Carbonization reaction device and method for nano calcium carbonate production

A technology of nano-calcium carbonate and carbonization reaction, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, nanotechnology, etc., can solve the problems of limited industrial application and promotion, difficult to control the production process, and difficult operation, so as to improve grinding and emulsification effect, speed up the progress of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

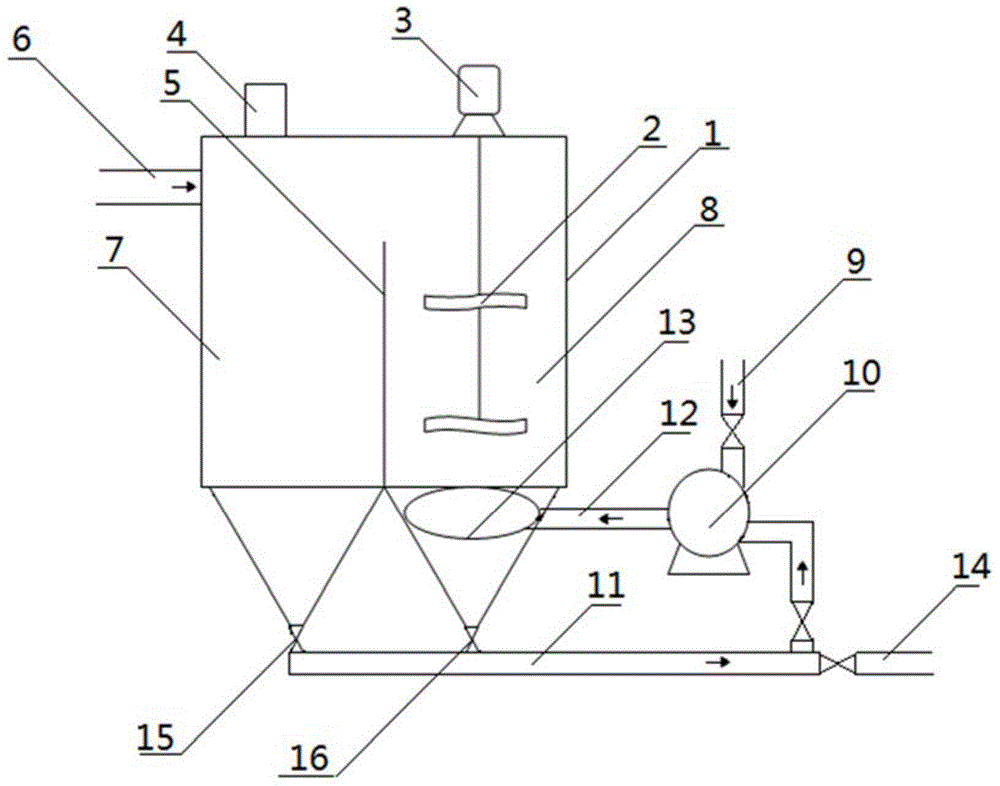

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

[0028] A carbonization reaction device produced by nano-calcium carbonate, such as figure 1 shown, including Ca(OH) 2 Slurry feed pipe 6, carbonization tower 1, agitator 2, annular gas-liquid distributor 13, CO 2 Gas inlet pipe 9 and emulsification disperser 10. The inner cavity of the carbonization tower 1 is provided with a dividing plate 5, the dividing plate 5 divides the interior of the carbonizing tower 1 into a reaction zone 8 and a reflux zone 7, and the dividing plate 5 is closed and connected with the bottom and both sides of the carbonizing tower 1, An opening is provided between the dividing plate 5 and the top of the carbonization tower 1, and the Ca(OH) 2The slurry feed pipe 6 communicates with the reflux zone of the carbonization tower 1, the top of the reflux zone of the carbonization tower 1 is provided with an exhaust po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com