Patents

Literature

119results about How to "Fast nucleation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

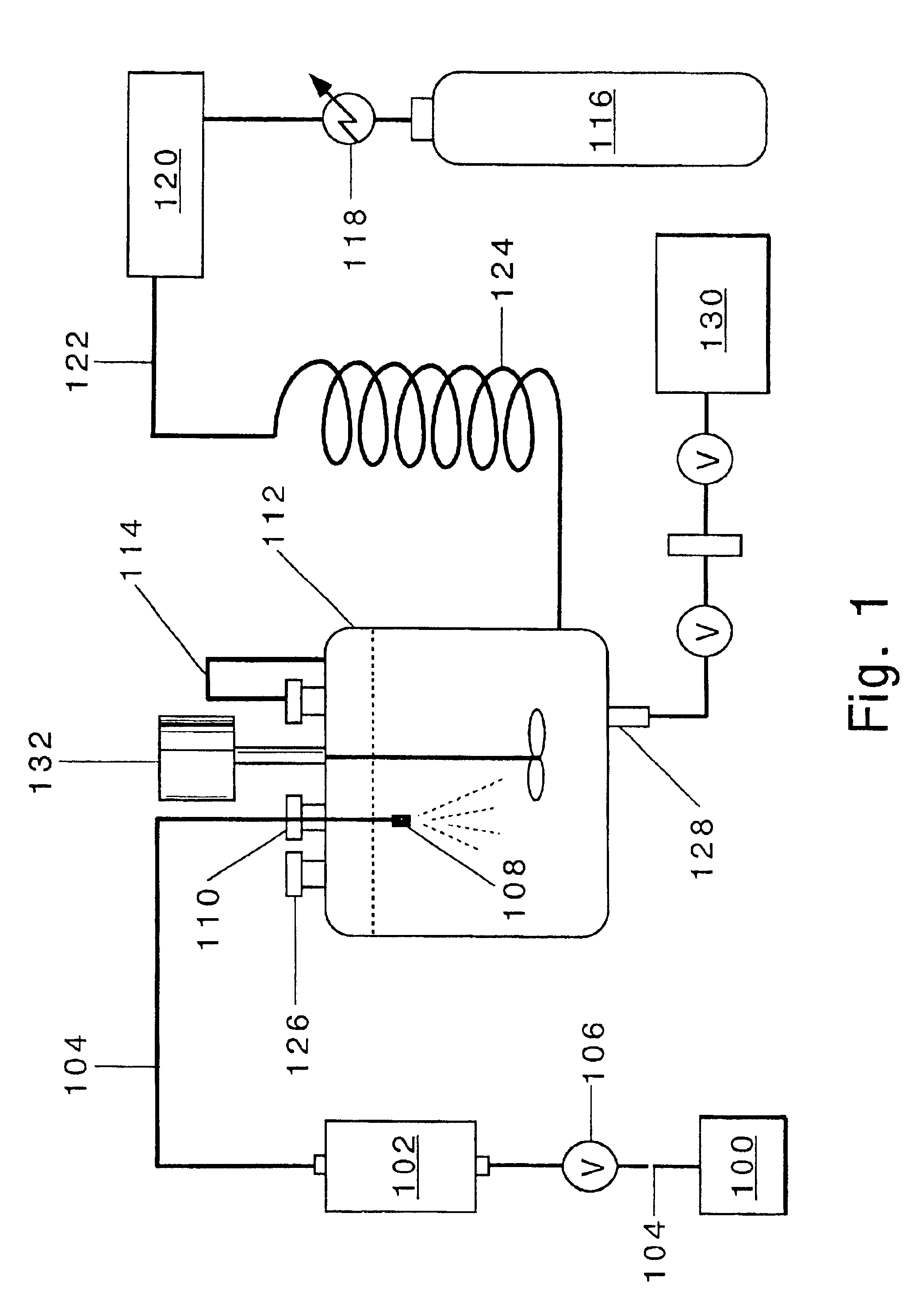

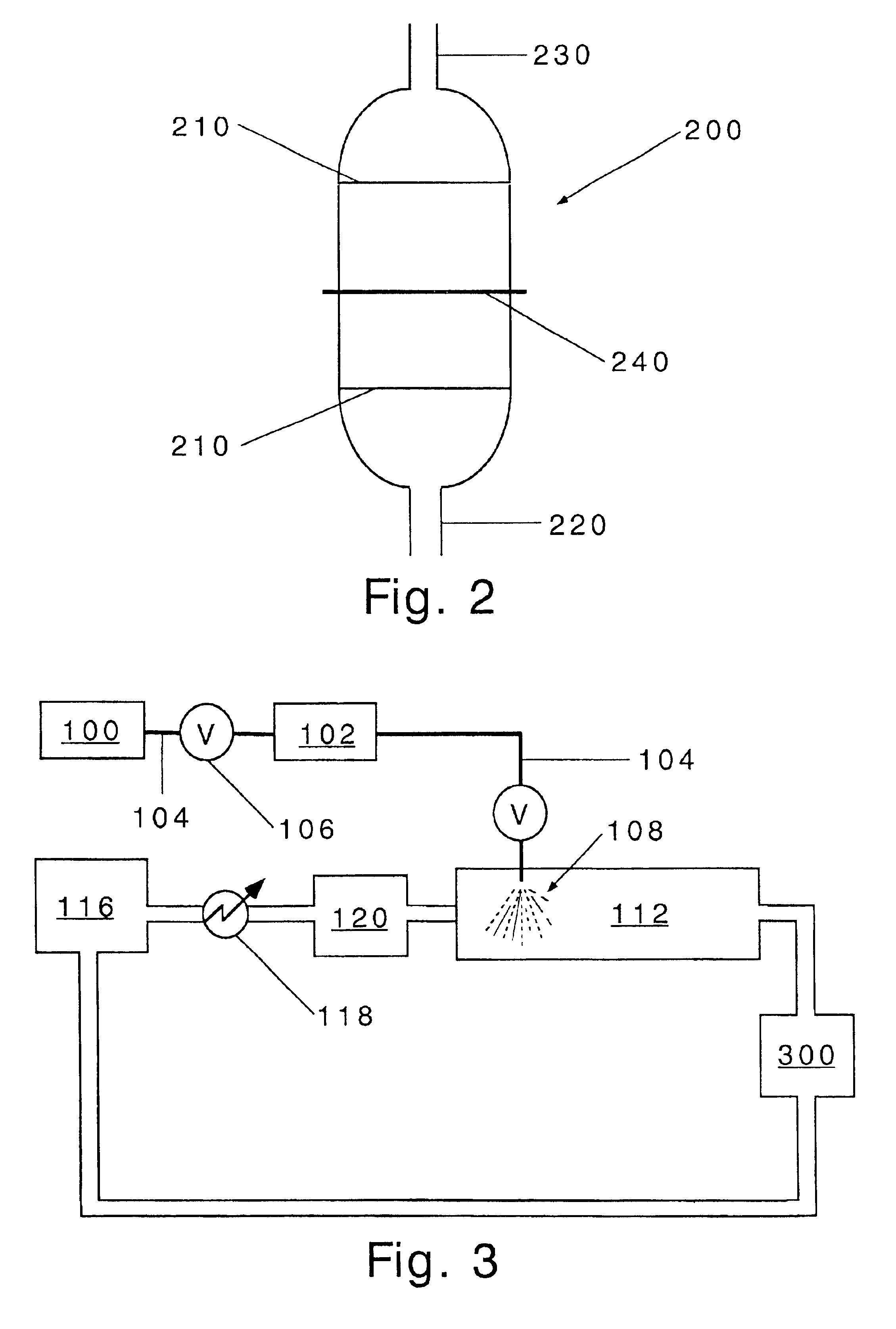

Process for production of nanoparticles and microparticles by spray freezing into liquid

InactiveUS6862890B2Improve efficiencyImprove efficacyPowder deliveryNervous disorderPorosityNanoparticle

The present invention provides a system and a method for the production of microparticles and nanoparticles of materials that can be dissolved. The system and method of the present invention provide quicker freezing times, which in turn produces a more uniform distribution of particle sizes, smaller particles, particles with increased porosity and a more intimate mixing of the particle components. The system and method of the present invention also produce particles with greater surface area than conventional methods. One form of the present invention provides a method for the preparation of particles. An effective ingredient is mixed with water, one or more solvents, or a combination thereof, and the resulting mixture is sprayed through an insulating nozzle located at or below the level of a cryogenic liquid. The spray generates frozen particles.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

