Magnesium-lithium-aluminum-neodymium alloy

A magnesium alloy and alloy technology, applied in the field of magnesium alloys, can solve the problems of insufficient comprehensive mechanical properties such as limitation and strength, and achieve the effects of inhibiting grain growth, enhancing dislocation pinning effect, and avoiding component segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

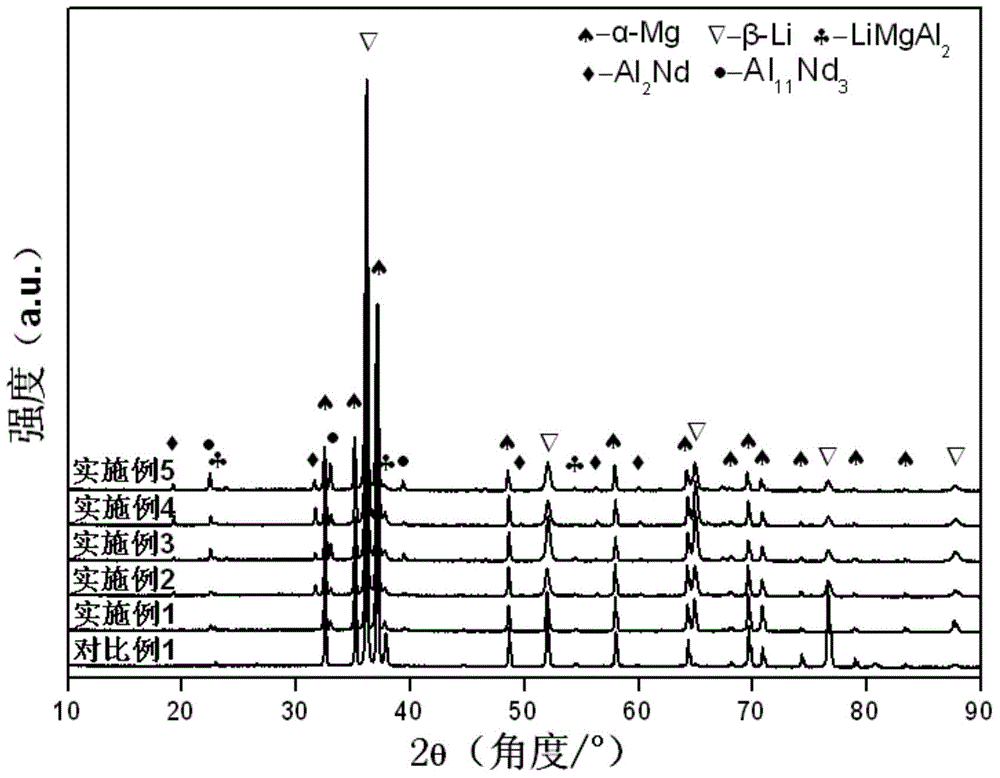

Embodiment 1

[0054] The method for preparing magnesium-lithium-aluminum-neodymium alloy in this embodiment comprises the following steps:

[0055] First, select industrial pure magnesium, industrial pure lithium, industrial pure aluminum, Mg-25% Nd rare earth master alloy, and adjust the ratio of various raw materials to make it consistent with Table 1 Example 1;

[0056] Second, evacuate the vacuum induction furnace and fill it with argon protection, use a crucible to hold all raw materials except industrial pure lithium, then place it in the vacuum induction furnace to heat, melt and stir evenly, and finally add industrial pure lithium to keep the alloy completely melted Afterwards, stir and remove slag;

[0057] The 3rd, take out the crucible water cooling that fills magnesium alloy melt;

[0058] Fourth, the alloy obtained by wagon processing is suitable for the size of the extrusion barrel of the extruder and the oxide layer on the surface of the alloy obtained by smelting is removed...

Embodiment 2

[0063] The difference between this example and Example 1 is that the content of each component in this example is the same as that of Example 2 in Table 1.

Embodiment 3

[0065] The difference between this example and Example 1 is that the content of each component in this example is the same as that of Example 3 in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com