Micro-channel evaporator with staggered saw-tooth type rib walls

A micro-channel, sawtooth-shaped technology, applied in electric solid devices, semiconductor devices, cooling/ventilation/heating transformation, etc., can solve problems such as inability to meet equipment heat dissipation requirements, device thermal fatigue damage, device over-temperature burnout, etc., and achieve improvement. The effect of temperature uniformity along the process, increasing critical heat flux density and reducing wall superheat degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention provides a microchannel evaporator with staggered zigzag rib walls. The evaporator processes zigzag structures on both side walls of the silicon substrate and the rib walls on both sides of the microchannel, and the zigzag rib walls are staggered. . The content of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

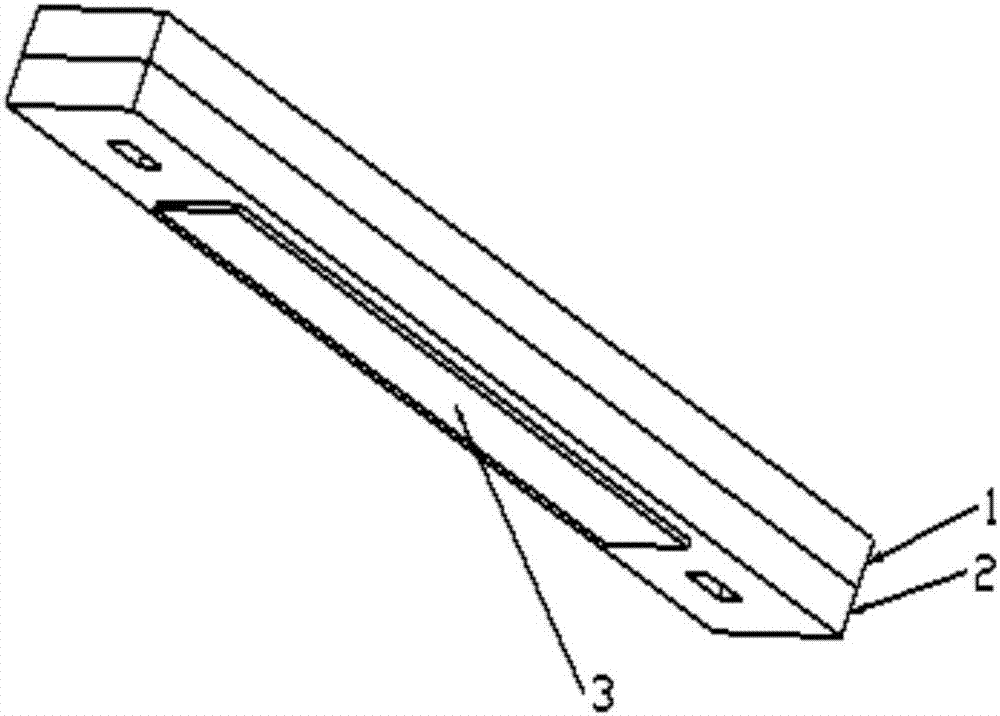

[0016] figure 1 Shown is the general assembly diagram of the microchannel evaporator with staggered zigzag rib walls, which consists of an upper cover plate 1 , a silicon microchannel plate 2 and a heating film 3 . The upper cover plate 1 and the silicon microchannel plate 2 are bonded by MEMS, and the heating film 3 is processed on the back of the silicon microchannel plate 2 by sputtering.