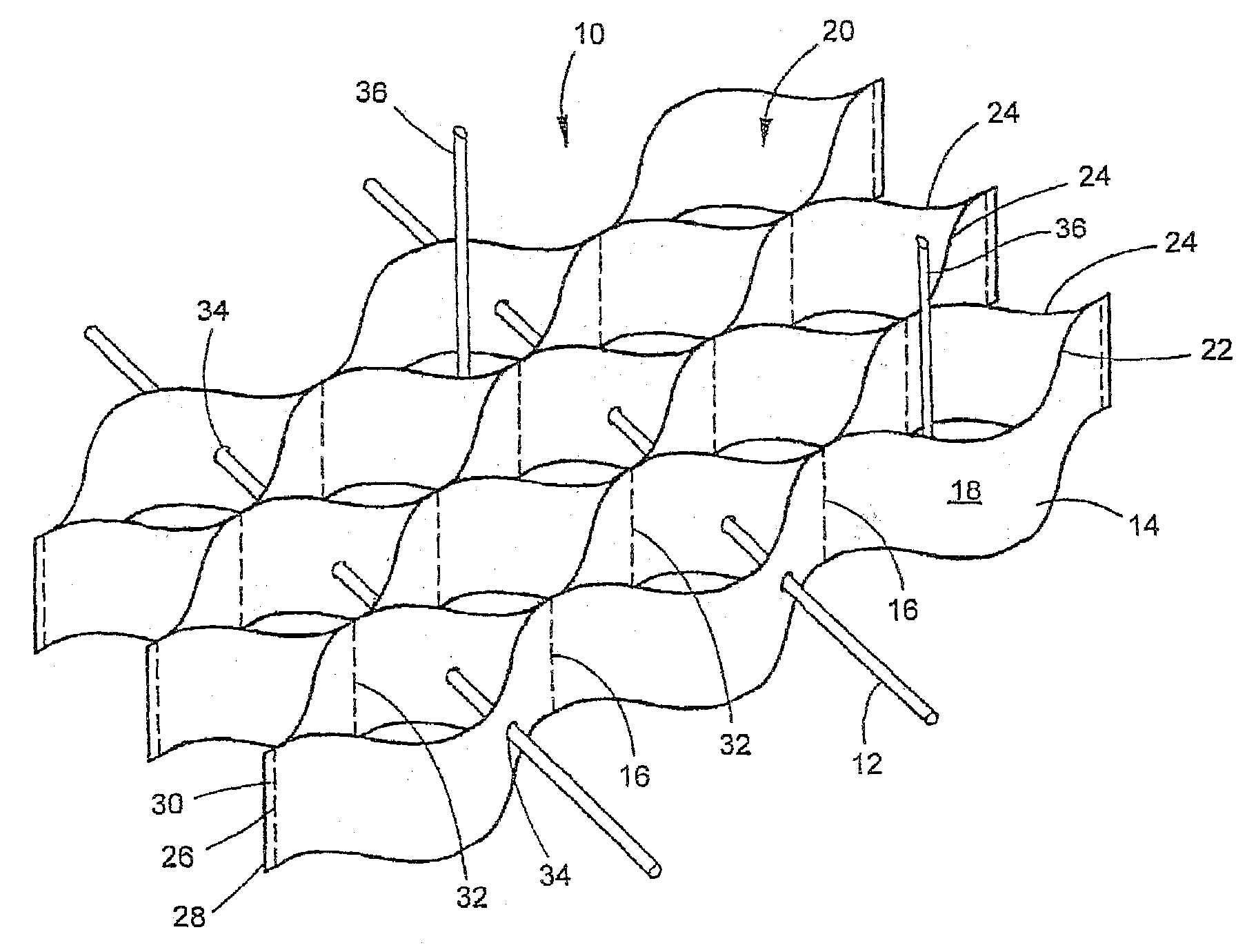

Geotechnical articles

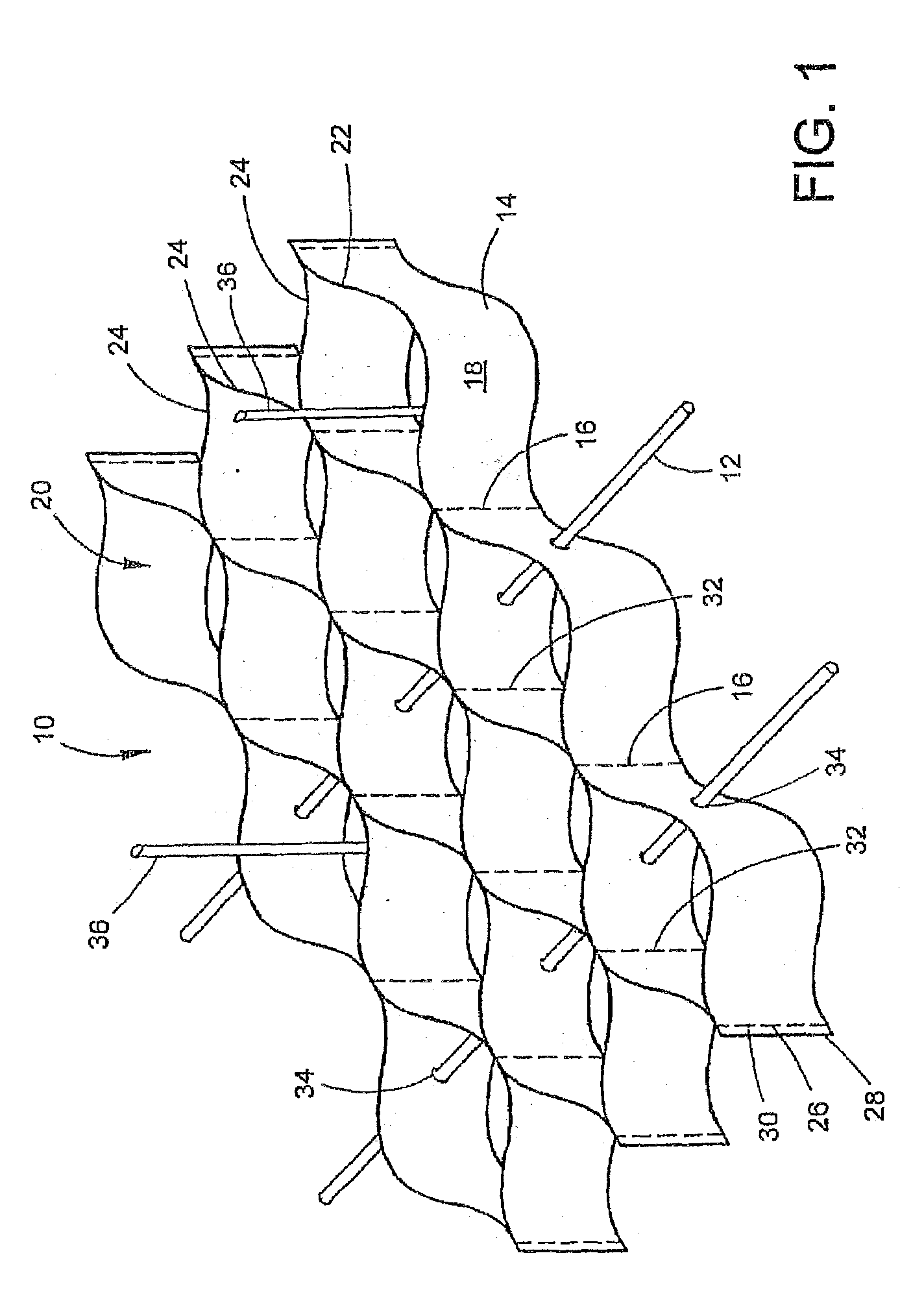

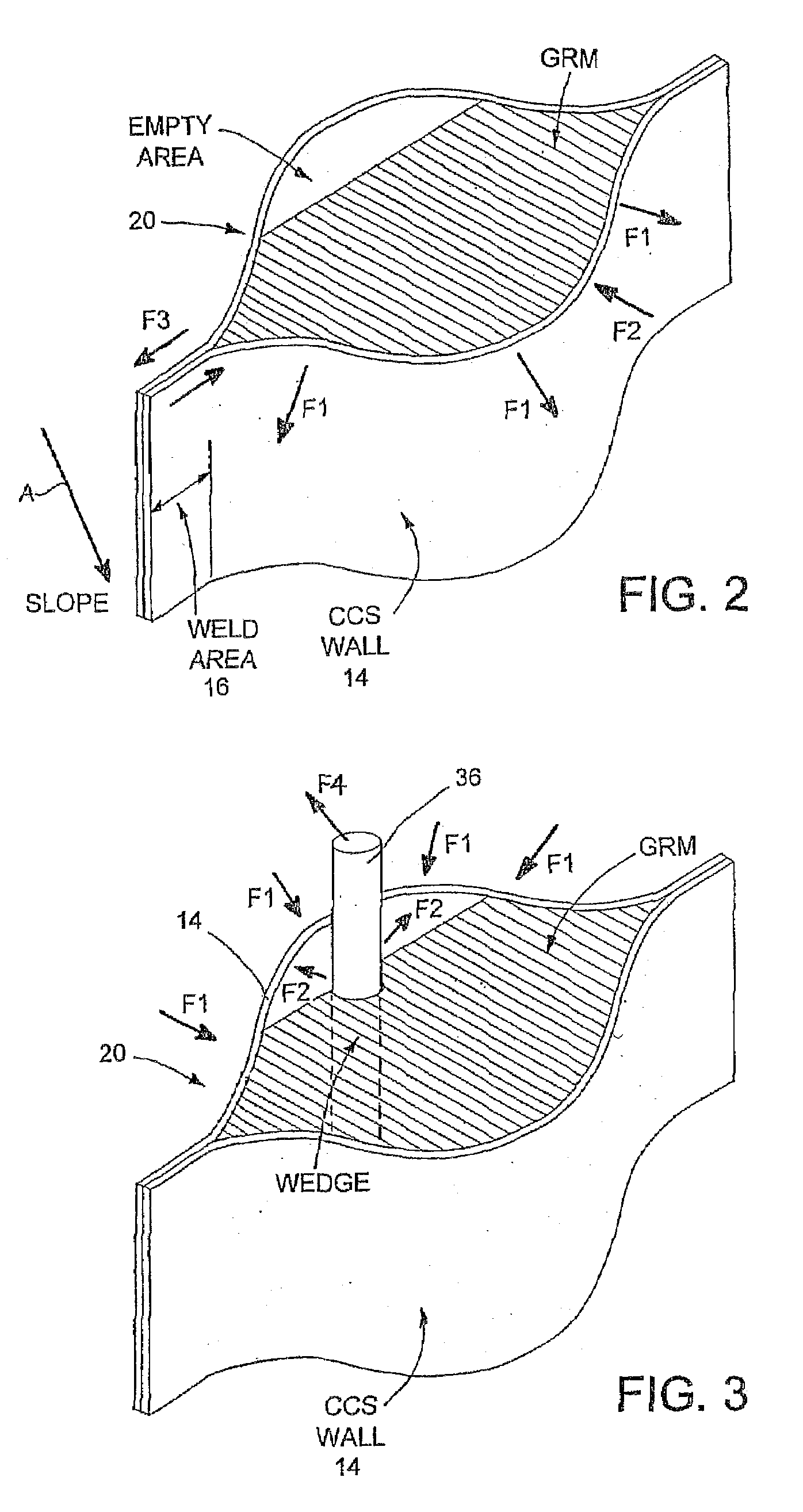

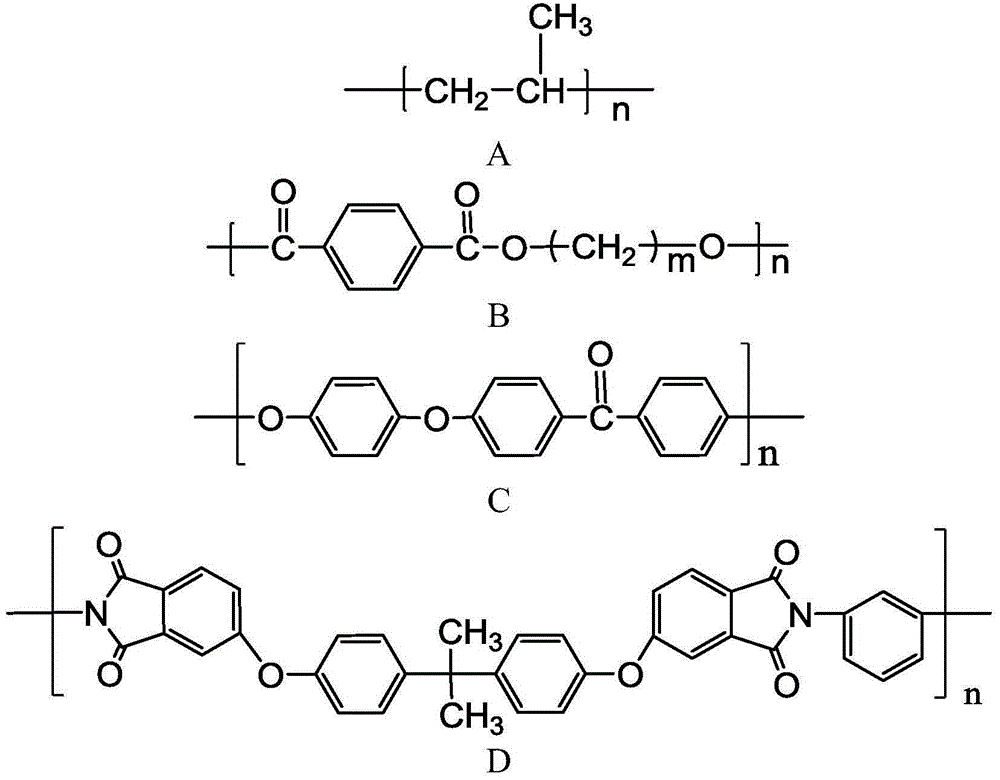

InactiveUS20080213521A1Improve creep resistanceImprove tear resistanceDomestic netsThin material handlingCold areaCellular confinement

A multiphase polymeric material comprises a first rigid continuous phase and a second elastic phase dispersed in the first phase. The multiphase polymeric material may be formed into polymeric strips and used to make a cellular confinement system which is suitable for use in cold areas.

Owner:PRS MEDITERRANEAN

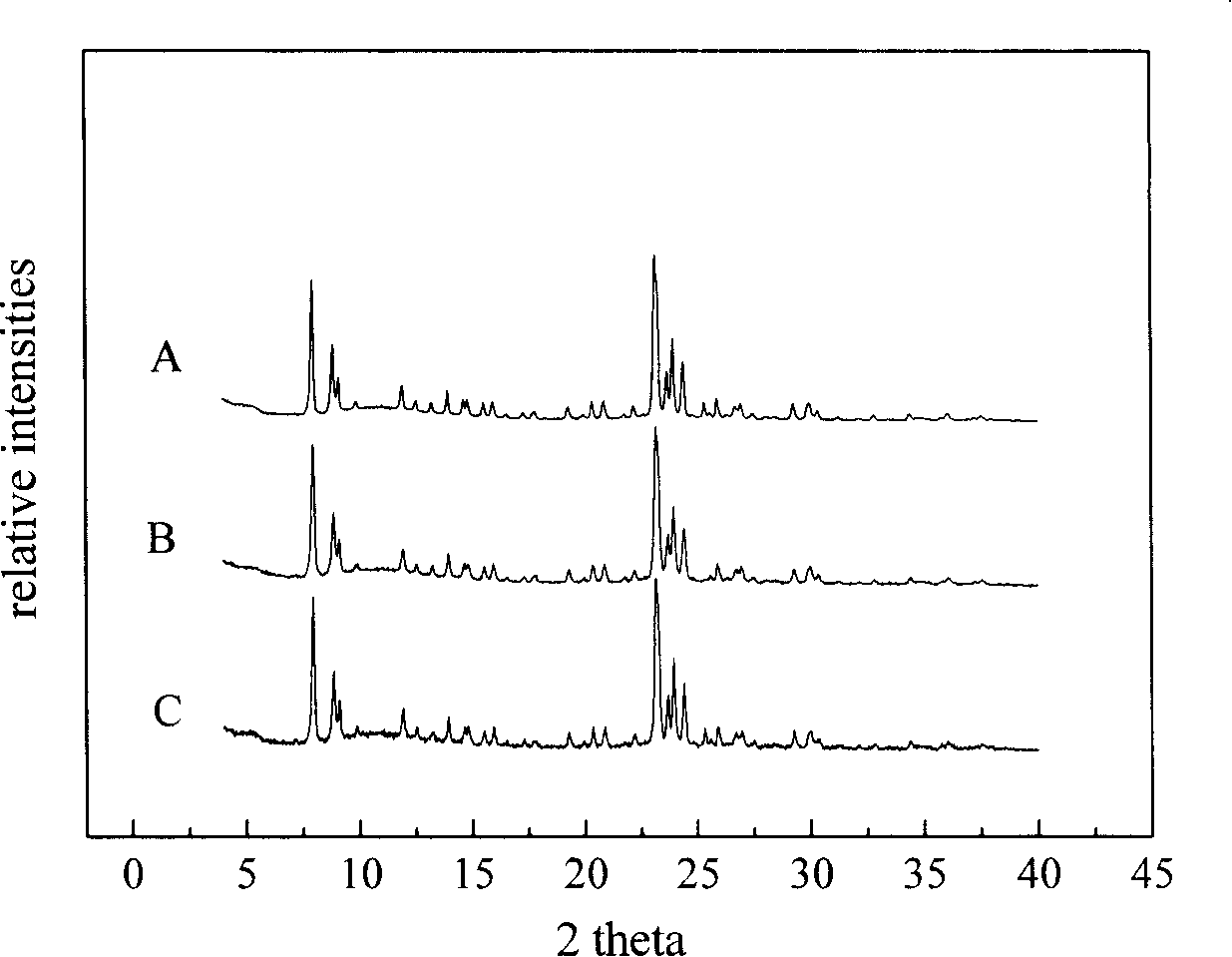

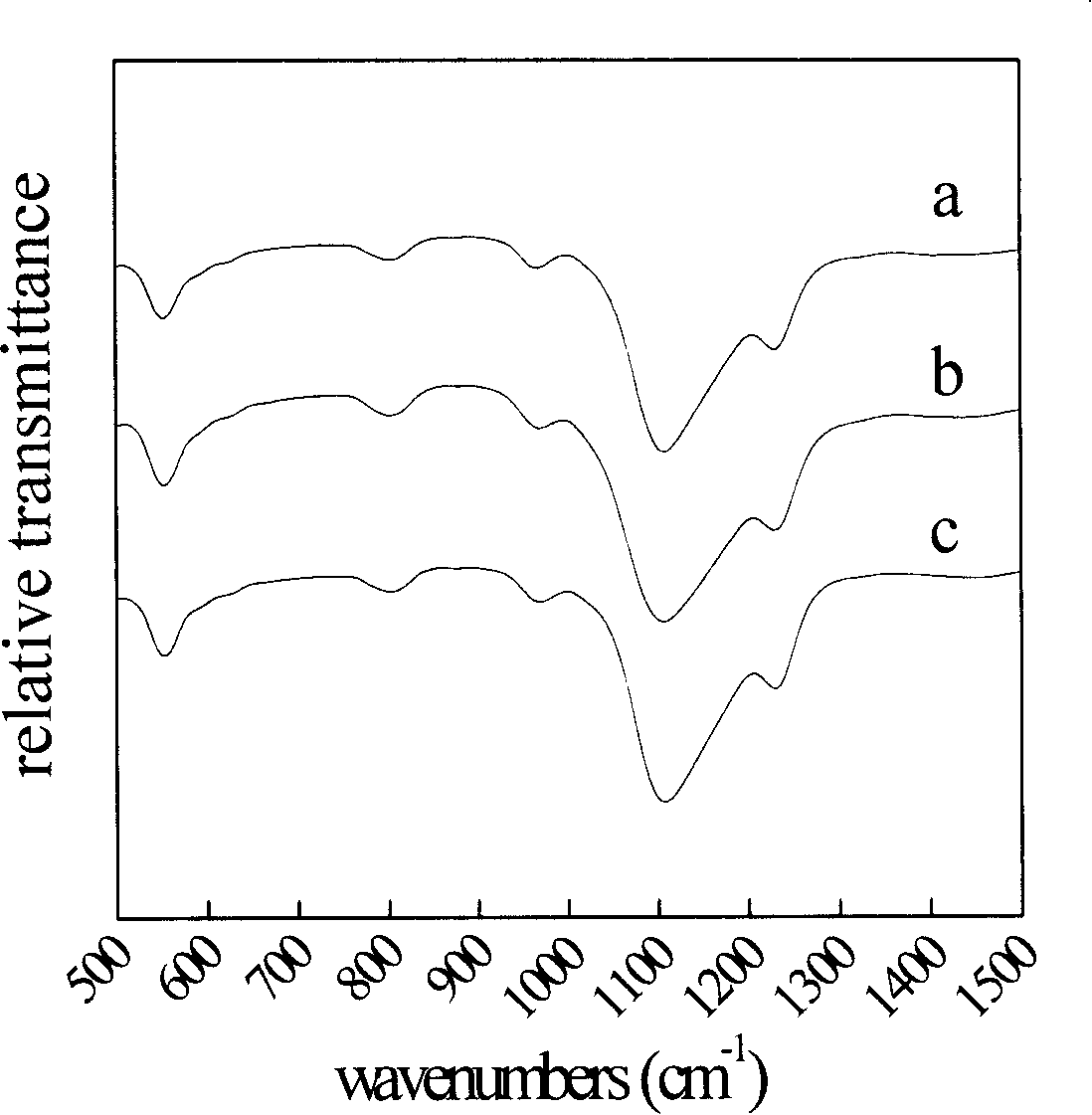

Method for synthesizing titanium-silicon molecular screen

ActiveCN101190792AReduce generationEliminate local concentration unevennessMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveCatalytic oxidation

A method of synthesizing titanium silicate molecular sieve is to hydrothermally crystallize the hydrolytic solution of silicon and titanium in a closed reaction vessel and then recycle the product. The method is characterized in that the hydrolytic solution of silicon and titanium is gotten by any one of the following three methods: A. under ultrasonic agitation, silicon source is first hydrolyzedin organo-alkali compound solution and then the titanium source is hydrolyzed in the solution; B. under the ultrasonic agitation, titanium source is first hydrolyzed in organo-alkali compound solution and then the silicon source is hydrolyzed in the solution; C. under the ultrasonic agitation, silicon source and titanium source are respectively hydrolyzed in organo-alkali compound solution and then mixed together. The synthetic method can eliminate partial uneven concentration, leads the amount of TiO2 generated by self agglomeration after the hydrolysis of titanium source to be as little as possible and reduces the production of extra framework titanium. Compared with the prior art, the TS-1 molecular sieve synthesized by the method not only has better catalytic oxidation activity and selectivity but also has better stability of catalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving bonding strength of hard alloy and diamond coating

ActiveCN104746030AAvoid the problem of interfacial stressHigh bonding strengthVacuum evaporation coatingSputtering coatingShielding gasGlow plasma

The invention relates to a method for improving the bonding strength of a hard alloy and a diamond coating. The method is realized by the technical scheme that by adopting a double glow plasma surface alloying technology, taking a metal carbide forming element material or a composite material of metal carbide forming elements as a target, inert gases as protecting gases, as well as carbon-containing gases as precursors, a diffusion barrier layer is prepared on the surface layer of the hard alloy, and then the diamond coating is deposited on the hard alloy surface on which the diffusion barrier layer is prepared by using a chemical vapor deposition method. By the use of the diffusion barrier layer prepared by the method disclosed by the invention, the diffusion of Co element to the surface layer of the hard alloy can be effectively stopped, the damage to a hard alloy matrix due to a surface Co removing treatment method is avoided, and the interface stress problem introduced by a transition layer applying method due to new interface addition can be avoided, so that the bonding strength between the diamond coating and the hard alloy matrix can be greatly improved.

Owner:TAIYUAN UNIV OF TECH

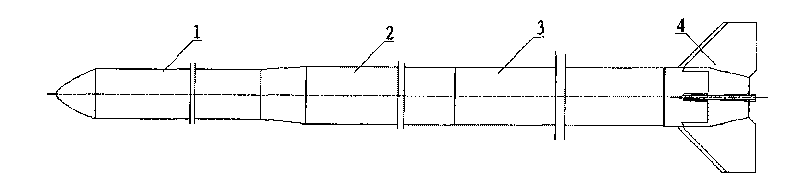

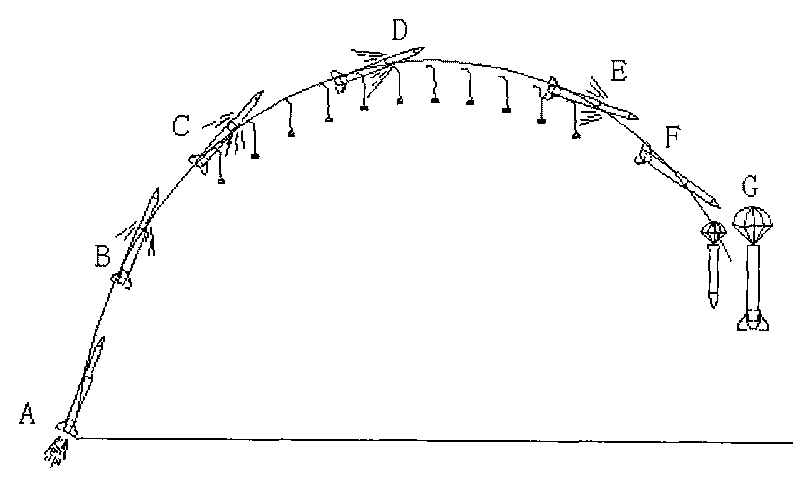

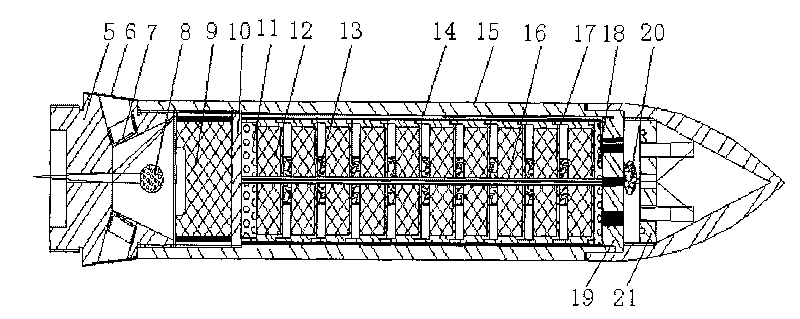

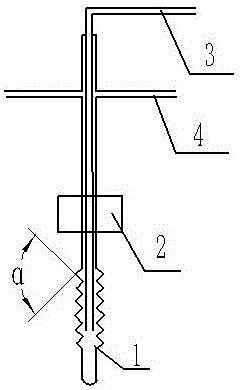

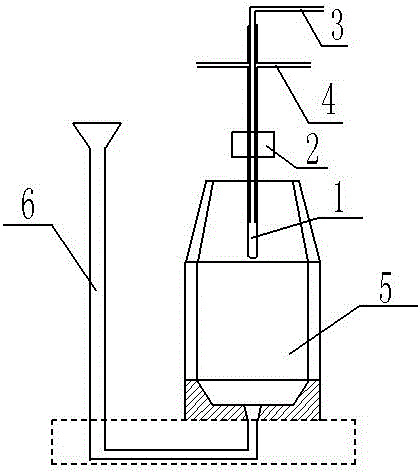

Multielement seeding combustion explosion type rainfall-increasing and anti-hail rocket

InactiveCN101726219ANo pollution in the processLarge coverage areaWeather influencing devicesSelf-propelled projectilesCombustionEngineering

The invention relates to a multielement seeding combustion explosion type rainfall-increasing and anti-hail rocket. In the rocket, one end of a safety system (2) is connected with a flame bullet seeding catalyst system (1), the other end is connected with the front end of a solid motor (3); the back end of the motor (3) sticks to an empennage; four catalyst seeding holes are evenly distributed in the middle part of a nozzle (5), a plurality of flame bullets (12) are sleeved together to be arranged in a shell (15), safety fuses (16) are arranged in the centre bores of the flame bullets (12), a propelling medicine (13) is filled to one end of each flame bullet (12); a cladding medicine block(9) is filled in the threaded connection section capsule of the shell (15), an ignition medicine package (8) is arranged in the counter bore of the cladding medicine block(9), and the ignition wire of the ignition medicine package passes through the centre bore of the nozzle (5). The invention adopts the flame bullet burning mode that catalyst is burnt and seeded continuously and a plurality of flame bullets are thrown along the parent trajectory, for seeding the catalyst, thus requiring that the flame bullets are thrown reliably and the burning is stable. The flame bullets of the invention adopt casting moulding for structure design, the technology is easy and stable, and the flame bullets are easy for the batch production.

