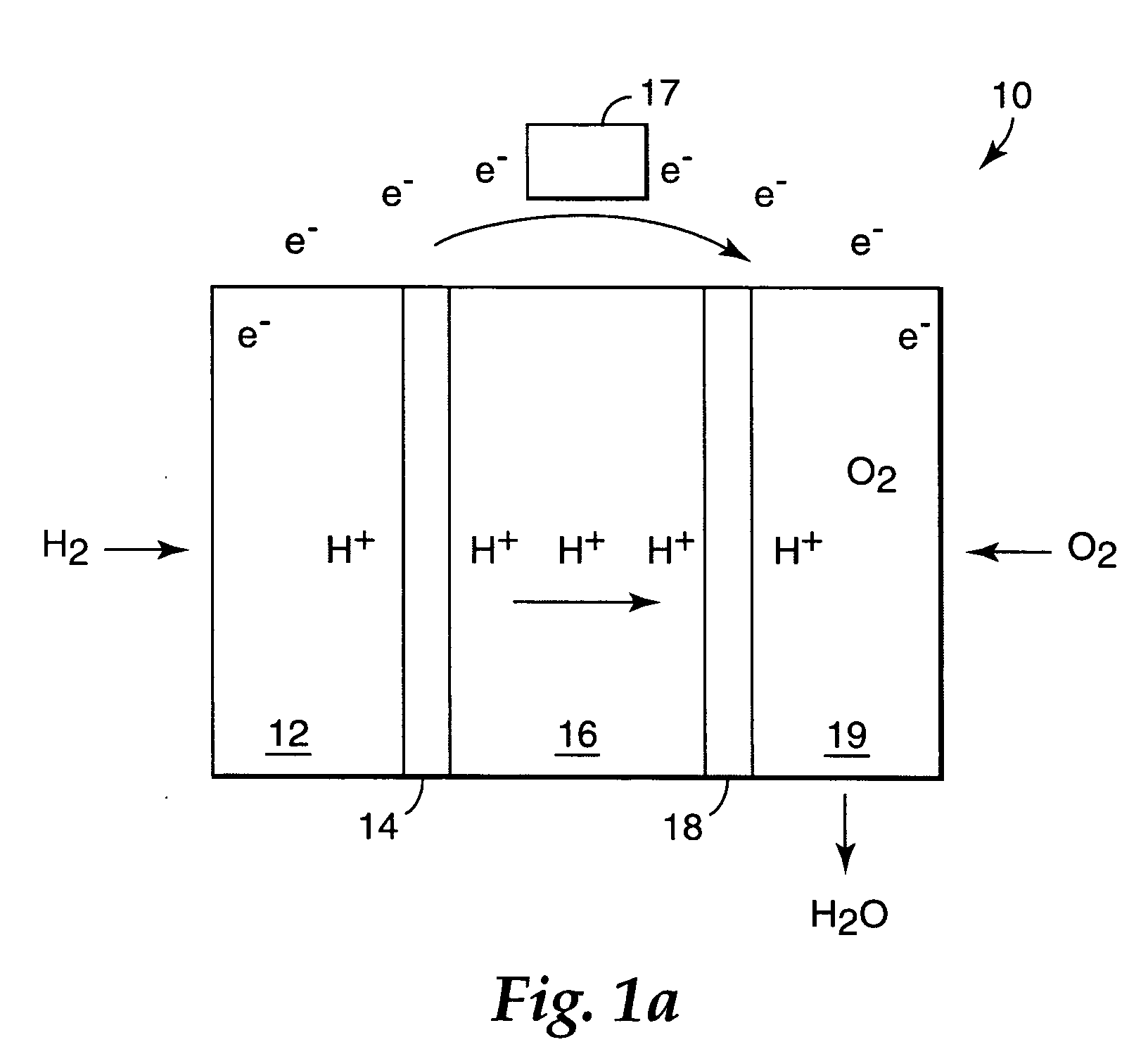

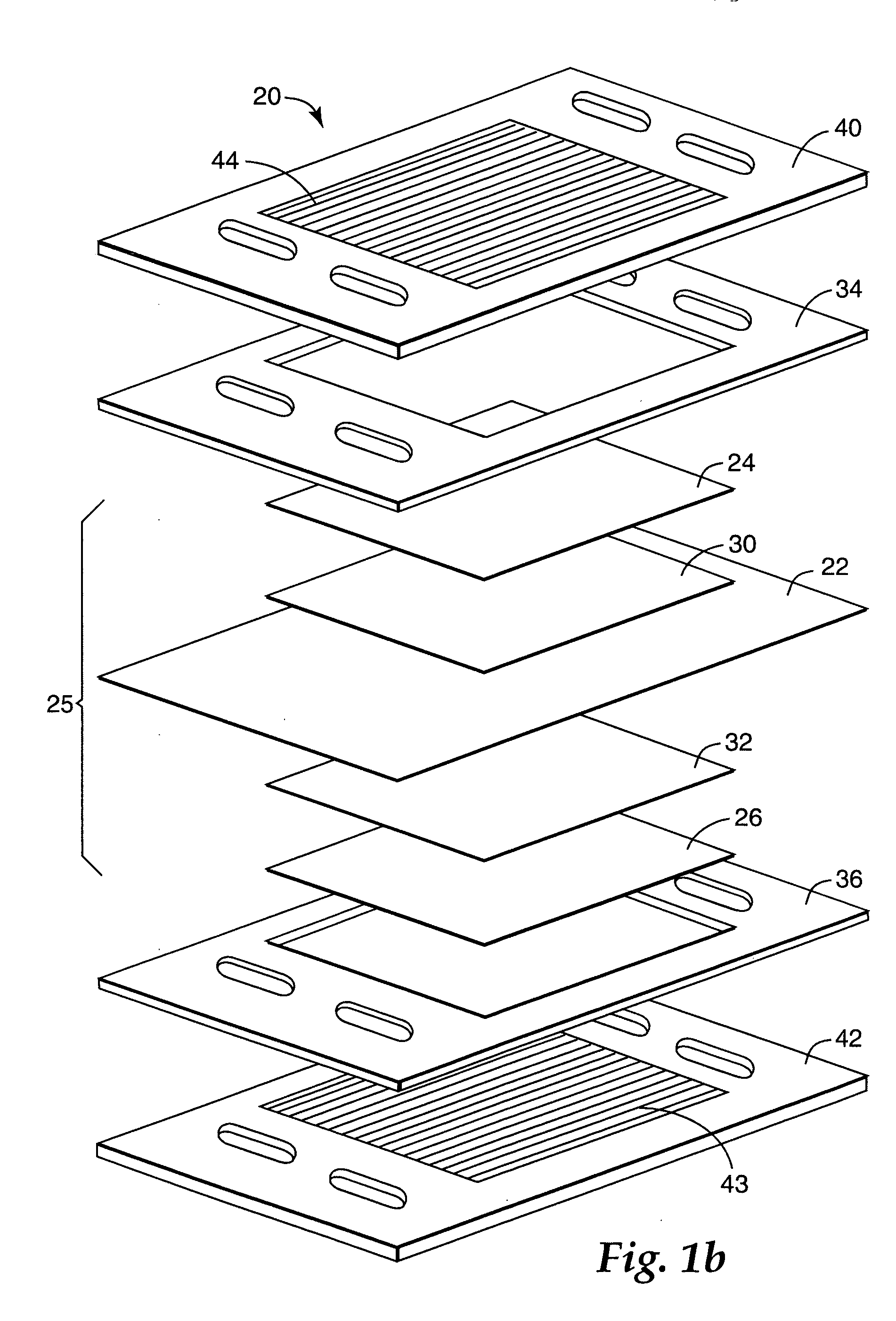

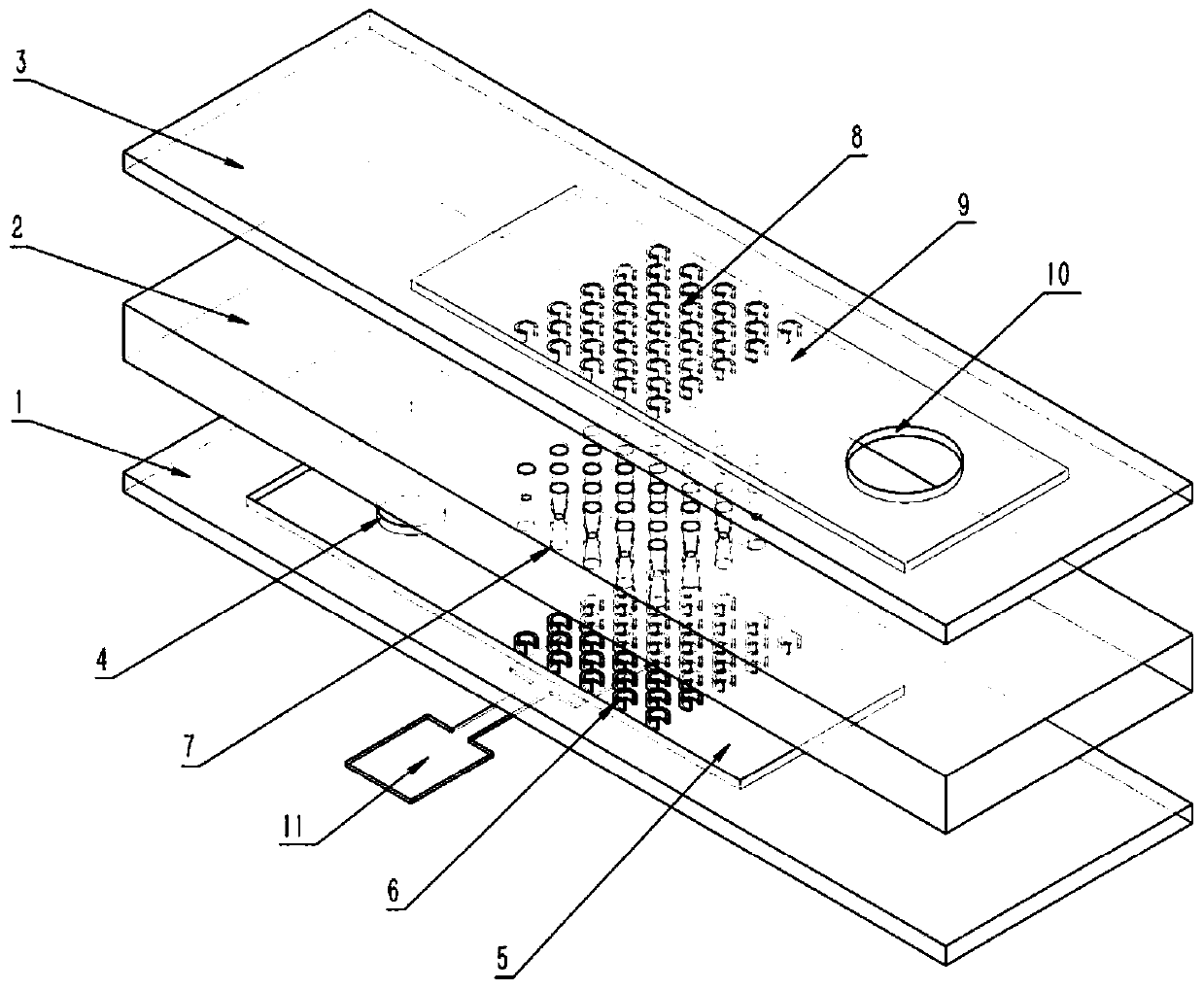

Passive dual-phase cooling for fuel cell assemblies

InactiveUS20060088746A1Improved temperature uniformityReduce cool plate thicknessMaterial nanotechnologyFuel cells groupingChannel widthHeat transfer fluid

A cooling apparatus for a fuel cell assembly includes a heat transfer fluid and at least one fluid flow field plate configured to facilitate essentially passive, two-phase cooling for an membrane electrode assembly (MEA) as the MEA is subject to changes in heat flux to the heat transfer fluid from about 0 W / cm2 to about 1.5 W / cm2. The flow field plate includes fluid flow channels that have a channel depth, a channel spacing, a channel length, and a channel width, which are dimensioned to promote nucleated boiling of the heat transfer fluid below a critical heat flux and to prevent dryout as the heat transfer fluid passes along the length of the channels. The channels may include coatings and / or features, such as microporous or nanostructured coatings, that extend the critical heat flux and preclude dryout at the distal sections of the fluid flow channels.

