Gas separation flow system and gas separation flow method for photochemical synthesis of 9-beta,10-alpha-dehydroprogesterone ketal

A photochemical synthesis, ketone ketal technology, applied in chemical instruments and methods, organic chemistry, steroids, etc., can solve the problems of gas expansion, large pressure drop, and reduced light exposure time, and achieve increased pipe diameter and system Effects of flux, increased conversion and yield, and reduced boundary layer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

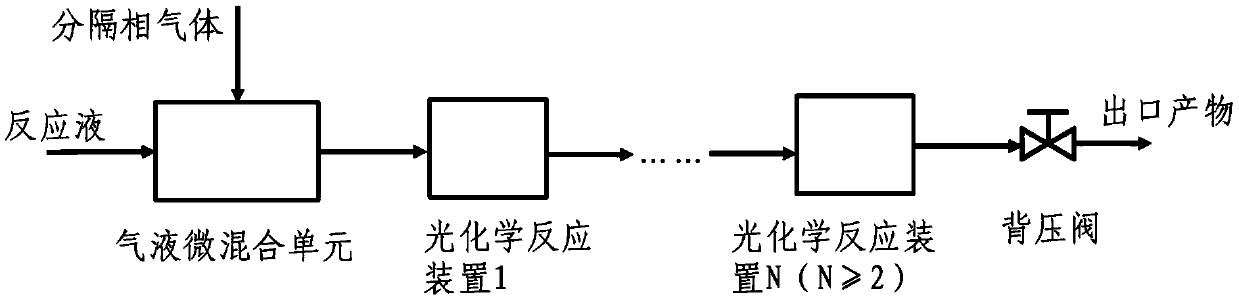

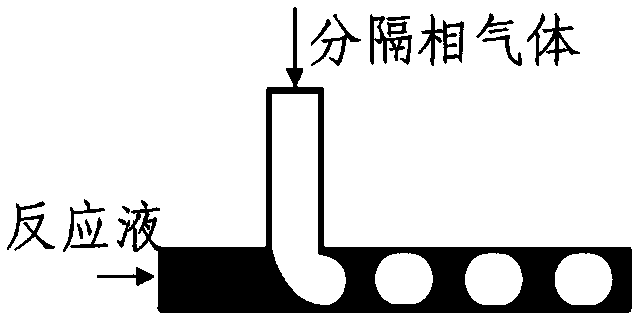

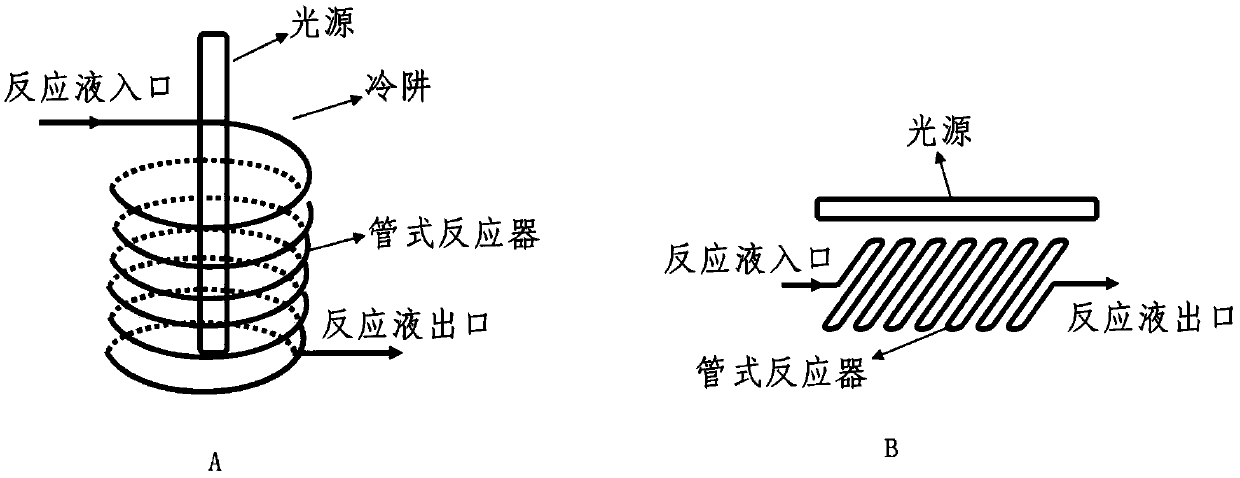

[0051] A gas-separated flow system for two-step photochemical synthesis of 9-β, 10-α-dehydroprogesterone ketal, which includes a gas-liquid micro-mixing unit, 2 sets of photochemical reaction devices with built-in light sources and a back pressure valve, that is, gas-liquid The micro-mixing unit and the first photochemical reaction device (comprising the first tube reactor, the first tube light source and the first cold trap) and the second photochemical reaction device (comprising the second tube reactor, the second light source and the second cold trap) trap), and the outlet of the reactor was connected to a back pressure valve.

[0052] The inner diameter of the main pipe in the gas-liquid micro-mixing unit is 1 mm, and the inner diameter of the side pipe is 0.1 mm; the first tubular reactor is a polytetrafluoroethylene tube with an inner diameter of 1 mm and an outer diameter of 2 mm; the second tubular reactor is a polytetrafluoroethylene tube with an inner diameter of 2m...

Embodiment 2

[0059] A gas-separated flow system for the one-step photochemical synthesis of 9-β, 10-α-dehydroprogesterone ketal, which consists of a gas-liquid micro-mixing unit, 3 sets of photochemical reaction devices with built-in light sources and a back pressure valve, that is, gas-liquid The micro-mixing unit and the first photochemical reaction device (comprising the first tube reactor, the first light source and the first cold trap), the second photochemical reaction device (comprising the second tube reactor, the second light source and the second cold trap ) and a third photochemical reaction device (including a third tubular reactor, a third light source and a third cold trap), and the outlet of the reactor is connected to a back pressure valve.

[0060] The inner diameter of the main pipe in the gas-liquid micro-mixing unit is 2mm, and the inner diameter of the side pipe is 1mm; the first, second and third tubular reactors are all perfluoroethylene propylene copolymer tubes with...

Embodiment 3

[0067]A gas-separated flow system for the two-step photochemical synthesis of 9-β, 10-α-dehydroprogesterone ketal, which includes a gas-liquid micro-mixing unit, 4 sets of photochemical reaction devices with built-in light sources and a back pressure valve, that is, gas-liquid The micro-mixing unit and the first photochemical reaction device (comprising the first tube reactor, the first light source and the first cold trap), the second photochemical reaction device (comprising the second tube reactor, the second light source and the second cold trap ), the third photochemical reaction device (comprising the third tube reactor, the third light source and the third cold trap) and the fourth photochemical reaction device (comprising the fourth tube reactor, the fourth light source and the fourth cold trap) , the outlet of the reactor is connected to a back pressure valve.

[0068] The gas-liquid micro-mixing unit is that the inner diameter of the main pipe is 2mm, and the inner d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com