Owner:SHAANXI ZHONGTIAN ROCKET TECH CO LTD

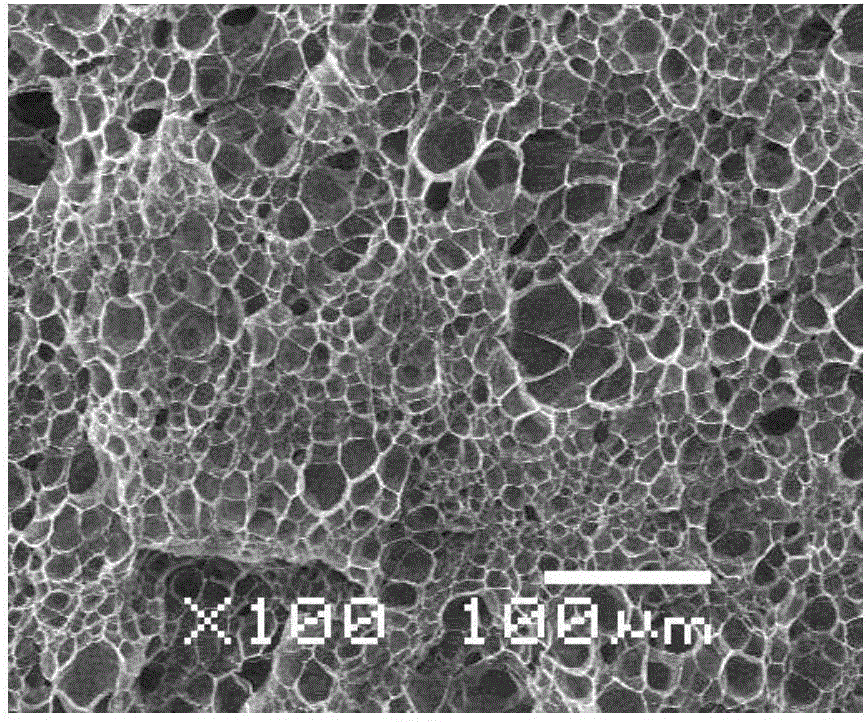

Preparation method of polymer micro-foaming film

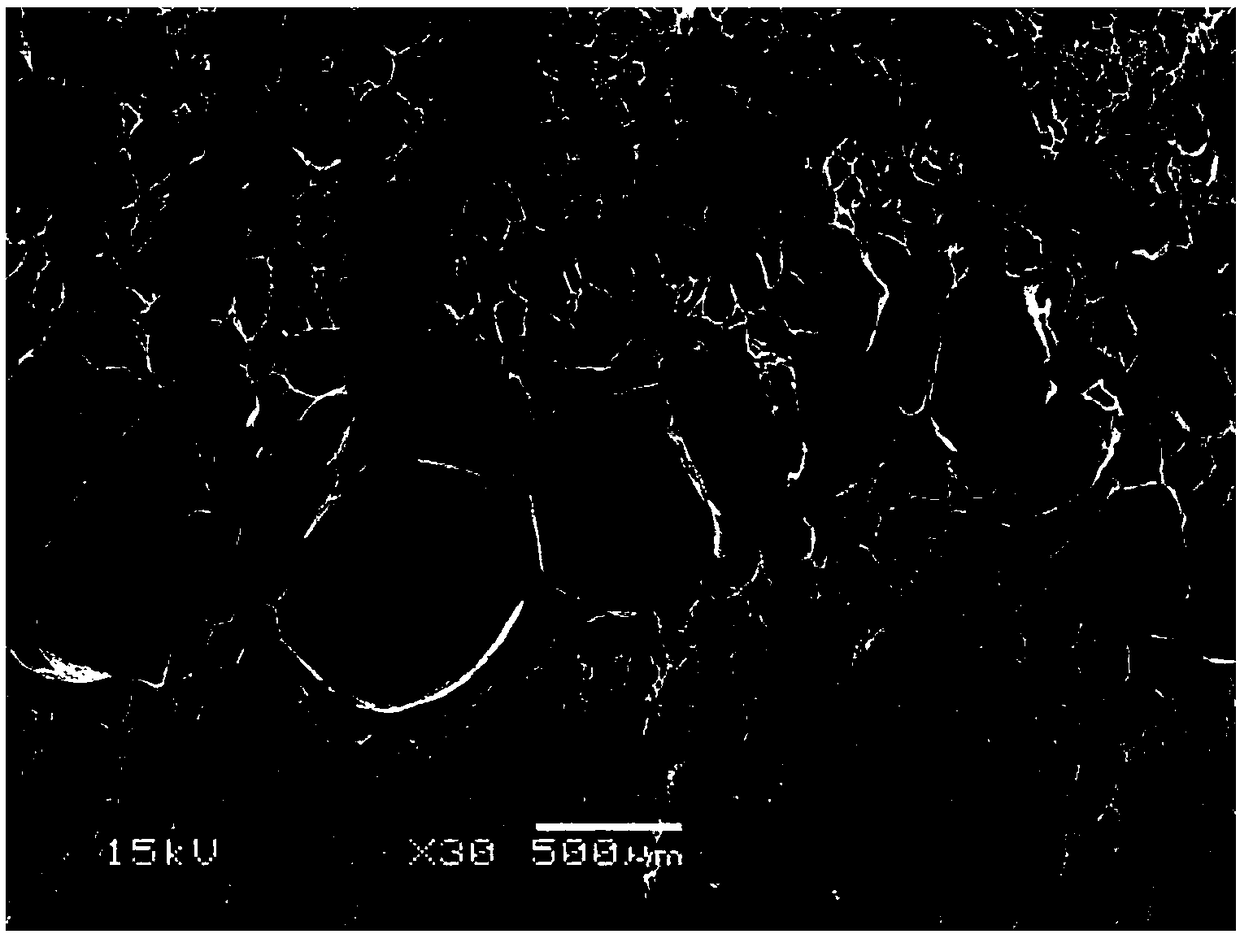

ActiveCN104987523ASimple processImprove efficiencySynthetic resin layered productsLaminationPolyesterPolymer science

The invention discloses a preparation method of a polymer micro-foaming film. The preparation method comprises the following steps of: (1) uniformly rolling a polymer film of which the thickness is 200-500 mu m and an interval material into a coiled material; (2) putting the coiled material in a supercritical fluid reaction kettle, controlling the coiled material to be at a higher temperature and a higher pressure, so that the supercritical fluid is permeated and swelled in a polyester coiled material so as to achieve the state of saturation; (3) after achieving the state of saturation, using an ultrasonic technology in an assisting manner, enabling kernels to be uniformly formed in the inner part of a polymer film, releasing the supercritical fluid in the reaction kettle, and taking out the coiled material in which the kernels are formed; and (4) putting the coiled material in a heat source, enabling internal gas nucleus to grow, and foaming pores to form so as to prepare micro-foaming film of which the pore diameters are uniform and the foaming pores are close. The preparation method disclosed by the invention is simple in technology, is clean and pollution-free, and is higher in efficiency; the thickness of the prepared polymer micro-foaming film is between 300-1000 mu m, the density of products is between 0.25-0.65g / cm<3>, the pore diameters are between 5-20 mu m, and the density of the pores is 1010-1012cells / cm<3>; reflection of visible light can reach more than 98%.

Owner:青岛中诚高分子科技有限公司

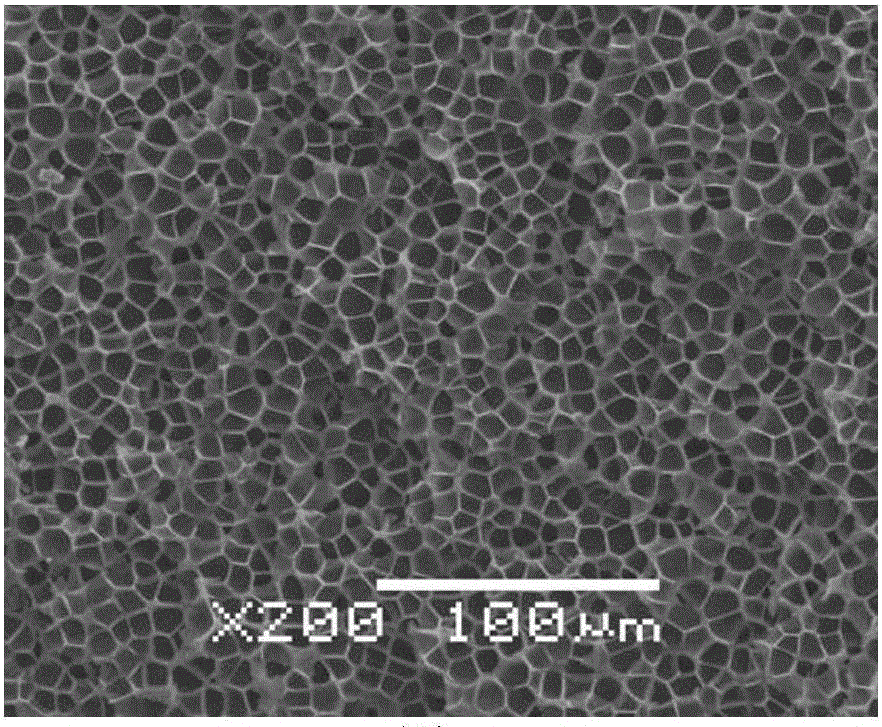

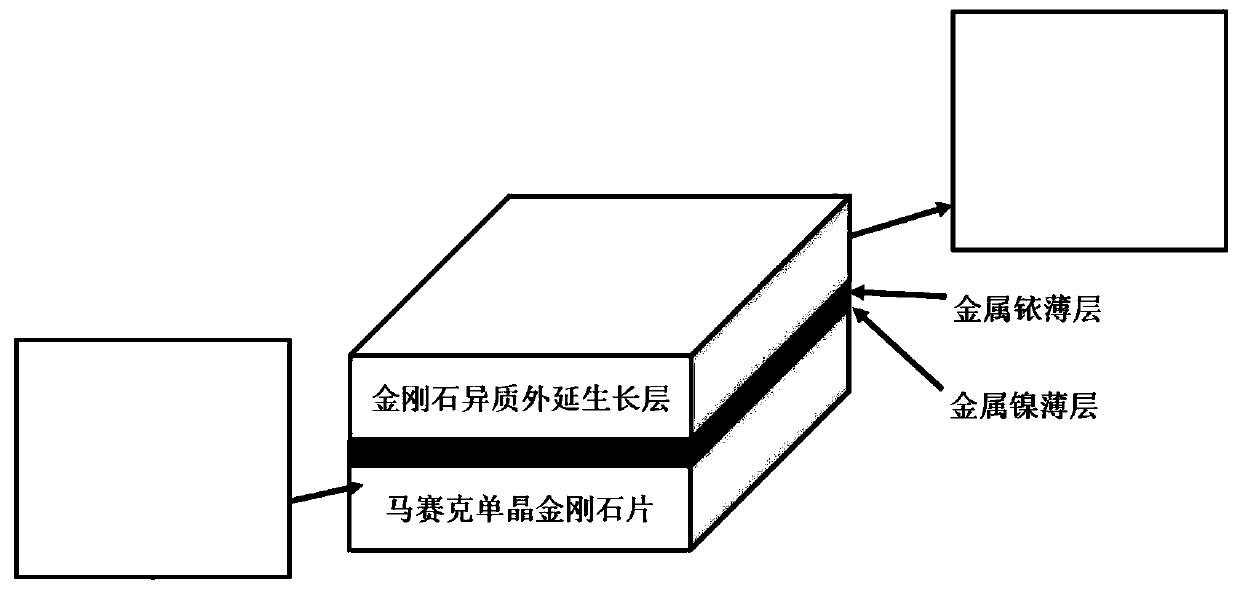

Method for epitaxial growth of high-quality and large-size monocrystalline diamond

ActiveCN111206280AImprove thermal conductivityLight in massPolycrystalline material growthFrom chemically reactive gasesIridiumCarbon layer

The invention discloses a method for epitaxial growth of high-quality and large-size monocrystal diamond, and belongs to the field of preparation of semiconductor materials. The method is characterized in that the surface roughness of a large-size single crystal diamond sheet grown through mosaic splicing is reduced to be lower than 0.2 nm through precision polishing; then electron beam evaporation is adopted to deposit metal nickel with the thickness of 100-200 nm on the surface of a substrate at the speed of 0.01-0.1 nm / s while the substrate is heated at the temperature of 100-500 DEG C, andthen metal iridium is deposited at the speed of 0.01-0.5 nm / s; after the thickness of iridium reaches 15-40 nm, the temperature of the heated substrate is increased to 700-1000 DEG C, meanwhile, thedeposition speed is increased to 0.5-1 nm / s, and finally, an iridium thin layer with the total thickness of 150-300 nm is deposited; then a plasma chemical vapor deposition technology is adopted to pre-deposit a 4-10 nm amorphous carbon layer after the iridium surface is cleaned by hydrogen plasma so as to promote the enrichment of carbon atoms on the sub-surface of the iridium thin layer; and finally, after the substrate is subjected to pure hydrogen plasma etching for 6-15 s, the negative bias voltage and the methane flux are regulated to achieve bias voltage in-situ nucleation of the large-size single crystal diamond on the iridium surface and subsequent non-bias voltage epitaxial growth.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of continuous controllable monodispersed silica microspheres

InactiveCN104003408AImprove heat transfer performanceEnhanced mass transferMaterial nanotechnologySilicaMicrosphereNucleation

The invention discloses a preparation method of continuous controllable monodispersed silica microspheres, and the process includes the steps of nucleation, growth and separation. The process can achieve batching preparation of the monodispersed silica microspheres with high degree of sphericity and narrow particle size distribution; according to the method, in the nucleation step of silica microsphere seeds, a reaction system is a boiling system, heat transfer and mass transfer are good in a strong convective state, the silica microsphere seeds can homogeneously and rapidly nucleate, the agglomeration problem in the prior art can be solved, the reaction time is shortened, and monodispersed microsphere seeds with narrower particle size distribution can be obtained. The monodispersed silica microspheres with high degree of sphericity and controllable particle size distribution can be obtained by one step growth or multi step growth to separate the steps of nucleation and growth, the particle size distribution deviation is less than 2%, and the performance is better. According to the actual need, monodispersed silica microspheres with various particle sizes from 20 to 10000nm can be obtained, and various problems of the prior art can be overcome.

Owner:NANJING DONGJIAN BIOLOGICAL TECH

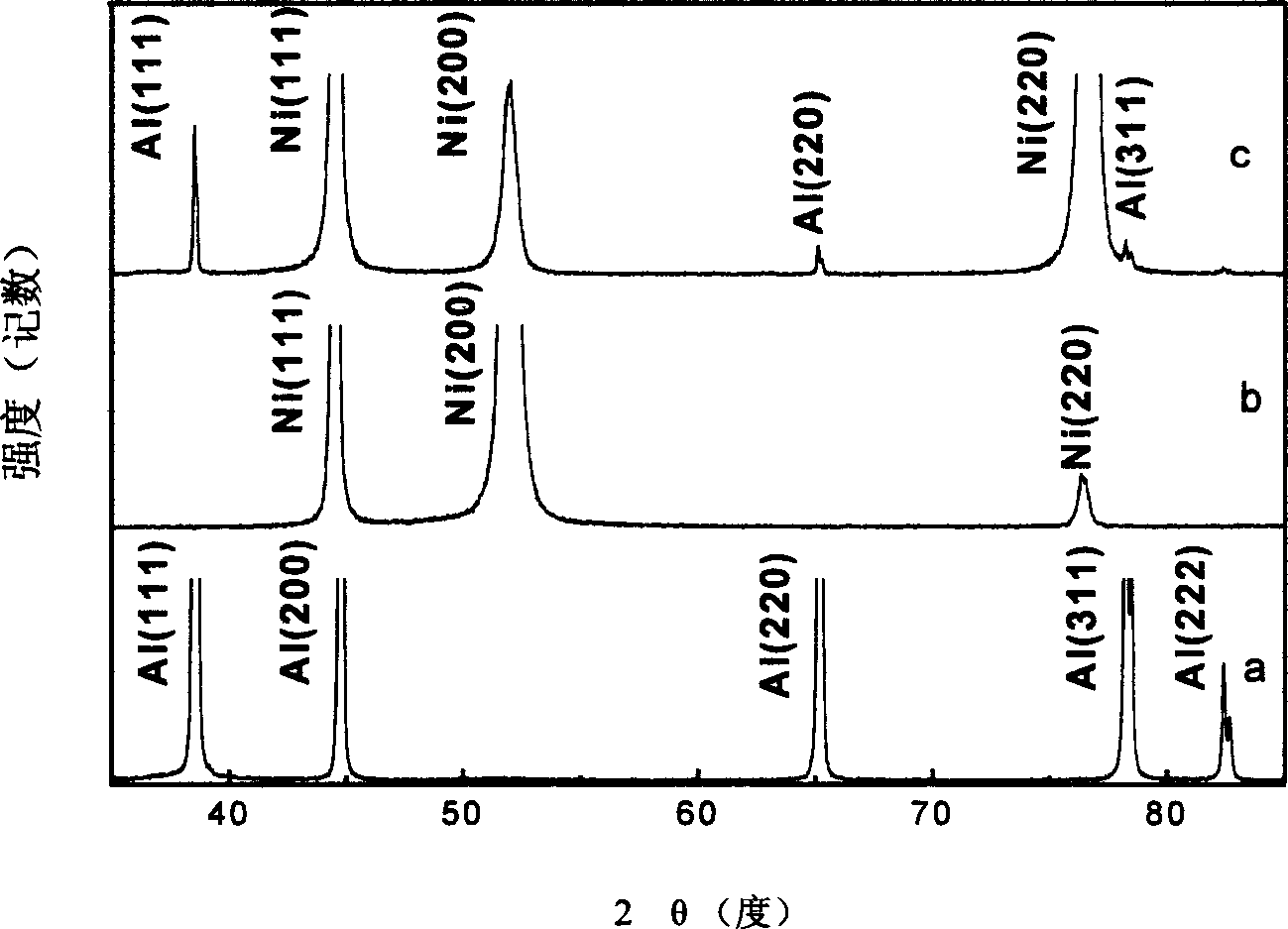

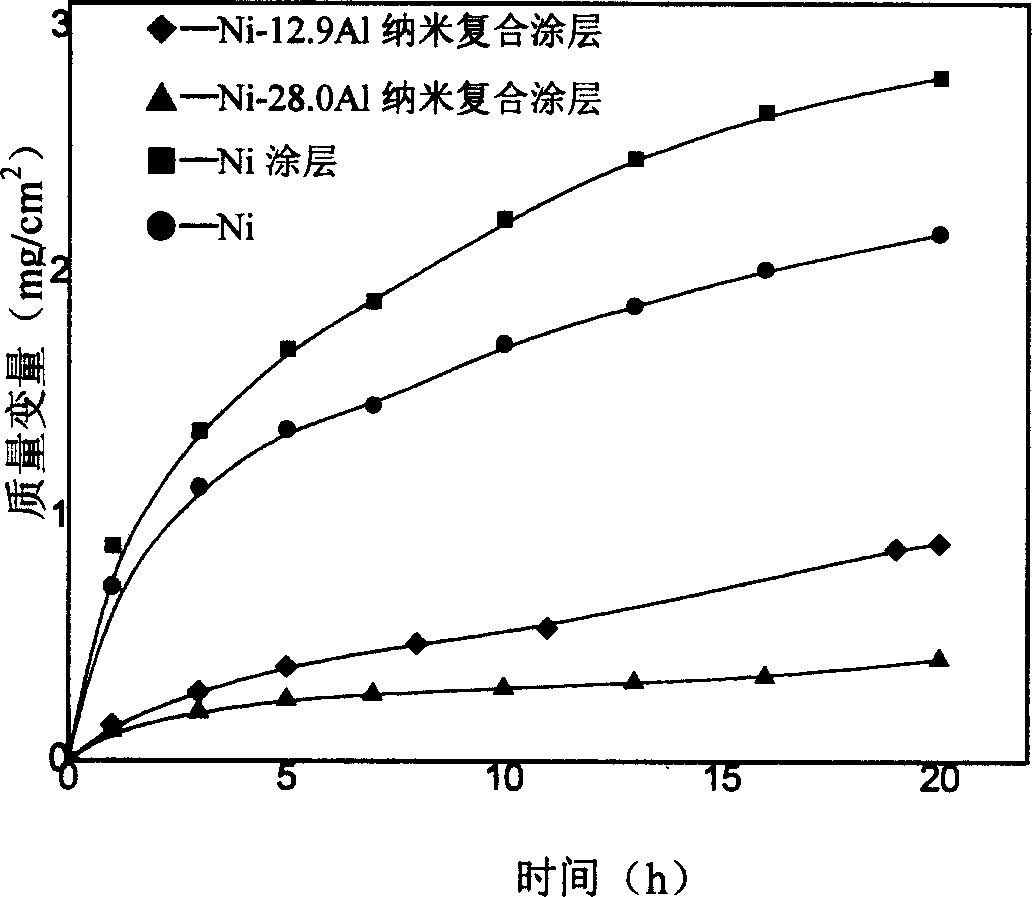

Thermal growth AL2O3 film type M A1 nano composite plating and producing process and application