Owner:3M INNOVATIVE PROPERTIES CO

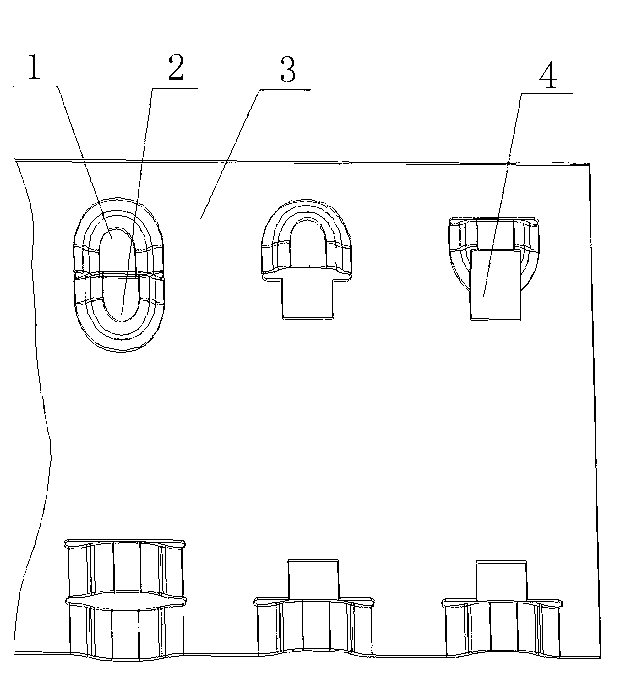

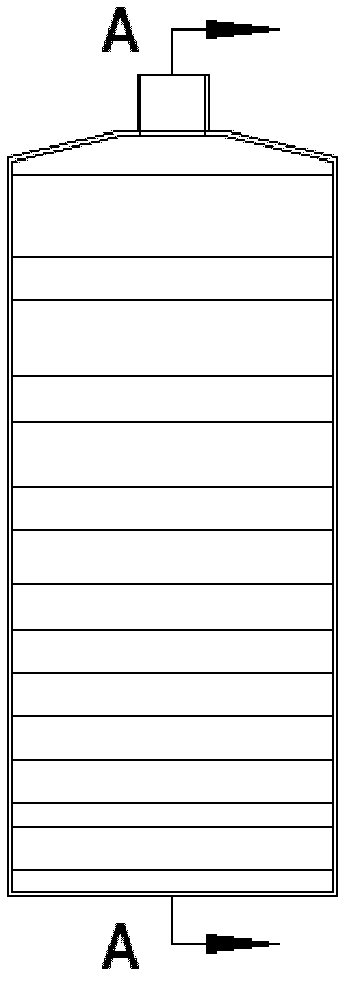

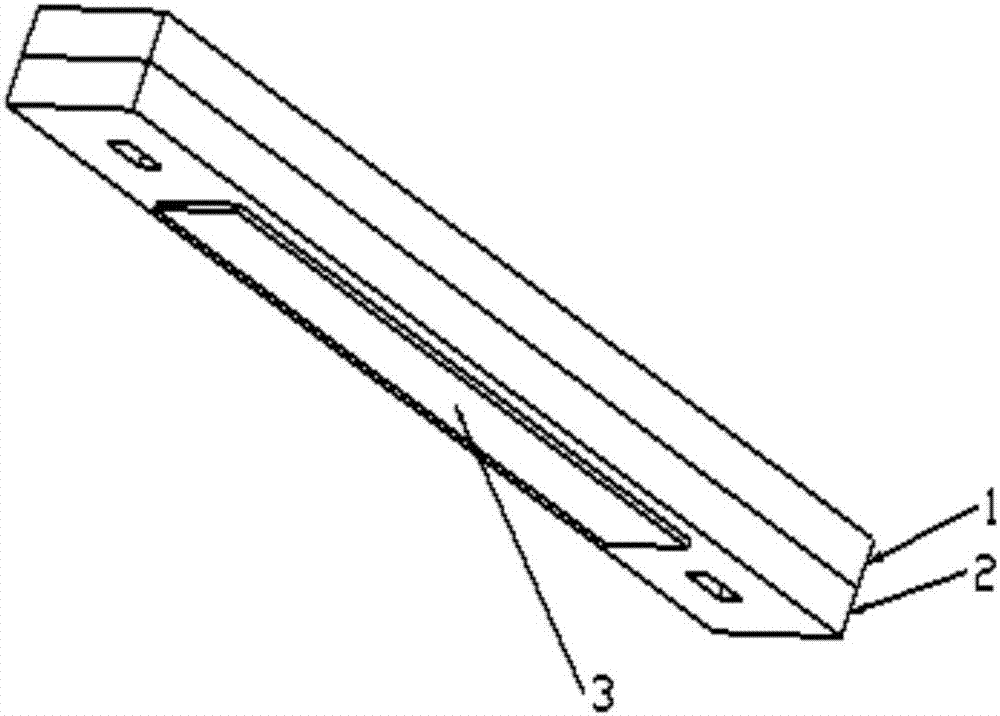

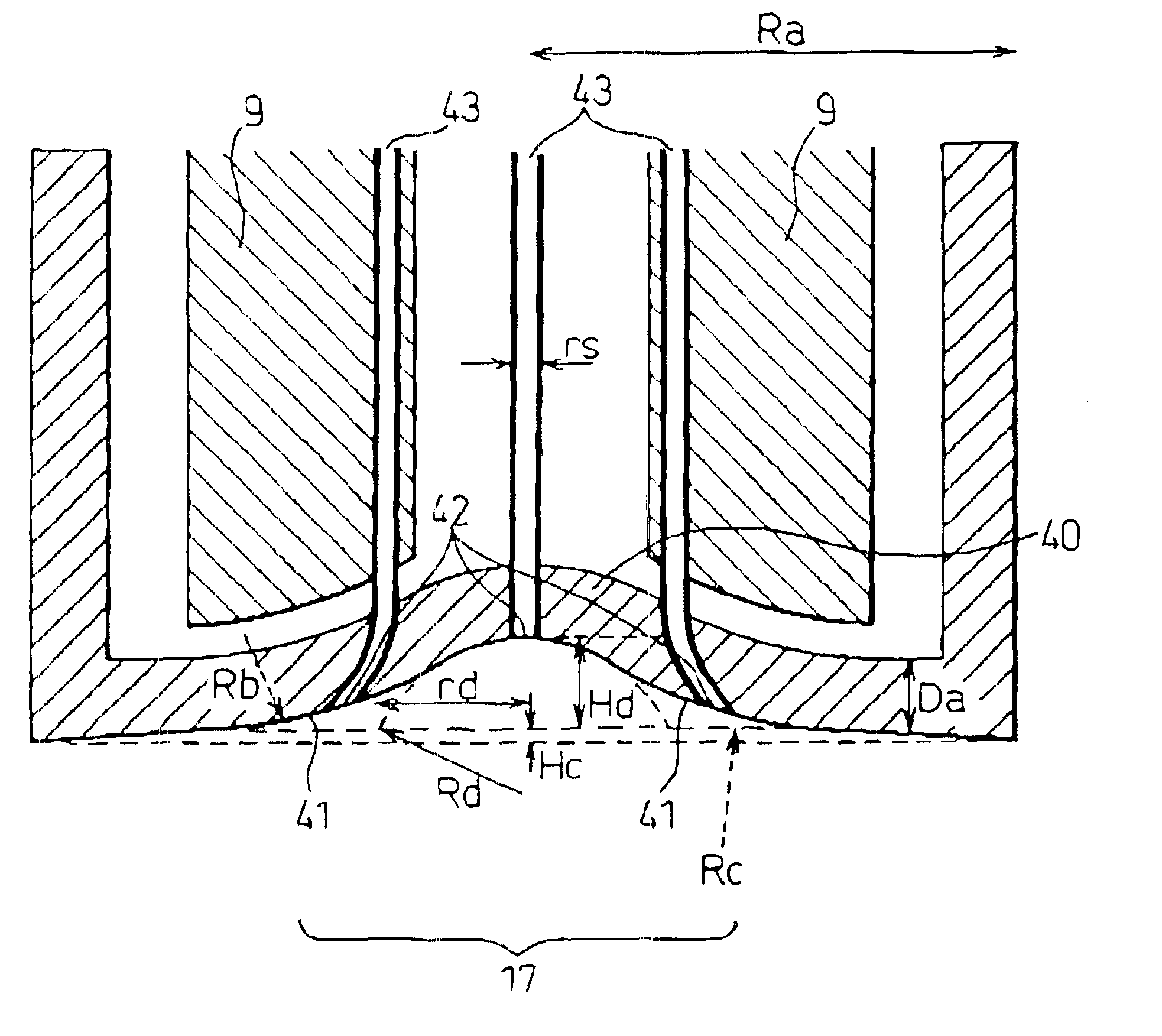

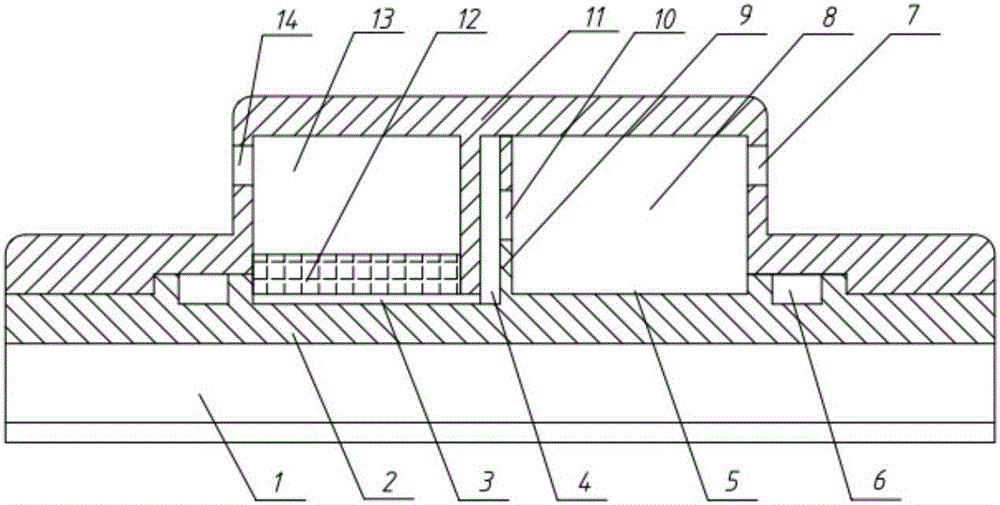

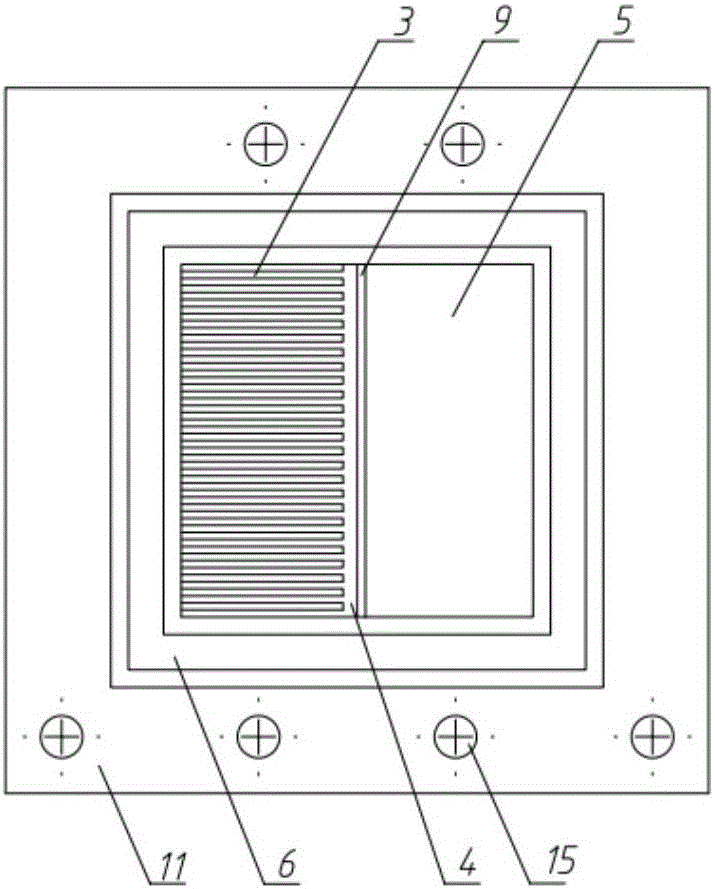

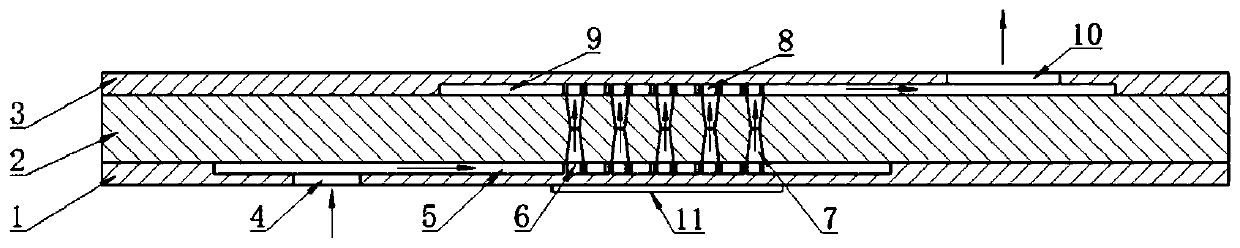

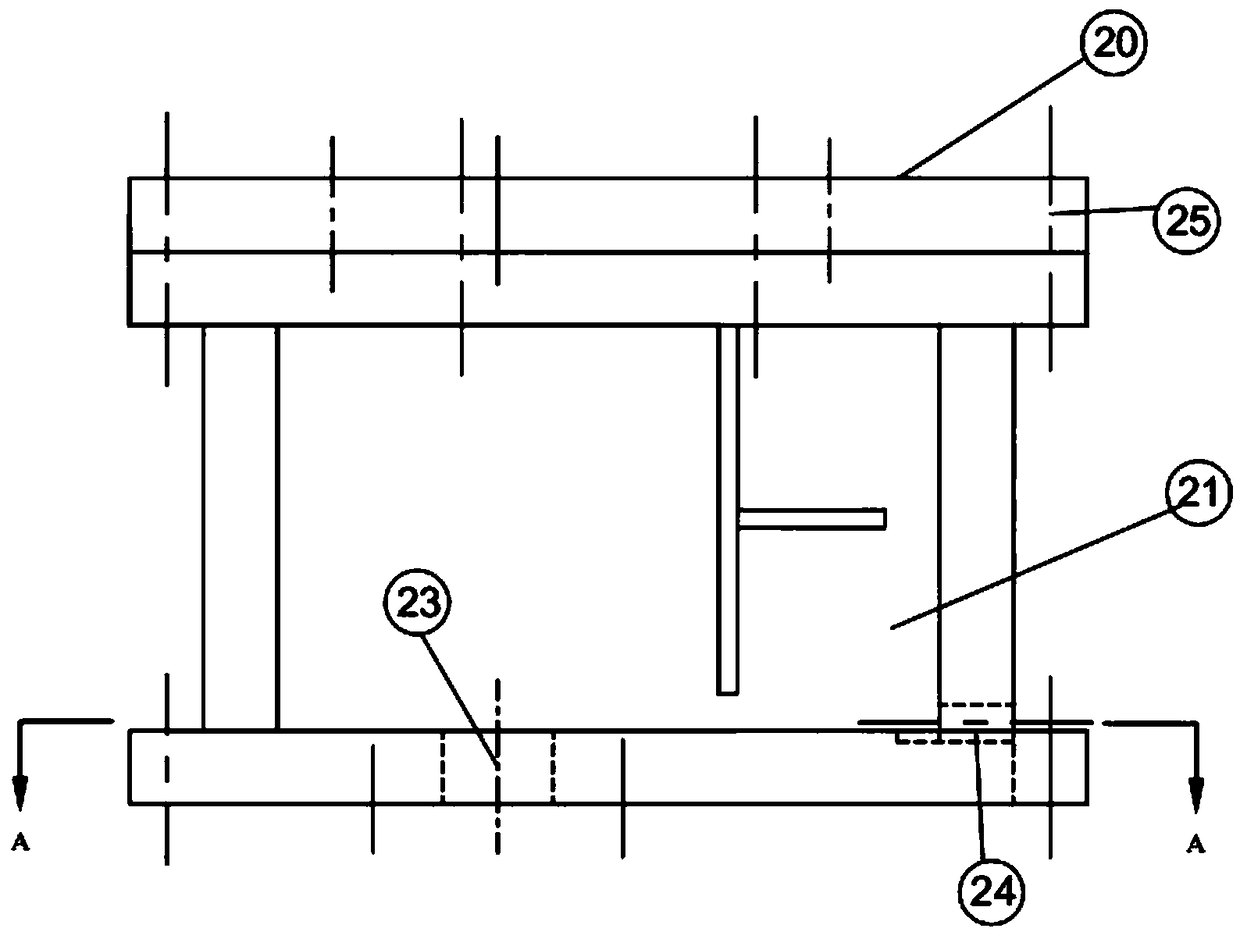

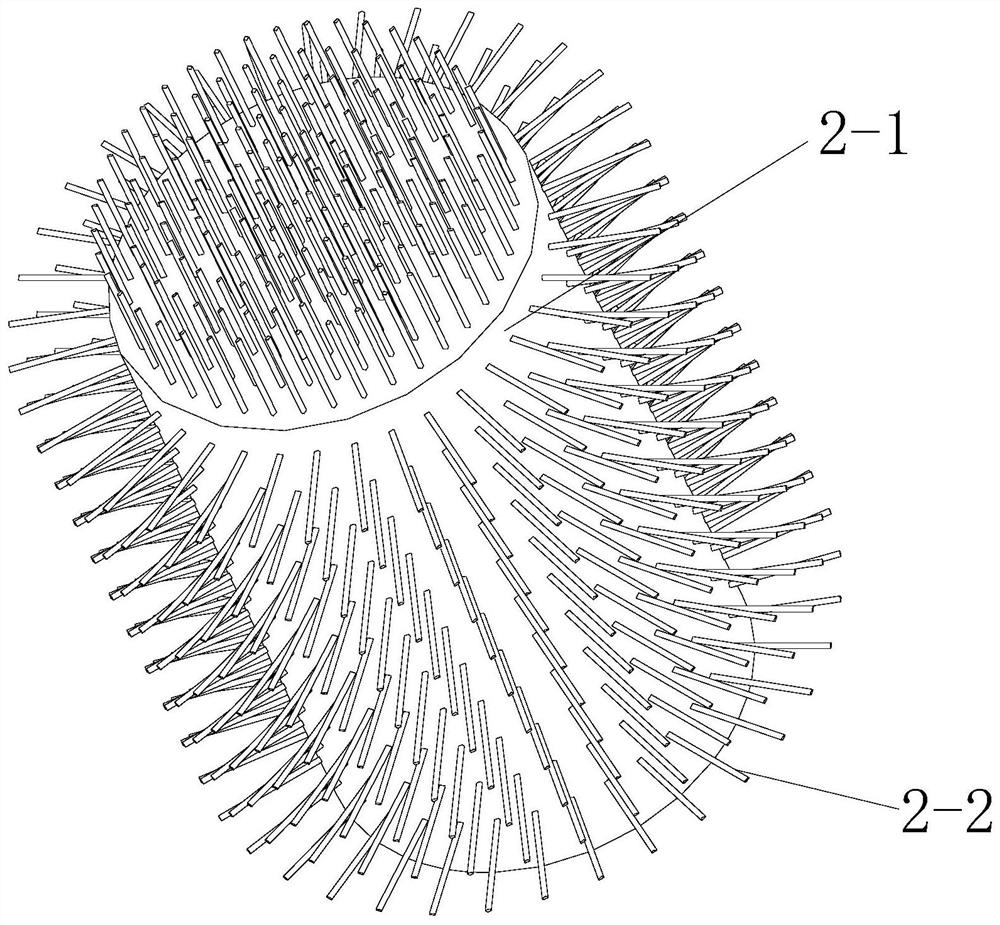

Boiling heat-exchange reinforced wall-attached orifice plate assembly shell component

InactiveCN102969033AHigh densityEnhanced boiling heat transferNuclear energy generationCooling arrangementVena contracta diameterReactor pressure vessel

A boiling heat-exchange reinforced wall-attached orifice plate assembly shell component relates to the technical field of reinforced heat exchange. A wall-attached orifice plate assembly is mounted on an outer wall of a reactor pressure vessel and is supported and fixed by a fixing assembly, and is composed of a plurality of wall-attached orifice plate units mutually connected with each other as one. The wall-attached orifice plate units are orifice plate structure and are provided with a plurality of plate holes in an array arrangement. A plurality of wall-attached supporting members in the array arrangement are arranged at the inner side of the wall-attached orifice plate units, so that a gap is formed between part of the inner wall of the wall-attached orifice plate units except the supporting members and the outer wall of the reactor pressure vessel. The wall-attached orifice plate units are composed of orifice plates and connecting and strengthening side plates, and the connecting and strengthening side plates are arranged at edges of the orifice plates. The component can substantially reinforce boiling heat-exchange process, improve critical hot-fluid density, and thus substantially improve security; and strengthens heat exchange and improve performance stability of critical hot-fluid density.

Owner:TSINGHUA UNIV

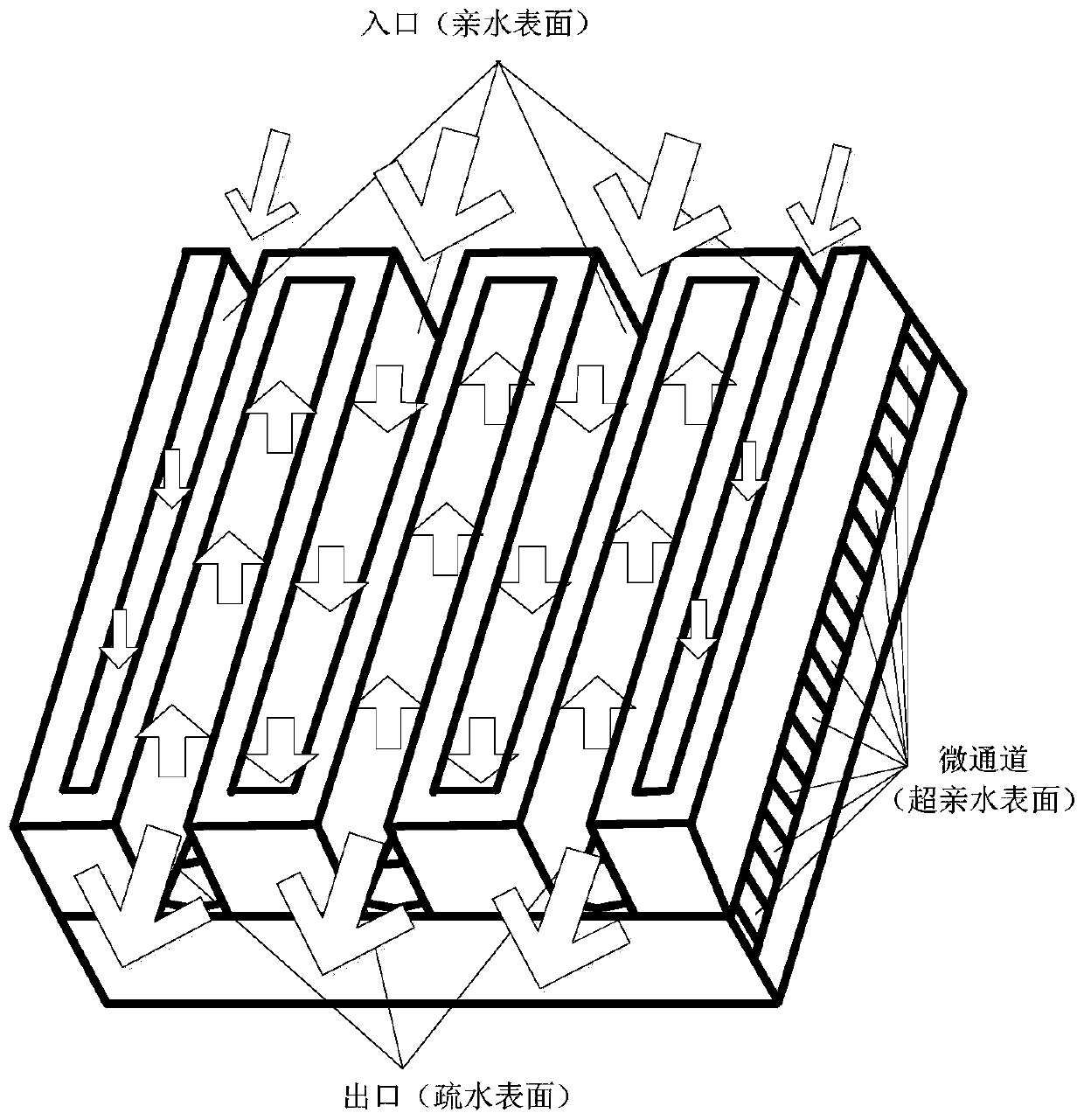

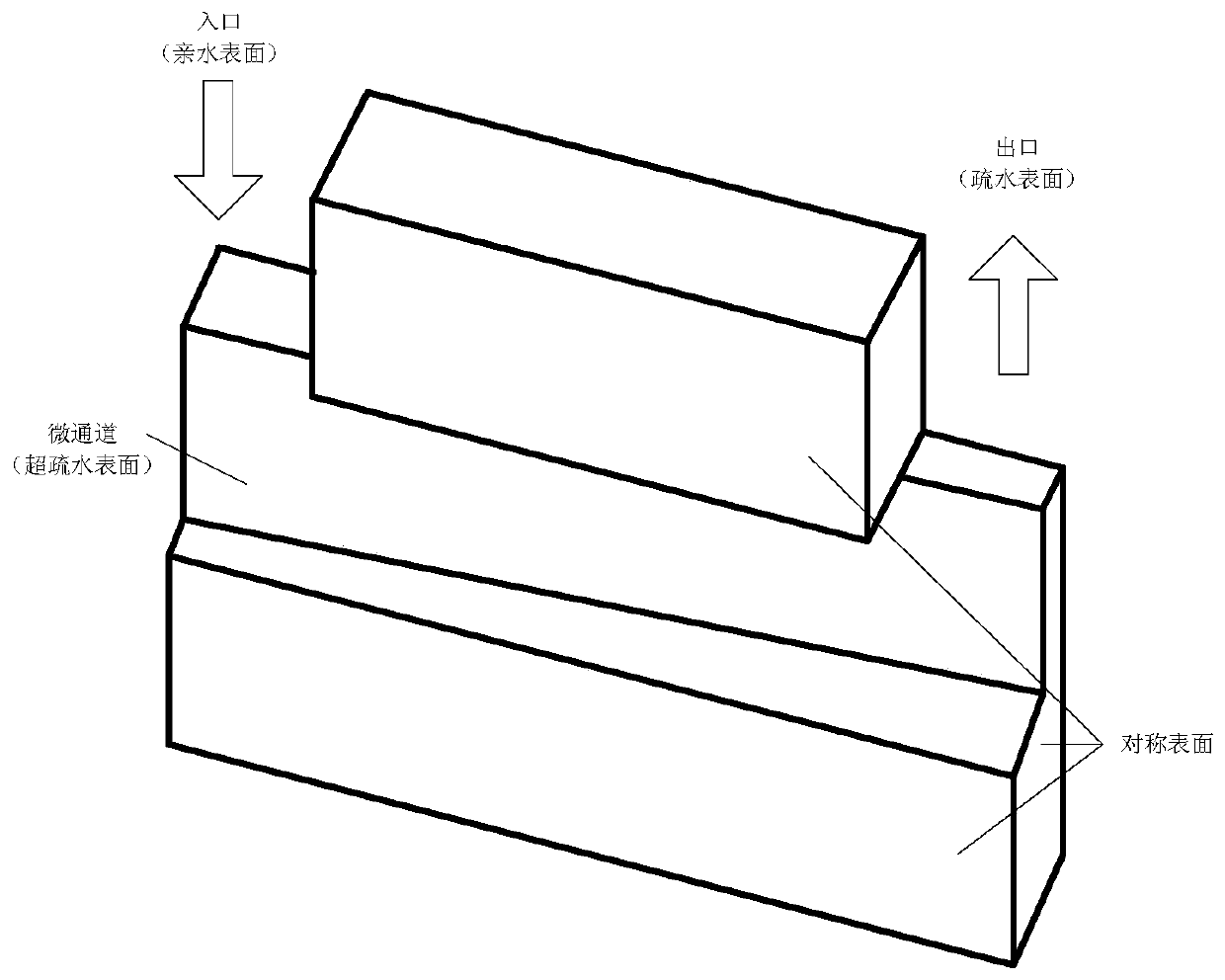

Low-resistance enhanced heat transfer structure based on nanometer super-wetting interface

ActiveCN110425914AShorten the length of the runnerReduce thicknessCoatingsModifications by conduction heat transferIsosceles trapezoidEnhanced heat transfer

The invention discloses a low-resistance enhanced heat transfer structure based on a nanometer super-wetting interface. The low-resistance enhanced heat transfer structure comprises a lower embedded microchannel layer and an upper manifold channel layer, wherein embedded microchannels are perpendicular to manifold channels; the lower embedded microchannel layer consists of a plurality of embeddedmicrochannel units; the cross section of each embedded microchannel of each unit is a rectangular divergent cross section along the flowing direction of a cooling working medium; the shape of each embedded microchannel of each unit is isosceles trapezoid; the upper manifold channel layer is composed of the S-shaped manifold channels; and two adjacent S-shaped manifold channels form inlets and outlets of the manifold channels. According to the low-resistance enhanced heat transfer structure, a microchannel radiator is constructed by utilizing a layered flow structure, the heat transfer characteristic and the resistance characteristic can be simultaneously improved by combining the microchannel radiator with the nano super-wetting interface and the divergent microchannel section, and the low-resistance enhanced heat exchange of the microchannel radiator is achieved under the condition of higher heat dissipation efficiency.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

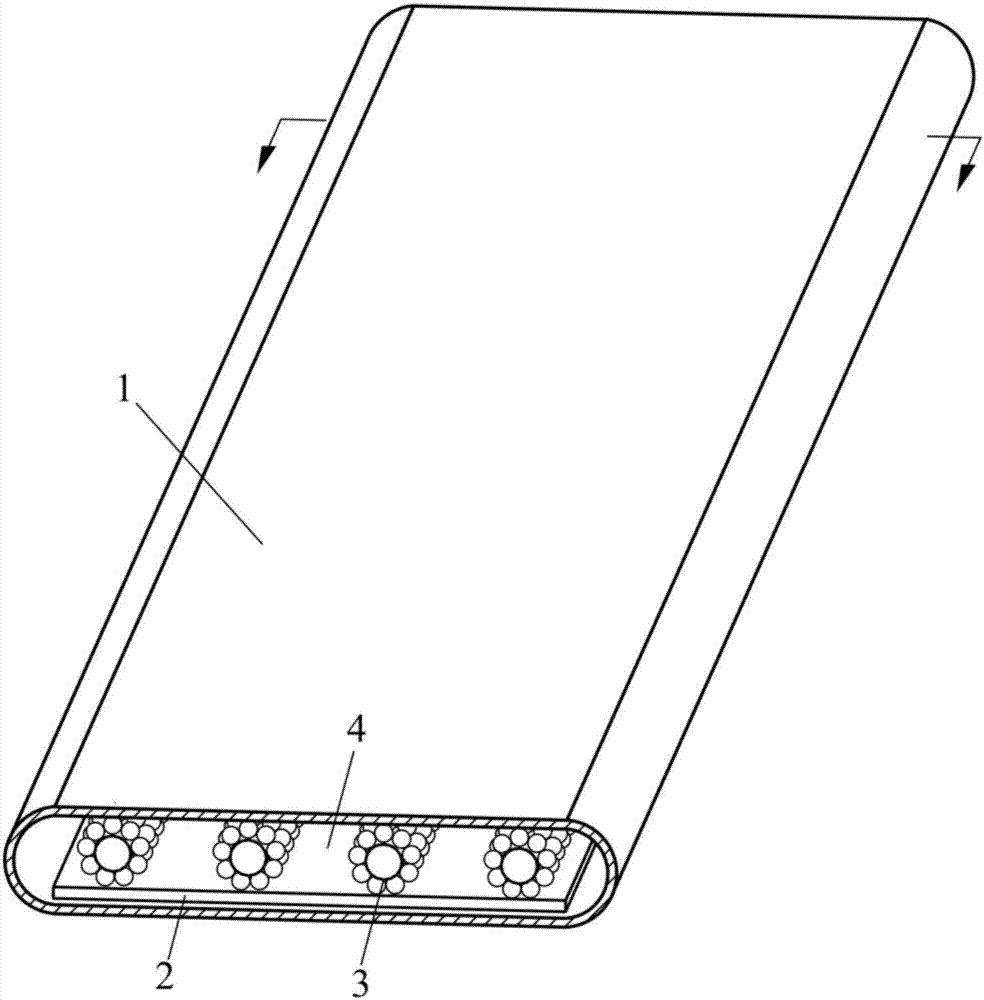

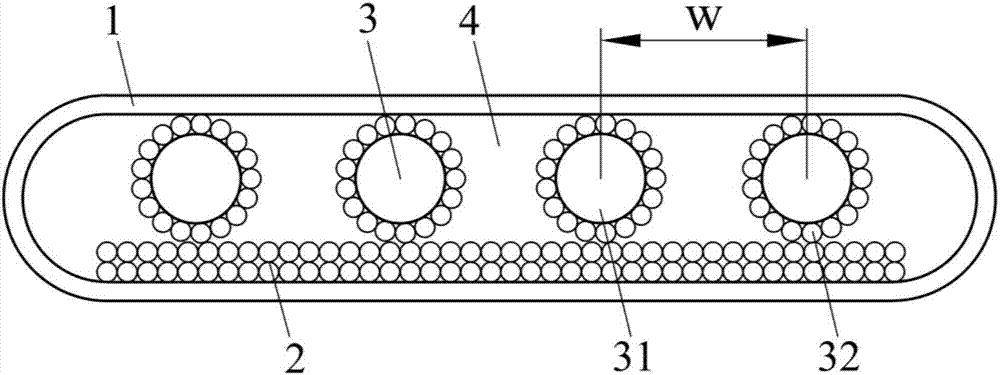

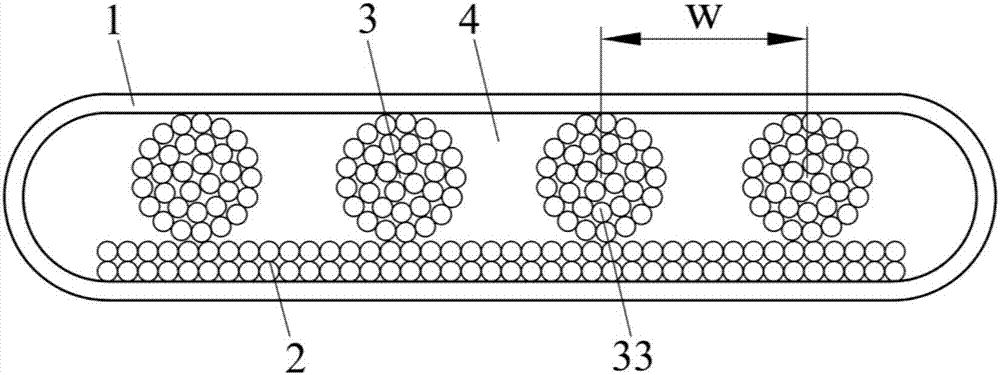

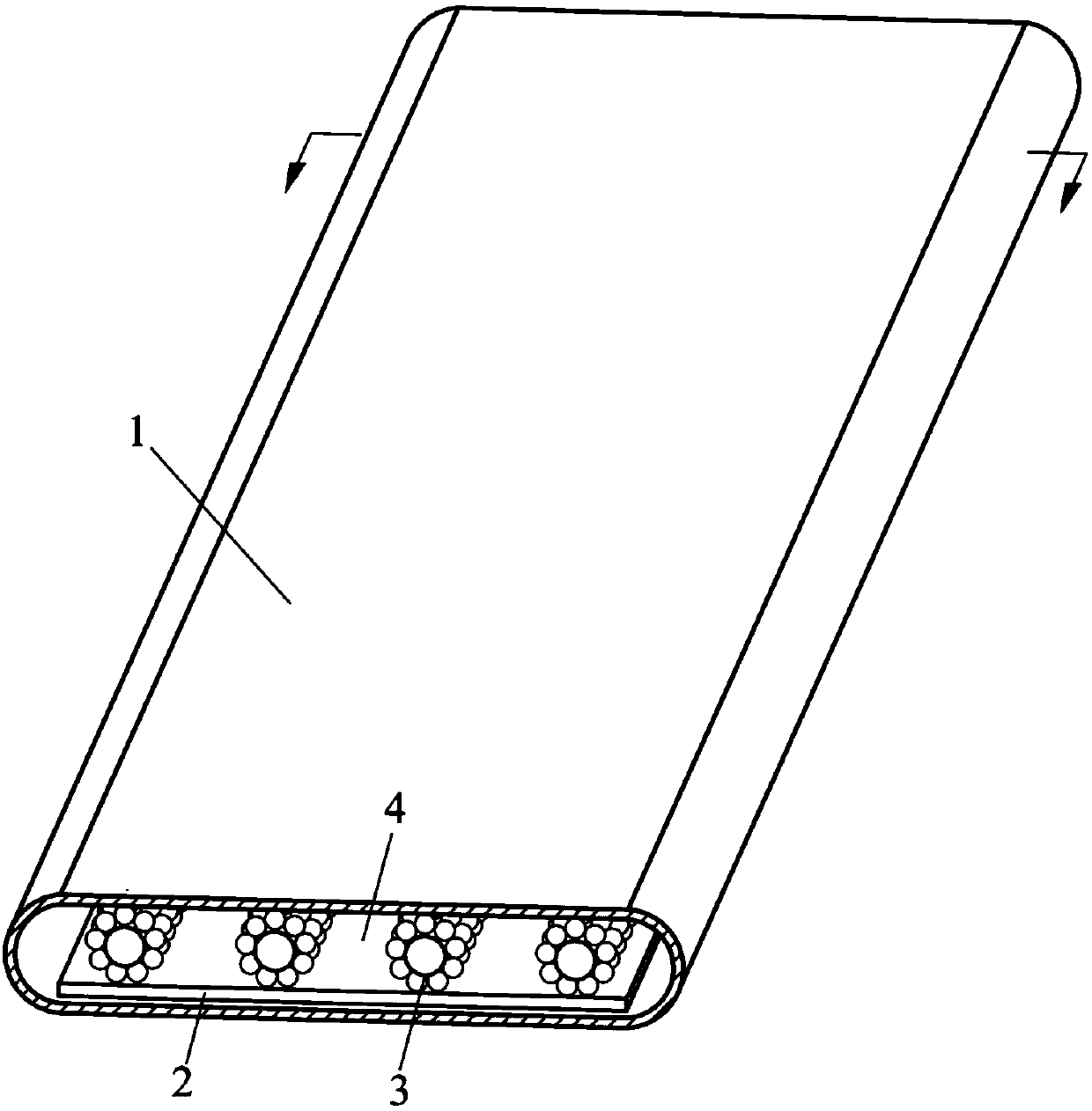

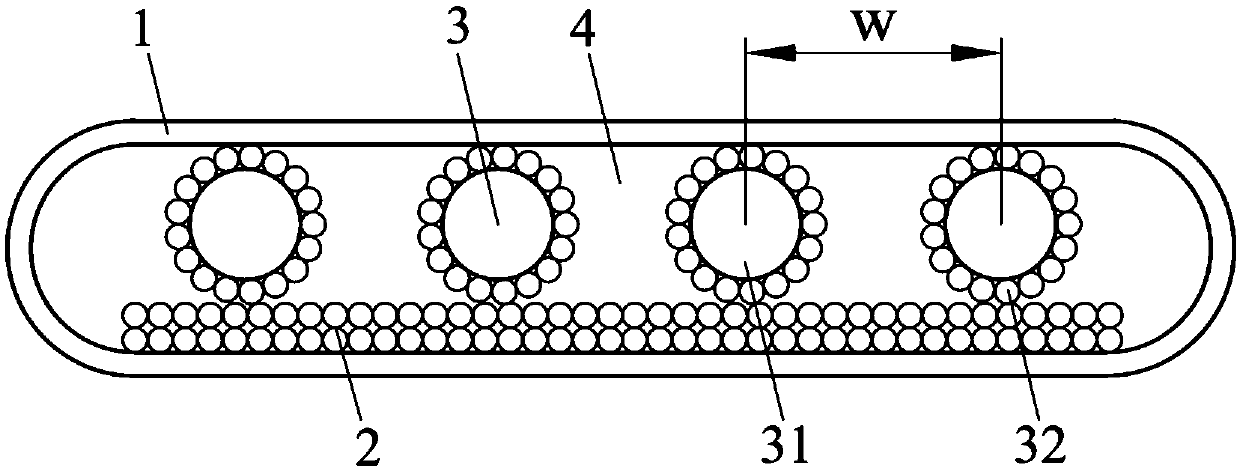

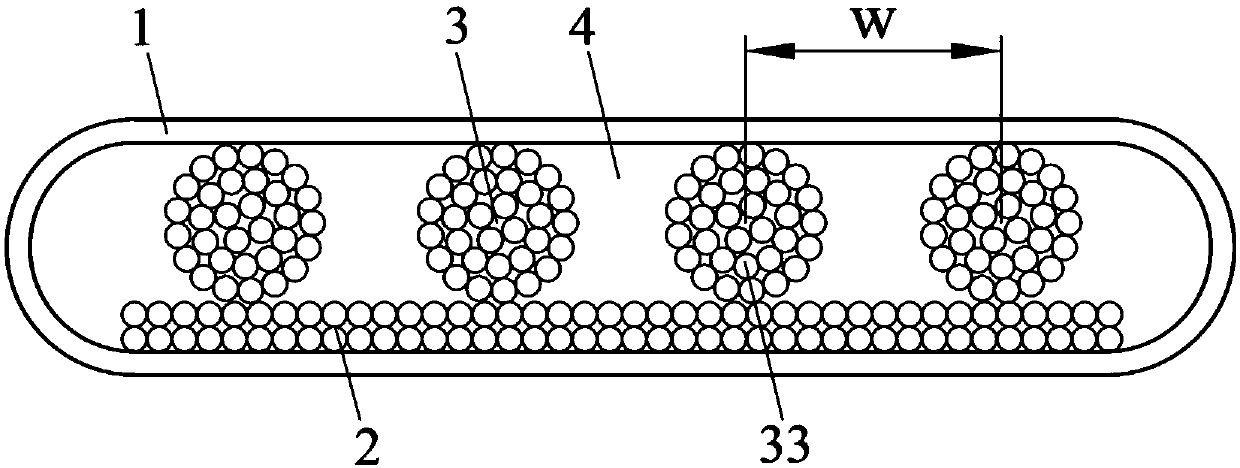

Ultra-thin flat panel heat pipe and manufacturing method thereof

ActiveCN107167008AEasy to moveIncrease heat transfer limitIndirect heat exchangersVapor liquidHeat flux

