Reactor pressure vessel lower seal head with porous coating on outer wall surface

A porous coating and pressure vessel technology, applied in the field of reactor pressure vessel lower head, can solve problems such as threats to the integrity of the containment vessel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

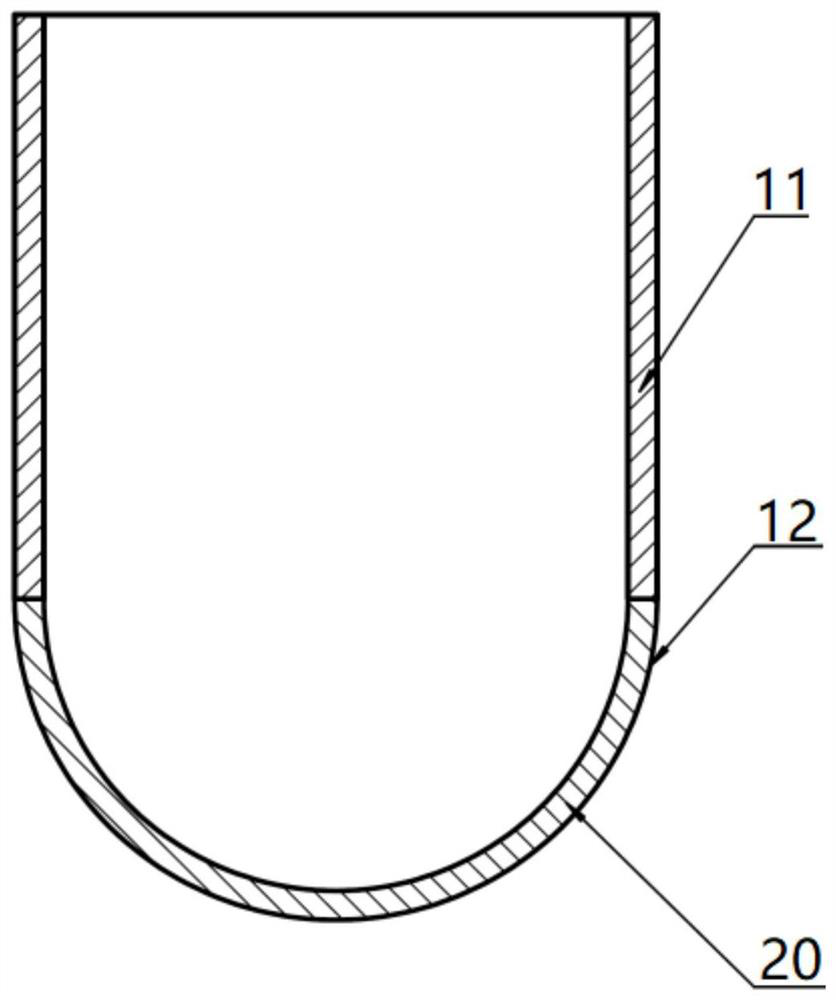

[0019] Such as figure 1 As shown, the reactor pressure vessel lower head with a porous coating on the outer wall of the present invention includes a bowl-shaped shell structure and a fixed porous coating 20 on the outer wall. The porous coating 20 is formed by spraying stainless steel powder.

[0020] In this embodiment, the bowl-shaped shell structure includes a barrel body 11 and a lower head 12 , and the lower head 12 is connected to the bottom of the barrel body 11 .

[0021] In this embodiment, the porous coating 20 is provided on all or part of the outer wall of the bowl-shaped housing structure.

[0022] In this embodiment, the porous coating 20 is formed by cold spraying or thermal spraying of stainless steel powder.

[0023] In this embodiment, the porosity of the porous coating 20 is 35-55%, and the thickness of the porous coating 20 is 200-500 microns.

[0024] The main process of the spraying process of the lower head of the reactor pressure vessel with a porous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com