InactiveCN1576398AIncrease the number of nucleiDiffusion fastElectrolytic coatingsGrown filmNanoparticle

The thermally grown Al2O3 film type M-Al nano composite coating consists of nano crystal M coating and nano metal Al grains dispersed in the coating, where M is Ni, Fe or Co. The Al content is 9.8-35 wt%, and M is the rest. The nano composite Ni-Al, Fe-Al or Co-Al coating is prepared through composite electroplating process to deposit metal M and Al coating on to the base material of Ni, Fe or Co, carbon steel or alloy steel. The present invention has the features of simple technological process, low cost, high and controllable compounded amount, compact coating, no need of vacuum diffusion treatment of the nano composite coating, direct thermally growth of protecting Al2O3 film, etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

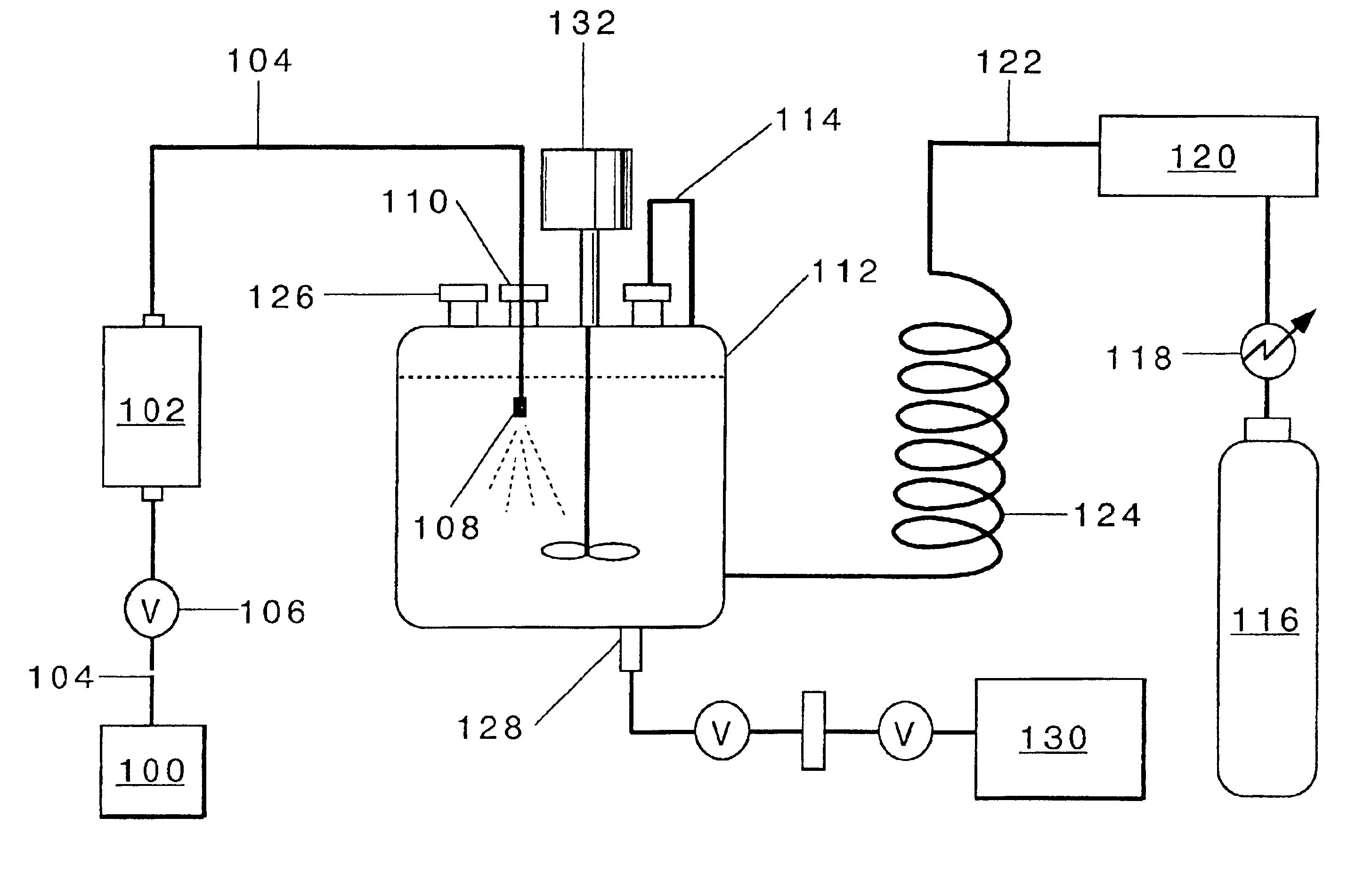

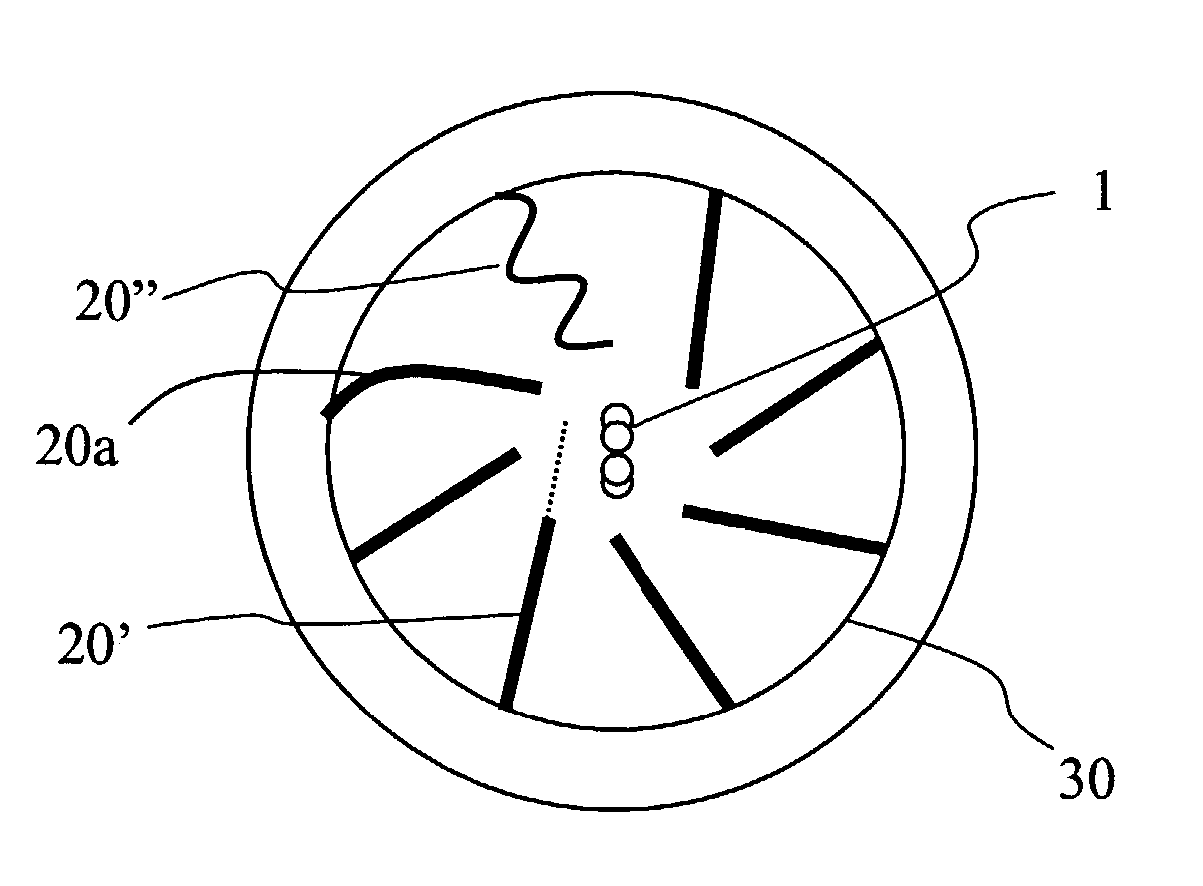

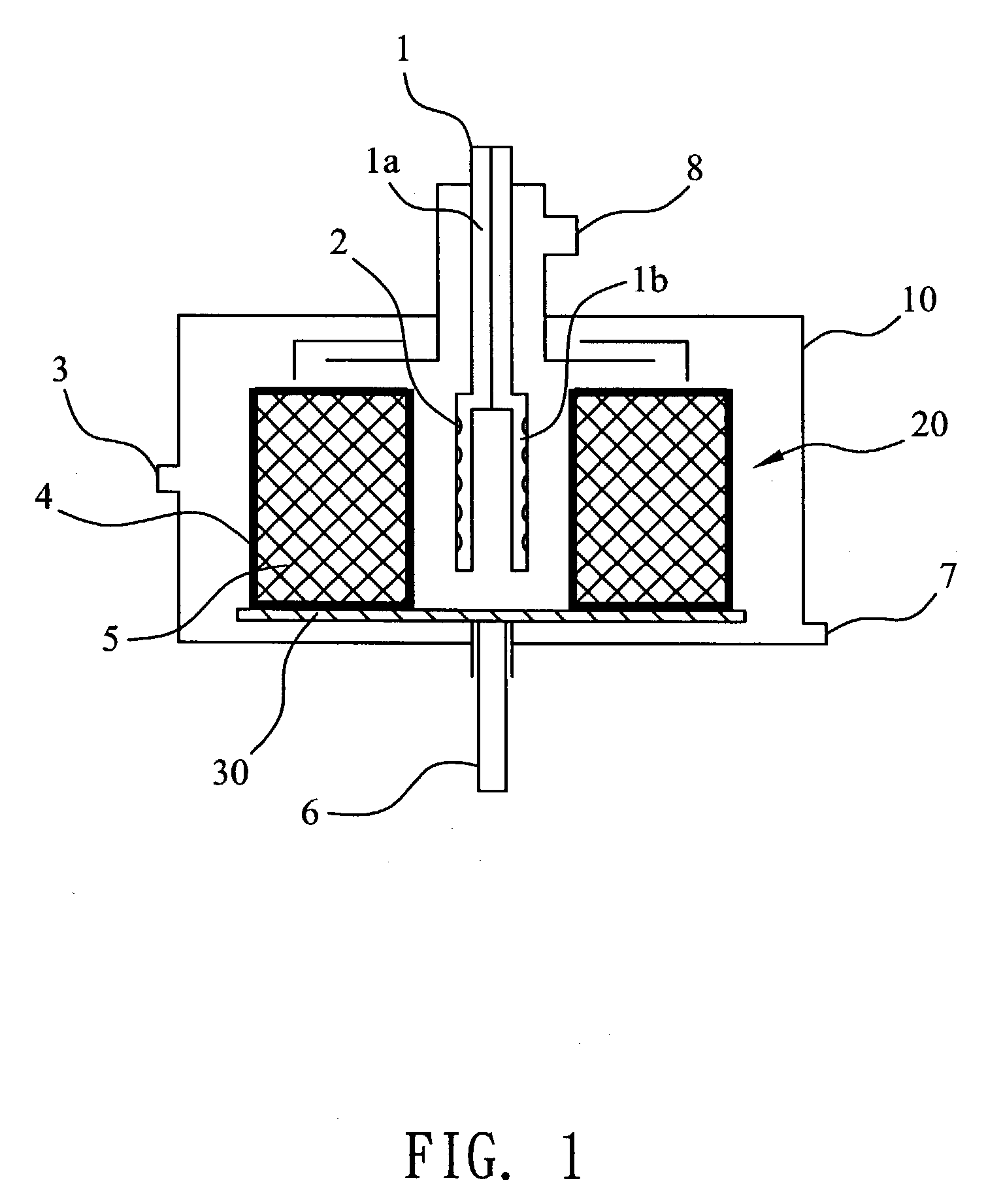

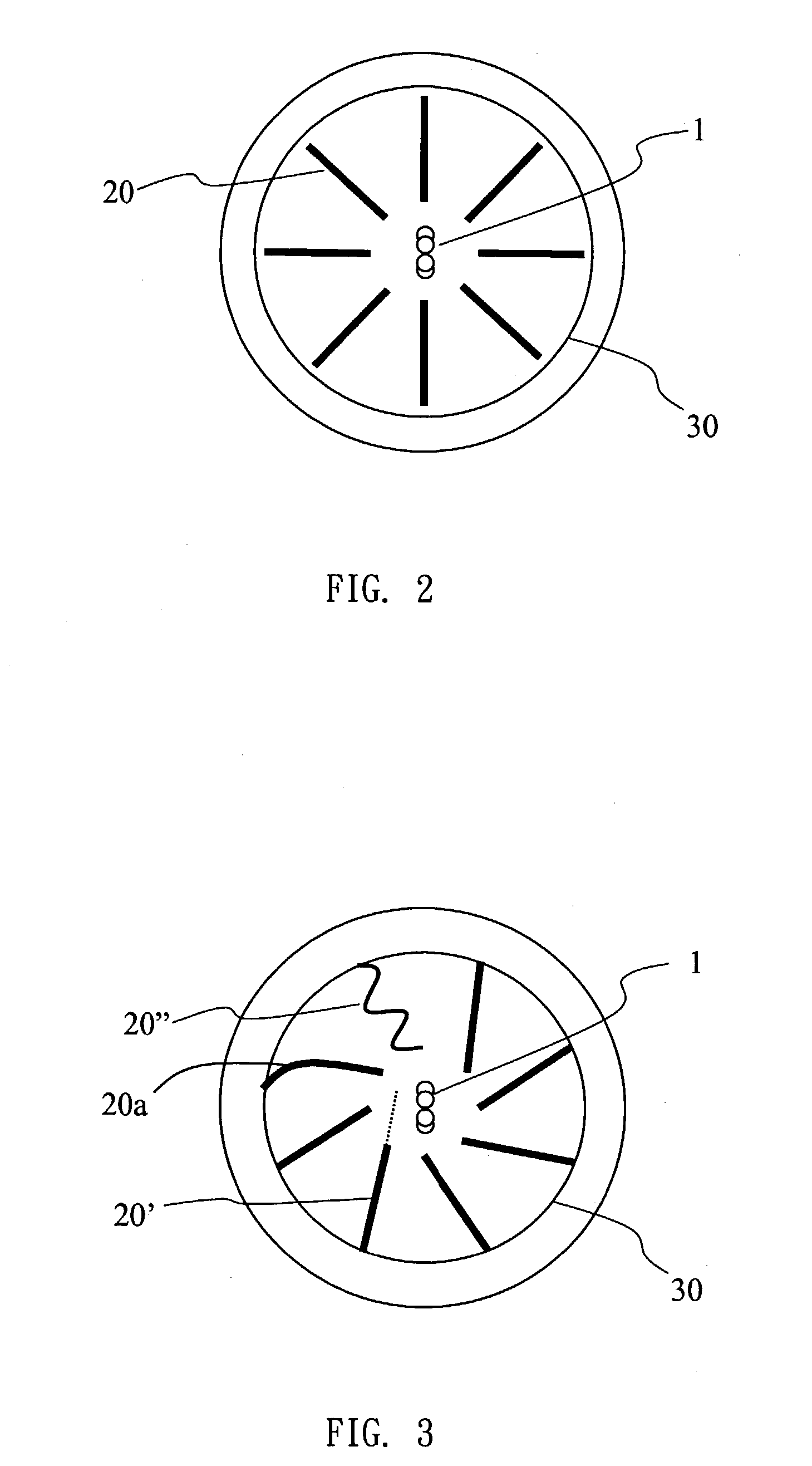

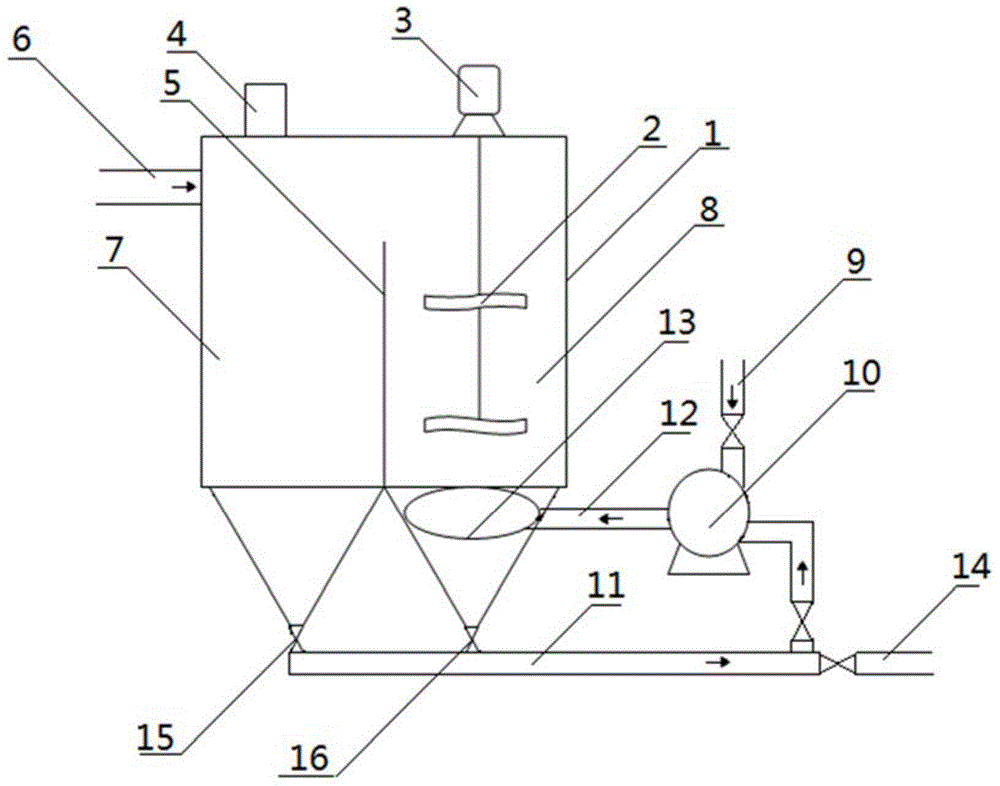

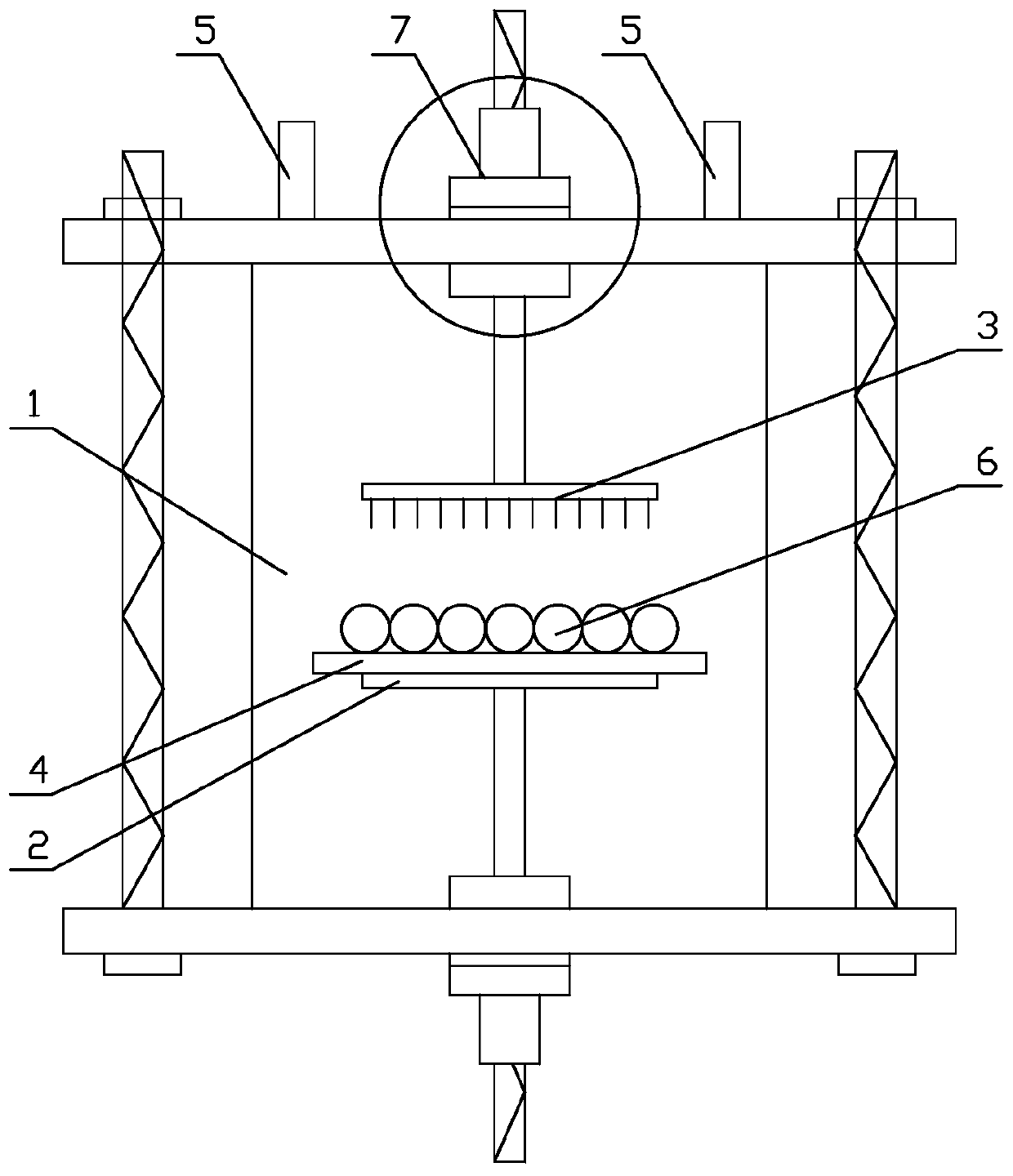

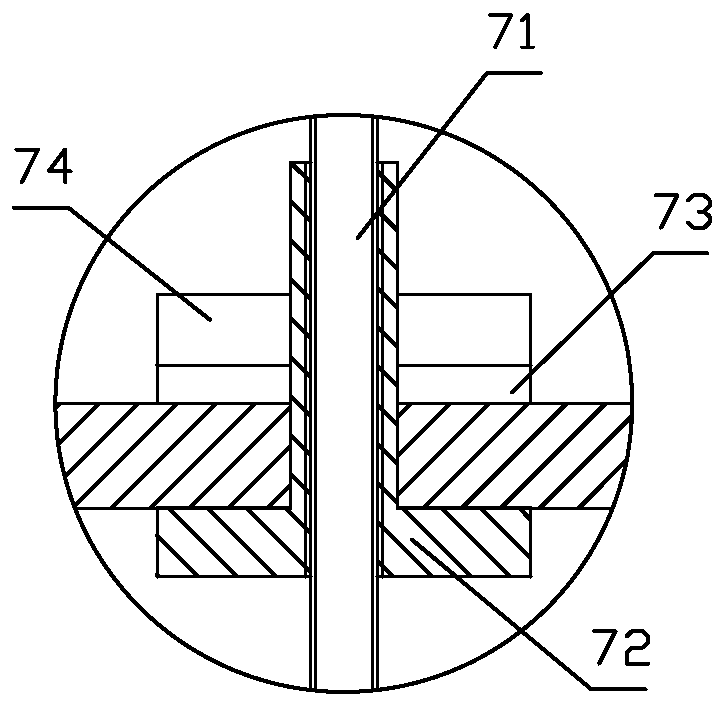

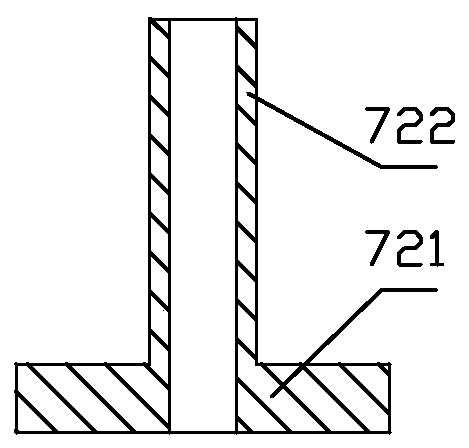

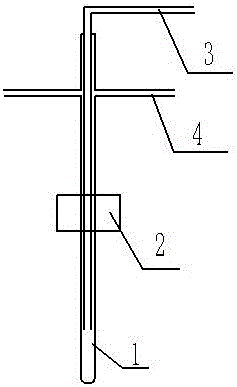

Reactor for producing ultra fine particles

InactiveUS7166260B2Fast nucleationMore reactantTransportation and packagingRotary stirring mixersUltra fineReagent

A reactor containing a plurality of porous rotors is disclosed. A liquid sprayed in a direction from a rotating axis to the rotors is hit by the porous rotors, creating fine liquid particles, so that a mass transfer takes place between the surfaces of the liquid particles and a gas injected into the reactor, and thus a crystallization reaction is initiated. The crystallization reaction is confined by the amounts of the reactants contained in the liquid particles, and will