The invention relates to an ultra-thin flat heat pipe and a manufacturing method thereof. A wick comprises a porous medium bottom layer and a plurality of porous medium filaments arranged side by side; the porous medium filaments make contact with the top of a tube shell; the wick inside the heat pipe, a sharp angled area between the porous medium filaments and the upper surface of the tube shell, and a sharp angled area between the porous medium filaments and the porous medium bottom layer provide liquid return capillary driving force which is large enough in a limited space; spaces formed between the porous medium filaments provide steam flow channels, and the steam flow channels communicate with one another; and reasonable matching of vapor-liquid phase distribution is achieved, and steam and condensed liquid can flow easily. According to the ultra-thin flat heat pipe, efficient operation can be maintained at various angles, the performance of anti-gravity operation is excellent, the heat flux which can be borne by the heat pipe is high, and the heat transfer performance of the heat pipe is remarkably improved after further modification treatment.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

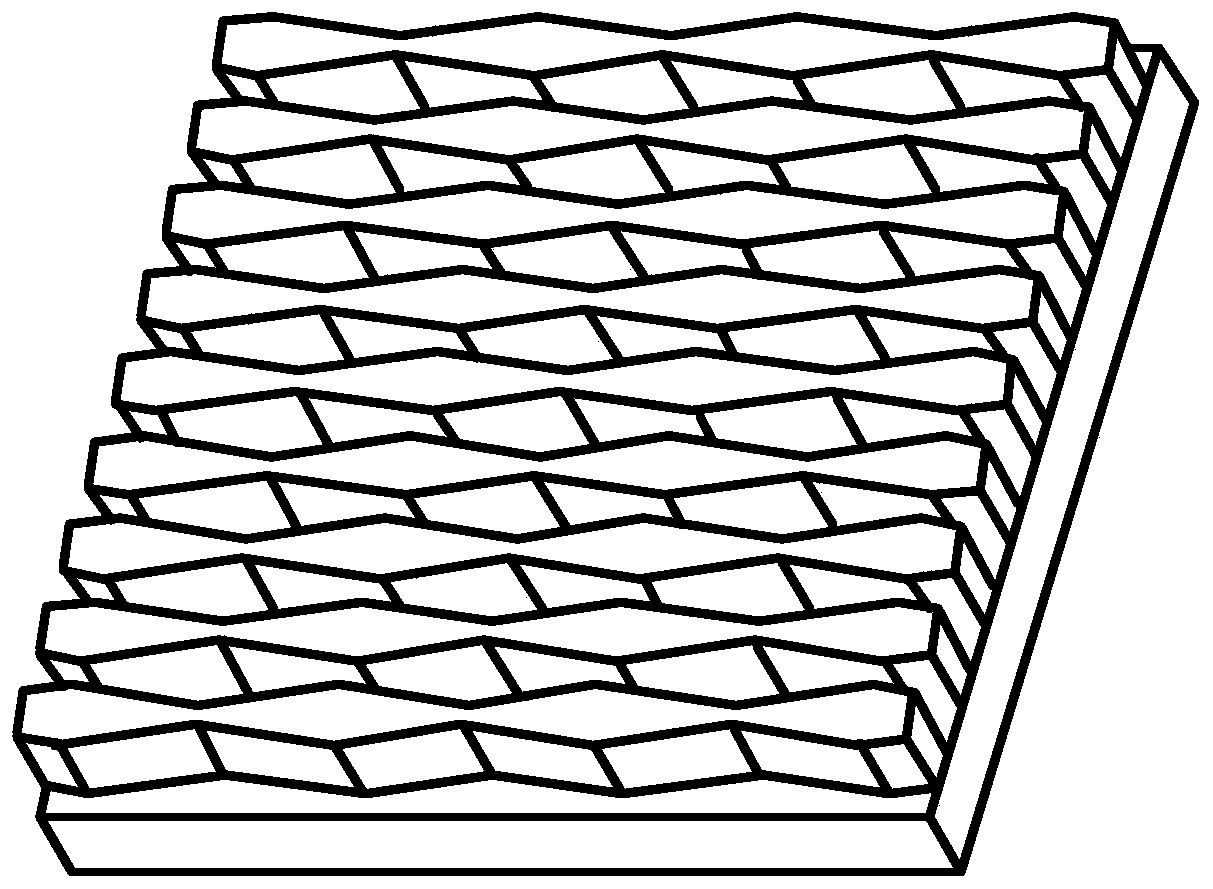

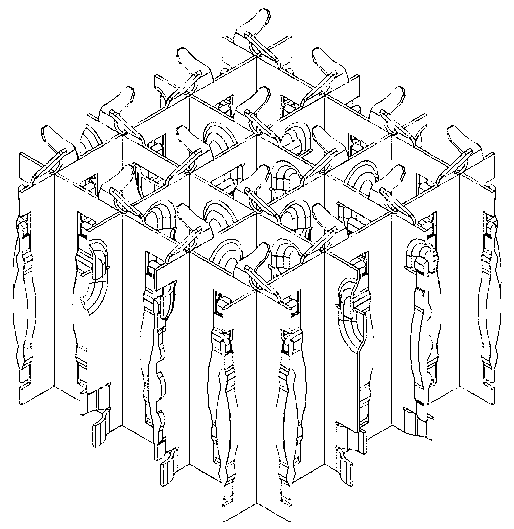

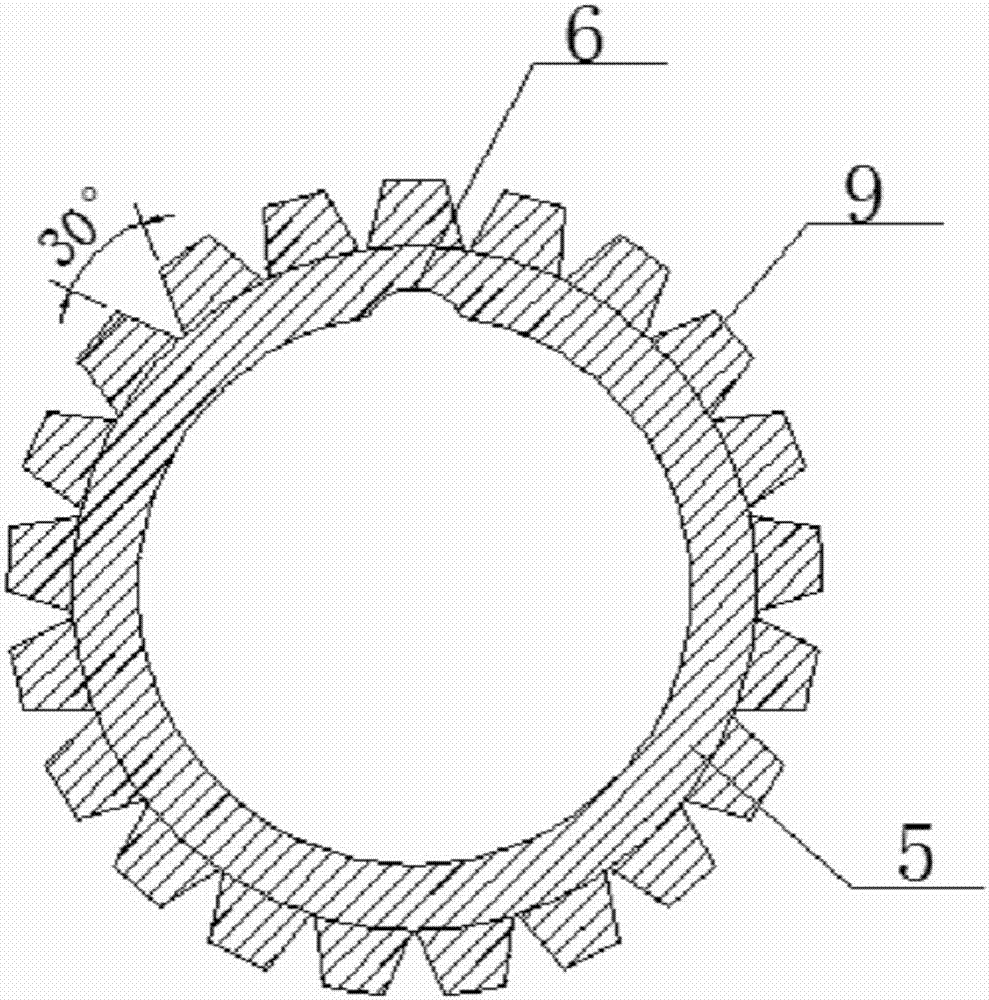

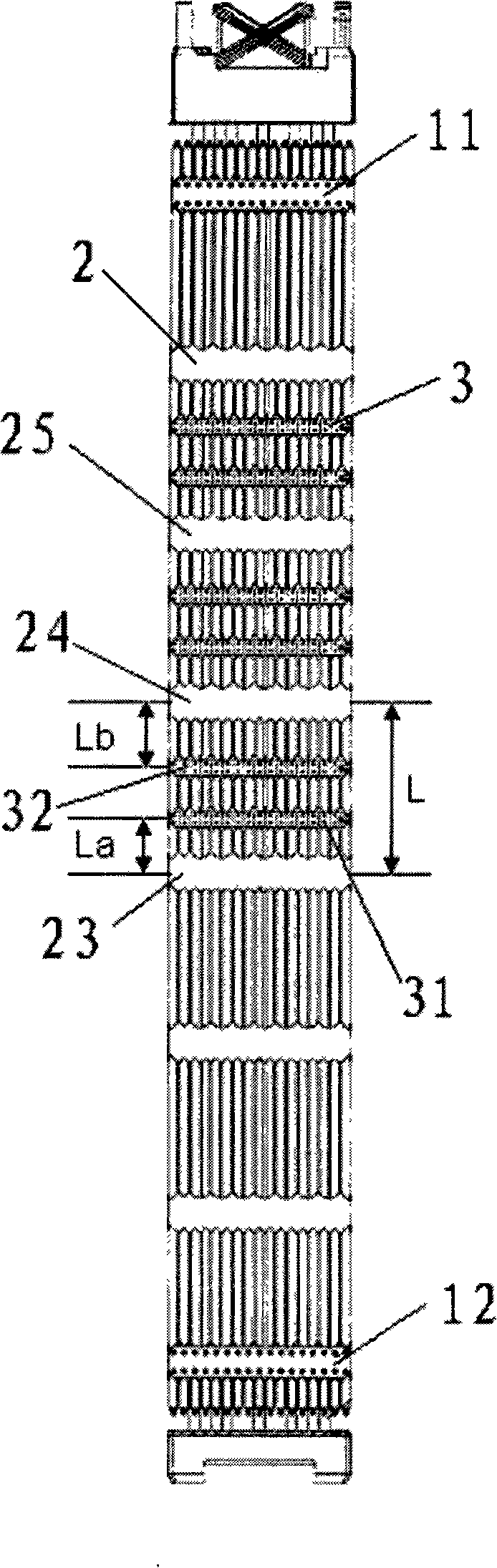

Nuclear fuel assembly based structural grillwork with flow hybrid coordinating effect

ActiveCN103021478AAchieve coordinationEnhanced Blending PerformanceNuclear energy generationShieldingEngineeringChannel types

The invention discloses a nuclear fuel assembly based structural grillwork with a flow hybrid coordinating effect. The structural grillwork comprises a grillwork formed by mutually perpendicularly interweaving a plurality of stripes, a pair of mixing wings are respectively arranged on the two sides of the top of the intersection position of the stripes, and each stripe is recessed to form a half-buckled-shaped rigid protruding structure. With the adoption of the half-buckled-shaped rigid protruding structure, the coordination between a clamping system and a mixing system is achieved, the hybrid performance of the structural grillwork is enhanced, thereby improving the critical heat flux density of a nuclear fuel assembly; and with the oblique channel type paired half-buckled-shaped rigid protruding structure, the internal flow of the structural grillwork is effectively rectified, so that the pressure loss is reduced to some extent.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Radiating device of wind power generation water cooling system and water cooling system

InactiveCN102562484ASimple preparation processImprove heat transfer efficiencyIndirect heat exchangersWind energy generationPlate heat exchangerEngineering

The invention discloses a radiating device of a wind power generation water cooling system used for radiating cooling liquid in a liquid collection box of the water cooling system arranged in an engine room cover, wherein the radiating device comprises a plurality of heat pipes, heat absorption segments of the heat pipes are arranged in the liquid collection box, and heat release segments of the heat pipes are arranged at the outside of the engine room cover. The invention further discloses the wind power generation water cooling system comprising the radiating device, wherein the radiating device disclosed by the invention indirectly cools the cooling liquid of the cooling system substantially by means of the heat exchange property of the heat pipes and natural gas with excellent wind field without utilizing cooling fans or plate heat exchangers, thereby avoiding the energy consumption of the fans and avoiding the high braze welding technology of the plate heat exchangers; besides, the radiating device can fully utilize the excellent natural wind in a wind field to cool and radiate the cooling liquid so as to exert the energy saving effect.

Owner:GUODIAN UNITED POWER TECH

Micro-channel evaporator with staggered saw-tooth type rib walls

ActiveCN107241887AUniform temperature distributionIncrease critical heat fluxSemiconductor/solid-state device detailsSolid-state devicesMicroelectronicsHeating film

The invention discloses a micro-channel evaporator with staggered saw-tooth type rib walls, which belongs to the technical field of microelectronic chip cooling. The evaporator consists of an upper cover plate, a silicon substrate processed with staggered saw-tooth micro-channels and a heating film. Among the staggered saw-tooth type micro-channels on the silicon substrate, converging and connecting boxes are arranged. The heating film, as a simulated heat source, heats the micro-channels. When liquid phase working medium flows in from the liquid entering mouth, it inhales the heat in the micro-channels and is subjected to the gas-liquid phase change so as to cool the silicon substrate. On the saw-tooth roots of the rib walls on the micro-channels, a plurality of nucleated cavities are formed. The saw-tooth structure plays a role in similar like a fine blood vessel, making it possible to form high efficient and stable heat transmission mode for the annular gas-liquid phase split flow in the channels easily. The present invention has a lower boiling start superheat degree, an efficient and stable heat transfer capacity and a high critical heat flux density. Therefore, the evaporator has broad application prospects in the field of microelectronics chip cooling technology.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

High-power LED radiating lamp and preparation method for non-uniform wettability patterned surface

PendingCN107191796AEfficient conductionIncrease the heat exchange areaElectric circuit arrangementsLighting heating/cooling arrangementsPhysicsEngineering

The invention discloses a high-power LED radiating lamp and a preparation method for a non-uniform wettability patterned surface. The LED radiating lamp comprises a gravity heat pipe radiator, an LED circuit substrate and an LED light source module; the gravity heat pipe radiator comprises an upper condensation section and a lower evaporation section condensation section; the condensation section comprises a heat pipe, trapezoidal fins and a cover plate; the inner side of the heat pipe and the bottom surface of the cover plate are subjected to super-hydrophobic treatment and have the super-hydrophobic properties; the evaporation section is a cylindrical cavity, a base plate of the cavity is connected to the LED circuit substrate through bolts; the cavity is internally filled with heat exchange working mediums; the surface of the base plate of the cavity is subjected to non-uniform wettability treatment and is divided into a super-hydrophobic region and a super-hydrophilic region; and the super-hydrophobic area is radialized. The LED radiating lamp has teh advantages of being simple in structure, high in response speed and high in radiating capacity, the high-power LED lamp can be effectively maintained to operate at the normal temperature, the luminous efficiency can be enhanced, and the service life can be prolonged.