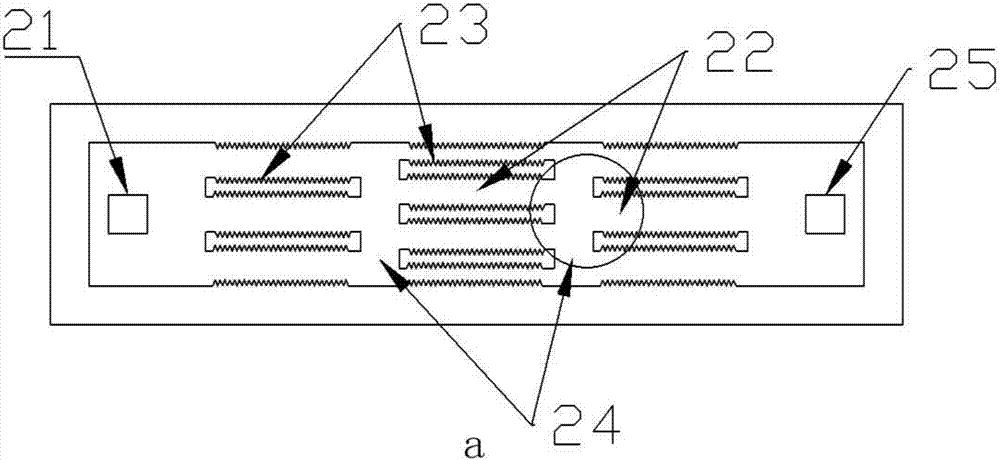

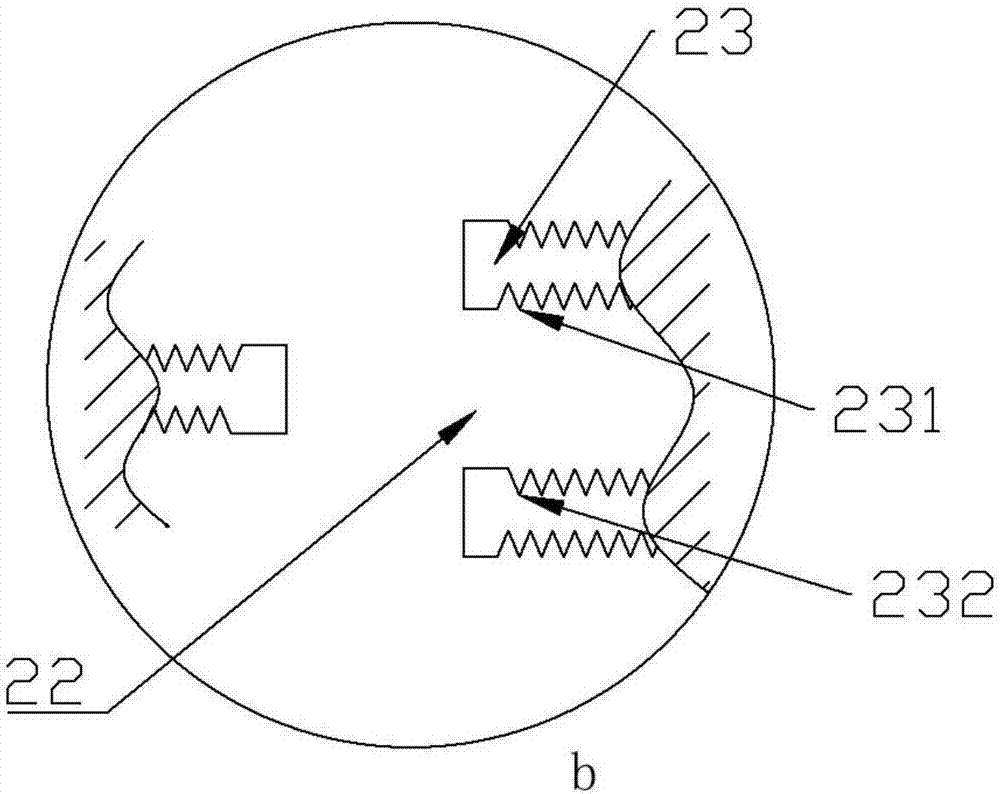

[0017] figure 2 Shown is a schematic structural view of the silicon microchannel plate, wherein a is a two-dimensional top view, and b is a partially enlarged view. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com