stop as soon as one of the reactants is consumed, so that the resulting crystals can be controlled in nanometer level. The reactor of the present invention is also suitable for use in a liquid-liquid reaction, wherein two different liquids are separately sprayed in a direction from the rotating axis and hit by the porous rotors, and the resulting fine liquid particles of the two different liquids contact and react with each other, so that ultra fine particles are formed.

Owner:IND TECH RES INST

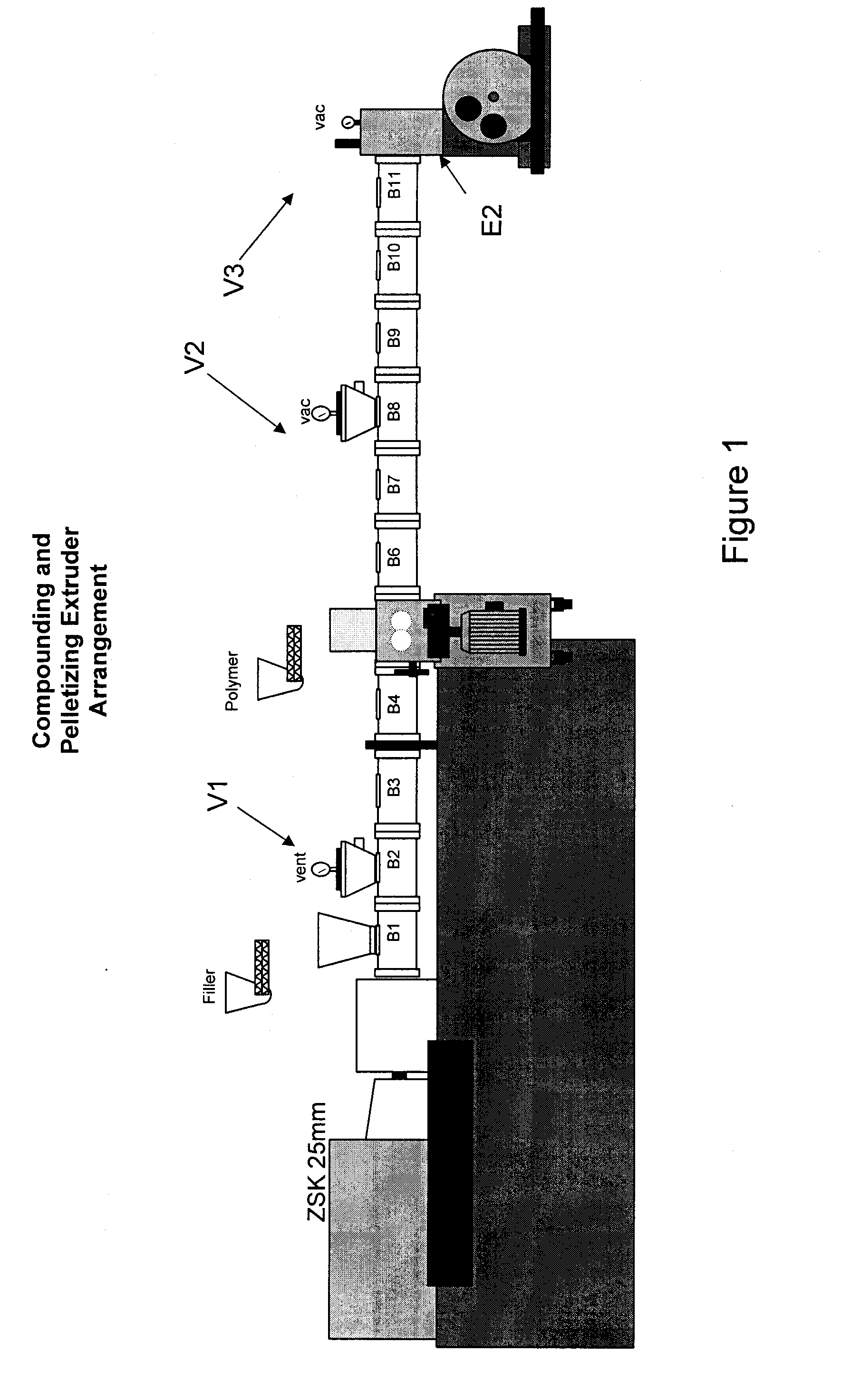

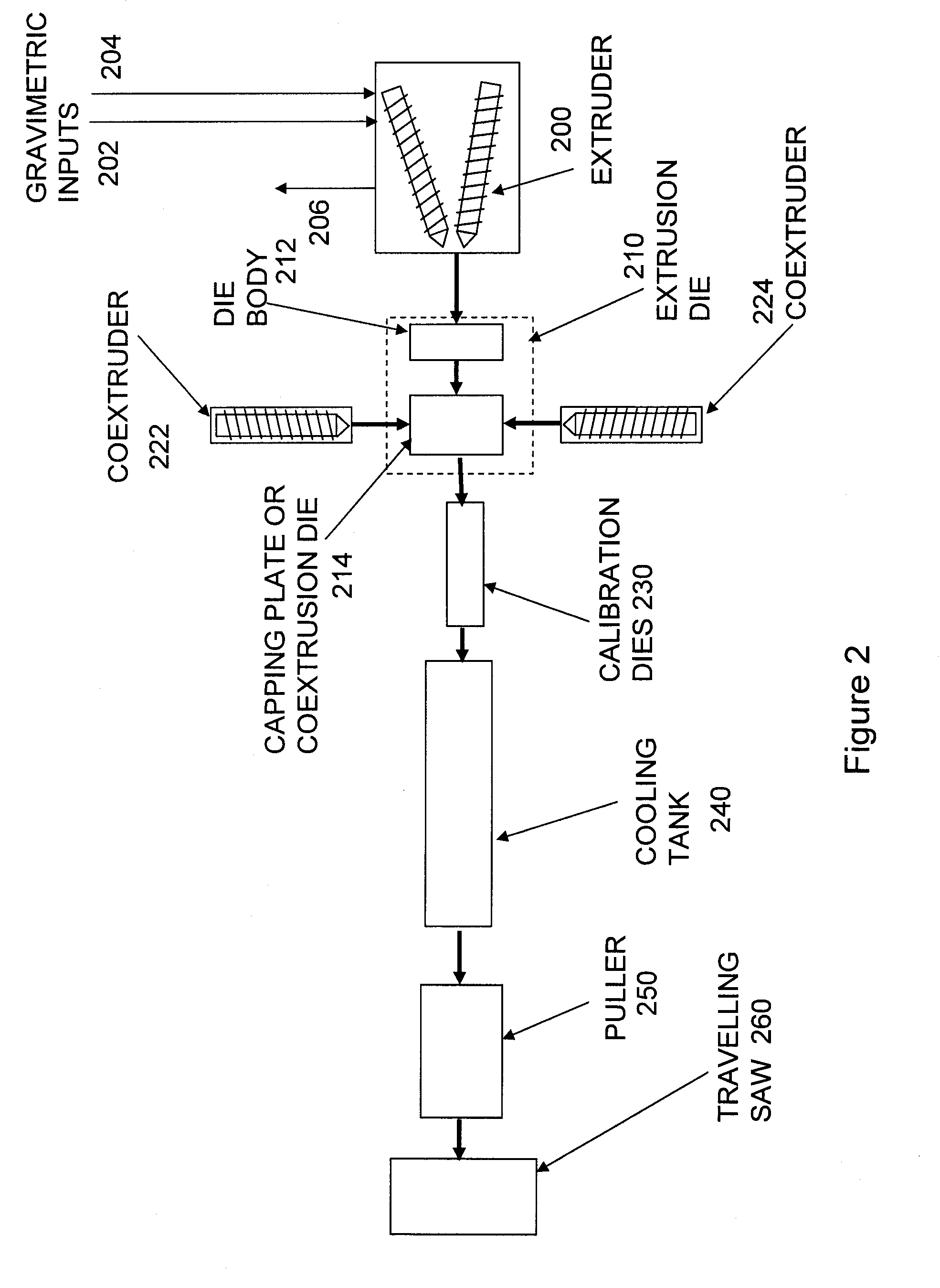

Sustainable Compositions, Related Methods, and Members Formed Therefrom

Members including components of windows and doors are formed by a method that includes obtaining a biopolymer and a filler, feeding them into an extruder, controlling at least the temperature of the biopolymer and the filler within the extruder to promote the initiation of nucleation of the biopolymer, extruding the composite through a die of the extruder to form an extruded member and controlling at least the cooling rate of the extruded member after it leaves the die to promote crystallization of the biopolymer. Methods are disclosed for compounding and pelletizing as well as direct extrusion of the composite. In a preferred embodiment, the biopolymer is polylactic acid (PLA) and the filler is wood fiber. In addition, neat PLA formulations are also disclosed. Further, the heat distortion temperature and the hydrolysis resistance of these members are greatly increased through specific processing conditions and the addition of strategic quantities of additives.

Owner:ANDERSEN CORPORATION

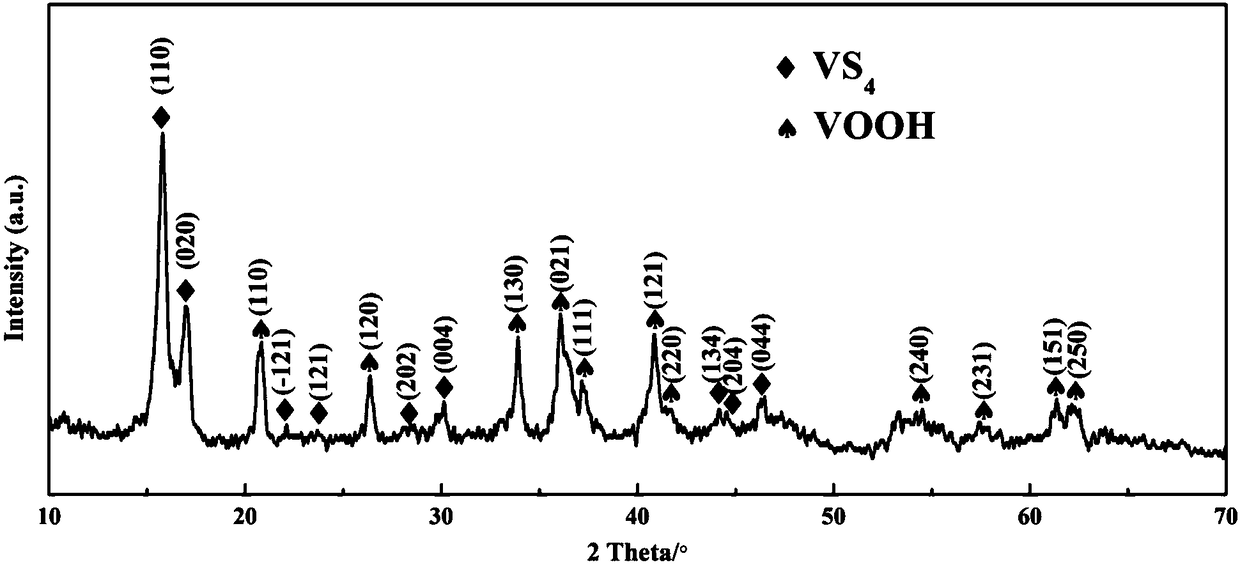

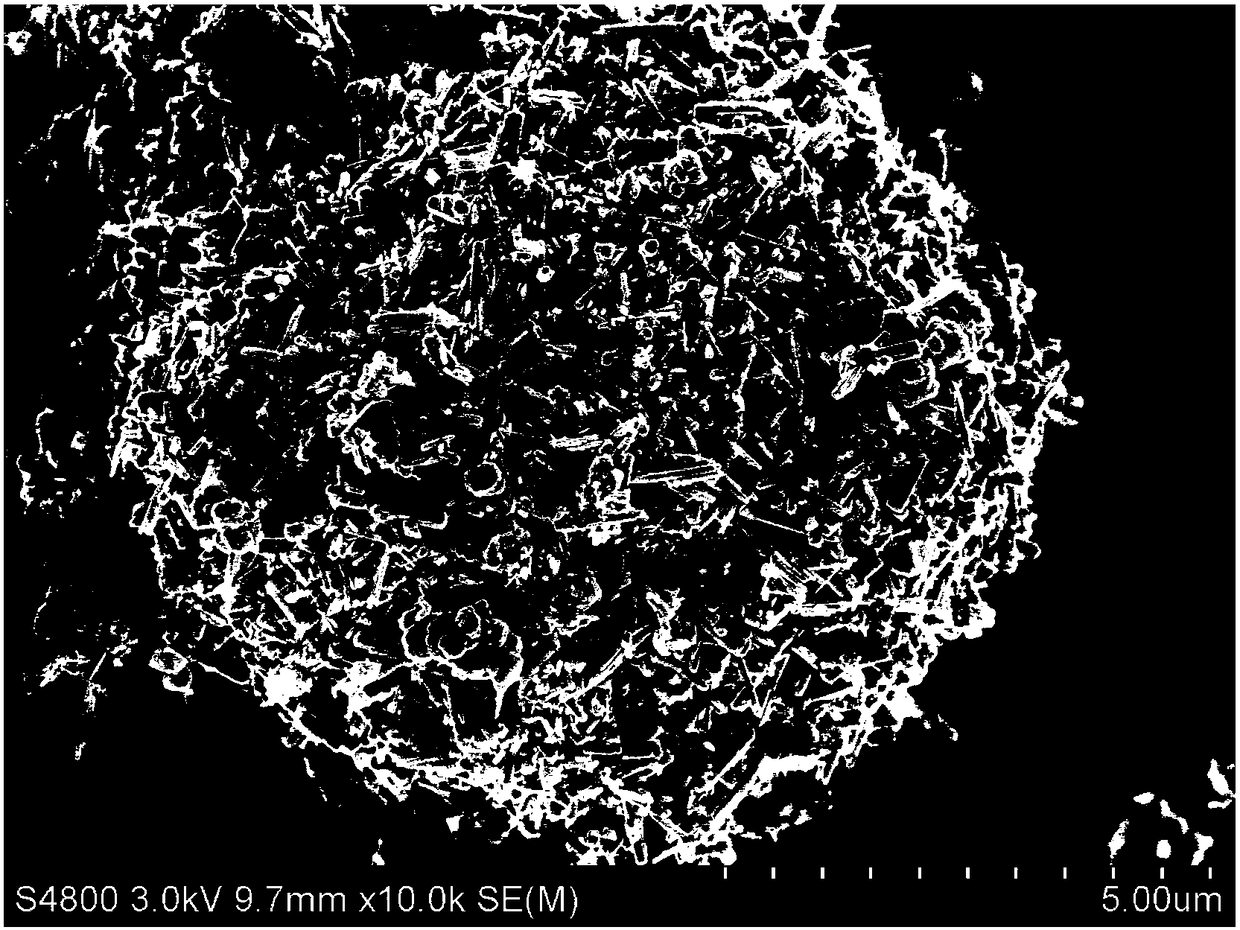

VOOH/VS4 micrometer composite powder as well as preparation method and application of VOOH/VS4 micrometer composite powder