Owner:SOUTH CHINA UNIV OF TECH

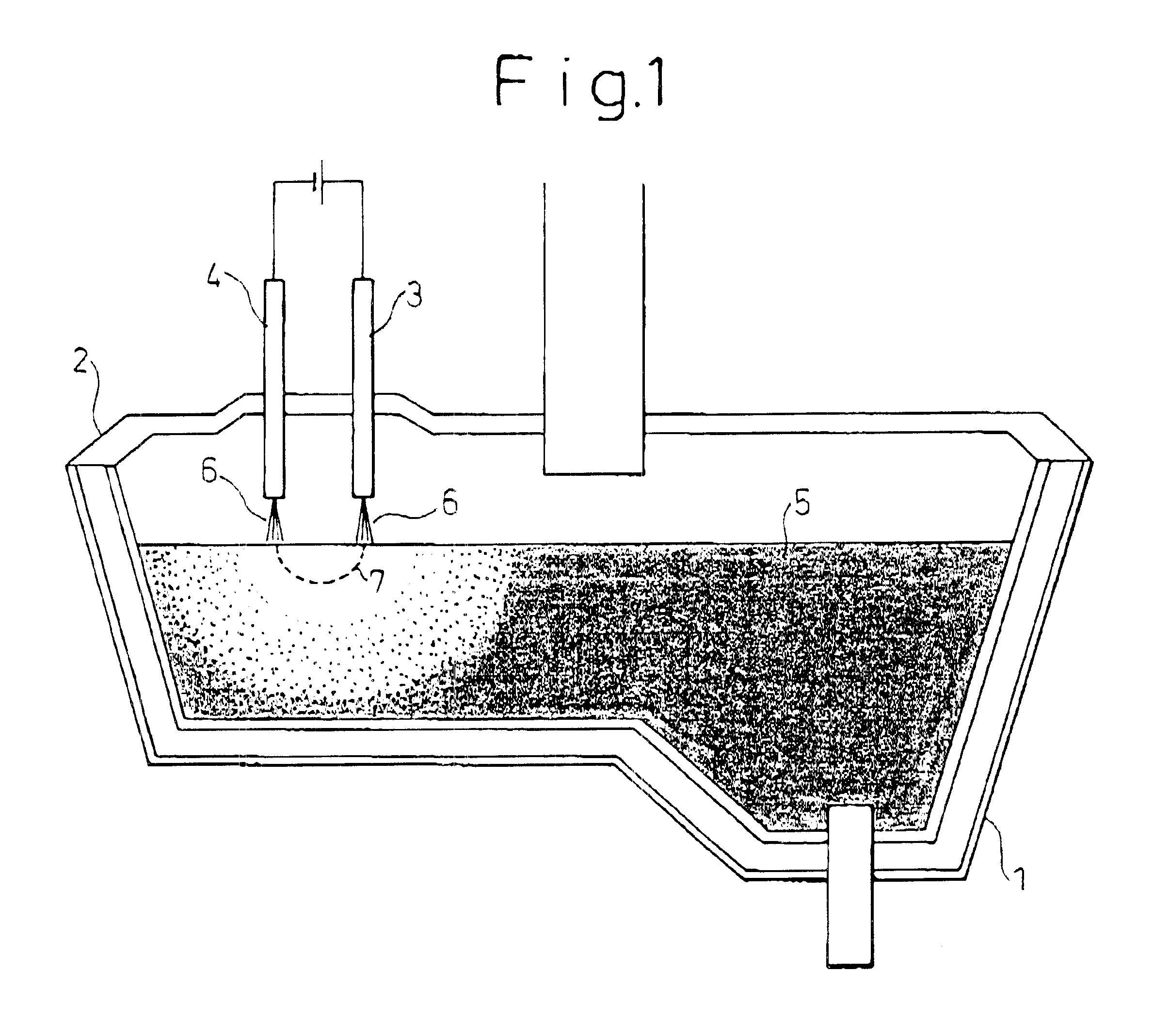

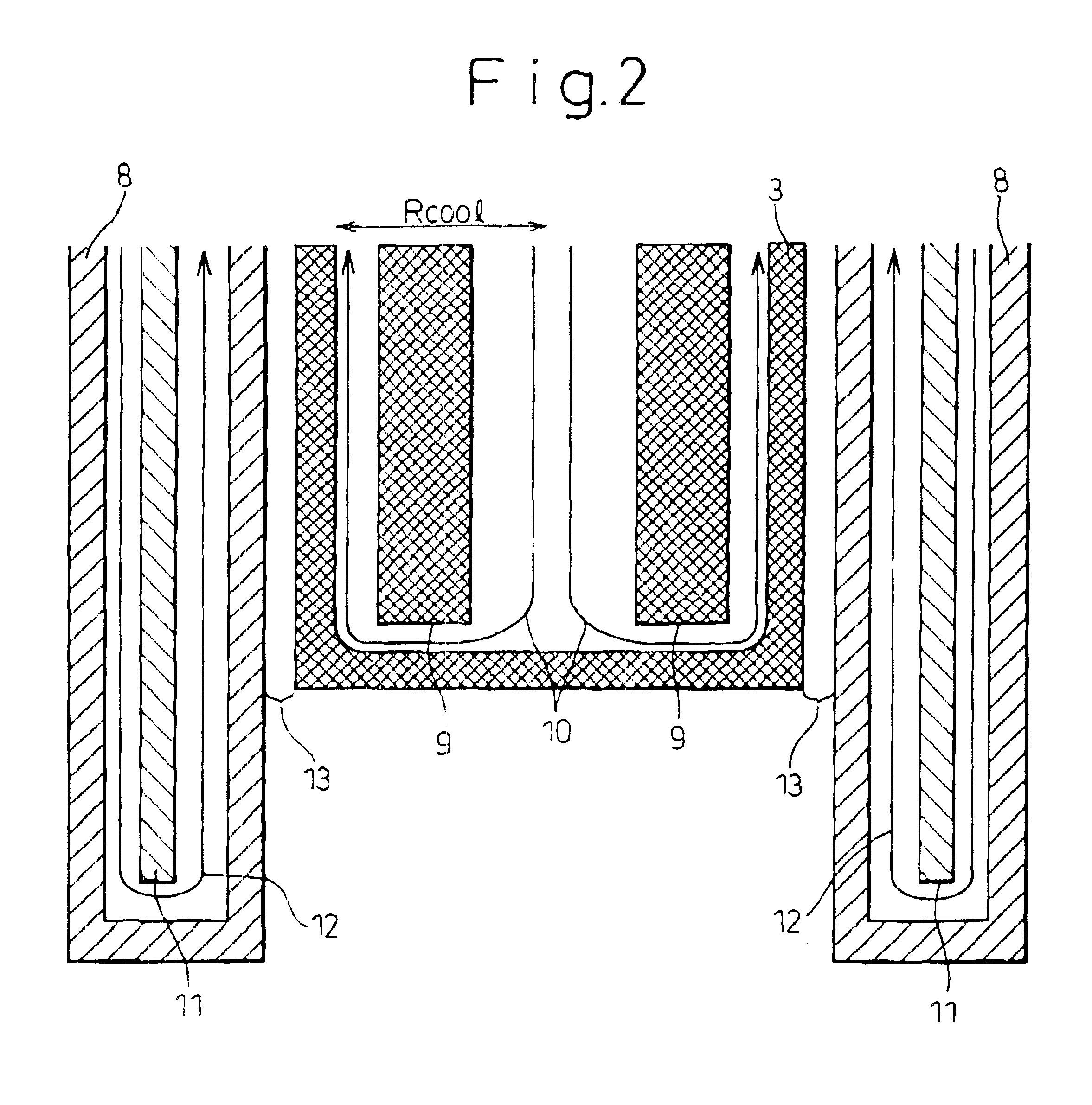

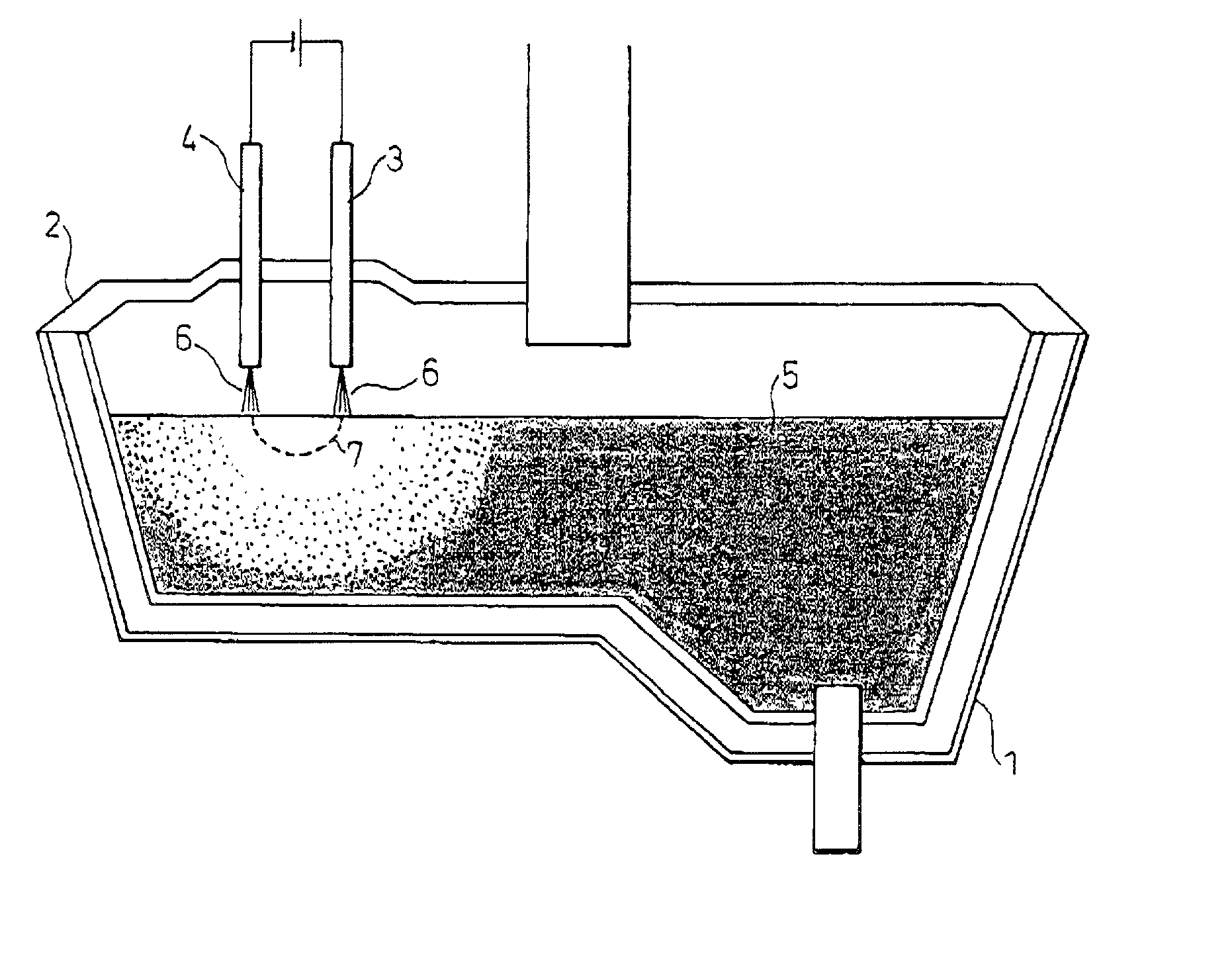

Transfer type plasma heating anode

InactiveUS6649860B2Prolong lifeInhibit currentMelt-holding vesselsElectric discharge heatingMetallurgyDc current

A transferred plasma heating anode for heating a molten metal in a container by applying Ar plasma generated by passing a direct current through the molten metal, the transferred plasma heating anode comprising; an anode, composed of a conductive metal, that has an internal cooling structure, a metal protector having an internal cooling structure that is placed outside the anode with a constant gap between the anode and the protector, and a gas supply means that supplies an Ar-containing gas to the gap, is characterized by the central portion on the external surface of the anode tip end being inwardly recessed.

Owner:NIPPON STEEL CORP

Transfer-type plasma heating anode

InactiveUS20020134766A1Prolong lifeDelay” in damageMelt-holding vesselsElectric discharge heatingDc currentPlasma heating

A transferred plasma heating anode for heating a molten metal in a container by applying Ar plasma generated by passing a direct current through the molten metal, the transferred plasma heating anode comprising; an anode, composed of a conductive metal, that has an internal cooling structure, a metal protector having an internal cooling structure that is placed outside the anode with a constant gap between the anode and the protector, and a gas supply means that supplies an Ar-containing gas to the gap, is characterized by the central portion on the external surface of the anode tip end being inwardly recessed.

Owner:NIPPON STEEL CORP

Integrated loop heat pipe cooling device with boiling pool

ActiveCN105890415AContinuous and efficient heat dissipationCompact structureIndirect heat exchangersEngineeringLoop heat pipe

An integrated loop heat pipe cooling device with a boiling pool comprises an evaporator, the boiling pool and a condenser, wherein the evaporator comprises a compensating chamber; a capillary core for providing power is arranged below the compensating chamber; a steam channel is formed below the capillary core; an air collecting groove which communicates with the steam channel is formed between the compensating chamber and the boiling pool; a connecting hole which communicates with the air collecting groove is formed in a side wall of the boiling pool; steam generated from the bottom of the compensating chamber enters the air collecting groove and enters the boiling pool through the connecting hole; the compensating chamber communicates with an outlet of the condenser; and the boiling pool communicates with an inlet of the condenser. The evaporator for proving power and the boiling pool as a main cooling component are integrally designed, the integral size is small, the structure is compact, the integrated loop heat pipe cooling device is suitable for cooling electronic devices with small space, by the compact design of the evaporator and the boiling pool, a system only needs a heat source which is a cooled device, an additional heat source or a power device is not required, energy is saved, and the electronic devices can be continuously and efficiently cooled.

Owner:XI AN JIAOTONG UNIV

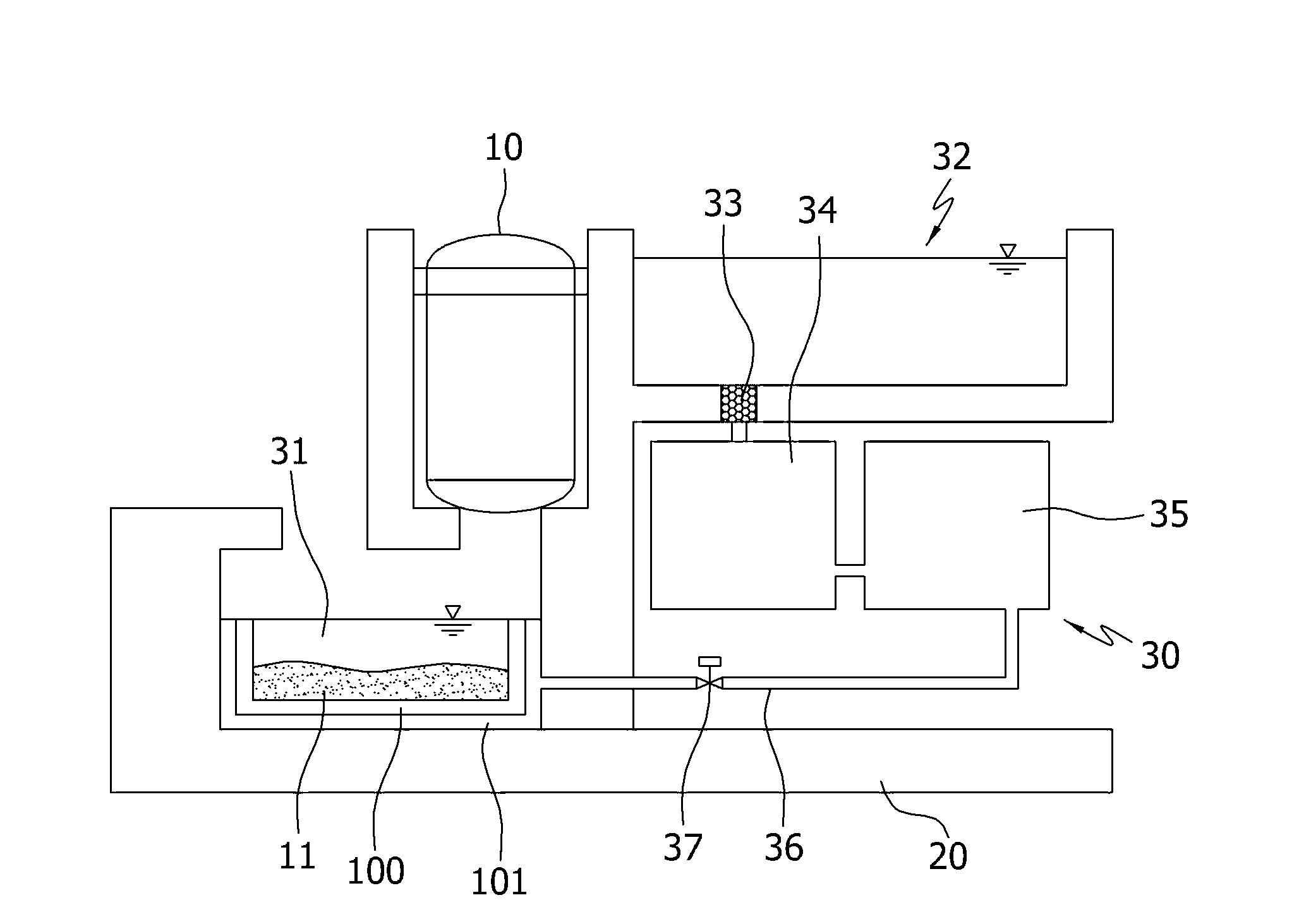

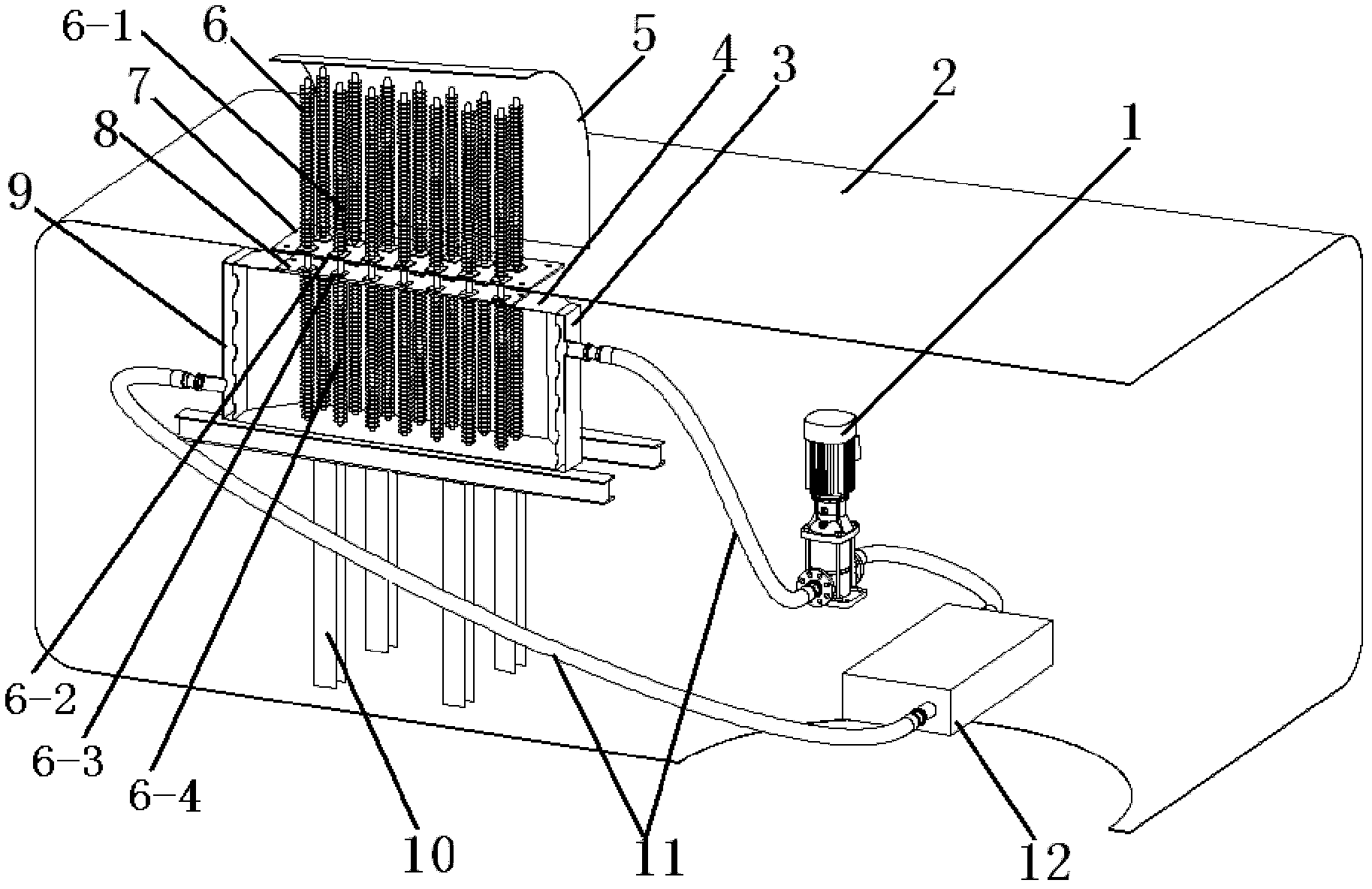

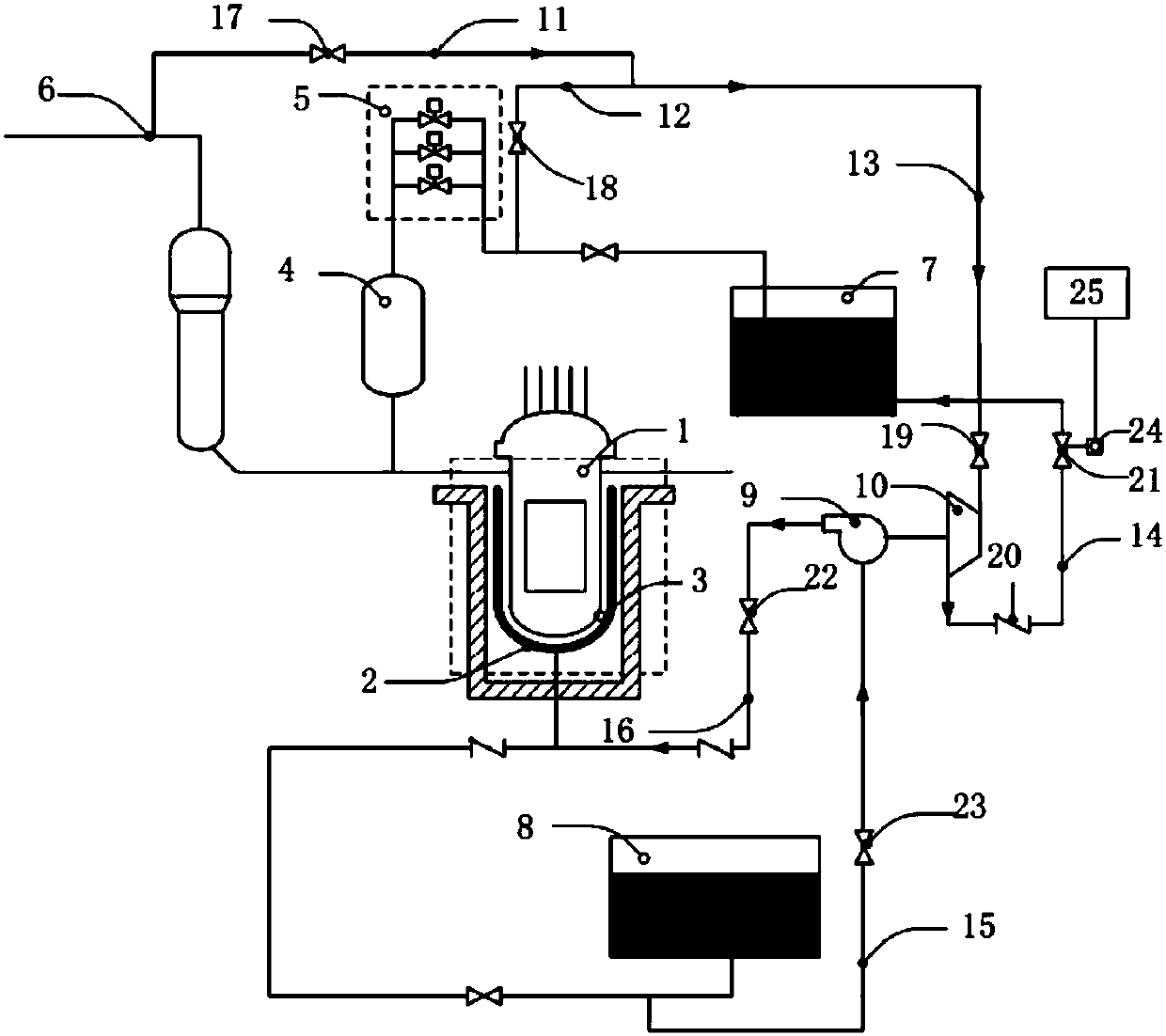

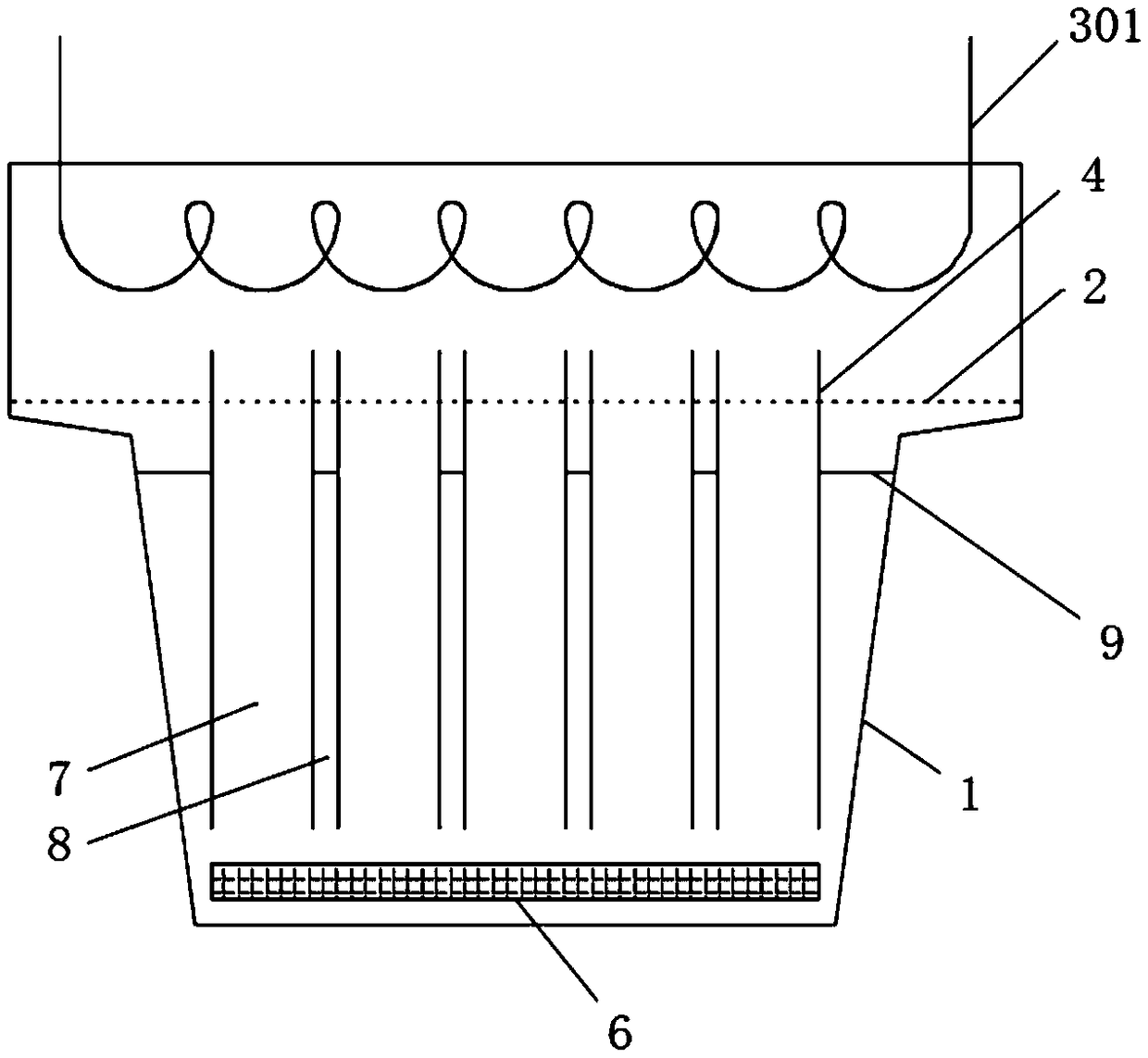

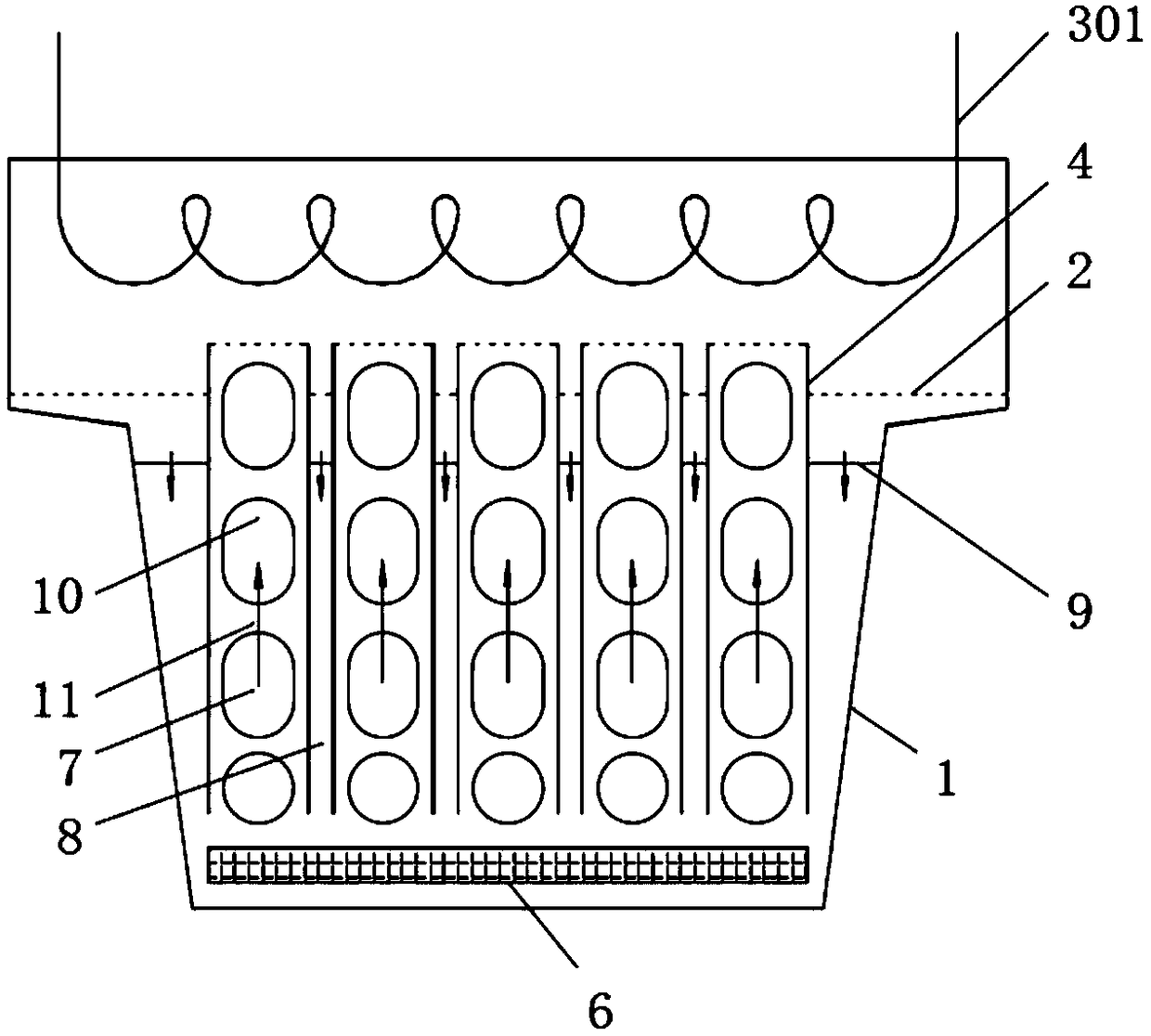

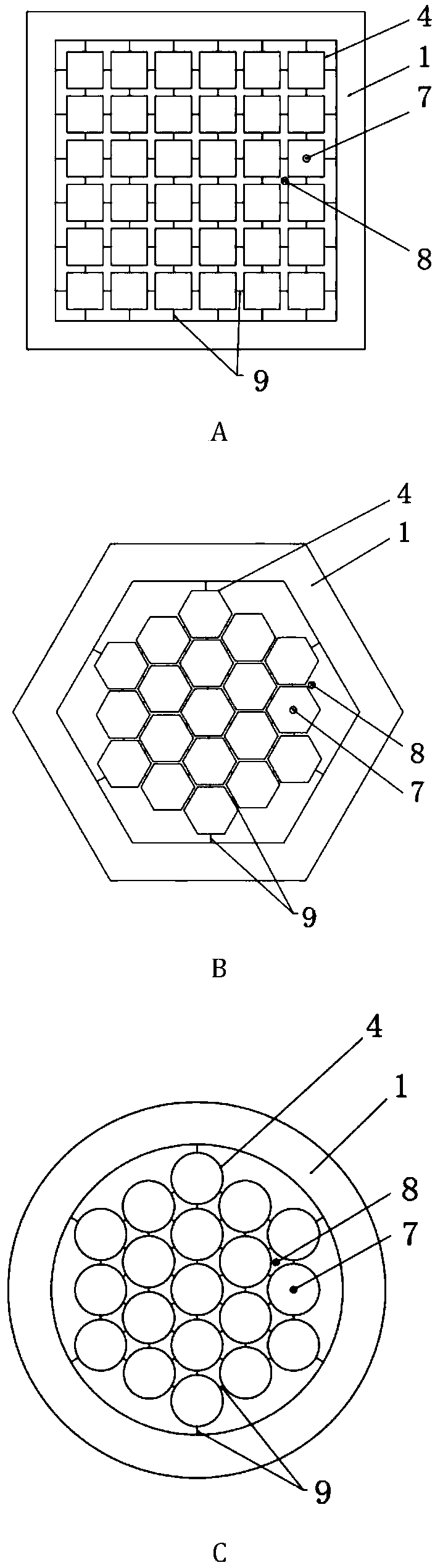

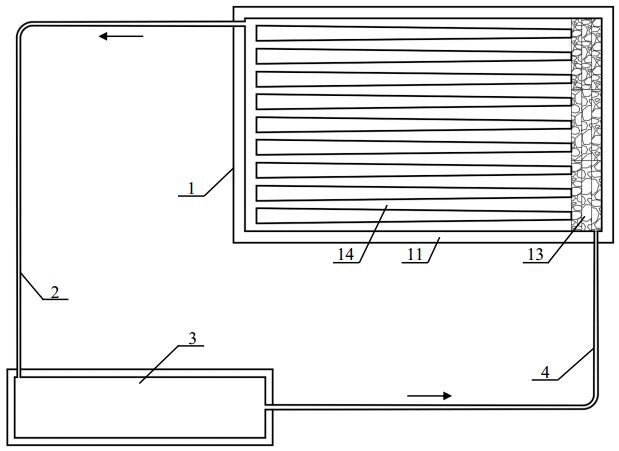

Auxiliary cooling system for reaction core of passive reactor

ActiveCN107845434AIncrease critical heat fluxAvoid boiling crisisNuclear energy generationCooling arrangementWater dischargeNuclear engineering