ActiveCN108126712AImprove responseReduce the temperaturePhysical/chemical process catalystsCell electrodesMicrosphereSingle crystal

The invention discloses a VOOH / VS4 micrometer composite powder as well as a preparation method and application of the VOOH / VS4 micrometer composite powder. The preparation method comprises the steps:simultaneously adding sodium metavanadate and thioacetamide into deionized water to obtain a solution A; then, dropwise adding an aqueous ammonia solution into the solution A to obtain a solution B; pouring the solution B into a reaction liner, and then, carrying out sealing for a hydrothermal reaction; next, taking out a product cooled after being reacted, alternately cleaning the product by using water and alcohol, and then, collecting the product; and freezing the cleaned product, and then, drying the product to obtain the VOOH / VS4 micrometer composite powder. The VOOH / VS4 micrometer composite powder prepared according to the preparation method is composed of uniform spheroidal structures of which the diameters are about 10mu m, parts of spheroidal structures are gathered, the insides of microspheres are formed by self-stacking micrometer VS4 short rods of which the diameters are 0.5-1.0mu m and the length is 1.0-2.0mu m, and the outsides of the microspheres are randomly formed fromVOOH long rods having the diameters of 50-200nm and single-crystal structures. The VOOH / VS4 micrometer composite powder is applied to the fields of lithium / sodium ion batteries and photo / electric catalysis. The VOOH / VS4 micrometer composite powder shows excellent electrochemical properties and catalytic property when being applied as an anode material of a sodium / lithium ion battery and a photo / electric catalyst.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing monodisperse cation type polymer micro-sphere

The invention relates to a method of preparing cationic type polymeric microspheres. According to the mass ratio of 0.25 to 3:8 to 12:0.5 to 2.5:0.05 to 0.2:0 to 50:50 to 100, cationic type monomers, vinyl monomers, dispersant, initiator, dispersing medium A and dispersing medium B are added into a reactor and are continuously stirred until temperature is raised to and kept at 75 DEG C, and reaction lasts three to five hours in order to obtain emulsion; the obtained emulsion is washed and centrifugated by methyl alcohol for three times and then is washed and centrifugated by deionized water for three times, so that the monodisperse cationic type polymeric microspheres with a particle diameter between 0.5 to 50 Mu m are produced. The method is characterized in high nucleation speed, easy acquirement of uniformly dispersed cationic type polymeric microspheres, simple technique and no need of nitrogen protection in the course of reaction, and the particle diameter of the microspheres can be controlled by changing the proportion between cationic type monomers and vinyl monomers.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

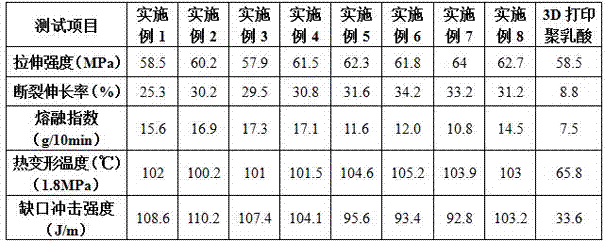

Toughening and heat-resistant PET material for 3D printing and preparation method thereof

InactiveCN107513255AWell mixedHigh heat distortion temperatureAdditive manufacturing apparatusHeat deflection temperatureNanoparticle

The invention discloses a toughening and heat-resistant PET material for 3D printing and a preparation method thereof. The toughening and heat-resistant PET material for 3D printing comprises PET, a chain extender, a nucleation agent, a nucleation promoter, a toughening agent, an inorganic reinforcing agent, an antioxidant, a lubricant and nano-particles. The preparation method comprises 1) drying PET, 2) mixing the PET, a chain extender, a nucleation agent, a nucleation promoter, a toughening agent, an inorganic reinforcing agent, an antioxidant, a lubricant and nano-particles and carrying out uniform stirring, and 3) adding the mixed materials into an extruder, and carrying out mixing, extruding and granulation to obtain the toughening and heat-resistant PET material for 3D printing. The toughening and heat-resistant PET material for 3D printing has a heat deflection temperature of 105 DEG C, notched impact strength of about 110 J / m, good toughness and an appropriate heat deflection temperature, realizes a low production cost, is easy to industrialize and can be widely used for electronic components products and electronic products for 3D printing formation.

Owner:GUANGDONG JUSHI CHEM CO LTD

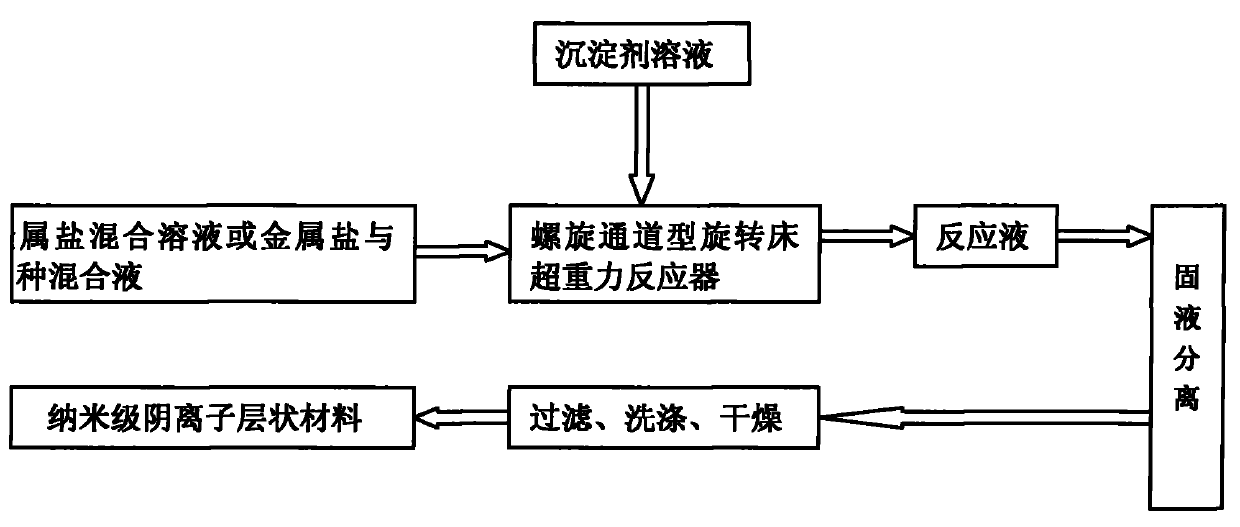

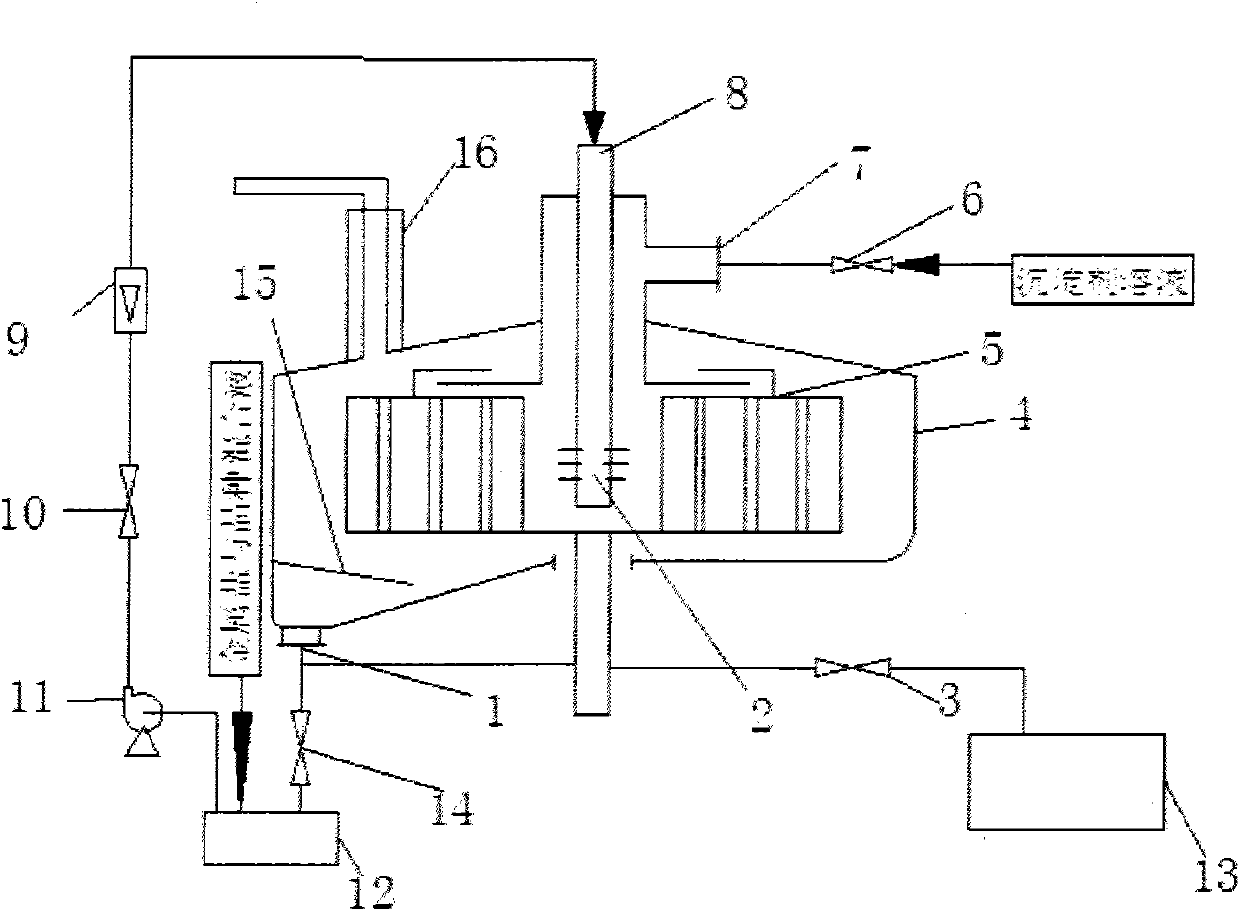

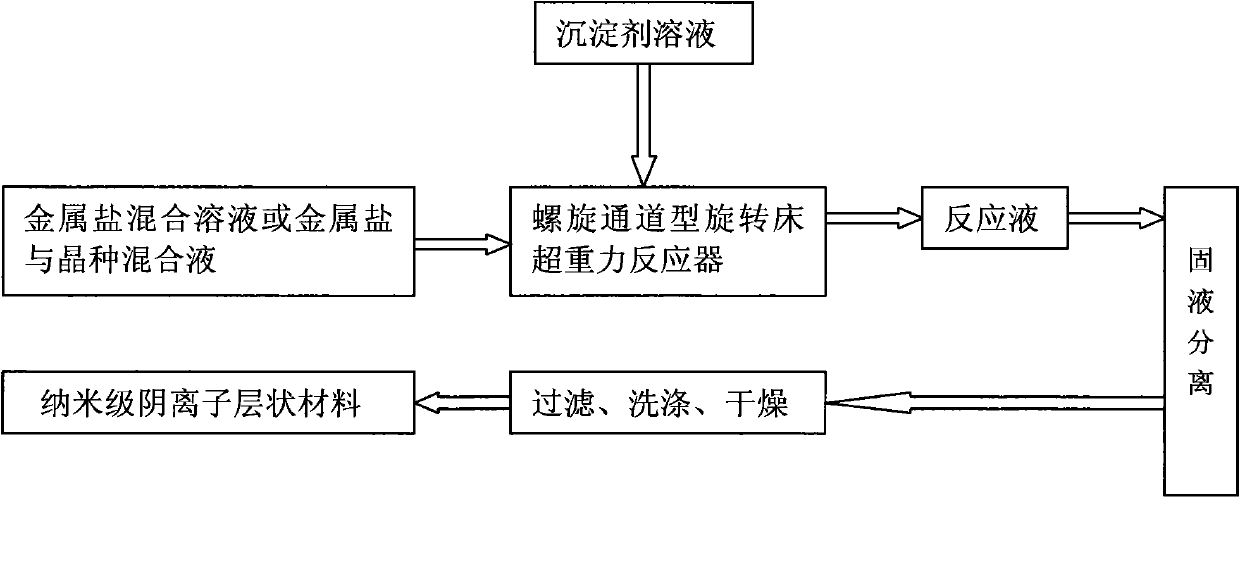

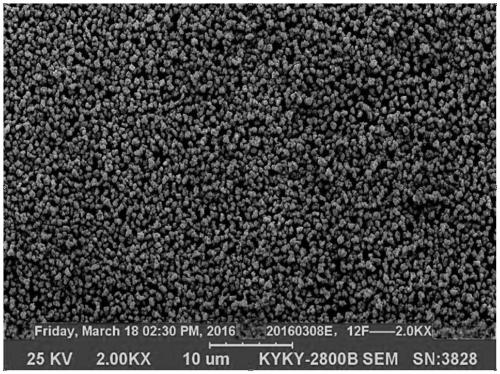

Method for preparing nanoscale anionic laminar material continuously

InactiveCN101905870AFast nucleationParticle size distribution narrowingOxygen/ozone/oxide/hydroxideChemistryHigh Gravity

The invention discloses a method for preparing a nanoscale anionic laminar material continuously, which mainly comprises the steps of reacting, filtering, washing and drying. Compared with the conventional method for preparing the anionic laminar material in China, the method has the following advantages: (1) a helix channel rotating bed high gravity reactor is adopted to enable nucleus formation to be formed in a uniform micro hybrid environment quickly with a narrowed particle size distribution, the reaction solution in the reactor is kept under a stable high pH value condition by condensing NH3 so as to avoid generating an impurity phase, the reaction time is short and the operation is simple; (2) crystal seeds are added during reaction to greatly reduce the induction period of nucleus formation and accelerate nucleus formation, the crystallinity is high, the particle size distribution is more uniform, the size and distribution of newly generated particles can be controlled according to the particle size of the added crystal seeds, and thus, the particle size is controllable; (3) a crystallization process is not required for product post processing; and (4), the process is quick and allows for continuous production, and the average particle size of the prepared anionic laminar material is 30 to 90 nanometers.

Owner:XIANGTAN UNIV

Ultraviolet curing adhesive for temporary protection and preparation method of ultraviolet curing adhesive

ActiveCN107474786ASuitable Thixotropic ViscosityReduce hardnessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterNanowire

The invention relates to an ultraviolet curing adhesive for temporary protection and a preparation method of the ultraviolet curing adhesive. The ultraviolet curing adhesive is prepared from the following raw materials by weight: 20-60 parts of a self-made bifunctional polyurethane acrylate prepolymer, 5-15 parts of a multi-functional polyurethane acrylate prepolymer, 5-15 parts of a polyester acrylate prepolymer, 5-20 parts of a reactive amine compounding agent, 10-30 parts of acrylate type active diluents, 0.5%-5% of a leveling wetting agent, 1%-5% of a photoinitiator, 0.5-5 parts of titanium dioxide nanowires and 0.1-10 parts of fumed silica. The ultraviolet curing adhesive is suitable for temporary protection of a metal casing and plays a protective role in post-processing of CNC, and can be easily peeled off after CNC processing. Residues on the metal casing and falling off of the adhesive are avoided.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

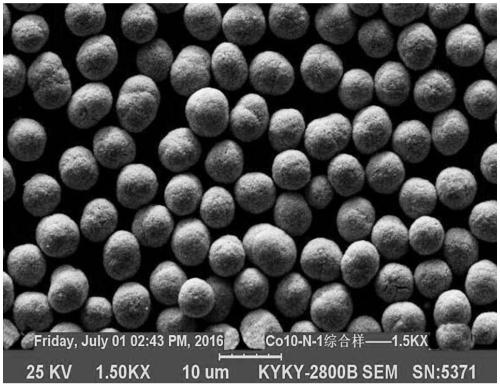

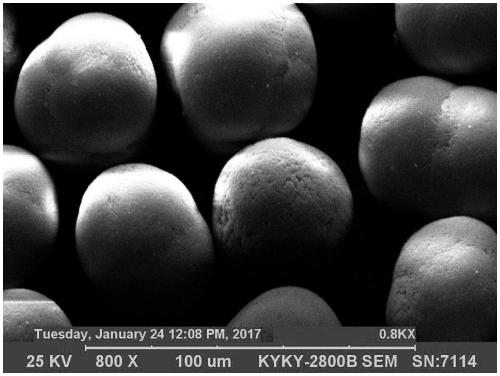

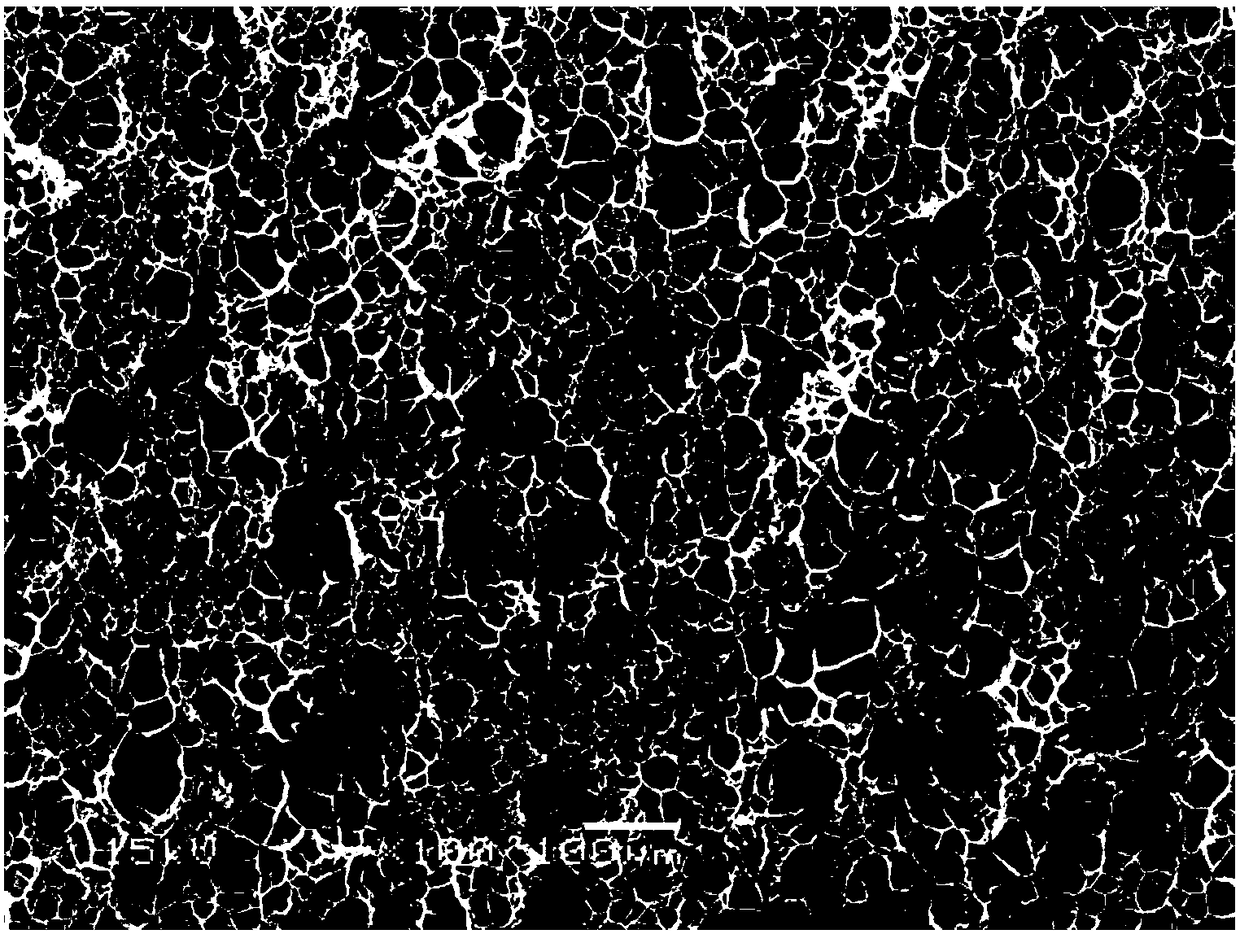

Production method of spherical basic cobalt carbonate with controllable particle size