The invention belongs to the technical field of nuclear safety control and relates to an auxiliary cooling system for a reaction core of a passive reactor. The auxiliary cooling system for the reaction core of the passive reactor comprises a pressure container, a heat insulation layer, an annular space, a built-in material changing water tank, a water feeding pump, a steam turbine, a water feedingpipeline and a water discharging pipeline, wherein the sealed annular space is formed between an outer wall of the pressure container and the heat insulation layer at the periphery of the pressure container; the built-in material changing water tank is used for supplying water to the water feeding pump through the water feeding pipeline; the water feeding pump is driven by the steam turbine to inject cooling water into the annular space through the water discharging pipeline. By adopting the auxiliary cooling system for the reaction core of the passive reactor, provided by the invention, theimmersion of a reactor cavity of the reactor can be accelerated through a passive means and the critical heat flux density of an in-reactor melt retention device is improved, so that a phenomenon thata wall surface of the pressure container has a boiling crisis is avoided and an IVR system is effective.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Enhanced immersion cooling device with diversion function

ActiveCN109216302AIncrease the supply flowPrevent retrogradeSemiconductor/solid-state device detailsSolid-state devicesBoiling processEngineering

An enhanced immersion cooling device with a diversion function comprises a sealed casing, a deflector and an insulating working medium arranged in the casing, wherein the air deflector is vertically arranged in the shell, the air deflector is an ascending channel of the insulating working substance and a return channel of the insulating working substance is formed between the adjacent air deflector, the cold source and the heat source are respectively located above and below the shell, and the insulating working substance flows through the ascending channel and the return channel in the shellto form a directional circulation of an enclosed space. The directional cycle of the invention can enhance the liquid supply flow of the heat source, enhance heat exchange, and delay the appearance ofthe critical heat flux. The upward gas column or liquid column and downward liquid in different channels can effectively avoid gas-liquid retrogression, that is, the phenomenon of ascending bubbles entrapping downward liquid in the process of violent boiling does not occur, which reduces most of the flow resistance and is also conducive to the heat transfer of the device.

Owner:SHANGHAI JIAO TONG UNIV

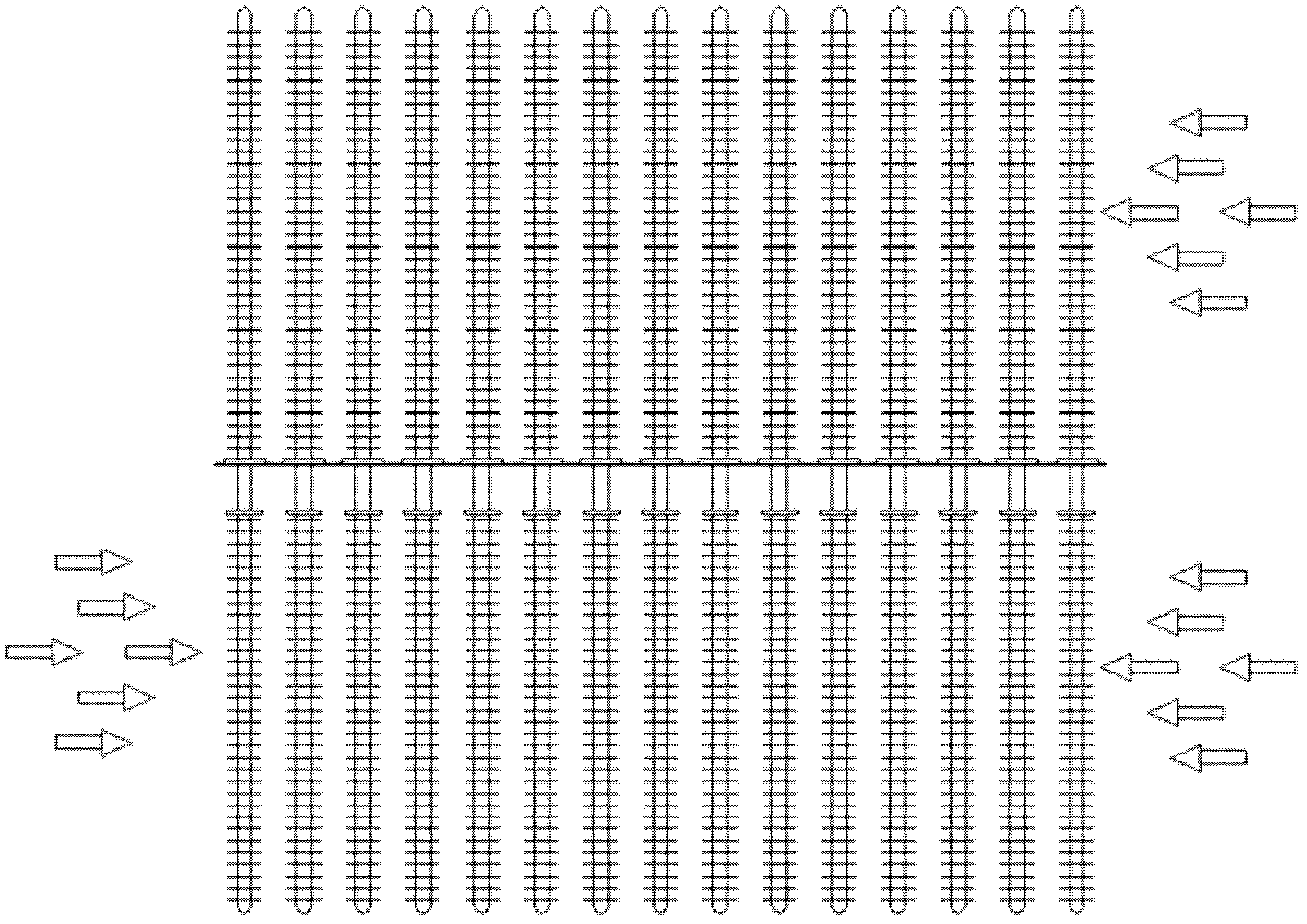

Microchannel heat exchanger structure with spray pipe and work method

PendingCN109764706AImprove heat transfer effectIncrease critical heat fluxSemiconductor/solid-state device detailsStationary conduit assembliesHeat fluxEngineering

The invention relates to a microchannel heat exchanger structure with a spray pipe and a work method. The microchannel heat exchanger structure comprises a first heat exchange portion, a second heat exchange portion and at least one spray pipe portion located between the first heat exchange portion and the second heat exchange portion. A high pressure heat exchange flow channel is arranged in thefirst heat exchange portion, a first micro rib array is arranged in the high pressure heat exchange flow channel, a low pressure heat exchange flow channel is arranged in the second heat exchange portion, and the high pressure heat exchange flow channel communicates with the low pressure heat exchange flow channel through at least one spray pipe arranged in the spray pipe portion. The heat exchanger structure is good in heat exchange effect, and can achieve the better heat exchange heat flux.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

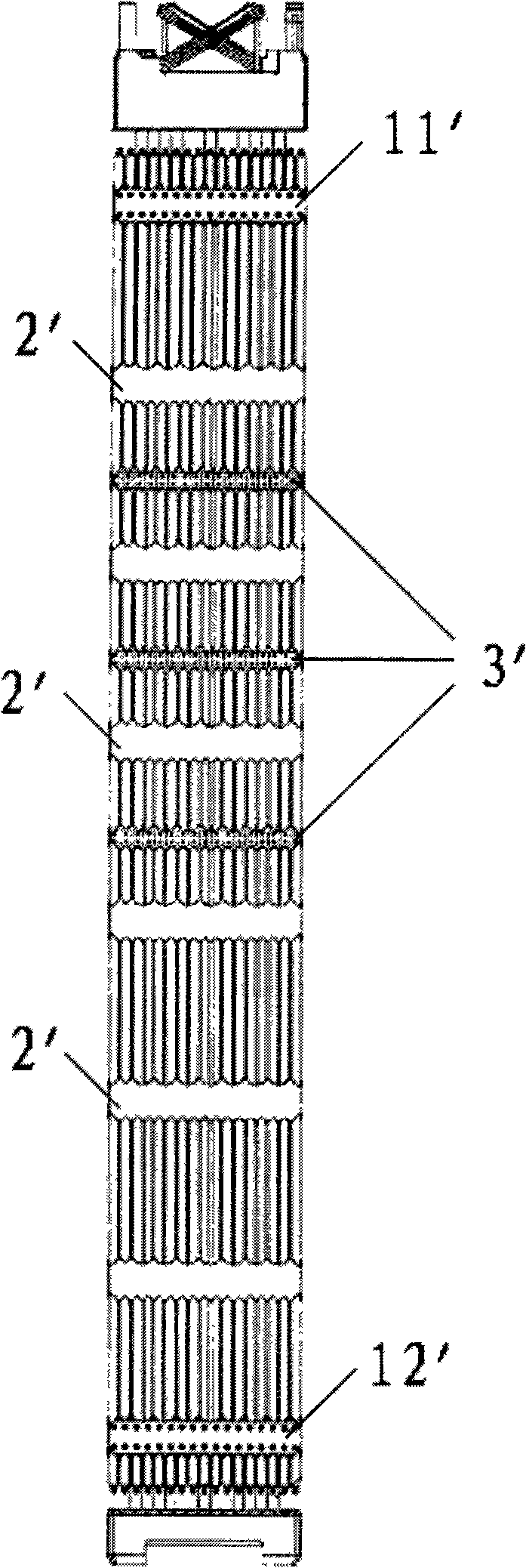

Fuel assembly and nuclear reactor core using the same

ActiveCN101303905AEnhanced blendingIncrease critical heat fluxNuclear energy generationFuel element assembliesNuclear reactor coreNuclear reactor

The invention belongs to the technical field of nuclear fuel components and the design of nuclear reactors and provides a fuel component used for a nuclear reaction core. The fuel component consists of an end framework and at least two mixing frameworks. The end framework consists of an upper end framework and a lower end framework; the mixing frameworks are up-down alternate and are arranged between the upper end framework and the lower end framework in sequence; at least two span mixing frameworks are arranged between the two adjoining mixing frameworks; and the nuclear reaction core using the fuel component is also provided and the core comprises 157 units of the fuel components which are arranged to be 15 lines and 15 rows and are parallel with each other. Compared with the prior art, the fuel component can dramatically increase the thermal allowance of the core under normal and accident working conditions and improve the safety of nuclear power stations.

Owner:LINGAO NUCLEAR POWER +1

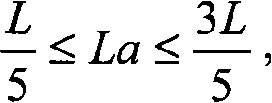

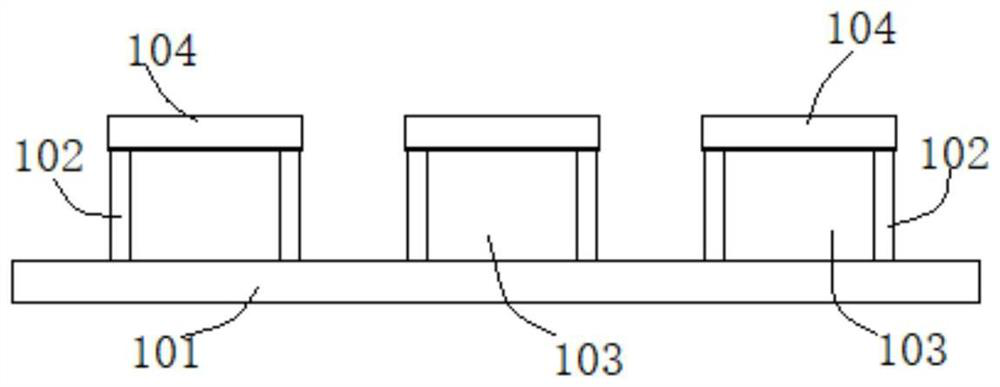

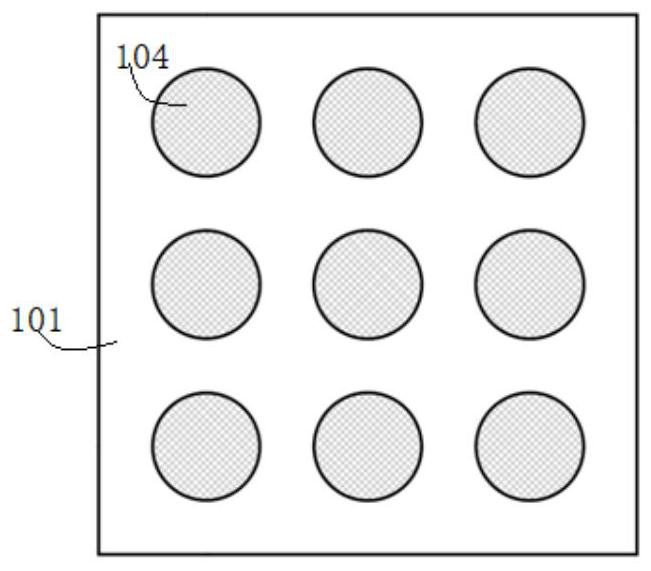

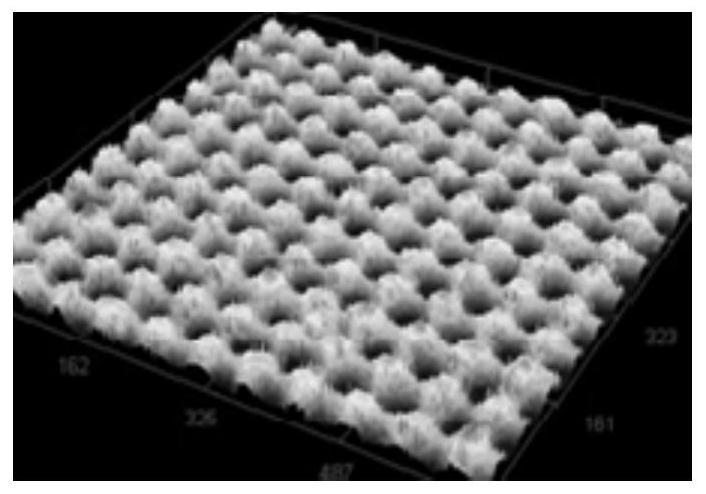

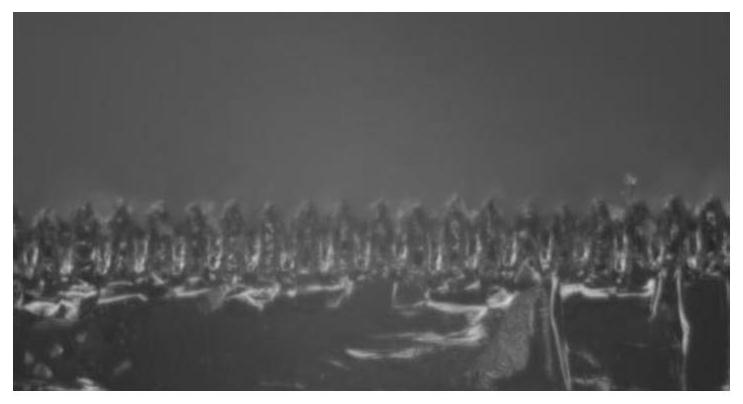

Composite microcolumn-porous surface structure for enhancing boiling heat transfer

InactiveCN114023710AReduce lossHypernucleated pointSemiconductor/solid-state device detailsSolid-state devicesBoiling heat transferMaterials science

The invention discloses a composite microcolumn-porous surface structure for enhancing boiling heat transfer, and belongs to the field of boiling heat transfer enhancing. The structure comprises a heating substrate and a plurality of micro-column-shaped composite porous surface micro-structures on the substrate. The tops of the micro-column structures are capillary cores made of a porous material, the bottoms of the micro-column structures are made of a composite material, the interiors of the structures are made of a high-thermal-conductivity material, the exteriors of the structures are wrapped with a layer of high-thermal-resistance materials, and channels are formed among the micro-structures. According to the surface structure, heat is introduced into fluid through the high-heat-conductivity micro-columns, the porous material is used for increasing the gasification core, reducing the boiling starting point and sucking the supplied liquid, the temperature superheat degree of the boiling wall surface is reduced, and the bubble separation rate is increased; and a fluid working medium is timely ejected into the porous core to form a stable gas-liquid flowing path, a gas film formed by direct boiling on a heating surface is avoided, and boiling heat transfer is enhanced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

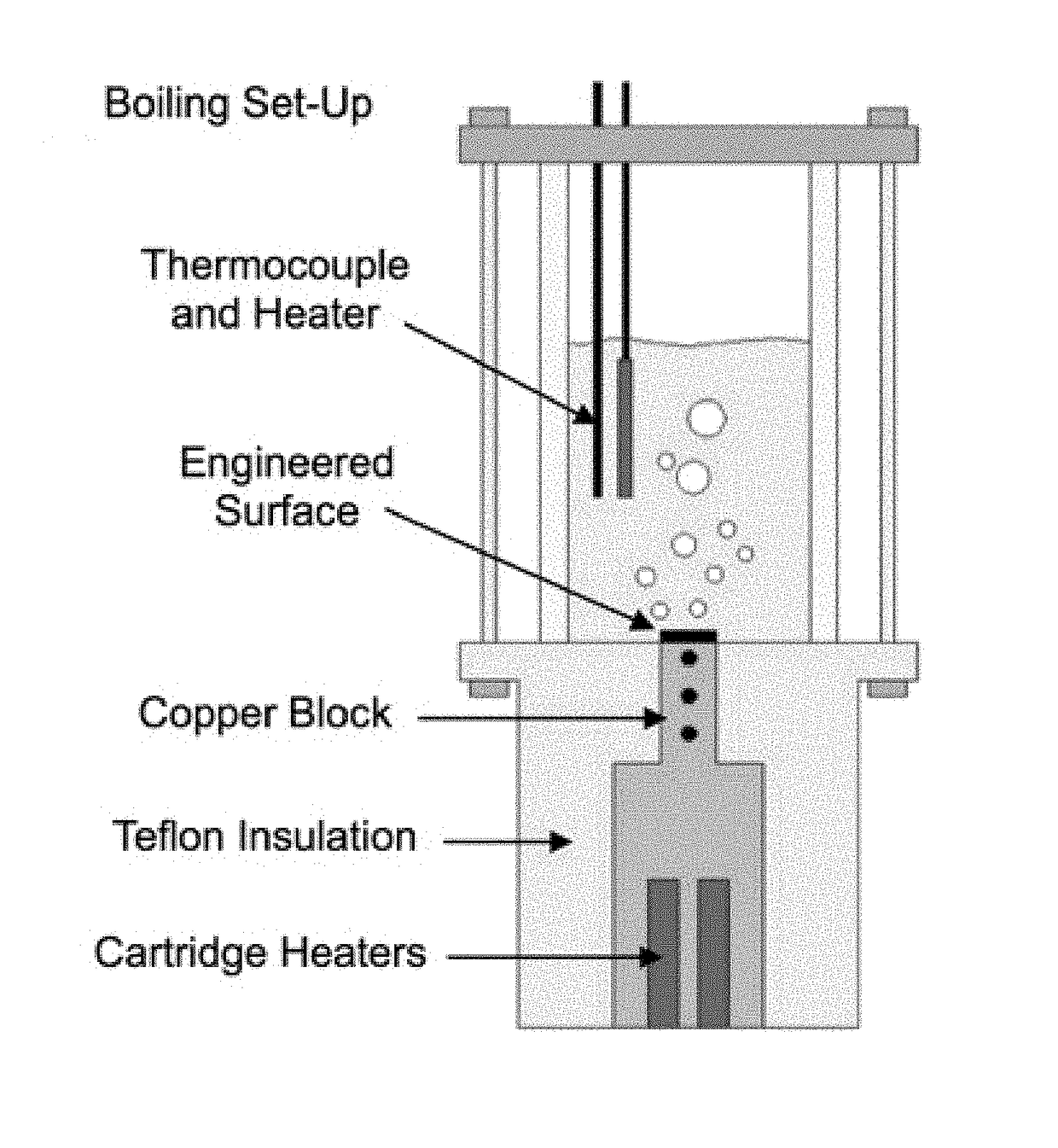

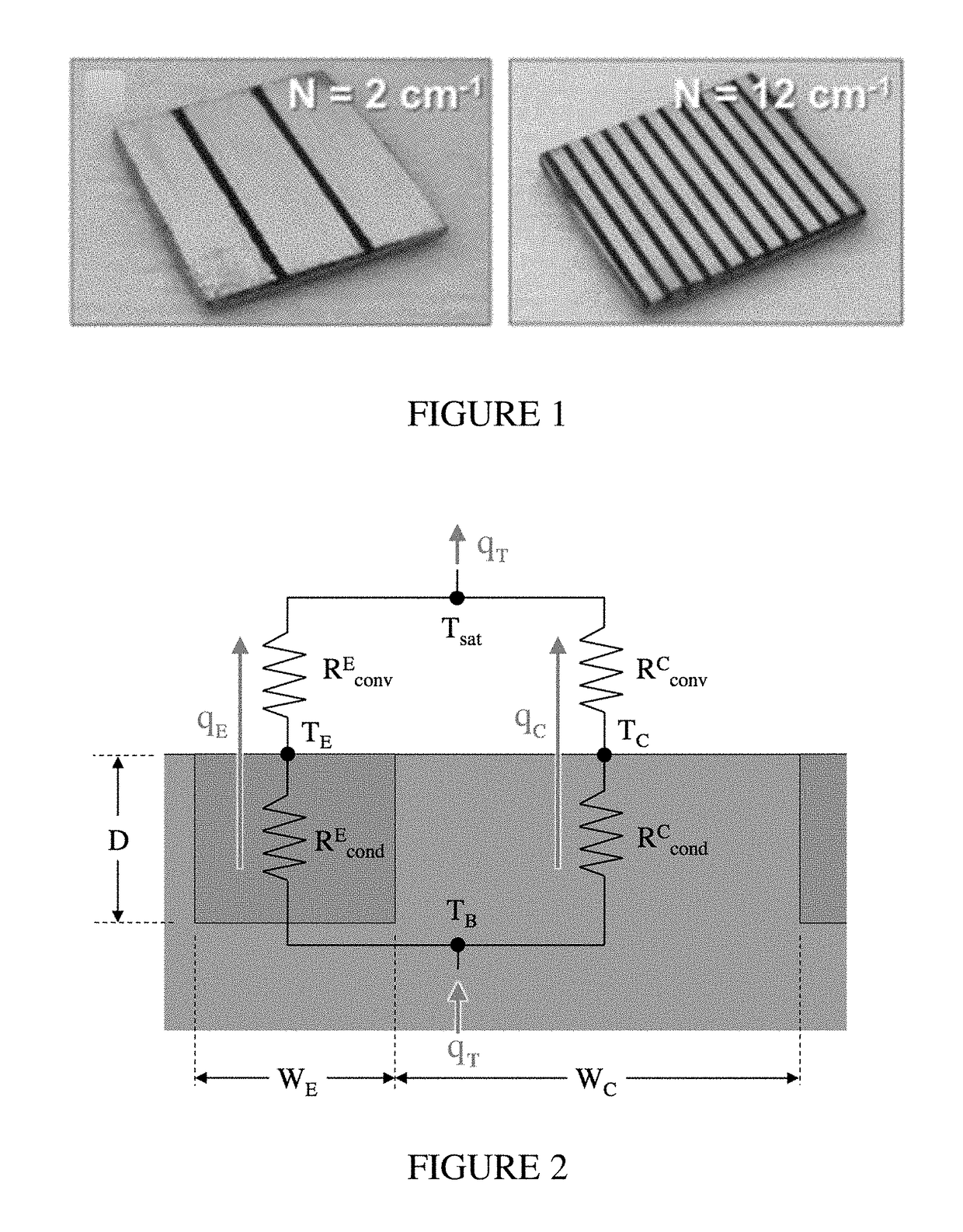

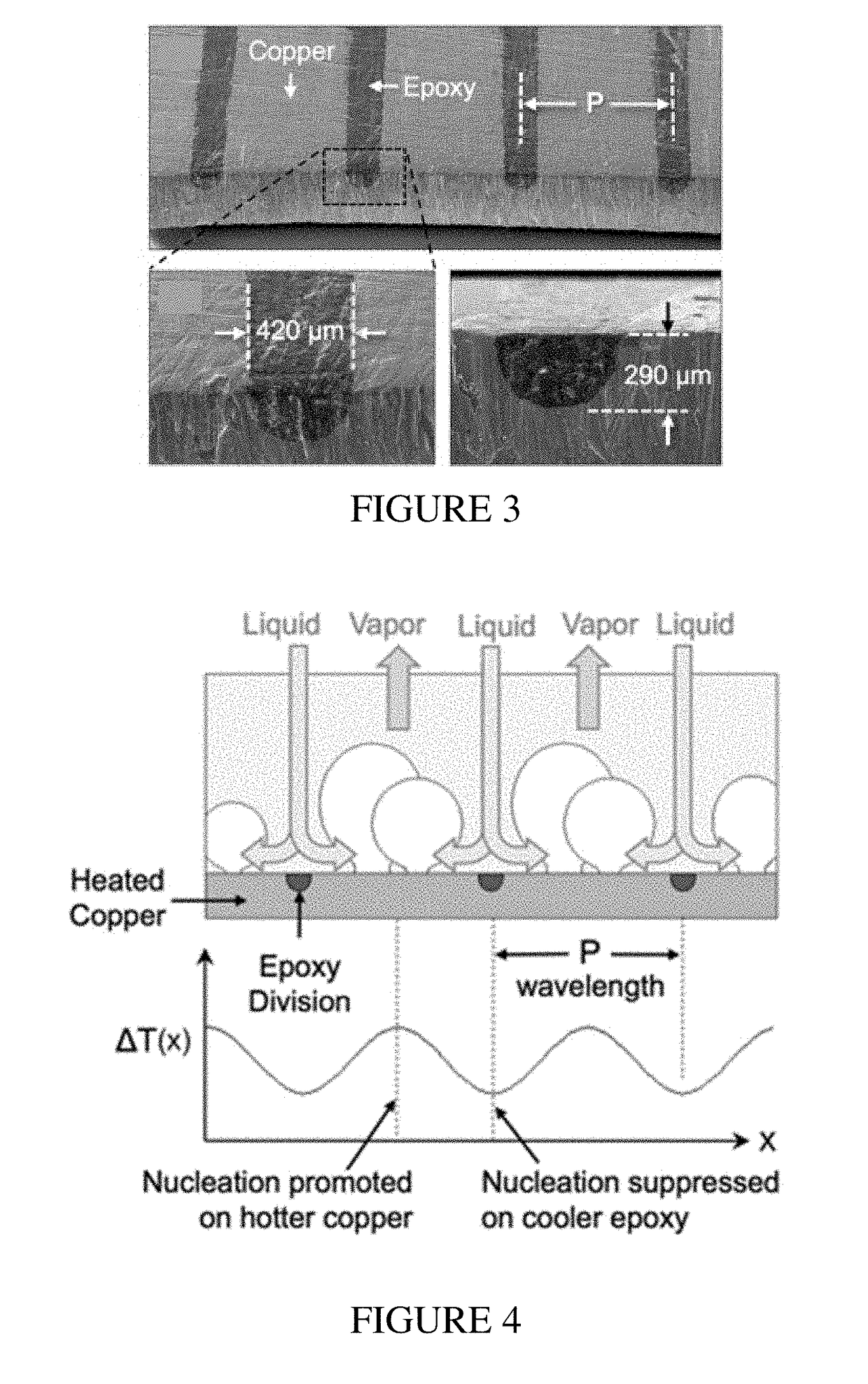

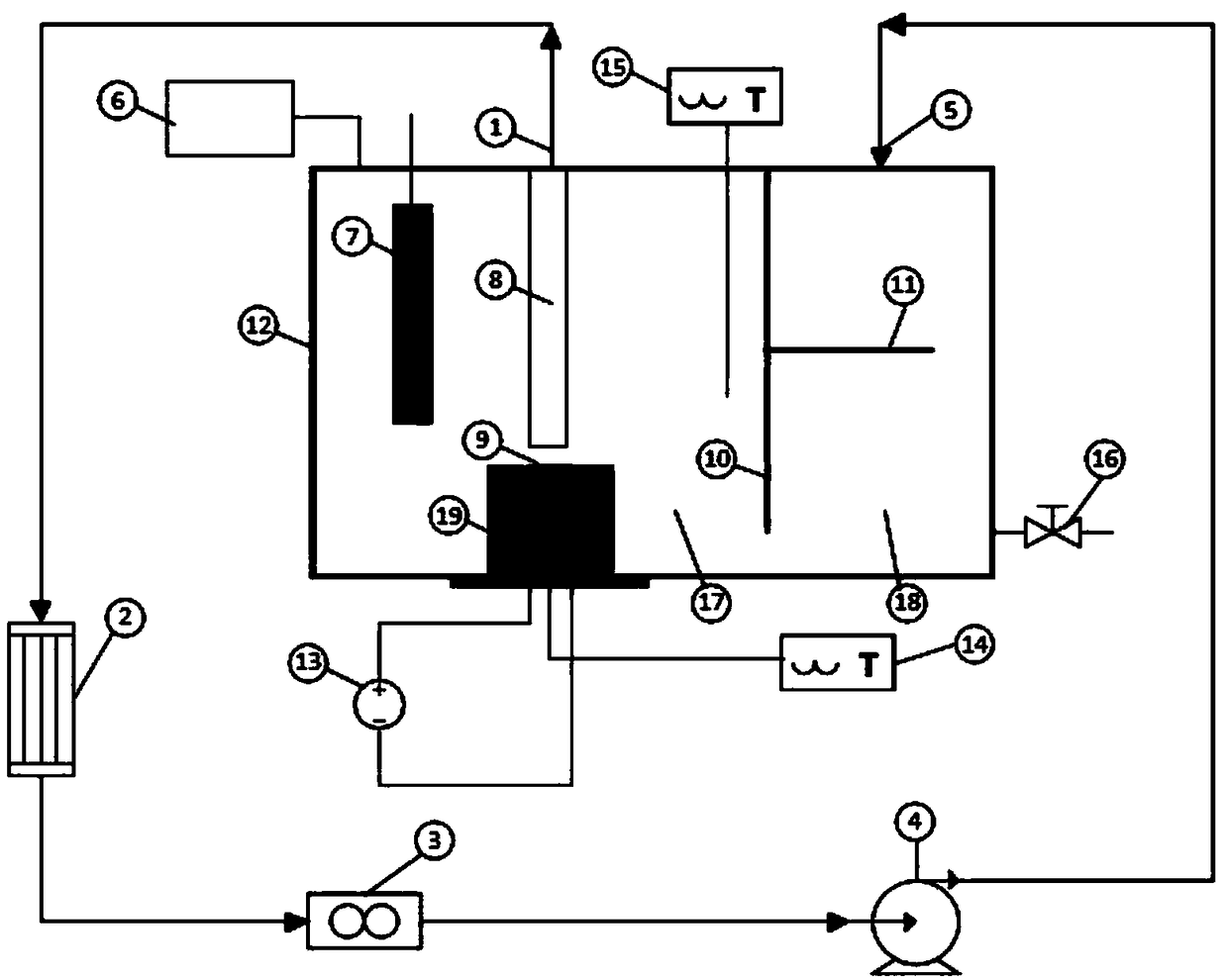

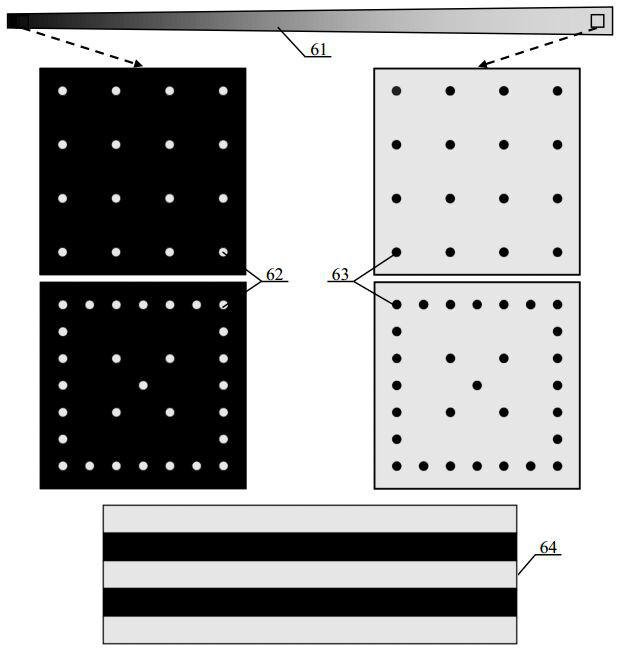

Increasing boiling heat transfer using low thermal conductivity materials

InactiveUS20180017344A1Increase critical heat fluxSemiconductor/solid-state device detailsIndirect heat exchangersThermal transmittanceThermal conductivity

An apparatus having a heat transfer surface for transfer of heat from the apparatus to a liquid. The heat transfer surface includes at least two different materials and at least two of said materials have different thermal conductivities. A method of boiling at least one liquid which provides increased heat transfer from a heat transfer surface of an apparatus to a liquid comprising a step of boiling said liquid in contact with the apparatus, is also disclosed. Also described is a method of tuning a heat transfer surface by forming the heat transfer surface using at least two different materials having different thermal conductivities arranged in a predetermined spatial relationship including a spacing between the portions of one said material that is from about 0.1λC to about 5λC, wherein λC is a capillary length of a bubble of a predetermined liquid to be boiled using said heat transfer surface.

Owner:DREXEL UNIV

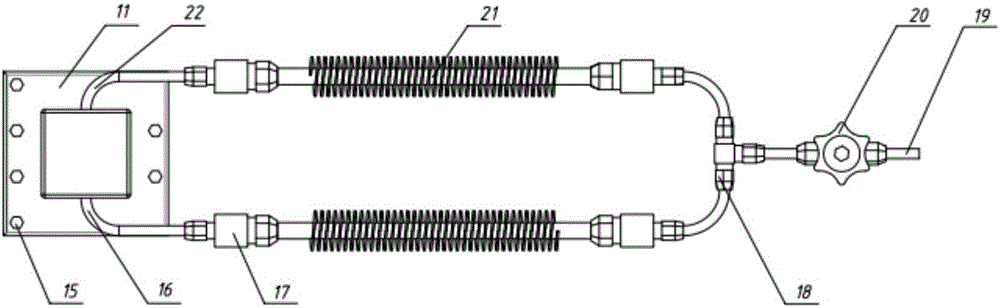

Suction-type electronic chip cooling boiling enhanced heat transfer experiment device and method

ActiveCN108844992AReduce wall superheatIncrease critical heat fluxMaterial heat developmentSmall footprintEngineering

The invention discloses a suction-type electronic chip cooling boiling enhanced heat transfer experiment device and a suction-type electronic chip cooling boiling enhanced heat transfer experiment method. The suction-type electronic chip cooling boiling enhanced heat transfer experiment device comprises a suction experiment boiling tank, wherein the suction experiment boiling tank is partitioned into a suction chamber and a liquid draining chamber through a partition board with an opening in the lower side; a carrying lug boss is mounted on a bottom plate of the suction experiment boiling tank; the upper part of the carrying lug boss stretches into the suction chamber; a test chip is arranged on the upper part of the carrying lug boss; the two ends of the test chip are connected to a direct current power supply through conductive wires; a suction tube bundle is arranged right above the test chip; the suction tube bundle is connected to a condenser through a liquid conveying pipe connected to the suction experiment boiling tank; the outlet end of the condenser is connected to a liquid returning pipe through a unidirectional flow pump; the liquid returning pipe is connected to the suction experiment boiling tank; the liquid returning pipe is communicated with the liquid draining chamber. The suction-type electronic chip cooling boiling enhanced heat transfer experiment device generates a low pressure through suction, so that bubble removal from the surface of the chip and rapid replenishment of a surrounding cold fluid are accelerated; the suction-type electronic chip coolingboiling enhanced heat transfer experiment device has the advantages of flexible operation, simple control, small floor space, convenient chip replacement and the like.

Owner:XI AN JIAOTONG UNIV

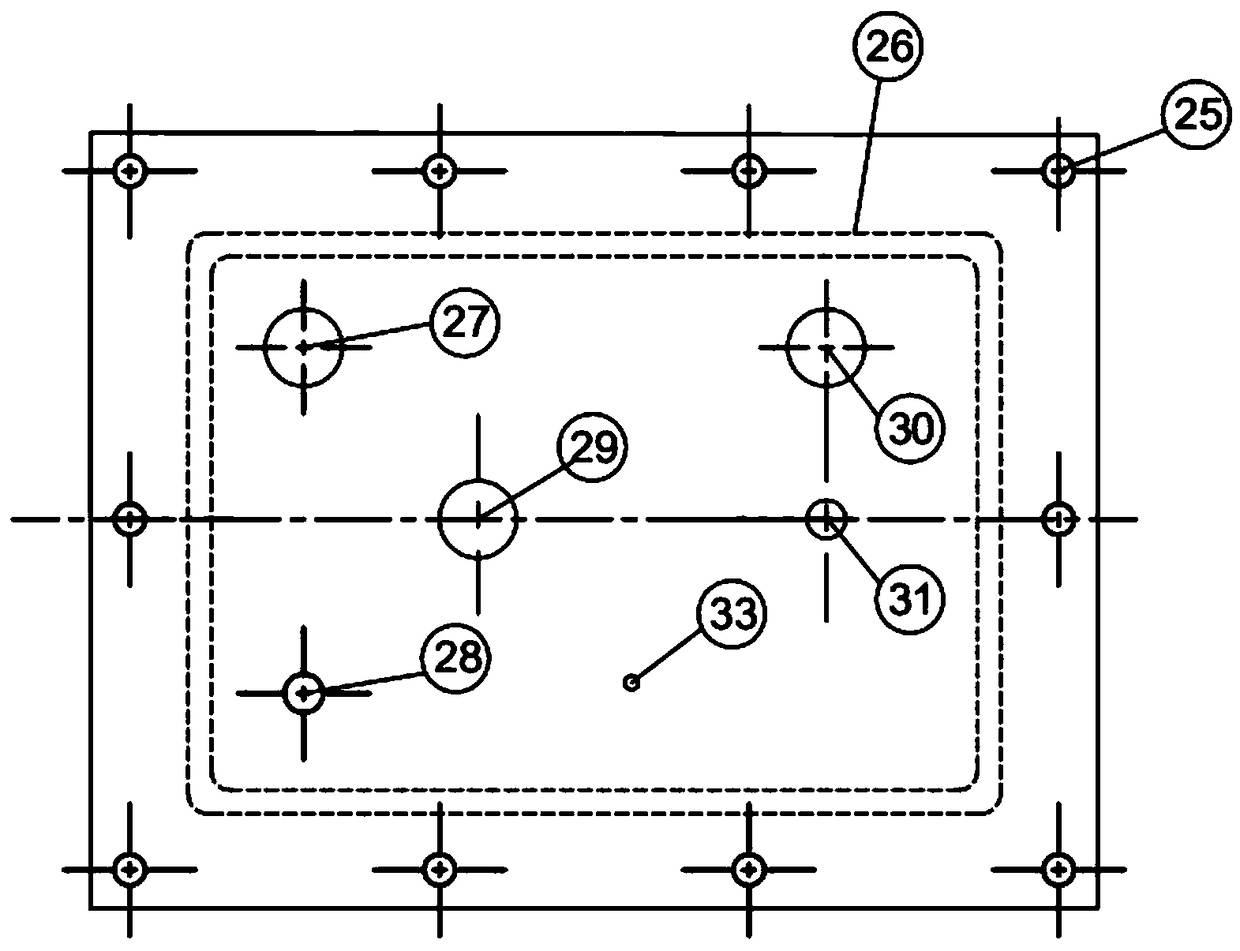

Method for manufacturing foam stainless steel composite tube

The invention discloses a method for manufacturing a foam stainless steel composite tube. The method includes the first step of preparing a dispersant, the second step of preparing stainless steel powder slurry, the third step of evenly coating the stainless steel powder slurry on the outer surface of a stainless steel tube, carrying out heat treatment after drying and obtaining a stainless steel powder sintered porous layer, the fourth step of covering the surface of the stainless steel powder sintered porous layer with a foam formwork, evenly applying the stainless steel powder slurry to the foam formwork, carrying out heat treatment after drying and obtaining a stainless steel foam layer, namely obtaining the foam stainless steel composite tube. According to the method, raw materials are wide in source range and easy to obtain, the manufacturing process is simple, the heat conductivity coefficient of the obtained foam stainless steel composite tube is reduced by more than 10 times compared with that of a stainless steel bare tube, critical heat flux density is improved more than twice, the specific area is large, and the foam stainless steel composite tube has the advantages of being good in machining performance, little in raw material consumption, large in heat exchange specific area and stable in repetitive use performance and can serve as a key part of a radiator.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Loop heat pipe with multi-scale structure synergistic mixed wettability inner surface

PendingCN113048824AEnhanced boiling heat transferSatisfy nuclearizationIndirect heat exchangersLiquid lineEngineering

The invention discloses a loop heat pipe with a multi-scale structure synergistic mixed wettability inner surface. All parts are sequentially connected in series to form a cycle, the interior of the loop heat pipe is provided with the multi-scale structure synergistic mixed wettability inner surface, and the loop heat pipe comprises an evaporator, a condenser, a steam line and a liquid line, and the evaporator is provided with a multi-scale capillary core with gradient hydrophilicity and hydrophobicity. The size is gradually reduced in the circulation direction, the surface is transited from hydrophobicity to hydrophilicity, hydrophobic points are arranged in a hydrophilic area, and hydrophilic points are arranged in a hydrophobic area. The condenser is provided with a multi-scale micro-column inner surface with gradient hydrophobicity, the surface of a nanoneedle transits from super hydrophobicity to hydrophobicity in the circulation direction, and the top end of the embedded micro-column is hydrophilic and forms a hydrophilic point. The steam line and the liquid line are reducing pipes, the pipe diameter and the size of the porous structure on the inner surface are gradually reduced in the circulation direction, and gradient wettability is achieved. By means of the reasonably-designed cooperation mode of the surface multi-scale structure and the mixed wettability, the requirements of different areas and stages of the loop heat pipe for the structure scale and wettability can be met, and the heat exchange performance of the loop heat pipe is improved through all-around cooperation.