ActiveCN110092421AGood removal effectShorten the induced nucleation periodCobalt carbonatesReaction temperatureCobalt

The invention discloses a production method of spherical basic cobalt carbonate with a controllable particle size, and the production method comprises the following general steps of: (1) preparing ofa solution; (2) magnetic inducing nucleation; (3) grain growth; (4) filter pressing and washing; and (5) drying. According to the method, nucleation supersaturation is reduced by applying of an external magnetic field during the synthesis of the basic cobalt carbonate, the induction nucleation period is shortened, and a large amount of basic cobalt carbonate crystal nuclei are instantly formed inthe solution; meanwhile, the quality of the product can be well adjusted by controlling the stirring speed, the reaction temperature and the adding speed of a cobalt liquid, so that the effects of uniform particles and spherical morphology are achieved, and the cobalt content can reach more than 52%. The basic cobalt carbonate product has standard normal distribution of particle size, uniform particle size and good fluidity, and the maximum D50 exceeds 40mu m, the uniformity and stability of the particle size of large-scale continuous produced spherical basic cobalt carbonate can be realized,and the production method simple process, easy operation and low cost, and provides a high-quality raw material for the production of high-end lithium batteries.

Owner:赣州逸豪优美科实业有限公司 +1

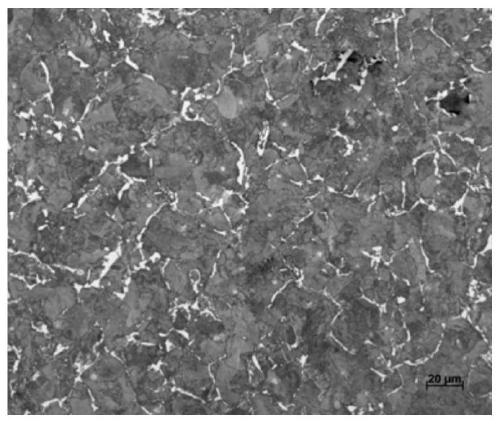

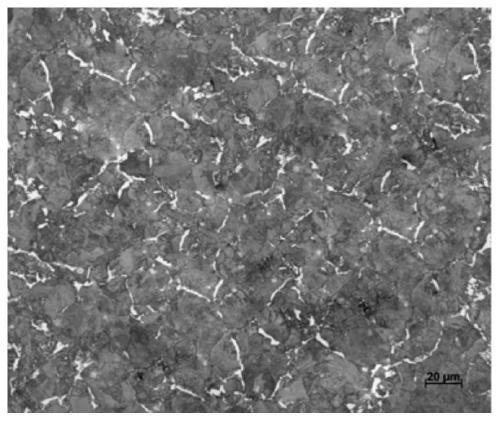

Medium-carbon wheel steel suitable for freight trains in alpine regions and method for producing wheels by using medium-carbon wheel steel

ActiveCN111270154AIncrease supersaturationImprove low temperature toughnessFurnace typesHeat treatment furnacesFreight trainsTempering

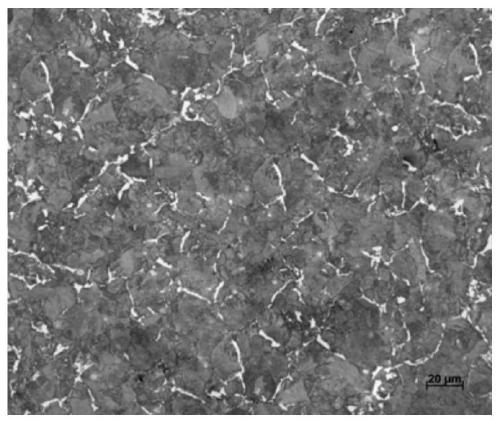

The invention provides medium-carbon wheel steel suitable for freight trains in alpine regions and a method for producing wheels by using the medium-carbon wheel steel. The medium-carbon wheel steel comprises the following components of 0.55% - 0.63% of C, 0.25% - 0.45% of Si, 0.65% - 0.90% of Mn, less than or equal to 0.030% of P, less than or equal to 0.025% of S, less than or equal to 0.10% ofV, less than or equal to 0.30% of Cr, less than or equal to 0.30% of Ni and 0.0050% - 0.0100% of N, and the balance Fe and inevitable impurity elements. Compared with the prior art, according to the medium-carbon wheel steel suitable for the freight trains in the alpine regions and the method for producing the wheels by using the medium-carbon wheel steel, the N is used for generating precipitatessuch as MX nitride or carbonitride, so that the supersaturation degree of ferrite is improved, V(CN) particles are promoted to nucleate quickly, the particle spacing is reduced, and the precipitationcondition effect is improved; and according to the medium-carbon wheel steel suitable for the freight trains in the alpine regions and the method for producing the wheels by using the medium-carbon wheel steel, an ideal fine pearlite and ferrite (less than 4%) structure is obtained by adopting a circulating quenching and tempering process, so that the mechanical property level of rims is higher,and the fracture resistance of the wheels under a low-temperature service condition is enhanced.

Owner:MAANSHAN IRON & STEEL CO LTD

Carbonization reaction device and method for nano calcium carbonate production

ActiveCN104891545AAvoid backmixingGood for pulpingCalcium/strontium/barium carbonatesMaterial nanotechnologyRefluxCarbonization

The invention discloses a carbonization reaction device and a carbonization reaction method for nano calcium carbonate production. The carbonization reaction device comprises a Ca(OH)2 slurry feeding tube, a carbonization tower, a stirrer, an annular gas-liquid distributor, a CO2 gas inlet tube and an emulsion dispersing machine. The carbonization reaction method comprises the following steps: (1) feeding Ca(OH)2 slurry into a reflux area of the carbonization tower; (2) continuously feeding the Ca(IH)2 slurry into the emulsion dispersing machine to mix and react with a CO2 gas, and feeding the obtained product into the reaction area of the carbonization tower; (3) continuously circulating the mixed slurry between the carbonization tower and the emulsion dispersing machine for carbonization and emulsion dispersion; (4) adding a dispersing agent, continuously circulating the mixed slurry between the carbonization tower and the emulsion dispersing machine for secondary carbonization and emulsion dispersion; and (5) stopping introduction of CO2 for reaction and operation of the emulsion dispersing machine, thereby obtaining prepared nano calcium carbonate slurry. The carbonization reaction device and the carbonization reaction method for nano calcium carbonate production are rapid in carbonization reaction speed, high efficiency, good effect, small investment and low cost.

Owner:FUJIAN HONGFENG NANO TECH

Application method of ultraviolet curing adhesive for temporary protection

ActiveCN107474787ASuitable Thixotropic ViscosityReduce hardnessAdhesive processesNon-macromolecular adhesive additivesNumerical controlAfter treatment

The invention relates to an application method of an ultraviolet curing adhesive for temporary protection. The adhesive is put in a light-proof needle tube, a needle is mounted, then, the needle tube is put in an automatic dispensing machine, a dispensing procedure is set according to a dispensing route, the air pressure is controlled, the adhesive is injected into screw holes of a metal shell and completely cured under ultraviolet irradiation, the ultrasonic irradiation energy is 600-1,200 mJ / cm<2>, and post-treatment of a CNC (computer numerical control) technology is implemented; ultraviolet irradiation is performed under the ultrasonic irradiation energy of 3,000-6,0 00 mJ / cm<2>after treatment with the CNC technology, and cured adhesive plugs in the screw holes are stripped by hand or ultrasonic waves. The application method is simple to operate, stripping is easy, and residues and falling can be avoided.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

Method for synthesizing low-impurity content glyoxal through gas phase oxidation

ActiveCN103772169AFast nucleationImprove bindingOrganic compound preparationCatalyst activation/preparationGas phaseCatalytic oxidation

The invention belongs to the technical fields of chemistry and chemical engineering and in particular relates to a method for synthesizing low-impurity content glyoxal through gas phase catalytic oxidation. The method comprises the following steps: taking crystallized silver prepared by an electrolytic process as a carrier; performing high-temperature treatment, performing metal deposition, drying and roasting to obtain crystallized silver containing copper-silver alloy particles; taking the crystallized silver loaded with the copper-silver alloy particles as a catalyst, carrying out an oxidizing reaction among ethylene glycol, oxygen, water and inert gases to generate glyoxal in the presence of a catalyst. The 40 percent of glyoxal aqueous liquid in which the formaldehyde content is less than 500ppm and the glycolaldehyde content is less than 0.5 percent is directly obtained by performing air oxidation on ethylene glycol. The catalyst is easily regenerated and can be regenerated with a similar electrolytic silver method, and the prepared glyoxal is high in product quality.

Owner:FUDAN UNIV +1

Cored wire for modifying and removing foreign materials in container filled with steel

The present invention discloses a cored wire for modifying and removing foreign materials in a container filled with steel. The wire core components of the cored wire comprise, by mass, 20-90% of CaO, 9-45% of Al2O3 and 1-35% of CaF. With the cored wire, the formations, the sizes and the quantity distributions of the foreign materials in the molten steel can be stabilized; the foreign materials in the molten steel can be effectively removed; the smelting cost can be reduced; the purity of the molten steel can be improved; the traditional calcium treatment of the aluminum-killed steel can be replaced.

Owner:CHONGQING UNIV

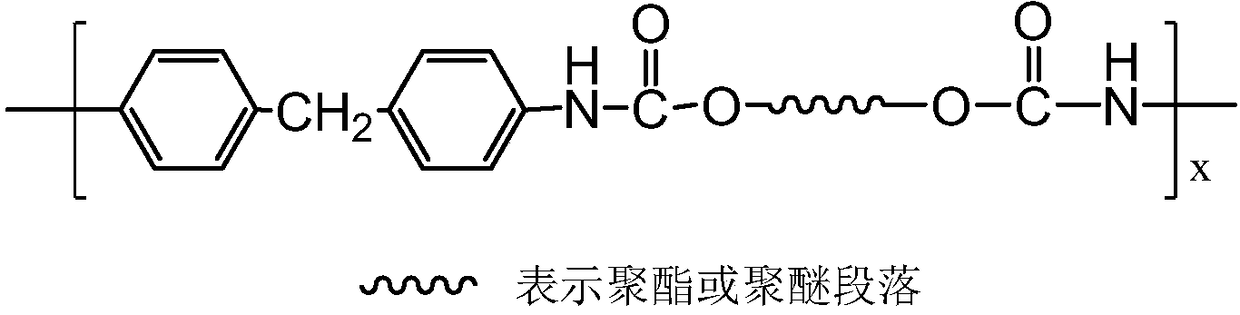

Thermoplastic polyurethane foaming bead particle and preparation method thereof

ActiveCN108503879AImprove foaming efficiencyHigh magnificationThermoplastic polyurethaneHigh pressure

The invention discloses a thermoplastic polyurethane foaming bead particle and a preparation method thereof. The preparation method comprises the following steps of (1) extruding a foaming-level thermoplastic polyurethane resin composition, and granulating, so as to form the to-be-foamed particles with uniform shape and weight; (2) uniformly heating the to-be-foamed particles by screw conveying heating equipment to approximate the foaming temperature, conveying into a constant-temperature high-pressure reaction kettle, filling supercritical fluid, permeating and swelling to reach dispersion balance, so as to form a polymer-supercritical fluid homogeneous system; (3) controlling the pressure release speed in the system, and foaming and swelling the to-be-foamed particles, so as to form thefoaming bead particle with special structure. The preparation method has the advantages that the production process is clean and environmentally friendly, the efficiency is higher, the prepared foaming bead particle has light specific weight and high mechanical property, and the thermoplastic polyurethane foaming bead particle can be applied to the fields of package, shoes, sports articles and thelike.

Owner:常州晟润新材料科技有限公司

Internally-plasticized antistatic polyformaldehyde material and preparation method thereof

The invention discloses an internally-plasticized antistatic polyformaldehyde material and a preparation method thereof. The polyformaldehyde material is a mixture of polyformaldehyde and ironic liquid. The preparation method comprises the following steps: respectively carrying out vacuum drying on polyformaldehyde and ironic liquid at 80-120 DEG C for 24-48 hours; adding the dried polyformaldehyde and ironic liquid into fusion mixing equipment in a mass ratio of 100 to (0.01-10), and carrying out fusion mixing at 170-200 DEG C, so as to obtain a mixture; and discharging the mixture out of the fusion mixing equipment, and cooling to the room temperature, so as to obtain the polyformaldehyde material. The polyformaldehyde material disclosed by the invention has excellent antistatic performance; by adding ironic liquid, the size of a spherocrystal of a polyformaldehyde matrix can be effectively reduced, so that a certain plasticization effect is achieved; and only common fusion mixing equipment is used in the preparation method, so that the industrial preparation is simple.

Owner:安徽贺赢新材料科技有限公司

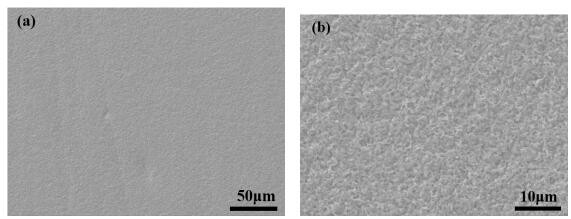

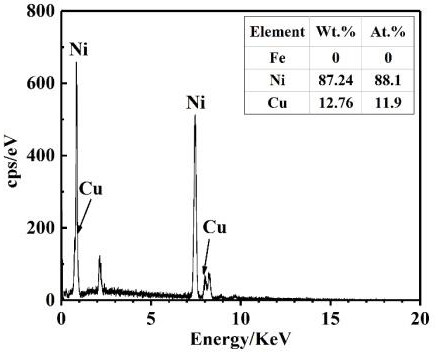

Method for preparing nickel-copper alloy plating layer on surface of carbon steel

The invention discloses a method for preparing a nickel-copper alloy plating layer on the surface of carbon steel. The method specifically comprises the following steps: (1) pretreatment, wherein a carbon steel workpiece is pretreated to obtain a carbon steel base material for later use; (2) preparation of an electroplating solution, wherein nickel sulfate, copper sulfate, trisodium citrate, boric acid, an additive and a brightener are dissolved in deionized water to prepare the electroplating solution for later use, and the concentrations of nickel sulfate, copper sulfate, trisodium citrate, boric acid, the additive and the brightener in the electroplating solution are 170-200 g / L, 5-20 g / L, 60-100 g / L, 10-25 g / L, 0.05-1 g / L and 0.1-1 g / L respectively; and (3) preparation of the nickel-copper alloy plating layer, wherein the carbon steel base material is immersed into the electroplating solution, the carbon steel base material serves as a cathode, one of monel alloy, pure nickel, graphite and pure copper serves as an anode, and electroplating deposition is conducted on the carbon steel base material to form the nickel-copper alloy plating layer. The nickel-copper alloy plating layer prepared through the method not only can effectively solve the problem of corrosion of a fluorine-making electrolytic cell made of carbon steel, but also has good thermal conductivity and strong binding force with the carbon steel base material.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

A hydrogenation catalyst and a preparation method thereof

ActiveCN109718796ALarge apertureLarge hole volumeMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsMicroreactorSurface phase

The invention discloses a hydrogenation catalyst and a preparation method thereof. A reaction system adopted for preparation of the hydrogenation catalyst comprises N micro-reactors connected in series, the first micro-reactor is an impinging stream reactor, acidic and alkaline materials enter the first micro-reactor for a neutralization reaction, and products sequentially enter the second micro-reactor to the (N-1)th micro-reactor with the pH value swing, wherein the reaction temperature is 20-30 DEG C lower than that of the first micro-reactor when the pH value swings towards the alkali sidewhile the reaction temperature is 20-30 DEG C higher than that of the first micro-reactor when the pH value swings towards the acid side, and the obtained reaction product enters the Nth micro-reactor to be subjected to an aging reaction and is roasted to obtain the hydrogenation catalyst. The acidic material is an acidic aluminum salt solution and an acidic active metal solution, and the alkaline material is an alkaline aluminate solution and an alkaline active metal solution. The hydrogenation catalyst prepared by the method is relatively large in pore diameter and pore volume, uniform in grain size and high in catalyst surface phase active metal density, eliminates an amplification effect, and is suitable for being applied to hydrodesulfurization and denitrification processes of residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device and method for preparing metal catalyst by using plasma

PendingCN110918028AImprove performancePrevent sinteringCatalyst activation/preparationEnergy based chemical/physical/physico-chemical processesPtru catalystHigh density

The invention discloses a device for preparing a metal catalyst by using plasma. The device comprises a reaction chamber, a metal plate electrode and a multi-needle electrode are arranged in the reaction chamber, the metal plate electrode and the multi-needle electrode are oppositely arranged, and a dielectric plate is pressed and covered on the metal plate electrode. According to the invention, uniform, large-area and high-density plasmas are generated, the metal catalyst can be prepared with high efficiency and high quality, transition from corona discharge to spark discharge can be effectively avoided, excessive sintering in the catalyst preparation process is avoided, and preparation of the catalyst is facilitated. The device is simple and convenient in design, low in cost and convenient to disassemble, and can be applied to other fields of discharge plasma application.