Owner:CHINA UNIV OF MINING & TECH

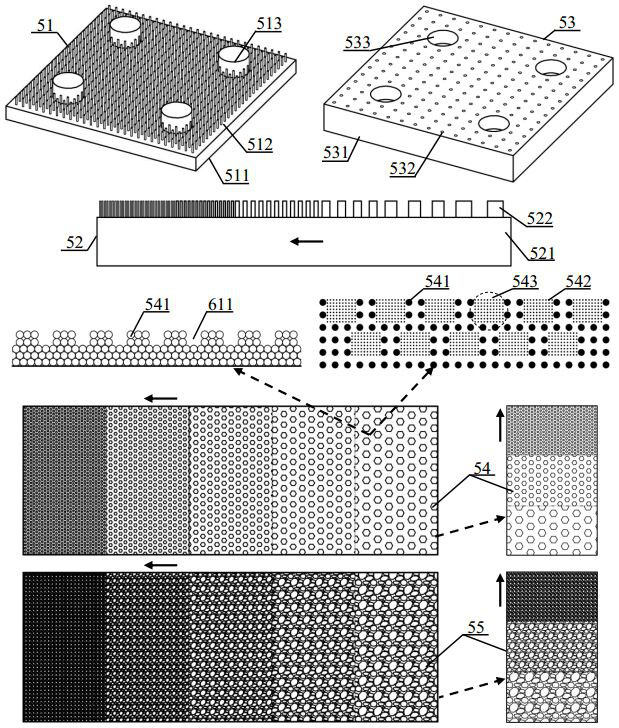

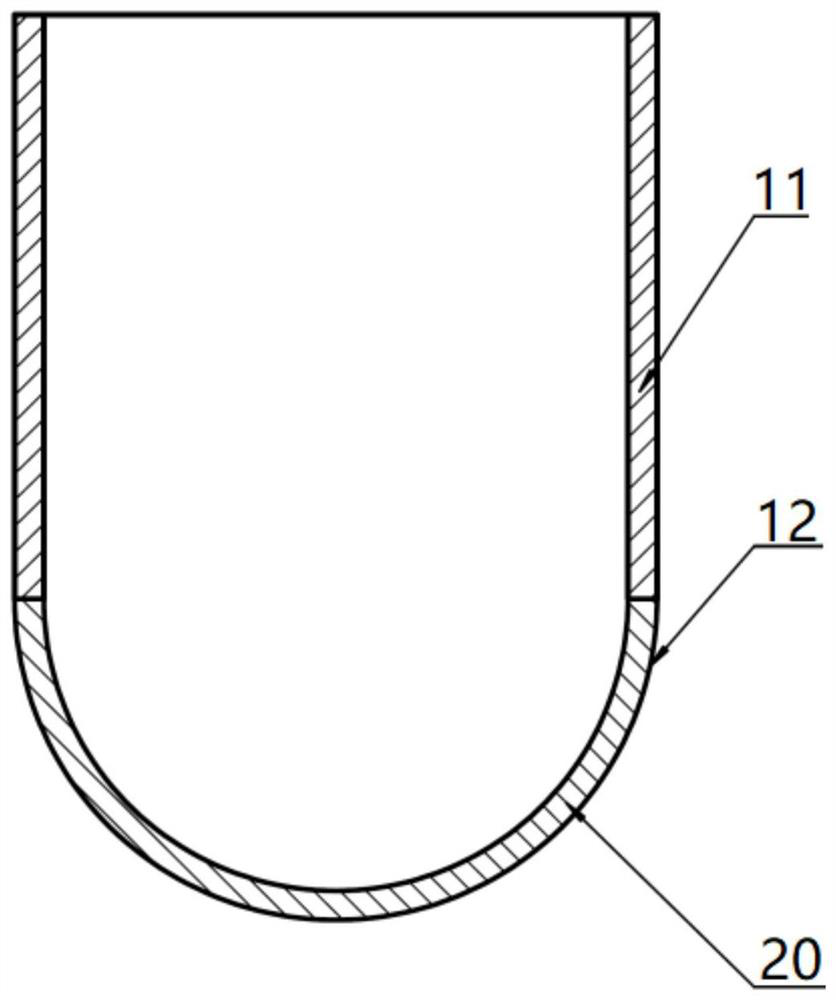

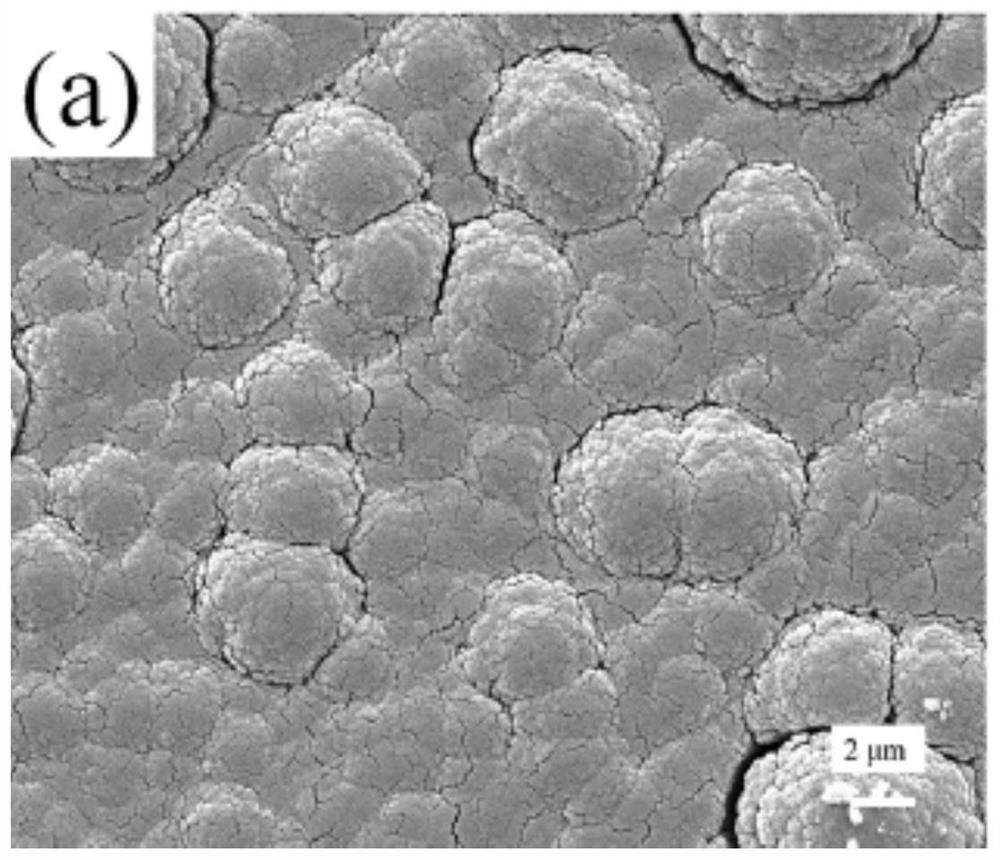

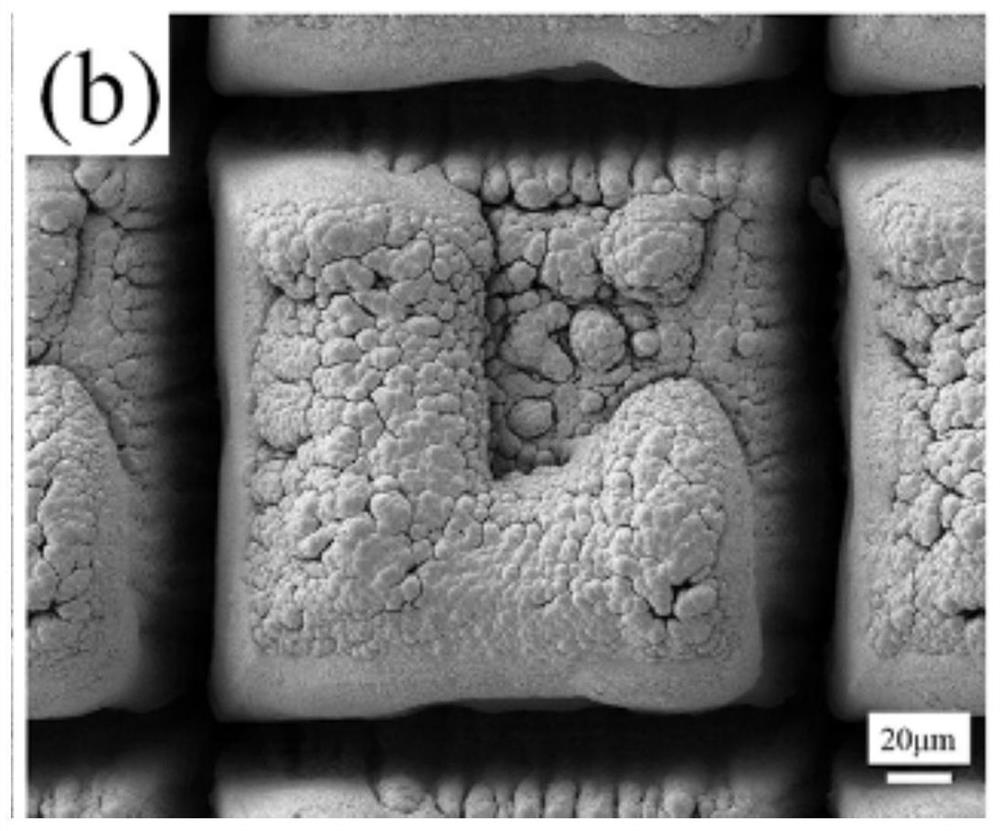

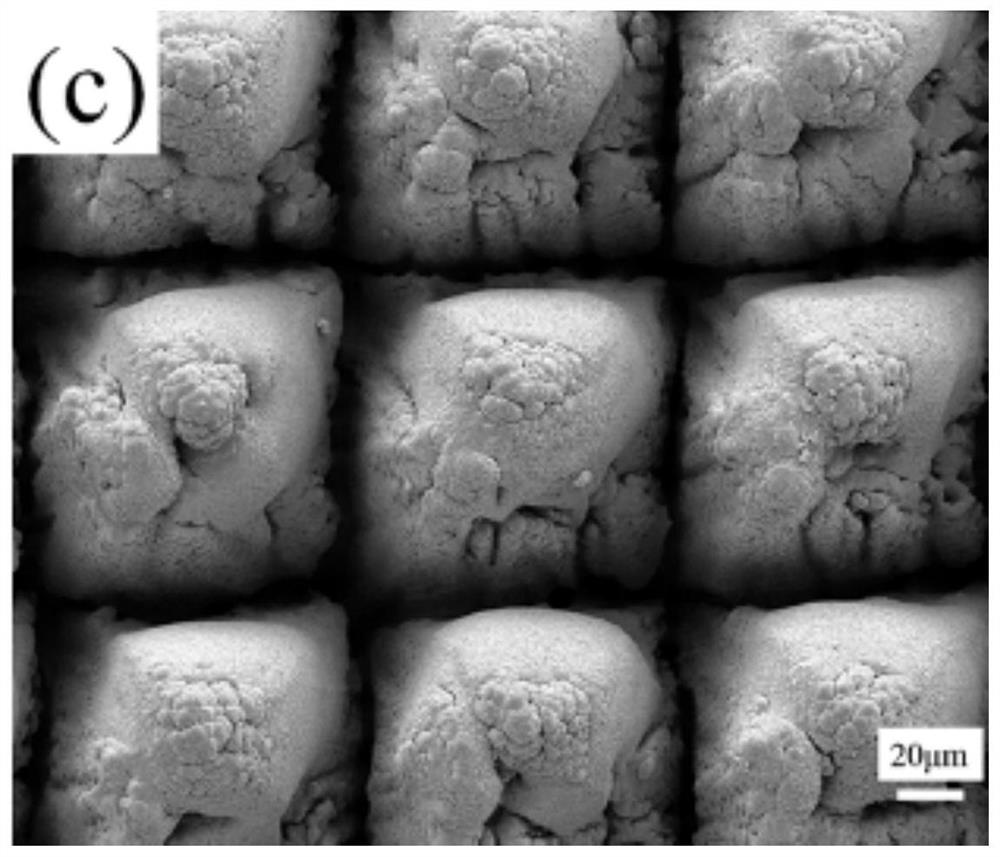

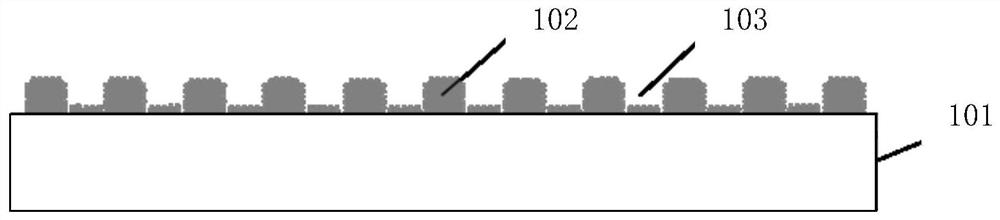

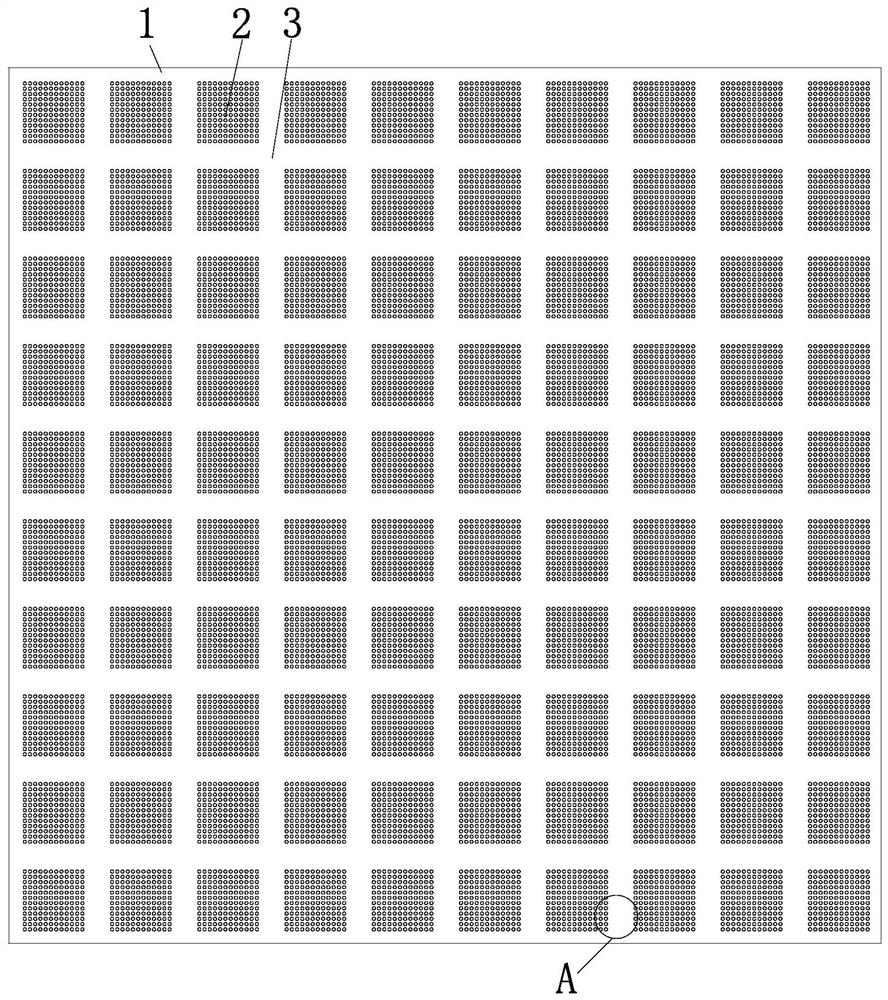

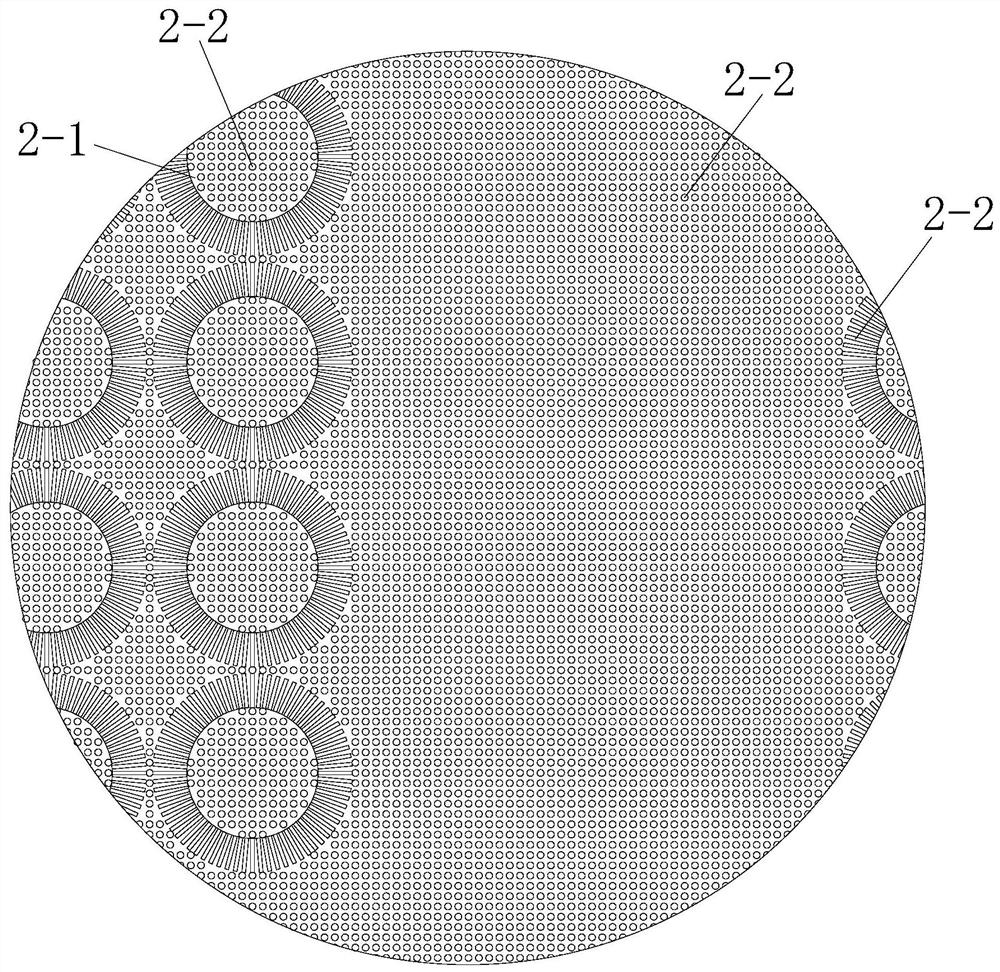

Reactor pressure vessel lower seal head with porous coating on outer wall surface

PendingCN112002446AFast nucleationIncrease critical heat fluxNuclear energy generationReactors manufacturePorous coatingNuclear plant

The invention aims at disclosing a reactor pressure vessel lower seal head with a porous coating on the outer wall surface. The reactor pressure vessel lower seal head comprises a bowl-shaped shell structure and a porous coating fixed on the outer wall, and the porous coating is formed by spraying stainless steel powder. Compared with the prior art, the number of vaporization cores can be greatlyincreased, and the bubble nucleation speed is increased; the heat exchange area is increased; bubbles are enabled to grow up and escape, localized fluid is stirred to enhance surface convection, and the heat exchange capability of the fluid and the outer wall surface of the reactor pressure vessel is enhanced; and compared with a smooth outer surface, the critical heat flux density of fluid at thecorresponding position of the outer wall surface of the reactor pressure vessel can be improved by 50% or above, implementation of in-reactor retention of in-reactor melts is facilitated, the safetymargin of a nuclear power plant under the accident condition can be improved, and the purpose of the invention is achieved.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

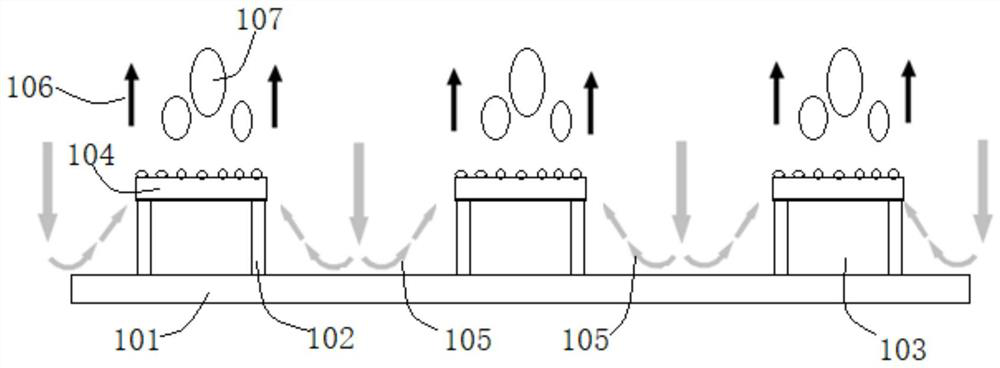

Design and preparation method of micro-channel structure of efficient enhanced boiling heat transfer surface

PendingCN113782452AIncrease critical heat fluxReduce CTE MismatchSemiconductor/solid-state device detailsSolid-state devicesNanopillarHeat flow

The invention relates to a design and preparation method of a micro-channel structure of an efficient enhanced boiling heat transfer surface. According to the invention, a micro-channel structure is cut on a high-thermal-conductivity metal copper surface through laser, then a copper nano layer is deposited on the micro-channel structure through a magnetron sputtering method, the superheat temperature of the high-thermal-conductivity metal surface is reduced while the critical heat flux density of the high-thermal-conductivity metal surface is improved, and the critical heat flux density and the heat exchange coefficient are enhanced at the same time. The number of nucleation sites of the micro-channel structure is increased, the critical heat flux density is increased by 1.61 times compared with the surface of a copper material, meanwhile, the heat exchange coefficient is increased by 2.26 times, and the superheat degree of the metal heat exchange surface making contact with liquid is greatly reduced. The surface of the micro-channel structure is provided with the closely-stacked nano-column layer, the bubble removal diameter is smaller, and the bubble removal frequency is higher. According to the efficient enhanced boiling heat transfer surface with the multi-stage micro-channel structure, the critical heat flux is as high as 141.3 W / cm < 2 >, and the superheat degree of the wall surface is only 8.9 K.

Owner:BEIHANG UNIV

Intensified boiling structure and preparation method and application thereof

PendingCN112582361AIncrease critical heat fluxImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesHeat flowEngineering

The invention provides an intensified boiling structure and a preparation method and application thereof, and relates to the technical field of heat dissipation. The intensified boiling structure comprises a heat conduction substrate, heat dissipation ribs and micro-nano concave-convex structures. The heat dissipation ribs are located on the first surface of the heat conduction substrate, and themicro-nano concave-convex structures are formed on the first surface and the surfaces of the heat dissipation ribs; and the sizes of the radiating ribs are micron-sized to millimeter-sized. Accordingto the intensified boiling structure, through the heat dissipation ribs and the micro-nano concave-convex structure, the nuclear boiling heat exchange performance and the critical heat flux density ofthe electronic chip are improved, and therefore the heat dissipation effect of the electronic chip is improved.

Owner:SUGON DATAENERGYBEIJING CO LTD

Mixed wettability micro-nano composite enhanced heat exchange structure and preparation method thereof

ActiveCN111834309AEfficient separationLeave in timeSemiconductor/solid-state device detailsSolid-state devicesPhysicsChemistry

The invention discloses a mixed wettability micro-nano composite enhanced heat exchange structure. The structure comprises a heat dissipation substrate, wherein a plurality of square micro-cylindricalarray units and groove channels arranged among the micro-cylindrical array units are etched on the heat dissipation substrate. Each micro-cylinder array unit comprises a plurality of micro-cylinderswhich are arranged in order, nanowires are arranged on the groove channels and the micro-cylinders, the diameter of the nanowires ranges from 200 nm to 500 nm, and the height of the nanowires ranges from 10 micrometers. The invention further discloses a manufacturing method of the mixed wettability micro-nano composite enhanced heat exchange structure. The micro-cylindrical array unit and the nanowire structure adopted by the invention can effectively enhance the boiling heat transfer coefficient of high heat flux and delay the boiling dry burning phenomenon.

Owner:XIAN UNIV OF SCI & TECH

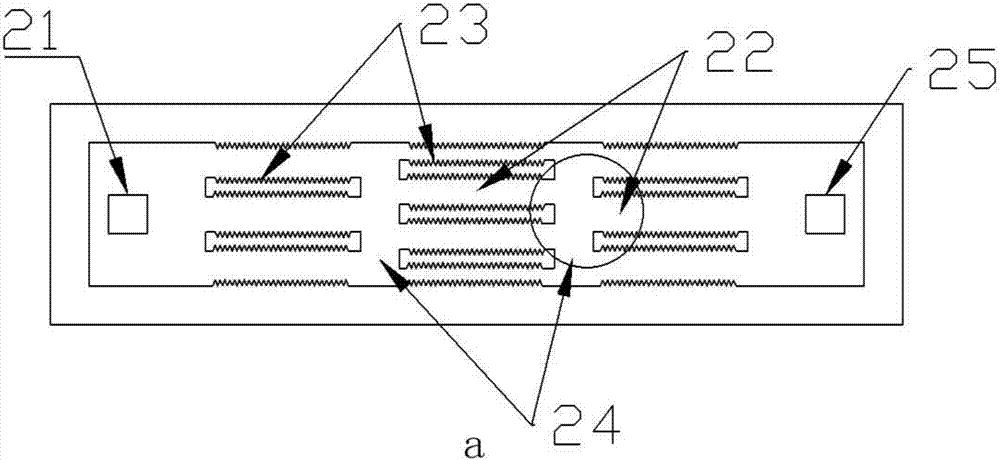

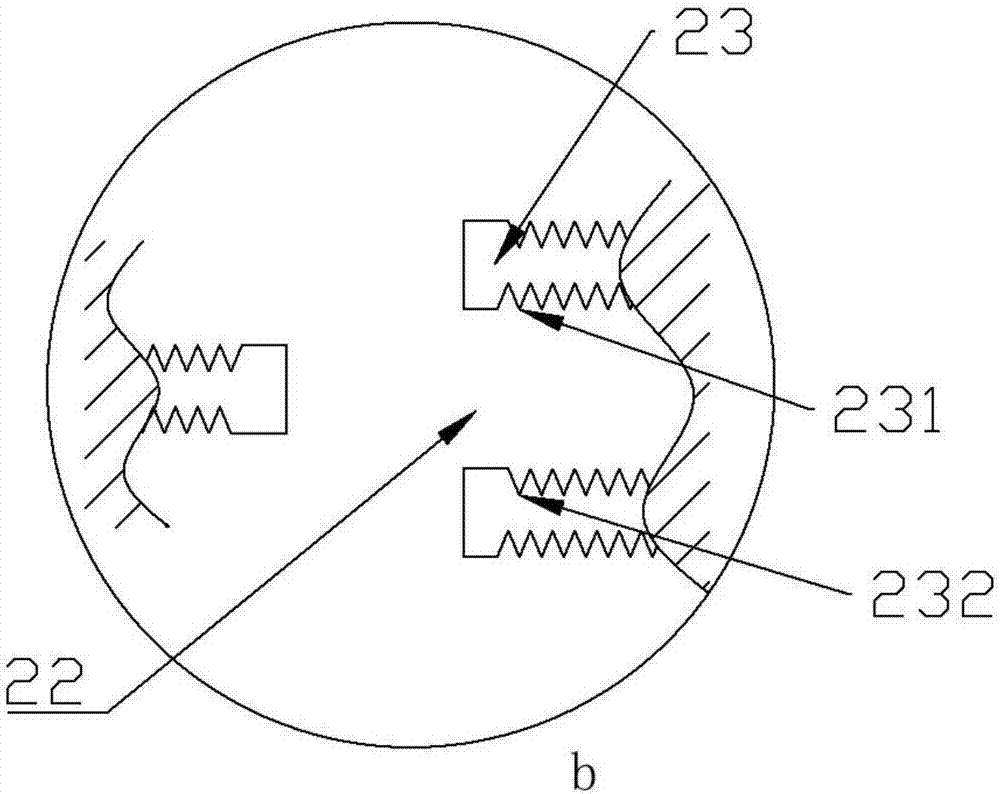

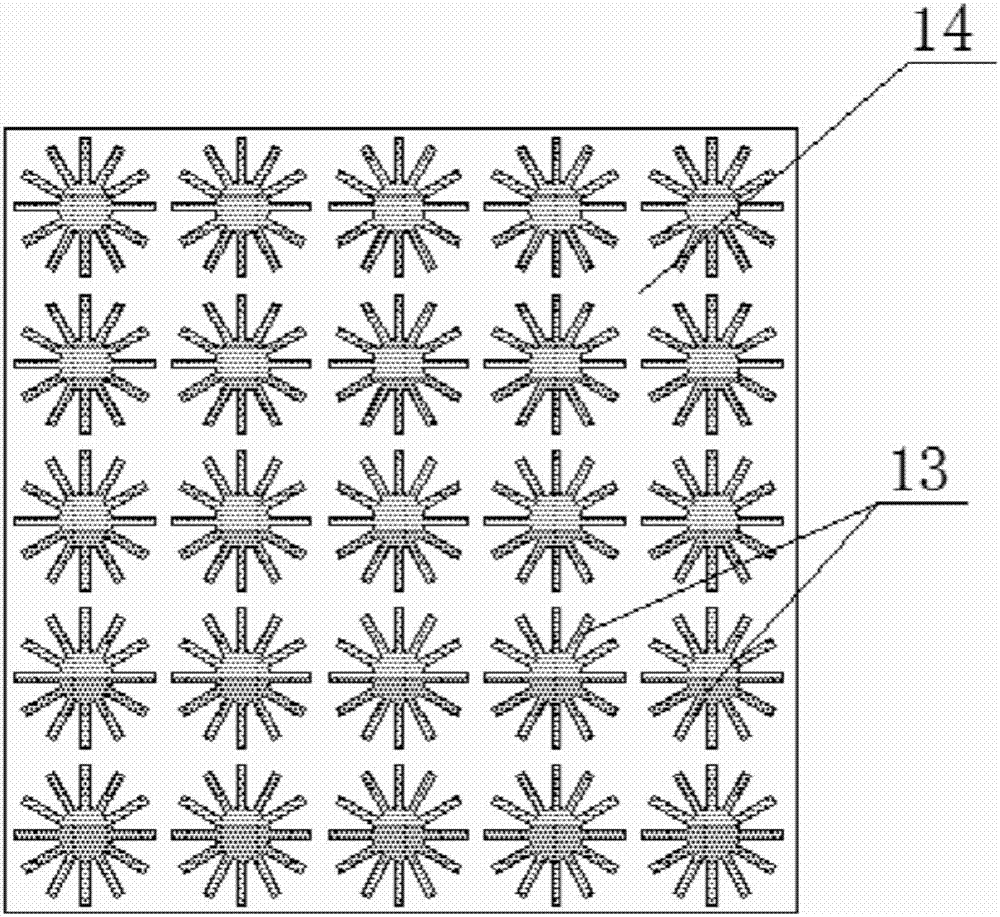

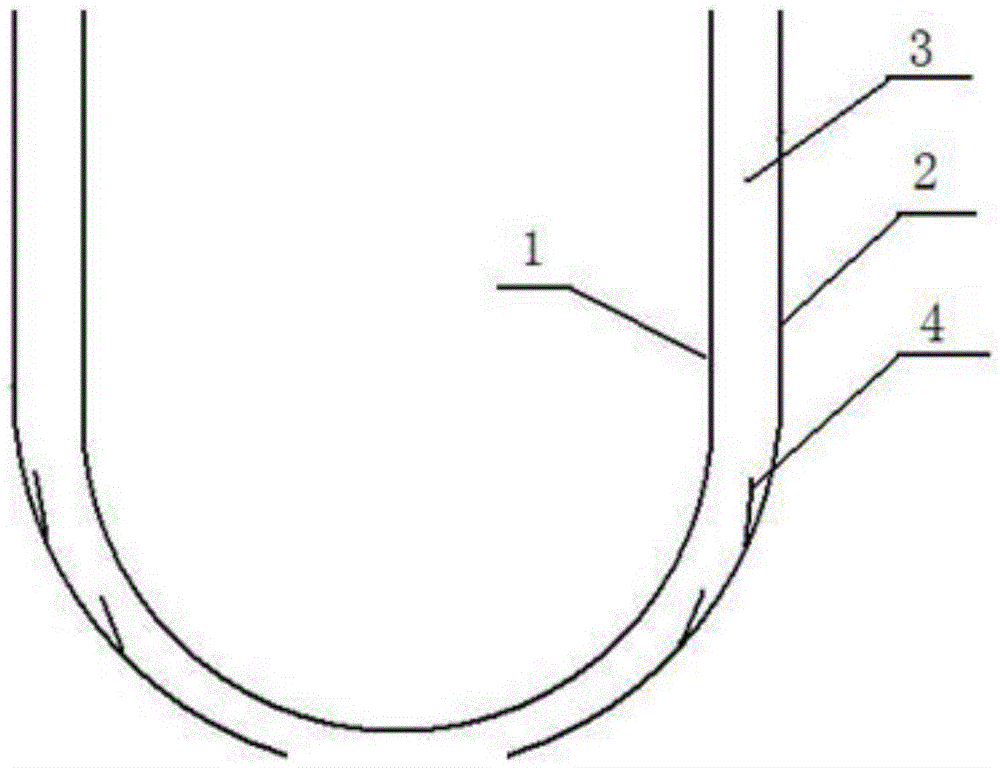

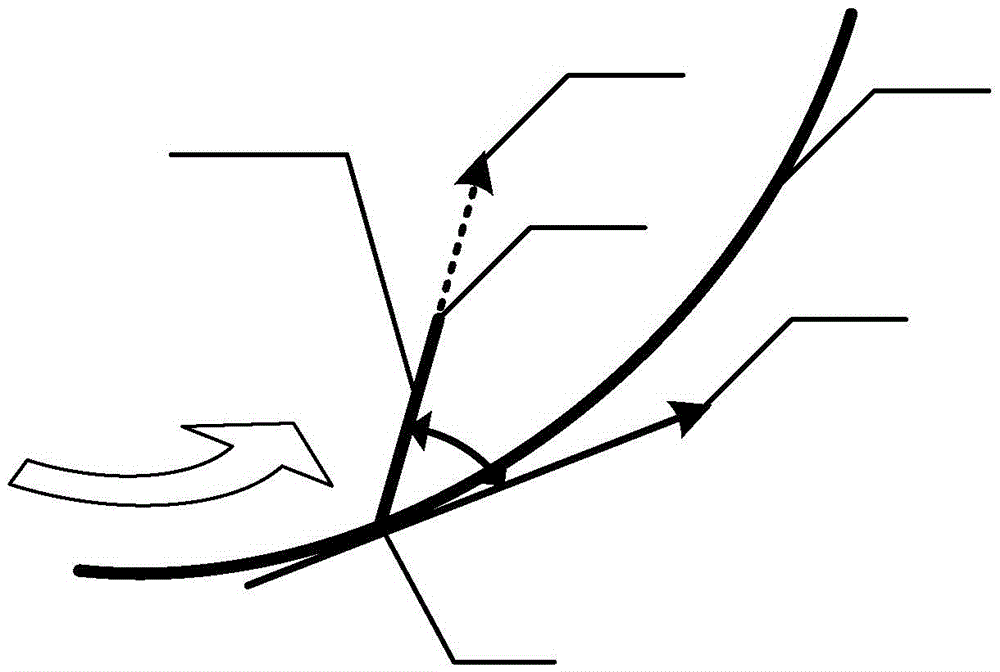

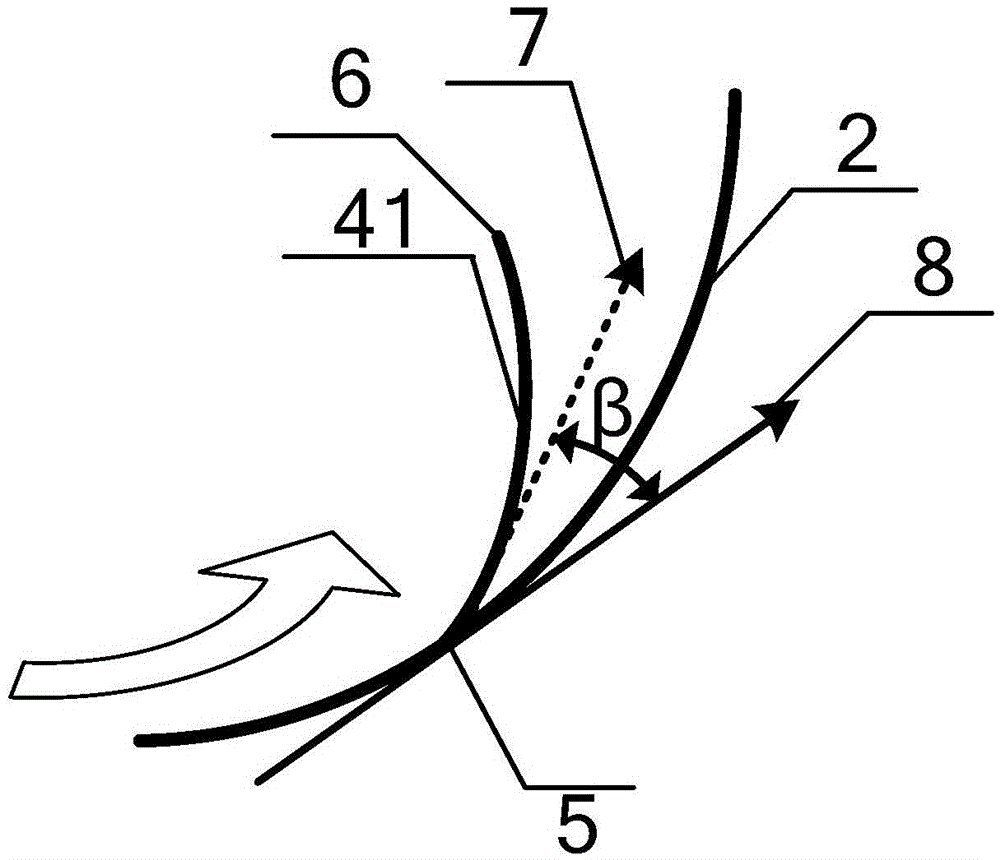

A device for increasing the heat flux density at the boundary of the outer wall of a pressure vessel

ActiveCN103440886BIncrease critical heat fluxImprove securityNuclear energy generationCooling arrangementVapor bubbleHeat flow

The invention discloses a device for increasing the critical heat flux density of an outer wall surface of a pressure vessel, comprises a reactor pressure vessel and a heat-insulating layer coated outside the reactor pressure vessel. A flow passage is formed between the outer wall surface and the heat-insulating layer of the reactor pressure vessel, a plurality of protrusions which are fixed on the inner wall surface of the heat-insulating layer are arranged in the flow passage, and the plurality of protrusions are out of contact and arranged in a circumferential or staggered manner. According to the invention, the staggered arrangement of the protrusions enhances the turbid effect of a fluid during the flowing process, changes the phenomenon of vapor bubble accumulation in the outer wall surface of the pressure vessel, improves the heat transfer capability of the fluid, and increases the critical heat flux density of the fluid in the corresponding position of the outer wall surface of the pressure vessel, so as to facilitate the implementation of melt retention measures in a nuclear power plant and improve the security of the nuclear power plant under accident conditions. The device disclosed in the invention has a simple structure, low manufacturing cost, low introduction resistance and high system reliability.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

A kind of ultra-thin flat heat pipe and its manufacturing method

ActiveCN107167008BEasy to moveImprove mechanical propertiesIndirect heat exchangersVapor liquidHeat flux

The invention relates to an ultra-thin flat heat pipe and a manufacturing method thereof. A wick comprises a porous medium bottom layer and a plurality of porous medium filaments arranged side by side; the porous medium filaments make contact with the top of a tube shell; the wick inside the heat pipe, a sharp angled area between the porous medium filaments and the upper surface of the tube shell, and a sharp angled area between the porous medium filaments and the porous medium bottom layer provide liquid return capillary driving force which is large enough in a limited space; spaces formed between the porous medium filaments provide steam flow channels, and the steam flow channels communicate with one another; and reasonable matching of vapor-liquid phase distribution is achieved, and steam and condensed liquid can flow easily. According to the ultra-thin flat heat pipe, efficient operation can be maintained at various angles, the performance of anti-gravity operation is excellent, the heat flux which can be borne by the heat pipe is high, and the heat transfer performance of the heat pipe is remarkably improved after further modification treatment.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

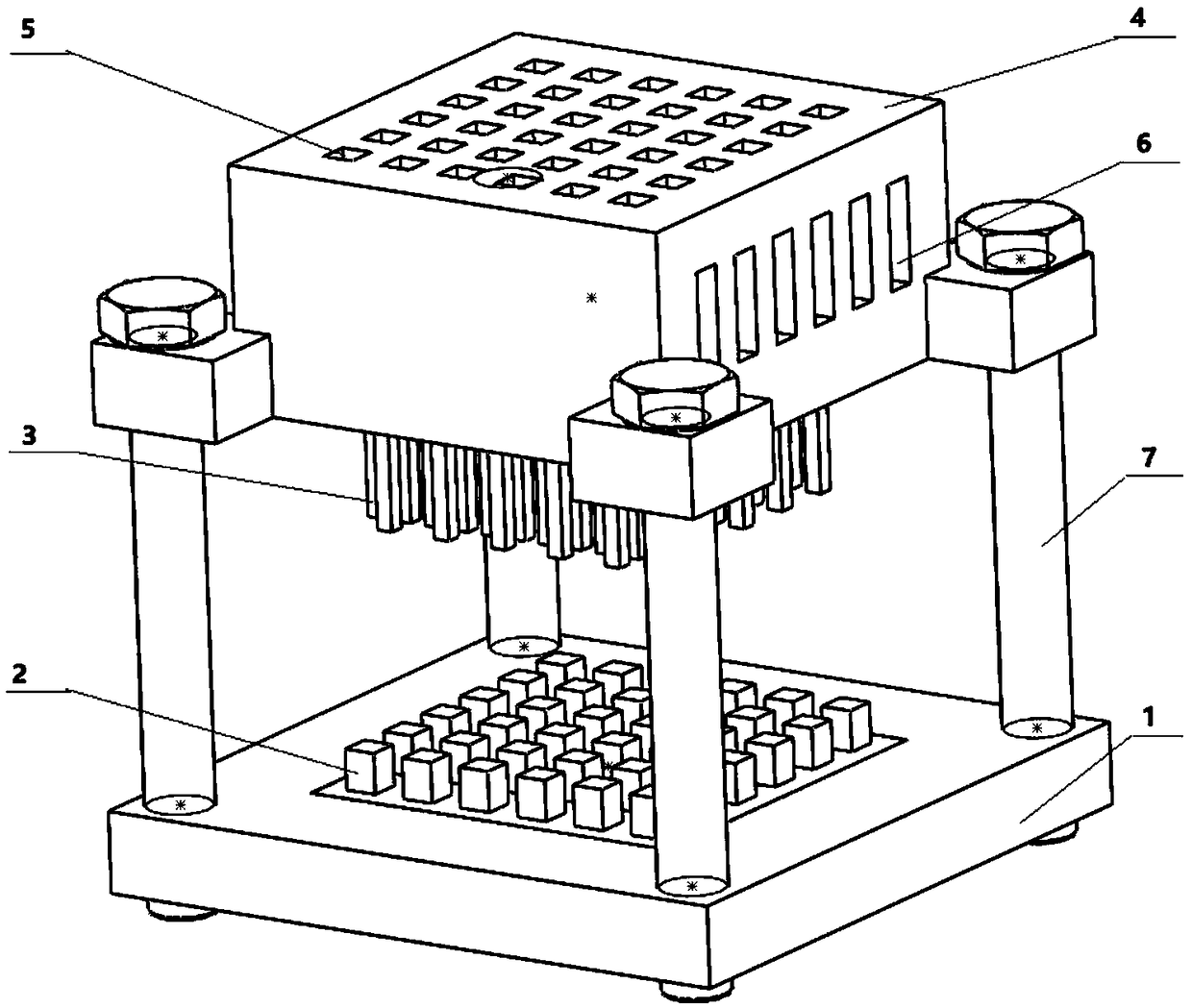

Device for strengthening rapid separation of bubbles on boiling surface and manufacturing method of device

ActiveCN108878388AIncreased efficiency and critical heat fluxIncrease critical heat fluxSemiconductor/solid-state device detailsSolid-state devicesEngineeringHydrophobic surfaces

The invention discloses a device for strengthening rapid separation of bubbles on a boiling surface and a manufacturing method of the device. The device comprises a base table, and a strengthening boiling heat exchange structure is arranged in the middle of the base table; the outer edge of the base table is connected with a condenser through a plurality of distance adjusting studs, and the condenser is located right above the strengthening boiling heat exchange structure; a plurality of run-through air channel channels are formed in the upper surface of the condenser, and a bubble auxiliary separating structure is arranged on the lower surface of the condenser; a plurality of run-through cooling working medium channels are arranged in the side surface of the condenser; and the outer surfaces of the condenser and the bubble auxiliary separation structure are hydrophobic surfaces, and the inner wall of the air channel is a hydrophilic surface. According to the invention, the separationsize of the bubbles can be reduced, the bubbles can be driven to be quickly separated, and the aggregation of the bubbles can be avoided, meanwhile, the liquid supplementing capability is enhanced, and the boiling heat transfer coefficient and the critical heat flux density can be remarkably improved.

Owner:XI AN JIAOTONG UNIV

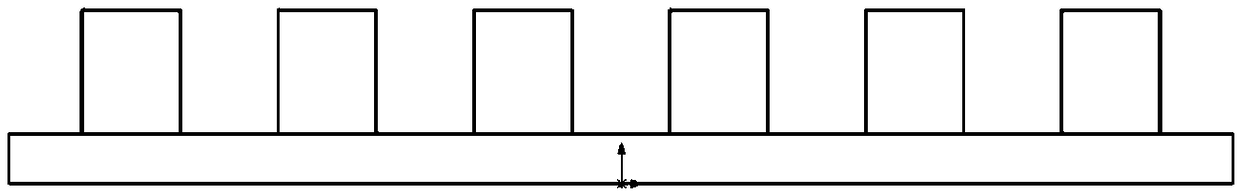

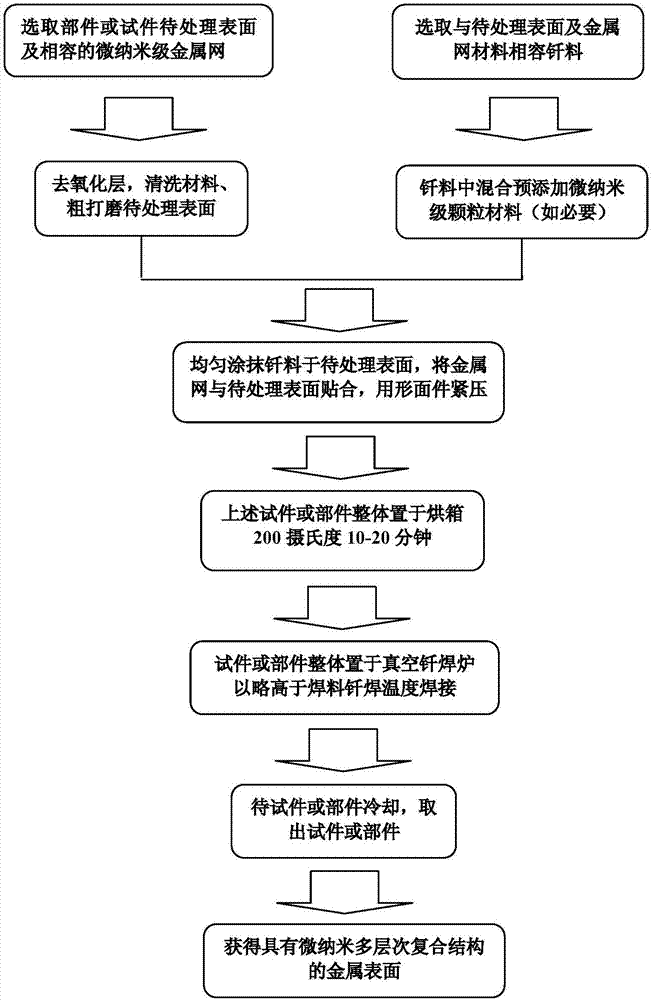

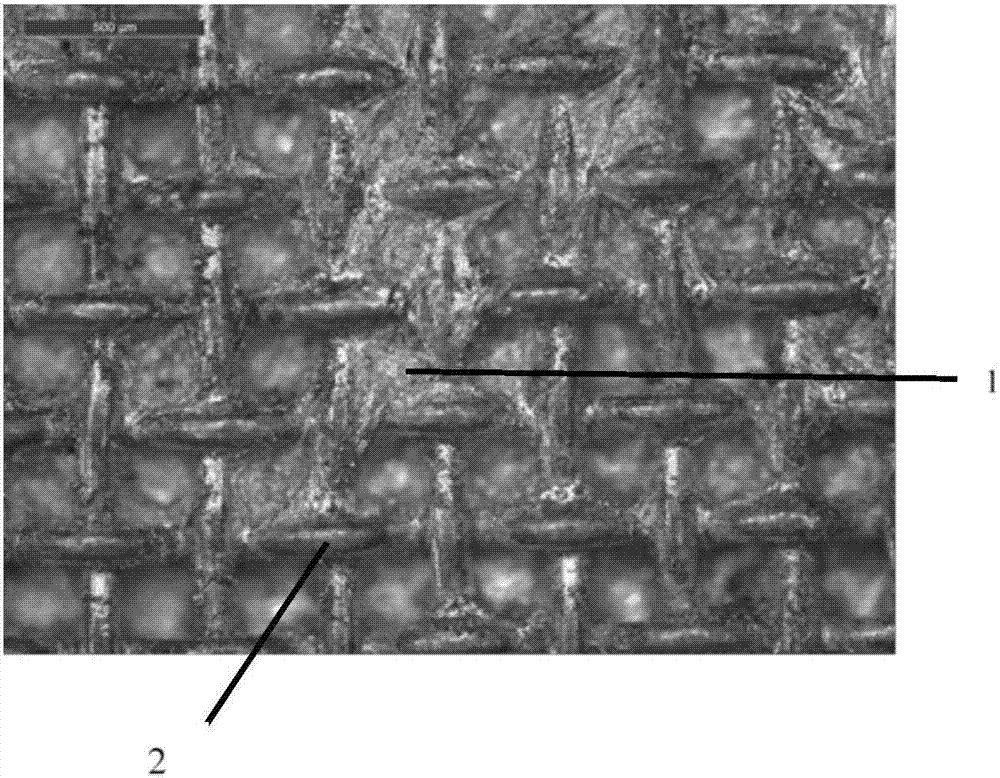

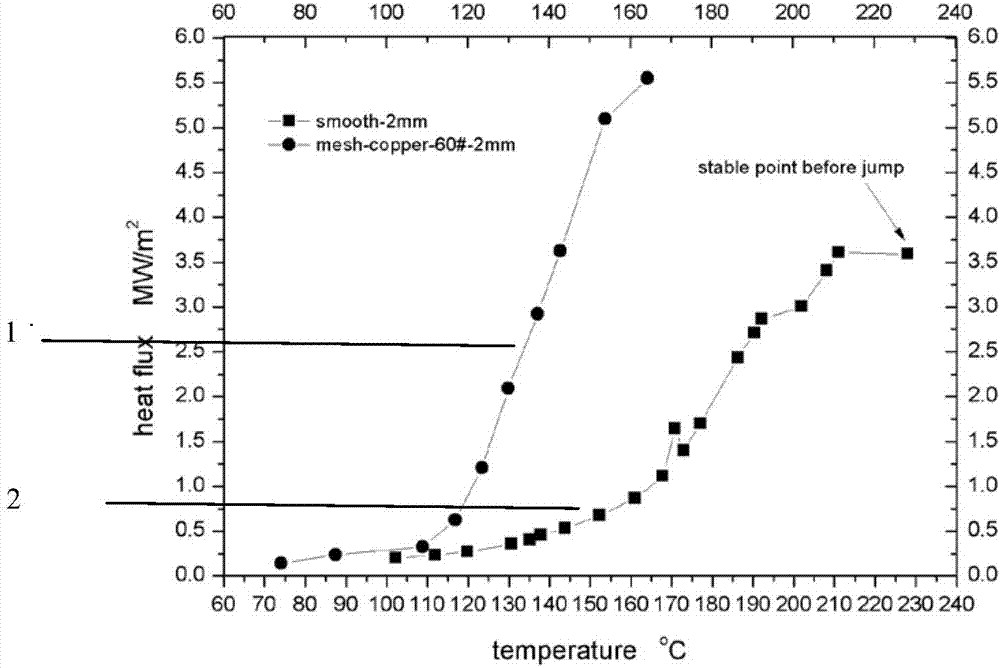

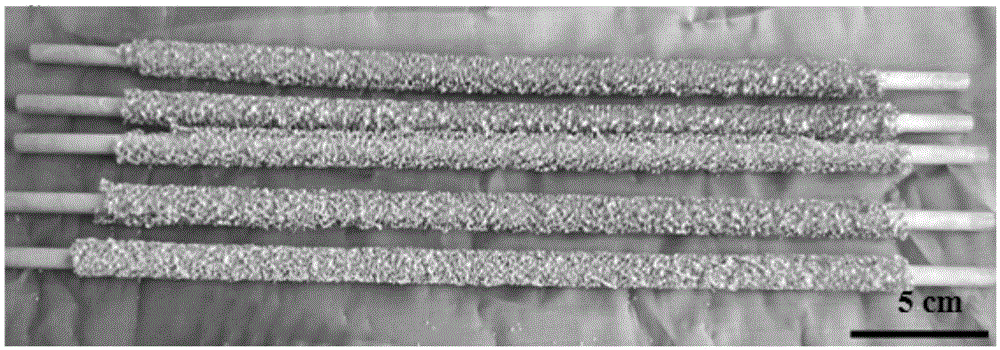

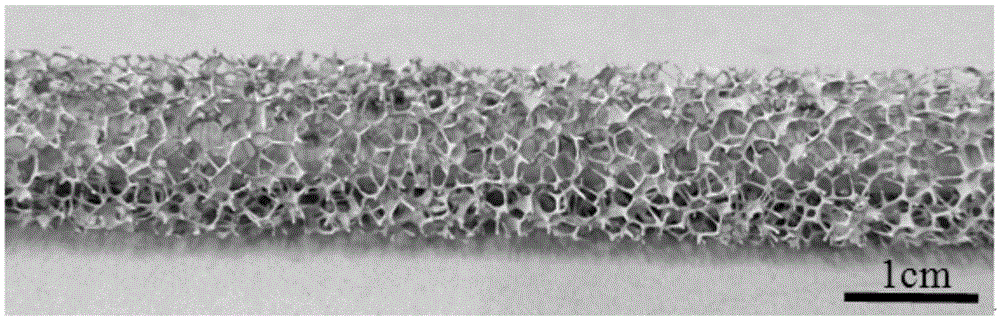

Processing technology for forming micro-nano multi-layer composite structure on metal surface

ActiveCN107252942ALow costStructural process controllableSoldering apparatusControllabilityFiller metal

The invention relates to a processing technology for forming micro-nano multi-layer composite structure on the metal surface. The processing technology is suitable for improving the supercooling boiling surface heat exchange performance and mainly applied to high heat flow parts which adopt liquid working medium supercooling boiling surface heat exchange such as fusion reactor first wall. The basic method comprises the following steps that according to practical parts or test parts, the metal surface to be disposed, corresponding micron grade pore metal nets and compatible brazing filler metal are selected, planishing is conducted on the metal surface to be disposed, oxide layer removing is conducted, and the selected brazing filler metal is painted evenly; then the metal surface is attached to the metal nets, and drying is conducted.; the metal nets and the metal surface to be disposed are pressed by profile objects, and vacuum brazing is conducted; and after finishing, a micro-nano multi-layer composite structure surface is obtained, the metal nets constitute micron grade convex-concave surface pores, and a surface after the brazing filler metal is melted and planes which is connected with metal wires present nano-grade holes and rough units. The processing technology has the characteristics that the controllability is high, the cost is low, the processing technology is simple and convenient, and the formed surface structure does not damage base materials.

Owner:UNIV OF SCI & TECH OF CHINA

A kind of preparation method of foam stainless steel composite pipe

The invention discloses a method for manufacturing a foam stainless steel composite tube. The method includes the first step of preparing a dispersant, the second step of preparing stainless steel powder slurry, the third step of evenly coating the stainless steel powder slurry on the outer surface of a stainless steel tube, carrying out heat treatment after drying and obtaining a stainless steel powder sintered porous layer, the fourth step of covering the surface of the stainless steel powder sintered porous layer with a foam formwork, evenly applying the stainless steel powder slurry to the foam formwork, carrying out heat treatment after drying and obtaining a stainless steel foam layer, namely obtaining the foam stainless steel composite tube. According to the method, raw materials are wide in source range and easy to obtain, the manufacturing process is simple, the heat conductivity coefficient of the obtained foam stainless steel composite tube is reduced by more than 10 times compared with that of a stainless steel bare tube, critical heat flux density is improved more than twice, the specific area is large, and the foam stainless steel composite tube has the advantages of being good in machining performance, little in raw material consumption, large in heat exchange specific area and stable in repetitive use performance and can serve as a key part of a radiator.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com