Owner:DALIAN MARITIME UNIVERSITY

Device for refining grain structure and application method

The invention discloses a device for refining grain structure and an application method, and belongs to the technical field of metallurgy. The device comprises a vibration device inserted in a steel ingot mold; the vibration device includes a vibration rod making direct contact with molten steel; the vibration rod is provided with a vibration generation source for driving the vibration rod to move; an introduction pipe for circulating a cooling medium is arranged in the center of the vibration rod; and discharge pipes for circulating the cooking medium are arranged on two sides of the upper end of the vibration rod. A steel ingot is vibrated in the solidification process to urge fusing and breakage of dendrites; and the number of free cold crystals is increased to inhibit growth of columnar crystals, so that the isometric crystal rate is increased, the solidification structure is refined, and the purpose of relieving segregation is achieved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

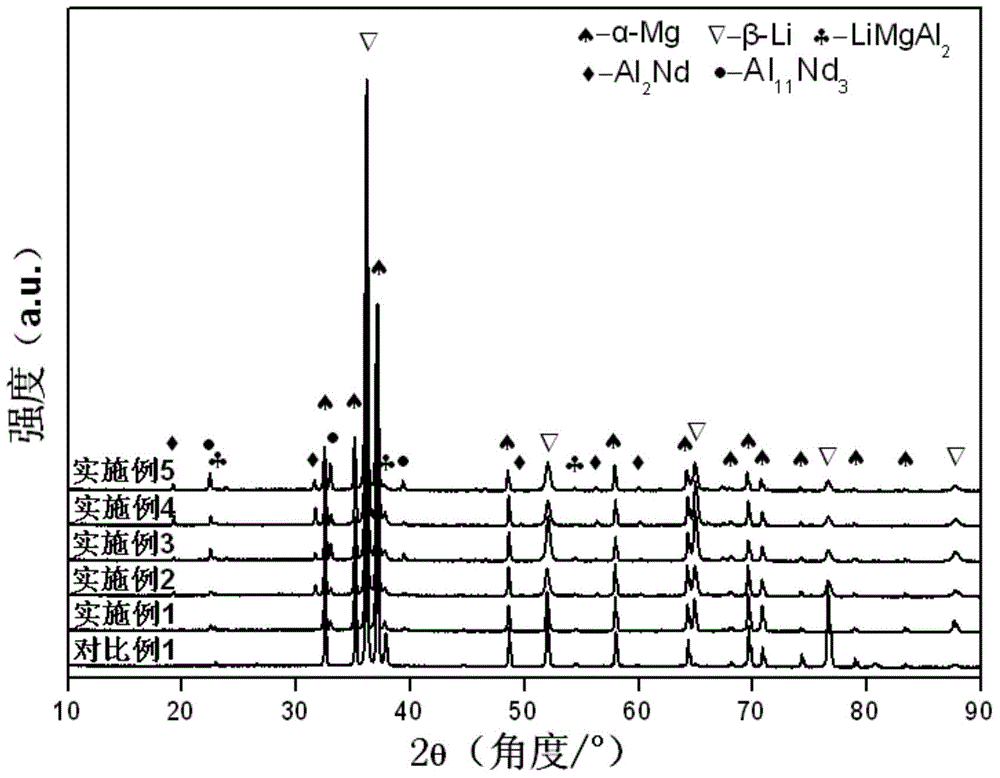

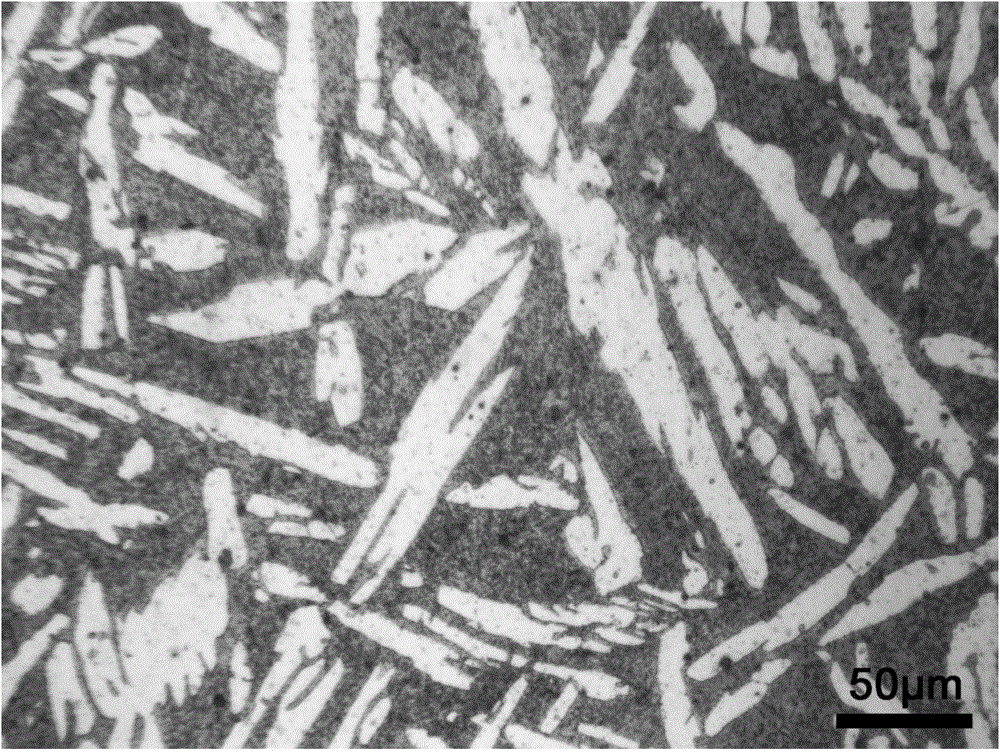

Magnesium-lithium-aluminum-neodymium alloy

The invention discloses a magnesium-lithium-aluminum-neodymium alloy. The magnesium-lithium-aluminum-neodymium alloy comprises the following components in percentage by mass: 8.97-9.36% of Li, 3.2-3.45% of Al, 0.4-2.75% of Nd, inevitable impurities not greater than 0.3%, and the balance of magnesium. The magnesium alloy is prepared by the following method: firstly, the raw materials are selected in proportion, and are mixed and smelted to obtain an alloy melt; then, the alloy melt is cooled by water to obtain a cast magnesium alloy; the cast magnesium alloy is heated up to 250-300 DEG C, and the temperature is kept for 8-10 hours; and finally, a finished product is obtained through extrusion. A certain quantity of rare earth Nd is added in an Mg-Li alloy, and is enriched in front of a solid-liquid interface, so that the components are tool cold, the growth of crystal grains is restrained, and the crystal grains are refined; a proper amount of Al is further added in the alloy; Al and Nd form Al2Nd and Al11Nd3 compound phases with high melting point and high heat stability in the smelting process; and the phase generates grain boundary pinning and dislocation in the heat working process to block the growth of dynamically recrystallized grains so as to further refine the crystal grains.

Owner:CHONGQING UNIV

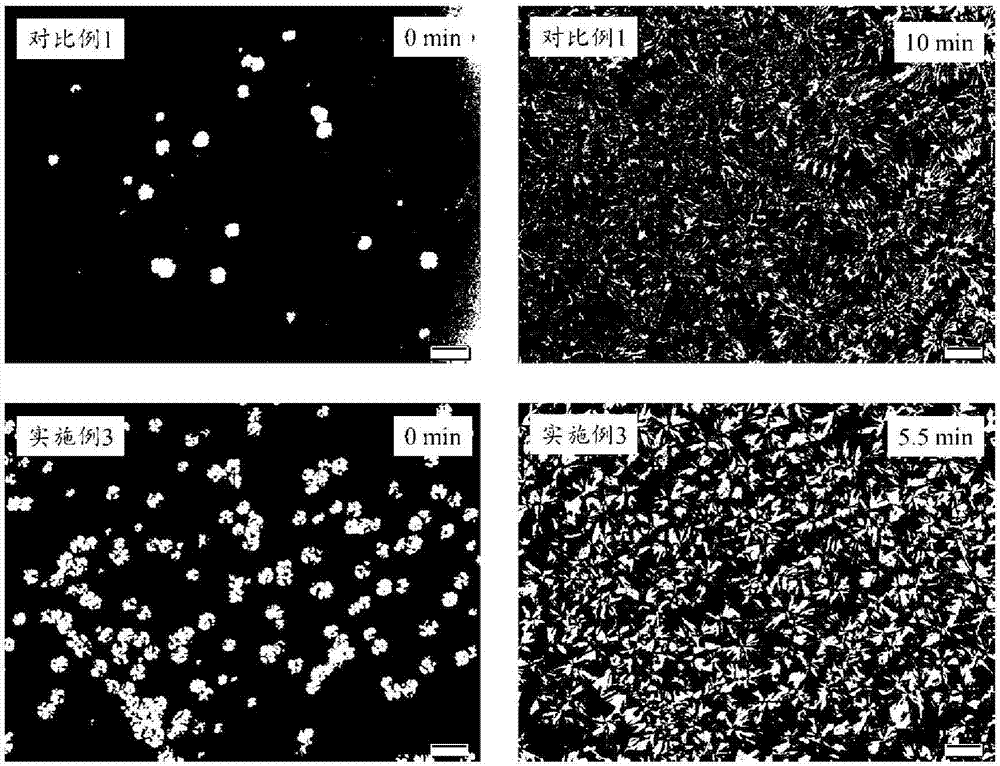

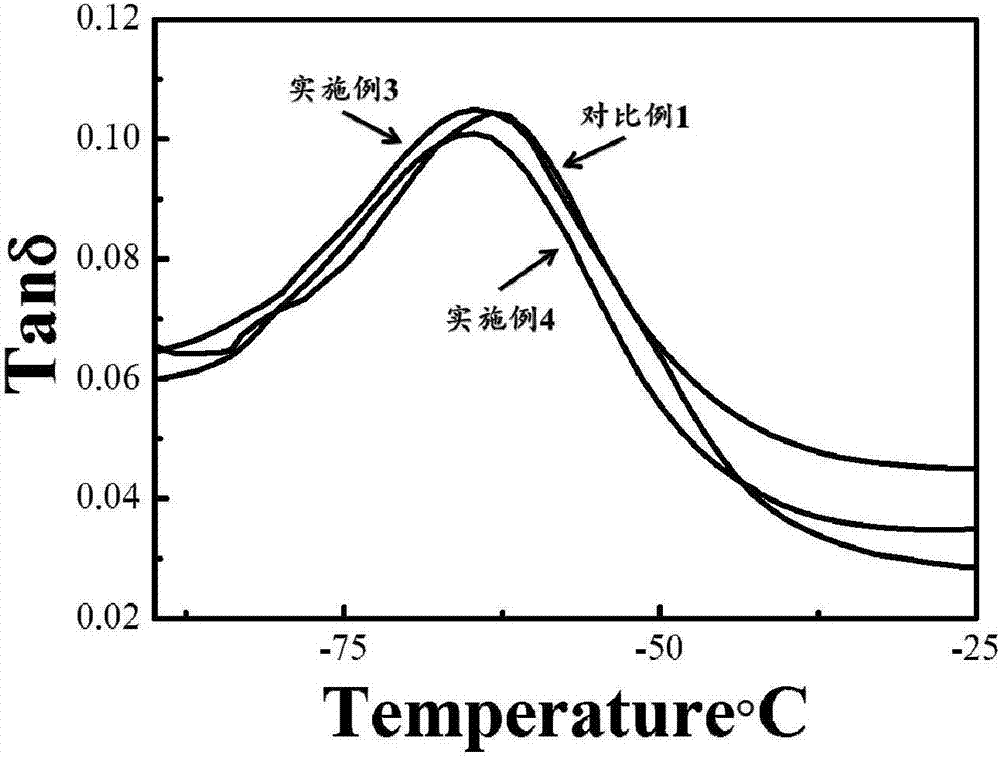

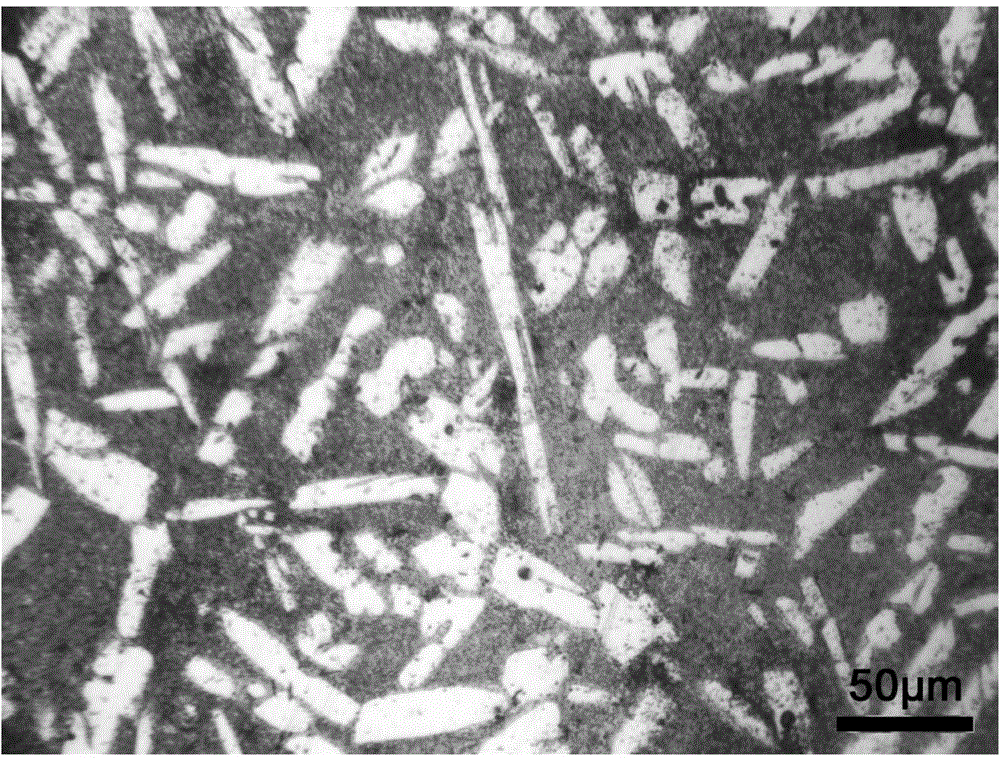

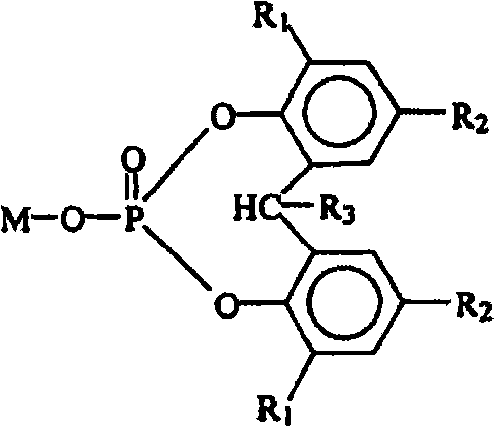

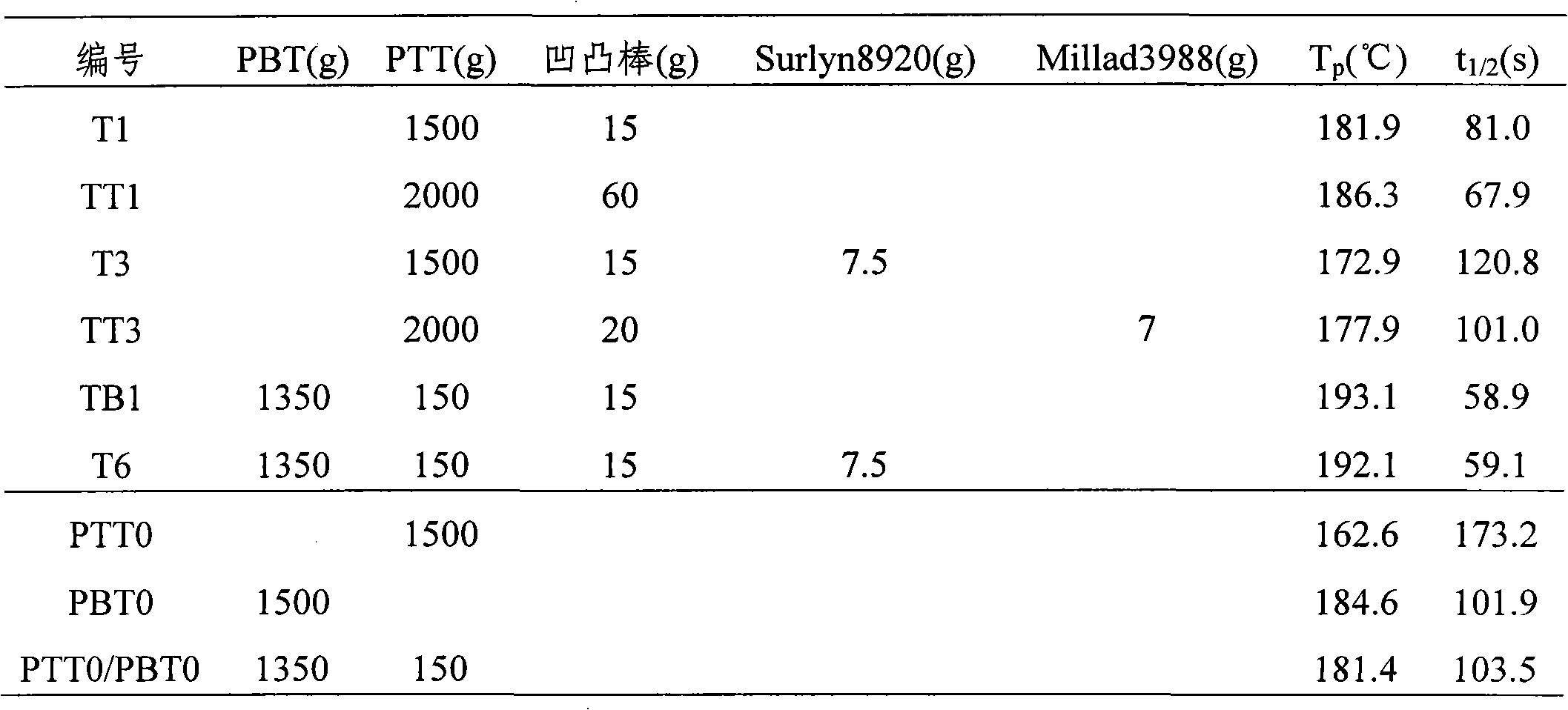

Method for improving crystallization property of PTT or PTT/PBT blend

InactiveCN102002219AIncrease the rate of crystallizationRaise the crystallization temperaturePolytetramethylene terephthalatePolytrimethylene terephthalate

The invention relates to a method for improving the crystallization property of a polytrimethylene terephthalate (PTT) or PTT / (polybutylece terephthalate) PBT blend, which comprises the step of adding a compound nucleating agent in the PTT or PTT / PBT blend. The method can remarkably improve the crystallization rate and the crystallization temperature of the PTT or PTT / PBT blend, and is beneficial to the improvement of the processing forming performance and the forming efficiency of a composite material of basic resin using the PTT or PTT / PBT blend as a main body.

Owner:CHINA NAT BLUESTAR GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com